A Review of Stability of Dam Structures in Coal Mine Underground Reservoirs

Abstract

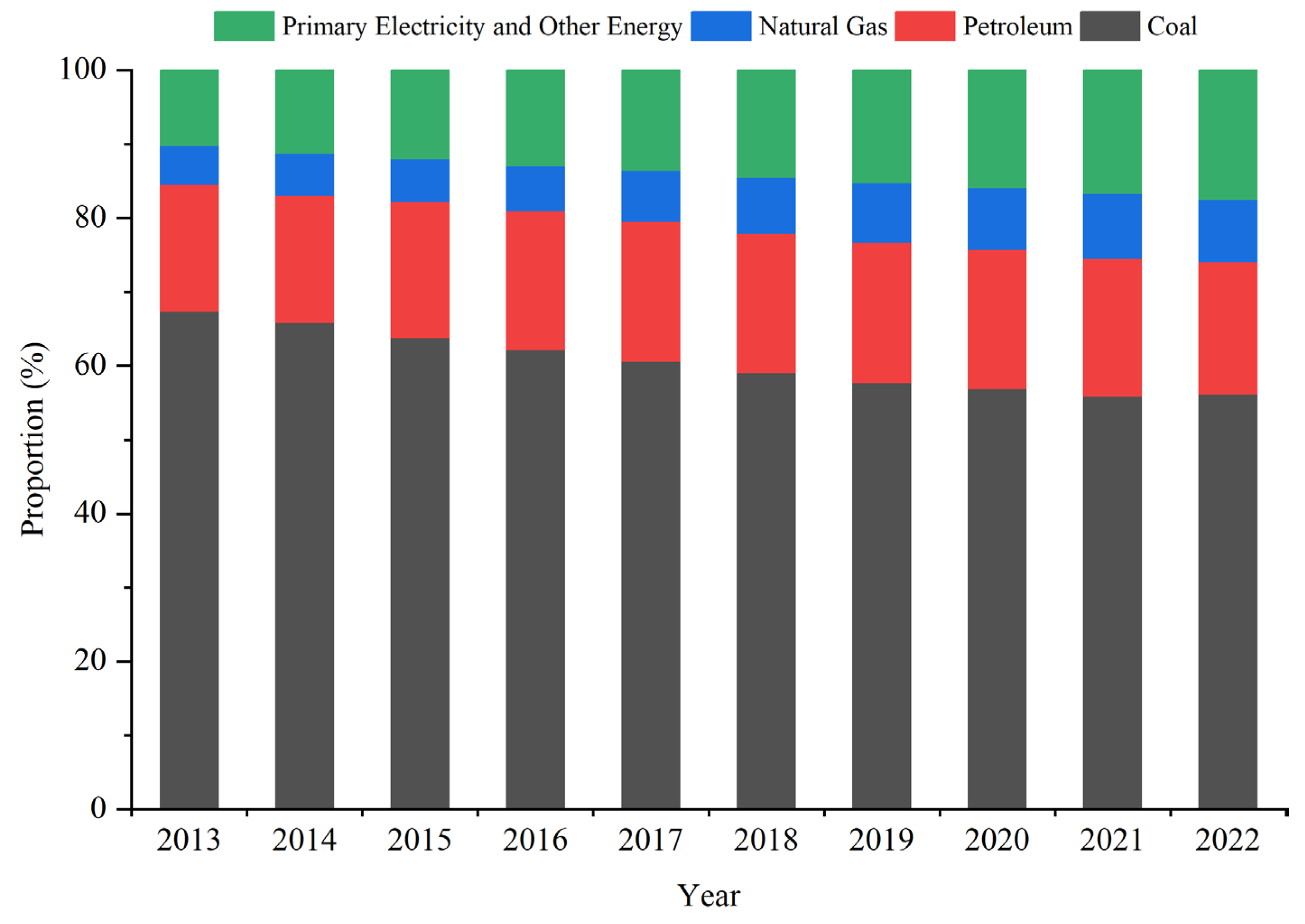

:1. Introduction

