Effects of Sample Preparation Methods on Permeability and Microstructure of Remolded Loess

Abstract

:1. Introduction

2. Materials and Methods

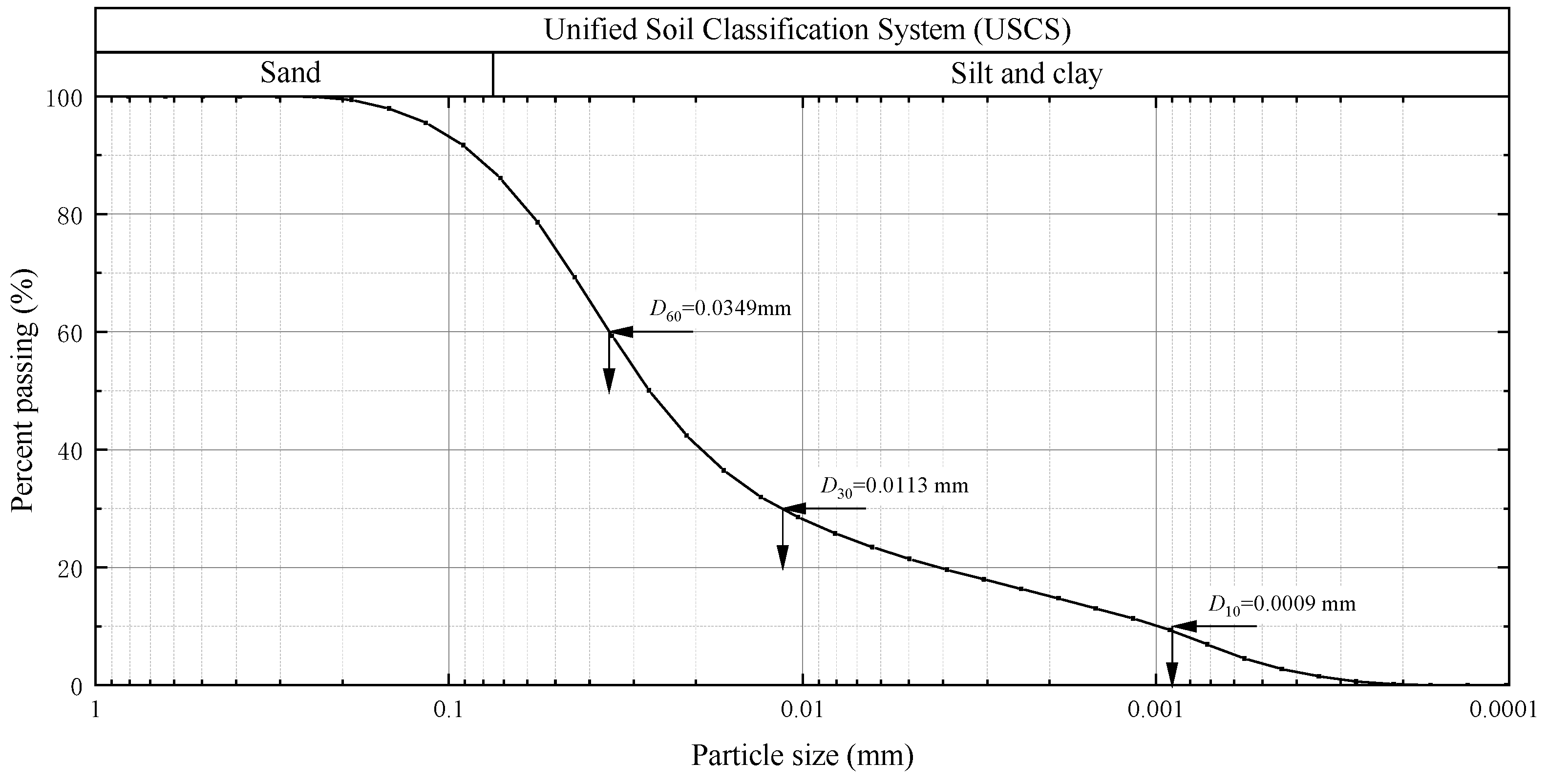

2.1. Sample Characteristics

2.2. Experimental Design

2.3. Sample Preparation

2.4. Permeability Coefficient Test

