Environmental Implications of Shale Gas Hydraulic Fracturing: A Comprehensive Review on Water Contamination and Seismic Activity in the United States

Abstract

:1. Introduction

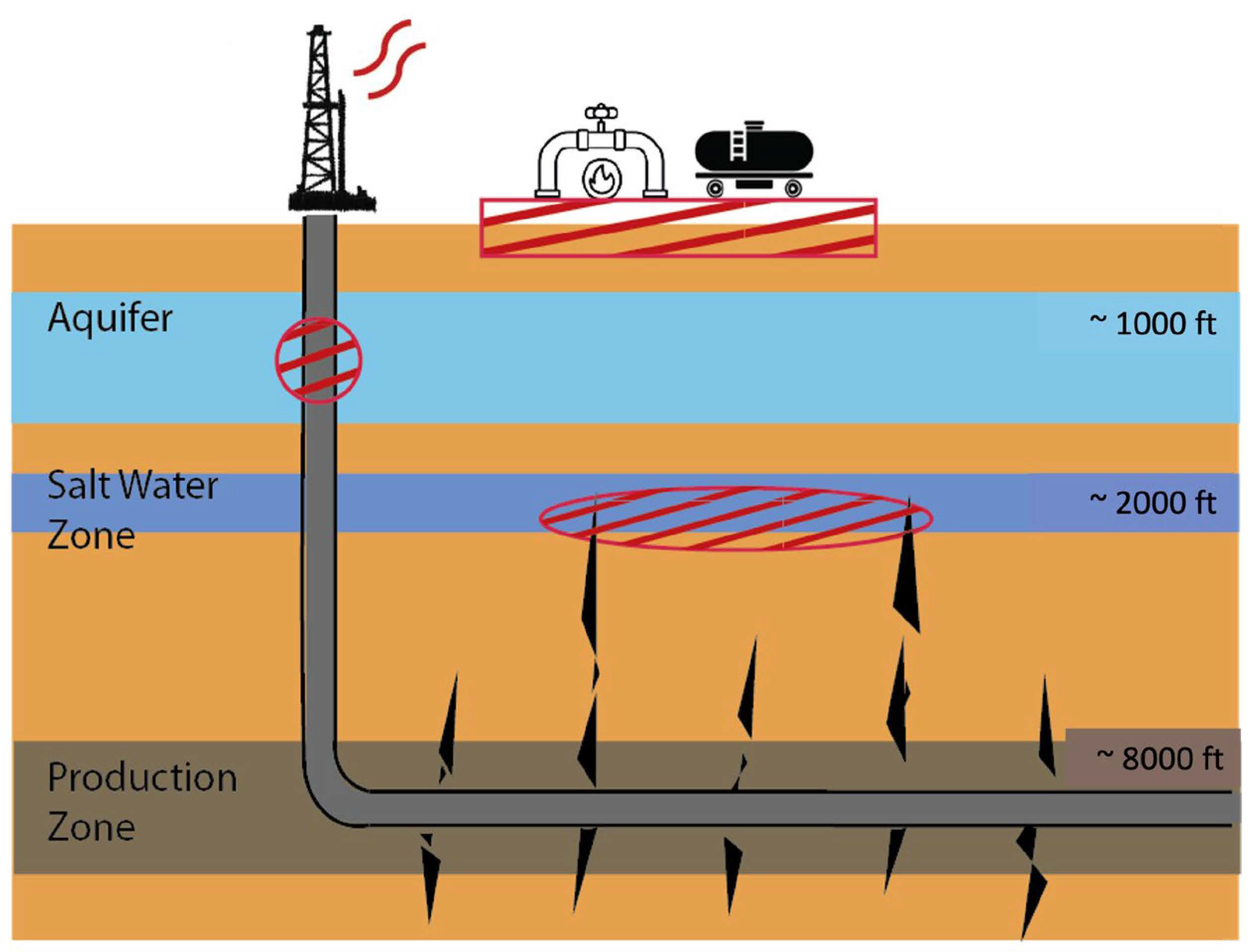

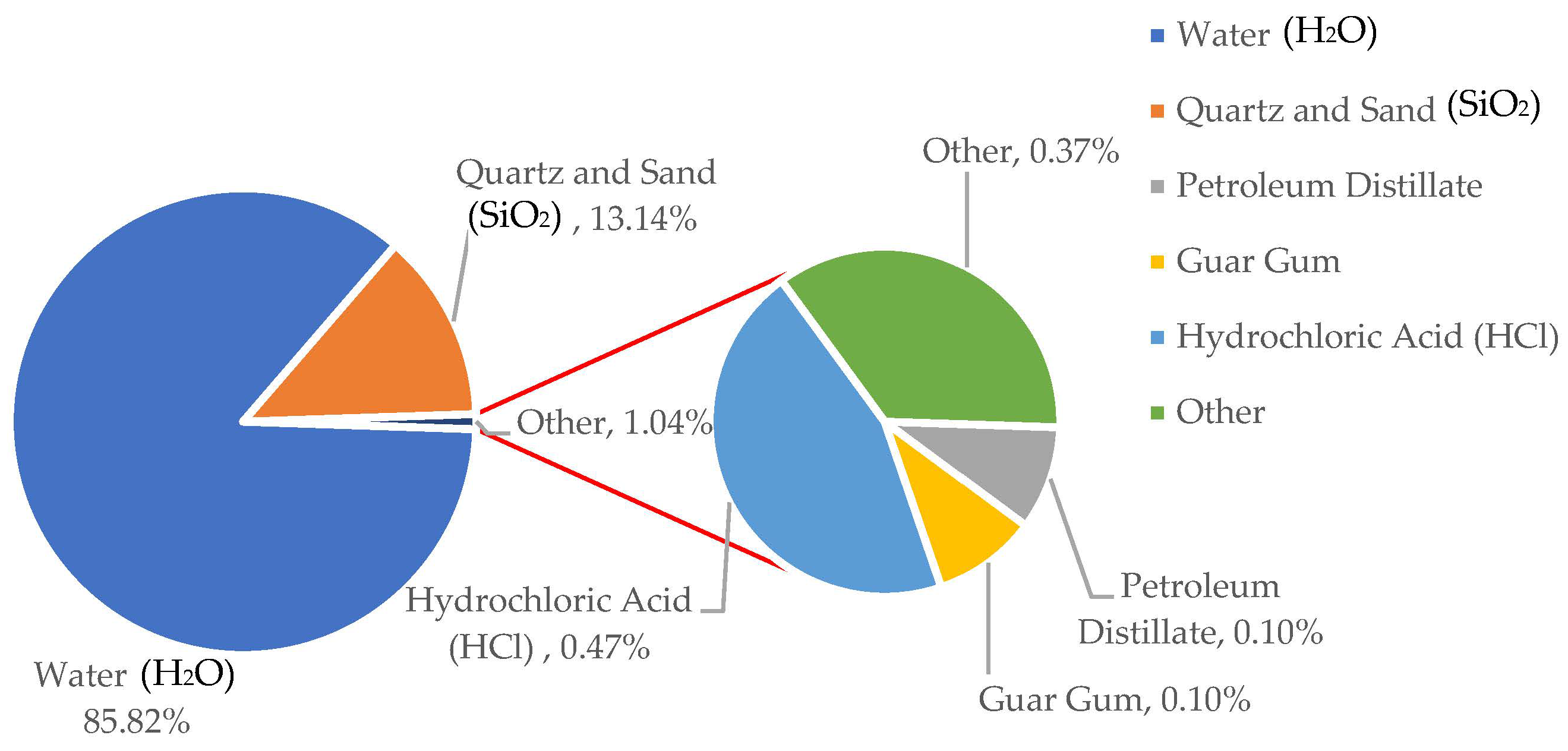

1.1. Overview of Shale Gas and Hydraulic Fracturing

1.2. Shale Gas in the U.S.: Successes, Challenges, and Mitigations

2. Environmental Problems Caused by Hydraulic Fracturing

2.1. Surface and Groundwater Contamination

2.2. Soil and Environmental Contamination

2.3. Earthquakes

2.4. Air Pollution

3. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Arthur, M.A.; Cole, D.R. Unconventional Hydrocarbon Resources: Prospects and Problems. Elements 2014, 10, 257–264. [Google Scholar] [CrossRef]

- Striolo, A.; Cole, D.R. Understanding Shale Gas: Recent Progress and Remaining Challenges. Energy Fuels 2017, 31, 10300–10310. [Google Scholar] [CrossRef]

- EIA. International Energy Statistics; Energy Information Administration (EIA): Washington, DC, USA, 2023.

- EIA. Shale Oil and Shale Gas Resources Are Globally Abundant; Energy Information Administration (EIA): Washington, DC, USA, 2013.

- Wang, Z.; Akhavan, M.; Kashkouli, M.N.I.; Opulencia, M.J.C.; Huy, D.T.N.; Van Tuan, P.; Davarpanah, A. Sustainable Wastewater Management from Shale Oil Production Wells: Emerging Opportunities and Barriers. Appl. Water Sci. 2022, 12, 147. [Google Scholar] [CrossRef]

- API. Hydraulic Fracturing: Unlocking America’s Natural Gas Resources; American Petroleum Institute (API): Washington, DC, USA, 2017.