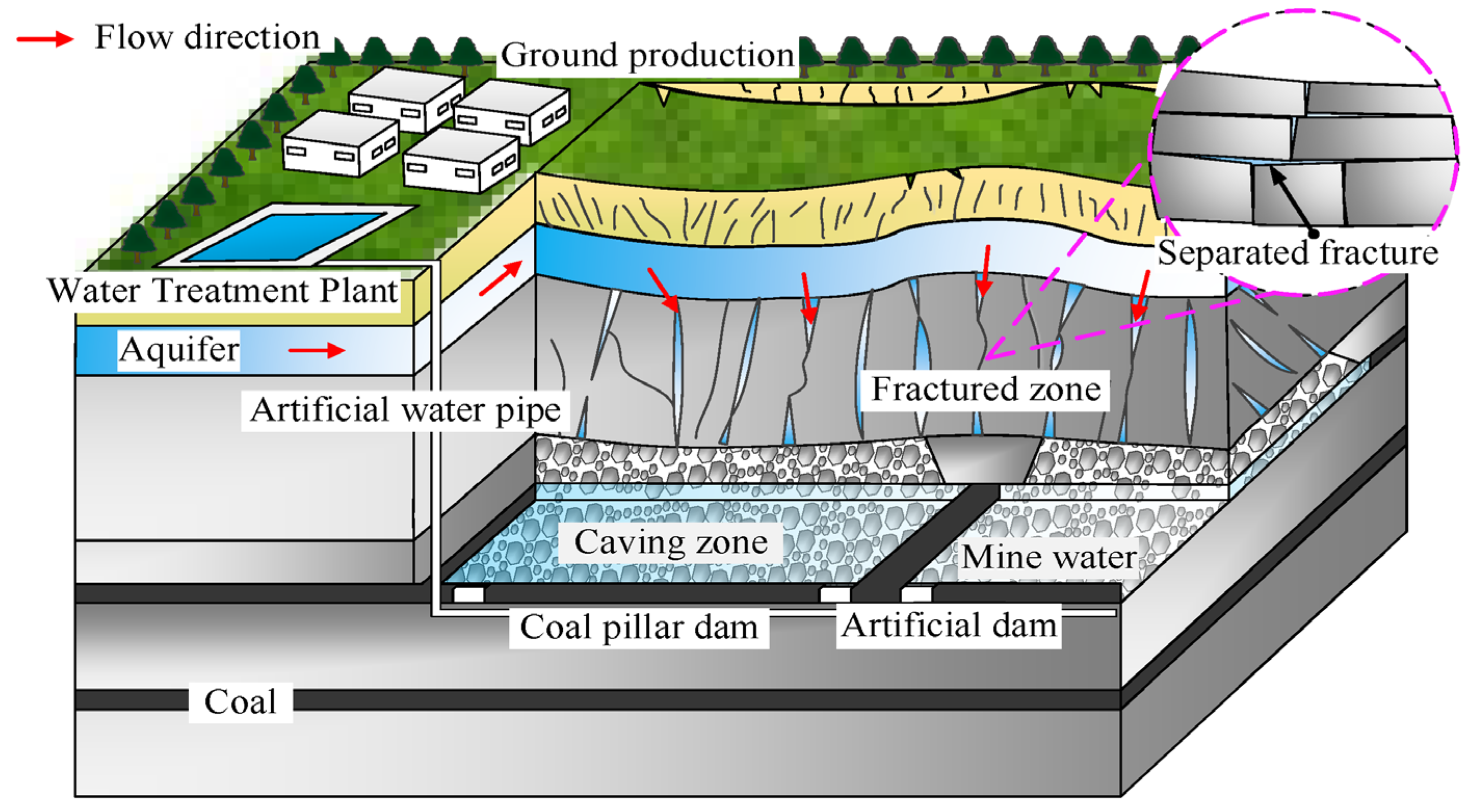

2. Main Technologies and Key Structures of CMURs

2.1. Reservoir Site Selection

