Upgrading the MBBR Process to Reduce Excess Sludge Production in Activated Sludge System Treating Sewage

Abstract

:1. Introduction

2. Materials and Methods

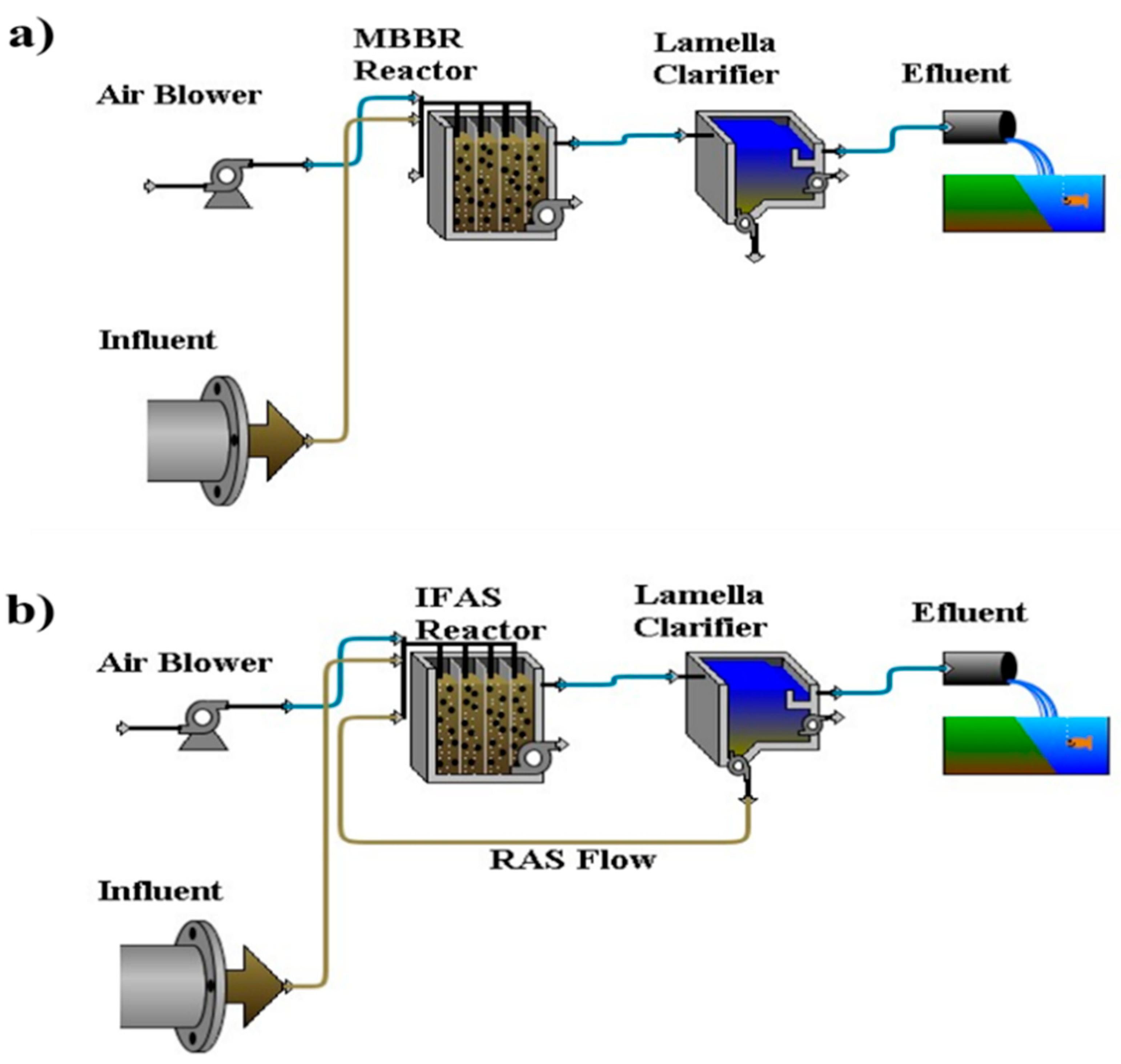

2.1. Pilot System Set-Up

2.2. Wastewater and Seed Sludge Characteristics

2.3. Pilot System Start-Up and Sampling Procedures

- On the first day, the pilot was supplied with 0.5 m3/day, representing 10% of the total process flow. The air blower was operated after initial influent feeding until DO levels reached 4 mg/L.

- On the second day, an additional 10% of the process flow was fed into the pilot MBBR to reach 1 m3/day discharge. The DO was maintained at 4.5 mg/L and 25% of the total volume was introduced as media.

- On the third day, another 20% of flowrate was introduced to become the amount of discharge within 2 m3/day, adding another 25% of media.

- On the fourth day, 20% of the mainstream were fed into the pilot to achieve 3 m3/day discharge. On this day, the heterotrophic seed was added to the first phase of the pilot, while the autotrophic seed was added to the second phase. The amount of seed per phase was 0.5 L.

- On the fifth day, 20% of the flow rate was introduced to reach 4 m3/day discharge, along with a 25% increase in media.

- On the sixth day, the influent was added to complete the total amount of media supplied for the design, along with 0.5 L of seed for each phase. Throughout the six days, DO concentrations were maintained between 4 and 5 mg/L.

