Study on Plugging Material and Plugging Mechanism of Crude Oil Sand Water Filter Pipe

Abstract

:1. Introduction

2. Oilfield Overview

3. Experimental Part

3.1. Experimental Reagent

3.2. Experimental Instrument

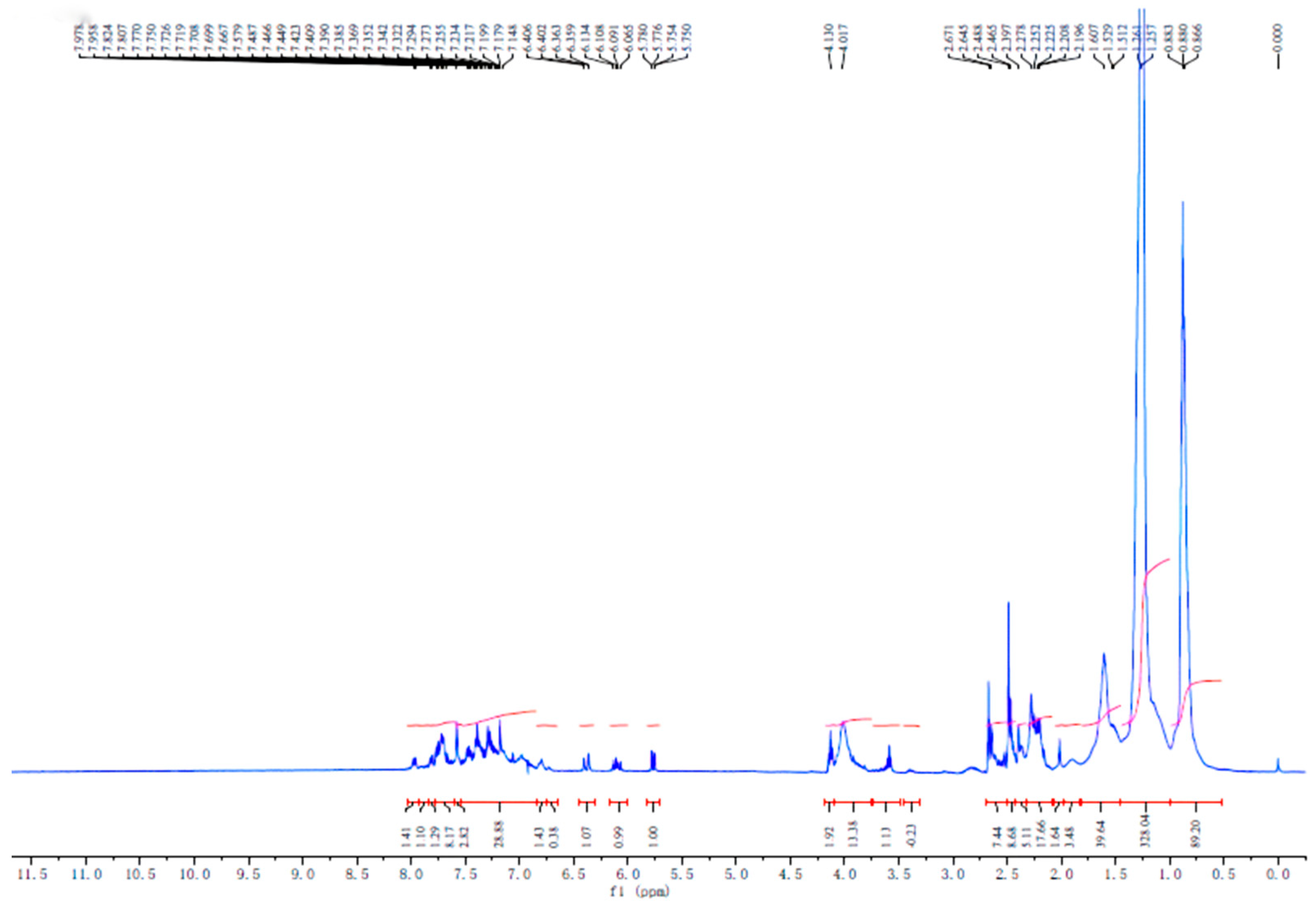

3.3. Crude Oil Composition Analysis

4. Analysis of Experiment

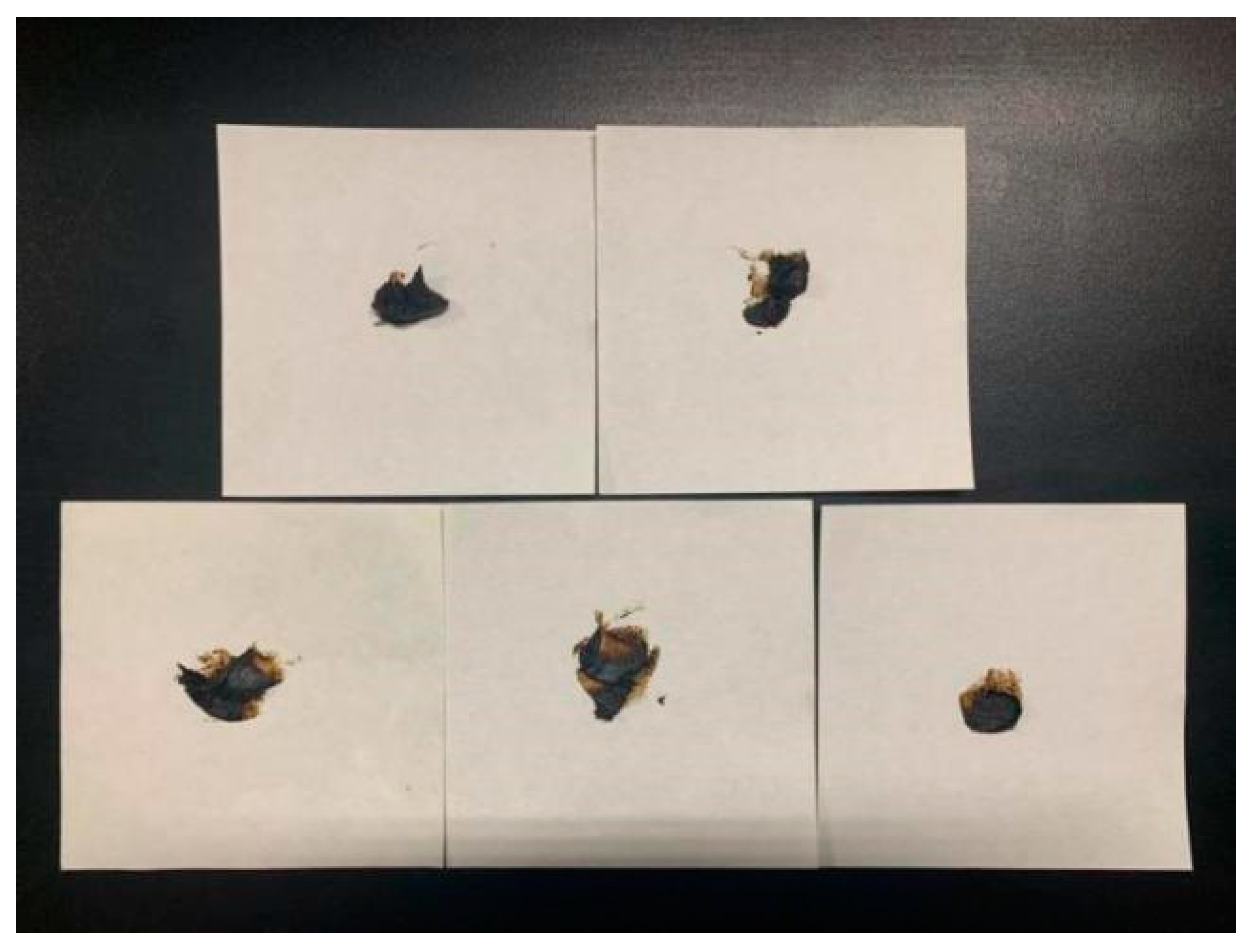

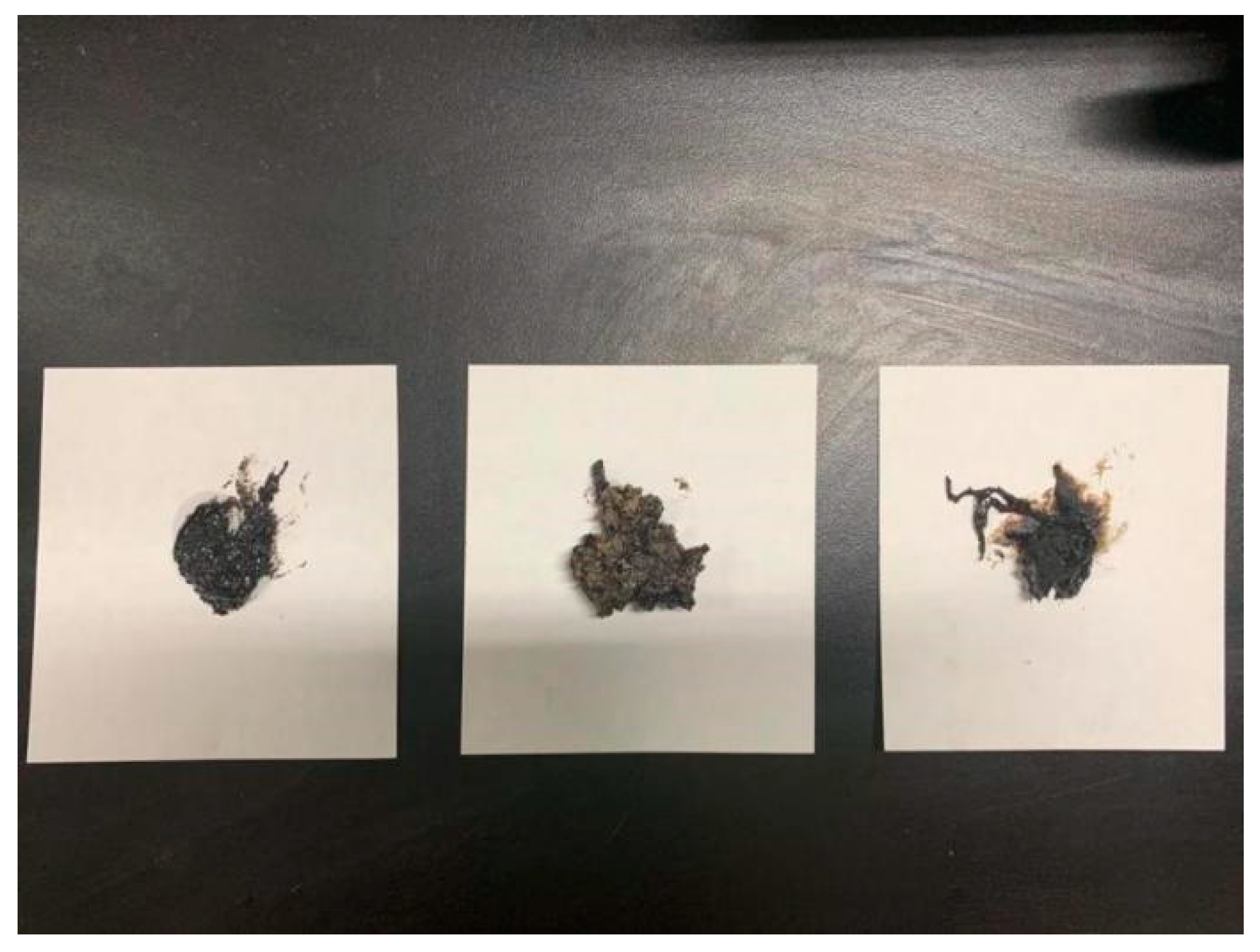

4.1. Experimental Results

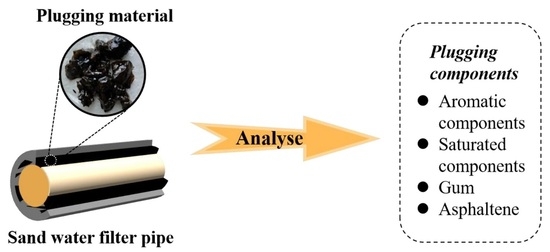

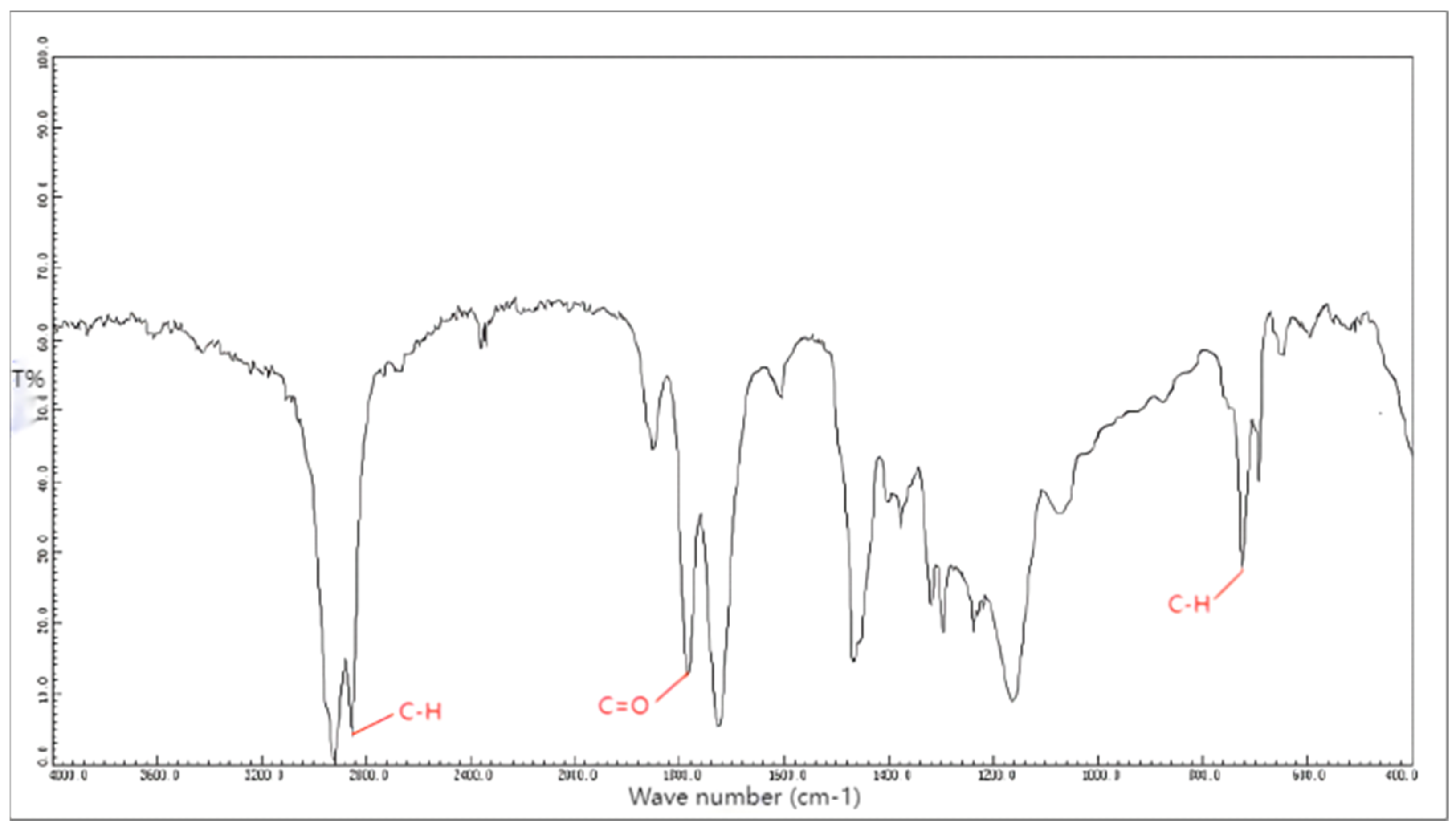

4.2. Composition Analysis of Plugging Materials

5. Analysis of Clogging Mechanism

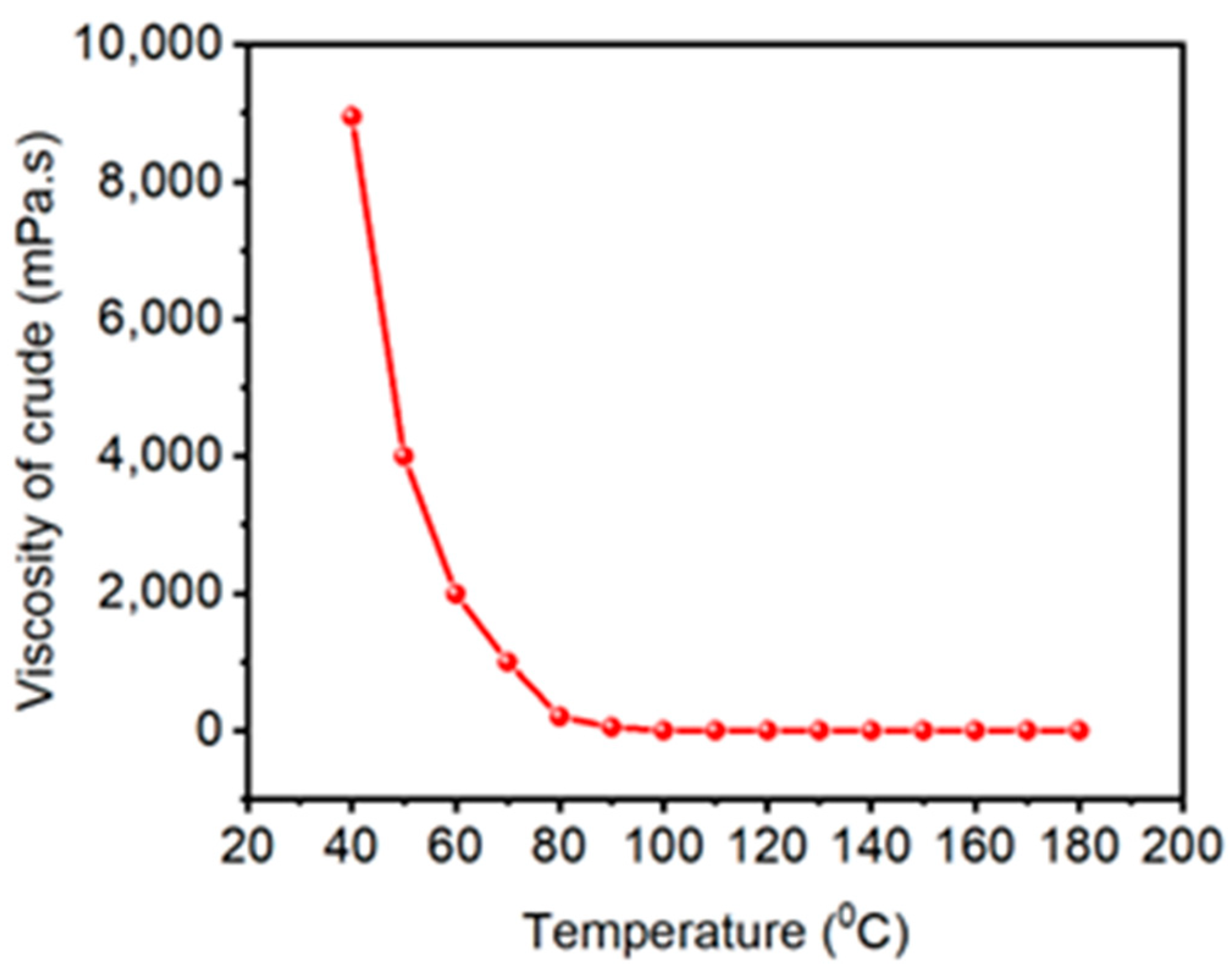

