Three-Dimensional Numerical Analysis and Operational Optimization of High-Efficiency Sedimentation Tank

Abstract

:1. Introduction

2. Calculation Model and Methods

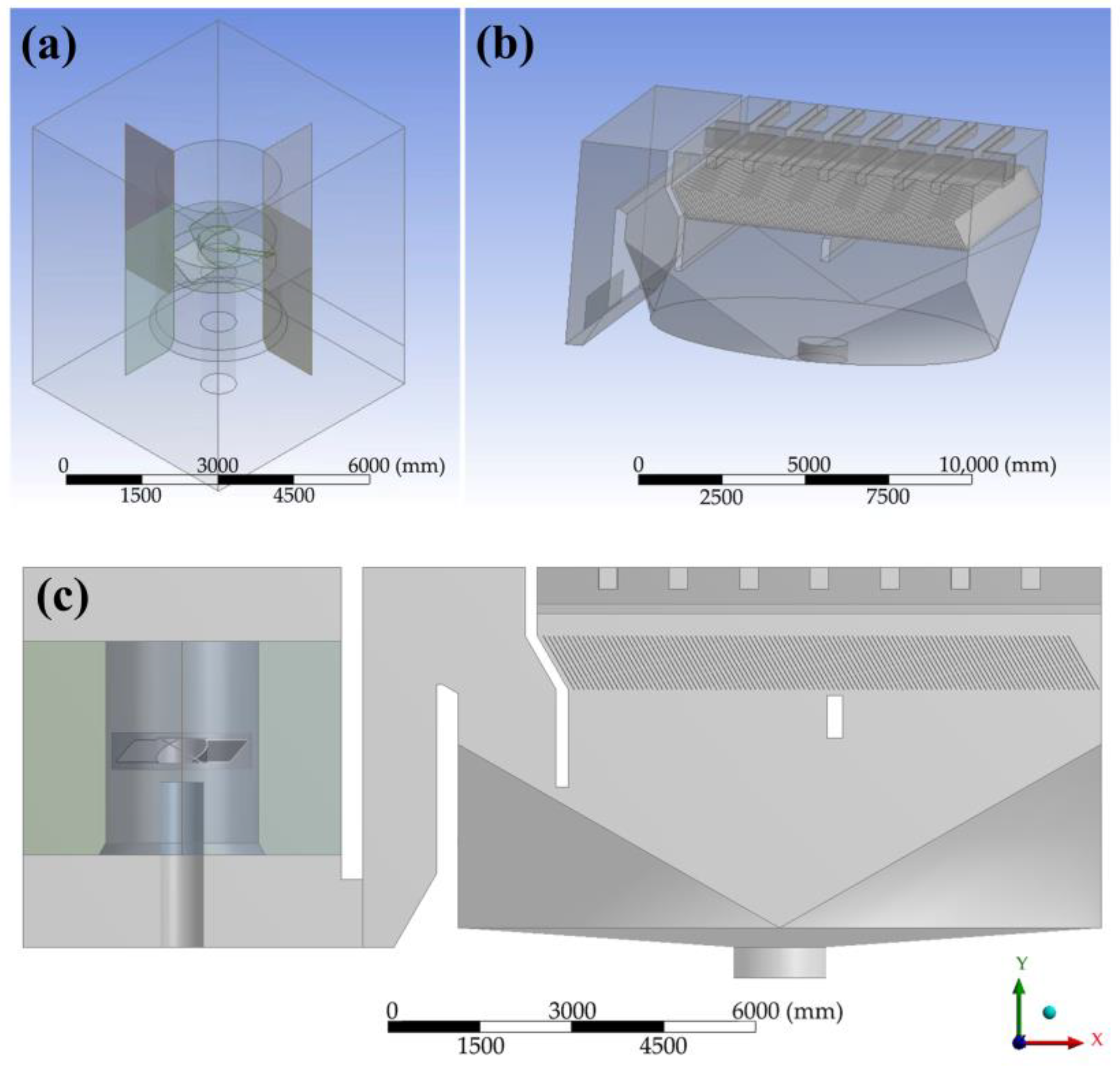

2.1. Geometric Model

2.2. Boundary Conditions and Grid Settings

3. Results and Discussion

3.1. Optimization of the Flocculation Zone

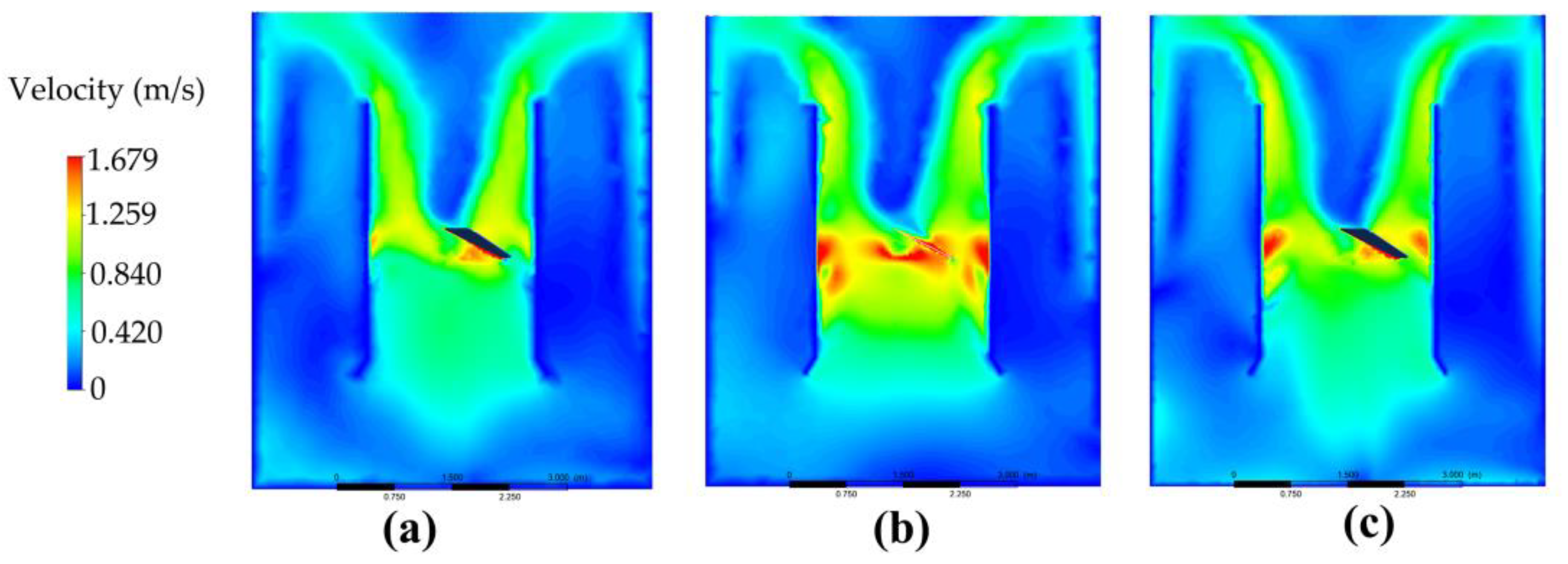

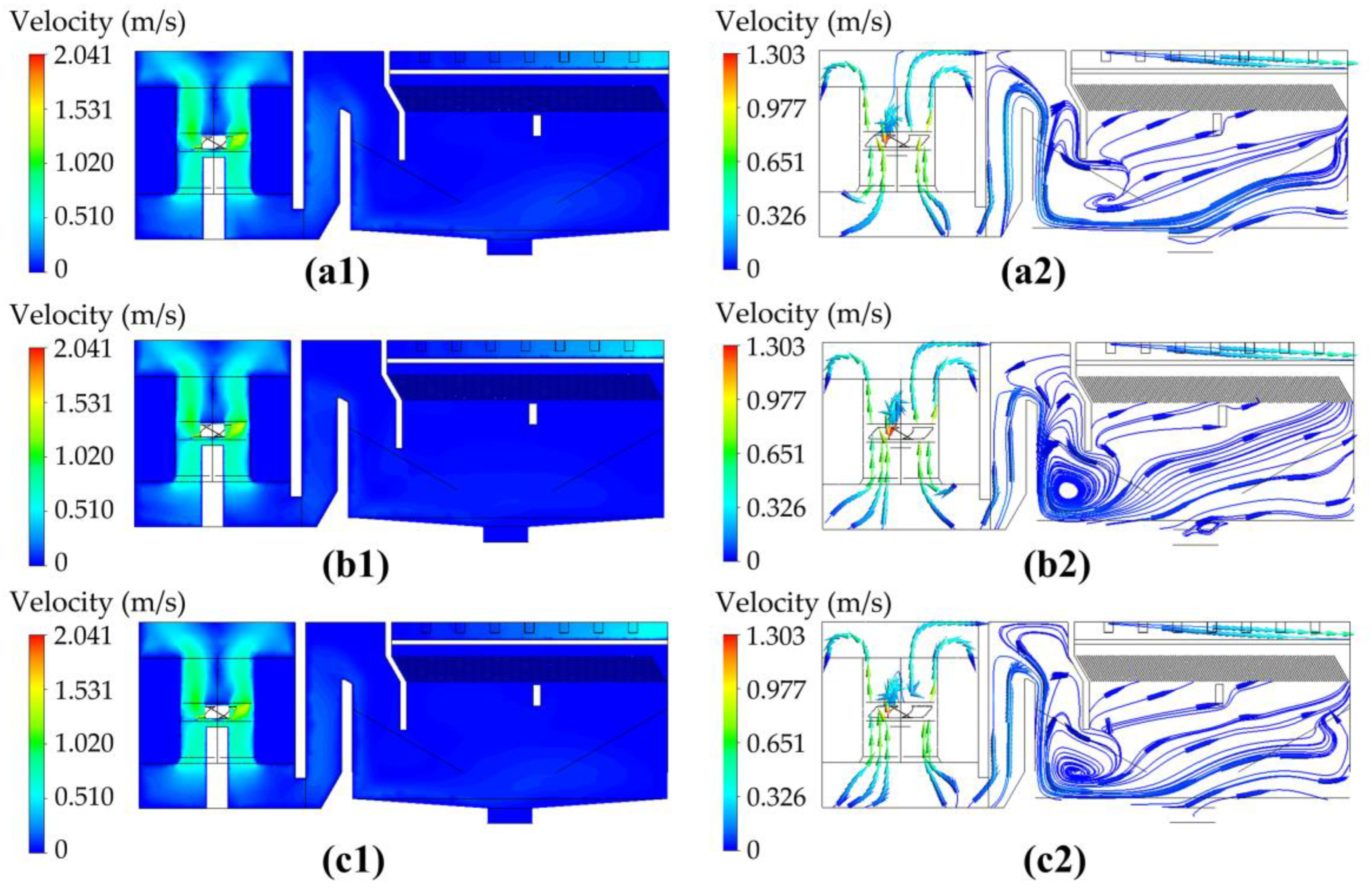

3.1.1. Diameter of the Draft Tube

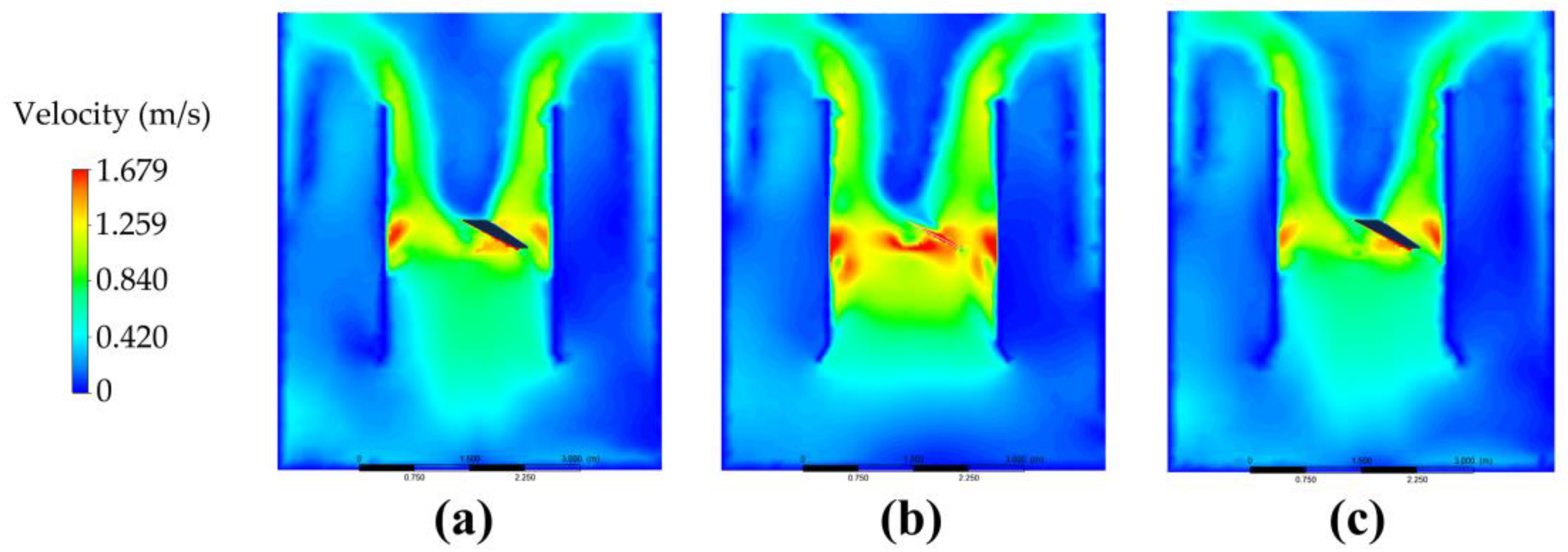

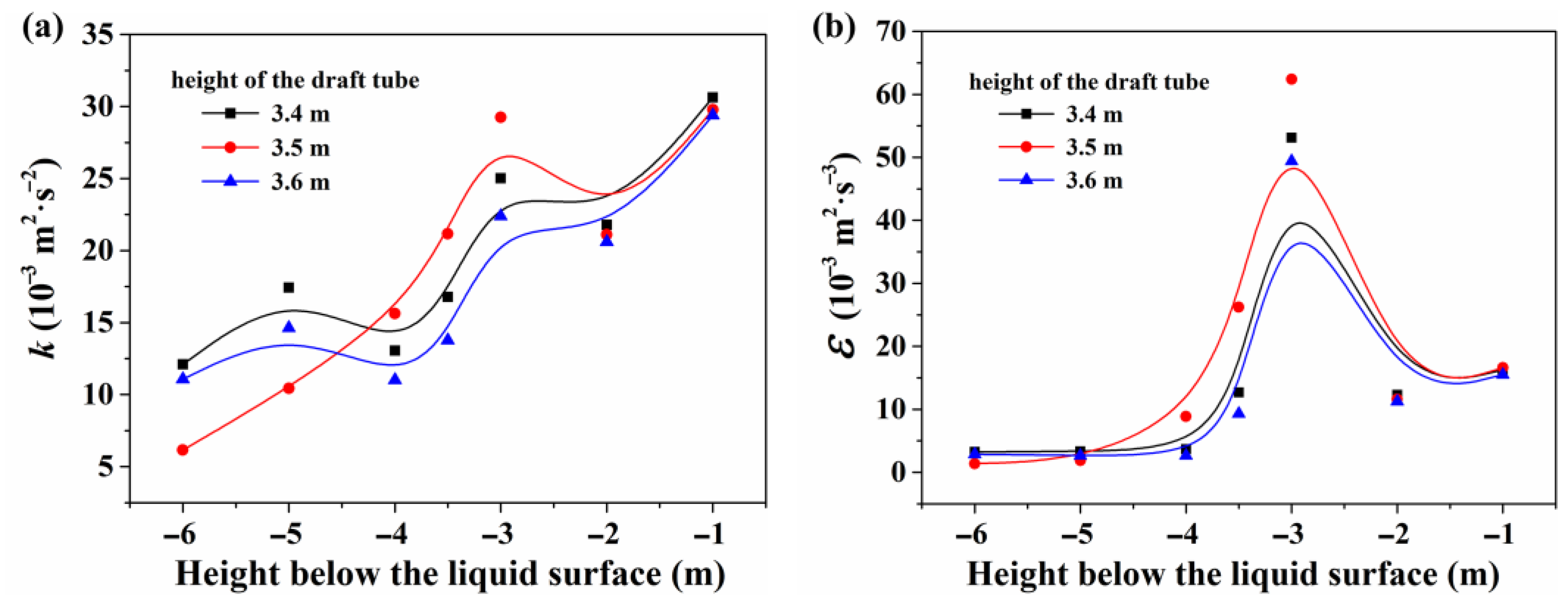

3.1.2. Height of the Draft Tube

