Full-Scale Sewage Sludge Reduction Technologies: A Review with a Focus on Energy Consumption

Abstract

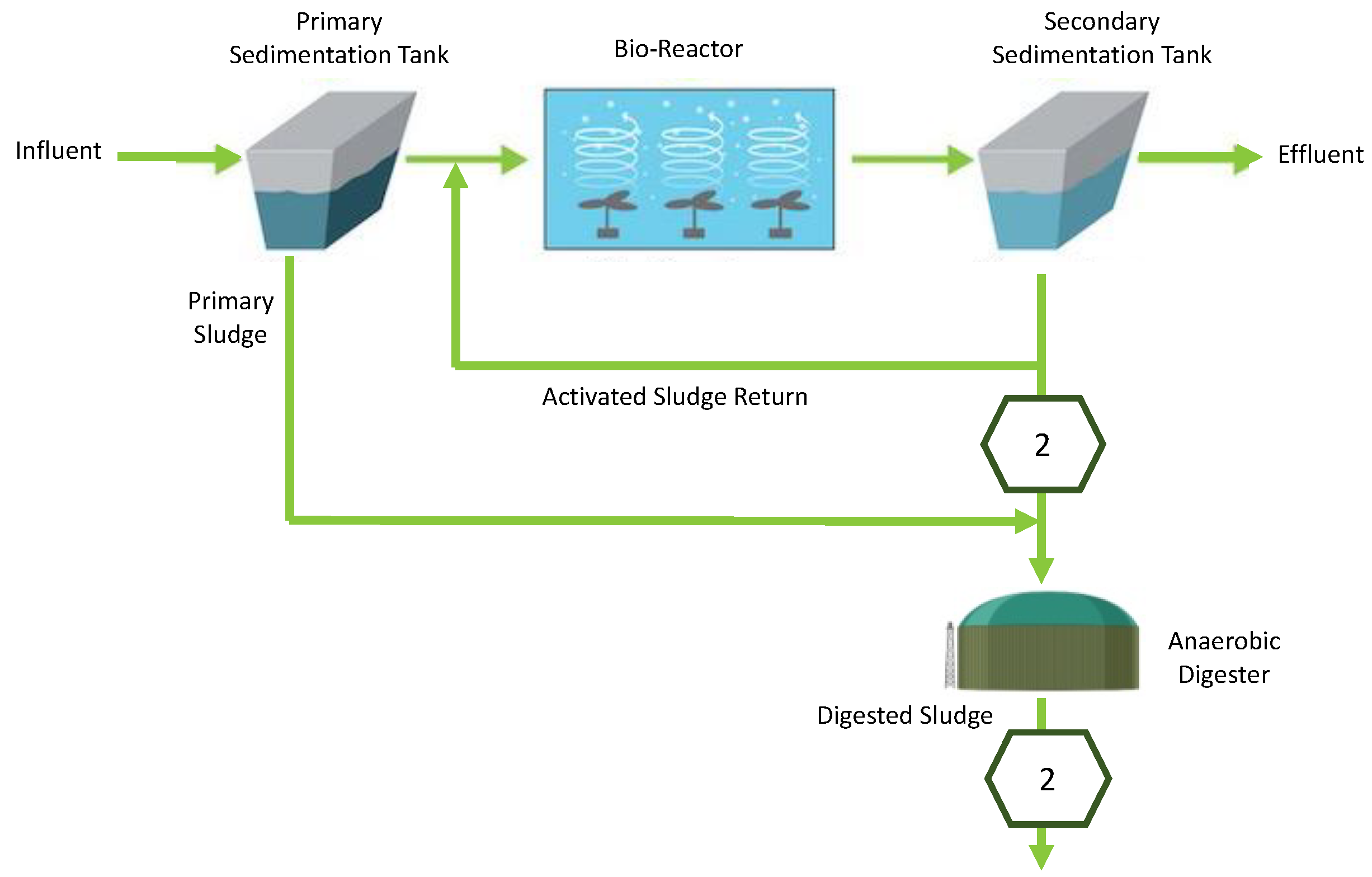

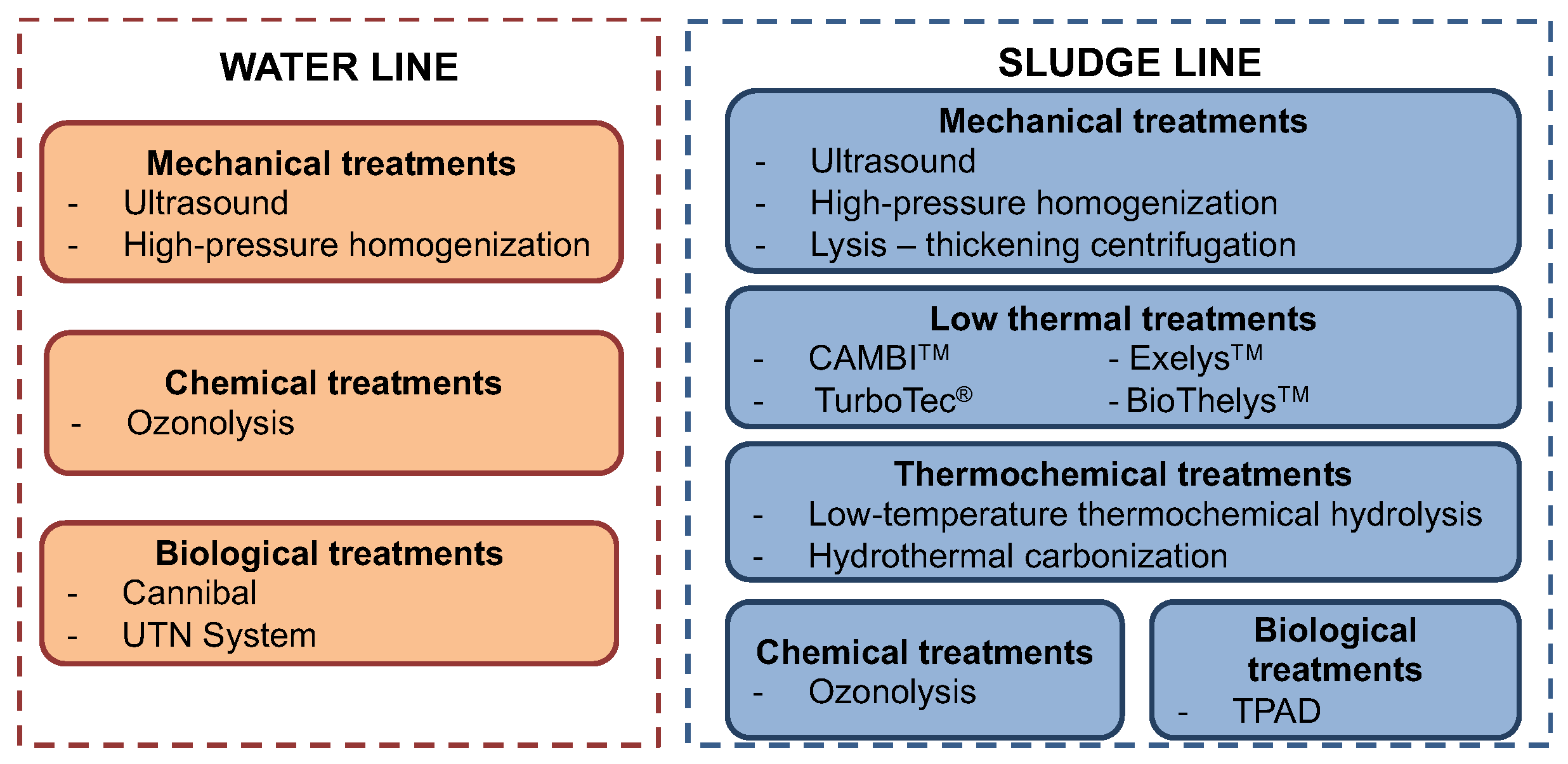

:1. Introduction

2. Methodology

3. Mechanical Treatments

3.1. Ultrasound Treatment

3.2. High-Pressure Homogenization

3.3. Lysis-Thickening Centrifugation

4. Chemical Treatments

5. Low-Temperature Thermal Treatments

6. Thermochemical Treatments

6.1. Low-Temperature Thermochemical Hydrolysis

6.2. Hydrothermal Carbonization

7. Biological Treatments

7.1. The Cannibal Process

7.2. The UTN Process

7.3. Temperature-Phased Anaerobic Digestion (TPAD) Process

8. Performance Overview

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ferrentino, R.; Langone, M.; Andreottola, G.; Rada, E.C. An anaerobic side-stream reactor in wastewater treatment: A review. WIT Trans. Ecol. Environ. 2014, 191, 1435–1446. [Google Scholar]

- Gao, N.; Kamran, K.; Quan, C.; Williams, P.T. Thermochemical conversion of sewage sludge: A critical review. Prog. Energy Combust. Sci. 2020, 79, 100843. [Google Scholar] [CrossRef]