5.1. With the Decrease of Temperature, the Viscosity of Crude Oil

5.2. Good Wettability of Crude Oil to Stainless Steel

5.3. Low Degree Polymerization of Aromatic Hydrocarbon and Unsaturated Hydrocarbon Occurred in Crude Oil

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Ji, M.; Qin, J. Catalytic Performance of Fe-Rich Sludge in Pyrolysis of Waste Oil Scum as Volatiles and Magnetic Char. Water 2023, 15, 2637. [Google Scholar]

- Ikporo, B.; Sylvester, O. Effect of sand invasion on oil well production: A case study of Garon field in the Niger Delta. Int. J. Eng. Sci. 2015, 4, 64–72. [Google Scholar]

- Naseer, M.T.; Khalid, R.H.; Naseem, S. Static Reservoir Simulations and Seismic Attributes Application to Image the Miocene Deep-Water Reservoirs in Southeast Asia. Water 2023, 15, 2543. [Google Scholar]

- Sanni, S.E.; Adefila, S.S.; Anozie, A.N. Prediction of sand kinematic pressure and fluid-particle interaction coefficient as means of preventing sand-induced corrosion in crude oil pipelines. Ain Shams Eng. J. 2019, 10, 55–62. [Google Scholar]

- Ding, B.; Dong, M. Optimization of plugging high mobility zones in oil sands by injection of oil-in-water emulsion: Experimental and modeling study. Fuel 2019, 257, 116024. [Google Scholar]

