A Comparative and Optimal Experiment of a Sequential Batch Enhanced Pre-Treatment Reactor without Sludge Retention

Abstract

:1. Introduction

2. Mechanism Analysis of the SBER

2.1. The Basic Characteristics of the SBER

2.2. The Theory of the Biochemical Reaction of the SBER

2.3. The Theory of Hydrolysis Acidification of the SBER

2.4. The Theory of Nitrification and Denitrification of the SBER

3. Comparative Experiment of Pre-Treatment Processes

3.1. Test Method

3.1.1. Test Model Device

3.1.2. Testing the Water Quality

3.1.3. Operation Mode

3.2. Comparison and Analysis of Treatment Effects

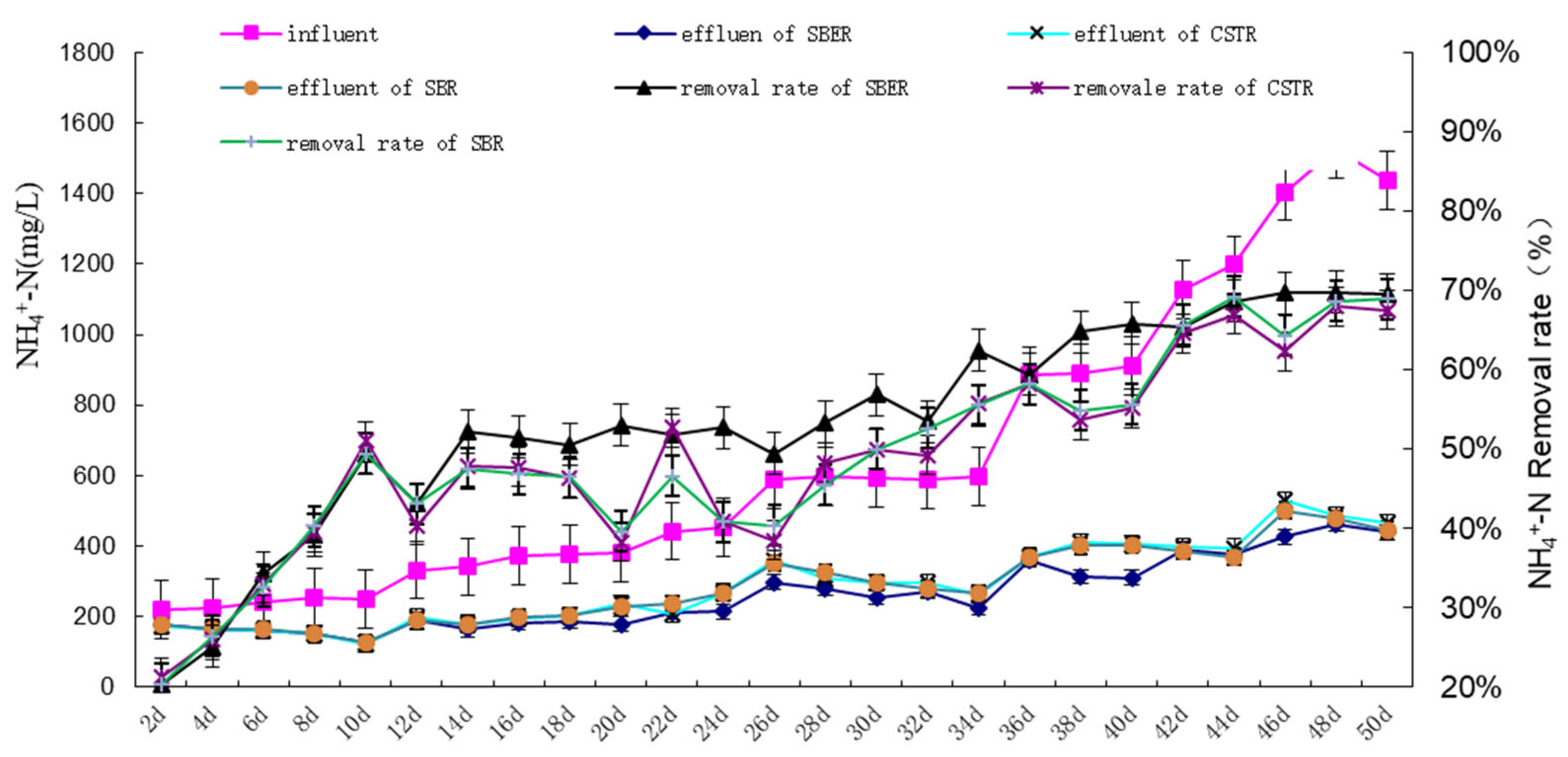

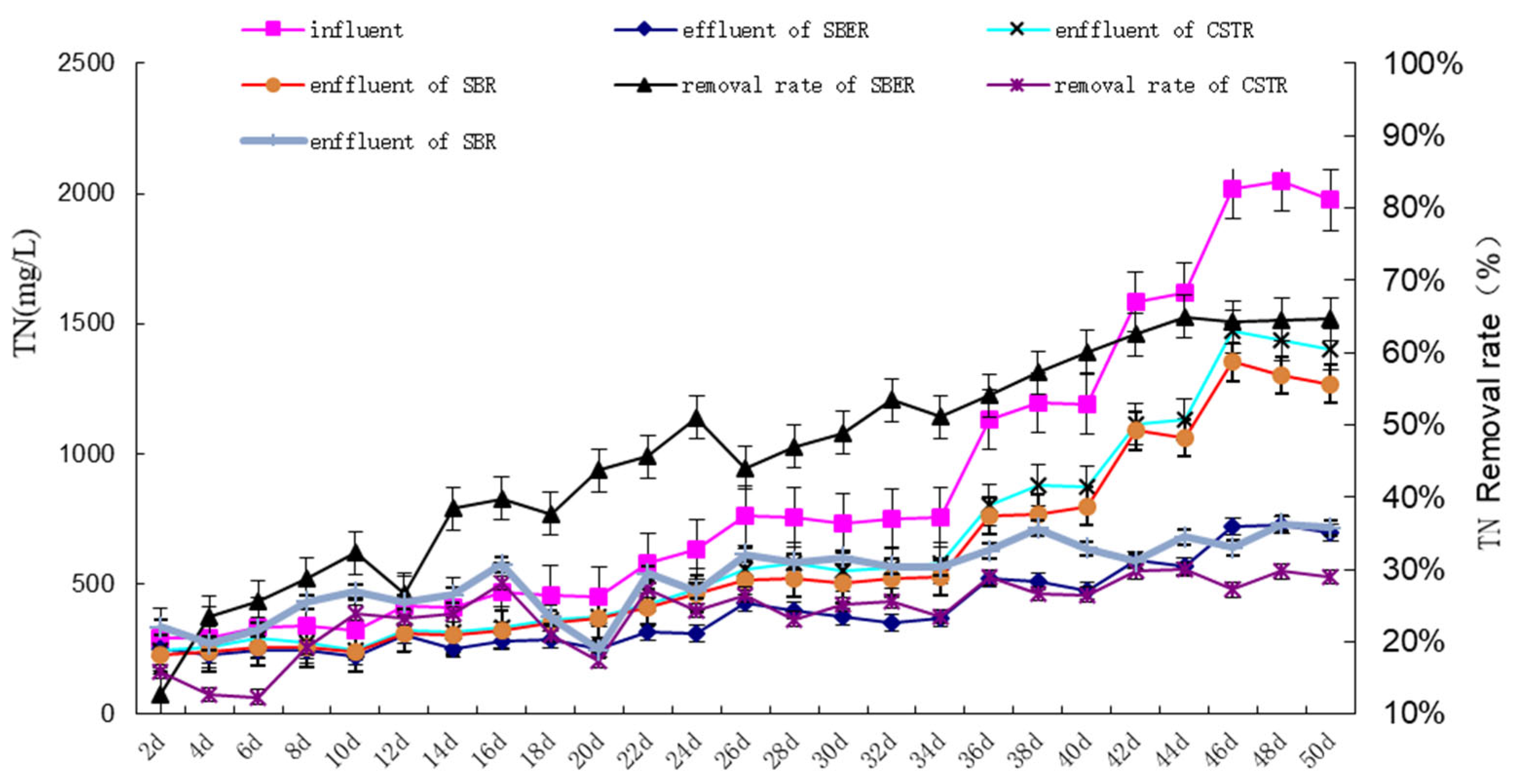

3.2.1. Comparison of Removal Effects

3.2.2. Comparison of Biodegradability

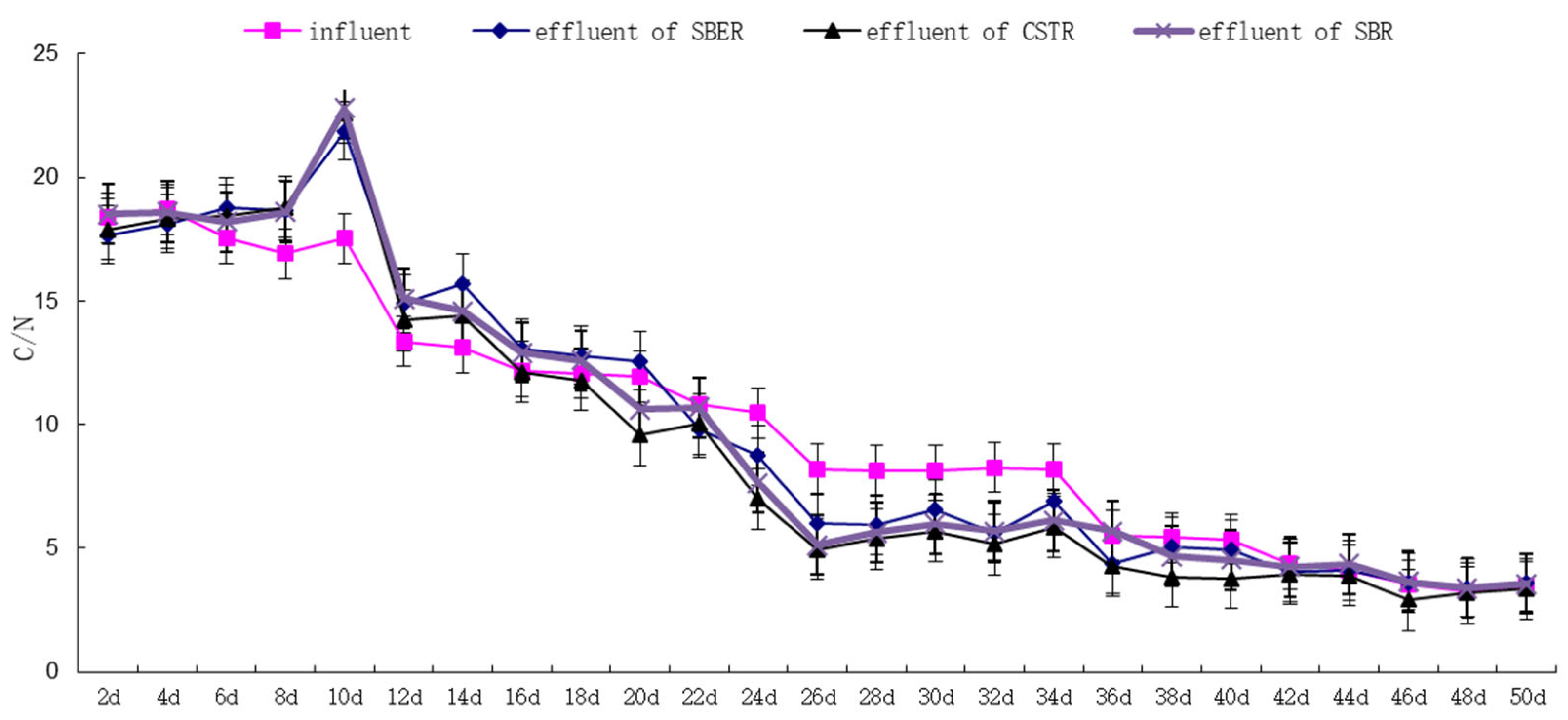

3.2.3. Comparison of Nutrient Proportions

4. Optimal Experiment of the SBER

4.1. Design of the Orthogonal Test

4.2. Statistical Analysis of the Orthogonal Test

4.2.1. Analysis of Influencing Factors

4.2.2. Significance Test of Influencing Factors