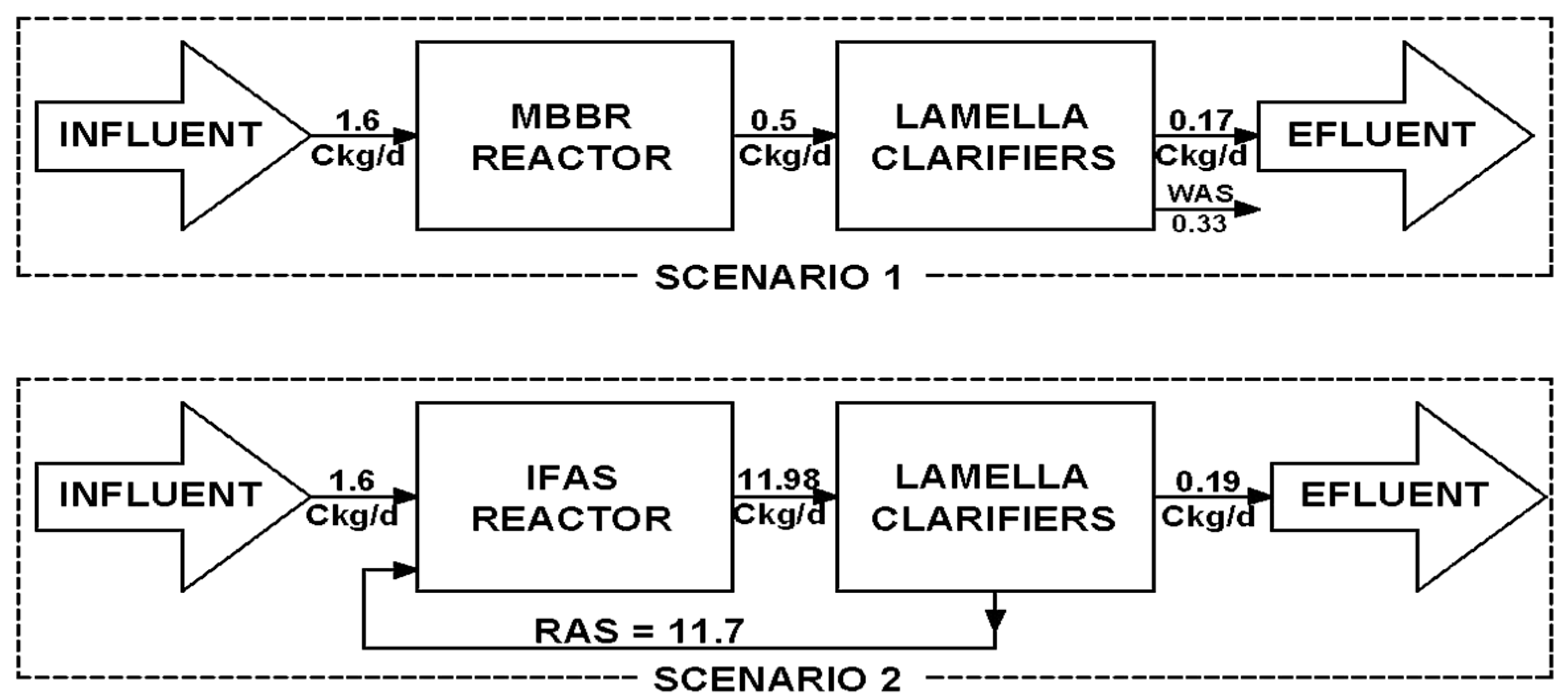

2.4. Pilot System Operation Scenarios

- First Scenario:

- Operating the pilot with an (HRT) of 9 h and WAS of 100 L/d for 13 days.

- Operating the pilot with an HRT of 18 h and WAS of 100 L/d for 30 days.

- Operating the pilot with an HRT of 26 h and WAS of 100 L/d for 30 days.

- Second Scenario:

- Operating the pilot at a RAS flowrate of 50% with HRT of 6 h and complete sludge retention time (SRT) for a period of 30 days.

- Operating the pilot at a RAS flowrate of 50% with HRT of 12 h and complete sludge SRT for a period of 40 days.

- Operating the pilot at RAS flowrate of 100% with HRT of 14 h and complete sludge SRT for a period of 35 days.

- Operating the pilot at RAS flowrate of 150% with HRT of 14 h and complete sludge SRT for a period of 45 days.

- Operating the pilot at RAS flowrate of 150% with HRT of 20 h and complete sludge SRT for a period of 50 days.