- Hua, Z.; Lin, M.; Dong, Z. Study of deep profile control and oil displacement technologies with nanoscale polymer microspheres. J. Colloid Interface Sci. 2014, 424, 67–74. [Google Scholar]

- Zhang, Z.; Cao, G.; Zuo, J. Rheological properties and plugging behavior of active crude oil. Pet. Sci. Technol. 2020, 38, 131–145. [Google Scholar]

- Gao, X.; Huang, Q.; Zhang, X. Estimating wax plug transportation force in crude oil pipeline pigging. Energy Fuels 2020, 34, 3110–3120. [Google Scholar]

- Yang, B.; Ma, S.; Cui, R. Simultaneous removal of NOx and SO2 with H2O2 catalyzed by alkali/magnetism-modified fly ash: High efficiency, low cost and catalytic mechanism. Chem. Eng. J. 2019, 359, 233–243. [Google Scholar]

- Huang, X.; Gu, X.; Zhang, H. Decavanadate-based clusters as bifunctional catalysts for efficient treatment of carbon dioxide and simulant sulfur mustard. J. CO2 Util. 2021, 45, 101419. [Google Scholar]

- Yang, B.; Ma, S.; Cui, R. Novel low-cost simultaneous removal of NO and SO2 with ·OH from decomposition of H2O2 catalyzed by alkali-magnetic modified fly ash. Ind. Eng. Chem. Res. 2019, 58, 5339–5347. [Google Scholar]

- Huang, X.; Gu, X.; Qi, Y. Decavanadate-based Transition Metal Hybrids as Bifunctional Catalysts for Sulfide Oxidation and C—C Bond Construction. Chin. J. Chem. 2021, 39, 2495–2503. [Google Scholar]

- Sanni, S.E.; Adefila, S.S.; Anozie, A.N. Mechanisms for Controlling Sand-Induced Corrosion in Horizontal Pipe Flow of Sand, Crude Oil and Water. Open Pet. Eng. J. 2017, 10, 220–238. [Google Scholar]

- Dong, W.; Zhang, D.; Wang, K. Investigation on degradation mechanism of polymer blockages in unconsolidated sandstone reservoirs. e-Polymers 2020, 20, 55–60. [Google Scholar]

- Wang, F.; Yang, H.; Jiang, H. Formation mechanism and location distribution of blockage during polymer flooding. J. Pet. Sci. Eng. 2020, 194, 107503. [Google Scholar]