2.5. Microstructure Testing

3. Results and Analysis

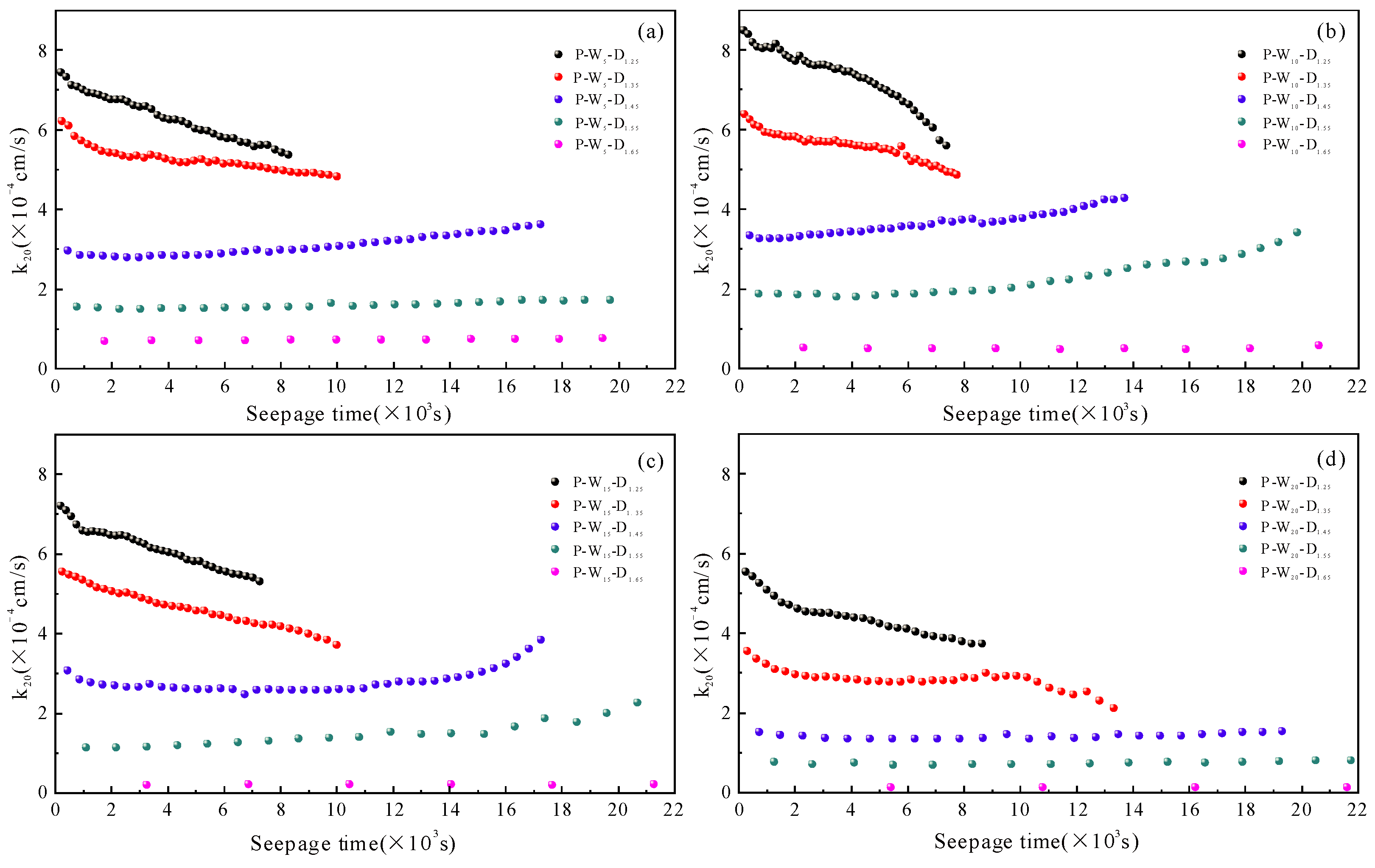

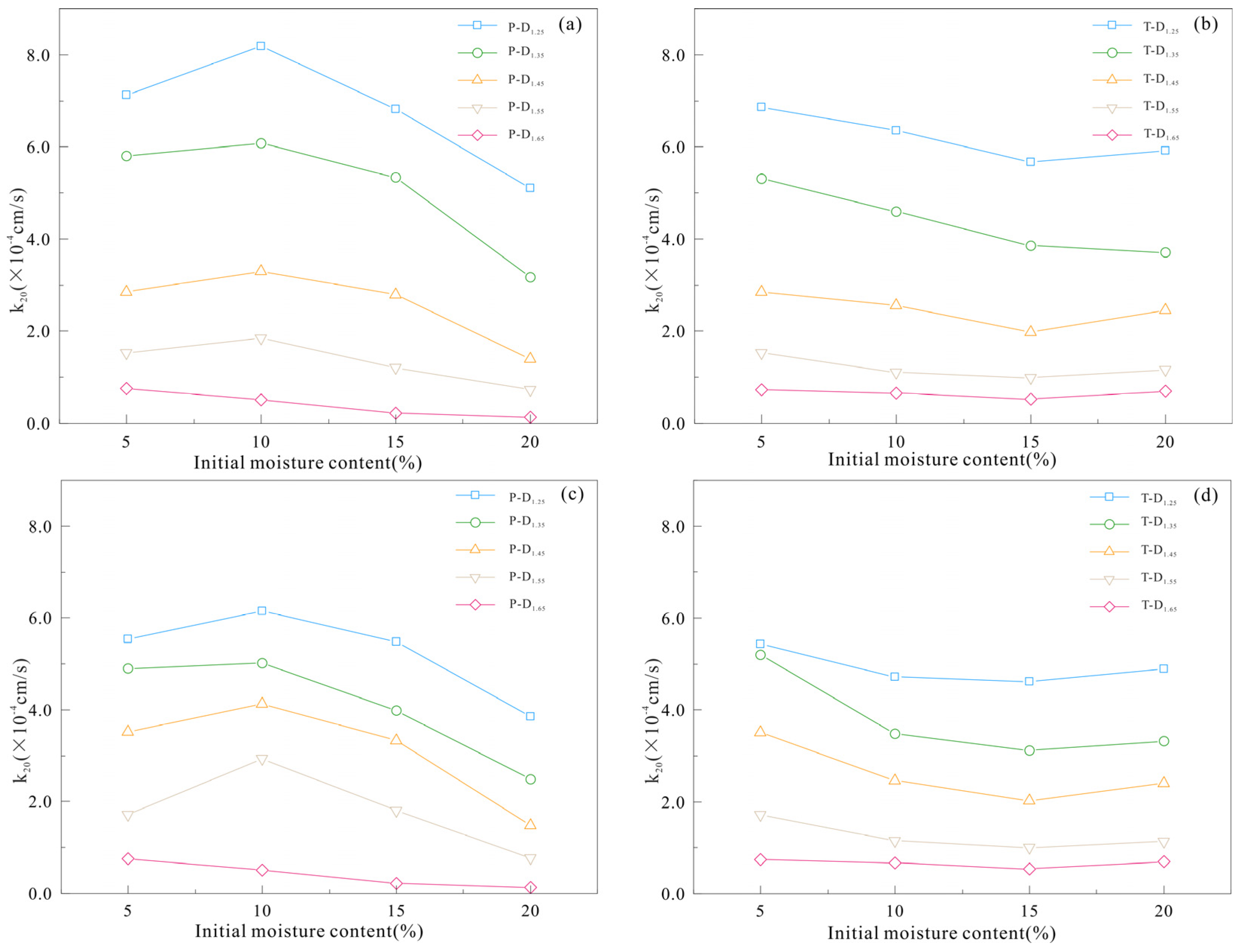

3.1. Permeability Test Results of Remolded Loess under Pre-Wetting

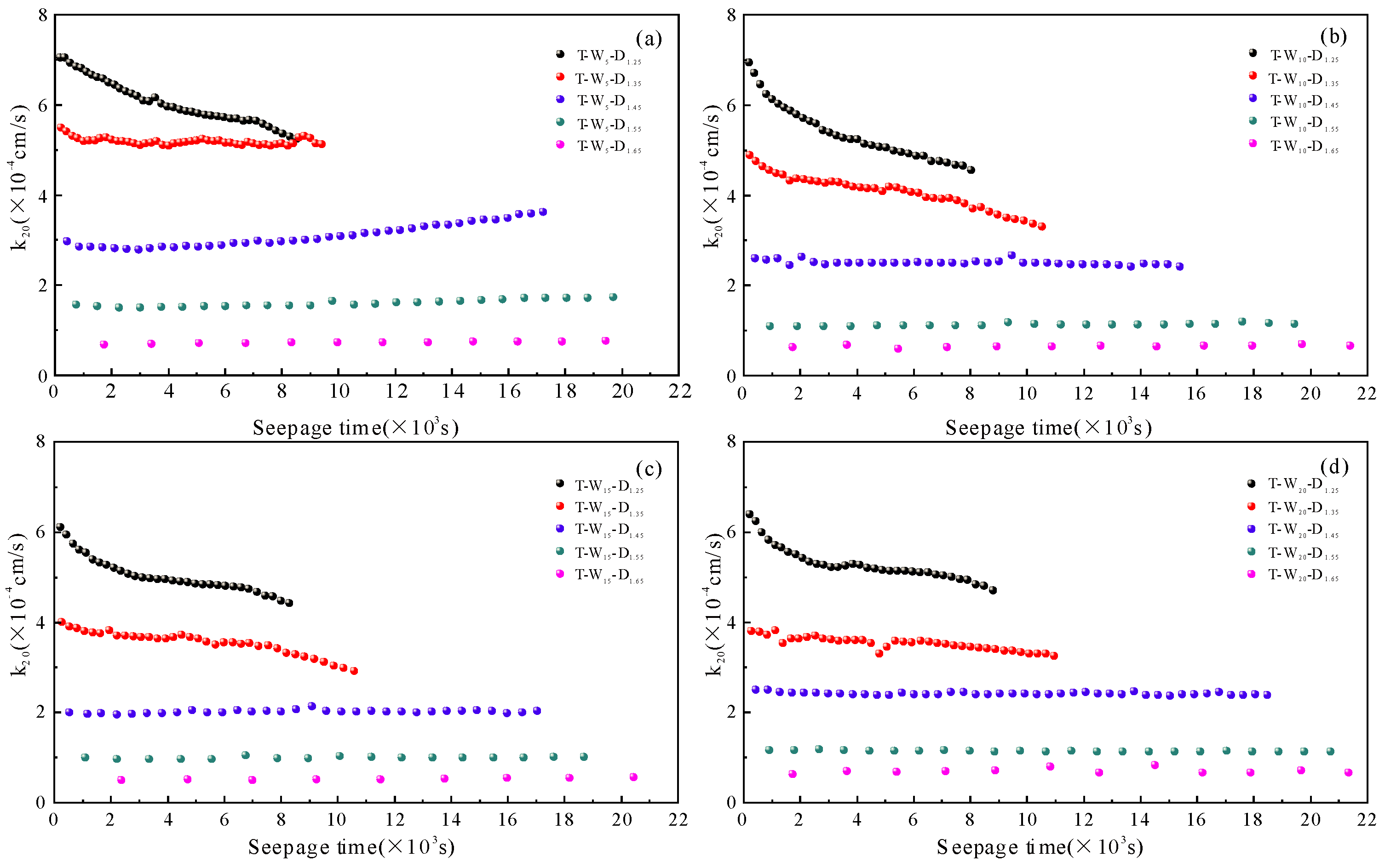

3.2. Permeability Test Results of Remolded Loess under Transfer Wetting Method