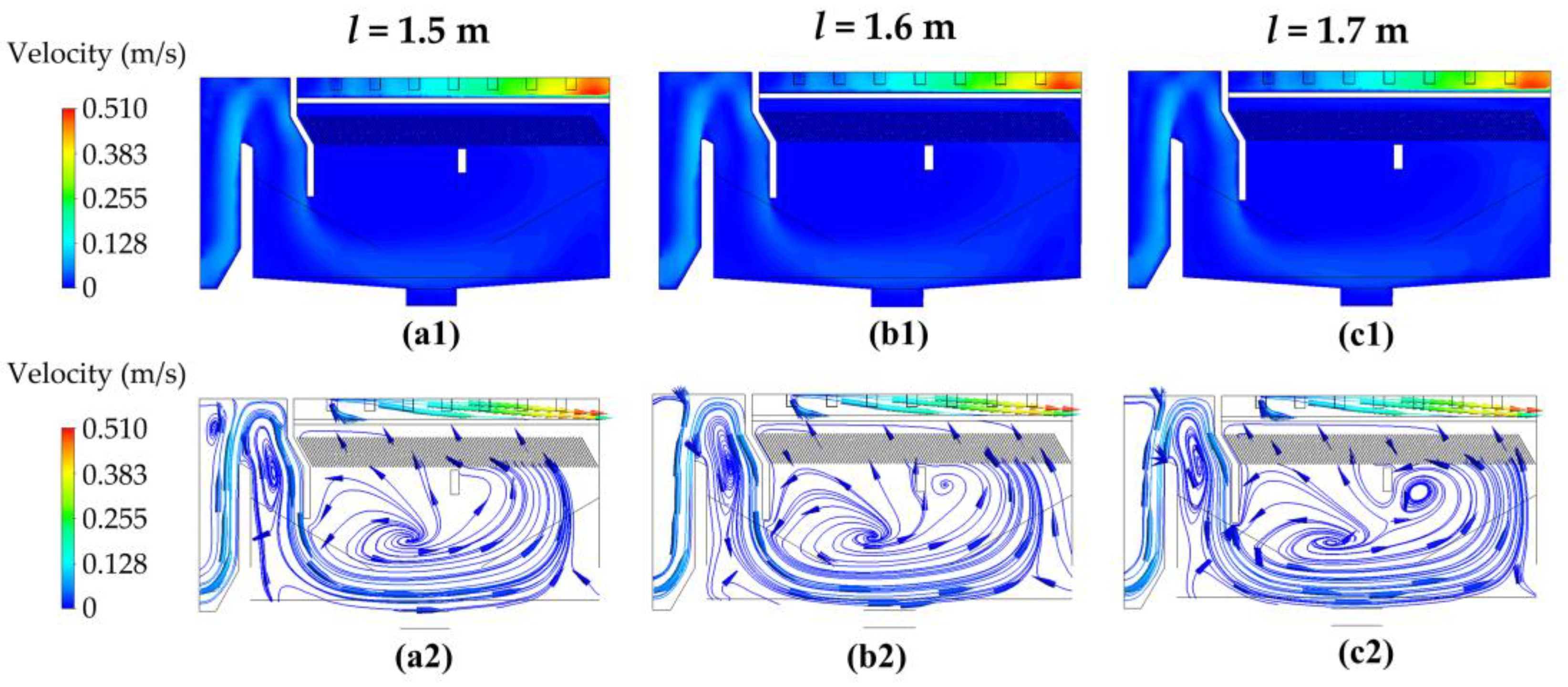

3.2. Optimization of the Plug-Flow/Clarification Zone

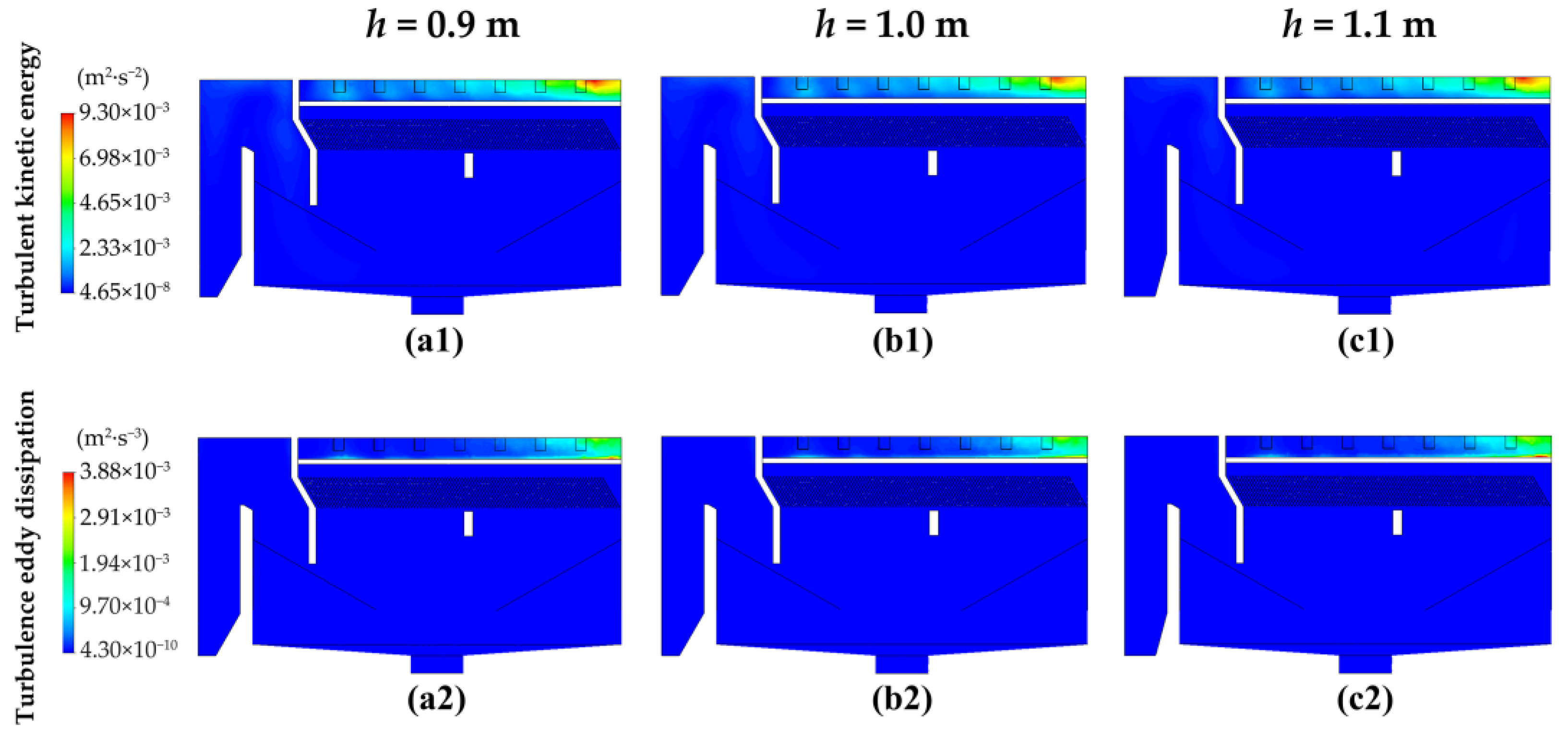

3.2.1. Height of the Water Tunnel

3.2.2. Height of the Water-Retaining Weir

3.3. Optimization of the Operation Parameters

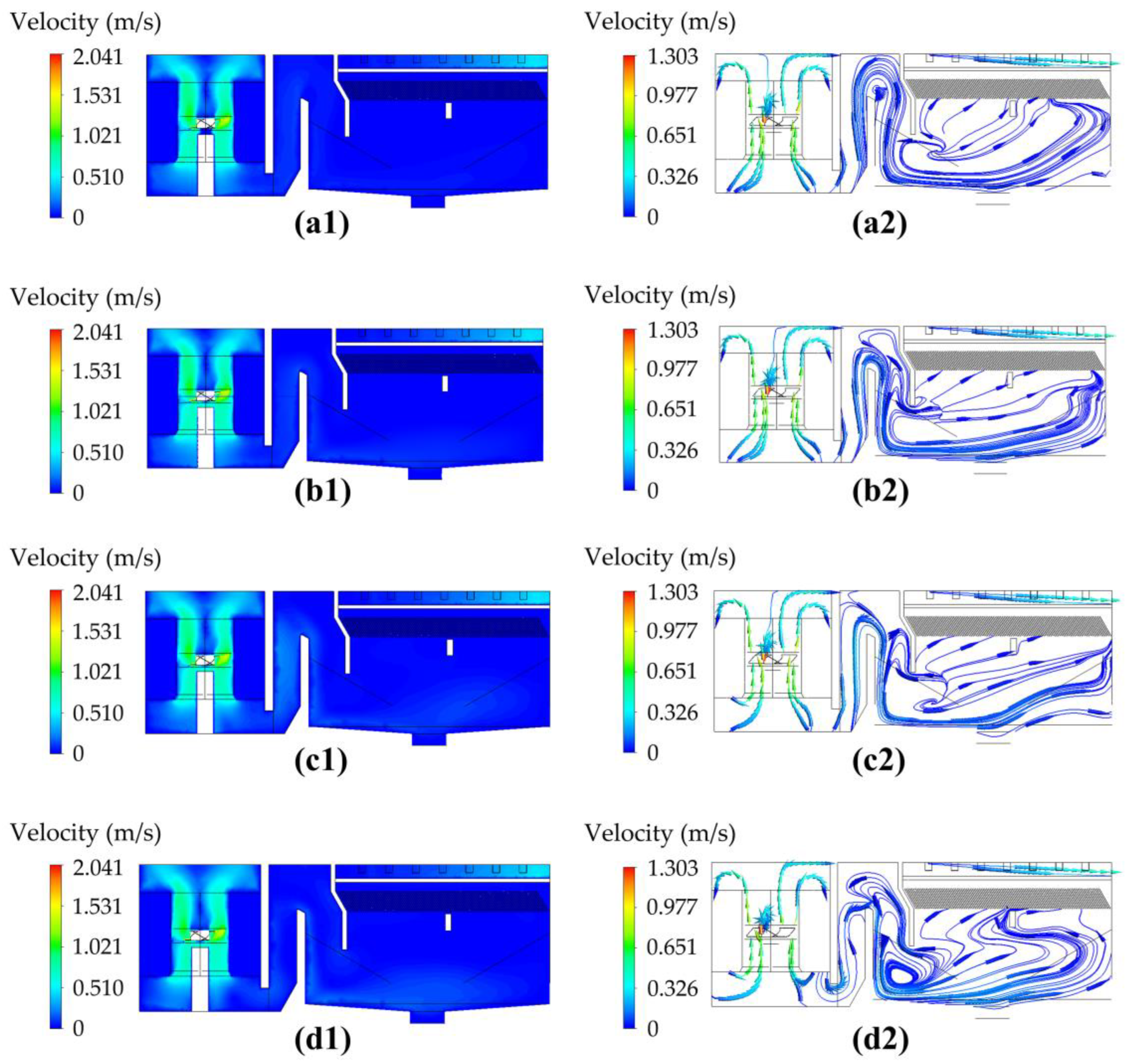

3.3.1. Dosage of Heavy Medium Particles

3.3.2. Stirring Rate

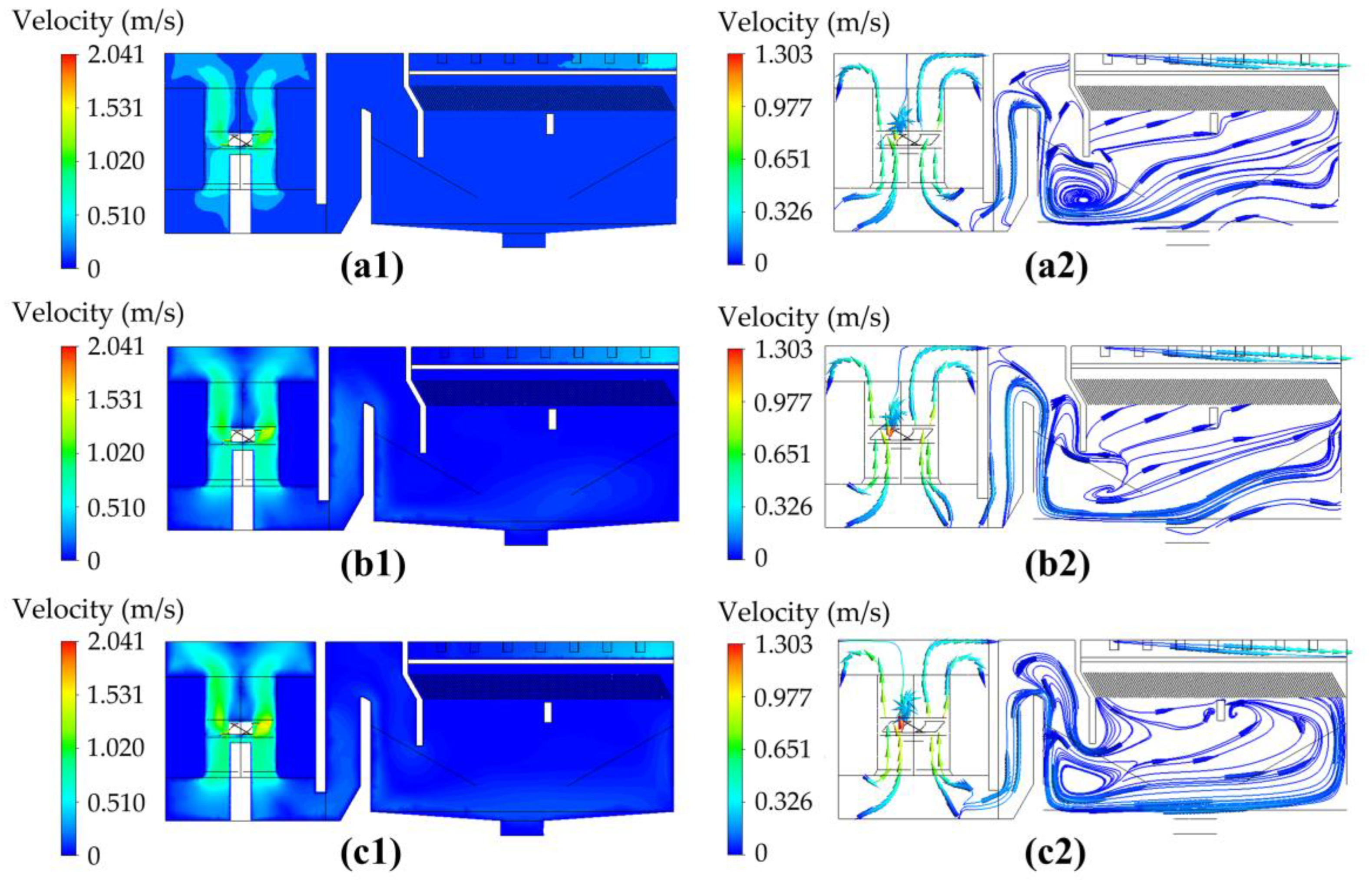

3.3.3. Inlet Velocity

3.4. Comparison between High-Efficiency Settling Tank and Conventional Clarifier