- Wilson, T.H.; Smith, V.; Brown, A. Developing a Model Discrete Fracture Network, Drilling, and Enhanced Oil Recovery Strategy in an Unconventional Naturally Fractured Reservoir Using Integrated Field, Image Log, and Three-Dimensional Seismic Data. AAPG Bull. 2015, 99, 735–762. [Google Scholar] [CrossRef]

- EIA. Oil and Gas Supply Module—NEMS Documentation; Energy Information Administration: Washington, DC, USA, 2020.

- Holditch, S. Tight Gas Sands. J. Pet. Technol. 2006, 58, 86–93. [Google Scholar] [CrossRef]

- King, G.E. Hydraulic Fracturing 101: What Every Representative, Environmentalist, Regulator, Reporter, Investor, University Researcher, Neighbor and Engineer Should Know About Estimating Frac Risk and Improving Frac Performance in Unconventional Gas and Oil Wells. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 6 February 2012. SPE-152596-MS. [Google Scholar]

- Zhang, D.; Yang, T. Environmental Impacts of Hydraulic Fracturing in Shale Gas Development in the United States. Pet. Explor. Dev. 2015, 42, 876–883. [Google Scholar] [CrossRef]

- Li, Q.; Lu, L.; Zhao, Q.; Hu, S. Impact of Inorganic Solutes’ Release in Groundwater during Oil Shale In Situ Exploitation. Water 2022, 15, 172. [Google Scholar] [CrossRef]

- Montgomery, S.L.; Jarvie, D.M.; Bowker, K.A.; Pollastro, R.M. Mississippian Barnett Shale, Fort Worth Basin, North-Central Texas: Gas-Shale Play with Multi–Trillion Cubic Foot Potential. AAPG Bull. 2005, 89, 155–175. [Google Scholar] [CrossRef]

- EIA. Technically Recoverable Shale Oil and Shale Gas Resources: An Assessment of 137 Shale Formations in 41 Countries Outside the United States; Energy Information Administration (EIA): Washington, DC, USA, 2013.