4.3. Determination of Optimal Parameters

4.3.1. Determination of Single Operating Parameters

4.3.2. Determination of Overall Operating Parameters

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Regan, J.M.; Harington, G.W.; Noguera, D.R. Ammonia and denitrite-oxidizing bacterial communities in a pilot-scale chloraminsted drinking water distribution system. Appl. Environ. Microbiol. 2002, 68, 73–81. [Google Scholar] [CrossRef]

- Chen, W.; Koo, C.-p.; He, C.; Li, Q. Transformation characteristics of dissolved organic matter in aged landfill leachate treated with SAARB and MBR. J. Environ. Sci. 2021, 41, 4637–4647. [Google Scholar]

- Liu, Y. Study on SIPR-SBBR Landfill Leachate Treatment Process. Master’s Thesis, Chongqing University, Chongqing, China, 2008. [Google Scholar]

- Zhang, Z.; Jiang, C.; Zhang, W.; Xiao, Z.; Huang, X.; Hua, T.; Shi, W. Experimental study on shortcut nitrification and denitrification of landfill leachate. J. Saf. Environ. 2020, 20, 1083–1089. [Google Scholar]

- Hellinga, C.S.; Schellen, A.A.; Mulder, J.W.; van Loosdrecht, M.V.; Heijnen, J.J. The SHARON process: An innovative method for nitrogen removal from ammonium-rich waste water. Water Sci. Technol. 1998, 37, 135–142. [Google Scholar] [CrossRef]

- Mulder, J.W. Full scale application of the Sharon process for treatment of rejection water of digested sludge dewatering. In Proceedings of the First IWA Conference, Paris, France, 3–7 July 2000; pp. 267–274. [Google Scholar]

- Deng, D. Study on Biological Treatment Technology of Leachate from Refuse Storage Pit in Municipal Solid Waste Incineration Plant. Doctoral Dissertation, Tongji University, Shanghai, China, 2006. [Google Scholar]

- Hellinga, C.; Van Loosdnecht, M.C.M.; Heijnen, J.J. The Sharon process for nitrogen removal in ammonium rich wastewater. Univ. Gent 1997, 62, 1743–1750. [Google Scholar]

- Michael, N.; Annette, B. Kinetics, diffusional limitation and microscale distribution of chemistry and organisms in a CANON reactor. FEMS Microbiol. Ecol. 2005, 51, 247–256. [Google Scholar]