- Semblante, G.U.; Hai, F.I.; Bustamante, H.; Price, W.E.; Nghiem, L.D. Effects of sludge retention time on oxic-settling-anoxic process performance: Biosolids reduction and dewatering properties. Bioresour. Technol. 2016, 218, 1187–1194. [Google Scholar] [CrossRef] [PubMed]

- EEA. Bio-Waste in Europe—Turning Challenges into Opportunities (Issue 04); Publication Office of the European Union: Luxembourg, 2020; ISBN 9789294802231. [Google Scholar]

- Fytili, D.; Zabaniotou, A.Ã. Utilization of sewage sludge in EU application of old and new methods—A review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Ferrentino, R.; Langone, M.; Andreottola, G. Progress toward full scale application of the anaerobic side-stream reactor (ASSR) process. Bioresour. Technol. 2019, 272, 267–274. [Google Scholar] [CrossRef]

- Clarke, R.M.; Cummins, E. Evaluation of “Classic” and Emerging Contaminants Resulting from the Application of Biosolids to Agricultural Lands: A Review. Hum. Ecol. Risk Assess. Int. J. 2015, 21, 492–513. [Google Scholar] [CrossRef]

- Neczaj, E.; Fija, K.; Grobelak, A.; Grosser, A. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar]

- Ragazzi, M.; Rada, E.C.; Ferrentino, R. Analysis of real-scale experiences of novel sewage sludge treatments in an Italian pilot region. Desalin. Water Treat. 2015, 55, 783–790. [Google Scholar] [CrossRef]

- Campanelli, M.; Foladori, P.; Vaccari, M. Consumi Elettrici ed Efficienza Energetica nel Trattamento delle Acque Reflue; Maggioli Editore: Rimini, Italy, 2013. [Google Scholar]

- Foladori, P.; Andreottola, G.; Ziglio, G. Sludge Reduction Technologies in Wastewater Treatment Plants; IWA Publishing: London, UK, 2010. [Google Scholar]

- Wang, Q.; Wei, W.; Gong, Y.; Yu, Q.; Li, Q.; Sun, J.; Yuan, Z. Technologies for reducing sludge production in wastewater treatment plants: State of the art. Sci. Total Environ. 2017, 587–588, 510–521. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, A.R.; Mehrdadi, N.; Bidhendi, G.N.; Torabian, A. Excess sludge reduction using ultrasonic waves in biological wastewater treatment. Desalination 2011, 275, 67–73. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, P.; Yang, J.; Chen, Y. Ultrasonic reduction of excess sludge from the activated sludge system. J. Hazard. Mater. 2007, 145, 515–519. [Google Scholar] [CrossRef]

- Neis, U.; Nickel, K.; Lundén, A. Improving anaerobic and aerobic degradation by ultrasonic disintegration of biomass. J. Environ. Sci. Health-Part A Toxic/Hazardous Subst. Environ. Eng. 2008, 43, 1541–1545. [Google Scholar] [CrossRef]

- Ultrawaves. Available online: https://ultrawaves.de/de/ (accessed on 2 December 2022).

- Xie, R.; Xing, Y.; Ghani, Y.A.; Ooi, K.E.; Ng, S.W. Full-scale demonstration of an ultrasonic disintegration technology in enhancing anaerobic digestion of mixed primary and thickened secondary sewage sludge. J. Environ. Eng. Sci. 2007, 6, 533–541. [Google Scholar] [CrossRef]

- Pérez-Elvira, S.I.; Fernández-Polanco, F.; Fernández-Polanco, M.; Rodríguez, P.; Rouge, P. Hydrothermal multivariable approach. Full-scale feasibility study. Electron. J. Biotechnol. 2008, 11, 7–8. [Google Scholar] [CrossRef]

- Ladurner Ambiente. Available online: www.ladurnerambiente.it (accessed on 15 November 2022).