- Allen, D.T.; Torres, V.M.; Thomas, J.; Sullivan, D.W.; Harrison, M.; Hendler, A.; Herndon, S.C.; Kolb, C.E.; Fraser, M.P.; Hill, A.D.; et al. Measurements of Methane Emissions at Natural Gas Production Sites in the United States. Proc. Natl. Acad. Sci. USA 2013, 110, 17768–17773. [Google Scholar] [CrossRef]

- Osborn, S.G.; Vengosh, A.; Warner, N.R.; Jackson, R.B. Methane Contamination of Drinking Water Accompanying Gas-Well Drilling and Hydraulic Fracturing. Proc. Natl. Acad. Sci. USA 2011, 108, 8172–8176. [Google Scholar] [CrossRef]

- Vidic, R.D.; Brantley, S.L.; Vandenbossche, J.M.; Yoxtheimer, D.; Abad, J.D. Impact of Shale Gas Development on Regional Water Quality. Science 2013, 340, 1235009. [Google Scholar] [CrossRef] [PubMed]

- Vengosh, A.; Jackson, R.B.; Warner, N.; Darrah, T.H.; Kondash, A. A Critical Review of the Risks to Water Resources from Unconventional Shale Gas Development and Hydraulic Fracturing in the United States. Environ. Sci. Technol. 2014, 48, 8334–8348. [Google Scholar] [CrossRef] [PubMed]

- Cooper, J.; Stamford, L.; Azapagic, A. Economic Viability of UK Shale Gas and Potential Impacts on the Energy Market up to 2030. Appl. Energy 2018, 215, 577–590. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, D.; Tsang, D.C.W.; Wang, L.; Ok, Y.S.; Feng, Y. A Critical Review of Risks, Characteristics, and Treatment Strategies for Potentially Toxic Elements in Wastewater from Shale Gas Extraction. Environ. Int. 2019, 125, 452–469. [Google Scholar] [CrossRef] [PubMed]

- Stringfellow, W.T.; Domen, J.K.; Camarillo, M.K.; Sandelin, W.L.; Borglin, S. Physical, Chemical, and Biological Characteristics of Compounds Used in Hydraulic Fracturing. J. Hazard. Mater. 2014, 275, 37–54. [Google Scholar] [CrossRef] [PubMed]

- Wollin, K.-M.; Damm, G.; Foth, H.; Freyberger, A.; Gebel, T.; Mangerich, A.; Gundert-Remy, U.; Partosch, F.; Röhl, C.; Schupp, T.; et al. Critical Evaluation of Human Health Risks Due to Hydraulic Fracturing in Natural Gas and Petroleum Production. Arch. Toxicol. 2020, 94, 967–1016. [Google Scholar] [CrossRef] [PubMed]

- Abraham, D.G.; Liberatore, H.K.; Aziz, M.T.; Burnett, D.B.; Cizmas, L.H.; Richardson, S.D. Impacts of Hydraulic Fracturing Wastewater from Oil and Gas Industries on Drinking Water: Quantification of 69 Disinfection by-Products and Calculated Toxicity. Sci. Total Environ. 2023, 882, 163344. [Google Scholar] [CrossRef]

- Shaheen, S.W.; Wen, T.; Herman, A.; Brantley, S.L. Geochemical Evidence of Potential Groundwater Contamination with Human Health Risks Where Hydraulic Fracturing Overlaps with Extensive Legacy Hydrocarbon Extraction. Environ. Sci. Technol. 2022, 56, 10010–10019. [Google Scholar] [CrossRef]

- Ellsworth, W.L. Injection-Induced Earthquakes. Science 2013, 341, 1225942. [Google Scholar] [CrossRef]

- Weingarten, M.; Ge, S.; Godt, J.W.; Bekins, B.A.; Rubinstein, J.L. High-Rate Injection Is Associated with the Increase in U.S. Mid-Continent Seismicity. Science 2015, 348, 1336–1340. [Google Scholar] [CrossRef]

- Schultz, R.; Skoumal, R.J.; Brudzinski, M.R.; Eaton, D.; Baptie, B.; Ellsworth, W. Hydraulic Fracturing-Induced Seismicity. Rev. Geophys. 2020, 58, e2019RG000695. [Google Scholar] [CrossRef]

- Kreipl, M.P.; Kreipl, A.T. Hydraulic Fracturing Fluids and Their Environmental Impact: Then, Today, and Tomorrow. Environ. Earth Sci. 2017, 76, 160. [Google Scholar] [CrossRef]

- Davoodi, S.; Al-Shargabi, M.; Wood, D.A.; Rukavishnikov, V.S. A Comprehensive Review of Beneficial Applications of Viscoelastic Surfactants in Wellbore Hydraulic Fracturing Fluids. Fuel 2023, 338, 127228. [Google Scholar] [CrossRef]