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Imasuen, E.; Judd, S.; Sauvignet, P. High-rate clarification of municipal wastewaters: A brief appraisal. J. Chem. Technol. Biotechnol. 2004, 79, 914–917. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, Q.; Ji, H. Research on zero discharge treatment technology of mine wastewater. Energy Rep. 2022, 8, 275–280. [Google Scholar] [CrossRef]

- Chen, Z.; Yang, B.; Wen, Q.; Chen, C. Evaluation of enhanced coagulation combined with densadeg-ultrafiltration process in treating secondary effluent: Organic micro-pollutants removal, genotoxicity reduction, and membrane fouling alleviation. J. Hazard. Mater. 2020, 396, 122697. [Google Scholar] [CrossRef]

- Song, W.; Ren, Y.; Jia, R.; Zhao, L.; Chen, F.; Zhu, Z. Removal of organic pollutants by contact oxidation of biological carbon sludge. Water Environ. Res. 2020, 92, 1975–1982. [Google Scholar] [CrossRef]

- Kumar, S.; Kazmi, A.A.; Ghosh, N.C.; Kumar, V.; Rajpal, A. Urban stormwater runoff treatment of Nainital Lake’s catchment: An application of ballasted sand flocculation technology. Water Supply 2018, 19, 1017–1025. [Google Scholar] [CrossRef]