4. Discussion

4.1. Effect of Dry Density on the Permeability

4.2. Effect of Initial Moisture Content on the Permeability

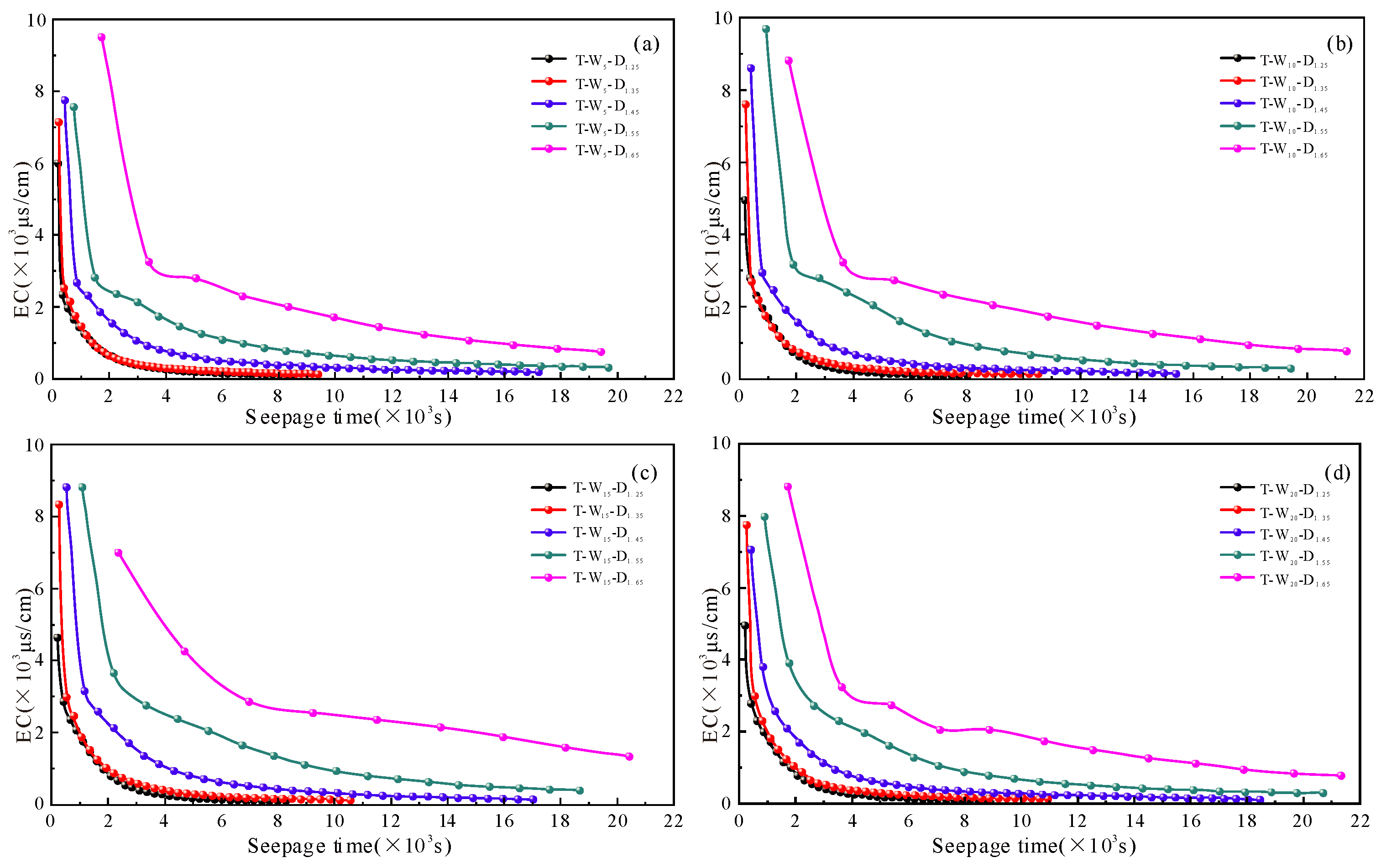

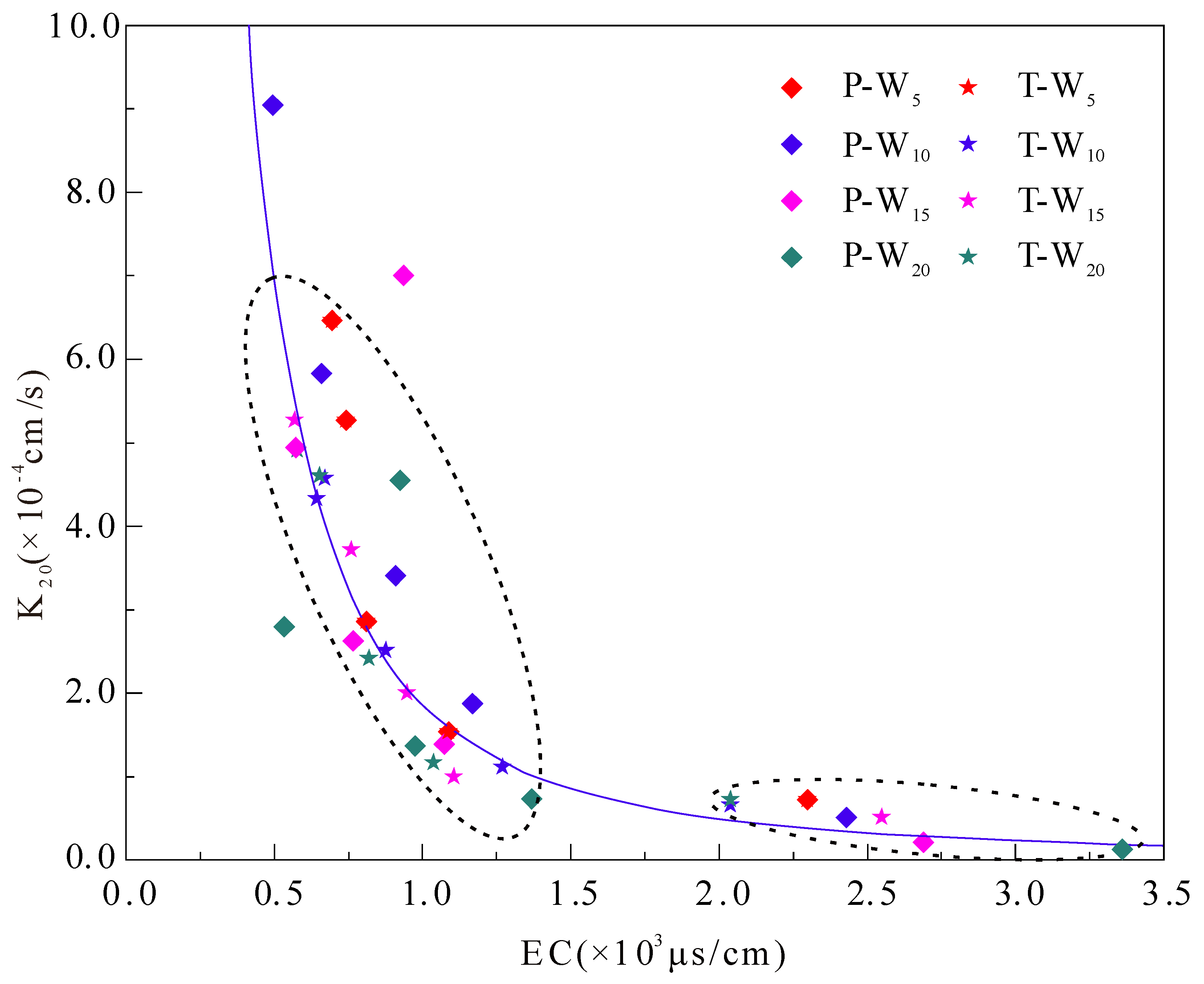

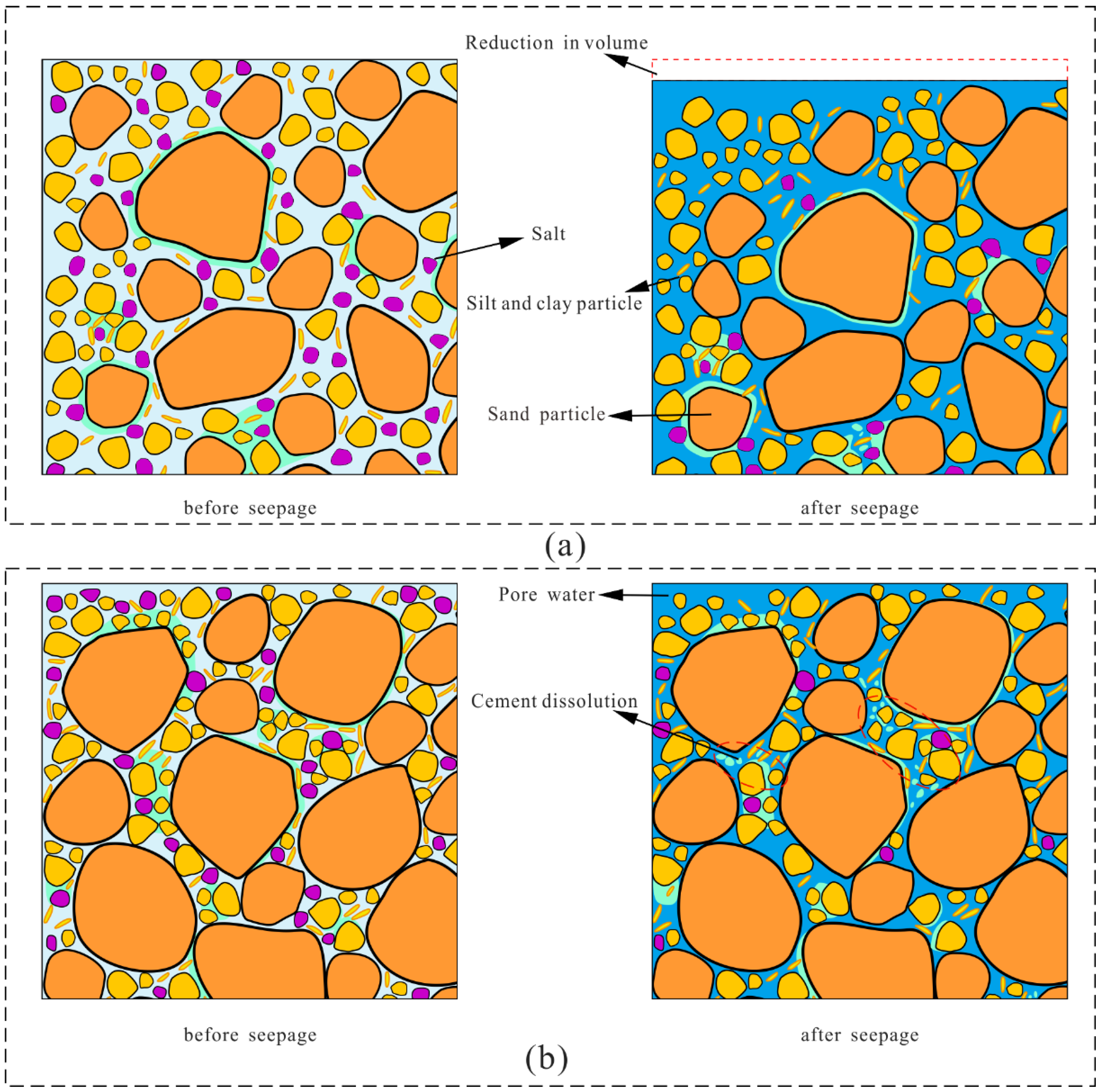

4.3. Relationship between Concentration of Leaching