2.2. Storage Capacity Calculation

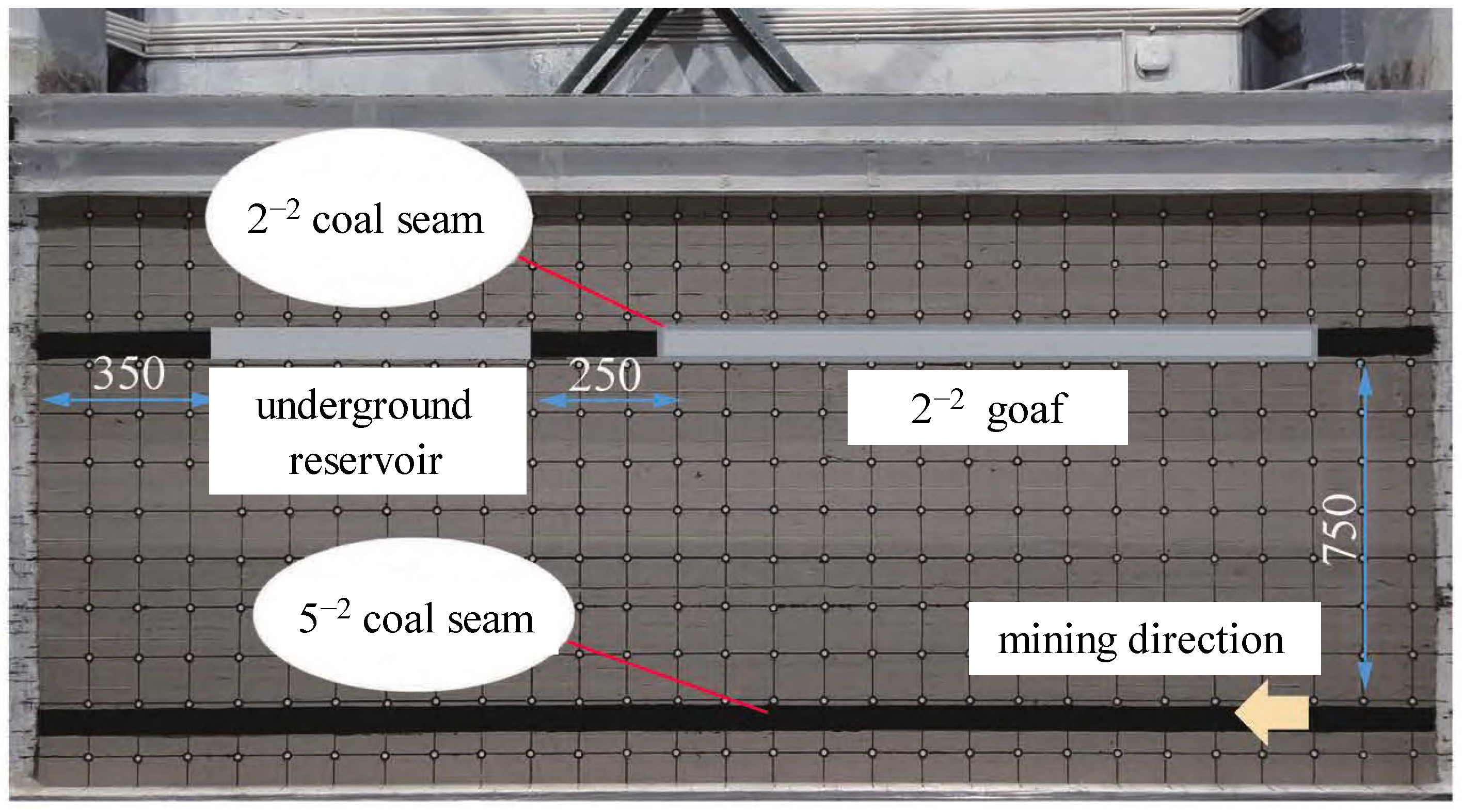

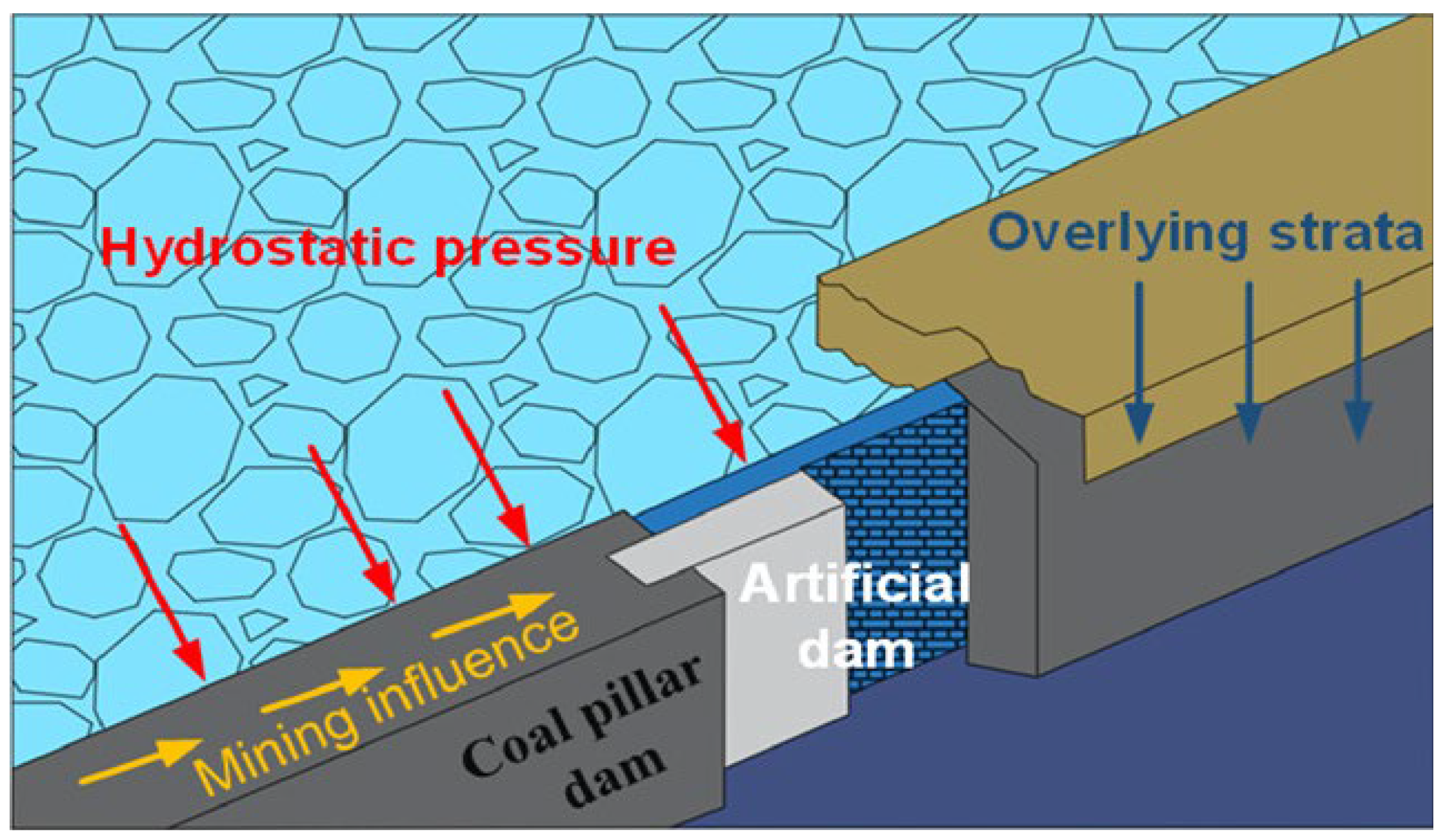

2.3. Coal Pillar Dam

2.4. Artificial Dam

3. Key Theories and Technologies for the Stability of Coal Pillar Dams

3.1. Mechanical Properties of Coal Pillar Dams

- (1)