- Xu, Q.; Luo, X.; Xu, C.; Wan, Y.; Xiong, G.; Chen, H.; Zhou, Q.; Yan, D.; Li, X.; Li, Y.; et al. The whole process CFD numerical simulation of flow field and suspended solids distribution in a full-scale high-rate clarifier. Sustainability 2022, 14, 10624. [Google Scholar] [CrossRef]

- Vahidifar, S.; Saffarian, M.R.; Hajidavalloo, E. Introducing the theory of successful settling in order to evaluate and optimize the sedimentation tanks. Meccanica 2018, 53, 3477–3493. [Google Scholar] [CrossRef]

- Teh, C.Y.; Budiman, P.M.; Shak, K.P.Y.; Wu, T.Y. Recent advancement of coagulation-flocculation and its application in wastewater treatment. Ind. Eng. Chem. Res. 2016, 55, 4363–4389. [Google Scholar] [CrossRef]

- Vahidifar, S.; Saffarian, M.R.; Hajidavalloo, E. Numerical simulation of particle-laden flow in an industrial wastewater sedimentation tank. Meccanica 2019, 54, 2367–2383. [Google Scholar] [CrossRef]

- Wang, H.; Yu, X.; Li, Y.; Cui, Y.; Zhang, K. Effect of sludge return ratio on the treatment characteristics of high-efficiency sedimentation tank. Desalin Water Treat. 2014, 52, 5118–5125. [Google Scholar] [CrossRef]