- Hogan, F.; Mormede, S.; Clark, P.; Crane, M. Ultrasonic sludge treatment for enhanced anaerobic digestion. Water Sci. Technol. 2004, 50, 25–32. [Google Scholar] [CrossRef] [PubMed]

- Troncon, M. Trattamento di Sonolisi dei Fanghi: Esperienze Italiane ed Europee; Internal Seminar at the University of Trento: Trento, Italy, 2008. [Google Scholar]

- Bamberg, H.W.; Nickel, K.; Houy, A.; Lunden, A. Intensivierung der anaeroben Schlammstabilisierung mit Ultraschall. KA Abwasser Abfall 2009, 2009, 492–498. [Google Scholar]

- Mancuso, G.; Langone, M.; Andreottola, G. A critical review of the current technologies in wastewater treatment plants by using hydrodynamic cavitation process: Principles and applications. J. Environ. Health Sci. Eng. 2020, 18, 311–333. [Google Scholar] [CrossRef]

- Camacho, P.; Geaugey, V.; Ginestet, P.; Paul, E. Feasibility study of mechanically disintegrated sludge and recycle in the activated-sludge process. Water Sci. Technol. 2002, 46, 97–104. [Google Scholar] [CrossRef] [PubMed]

- Onyeche, T.I. Sludge as source of energy and revenue. Water Sci. Technol. 2004, 50, 197–204. [Google Scholar] [CrossRef]

- Garuti, M.; Langone, M.; Fabbri, C.; Piccinini, S. Monitoring of full-scale hydrodynamic cavitation pretreatment in agricultural biogas plant. Bioresour. Technol. 2018, 247, 599–609. [Google Scholar] [CrossRef]

- Dohányos, M.; Zábranská, J.; Kutil, J.; Jeníček, P. Improvement of anaerobic digestion of sludge. Water Sci. Technol. 2004, 49, 89–96. [Google Scholar] [CrossRef] [PubMed]

- Carrère, H.; Dumas, C.; Battimelli, A.; Batstone, D.J.; Delgenès, J.P.; Steyer, J.P.; Ferrer, I. Pretreatment methods to improve sludge anaerobic degradability: A review. J. Hazard. Mater. 2010, 183, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Romero, P.; Coello, M.D.; Aragón, C.A.; Battistoni, P.; Eusebi, A.L. Sludge Reduction through Ozonation: Effects of Different Specific Dosages and Operative Management Aspects in a Full-Scale Study. J. Environ. Eng. (United States) 2015, 141, 04015043. [Google Scholar] [CrossRef]

- Déléris, S.; Larose, A.; Geaugy, V.; Lebrun, T. Innovative Strategies for the reduction of sludge production un activated sludge plant: BIOLYSIS O and BIOLYSIS E. Int. IWA Spec. Conf. BIOSOLIDS 2003 Wastewater Sludge Ressour. 2003, 33, 55–61. [Google Scholar]

- Dytczak, M.A.; Londry, K.; Siegrist, H.; Oleszkiewicz, J.A. Extracellular polymers in partly ozonated return activated sludge: Impact on flocculation and dewaterability. Water Sci. Technol. 2006, 54, 155–164. [Google Scholar] [CrossRef] [PubMed]

- Richardson, E.E.; Edwards, F.; Hernandez, J. Ozonation in Sequencing Batch Reactors for Reduction of Waste Solids. Water Environ. Res. 2009, 81, 506–513. [Google Scholar] [CrossRef]

- Egemen, E.; Corpening, J.; Padilla, J.; Brennan, R.; Nirmalakhandan, N. Evaluation of ozonation and cryptic growth for biosolids management in wastewater treatment. Water Sci. Technol. 1999, 39, 155–158. [Google Scholar] [CrossRef]

- Dallera, F. Ozonolisi dei Fanghi Biologici: Valutazione dei Risparmi Economico-Gestionali; University of Palermo: Palerno, Italy, 2016; pp. 1–8. Available online: https://www.unipa.it/strutture/depa/.content/documenti/Dallera.pdf (accessed on 6 January 2023).

- Sakai, Y.; Fukase, T.; Yasui, H.; Shibata, M. An activated sludge process without excess sludge production. Water Sci. Technol. 1997, 36, 163–170. [Google Scholar] [CrossRef]

- Lee, J.W.; Cha, H.Y.; Park, K.Y.; Song, K.G.; Ahn, K.H. Operational strategies for an activated sludge process in conjunction with ozone oxidation for zero excess sludge production during winter season. Water Res. 2005, 39, 1199–1204. [Google Scholar] [CrossRef]

- Chu, L.; Yan, S.; Xing, X.-H.; Sun, X.; Jurcik, B. Progress and perspectives of sludge ozonation as a powerful pretreatment method for minimization of excess sludge production. Water Res. 2009, 43, 1811–1822. [Google Scholar] [CrossRef]

- Scheminski, A.; Krull, R.; Hempel, D.C. Oxidative treatment of digested sewage sludge with ozone. Water Sci. Technol. 2000, 42, 151–158. [Google Scholar] [CrossRef]