Solution (TDS), Dry Density, and Permeability

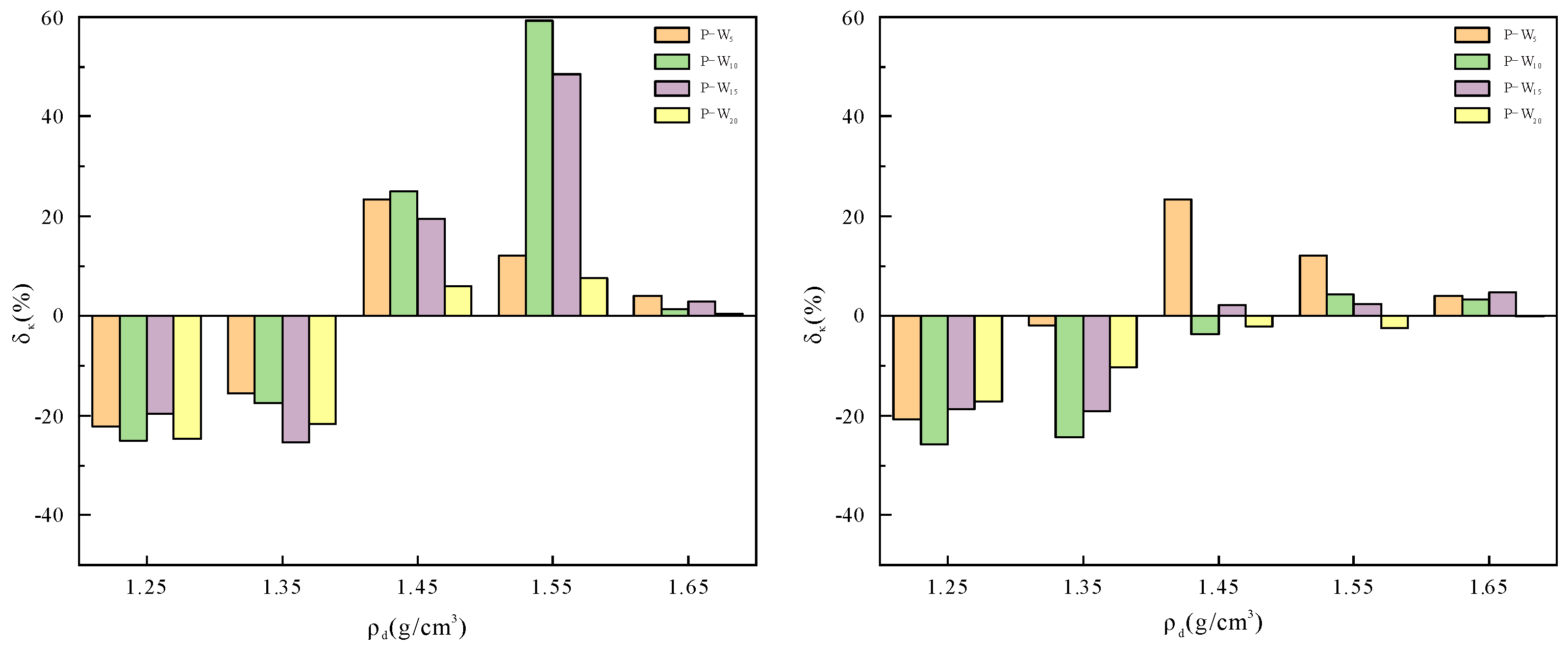

4.4. Effect of Sample Preparation Method on Permeability

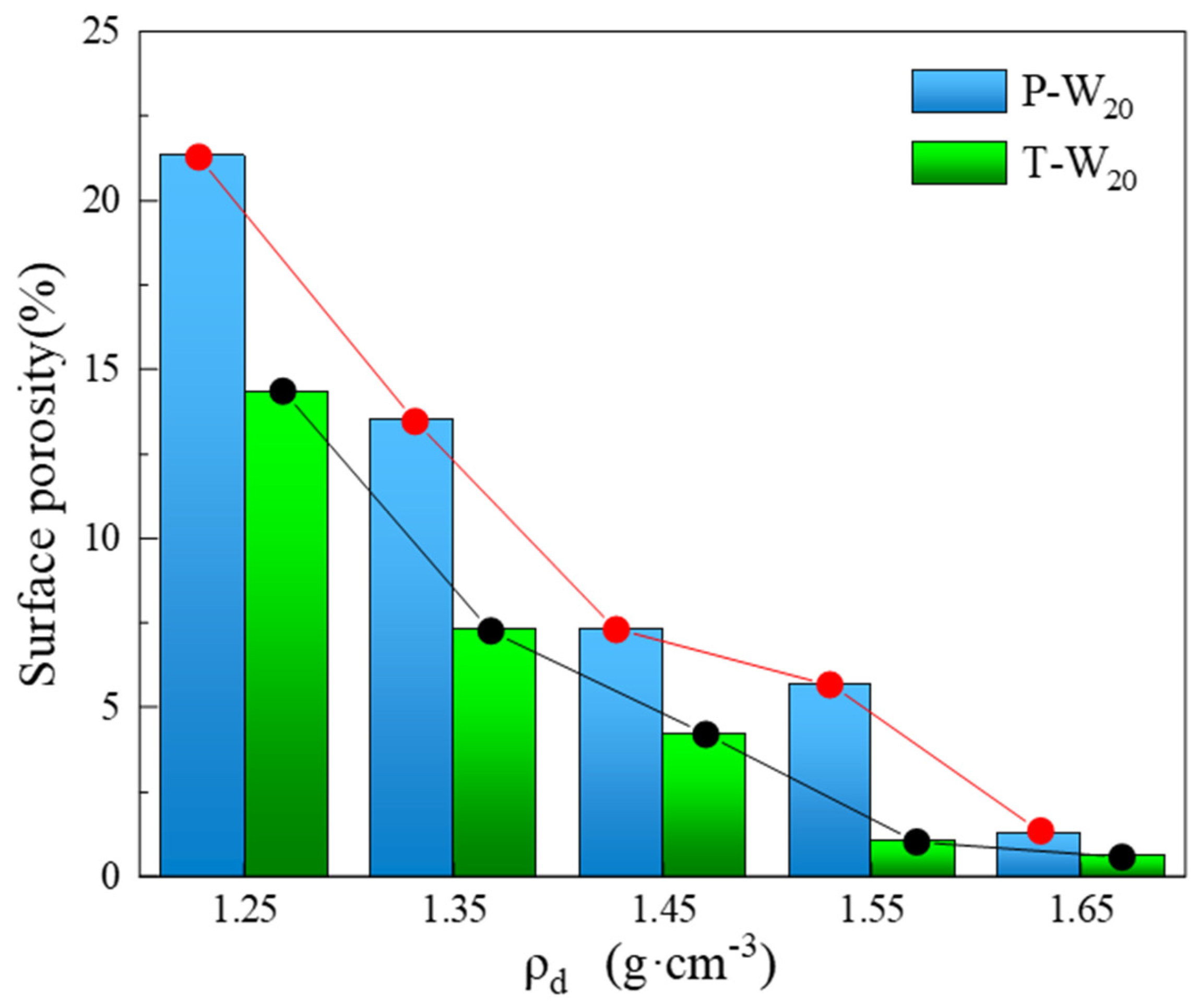

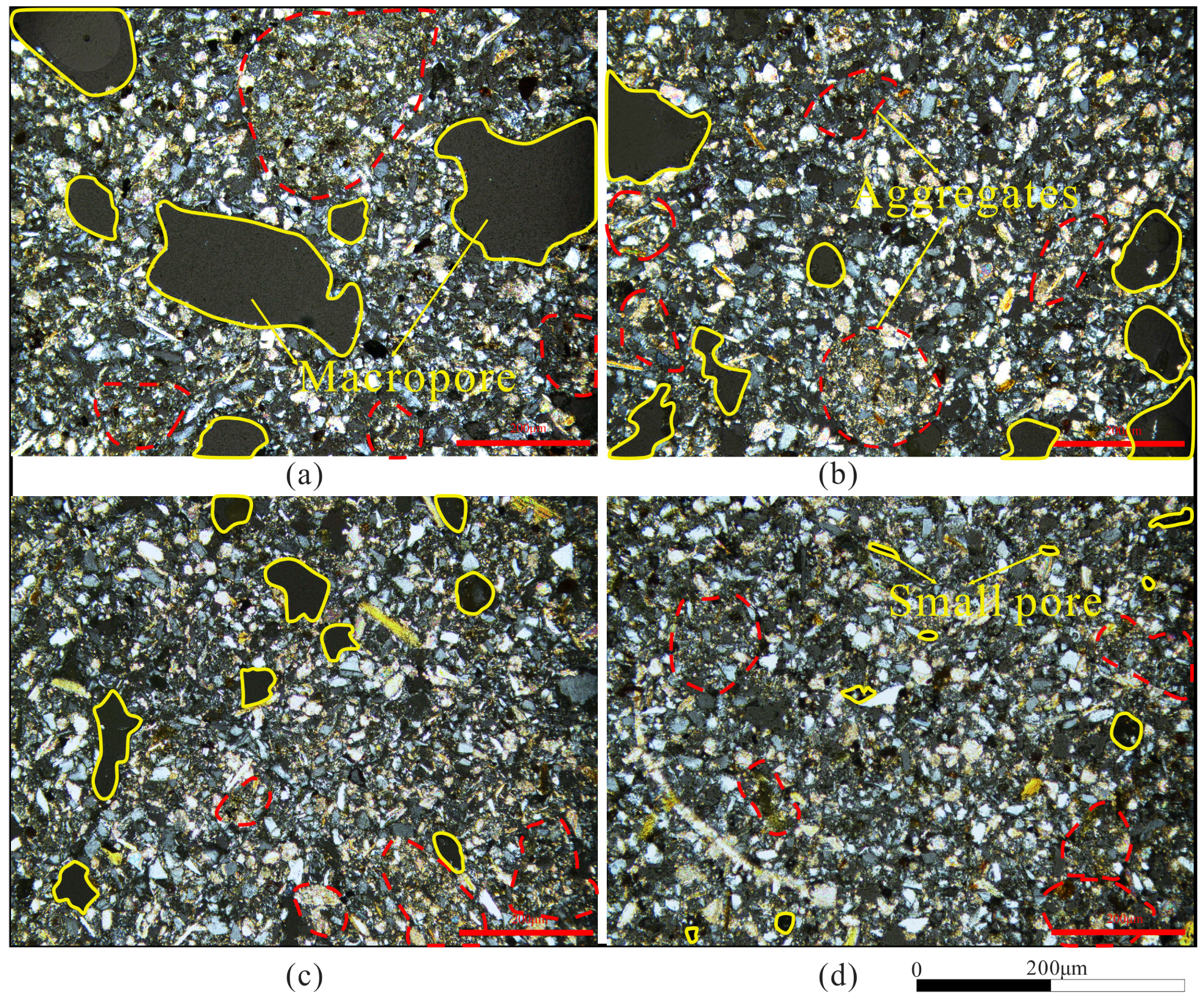

4.4.1. Pore Distribution Characteristics under Sample Preparation Method

4.4.2. Cementation Degree and Contact Relation Characteristics of Soil Particles under Sample Preparation Method

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xianmo, Z.; Yushan, L.; Xianglin, P.; Shuguang, Z. Soils of the loess region in China. Geoderma 1983, 29, 237–255. [Google Scholar] [CrossRef]