3. Results

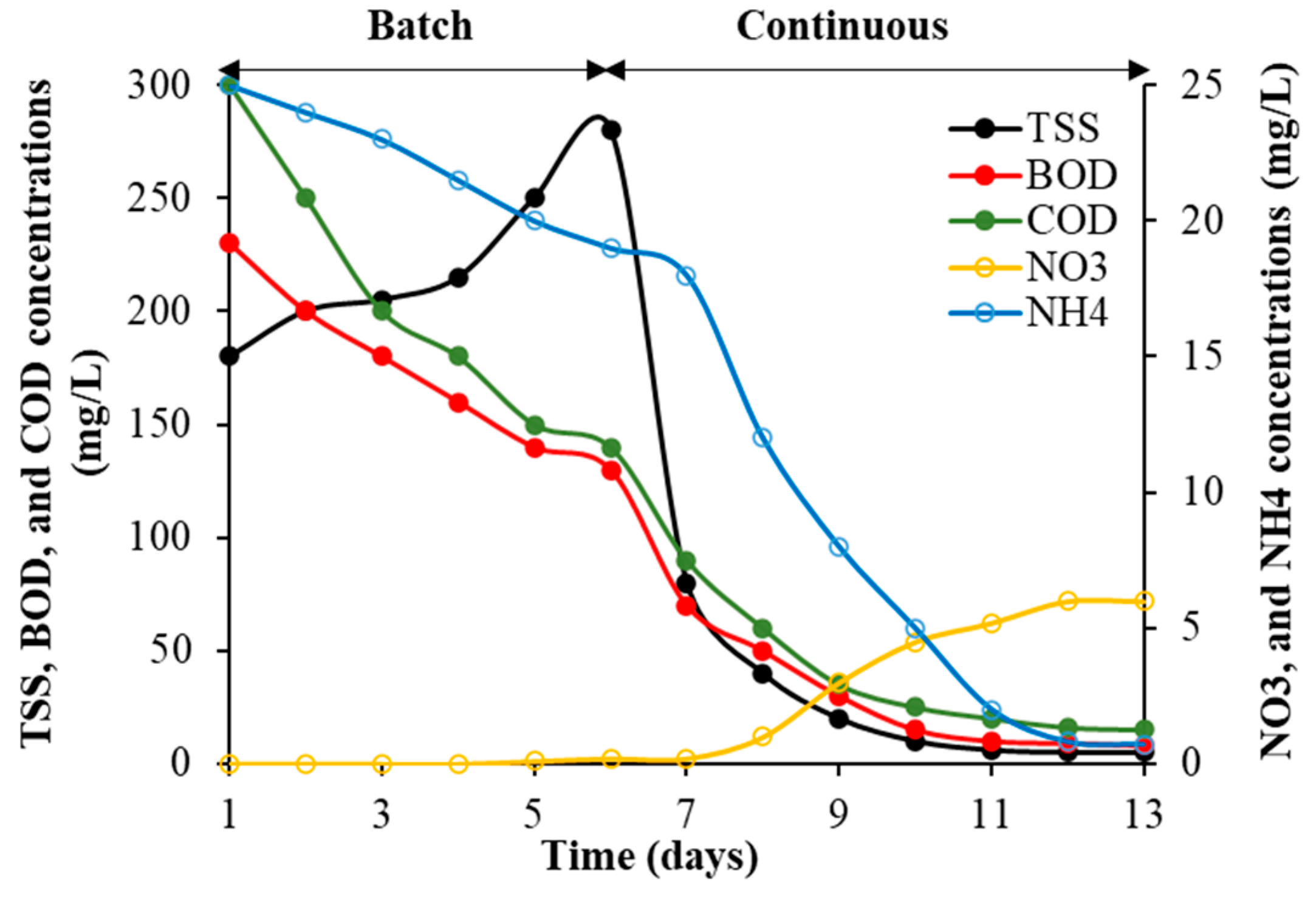

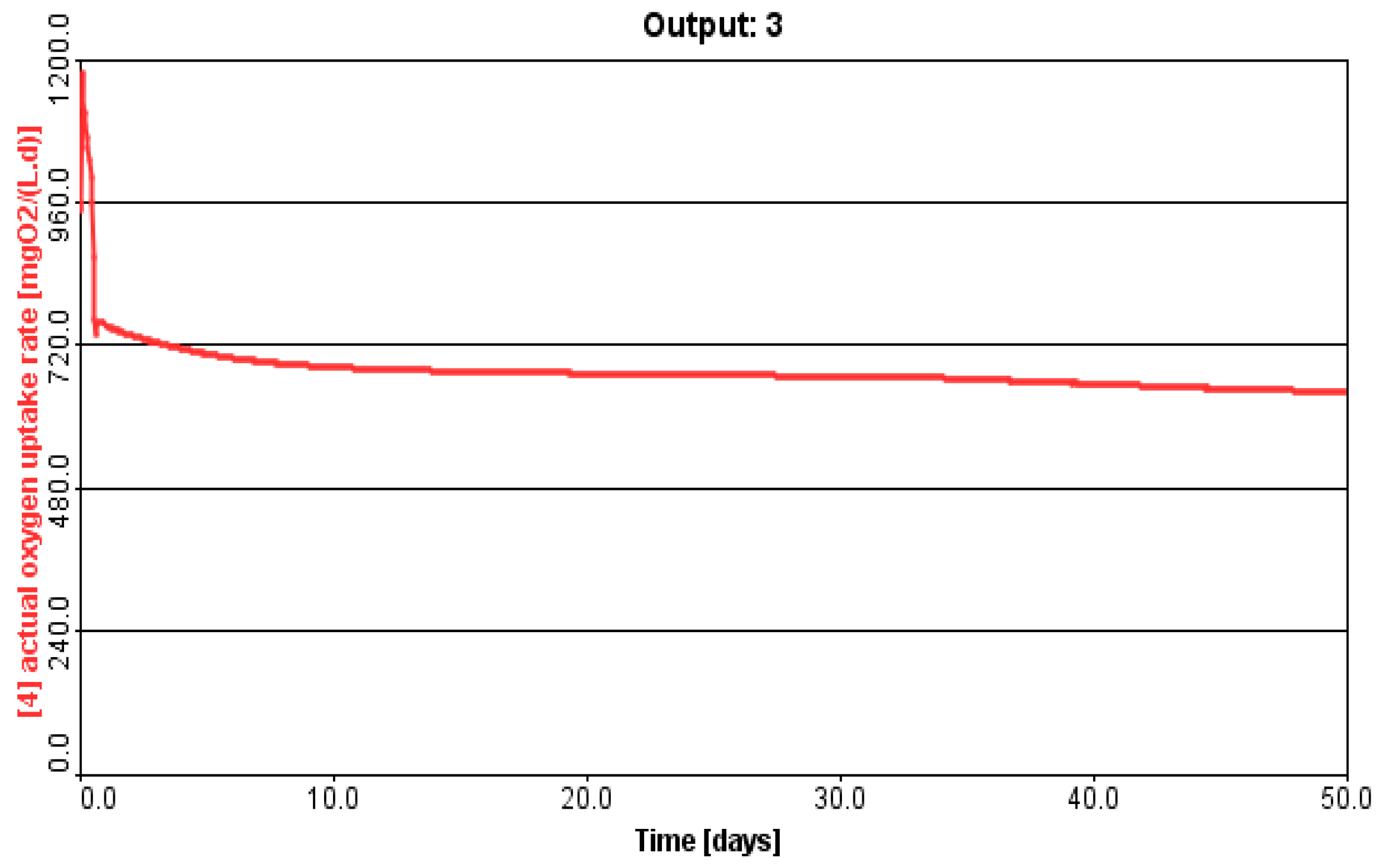

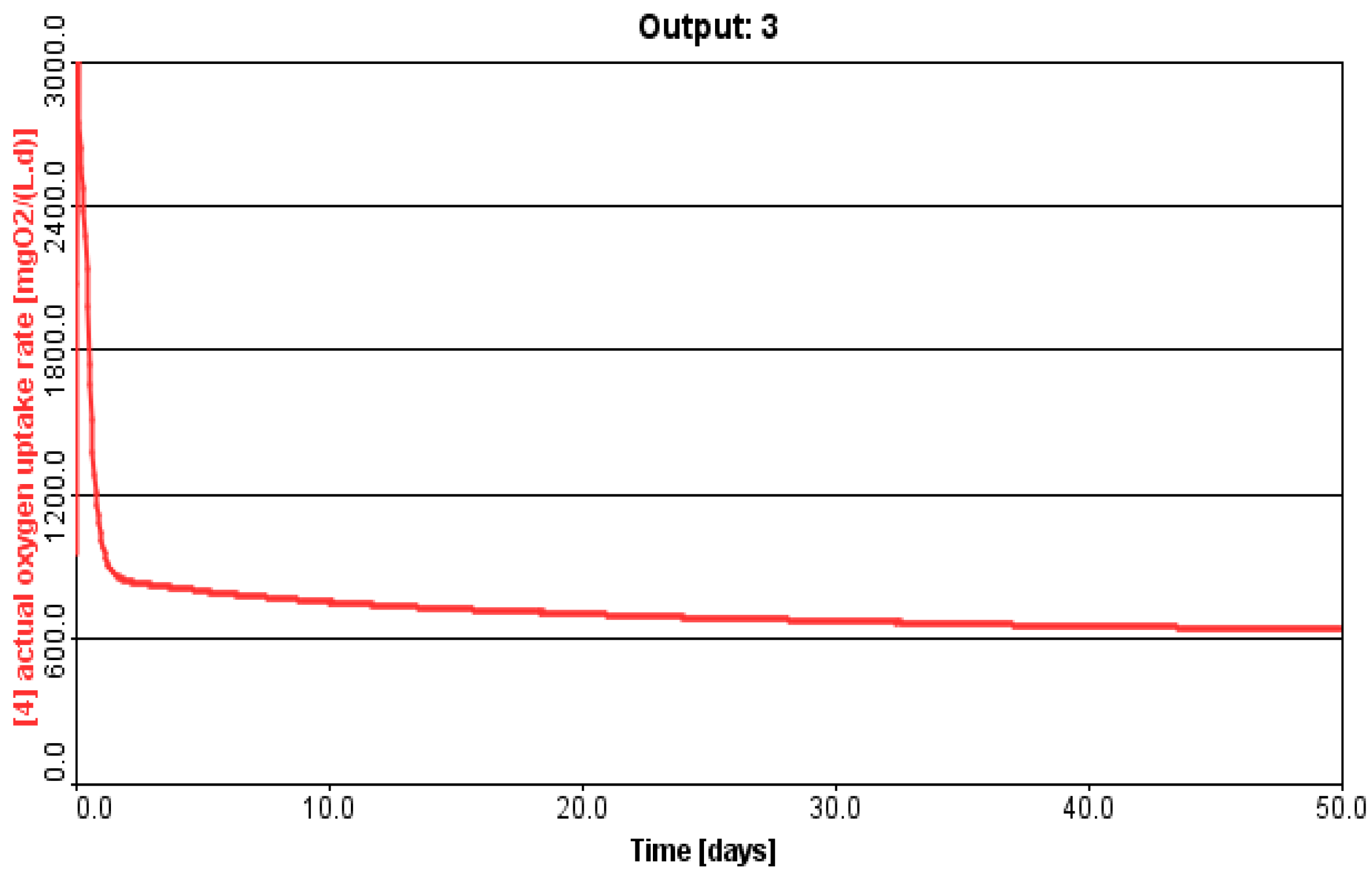

3.1. MBBR System Start-Up Performance

biomass + CO2 + H2O

biomass + CO2 + H2O

2NO2 + 4H+ + 2H2O

2NO2 + 4H+ + 2H2O

2NO3

2NO3

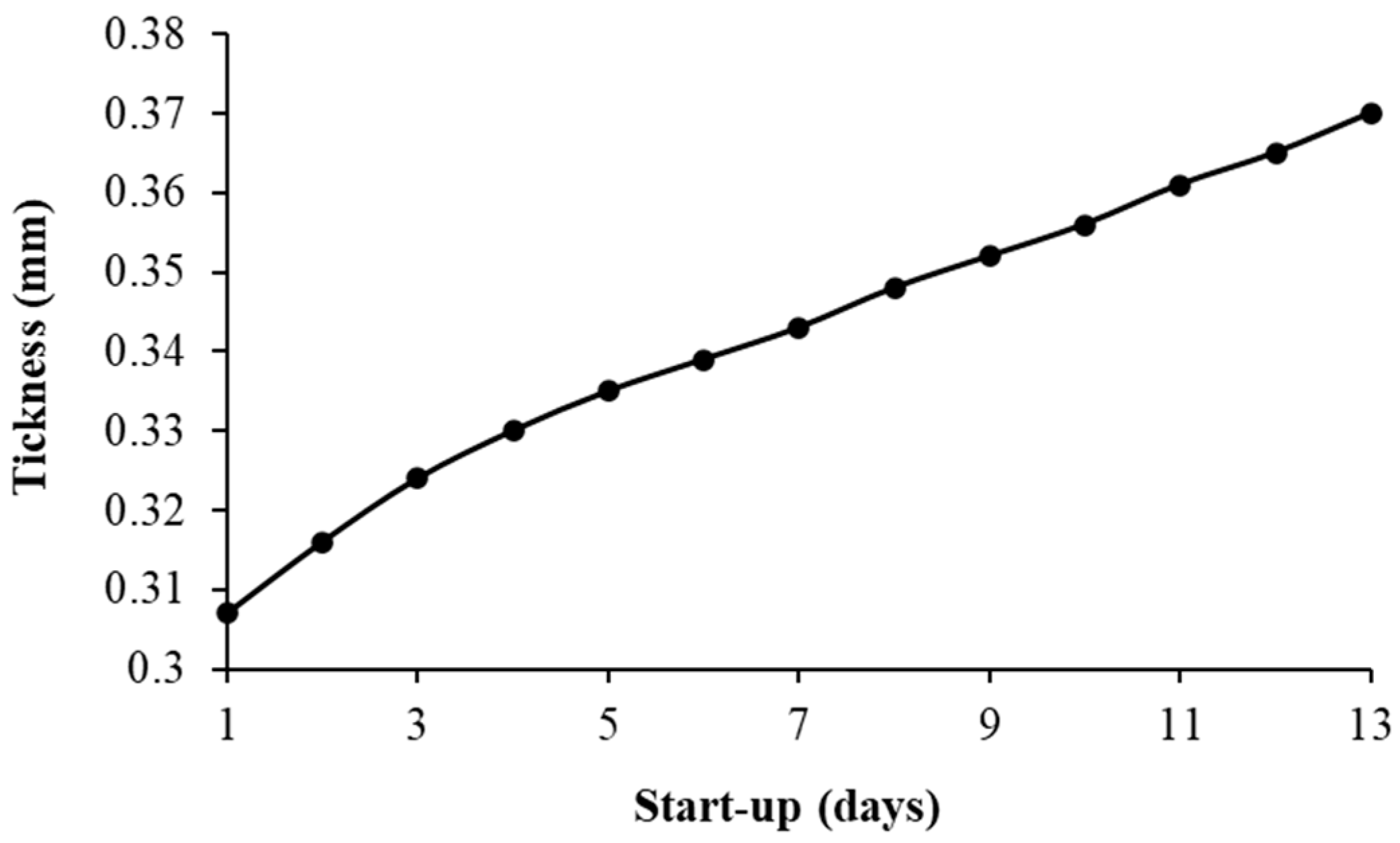

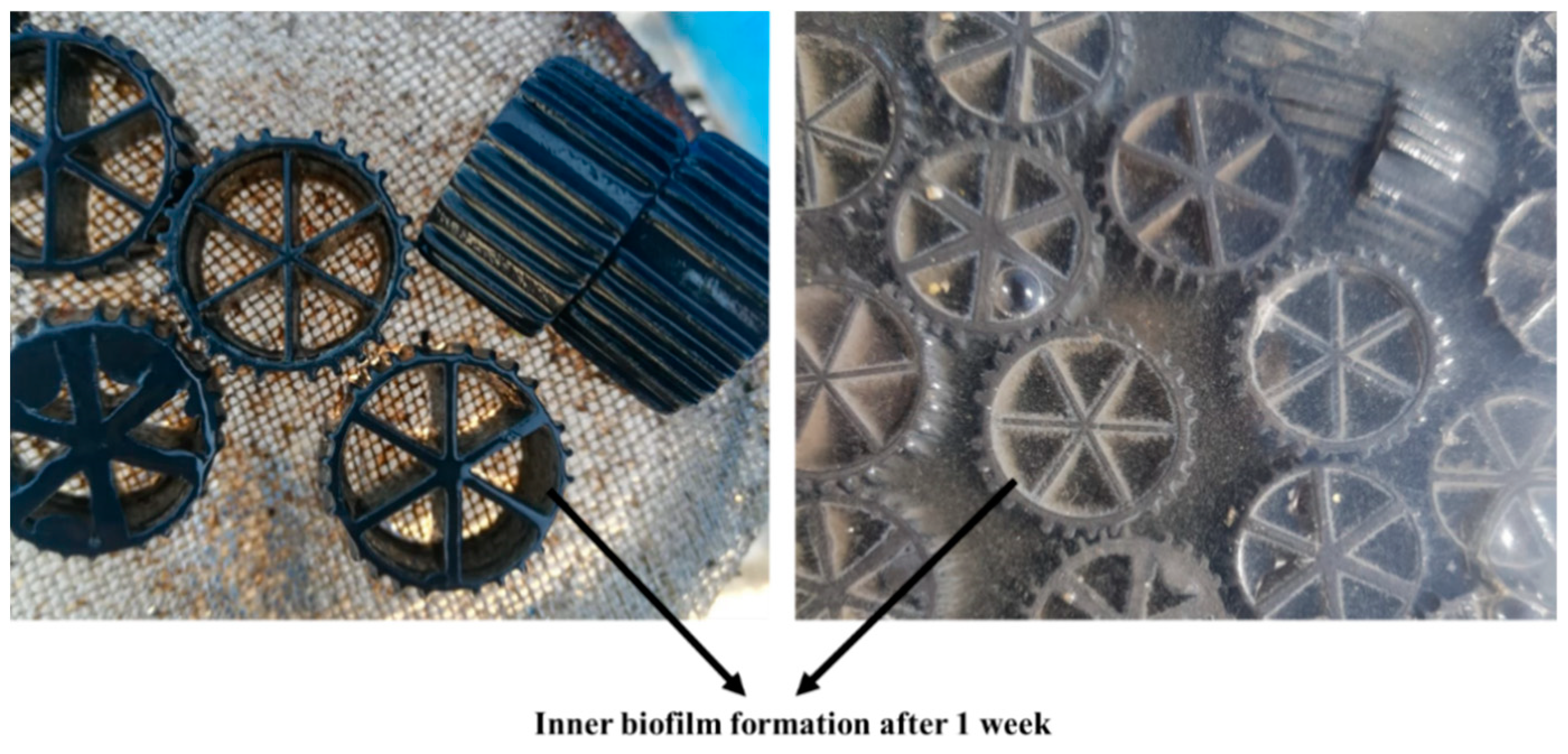

3.2. Biofilm Formation during Start-Up Performance

3.3. Sludge Reduction in MBBR System (Scenario 1)

3.4. Sludge Elimination at IFAS System (Scenario 2)

CO2 + H2O + NH3 + energy

CO2 + H2O + NH3 + energy