- Xu, R.; Cao, J.; Fang, F.; Feng, Q.; Yang, E.; Luo, J. Integrated data-driven strategy to optimize the processes configuration for full-scale wastewater treatment plant predesign. Sci. Total Environ. 2021, 785, 147356. [Google Scholar] [CrossRef]

- Xu, Q.; Xiao, K.; Wu, Q.; Wang, H.; Liang, S.; Yu, W.; Tao, S.; Hou, H.; Liu, B.; Hu, J.; et al. The optimization on distributions of flow field and suspended solids in a full-scale high-rate clarifier using computational fluid dynamics. Biochem. Eng. J. 2020, 155, 107489. [Google Scholar] [CrossRef]

- Vakili, M.H.; Esfahany, M.N. CFD analysis of turbulence in a baffled stirred tank, a three-compartment model. Chem. Eng. Sci. 2009, 64, 351–362. [Google Scholar] [CrossRef]

- Samstag, R.W.; Ducoste, J.J.; Griborio, A.; Nopens, I.; Batstone, D.J.; Wicks, J.D.; Saunders, S.; Wicklein, E.A.; Kenny, G.; Laurent, J. CFD for wastewater treatment: An overview. Water Sci. Technol. 2016, 74, 549–563. [Google Scholar] [CrossRef]

- Hirom, K.; Devi, T.T. Application of computational fluid dynamics in sedimentation tank design and its recent developments: A review. Water Air Soil. Pollut. 2022, 233, 22. [Google Scholar] [CrossRef]

- Sadino-Riquelme, M.C.; Donoso-Bravo, A.; Zorilla, F.; Valdebenito-Rolack, E.; Gomez, D.; Hansen, F. Computational fluid dynamics (CFD) modeling applied to biological wastewater treatment systems: An overview of strategies for the kinetics integration. Chem. Eng. J. 2023, 466, 143180. [Google Scholar] [CrossRef]

- Patziger, M.; Kainz, H.; Hunze, M.; Józsa, J. Influence of secondary settling tank performance on suspended solids mass balance in activated sludge systems. Water Res. 2012, 46, 2415–2424. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, R.; Xu, J.; Wang, Y. Large-scale hydraulic optimization of high-efficiency clarifiers in water plants. Proc. IOP Conf. Ser. Earth Environ. Sci. 2022, 1011, 012031. [Google Scholar] [CrossRef]

- Iserte, S.; Carratalà, P.; Arnau, R.; Martínez-Cuenca, R.; Barreda, P.; Basiero, L.; Climent, J.; Chiva, S. Modeling of wastewater treatment processes with hydrosludge. Water Environ. Res. 2021, 93, 3049–3063. [Google Scholar] [CrossRef]

- Hong, F.; Tian, H.; Yuan, X.; Liu, S.; Peng, Q.; Shi, Y.; Jin, L.; Ye, L.; Jia, J.; Ying, D.; et al. CFD-assisted modeling of the hydrodynamic cavitation reactors for wastewater treatment—A review. J. Environ. Manag. 2022, 321, 115982. [Google Scholar] [CrossRef]

- Sharma, M.; Mohapatra, T.; Ghosh, P. Hydrodynamics, mass and heat transfer study for emerging heterogeneous Fenton process in multiphase fluidized-bed reactor system for wastewater treatment—A review. Chem. Eng. Res. Des. 2021, 171, 48–62. [Google Scholar] [CrossRef]

- Kostoglou, M.; Karapantsios, T.D.; Matis, K.A. CFD model for the design of large scale flotation tanks for water and wastewater treatment. Ind. Eng. Chem. Res. 2007, 46, 6590–6599. [Google Scholar] [CrossRef]

- Shahrokhi, M.; Rostami, F.; Md Said, M.A.; Sabbagh Yazdi, S.R.; Syafalni. The effect of number of baffles on the improvement efficiency of primary sedimentation tanks. Appl. Math. Model. 2012, 36, 3725–3735. [Google Scholar] [CrossRef]

- Feng, Q.; Ge, R.; Sun, Y.; Fang, F.; Luo, J.; Xue, Z.; Cao, J.; Li, M. Revealing hydrodynamic effects on flocculation performance and surface properties of sludge by comparing aeration and stirring systems via computational fluid dynamics aided calculation. Water Res. 2020, 172, 115500. [Google Scholar] [CrossRef] [PubMed]

- Rezavand, M.; Winkler, D.; Sappl, J.; Seiler, L.; Meister, M.; Rauch, W. A fully Lagrangian computational model for the integration of mixing and biochemical reactions in anaerobic digestion. Comput. Fluids 2019, 181, 224–235. [Google Scholar] [CrossRef]

- Miller, K.; Chuang, W.L.; Kim, K.; Chang, K.A.; Chellam, S. Simultaneous in situ characterization of turbulent flocculation and reactor mixing using image analysis and particle image velocimetry in unison. ACS EST Eng. 2023, 3, 295–305. [Google Scholar] [CrossRef]

- Lin, Z.; Sun, X.; Wang, Q.; Cao, J.; Wang, C.; Kuang, Y. Evaluation of the effect of hydraulic shear intensity on coal-slime water flocculation in a gradient fluidized bed. Powder Technol. 2020, 360, 392–397. [Google Scholar] [CrossRef]

- Raeesh, M.; Devi, T.T.; Hirom, K. Recent developments on application of different turbulence and multiphase models in sedimentation tank modeling—A review. Water Air Soil. Pollut. 2022, 234, 5. [Google Scholar] [CrossRef]

- Lapointe, M.; Barbeau, B. Selection of media for the design of ballasted flocculation processes. Water Res. 2018, 147, 25–32. [Google Scholar] [CrossRef]