- Nikoo, A.H.; Ghaedi, M.; Malayeri, M.R. Analysis of wellbore clogging by asphaltene deposition using interaction energies. Fuel 2023, 352, 129111. [Google Scholar]

- Dong, C.; Jia, B.; Liu, C. Blocking mechanism and blocking laws experiments of sand retention media in mechanical screens. J. China Univ. Pet. Ed. Nat. Sci. 2011, 35, 82–88. [Google Scholar]

- Ma, C.; Feng, Y.; Deng, J. Experimental investigation of the plugging mechanisms of non-consolidated prepacked gravel screens. Int. J. Hydrogen Energy 2021, 46, 34638–34651. [Google Scholar]

- Ma, C.; Deng, J.; Dong, X. A new laboratory protocol to study the plugging and sand control performance of sand control screens. J. Pet. Sci. Eng. 2020, 184, 106548. [Google Scholar]

- Liu, D.; Liu, H.; Li, L. Corrosion of water injection system in Shengli Oil Field. Anti-Corros. Methods Mater. 2013, 60, 185–193. [Google Scholar]

- Li, C.-F.; Li, Y.; Li, X.-M.; Cao, Y.-B.; Song, Y.-T. The application of microbial enhanced oil recovery technology in Shengli Oilfield. Pet. Sci. Technol. 2015, 33, 556–560. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, W.; Chen, G. Preparation of petroleum-degrading bacterial agent and its application in remediation of contaminated soil in Shengli Oil Field, China. Environ. Sci. Pollut. Res. 2014, 21, 7929–7937. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Song, X.; Sun, R. A Petroleum pollution and the microbial community structure in the soil of Shengli Oilfield. Yingyong Shengtai Xuebao 2014, 25, 850–856. [Google Scholar] [PubMed]

- Wu, X.; Li, S.; Yan, F. The Application of Cluster Analysis Method in Reservoir Evaluation of Qingdong 5 Block in Shengli Oilfield. Adv. Geosci. 2017, 7, 135–141. [Google Scholar] [CrossRef]

| Well Number | Aromatic Components% | Saturated Component% | Gum% | Asphaltene% | Gum + Asphaltene% |

|---|---|---|---|---|---|

| 641-X15 | 32.1 | 31.5 | 28.9 | 7.5 | 36.4 |

| 822-P5 | 28.9 | 29.4 | 33.5 | 8.2 | 41.7 |

| 827-P1 | 31.4 | 28.9 | 32.9 | 6.8 | 39.7 |

| 9-P13 | 26.5 | 27.3 | 38.3 | 7.9 | 46.2 |

| 10-N14 | 33.6 | 32.7 | 25.9 | 7.8 | 33.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Liu, Q.; Chen, H.; Sheng, H.; Yan, J.; Gu, Y.; Huang, X.; Yang, B. Study on Plugging Material and Plugging Mechanism of Crude Oil Sand Water Filter Pipe. Water 2023, 15, 3714. https://doi.org/10.3390/w15213714

Zhang W, Liu Q, Chen H, Sheng H, Yan J, Gu Y, Huang X, Yang B. Study on Plugging Material and Plugging Mechanism of Crude Oil Sand Water Filter Pipe. Water. 2023; 15(21):3714. https://doi.org/10.3390/w15213714

Chicago/Turabian StyleZhang, Wenhui, Qingfeng Liu, Hengyu Chen, Huibin Sheng, Jingen Yan, Yongtao Gu, Xianqiang Huang, and Bingchuan Yang. 2023. "Study on Plugging Material and Plugging Mechanism of Crude Oil Sand Water Filter Pipe" Water 15, no. 21: 3714. https://doi.org/10.3390/w15213714

APA StyleZhang, W., Liu, Q., Chen, H., Sheng, H., Yan, J., Gu, Y., Huang, X., & Yang, B. (2023). Study on Plugging Material and Plugging Mechanism of Crude Oil Sand Water Filter Pipe. Water, 15(21), 3714. https://doi.org/10.3390/w15213714