3.5. System Operating Cost Reduction, Limitation and Advantages

- Completely eliminates sludge.

- No odor removal system required.

- System administration is very easy.

- It does not need large spaces.

- It does not require complex mechanical equipment.

| Unit | Full Scale MBBR System | This MBBR System |

|---|---|---|

| Gravity thickener and Aerobic digester | 10 (USD $ per m3/day) | None |

| Excess sludge pump | 6 (USD $ per m3/day) | None |

| Centrifuge and dosing polymer pump | 30 (USD $ per m3/day) | None |

| Odor removal system | 20 (USD $ per m3/day) | None |

| Electricity usage of sludge line (per year) | 60 (USD $ per m3/day) | None |

| Maintenance of sludge line (per year) | 80 (USD $ per m3/day) | None |

| Operation of sludge line (per year) | 70 (USD $ per m3/day) | None |

| Environmental feasibility | Odor emission and insects gathering | No odor |

| Economic feasibility | High cost | Low cost |

| Technical feasibility | Large space needed | No space needed |

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, F.; Zhou, L.; Zhao, J. The performance of biocarrier containing zinc nanoparticles in biofilm reactor for treating textile wastewater. Process Biochem. 2018, 74, 125–131. [Google Scholar] [CrossRef]

- Amanatidou, E.; Samiotis, G.; Trikoilidou, E.; Pekridis, G.; Tsikritzis, L. Complete solids retention activated sludge process. Water Sci. Technol. 2015, 73, 1364–1370. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, N.; Wei, Y.; Dang, K.; Li, M.; Li, Y.; Li, Q.; Mu, R. Pilot study on the upgrading configuration of UASB-MBBR with two carriers: Treatment effect, sludge reduction and functional microbial identification. Process Biochem. 2020, 99, 211–221. [Google Scholar] [CrossRef]