- Derbyshire, E. Geological hazards in loess terrain, with particular reference to the loess regions of China. Earth-Sci. Rev. 2001, 54, 231–260. [Google Scholar] [CrossRef]

- Gao, Y.; Qian, H.; Li, X.; Chen, J.; Jia, H. Effects of lime treatment on the hydraulic conductivity and microstructure of loess. Environ. Earth Sci. 2018, 77, 529. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, G.; Chunyong, L.; Chen, J.; Zhou, Y. A rapid loess flowslide triggered by irrigation in China. Landslides 2009, 6, 55–60. [Google Scholar] [CrossRef]

- Wen, B.; He, L. Influence of lixiviation by irrigation water on residual shear strength of weathered red mudstone in Northwest China: Implication for its role in landslides’ reactivation. Eng. Geol. 2012, 151, 56–63. [Google Scholar] [CrossRef]

- Deng, L.-S.; Fan, W.; Yin, Y.-P.; Cao, Y.-B. Case Study of a Collapse Investigation of Loess Sites Covered by Very Thick Loess-Paleosol Interbedded Strata. Int. J. Geomech. 2018, 18, 05018009. [Google Scholar] [CrossRef]

- Wu, L.Z.; Selvadurai, A.P.S.; Zhang, L.M.; Huang, R.Q.; Huang, J. Poro-mechanical coupling influences on potential for rainfall-induced shallow landslides in unsaturated soils. Adv. Water Resour. 2016, 98, 114–121. [Google Scholar] [CrossRef]

- Meng, X.; Derbyshire, E. Landslides and Their Control in the Chinese Loess Plateau: Models and Case Studies from Gansu Province, China; Engineering Geology Special Publications; Geological Society: London, UK, 1998; Volume 15, pp. 141–153. [Google Scholar]

- Xu, L.; Dai, F.; Tu, X.B.; Tham, L.; Zhou, Y.; Iqbal, J. Landslides in a Loess Platform, North-west China. Landslides 2013, 11, 993–1005. [Google Scholar] [CrossRef]

- Xu, L.; Coop, M.; Zhang, M.; Wang, G. The Mechanics of a Saturated Silty Loess and Implications for Landslides. Eng. Geol. 2017, 236, 29–42. [Google Scholar] [CrossRef]

- Liang, C.; Cao, C.; Wu, S. Hydraulic-mechanical properties of loess and its behavior when subjected to infiltration-induced wetting. Bull. Eng. Geol. Environ. 2016, 77, 385–397. [Google Scholar] [CrossRef]

- Anthony, E.; Agunwamba, J. Experimental Determination of Dispersion Coefficient in Soil. Emerg. Sci. J. 2018, 2, 213–218. [Google Scholar]

- Li, J.; Leao, T. Application of Nor Sand Constitutive Model in a Highway Fill Embankment Slope Stability Failure Study. Civ. Eng. J. 2018, 4, 2252. [Google Scholar] [CrossRef]

- Kassou, F.; Bouziyane, J.; Ghafiri, A.; Sabihi, A. Slope Stability of Embankments on Soft Soil Improved with Vertical Drains. Civ. Eng. J. 2020, 6, 164–173. [Google Scholar] [CrossRef]

- Tarantino, A.; Col, E.D. Compaction behaviour of clay. Géotechnique 2008, 58, 199–213. [Google Scholar] [CrossRef]

- Wang, L.-Y.; Chen, W.-Z.; Zhang, Y.-J.; Zhang, X.-D.; Vuik, C. Investigating Effects of Heterogeneity and Fracture Distribution on Two-Phase Flow in Fractured Reservoir with adaptive time strategy. Transp. Porous Media 2023, 149, 175–203. [Google Scholar] [CrossRef]

- Hao, Y.-Z.; Wang, T.-H.; Wang, J.-J. Structural properties of unsaturated compacted loess for various sample moisture contents. Arab. J. Geosci. 2019, 12, 258. [Google Scholar] [CrossRef]

- Lu, J.; Wang, T.-H.; Cheng, J.W.-C.; Yang, T.; Luo, Y. Permeability anisotropy of loess under the influence of dry density and freeze-thaw cycles. Int. J. Geomech. 2019, 19, 04019103. [Google Scholar] [CrossRef]

- Zhai, Q.; Rahardjo, H.; Satyanaga, A. Uncertainty in the estimation of hysteresis of soil–water characteristic curve. Environ. Geotech. 2017, 6, 204–213. [Google Scholar] [CrossRef]

- Leong, E.; Wijaya, M.; Tong, W.; Lu, Y. Examining the Contact Filter Paper Method in the Low Suction Range. Geotech. Test. J. 2020, 43, 20190237. [Google Scholar] [CrossRef]

- Zhai, Q.; Rahardjo, H.; Satyanaga, A.; Dai, G.-L.; Du, Y.-J. Effect of the uncertainty in soil-water characteristic curve on the estimated shear strength of unsaturated soil. J. Zhejiang Univ.-Sci. A 2020, 21, 317–330. [Google Scholar] [CrossRef]

- Xu, P.; Zhang, Q.; Qian, H.; Qu, W.; Li, M. Microstructure and permeability evolution of remolded loess with different dry density under saturated seepage. Eng. Geol. 2020, 282, 105875. [Google Scholar] [CrossRef]

- Cuisinier, O.; Auriol, J.-C.; Le Borgne, T.; Deneele, D. Microstructure and hydraulic conductivity of a compacted lime-treated soil. Eng. Geol. 2011, 123, 187–193. [Google Scholar] [CrossRef]

- Kangze, Y.; Ni, W.-K.; Lü, X.; Wang, X.-J. Permeability characteristics and structural evolution of compacted loess under different dry density and wetting-drying cycles. PLoS ONE 2021, 16, e0253508. [Google Scholar]

- Zhang, Y.; Zou, Y.; Zhang, Y.; Wang, L.; Liu, D.; Sun, J.; Ge, H.; Zhou, D. Experimental study on characteristics and mechanisms of matrix pressure transmission near the fracture surface during post-fracturing shut-in in tight oil reservoirs. J. Pet. Sci. Eng. 2022, 219, 111133. [Google Scholar] [CrossRef]

- Wei, Y.-N.; Fan, W.; Yu, N.; Deng, L.-S.; Wei, T. Permeability of loess from the South Jingyang Plateau under different consolidation pressures in terms of the three-dimensional microstructure. Bull. Eng. Geol. Environ. 2020, 79, 4841–4857. [Google Scholar] [CrossRef]

- Li, X.; Li, L. Quantification of the pore structures of Malan loess and the effects on loess permeability and environmental significance, Shaanxi Province, China: An experimental study. Environ. Earth Sci. 2017, 76, 523. [Google Scholar] [CrossRef]

- Guo, Y.; Ni, W.; Kou, Z.; Zhao, Y.; Nie, Y. Experimental Study on the Permeability of Compacted Loess. Soil Mech. Found. Eng. 2020, 57, 394–400. [Google Scholar] [CrossRef]