- Li, X.; Yu, X.; Wang, Q.; Han, C. Engineering example of landfill leachate treatment by UASB-A/O-UF-NF-RO combined process. Water Treat. Technol. 2021, 47, 128–131. [Google Scholar]

- Hu, Y.; Zeng, Z. Engineering Application of Using Pre-treatment/EGSB/A2O-AO Methods for KitchenWaste Leachate. J. Anhui Jianzhu Univ. 2023, 31, 47. [Google Scholar]

- Ding, X.-M.; Ma, D.-J.; Kang, J.-C.; Min, H.-H.; Gao, B. Engineering Examples of Full Quantitative Treatment of Leachate from an Aging Landfill. China Water Wastewater 2023, 39, 90–95. [Google Scholar]

- Cai, B.; Tian, L.; Xiao, D.; Zhou, H. Case Analysis of Leachate Treatment in Domestic Waste Incineration Power Generation Projects. China Resour. Compr. Util. 2023, 41, 192–196. [Google Scholar]

- Michael, W.; Alexander, L. Bacterial community composition and function in sewage treatment systems. Curr. Opin. Biotechnol. 2002, 13, 218–227. [Google Scholar]

- Bock, E.; Koops, H.P. The genus Nitrobacter and relater genera. In The Prokaryotes: An Evolving Electronis Database for to Microbiological Community, 3rd ed.; Balowa, A., Ed.; Springer: New York, NY, USA, 2001. [Google Scholar]