- Zhang, X.; Song, Z.; Guo, W.; Lu, Y.; Qi, L.; Wen, H.; Ngo, H.H. Behavior of nitrogen removal in an aerobic sponge based moving bed biofilm reactor. Bioresour. Technol. 2017, 245, 1282–1285. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, K.; Ooi, G.T.H.; Litty, K.; Sundmark, K.; Kaarsholm, K.M.S.; Sund, C.; Kragelund, C.; Christensson, M.; Bester, K.; Andersen, H.R. Removal of pharmaceuticals in conventionally treated wastewater by a polishing moving bed biofilm reactor (MBBR) with intermittent feeding. Bioresour. Technol. 2017, 236, 77–86. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.-S.; Fang, F.; Yan, P.; Chen, Y.-P. Sludge reduction based on microbial metabolism for sustainable wastewater treatment. Bioresour. Technol. 2020, 297, 122506. [Google Scholar] [CrossRef] [PubMed]

- Semblante, G.U.; Hai, F.I.; Dionysiou, D.D.; Fukushi, K.; Price, W.E.; Nghiem, L.D. Holistic sludge management through ozonation: A critical review. J. Environ. Manag. 2017, 185, 79–95. [Google Scholar] [CrossRef] [Green Version]

- Salehiziri, M.; Amini Rad, H.; Novak, J.T. Disruption of cell to cell communication in the aeration unit of a cannibal process: Sludge reduction efficiency and related mechanisms. Biochem. Eng. J. 2018, 137, 326–333. [Google Scholar] [CrossRef]

- Zwain, H.M.; Nile, B.K.; Faris, A.M.; Vakili, M.; Dahlan, I. Modelling of hydrogen sulfide fate and emissions in extended aeration sewage treatment plant using TOXCHEM simulations. Sci. Rep. 2020, 10, 22209. [Google Scholar] [CrossRef]

- Faris, A.M.; Zwain, H.M.; Hosseinzadeh, M.; Majdi, H.S.; Siadatmousavi, S.M. Start-up and operation of novel EN-MBBR system for sidestreams treatment and sensitivity analysis modeling using GPS-X simulation. Alex. Eng. J. 2022, 61, 10805–10818. [Google Scholar] [CrossRef]

- Gu, Q.; Sun, T.; Wu, G.; Li, M.; Qiu, W. Influence of carrier filling ratio on the performance of moving bed biofilm reactor in treating coking wastewater. Bioresour. Technol. 2014, 166, 72–78. [Google Scholar] [CrossRef] [PubMed]

- Rout, P.R.; Shahid, M.K.; Dash, R.R.; Bhunia, P.; Liu, D.; Varjani, S.; Zhang, T.C.; Surampalli, R.Y. Nutrient removal from domestic wastewater: A comprehensive review on conventional and advanced technologies. J. Environ. Manag. 2021, 296, 113246. [Google Scholar] [CrossRef] [PubMed]

- Paśmionka, I.B.; Bulski, K.; Boligłowa, E. The Participation of Microbiota in the Transformation of Nitrogen Compounds in the Soil—A Review. Agronomy 2021, 11, 977. [Google Scholar] [CrossRef]

- Ani, J.S.; Manyala, J.O.; Masese, F.O.; Fitzsimmons, K. Effect of stocking density on growth performance of monosex Nile Tilapia (Oreochromis niloticus) in the aquaponic system integrated with lettuce (Lactuca sativa). Aquac. Fish. 2022, 7, 328–335. [Google Scholar] [CrossRef]

- He, T.; Xie, D.; Ni, J.; Li, Z.; Li, Z. Nitrous oxide produced directly from ammonium, nitrate and nitrite during nitrification and denitrification. J. Hazard. Mater. 2020, 388, 122114. [Google Scholar] [CrossRef]

- Skouteris, G.; Rodriguez-Garcia, G.; Reinecke, S.F.; Hampel, U. The use of pure oxygen for aeration in aerobic wastewater treatment: A review of its potential and limitations. Bioresour. Technol. 2020, 312, 123595. [Google Scholar] [CrossRef]

- Faris, A.M.; Zwain, H.M.; Hosseinzadeh, M.; Siadatmousavi, S.M. Modeling of novel processes for eliminating sidestreams impacts on full-scale sewage treatment plant using GPS-X7. Sci. Rep. 2022, 12, 2986. [Google Scholar] [CrossRef]

- Jiang, L.-M.; Zhou, Z.; Cheng, C.; Li, J.; Huang, C.; Niu, T. Sludge reduction by a micro-aerobic hydrolysis process: A full-scale application and sludge reduction mechanisms. Bioresour. Technol. 2018, 268, 684–691. [Google Scholar] [CrossRef]

- Chon, D.-H.; Rome, M.; Kim, Y.M.; Park, K.Y.; Park, C. Investigation of the sludge reduction mechanism in the anaerobic side-stream reactor process using several control biological wastewater treatment processes. Water Res. 2011, 45, 6021–6029. [Google Scholar] [CrossRef]