- Qajar, J.; Arns, C.H. A comparative study of micro-CT and mercury intrusion techniques for predicting permeability and surface area evolution during chemical dissolution. Adv. Water Resour. 2022, 168, 104301. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Wang, S.; Wang, Q.; Ding, J. Shear strength and mesoscopic character of undisturbed loess with sodium sulfate after dry-wet cycling. Bull. Eng. Geol. Environ. 2019, 79, 1523–1541. [Google Scholar] [CrossRef]

- Liu, D.; She, D.; Mu, X. Water flow and salt transport in bare saline-sodic soils subjected to evaporation and intermittent irrigation with saline/distilled water. Land Degrad. Dev. 2019, 30, 1204–1218. [Google Scholar] [CrossRef]

- Nimmo, J.R.; Akstin, K.C. Hydraulic conductivity of a sandy soil at low water content after compaction by various methods. Soil Sci. Soc. Am. J. 1988, 52, 303–310. [Google Scholar] [CrossRef]

- Jang, D.J.; Frost, J.D.; American Society of Civil Engineers. Sand Structure Differences Resulting from Specimen Preparation Procedures. In Speciality Conference, Geotechnical Earthquake Engineering and Soil Dynamics, 75th ed.; American Society of Civil Engineers: Seattle, WA, USA, 1998; pp. 234–245. [Google Scholar]

- Delage, P.; Audiguier, M.; Cui, Y.-J.; Howat, M. Microstructure of a compacted silt. Can. Geotech. J. 2011, 33, 150–158. [Google Scholar] [CrossRef]

- Gao, Y.; Sun, D.; Zhou, A. Hydromechanical behaviour of unsaturated soil with different specimen preparations. Can. Geotech. J. 2015, 53, 909–917. [Google Scholar] [CrossRef]

- Teng, J.; Kou, J.; Zhang, S.; Sheng, D. Evaluating the Influence of Specimen Preparation on Saturated Hydraulic Conductivity Using Nuclear Magnetic Resonance Technology. Vadose Zone J. 2019, 18, 180179. [Google Scholar] [CrossRef]

- ASTM. Annual Book of ASTM Standards; ASTM: West Conshohocken, PA, USA, 2006. [Google Scholar]

- ASTM (2009) D7263; Standard Test Methods for Laboratory Determination of Density (Unit Weight) of Soil Specimens. ASTM International: West Conshohocken, PA, USA.

- ASTM (2010) D4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA.

- ASTM (2010) D2216; Standard Test Methods for Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass. ASTM International: West Conshohocken, PA, USA.

- ASTM (2014) D854; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA.

- ASTM (2011) D2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA.

- Zhaoqiang, J.; Ren, T.; Hu, C. Soil Thermal Conductivity as Influenced by Aggregation at Intermediate Water Contents. Soil Sci. Soc. Am. J. 2011, 75, 26–29. [Google Scholar]

- Liu, W.; Wang, Q.; Lin, G.; Chen, W. Effect of pre-dynamic loading on dynamic liquefaction of undisturbed loess. Bull. Earthq. Eng. 2020, 18, 5779–5806. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, Y.; Li, X.; Lu, Y.; Pan, W. Microscopic structure changes of Malan loess after humidification in South Jingyang Plateau, China. Environ. Earth Sci. 2019, 78, 287. [Google Scholar] [CrossRef]

- Yan, X.; Duan, Z.; Sun, Q. Influences of water and salt contents on the thermal conductivity of loess. Environ. Earth Sci. 2021, 80, 52. [Google Scholar] [CrossRef]

- Xu, P.; Zhang, Q.; Qian, H.; Qu, W. Effect of Sodium Chloride Concentration on Saturated Permeability of Remolded Loess. Minerals 2020, 10, 199. [Google Scholar] [CrossRef]

- Jafari, R.; Sheikh, V.; Hossein-Alizadeh, M.; Rezaii-Moghadam, H. Effect of Soil Sample Size on Saturated Soil Hydraulic Conductivity. Commun. Soil Sci. Plant Anal. 2017, 48, 908–919. [Google Scholar] [CrossRef]

- Zhang, Y.; Qian, H.; Hou, K.; Qu, W. Investigating and predicting the temperature effects of permeability for loess. Eng. Geol. 2021, 285, 106050. [Google Scholar] [CrossRef]

- Romero, E.; Simms, P. Microstructure Investigation in Unsaturated Soils: A Review with Special Attention to Contribution of Mercury Intrusion Porosimetry and Environmental Scanning Electron Microscopy. Geotech. Geol. Eng. 2008, 26, 705–727. [Google Scholar] [CrossRef]

- Liu, Z.; Dugan, B.; Masiello, C.A.; Barnes, R.T.; Gallagher, M.E.; Gonnermann, H. Impacts of biochar concentration and particle size on hydraulic conductivity and DOC leaching of biochar–sand mixtures. J. Hydrol. 2016, 533, 461–472. [Google Scholar] [CrossRef]

- Yilmaz, G.; Yetimoglu, T.; Arasan, S. Hydraulic conductivity of compacted clay liners permeated with inorganic salt solutions. Waste Manag. Res. J. Int. Solid Wastes Public Clean. Assoc. ISWA 2008, 26, 464–473. [Google Scholar] [CrossRef] [PubMed]

- Rabot, E.; Wiesmeier, M.; Schlüter, S.; Vogel, H.J. Soil structure as an indicator of soil functions: A review. Geoderma 2018, 314, 122–137. [Google Scholar] [CrossRef]

- Xu, P.; Zhang, Q.; Qian, H.; Li, M.; Yang, F. An investigation into the relationship between saturated permeability and microstructure of remolded loess: A case study from Chinese Loess Plateau. Geoderma 2021, 382, 114774. [Google Scholar] [CrossRef]

- Hao, Y.-Z.; Wang, T.-H.; Jin, X.; Cheng, L.; Li, J.-L. Experimental Study on the Saturated Compacted Loess Permeability under K0 Consolidation. Adv. Civ. Eng. 2020, 2020, 1426485. [Google Scholar]

- Liu, J.; Li, X.; Xue, Q.; Guo, Z. Experimental study on air permeability and microscopic mechanism of intact and remolded Malan loess, Loess Plateau, China. Bull. Eng. Geol. Environ. 2020, 79, 3909–3919. [Google Scholar] [CrossRef]

- Wei, Y.-N.; Fan, W.; Yu, B.; Deng, L.-S.; Wei, T. Characterization and evolution of three-dimensional microstructure of Malan loess. Catena 2020, 192, 104585. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.M. Characterization of dual-structure pore-size distribution of soil. Can. Geotech. J. 2009, 46, 129–141. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Chen, R.; Wang, H.; Wu, L.; Xia, J. Liquefaction Resistance of Biocemented Loess Soil. J. Geotech. Geoenvironmental Eng. 2021, 147, 04021117. [Google Scholar] [CrossRef]

- Wang, X.; Nackenhorst, U. A coupled bio-chemo-hydraulic model to predict porosity and permeability reduction during microbially induced calcite precipitation. Adv. Water Resour. 2020, 140, 103563. [Google Scholar] [CrossRef]

- Dutta, J.; Mishra, A.K. A study on the influence of inorganic salts on the behaviour of compacted bentonites. Appl. Clay Sci. 2015, 116–117, 85–92. [Google Scholar] [CrossRef]

- Meng, J.; Li, X.-A. Effects of carbonate on the structure and properties of loess and the corresponding mechanism: An experimental study of the Malan loess, Xi’an area, China. Bull. Eng. Geol. Environ. 2019, 78, 4965–4976. [Google Scholar] [CrossRef]

- Corwin, D.L.; Lesch, S.M. Apparent soil electrical conductivity measurements in agriculture. Comput. Electron. Agric. 2005, 46, 11–43. [Google Scholar] [CrossRef]