- Sievers, M.; Ried, A.; Koll, R. Sludge treatment by ozonation-Evaluation of full-scale results. Water Sci. Technol. 2004, 49, 247–253. [Google Scholar] [CrossRef]

- Mundy, B.; Kuhnel, B.; Hunter, G.; Jarnis, R.; Funk, D.; Walker, S.; Burns, N.; Drago, J.; Nezgod, W.; Huang, J.; et al. A Review of Ozone Systems Costs for Municipal Applications. Report by the Municipal Committee–IOA Pan American Group. Ozone Sci. Eng. 2018, 40, 266–274. [Google Scholar] [CrossRef]

- Dallera, F. Applicazione dell’ozono nel trattamento delle acque reflue. In Proceedings of the Ecomondo, Rimini, Italy, 5–9 November 2015. [Google Scholar]

- Valo, A.; Carrère, H.; Delgenès, J.P. Thermal, chemical and thermo-chemical pre-treatment of waste activated sludge for anaerobic digestion. J. Chem. Technol. Biotechnol. 2004, 79, 1197–1203. [Google Scholar] [CrossRef]

- Tanaka, S.; Kobayashi, T.; Kamiyama, K.I.; Signey Bildan, M.L.N. Effects of thermochemical pretreatment on the anaerobic digestion of waste activated sludge. Water Sci. Technol. 1997, 35, 209–215. [Google Scholar] [CrossRef]

- CAMBI; ASA. Cambi thermal hydrolysis from waste to worth. In Proceedings of the Polish Cities to Norway, Lindum, Drammen, 14 September 2016. [Google Scholar]

- Veolia Il processo Biothelys. In Proceedings of the Festival dell’acqua, Venezia, Italy, 10–11 October 2019.

- Nielsen, P.J. 9. Klärschlammtage der DWA; DWA: Potsdam, Germany, 2015. [Google Scholar]

- Kepp, U.; Machenbach, I.; Weisz, N.; Solheim, O.E. Enhanced stabilisation of sewage sludge through thermal hydrolysis-Three years of experience with full scale plant. Water Sci. Technol. 2000, 42, 89–96. [Google Scholar] [CrossRef]

- Edgington, R.M.; Belshaw, D.; Lancaster, L.; Jolly, M. Thermal Hydrolysis at Davyhulme WwTP-One Year On. Eur. Biosolids Org. Resour. Conf. 2014. Available online: https://www.aquaenviro.co.uk/wp-content/uploads/2015/06/Thermal-Hydrolysis-at-Davyhulme-WWTW-One-Year-On-Edgington-R.pdf (accessed on 6 January 2023).

- Taboada-Santos, A.; Lema, J.M.; Carballa, M. Energetic and economic assessment of sludge thermal hydrolysis in novel wastewater treatment plant configurations. Waste Manag. 2019, 92, 30–38. [Google Scholar] [CrossRef] [PubMed]

- NewLisi. Available online: www.newlisi.com (accessed on 7 December 2022).

- Ferrentino, R.; Merzari, F.; Fiori, L.; Andreottola, G. Coupling hydrothermal carbonization with anaerobic digestion for sewage sludge treatment: Influence of HTC liquor and hydrochar on biomethane production. Energies 2020, 13, 6262. [Google Scholar] [CrossRef]

- Ahmed, M.; Andreottola, G.; Elagroudy, S.; Negm, M.S.; Fiori, L. Coupling hydrothermal carbonization and anaerobic digestion for sewage digestate management: Influence of hydrothermal treatment time on dewaterability and bio-methane production. J. Environ. Manag. 2021, 281, 111910. [Google Scholar] [CrossRef] [PubMed]

- Langone, M.; Sabia, G.; Petta, L.; Zanetti, L.; Leoni, P.; Basso, D. Evaluation of the aerobic biodegradability of process water produced by hydrothermal carbonization and inhibition effects on the heterotrophic biomass of an activated sludge system. J. Environ. Manag. 2021, 299, 113561. [Google Scholar] [CrossRef]

- Ferrentino, R.; Merzari, F.; Grigolini, E.; Fiori, L.; Andreottola, G. Hydrothermal carbonization liquor as external carbon supplement to improve biological denitrification in wastewater treatment. J. Water Proces.s Eng. 2021, 44, 102360. [Google Scholar] [CrossRef]

- Terranova Energy. Available online: www.terranova-energy.com (accessed on 22 November 2022).

- Ingelia. Available online: www.ingelia.it (accessed on 23 November 2022).

- Kläusli, T.M. Hydrothermal Carbonisation Energy from Biomass. Energy Future. 2013. Available online: http://duene-greifswald.de/doc/rrr2013/talks/HTC.pdf (accessed on 6 January 2023).