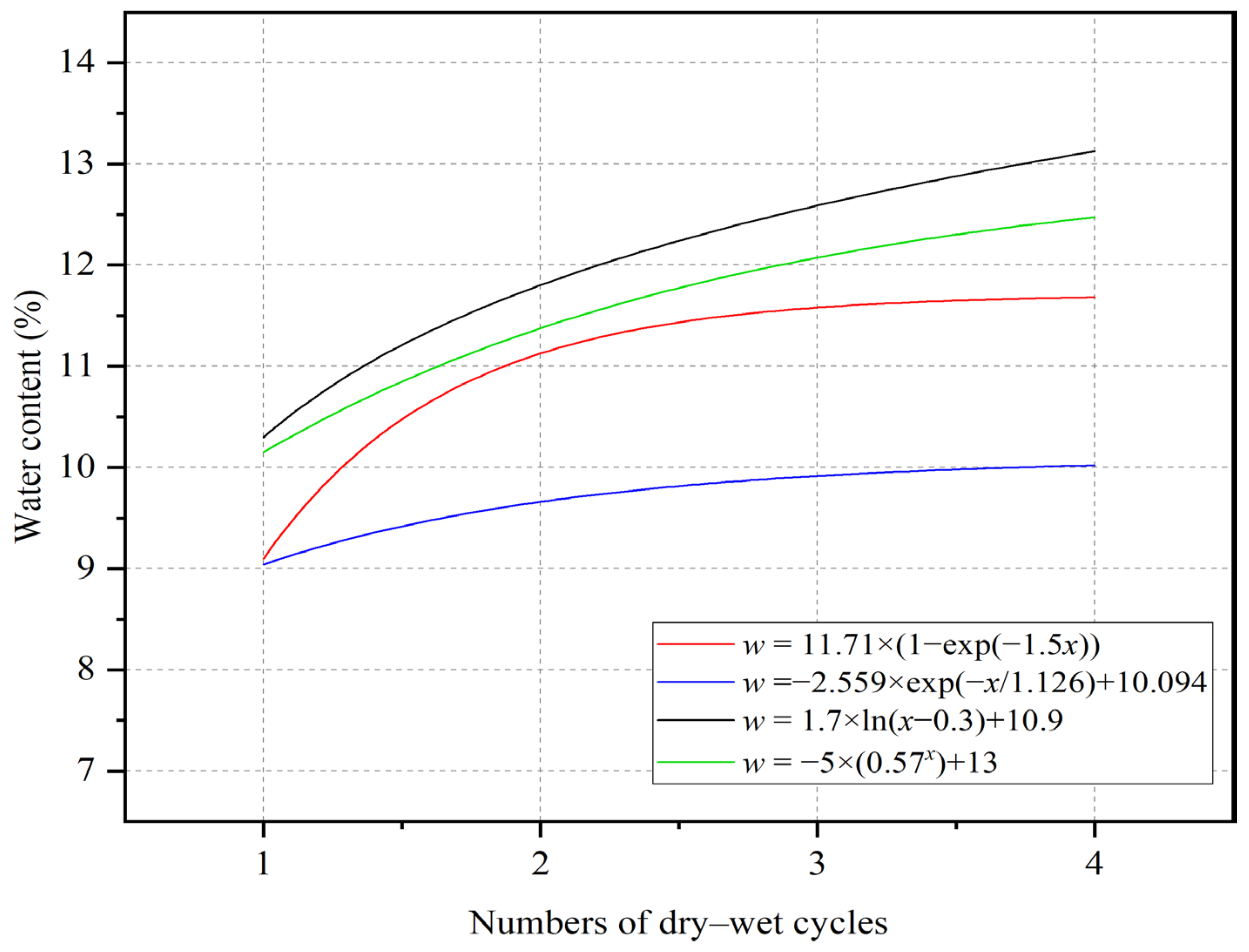

- Mechanical properties of coal pillar dams affected by water immersion

- (2)

- Mechanical properties of coal pillar dams affected by vibrational loads

3.2. Three-Field Patterns of Coal Pillar Dams

3.3. Size Optimization of Coal Pillar Dams

4. Key Theories and Technologies for the Stability of Artificial Dams

4.1. Mechanical Properties of Artificial Dams

- (1)

- Mechanical properties of artificial dams affected by water immersion

- (2)