- Sun, Y.; Zhou, S.; Chiang, P.-C.; Shah, K.J. Evaluation and optimization of enhanced coagulation process: Water and energy nexus. Water-Energy Nexus 2019, 2, 25–36. [Google Scholar] [CrossRef]

- Yadai, T.; Suzuki, Y. Development of softening and ballasted flocculation as a pretreatment process for seawater desalination through a reverse osmosis membrane. npj Clean. Water 2023, 6, 7. [Google Scholar] [CrossRef]

- Zhang, D. Optimize Sedimentation Tank and Lab Flocculation Unit by CFD. Master’s Thesis, Norwegian University of Life Sciences, Ås, Norway, 2014. [Google Scholar]

- Kim, K.Y.; Park, S.; Lee, W.H.; Kim, J.O. Simulating the behavior of ballasted flocs in circular lamellar settling tank using computational fluid dynamics (CFD). Desalination Water Treat. 2020, 183, 23–29. [Google Scholar] [CrossRef]

- Wang, X.; Cui, B.; Wei, D.; Song, Z.; He, Y.; Bayly, A.E. CFD-PBM modelling of tailings flocculation in a lab-scale gravity thickener. Powder Technol. 2022, 396, 139–151. [Google Scholar] [CrossRef]

| Diameter of Draft Tube (m) | Turbulent Kinetic Energy k (m2·s−2) | Dissipation Rate ε (m2·s−3) |

|---|---|---|

| 2.4 | 0.0236 | 0.0109 |

| 2.5 | 0.0289 | 0.0155 |

| 2.6 | 0.0285 | 0.0161 |

| Height of Draft Tube (m) | Turbulent Kinetic Energy k (m2·s−2) | Dissipation Rate ε (m2·s−3) |

|---|---|---|

| 3.4 | 0.0256 | 0.0133 |

| 3.5 | 0.0289 | 0.0155 |

| 3.6 | 0.0244 | 0.0125 |

| Height of Water Tunnel (m) | Turbulent Kinetic Energy k (m2·s−2) | Dissipation Rate ε (m2·s−3) |

|---|---|---|

| 0.9 | 0.7787 × 10−4 | 0.1245 × 10−4 |

| 1.0 | 0.7533 × 10−4 | 0.1205 × 10−4 |

| 1.1 | 0.7500 × 10−4 | 0.1224 × 10−4 |

| Dosage of Heavy Medium Particles (mg/L) | Flocculation Zone | Plug-Flow/Clarification Zone | ||

|---|---|---|---|---|

| k (10−2 m2·s−2) | ε (10−3 m2·s−3) | k (10−4 m2·s−2) | ε (10−5 m2·s−3) | |

| 0 | 1.97 | 6.94 | 1.89 | 1.34 |

| 20 | 1.96 | 6.96 | 3.48 | 2.16 |

| 40 | 2.11 | 7.25 | 4.09 | 2.90 |

| 60 | 1.88 | 7.05 | 7.42 | 6.46 |

| Inlet Velocity (m/s) | Flocculation Zone | Plug-Flow/Clarification Zone | ||

|---|---|---|---|---|

| k (10−2 m2·s−2) | ε (10−3 m2·s−3) | k (10−4 m2·s−2) | ε (10−5 m2·s−3) | |

| 0.72 | 2.11 | 7.247 | 4.09 | 2.902 |

| 0.79 | 1.96 | 6.996 | 4.43 | 3.553 |

| 0.86 | 1.99 | 6.796 | 4.73 | 3.755 |

| Parameter | Conventional Mechanically Accelerated Clarifier | High-Efficiency Settling Tank | |

|---|---|---|---|

| (Without Ballast) | (Use of Magnetite as a Ballast Material) | ||

| Dosages of additives NaOH | adjust pH to 9.8 | adjust pH to 9.8 | adjust pH to 9.8 |

| Na2CO3 (mg/L) | 60~80 | 60~80 | 60~80 |

| Polyferric coagulant (Fe3+, mg/L) | 12 | 10 | 6 |

| Polyacrylamide flocculant (mg/L) | 1.5 | 1.2 | 0.5 |

| Sludge return | hydraulically stimulated passive circulation | forced circulation | forced circulation |

| Removal efficiency of hardness (%) | 40~50 | ~80 | >90 |

| Removal efficiency organic substances (%) | 20~30 | 20~50 | 20~60 |

| Suspended solid’s concentration in produced water (mg/L) | <10 | <10 | <5 |

| Hydraulic surface loading (m3/(m2·h)) | 3~7 | 10~15 | 15~20 |

| Floor area (m2) | about 240 | about 104 | about 64 |

| Construction cost | $342,398 | $273,918 | $168,460 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, Z.; Kang, S.; Wang, Z.; Jiang, Q.; Zhang, J.; Zheng, B.; Wang, J. Three-Dimensional Numerical Analysis and Operational Optimization of High-Efficiency Sedimentation Tank. Water 2023, 15, 3656. https://doi.org/10.3390/w15203656

Ye Z, Kang S, Wang Z, Jiang Q, Zhang J, Zheng B, Wang J. Three-Dimensional Numerical Analysis and Operational Optimization of High-Efficiency Sedimentation Tank. Water. 2023; 15(20):3656. https://doi.org/10.3390/w15203656

Chicago/Turabian StyleYe, Zhian, Shaoxin Kang, Zhengjiang Wang, Qi Jiang, Jiangtao Zhang, Bin Zheng, and Jinlei Wang. 2023. "Three-Dimensional Numerical Analysis and Operational Optimization of High-Efficiency Sedimentation Tank" Water 15, no. 20: 3656. https://doi.org/10.3390/w15203656

APA StyleYe, Z., Kang, S., Wang, Z., Jiang, Q., Zhang, J., Zheng, B., & Wang, J. (2023). Three-Dimensional Numerical Analysis and Operational Optimization of High-Efficiency Sedimentation Tank. Water, 15(20), 3656. https://doi.org/10.3390/w15203656