- He, L.; Shi, W.; Zhao, M.; Lu, D.; Hua, T.; Zhang, W.; Xiao, C.; Huang, X.; Ruan, W. Performance of shortcut nitrification and denitrification of landfill leachate based on split-point influent. Environ. Eng. 2021, 15, 1753–1762. [Google Scholar]

- Gao, X. Combined Process and Characteristics of Leachate Treatment in Garbage Incineration Power Plant. Master’s Thesis, South China University of Technology, Guangzhou, China, 2014. [Google Scholar]

- Wang, H.; Zeng, X.; Liao, Y.; Tian, Y. Numerical Simulation Study on Air Distribution Optimization of Large Urban Domestic Waste Incinerators. Chem. Eng. Equip. 2020, 2, 10–11+19. [Google Scholar]

- Zhao, D. Study on the Characteristics of MBR-SAD Mud Film Symbiotic Nitrogen Removal Process. Master’s Thesis, Hebei University of Engineering, Handan, China, 2019. [Google Scholar]

- Chen, Y. Freeze Thaw Solubilization Microbial Fuel Cell Enhanced Residual Sludge Cracking Electricity Generation Performance. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2015. [Google Scholar]

- Hu, X.; Zhao, X.; Liu, X.; Wang, K.; Yang, Q.; Liu, J. Pilot Study on Deep Denitrification of Nitrobacterium Carrier and Its Supporting Device by Embedding Nitrobacterium Carrier. Mod. Chem. Ind. 2018, 38, 176–179. [Google Scholar]

- Gao, H.; Lin, Z. Renovation of Pharmaceutical Wastewater Treatment Process. Manag. Technol. Small Medium Enterp. 2011, 6, 263. [Google Scholar]

- Yang, N. Research and Engineering Application of Organic Wastewater Treatment Technology for Mixed Packaging Pharmaceutical Products. Master’s Thesis, Jilin University, Changchun, China, 2013. [Google Scholar]

- Lin, W. Effects of Autotoxic Agents of Casuarina equisetifolia on Endogenous Hormones in Its Seedlings. Chin. J. Agron. 2009, 25, 100–103. [Google Scholar]

- Yuan, Y. Research on Mainstream Ammonia Nitrogen Enrichment Sideflow Short Path Nitrification Anaerobic Ammonia Oxidation Denitrification Process. Master’s Thesis, Shanghai Electric Power University, Shanghai, China, 2021. [Google Scholar]

- Chai, X. Experimental Study on the Treatment of Banknote Printing Wastewater by Hydrolysis Acidification Biological Contact Oxidation Method. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2006. [Google Scholar]

- Shi, X. Research on the Coupling of Elastic Fillers and ABR for Rural Domestic Sewage Treatment. Master’s Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2020. [Google Scholar]

- Liu, Y. Research on Nitrogen and Phosphorus Removal Using SBR Single Stage Aerobic Method. Master’s Thesis, Hunan University, Changsha, China, 2008. [Google Scholar]

- Xie, X. Research on MBR-Fenton Technology for Treating Landfill Leachate. Master’s Thesis, Beijing Forestry University, Beijing, China, 2015. [Google Scholar]

- Wu, W.; Bai, Y. Experimental Study on the Treatment of Nitrobenzene Wastewater by Electrolysis SBR Combined Technology. Environ. Eng. 2007, 534–536+3. [Google Scholar]

- Yin, F. Research on the Stable Operation and Regulation of Nitrosated Granular Sludge. Master’s Thesis, Suzhou University of Science and Technology, Suzhou, China, 2015. [Google Scholar]

- Shi, H.; Zhang, W.; Rong, Y.; Zhang, W.; Jin, P. The treatment effect of new integrated rural sewage equipment under flow fluctuations. China Water Supply Drain. 2019, 35, 84–89. [Google Scholar]

- Du, M. Study on the Effects of Different TMR Diets on the Production Performance, Gastrointestinal Microbiome, and Metabolome of Fattening Sheep. Master’s Thesis, Shandong Agricultural University, Taian, China, 2021. [Google Scholar]

- Chen, L.; Peng, D.; Li, Y.; Wu, W.; Zheng, K. Computer Simulation of Activated Sludge Treatment System. Environ. Pollut. Prev. 2004, 1, 33–35+41. [Google Scholar]