- Sztekler, K.; Kalawa, W.; Nowak, W.; Mika, Ł.; Krzywański, J.; Grabowska, K.; Sosnowski, M.; Alharbi, A.A. Performance Evaluation of a Single-Stage Two-Bed Adsorption Chiller With Desalination Function. J. Energy Resour. Technol. 2021, 143, 082101. [Google Scholar] [CrossRef]

- Koushaeian, M.; Duong, X.Q.; Park, M.Y.; Lee, W.S.; Kwon, O.K.; Shah, N.A.; Chung, J.D. Investigation of the Cascade Type of Hybrid Adsorption-Vapor Compression Chiller. Case Stud. Therm. Eng. 2023, 47, 103037. [Google Scholar] [CrossRef]

- Llewellyn, G.T.; Dorman, F.; Westland, J.L.; Yoxtheimer, D.; Grieve, P.; Sowers, T.; Humston-Fulmer, E.; Brantley, S.L. Evaluating a Groundwater Supply Contamination Incident Attributed to Marcellus Shale Gas Development. Proc. Natl. Acad. Sci. USA 2015, 112, 6325–6330. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, J.; Heo, J.; Park, J.; Lee, S.-S.; Miranda, K. Inorganic Pollutants in the Water of Midland and Odessa, Permian Basin, West Texas. Air Soil Water Res. 2019, 12, 117862211986108. [Google Scholar] [CrossRef]

- Lozano, J.; Heo, J.; Seo, M. Historical Assessments of Inorganic Pollutants in the Sinkhole Region of Winkler County, Texas, USA. Sustainability 2021, 13, 7513. [Google Scholar] [CrossRef]

- Haskell, D.; Heo, J.; Park, J.; Dong, C. Hydrogeochemical Evaluation of Groundwater Quality Parameters for Ogallala Aquifer in the Southern High Plains Region, USA. Int. J. Environ. Res. Public. Health 2022, 19, 8453. [Google Scholar] [CrossRef]

- Folger, P.; Tiemann, M. The EPA Draft Report of Groundwater Contamination Near Pavillion, Wyoming: Main Findings and Stakeholder Responses; Congressional Research Service: Washington, DC, USA, 2016. [Google Scholar]

- Reagan, M.T.; Moridis, G.J.; Keen, N.D.; Johnson, J.N. Numerical Simulation of the Environmental Impact of Hydraulic Fracturing of Tight/Shale Gas Reservoirs on Near-surface Groundwater: Background, Base Cases, Shallow Reservoirs, Short-term Gas, and Water Transport. Water Resour. Res. 2015, 51, 2543–2573. [Google Scholar] [CrossRef]

- Investigation of Ground Water Contamination near Pavillion, Wyoming; US Environmental Protection Agency, Office of Research and Development, National Risk Management Research Laboratory: Washington, DC, USA, 2011.

- Olmstead, S.M.; Muehlenbachs, L.A.; Shih, J.-S.; Chu, Z.; Krupnick, A.J. Shale Gas Development Impacts on Surface Water Quality in Pennsylvania. Proc. Natl. Acad. Sci. USA 2013, 110, 4962–4967. [Google Scholar] [CrossRef] [PubMed]

- Skalak, K.J.; Engle, M.A.; Rowan, E.L.; Jolly, G.D.; Conko, K.M.; Benthem, A.J.; Kraemer, T.F. Surface Disposal of Produced Waters in Western and Southwestern Pennsylvania: Potential for Accumulation of Alkali-Earth Elements in Sediments. Int. J. Coal Geol. 2014, 126, 162–170. [Google Scholar] [CrossRef]

- Nelson, R.; Heo, J. Monitoring Environmental Parameters with Oil and Gas Developments in the Permian Basin, USA. Int. J. Environ. Res. Public. Health 2020, 17, 4026. [Google Scholar] [CrossRef] [PubMed]

- Jackson, R.B.; Lowry, E.R.; Pickle, A.; Kang, M.; DiGiulio, D.; Zhao, K. The Depths of Hydraulic Fracturing and Accompanying Water Use Across the United States. Environ. Sci. Technol. 2015, 49, 8969–8976. [Google Scholar] [CrossRef] [PubMed]

- Welch, S.A.; Sheets, J.M.; Daly, R.A.; Hanson, A.; Sharma, S.; Darrah, T.; Olesik, J.; Lutton, A.; Mouser, P.J.; Wrighton, K.C.; et al. Comparative Geochemistry of Flowback Chemistry from the Utica/Point Pleasant and Marcellus Formations. Chem. Geol. 2021, 564, 120041. [Google Scholar] [CrossRef]

- Rodriguez, J.; Heo, J.; Kim, K.H. The Impact of Hydraulic Fracturing on Groundwater Quality in the Permian Basin, West Texas, USA. Water 2020, 12, 796. [Google Scholar] [CrossRef]

- Heo, J.-H.; Lee, D.-H.; Koh, D.-C.; Chang, H.-W. The Effect of Ionic Strength and Hardness of Trichloroethylene-Contaminated Synthetic Groundwater on Remediation Using Granular Activated Carbon. Geosci. J. 2007, 11, 229–239. [Google Scholar] [CrossRef]

- Welch, S.A.; Sheets, J.M.; Saelans, E.; Saltzman, M.R.; Newby, S.M.; Darrah, T.H.; Lutton, A.; Olesik, J.W.; DeFranco, K.C.; Heraty, L.J.; et al. Chemical and Isotopic Evolution of Flowback Fluids from the Utica Gas Shale Play, Eastern Ohio USA. Chem. Geol. 2022, 614, 121186. [Google Scholar] [CrossRef]

- Cole, D.R.; Allen, G.R. Utica Shale Energy and Environment Laboratory Final Scientific/Technical Report; U.S. Department of Energy Office of Scientific and Technical Information: Oak Ridge, TN, USA, 2017; DOE-OSU--0024357, 1416539.