- Carborem ETV Statement of Verification Carborem Technology. 2020. Available online: https://ec.europa.eu/environment/ecoap/sites/ecoap_stayconnected/files/etv/etv_08_vstatement_carborem-tech_rev00_signed.pdf (accessed on 6 January 2023).

- Lucian, M.; Fiori, L. Hydrothermal carbonization of waste biomass: Process design, modeling, energy efficiency and cost analysis. Energies 2017, 10, 211. [Google Scholar] [CrossRef]

- Chen, G.; Yip, W.; Mo, H.; Liu, Y. Effect of sludge fasting/feasting on growth of activated sludge cultures. Water Res. 2001, 35, 1029–1037. [Google Scholar] [CrossRef]

- Novak, J.T.; Chon, D.H.; Curtis, B.-A.; Doyle, M. Biological Solids Reduction Using the Cannibal Process. Water Environ. Res. 2007, 79, 2380–2386. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Velho, V.F.; Foladori, P.; Andreottola, G.; Costa, R.H.R. Anaerobic side-stream reactor for excess sludge reduction: 5-year management of a full-scale plant. J. Environ. Manag. 2016, 177, 223–230. [Google Scholar] [CrossRef] [PubMed]

- Ferrentino, R.; Langone, M.; Andreottola, G. Sludge reduction by an anaerobic side-stream reactor process: A full-scale application. Environ. Chall. 2021, 2, 100016. [Google Scholar] [CrossRef]

- Summerville Cannibal Sludge Reduction Project-USA. Available online: https://www.penetron.com/projects/view/Summerville-Cannibal-Sludge-Reduction-Project (accessed on 14 October 2022).

- Bolzonella, D.; Cavinato, C.; Fatone, F.; Pavan, P.; Cecchi, F. High rate mesophilic, thermophilic, and temperature phased anaerobic digestion of waste activated sludge: A pilot scale study. Waste Manag. 2012, 32, 1196–1201. [Google Scholar] [CrossRef] [PubMed]

- Riau, V.; De la Rubia, M.Á.; Pérez, M. Temperature-phased anaerobic digestion (TPAD) to obtain class A biosolids: A semi-continuous study. Bioresour. Technol. 2010, 101, 2706–2712. [Google Scholar] [CrossRef] [PubMed]

- Climent, M.; Ferrer, I.; Baeza, M.D.M.; Artola, A.; Vázquez, F.; Font, X. Effects of thermal and mechanical pretreatments of secondary sludge on biogas production under thermophilic conditions. Chem. Eng. J. 2007, 133, 335–342. [Google Scholar] [CrossRef]

- Skiadas, I.V.; Gavala, H.N.; Lu, J.; Ahring, B.K. Thermal pre-treatment of primary and secondary sludge at 701 °C prior to anaerobic digestion. Water Sci. Technol. 2005, 52, 161–166. [Google Scholar] [CrossRef]

- Torres, L.G.; Bandala, E.R. Energy and Environment Nowadays; Nova Science Publisher: New York, NY, USA, 2014. [Google Scholar]

- Panter, K.; Jolis, D.; Solheim, O.E.; Seyffarth, T.; Fjaergard, T.; Sorensen, G. THyPAD–from Pilot to Full Scale Application at Hamar WWTP. Proc. Water Environ. Fed. 2014, 2006, 429–437. [Google Scholar] [CrossRef]

- Krugel, S.; Parella, A.; Ellquist, K.; Hamel, K. Five Years of Successful Operation-A Report on North Americas First TPAD System at the Western Lake Superior Sanitation District (WLSSD). Weftec 2006, 13, 357–373. [Google Scholar]

- Deleris, S.; Lebrun, T.; Geaugey, V. Biolysis, E. &Biolysis, O. Deux Innovations Technologiques Pour la reduction de la production de boues a la source. Revue Francophone d’Ecologie Industrielle 2002, 28, 33–37. [Google Scholar]

- Remy, C.; Diercks, K. Full scale demonstration of energy positive sewage treatment plant concepts towards market penetration. Horiz. 2020 Framew. Program. 2016, 1–47. Available online: http://powerstep.eu/system/files/generated/files/resource/d3-4-recommendations-for-improved-energy-management-wwtps.pdf (accessed on 6 January 2023).