- Mechanical properties of artificial dams affected by vibrational loads

4.2. Three-Field Patterns of Artificial Dams

4.3. Size Optimization of Artificial Dams

5. Conclusions and Prospects

- (1)

- Reservoir site selection and storage capacity calculation are prerequisites for the construction of CMURs. The water storage space in CMURs consists of the voids in the caved rock masses of the goaf, with the core element being the determination of the water storage coefficient. Further theoretical and predictive research on the development patterns of overburden fracture zones and groundwater migration mechanisms during coal seam mining should be conducted. A systematic understanding of the spatial and temporal evolution patterns of void spaces in caved rock masses within the goaf, as well as the seepage paths and migration patterns of mine water in the goaf and overburden, is necessary.

- (2)

- As core components of the dam structure in CMURs, coal pillar dams and artificial dams should address key issues during the design, construction, and operation stages. These include understanding the mechanical and hydrochemical mechanisms of coal pillar dams and artificial dams under complex hydraulic coupling stress conditions, such as overlying rock load, mining-induced load, and mine water pressure. It is essential to investigate the micro- to macro-scale failure, seepage, and instability mechanisms. Special attention should be given to the creep effects of coal pillar dams and the durability of artificial dams under long-term exposure to corrosive mine water. Additionally, the issue of steel reinforcement corrosion in artificial dams due to the influence of corrosive ions such as chloride and sulfate ions needs to be addressed.

- (3)

- Currently, the constructed CMURs are all near-horizontal reservoirs, with coal seams deposited at near-horizontal angles (0°–8°). There has been limited application and research under gently inclined coal seam conditions (8°–25°), with only the Lingxin Coal Mine having applications in gently inclined coal seams (10°–15°). At present, there are no engineering cases of CMURs constructed under complex steeply inclined coal seam conditions. The applicability and systematic technical standards for steeply inclined coal seams remain to be studied.

- (4)

- In eastern mining areas, due to resource depletion and capacity withdrawal, abandoned mines are increasing year by year. However, the water resources in these abandoned mines have not been effectively utilized. For abandoned mines, the impact of future coal mining on the mine reservoir does not need to be considered. Therefore, it is of great significance to fully utilize the underground space of coal mines for the construction of CMURs. The underground spaces of abandoned mines should be fully utilized to explore the application of CMUR technology, thereby achieving full utilization of mine water resources in abandoned mines.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, C.; Wang, F.; Bai, Q. Underground space utilization of coalmines in China: A review of underground water reservoir construction. Tunn. Undergr. Space Technol. 2021, 107, 103657. [Google Scholar] [CrossRef]

- The State Council Information Office of the People’s Republic of China. Energy in China’s New Era. Available online: https://english.mee.gov.cn/Resources/publications/Whitep/202012/t20201222_814160.shtml (accessed on 3 May 2024).

- National Bureau of Statistics of China. National Data of Total Energy Consumption. Available online: https://data.stats.gov.cn/english/easyquery.htm?cn=C01 (accessed on 3 May 2024).

- National Bureau of Statistics of China. Statistical Communiqué of The People’s Republic of China on the 2023 National Economic and Social Development. Available online: https://www.stats.gov.cn/english/PressRelease/202402/t20240228_1947918.html (accessed on 3 May 2024).

- Yuan, L. Chalenges and countermeasures for high quality development of China’s coal industry. China Coal 2020, 46, 6–12. (In Chinese) [Google Scholar]

- Gu, D.Z.; Cao, Z.G.; Li, J.F.; Wu, B.Y.; Zhang, Y.; Jiang, B.B.; Guo, Q.; Wang, H.P.; Wu, Y.; Shi, X.M.; et al. Original Experimental Platform System and Application of Underground Coal Mine Reservoirs. J. China Coal Soc. 2024, 49, 100–113. (In Chinese) [Google Scholar]

- Gu, D.Z.; Li, J.F.; Cao, Z.G.; Wu, B.Y.; Jiang, B.B.; Yang, Y.; Yang, J.; Chen, Y.P. Technology and engineering development strategy of water protection and utilization of coal mine in China. J. China Coal Soc. 2021, 46, 3079–3089. (In Chinese) [Google Scholar]