- Hwang, B.; Srivastava, D.J.; Deng, H.; Grandinetti, P.J.; Cole, D.R. Sodium Diffusion in Heterogeneous Porous Media: Connecting Laboratory Experiments and Simulations. Geochim. Cosmochim. Acta 2022, 338, 93–104. [Google Scholar] [CrossRef]

- Xiong, F.; Hwang, B.; Jiang, Z.; James, D.; Lu, H.; Moortgat, J. Kinetic Emission of Shale Gas in Saline Water: Insights from Experimental Observation of Gas Shale in Canister Desorption Testing. Fuel 2021, 300, 121006. [Google Scholar] [CrossRef]

- Swigart, J.; Heo, J.; Wolf, D. Soil Contamination Assessments from Drilling Fluids and Produced Water Using Combined Field and Laboratory Investigations: A Case Study of Arkansas, USA. Int. J. Environ. Res. Public. Health 2021, 18, 2421. [Google Scholar] [CrossRef] [PubMed]

- Fontenot, B.E.; Hunt, L.R.; Hildenbrand, Z.L.; Carlton, D.D., Jr.; Oka, H.; Walton, J.L.; Hopkins, D.; Osorio, A.; Bjorndal, B.; Hu, Q.H.; et al. An Evaluation of Water Quality in Private Drinking Water Wells Near Natural Gas Extraction Sites in the Barnett Shale Formation. Environ. Sci. Technol. 2013, 47, 10032–10040. [Google Scholar] [CrossRef] [PubMed]

- Luek, J.L.; Gonsior, M. Organic Compounds in Hydraulic Fracturing Fluids and Wastewaters: A Review. Water Res. 2017, 123, 536–548. [Google Scholar] [CrossRef] [PubMed]

- Warner, N.R.; Christie, C.A.; Jackson, R.B.; Vengosh, A. Impacts of Shale Gas Wastewater Disposal on Water Quality in Western Pennsylvania. Environ. Sci. Technol. 2013, 47, 11849–11857. [Google Scholar] [CrossRef] [PubMed]

- Warner, N.R.; Jackson, R.B.; Vengosh, A. Tracing the Legacy of Accidental Spills and Releases of Marcellus Wastewater in Pennsylvania; Geological Society of America: Denver, CO, USA, 2013. [Google Scholar]

- US Environmental Protection Agency. Inventory of US Greenhouse Gas Emissions and Sinks: 1990–2019; US Environmental Protection Agency: Washington, DC, USA, 2021.

- English, S.; Heo, J.; Won, J. Investigation of Sinkhole Formation with Human Influence: A Case Study from Wink Sink in Winkler County, Texas. Sustainability 2020, 12, 3537. [Google Scholar] [CrossRef]

- Daly, R.A.; Borton, M.A.; Wilkins, M.J.; Hoyt, D.W.; Kountz, D.J.; Wolfe, R.A.; Welch, S.A.; Marcus, D.N.; Trexler, R.V.; MacRae, J.D.; et al. Microbial Metabolisms in a 2.5-Km-Deep Ecosystem Created by Hydraulic Fracturing in Shales. Nat. Microbiol. 2016, 1, 16146. [Google Scholar] [CrossRef] [PubMed]

- Maloney, K.O.; Young, J.A.; Faulkner, S.P.; Hailegiorgis, A.; Slonecker, E.T.; Milheim, L.E. A Detailed Risk Assessment of Shale Gas Development on Headwater Streams in the Pennsylvania Portion of the Upper Susquehanna River Basin, U.S.A. Sci. Total Environ. 2018, 610–611, 154–166. [Google Scholar] [CrossRef] [PubMed]

- Seo, M.; Heo, J.; Kim, Y. Present and Potential Future Critical Source Areas of Nonpoint Source Pollution: A Case of the Nakdong River Watershed, South Korea. Environ. Sci. Pollut. Res. 2021, 28, 45676–45692. [Google Scholar] [CrossRef]

- Hildenbrand, Z.L.; Mach, P.M.; McBride, E.M.; Dorreyatim, M.N.; Taylor, J.T.; Carlton, D.D.; Meik, J.M.; Fontenot, B.E.; Wright, K.C.; Schug, K.A.; et al. Point Source Attribution of Ambient Contamination Events near Unconventional Oil and Gas Development. Sci. Total Environ. 2016, 573, 382–388. [Google Scholar] [CrossRef]

- U.S. Geological Survey USGS Earthquake Catalog; United States Geological Survey: Reston, VA, USA, 2023.

- Railroad Commission of Texas (RRC). Seismicity Response; Railroad Commission of Texas: Lubbock, TX, USA, 2023.