- Chauzy, J.; Kline, M.; Cabral, C.; Dimassimo, R.; Eveillard, F. The Different Solutions Proposed by Thermal Hydrolysis Process: Successful Implementation of LD, DL and DLD Configurations on Several WWTP. Proc. Water Environ. Fed. 2015, 2014, 1–13. [Google Scholar] [CrossRef]

- Djafer, M.; Crampon, C.; Dimassimo, R. Continuous “Digestion-THP-Digestion” (DLD) at Lille (France) WWTP: Results after one year operation. In Proceedings of the Water Environment Federation, Atlanta, GA, USA, 1–4 May 2016. [Google Scholar]

- Kjaer, R.; Chen, J.H.; Djafer, M.; Py, C.; Nielsen, B. Two-step digestion with continuous thermal hydrolysis to optimize sludge treatment at Marquette-lez-Lille WWTP. In Proceedings of the 2nd IWA Conference on Holistic Sludge Management, Malmo, Sweden, 7–9 June 2016; International Water Association: Malmo, Sweden, 2016. [Google Scholar]

- Cano, R.; Pérez-Elvira, S.I.; Fdz-Polanco, F. Energy feasibility study of sludge pretreatments: A review. Appl. Energy 2015, 149, 176–185. [Google Scholar] [CrossRef]

- Pereboom, J.; Luning, L.; Hol, A.; van Dijk, L.; de Man, A.W.A. Full scale experiences with TurboTec ® continuous thermal hydrolysis at WWTP Venlo (NL) and Apeldoorn (NL). In Proceedings of the Aqua-Enviro 19th European Biosolids and Organic Residuals Conference and Exhibition, Manchester, UK, 17–19 November 2014. [Google Scholar]

| Parameter | WWTP A | WWTP B |

|---|---|---|

| Capacity of the plant (PE) | 30,000 | 35,000 |

| Biological sludge treated (%) | 50–60 | 30–40 |

| Treated sludge flow (m3/h) | 0.3 | 0.75 |

| TSS concentration (g/L) | 60 | 55 |

| Number of sonicators | 4 | 5 |

| Treatment duration (min) | 300 | 120 |

| Specific power intake (kW/kg TSS) | 0.35 | 0.4 |

| Energy consumption (kWhel/m3) | 6.3 | 16 |

| Technology | Advantages | Disadvantages | ||

|---|---|---|---|---|

| Water Line | Mechanical treatment | Ultrasound | Low investment costs Low space requirements No production of odor | Erosion of sonotrodes High operating costs Increase in effluent COD |

| Chemical treatment | Ozonolysis | Improved sludge settleability | High investment and operating costs Increase in effluent COD and phosphorous | |

| Biological treatment | Cannibal | Easy to apply in existing plants | Increase in effluent phosphorous | |

| UTN | Low investment and operating costs Improved sludge settleability | Only one full-scale application | ||

| Sludge Line | Mechanical treatment | Ultrasound | Low investment costs Low space requirements No production of odor Improved sludge settleability | Erosion of sonotrodes High operating costs |

| High-pressure homogenization | Improved sludge settleability at high disintegration intensity Short contact time No production of odor Lower sludge viscosity | Deterioration of equipment High investment and operating costs No pathogen inactivation | ||

| Lysis-thickening centrifuge | Short contact time No production of odor | Deterioration of equipment High investment and operating costs No pathogen inactivation | ||

| Chemical treatment | Ozonolysis | Lower sludge viscosity Improved sludge settleability | High investment and operating costs Increase in the wastewater nitrogen and phosphorous Worsening of settleability at high ozone dosages | |

| Low-temperature thermal treatment | CAMBITM ExelysTM BioThelysTM TurboTec® | Pathogen inactivation Improved sludge settleability Thermal synergies increasing biogas production | Production of odor Deterioration of equipment | |

| Thermochemical treatment | NewLisi HTC | Pathogen inactivation Improved sludge settleability | Deterioration and erosion of equipment High operating and maintenance costs High chemical consumption Production of odor | |

| Thermal synergies increasing biogas production | ||||

| Biological treatment | TPAD | Pathogen inactivation Improved sludge settleability Low management costs | High investment costs Production of odor | |

| Technology | Sludge Treated | Treatment Conditions | Performance Indicators | References | ||

|---|---|---|---|---|---|---|

| Sludge Reduction (%) | Energy Consumption | Investment Cost | ||||

| Ultrasound | Biological sludge | 20–40 kHz | 25–78% | 2.4 kWhel/m3 | 0.97 EUR/PE | [15,22] |

| >90 s | 28.1 kWhel/m3 | 7 EUR/PE | ||||

| Ozonolysis | 0.01–0.15 kg O3/kg TS | 35–45% | 30 kWhel/kg O3 | 45–67 EUR/ton | [28,34,72] | |