- Gu, D.Z.; Li, T.; Li, J.F.; Guo, Q.; Jiang, B.B.; Bian, W.; Bao, Y.X. Current status and prospects of coal mine water treatment technology in China. Coal Sci. Technol. 2021, 49, 11–18. (In Chinese) [Google Scholar]

- Gu, D.Z. Water resource and surface ecology protection technology of modern coal mining in China’s energy “Golden Triangle”. Strateg. Study CAE 2013, 15, 102–107. (In Chinese) [Google Scholar]

- Peng, S.P.; Bi, Y.L. Strategic consideration and core technology about environmental ecological restoration in coal mine areas in the Yellow River basin of China. J. China Coal Soc. 2020, 45, 1211–1221. (In Chinese) [Google Scholar]

- Shi, X.C. Research progress and prospect of underground mines in coal mines. Coal Sci. Technol. 2022, 50, 216–225. (In Chinese) [Google Scholar]

- Meng, Z.P.; Shi, X.C.; Li, G.Q. Deformation, failure and permeability of coal-bearing strata during longwall mining. Eng. Geol. 2016, 208, 69–80. [Google Scholar] [CrossRef]

- Qian, M.G.; Miu, X.X.; Xu, J.L. Green mining of coal resources harmonizing with environment. J. China Coal Soc. 2007, 32, 1–7. (In Chinese) [Google Scholar]

- Qian, M.G.; Miu, X.X.; Xu, J.L. Resources and Environment Harmonics (Green) Mining and Its Technological System. J. Min. Saf. Eng. 2006, 23, 1–5. (In Chinese) [Google Scholar]

- Miu, X.X.; Wang, A.; Sun, Y.J.; Wang, L.G.; Pu, H. Research on Basic Theory of Mining with Water Resources Protection and Its Application to Arid and Semi-Arid Mining Areas. Chin. J. Rock. Mech. Eng. 2009, 28, 217–227. (In Chinese) [Google Scholar]

- Chen, S.S.; Huang, Q.X.; Xue, G.; Li, R.Q. Technology of underground reservoir construction and water resource utilization in Daliuta Coal Mine. Coal Sci. Technol. 2016, 44, 21–28. (In Chinese) [Google Scholar]

- Cairney, T. Utilisation of disused coal mines as water storage reservoirs. J. Hydrol. 1973, 19, 251–258. [Google Scholar] [CrossRef]

- Gu, D.Z.; Zhang, Y.; Cao, Z.G. Technical progress of water resource protection and utilization by coal mining in China. Coal Sci. Technol. 2016, 44, 1–7. (In Chinese) [Google Scholar]

- Gu, D.Z. Theory framework and technological system of coal mine underground reservoir. J. China Coal Soc. 2015, 40, 239–246. (In Chinese) [Google Scholar]

- Gu, D.Z.; Yan, Y.G.; Zhang, Y.; Wang, E.Z.; Cao, Z.G. Experimental study and numerical simulation for dynamic response of coal pillars in coal mine underground reservoir. J. China Coal Soc. 2016, 41, 1589–1597. (In Chinese) [Google Scholar]

- Kitsikoudis, V.; Archambeau, P.; Dewals, B.; Pujades, E.; Orban, P.; Dassargues, A.; Pirotton, M.; Erpicum, S. Underground Pumped-Storage Hydropower (UPSH) at the Martelange Mine (Belgium): Underground Reservoir Hydraulics. Energies 2020, 13, 16. [Google Scholar] [CrossRef]

- Kranz, K.; Dillenardt, J. Mine Water Utilization for Geothermal Purposes in Freiberg, Germany: Determination of Hydrogeological and Thermophysical Rock Parameters. Mine Water Environ. 2010, 29, 68–76. [Google Scholar] [CrossRef]

- Renz, A.; Rühaak, W.; Schätzl, P.; Diersch, H.J.G. Numerical Modeling of Geothermal Use of Mine Water: Challenges and Examples. Mine Water Environ. 2009, 28, 2–14. [Google Scholar] [CrossRef]