- Jiang, L.-M.; Zhou, Z.; Niu, T.; Jiang, L.; Chen, G.; Pang, H.; Zhao, X.; Qiu, Z. Effects of hydraulic retention time on process performance of anaerobic side-stream reactor coupled membrane bioreactors: Kinetic model, sludge reduction mechanism and microbial community structures. Bioresour. Technol. 2018, 267, 218–226. [Google Scholar] [CrossRef]

- Metcalf & Eddy; Tchobanoglous, G.; Stensel, H.D.; Tsuchihashi, R.; Burton, F.; Abu-Orf, M.; Bowden, G.; Pfrang, W. Wastewater Engineering: Treatment and Resource Recovery; McGraw Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Langone, M.; Sabia, G.; Petta, L.; Zanetti, L.; Leoni, P.; Basso, D. Evaluation of the aerobic biodegradability of process water produced by hydrothermal carbonization and inhibition effects on the heterotrophic biomass of an activated sludge system. J. Environ. Manag. 2021, 299, 113561. [Google Scholar] [CrossRef] [PubMed]

- Chiavola, A.; Salvati, C.; Bongirolami, S.; Di Marcantonio, C.; Boni, M.R. Techno-economic evaluation of ozone-oxidation for sludge reduction at the full-scale. Comparison between the application to the return activated sludge (RAS) and the sludge digestion unit. J. Water Process Eng. 2021, 42, 102114. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Flow (Q) | 5 m3/d |

| Surface area loading rate (SALR) for BOD removal | 7.5 g/m2·d |

| Surface area loading rate (SALR) for NH4 removal | 0.87 g/m2·d |

| Dissolved oxygen (DO) | 4 mg/L |

| BOD removal | ≥95% |

| NH4 removal | ≥95% |

| Carrier fill ratio | 40% |

| Hydraulic Retention time (HRT) for BOD and NH4 removals | 9 h |

| Specific surface area | 500 m2/m3 |

| Parameter | Inlet Concentration | Outlet Concentration |

|---|---|---|

| pH | 6.7–7.4 | 7–7.2 |

| COD (mg/L) | 345–440 | 20–30 |

| BOD (mg/L) | 140–245 | 4–9 |

| TSS (mg/L) | 155–325 | 4–9 |

| NO3 (mg/L) | 0–4 | 7–40 |

| NH4 (mg/L) | 20–28 | 0.5 |

| PO4-P (mg/L) | 20–26 | 0.5–2 |

| H2S (mg/L) | 15–30 | <0.5 |

| SRT (Day) | HRT (h) | WAS (m3/Day) | RAS (%) | Excess Sludge (g/Day) | Period (Days) | BOD (mg/L) | COD (mg/L) | TSS (mg/L) | NO3 (mg/L) | NH4 (mg/L) | Process | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Scenario 1 | Part 1 | 5 | 9 | 0.1 | 0 | 750 | 13 | 8 | 15 | 5 | 6 | 0.7 | MBBR |

| Part 2 | 10 | 18 | 0.1 | 0 | 370 | 30 | 4 | 13 | 4 | 19 | 0.4 | ||

| Part 3 | 15 | 26 | 0.1 | 0 | 150 | 30 | 2 | 8 | 4 | 32 | 0.2 | ||

| Scenario 2 | Part 1 | Complete | 6 | 0 | 50 | 0 | 30 | 40 | 85 | 80 | 16 | 0.3 | IFAS |

| Part 2 | Complete | 12 | 0 | 50 | 0 | 40 | 29 | 60 | 48 | 27 | 0.2 | ||

| Part 3 | Complete | 14 | 0 | 100 | 0 | 60 | 3 | 12 | 8 | 45 | 0.2 | ||

| Part 4 | Complete | 14 | 0 | 150 | 0 | 60 | 4 | 11 | 9 | 58 | 0.2 | ||

| Part 5 | Complete | 20 | 0 | 150 | 0 | 60 | 2 | 7 | 10 | 70 | 0.2 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khudhair, D.N.; Hosseinzadeh, M.; Zwain, H.M.; Siadatmousavi, S.M.; Majdi, A.; Mojiri, A. Upgrading the MBBR Process to Reduce Excess Sludge Production in Activated Sludge System Treating Sewage. Water 2023, 15, 408. https://doi.org/10.3390/w15030408

Khudhair DN, Hosseinzadeh M, Zwain HM, Siadatmousavi SM, Majdi A, Mojiri A. Upgrading the MBBR Process to Reduce Excess Sludge Production in Activated Sludge System Treating Sewage. Water. 2023; 15(3):408. https://doi.org/10.3390/w15030408

Chicago/Turabian StyleKhudhair, Duaa Natheer, Majid Hosseinzadeh, Haider M. Zwain, Seyed Mostafa Siadatmousavi, Ali Majdi, and Amin Mojiri. 2023. "Upgrading the MBBR Process to Reduce Excess Sludge Production in Activated Sludge System Treating Sewage" Water 15, no. 3: 408. https://doi.org/10.3390/w15030408

APA StyleKhudhair, D. N., Hosseinzadeh, M., Zwain, H. M., Siadatmousavi, S. M., Majdi, A., & Mojiri, A. (2023). Upgrading the MBBR Process to Reduce Excess Sludge Production in Activated Sludge System Treating Sewage. Water, 15(3), 408. https://doi.org/10.3390/w15030408