- Burnett, D.B. Potential for Beneficial Use of Oil and Gas Produced Water; Global Petroleum Institute; Texas Water Resources Institute: College Station, TX, USA, 2004; pp. 1–11. [Google Scholar]

- Foulger, G.R.; Wilson, M.P.; Gluyas, J.G.; Julian, B.R.; Davies, R.J. Global Review of Human-Induced Earthquakes. Earth Sci. Rev. 2018, 178, 438–514. [Google Scholar] [CrossRef]

- Frohlich, C.; Ellsworth, W.; Brown, W.A.; Brunt, M.; Luetgert, J.; MacDonald, T.; Walter, S. The 17 May 2012 M 4.8 Earthquake near Timpson, East Texas: An Event Possibly Triggered by Fluid Injection: 2012 May 17 East Texas Earthquake. J. Geophys. Res. Solid Earth 2014, 119, 581–593. [Google Scholar] [CrossRef]

- Deng, K.; Liu, Y.; Chen, X. Correlation Between Poroelastic Stress Perturbation and Multidisposal Wells Induced Earthquake Sequence in Cushing, Oklahoma. Geophys. Res. Lett. 2020, 47, e2020GL089366. [Google Scholar] [CrossRef]

- Rajesh, R.; Gupta, H.K. Characterization of Injection-Induced Seismicity at North Central Oklahoma, USA. J. Seismol. 2021, 25, 327–337. [Google Scholar] [CrossRef]

- Hough, S.E.; Page, M. A Century of Induced Earthquakes in Oklahoma? Bull. Seismol. Soc. Am. 2015, 105, 2863–2870. [Google Scholar] [CrossRef]

- Frohlich, C. Two-Year Survey Comparing Earthquake Activity and Injection-Well Locations in the Barnett Shale, Texas. Proc. Natl. Acad. Sci. USA 2012, 109, 13934–13938. [Google Scholar] [CrossRef] [PubMed]

- Magnani, M.B.; Blanpied, M.L.; DeShon, H.R.; Hornbach, M.J. Discriminating between Natural versus Induced Seismicity from Long-Term Deformation History of Intraplate Faults. Sci. Adv. 2017, 3, e1701593. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-W.; Lu, Z. Association between Localized Geohazards in West Texas and Human Activities, Recognized by Sentinel-1A/B Satellite Radar Imagery. Sci. Rep. 2018, 8, 4727. [Google Scholar] [CrossRef]

- Majer, E.; Nelson, J.; Robertson-Tait, A.; Savy, J.; Wong, I. Protocol for Addressing Induced Seismicity Associated with Enhanced Geothermal Systems; Office of Energy Efficiency and Renewable Energy: Washington, DC, USA, 2012; DOE/EE--0662, 1219482.

- Hofmann, H.; Zimmermann, G.; Zang, A.; Min, K.-B. Cyclic Soft Stimulation (CSS): A New Fluid Injection Protocol and Traffic Light System to Mitigate Seismic Risks of Hydraulic Stimulation Treatments. Geotherm. Energy 2018, 6, 27. [Google Scholar] [CrossRef]

- Verdon, J.P.; Bommer, J.J. Green, Yellow, Red, or out of the Blue? An Assessment of Traffic Light Schemes to Mitigate the Impact of Hydraulic Fracturing-Induced Seismicity. J. Seismol. 2021, 25, 301–326. [Google Scholar] [CrossRef]

- Colborn, T.; Schultz, K.; Herrick, L.; Kwiatkowski, C. An Exploratory Study of Air Quality Near Natural Gas Operations. Hum. Ecol. Risk Assess. Int. J. 2014, 20, 86–105. [Google Scholar] [CrossRef]

- Field, R.A.; Soltis, J.; Murphy, S. Air Quality Concerns of Unconventional Oil and Natural Gas Production. Environ. Sci. Process. Impacts 2014, 16, 954–969. [Google Scholar] [CrossRef] [PubMed]

- Helmig, D. Air Quality Impacts from Oil and Natural Gas Development in Colorado. Elem. Sci. Anthr. 2020, 8, 4. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Methane Emissions from the Global Energy Sector Rose to Nearly 135 Mt in 2022; International Energy Agency: Paris, France, 2022. [Google Scholar]

- Sargent, M.R.; Floerchinger, C.; McKain, K.; Budney, J.; Gottlieb, E.W.; Hutyra, L.R.; Rudek, J.; Wofsy, S.C. Majority of US Urban Natural Gas Emissions Unaccounted for in Inventories. Proc. Natl. Acad. Sci. USA 2021, 118, e2105804118. [Google Scholar] [CrossRef] [PubMed]

- Vinciguerra, T.; Yao, S.; Dadzie, J.; Chittams, A.; Deskins, T.; Ehrman, S.; Dickerson, R.R. Regional Air Quality Impacts of Hydraulic Fracturing and Shale Natural Gas Activity: Evidence from Ambient VOC Observations. Atmos. Environ. 2015, 110, 144–150. [Google Scholar] [CrossRef]

- Zhang, R.; Li, H.; Khanna, N.; Krupnick, A.J.; Hill, E.L.; Sullivan, D.M. Air Quality Impacts of Shale Gas Development in Pennsylvania. J. Assoc. Environ. Resour. Econ. 2023, 10, 447–486. [Google Scholar] [CrossRef]