| 10–30 EUR/PE | ||||||

| Cannibal | HRT 10 d | 20% | N.A. | N.A. | [62] | |

| UTN | HRT 2.5 d | 50–69% | 84 kWhel/PE | N.A. | [63] | |

| Technology | Sludge Treated | Treatment Conditions | Performance Indicators | PE | References | ||||

|---|---|---|---|---|---|---|---|---|---|

| Sludge Reduction (%) | Increase in Biogas Production (%) | Biogas Produced (Nm3/ t VS) | Energy Consumption | Investment Cost | |||||

| Ultrasound | Mixed sludge | 20–40 kHz 90–300 s | 10–60% | 20–30% | 442 | 2.4 kWhel/m3 28.1 kWhel/m3 | 0.97 EUR/PE 7 EUR/PE | 17,000 330,000 | [15,22] |

| Lysis- thickening centrifugation | Mixed sludge | 2250 rpm 3140 rpm | 60% | 15–26% | 362 | 11.4 kWhel/m3 | 1.22 EUR/PE | 650,000 100,000 70,000 | [27,28] |

| High-pressure homogenizer | Mixed sludge | 150 bar 36–38 °C | 23–57% | 30% | 478 | 5.5 kWhel/m3 0.2–0.4 kWh/kg TS | 2 EUR/PE | 55,000 100,000 | [25,73] |

| CAMBI® | Thickened sludge | 160–180 °C 5–6 bar 20–30 min | 65 | 50 | 252–442 | 7.2 kWhel/m3 116 kWhheat/m3 | 20.38 EUR/PE | 100,000 250,000 | [44,46,47,48] |

| BioThelys® | Secondary sludge | 150–180 °C 8–10 bar 30–60 min | 40–60% | 30–50% | 286 | N.A. | N.A. | 760,000 | [74] |

| Exelys® | Secondary sludge | 130–150 °C 8–15 bar Continuous | 64% | 30–50% | 600 | 6.4 kWhel/m3 | N.A. | 630,000 | [75,76,77] |

| TurboTec® | Thickened sludge | 140 °C | 41% | 35% | 350–410 | 52 kWhel/t TS 620 kWhheat/t TS | N.A. | 300,000 | [78] |

| TerraNova® Ultra | Thickened sludge Digested sludge | 200 °C 20–35 bar 2 h | 75% | 10% | N.A. | 15 kWhel/t 100 kWhheat/t | N.A. | N.A. | [55] |

| C700 | Thickened sludge Digested sludge | 200°C 20 bar <60 min | 43% | 50% | N.A. | 4.60 kWhel/m3 83 kWhheat/m3 | N.A. | N.A. | [58] |

| NewLisi | Mixed sludge | pH 1–3 pH 8–12 70–90 °C | 64% | 43% | N.A. | N.A. | N.A. | 195,000 | [50] |

| Ozone | Activated sludge Digested sludge | 0.01−0.15 O3/kg TS 0.02−0.87 O3/kg TS | 55% | 20–30% | 550 | 23.8 kWhel/m3 | 18 EUR/PE | 17,000 | [73] |

| TPAD (thermophilic–mesophilic) | Secondary sludge | 60–70 °C 9–48 h HRT55 °C: 9 d HRT35 °C: 18 d | 26–50% | 7–11% | 454 | N.A. | N.A. | N.A. | [67,68,71] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrentino, R.; Langone, M.; Fiori, L.; Andreottola, G. Full-Scale Sewage Sludge Reduction Technologies: A Review with a Focus on Energy Consumption. Water 2023, 15, 615. https://doi.org/10.3390/w15040615

Ferrentino R, Langone M, Fiori L, Andreottola G. Full-Scale Sewage Sludge Reduction Technologies: A Review with a Focus on Energy Consumption. Water. 2023; 15(4):615. https://doi.org/10.3390/w15040615

Chicago/Turabian StyleFerrentino, Roberta, Michela Langone, Luca Fiori, and Gianni Andreottola. 2023. "Full-Scale Sewage Sludge Reduction Technologies: A Review with a Focus on Energy Consumption" Water 15, no. 4: 615. https://doi.org/10.3390/w15040615

APA StyleFerrentino, R., Langone, M., Fiori, L., & Andreottola, G. (2023). Full-Scale Sewage Sludge Reduction Technologies: A Review with a Focus on Energy Consumption. Water, 15(4), 615. https://doi.org/10.3390/w15040615