- Jiang, Z.; Chen, L.; Wu, Y.; Shen, Z. Experiment and Engineering Debugging of Azodiisoheptanitrile Production Wastewater Treatment. Environ. Pollut. Prev. 2012. [Google Scholar]

- Leng, C.; Li, H.; Wang, X.; Hu, W.; Huang, K.; Gao, B. Study on the full quantitative treatment technology of membrane concentrate in domestic waste landfill and its engineering practice. Water Waste Water Eng. 2022, 48, 156–159. [Google Scholar]

- Ru, L.-y.; Liu, H.-y.; Li, L. Two-stage Simultaneous Nitrification and Denitrification Process for Treatmentof Low Carbon to Nitrogen Ratio InterflowRU. China Water Wastewater 2022, 38, 84–87. [Google Scholar]

| Factor Level | Aeration Time (Ta) (h/d) | HRT (h) | pH | Sequence Batch Cycle(Ts) (h) | Empty Column | Average Removal Rate of CODCr (%) | Average Removal Rate of NH4+-N (%) | Average Removal Rate of TN (%) |

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | ||||

| 1 | 1 (6 h/d) | 1 (1 d) | 1 (7.4 ± 0.2) | 1 (4 h) | 1 | 44.15 | 41.76 | 31.96 |

| 2 | 1 (6 h/d) | 2 (2 d) | 2 (7.6 ± 0.2) | 2 (6 h) | 2 | 54.46 | 47.72 | 49.91 |

| 3 | 1 (6 h/d) | 3 (4 d) | 3 (7.8 ± 0.2) | 3 (8 h) | 3 | 57.46 | 63.52 | 60.76 |

| 4 | 1 (6 h/d) | 4 (6 d) | 4 (8.0 ± 0.2) | 4 (10 h) | 4 | 62.09 | 57.13 | 53.72 |

| 5 | 2 (8 h/d) | 1 (1 d) | 2 (7.6 ± 0.2) | 3 (8 h) | 4 | 53.11 | 49.38 | 48.66 |

| 6 | 2 (8 h/d) | 2 (2 d) | 1 (7.4 ± 0.2) | 4 (10 h) | 3 | 60.45 | 51.03 | 46.50 |

| 7 | 2 (8 h/d) | 3 (4 d) | 4 (8.0 ± 0.2) | 1 (4 h) | 2 | 72.29 | 70.23 | 66.85 |

| 8 | 2 (8 h/d) | 4 (6 d) | 3 (7.8 ± 0.2) | 2 (6 h) | 1 | 70.98 | 71.26 | 66.63 |

| 9 | 3 (10 h/d) | 1 (1 d) | 3 (7.8 ± 0.2) | 4 (10 h) | 2 | 57.97 | 57.57 | 51.59 |

| 10 | 3 (10 h/d) | 2 (2 d) | 4 (8.0 ± 0.2) | 3 (8 h) | 1 | 72.06 | 63.16 | 57.20 |

| 11 | 3 (10 h/d) | 3 (4 d) | 1 (7.4 ± 0.2) | 2 (6 h) | 4 | 66.66 | 74.57 | 63.44 |

| 12 | 3 (10 h/d) | 4 (6 d) | 2 (7.6 ± 0.2) | 1 (4 h) | 3 | 73.18 | 72.78 | 53.61 |

| 13 | 4 (12 h/d) | 1 (1 d) | 4 (8.0 ± 0.2) | 2 (6 h) | 3 | 69.70 | 70.80 | 59.00 |

| 14 | 4 (12 h/d) | 2 (2 d) | 3 (7.8 ± 0.2) | 1 (4 h) | 4 | 73.70 | 71.44 | 48.82 |

| 15 | 4 (12 h/d) | 3 (4 d) | 2 (7.6 ± 0.2) | 4 (10 h) | 1 | 68.94 | 78.32 | 63.55 |

| 16 | 4 (12 h/d) | 4 (6 d) | 1 (7.4 ± 0.2) | 3 (8 h) | 2 | 77.73 | 79.99 | 51.93 |