- Srebotnjak, T.; Rotkin-Ellman, M. Fracking Fumes: Air Pollution from Hydraulic Fracturing Threatens Public Health and Communities; Natural Resources Defense Council: New York, NY, USA, 2014. [Google Scholar]

- Esswein, E.J.; King, B.; Ndonga, M.; Andronov, E. Respirable Crystalline Silica Is a Confirmed Occupational Exposure Risk during Hydraulic Fracturing: What Do We Know about Controls? Proceedings from the Silica in the Oilfield Conference. J. Occup. Environ. Hyg. 2019, 16, 669–674. [Google Scholar] [CrossRef] [PubMed]

- Raheja, G.; Harper, L.; Hoffman, A.; Gorby, Y.; Freese, L.; O’Leary, B.; Deron, N.; Smith, S.; Auch, T.; Goodwin, M.; et al. Community-Based Participatory Research for Low-Cost Air Pollution Monitoring in the Wake of Unconventional Oil and Gas Development in the Ohio River Valley: Empowering Impacted Residents through Community Science. Environ. Res. Lett. 2022, 17, 065006. [Google Scholar] [CrossRef]

| Reference (Year) | Location | Contaminant | Note |

|---|---|---|---|

| Osborn et al. (2011) [16] | Northeastern Pennsylvania and Upstate New York | Methane | Groundwater contamination in Marcellus and Utica formations |

| EPA (2011) [38] | Wyoming, Pavillion | Diesel Range Organics (DRO), Gasoline Range Organics (GRO), and Total Purgeable Hydrocarbons (TPH) | Soil and shallow groundwater contamination in Wind River formation |

| Vidic et al. (2013) [17] | Pennsylvania | Barium, Strontium, and Bromide | Surface water contamination in Marcellus formation |

| Olmstead et al. (2013) [39] | Pennsylvania | Chloride (Cl−) | Surface water contamination in Marcellus formation |

| Fontenot et al. (2013) [40] | North Texas | Total Dissolved Solids (TDS) | Soil contamination in Barnett formation |

| Warner et al. (2013) [41] | Western Pennsylvania | Chloride and Bromide | Surface Water contamination in Marcellus formation |

| Skalak et al. (2014) [42] | Appalachian Basin, Pennsylvania | Total Dissolved Solids (TDS), Total radium (specifically Ra-226), Extractable Ba, Ca, Na, Sr | No significant contaminant increases from treatment facilities but the spread of road brine raised levels near roads. |

| EPA (2016) [36] | Wyoming, Pavillion | Benzene, Toluene, Ethylbenzene, and Xylenes, as well as Methane and other Hydrocarbons | Groundwater contamination in Wind River formation |

| Nelson and Heo (2020) [43] | Permian Basin, Western Texas | Total Dissolved Solids (TDS), Chloride, Fluoride, Nitrate, and Arsenic | Groundwater contamination in Wolfcamp formation |

| Hydraulic Fracturing Depth (ft|m) | Water Volume Used (gal|L) | |||

|---|---|---|---|---|

| Alabama | 2210 | 674 | 37,600 | 142,331 |

| Arkansas | 4120 | 1256 | 5,230,000 | 19,797,694 |

| California | 2960 | 902 | 158,000 | 598,095 |

| Colorado | 7550 | 2301 | 1,410,000 | 5,337,428 |

| Kansas | 4910 | 1497 | 1,230,000 | 4,656,054 |

| Louisiana | 11,950 | 3642 | 5,140,000 | 19,457,007 |

| Montana | 9530 | 2905 | 1,650,000 | 6,245,927 |

| New Mexico | 6850 | 2088 | 706,000 | 2,672,499 |

| North Dakota | 10,370 | 3161 | 2,170,000 | 8,214,340 |

| Ohio | 7810 | 2380 | 4,310,000 | 16,315,117 |

| Oklahoma | 8560 | 2609 | 3,430,000 | 12,983,956 |

| Pennsylvania | 7040 | 2146 | 4,460,000 | 16,882,929 |

| Texas | 8750 | 2667 | 2,490,000 | 9,425,671 |

| Utah | 8360 | 2548 | 382,000 | 1,446,027 |

| Virginia | 4720 | 1439 | 42,100 | 159,366 |

| West Virginia | 6870 | 2094 | 5,040,000 | 19,078,466 |

| Wyoming | 9390 | 2862 | 793,000 | 3,001,830 |

| United States | ||||

| Mean | 8290 | 2527 | 2,430,000 | 9,198,546 |

| Min | 2210 | 674 | 37,600 | 142,331 |

| Max | 11,950 | 3642 | 5,230,000 | 19,797,694 |

| Standard deviation | 2657 | 810 | 1,933,877 | 7,320,518 |

| Coefficient of variation | 0.32 | 0.32 | 0.80 | 0.80 |

| Chemical | Purpose |

|---|---|

| Acid | Dissolving minerals and the initiation of rock fracturing (pre-fracturing) |

| Sodium Chloride | Delaying the decomposition of gel polymer chains |

| Polyacrylamide | Minimizing the friction between the fluid and pipes |

| Ethylene glycol | Preventing scale formation within the pipe |

| Boric acid salt | Maintaining fluid viscosity during temperature increases |

| Sodium/Potassium carbonate | Maintaining the effect of other ingredients as cross-linking agents |