- Sudduth, K.A.; Myers, D.B.; Kitchen, N.R.; Drummond, S.T. Modeling soil electrical conductivity-depth relationships with data from proximal and penetrating ECa sensors. Geoderma 2013, 199, 12–21. [Google Scholar] [CrossRef]

- Mooney, S.J. Three-dimensional visualization and quantification of soil macroporosity and water flow patterns using computed tomography. Soil Use Manag. 2002, 18, 142–151. [Google Scholar] [CrossRef]

- Luo, L.; Lin, H.; Halleck, P. Quantifying Soil Structure and Preferential Flow in Intact Soil Using X-ray Computed Tomography. Soil Sci. Soc. Am. J. 2008, 72, 1058–1069. [Google Scholar] [CrossRef]

- Katuwal, S.; Norgaard, T.; Moldrup, P.; Lamandé, M.; Wildenschild, D.; de Jonge, L.W. Linking air and water transport in intact soils to macropore characteristics inferred from X-ray computed tomography. Geoderma 2015, 237–238, 9–20. [Google Scholar] [CrossRef]

- Yue, F.; Ren, X.; Wang, X.; Tian, W. Experimental Study on the Influence of Soil Structure Index on Loess Permeability. Adv. Mater. Sci. Eng. 2022, 2022, 9618732. [Google Scholar] [CrossRef]

- Li, P.; Pan, Z.H.; Xiao, T.; Wang, J. Effects of molding water content and compaction degree on the microstructure and permeability of compacted loess. Acta Geotech. 2022, 18, 921–936. [Google Scholar] [CrossRef]

- Fannin, R.; Slangen, P. On the distinct phenomena of suffusion and suffosion. Géotechnique Lett. 2014, 4, 289–294. [Google Scholar] [CrossRef]

- Hunter, R.; Bowman, E. Visualisation of seepage-induced suffusion and suffosion within internally erodible granular media. Géotechnique 2018, 68, 918–930. [Google Scholar] [CrossRef]

| Physical Properties | Values | Determination Method | Limit Water Content and Related Properties | Values | Determination Method |

|---|---|---|---|---|---|

| Dry density, ρd (g/cm3) | 1.35 | ASTM D7263 [38] | Liquid Limit, ωL (%) | 25.7 | ASTM D4318 [39] |

| Natural moisture content, ω (%) | 7.01 | ASTM D2216 [40] | Plastic Limit, ωP (%) | 16.5 | |

| Plasticity Index, Ip (%) | 9.2 | ||||

| Specific gravity, Gs | 2.71 | ASTM D854 [41] | Classification | CL | ASTM D2487 [42] |

| Mineral | Quartz | Plagioclase | Potassium Feldspar | Calcite | Dolomite | Chlorite | Illite | Amphibole | Mundic |

|---|---|---|---|---|---|---|---|---|---|

| Wt (%) | 48.1 | 18.4 | 3.1 | 11.0 | 6.6 | 5.5 | 5.5 | 0.9 | 0.9 |

| Sample Number | Initial Moisture Content (%) | Dry Density (g/cm3) | Sample Preparation Method | Sample Number | Initial Moisture Content (%) | Dry Density (g/cm3) | Sample Preparation Method |

|---|---|---|---|---|---|---|---|

| P-W5-D1.25 | 5 | 1.25 | P | T-W5-D1.25 | 5 | 1.25 | T |

| P-W5-D1.35 | 5 | 1.35 | P | T-W5-D1.35 | 5 | 1.35 | T |

| P-W5-D1.45 | 5 | 1.45 | P | T-W5-D1.45 | 5 | 1.45 | T |

| P-W5-D1.55 | 5 | 1.55 | P | T-W5-D1.55 | 5 | 1.55 | T |

| P-W5-D1.65 | 5 | 1.65 | P | T-W5-D1.65 | 5 | 1.65 | T |

| P-W10-D1.25 | 10 | 1.25 | P | T-W10-D1.25 | 10 | 1.25 | T |

| P-W10-D1.35 | 10 | 1.35 | P | T-W10-D1.35 | 10 | 1.35 | T |

| P-W10-D1.45 | 10 | 1.45 | P | T-W10-D1.45 | 10 | 1.45 | T |

| P-W10-D1.55 | 10 | 1.55 | P | T-W10-D1.55 | 10 | 1.55 | T |

| P-W10-D1.65 | 10 | 1.65 | P | T-W10-D1.65 | 10 | 1.65 | T |

| P-W15-D1.25 | 15 | 1.25 | P | T-W15-D1.25 | 15 | 1.25 | T |

| P-W15-D1.35 | 15 | 1.35 | P | T-W15-D1.35 | 15 | 1.35 | T |

| P-W15-D1.45 | 15 | 1.45 | P | T-W15-D1.45 | 15 | 1.45 | T |

| P-W15-D1.55 | 15 | 1.55 | P | T-W15-D1.55 | 15 | 1.55 | T |

| P-W15-D1.65 | 15 | 1.65 | P | T-W15-D1.65 | 15 | 1.65 | T |

| P-W20-D1.25 | 20 | 1.25 | P | T-W20-D1.25 | 20 | 1.25 | T |

| P-W20-D1.35 | 20 | 1.35 | P | T-W20-D1.35 | 20 | 1.35 | T |

| P-W20-D1.45 | 20 | 1.45 | P | T-W20-D1.45 | 20 | 1.45 | T |

| P-W20-D1.55 | 20 | 1.55 | P | T-W20-D1.55 | 20 | 1.55 | T |

| P-W20-D1.65 | 20 | 1.65 | P | T-W20-D1.65 | 20 | 1.65 | T |

| Dry Density (g/cm3) | Microstructure Characteristics | The Pre-Wetting Method | The Transfer Wetting Method |

|---|---|---|---|

| 1.35 | Particle morphology | Large particles are scattered and fine particles are distributed among them | Large particles are scattered and fine particles are partially agglomerated |

| Contact relationship | Overhead contact mainly; angular contact is most common | Mainly overhead contact, followed by angular or edge contact | |

| Pore structure | Mostly large pores, and mainly overhead pores | Mostly mesoporous pores, and mainly overhead pores | |

| Cementation degree | Micro-cementation | Semi-cementation | |

| 1.55 | Particle morphology | Large particles are scattered and fine particles are clustered | Large particles are evenly distributed, with fine particles interspersed among them |

| Contact relationship | Mainly mosaic contact, followed by angular or edge contact | Mainly mosaic contact, mainly edge contact | |

| Pore structure | Mostly mesoporous pores, and mainly mosaic pores | Mostly small pores; the cementation pore is the main type, folllowed by mosaic pore | |

| Cementation degree | Partial cementation | Strong cementation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Qiu, Y.; Gao, Y.; An, Y.; Duan, Z.; Li, S. Effects of Sample Preparation Methods on Permeability and Microstructure of Remolded Loess. Water 2023, 15, 3469. https://doi.org/10.3390/w15193469

Ma J, Qiu Y, Gao Y, An Y, Duan Z, Li S. Effects of Sample Preparation Methods on Permeability and Microstructure of Remolded Loess. Water. 2023; 15(19):3469. https://doi.org/10.3390/w15193469

Chicago/Turabian StyleMa, Jianquan, Yongqiang Qiu, Yanbin Gao, Yuke An, Zhao Duan, and Shibo Li. 2023. "Effects of Sample Preparation Methods on Permeability and Microstructure of Remolded Loess" Water 15, no. 19: 3469. https://doi.org/10.3390/w15193469

APA StyleMa, J., Qiu, Y., Gao, Y., An, Y., Duan, Z., & Li, S. (2023). Effects of Sample Preparation Methods on Permeability and Microstructure of Remolded Loess. Water, 15(19), 3469. https://doi.org/10.3390/w15193469