| A | B | C | D | E | CODCr Removal Rate | NH4+-N Removal Rate | TN Removal Rate | ||

|---|---|---|---|---|---|---|---|---|---|

| CODCr Removal Rate | Kj1 | 218.16 | 224.92 | 249.00 | 263.32 | 256.13 | K = 1034.94 P = 66,944.32 Q = 68,249.32 | ||

| Kj2 | 256.83 | 260.68 | 249.69 | 261.80 | 262.46 | ||||

| Kj3 | 269.88 | 265.36 | 260.11 | 260.36 | 260.79 | ||||

| Kj4 | 290.07 | 283.98 | 276.15 | 249.46 | 255.56 | ||||

| Qj | 67,633.29 | 67,401.40 | 67,064.74 | 66,974.10 | 66,953.06 | ||||

| Sj2 | 688.98 | 457.09 | 120.42 | 29.78 | 8.74 | ST2 = 1305.01 | |||

| NH4+-N Removal Rate | Kj1 | 210.13 | 219.52 | 247.35 | 256.22 | 254.51 | K = 1020.66 P = 65,109.69 Q = 67,182.70 | ||

| Kj2 | 241.90 | 233.35 | 248.20 | 264.35 | 255.50 | ||||

| Kj3 | 268.08 | 286.64 | 263.78 | 256.05 | 258.14 | ||||

| Kj4 | 300.55 | 281.16 | 261.33 | 244.04 | 252.52 | ||||

| Qj | 66,217.40 | 65,962.98 | 65,165.12 | 65,162.17 | 65,113.79 | ||||

| Sj2 | 1107.72 | 853.29 | 55.43 | 52.48 | 4.10 | ST2 = 2073.01 | |||

| TN Removal Rate | Kj1 | 196.35 | 191.22 | 193.84 | 201.25 | 219.34 | K = 874.14 P = 47,757.28 Q = 48,960.84 | ||

| Kj2 | 228.65 | 202.43 | 215.73 | 238.97 | 220.28 | ||||

| Kj3 | 225.84 | 254.60 | 227.80 | 218.56 | 219.88 | ||||

| Kj4 | 223.31 | 225.89 | 236.77 | 215.35 | 214.64 | ||||

| Qj | 47,924.95 | 48,347.37 | 48,016.28 | 47,938.93 | 47,762.46 | ||||

| Sj2 | 167.66 | 590.09 | 259.00 | 181.64 | 5.18 | ST2 = 1203.56 | |||

| Factor | Freedom | Variance Analysis of CODCr Removal Rate | Variance Analysis of NH4+-N Removal Rate | Variance Analysis of TN Removal Rate | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean Square Sum | F | Significance | Mean Square Sum | F | Significance | Mean Square Sum | F | Significance | ||

| A | 3 | 229.66 | 78.82 | * | 369.24 | 270.12 | * | 55.89 | 32.40 | * |

| B | 3 | 152.36 | 52.29 | * | 284.43 | 208.07 | * | 196.70 | 114.02 | * |

| C | 3 | 40.14 | 13.78 | * | 18.48 | 13.52 | * | 86.33 | 50.05 | * |

| D | 3 | 9.93 | 3.41 | 17.49 | 12.80 | * | 60.55 | 35.10 | * | |

| error | 2.91 | 1.37 | 1.73 | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zhang, Z.; Yao, J.; Cao, C. A Comparative and Optimal Experiment of a Sequential Batch Enhanced Pre-Treatment Reactor without Sludge Retention. Water 2023, 15, 4072. https://doi.org/10.3390/w15234072

Liu Y, Zhang Z, Yao J, Cao C. A Comparative and Optimal Experiment of a Sequential Batch Enhanced Pre-Treatment Reactor without Sludge Retention. Water. 2023; 15(23):4072. https://doi.org/10.3390/w15234072

Chicago/Turabian StyleLiu, Yali, Zhi Zhang, Jingmei Yao, and Chunxia Cao. 2023. "A Comparative and Optimal Experiment of a Sequential Batch Enhanced Pre-Treatment Reactor without Sludge Retention" Water 15, no. 23: 4072. https://doi.org/10.3390/w15234072