| Glutaraldehyde | Elimination of bacteria in the water |

| Guar gum | Increase in water viscosity to keep the sand afloat |

| Citric acid | Preventing the precipitation of metallic oxides |

| Isopropanol | Decreasing the viscosity of fracturing fluid |

| Date | Location | Magnitude | Notes |

|---|---|---|---|

| 2008 and 2009 | Dallas-Fort Worth and Cleburne, Texas | >M 3 | Increased the number of small-magnitude earthquakes observed |

| 23 August 2011 | Trinidad, Colorado | M 5.3 | Largest earthquake linked to fracking in the state of Colorado |

| 11 September 2011 | Snyder, Texas | M 4.4 | Fracking-related earthquakes occurred over a period of two months |

| 16 December 2011 | Youngstown, Ohio | M 4.0 | Led to the suspension of fracking activities in the area |

| 17 May 2012 | East Texas | M 4.8 | linked to wastewater injection. Earthquake associated with fracking in the Haynesville Shale |

| 2 November 2016 | Cushing, Oklahoma | M 5.0 | Largest earthquake ever recorded in Cushing: a major oil hub |

| 7 November 2016 | Pawnee, Oklahoma | M 5.8 | The largest earthquake known to be induced by wastewater disposal and the strongest earthquake in Oklahoma history at the time, leading to the temporary shutdown of wells |

| 7 April 2018 | Lucien, Oklahoma | M 4.6 | |

| 9 April 2018 | Marshall, Oklahoma | M 4.6 | |

| 31 May 2018 | Pecos, Texas | M 4.5 | Part of a series of earthquakes linked to fracking activities in the Permian Basin |

| 26 March 2020 | Mentone, Texas | M 5.0 | Largest quake in two decades; linked to deep water injection seismicity |

| 4 March 2021 | Weld County, Colorado | M 4.2 | Earthquake linked to fracking operations in the Denver–Julesburg Basin |

| 28 December 2021 | Stanton, Texas | M 4.6 | Shanton in the Permian Basin identified as Seismic Response Areas (SRAs); saltwater disposal injections contributed to the region’s seismic activity. |

| 17 March 2021 25 March 2022 1 June 2022 21 July 2022 11 August 2022 | Whites city, New Mexico | M 4.5 M 4.6 M 4.6 M 4.9 M 4.5 | In New Mexico, seismic events occurred up to magnitudes of 5.0, linked to the oil and gas industry’s wastewater injection wells |

| 16 November 2022 | Mentone, Coalson Draw, Texas | M5.3–5.4 | In a region known for oil and gas production |

| 16 December 2022 | Range Hill, Texas | M 5.2 | Over 120 significant earthquakes have occurred since 2018 in this area, predominantly due to human activities |

| 9 March 2023 | Trinidad, Colorado | M 4.3 | Ten days later, a 3.8 magnitude earthquake struck, likely due to wastewater injections causing underground movement |

| Reference (Year) | Location | Contaminant | Notes |

|---|---|---|---|

| Colborn et al. (2014) [75] | Western Colorado | Non-methane hydrocarbons (NMHCs) and Polycyclic aromatic hydrocarbons (PAHs) | NMHC concentrations were highest during the initial drilling phase. |

| Field et al. (2014) [76] | Several basins in the US where airborne assessments have been conducted * | nitrogen oxides, particulate matter, volatile organic compounds, hazardous air pollutants (HAP), methane | Suggests that emissions of pollutants are possible close to well pads and are identified as pollutants of concern. |

| Vincigurra et al. (2015) [77] | Baltimore, MD and Washington, DC | Ethane (a VOC) | Significant increase in daytime ethane concentrations since 2010 |

| Helmig (2020) [78] | Denver–Julesburg Basin, Northern Colorado Front Range | Non-ethane VOCs, methane, and NOx | Based on observations of VOC/methane ratios and methane flux estimates. |

| Raheja et al. (2022) [79] | Belmont County, Ohio | Particulate matter (PM) and volatile organic compounds (VOC) | Air pollution sensor network of 35 particulate matter and 25 volatile organic compound sensors. |

| Zhang et al. (2023) [80] | Pennsylvania | Particulate matter (PM) | Casual increase in PM2.5 concentration in the vicinity of over 20,000 wells. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, B.; Heo, J.; Lim, C.; Park, J. Environmental Implications of Shale Gas Hydraulic Fracturing: A Comprehensive Review on Water Contamination and Seismic Activity in the United States. Water 2023, 15, 3334. https://doi.org/10.3390/w15193334

Hwang B, Heo J, Lim C, Park J. Environmental Implications of Shale Gas Hydraulic Fracturing: A Comprehensive Review on Water Contamination and Seismic Activity in the United States. Water. 2023; 15(19):3334. https://doi.org/10.3390/w15193334

Chicago/Turabian StyleHwang, Bohyun, Joonghyeok Heo, Chungwan Lim, and Joonkyu Park. 2023. "Environmental Implications of Shale Gas Hydraulic Fracturing: A Comprehensive Review on Water Contamination and Seismic Activity in the United States" Water 15, no. 19: 3334. https://doi.org/10.3390/w15193334

APA StyleHwang, B., Heo, J., Lim, C., & Park, J. (2023). Environmental Implications of Shale Gas Hydraulic Fracturing: A Comprehensive Review on Water Contamination and Seismic Activity in the United States. Water, 15(19), 3334. https://doi.org/10.3390/w15193334