- Raymond, J.; Therrien, R. Low-temperature geothermal potential of the flooded Gaspe Mines, Quebec, Canada. Geothermics 2008, 37, 189–210. [Google Scholar] [CrossRef]

- Ordóñez, A.; Jardón, S.; Alvarez, R.; Andrés, C.; Pendás, F. Hydrogeological definition and applicability of abandoned coal mines as water reservoirs. J. Environ. Monit. 2012, 14, 2127–2136. [Google Scholar] [CrossRef] [PubMed]

- Watzlaf, G.R.; Ackman, T.E. Underground Mine Water for Heating and Cooling using Geothermal Heat Pump Systems. Mine Water Environ. 2006, 25, 1–14. [Google Scholar] [CrossRef]

- Wang, W.A.; Yao, Q.L.; Xu, Q.; Chen, X.Y.; Liu, H.Y.; Li, X.H. Experimental Study on the Evolution Law of Coal Mine Underground Reservoir Water Storage Space under the Disturbance and Water-Rock Interaction Effect. Minerals 2022, 12, 21. [Google Scholar] [CrossRef]

- Menéndez, J.; Loredo, J.; Galdo, M.; Fernández-Oro, J.M. Energy storage in underground coal mines in NW Spain: Assessment of an underground lower water reservoir and preliminary energy balance. Renew. Energy 2019, 134, 1381–1391. [Google Scholar] [CrossRef]

- Xie, H.; Zhao, J.W.; Zhou, H.W.; Ren, S.H.; Zhang, R.X. Secondary utilizations and perspectives of mined underground space. Tunn. Undergr. Space Technol. 2020, 96, 14. [Google Scholar] [CrossRef]

- Pujades, E.; Orban, P.; Bodeux, S.; Archambeau, P.; Erpicum, S.; Dassargues, A. Underground pumped storage hydropower plants using open pit mines: How do groundwater exchanges influence the efficiency? Appl. Energy 2017, 190, 135–146. [Google Scholar] [CrossRef]

- Winde, F.; Kaiser, F.; Erasmus, E. Exploring the use of deep level gold mines in South Africa for underground pumped hydroelectric energy storage schemes. Renew. Sust. Energ. Rev. 2017, 78, 668–682. [Google Scholar] [CrossRef]

- Jiang, D.Y.; Chen, S.; Liu, W.H.; Ren, Y.W.; Guo, P.Y.; Li, Z.Z. Underground Hydro-Pumped Energy Storage Using Coal Mine Goafs: System Performance Analysis and a Case Study for China. Front. Earth Sci. 2021, 9, 15. [Google Scholar] [CrossRef]

- Chen, Y.M.; Zhang, Y.; Xia, F.; Xing, Z.; Wang, L.C. Impacts of Underground Reservoir Site Selection and Water Storage on the Groundwater Flow System in a Mining Area-A Case Study of Daliuta Mine. Water 2022, 14, 19. [Google Scholar] [CrossRef]

- Zhang, H.; Li, G.Q.; Xing, Z.G.; Wang, L.; Zou, W.K. A Geological Site Selection Method of a Coal Mine Underground Reservoir and Its Application. Water 2023, 15, 21. [Google Scholar] [CrossRef]

- Guo, Y.N.; Li, G.Q.; Wang, L.; Zhang, Z. Hydrochemical Characteristics of Mine Water and Their Significance for the Site Selection of an Underground Reservoir in the Shendong Coal Mining Area. Water 2023, 15, 20. [Google Scholar] [CrossRef]

- Ju, J.F.; Xu, J.L.; Zhu, W.B. Storage capacity of underground reservoir in the Chinese western water-short coalfield. J. China Coal Soc. 2017, 42, 381–387. (In Chinese) [Google Scholar]

- Fan, K.F.; Xie, P.; Liu, Z.C. Analytical method of reservoir capacity of underground reservoir in coal mine: A case study. Water Supply 2023, 23, 581–598. [Google Scholar] [CrossRef]

- Song, H.Q.; Xu, J.J.; Fang, J.; Cao, Z.G.; Yang, L.Z.; Li, T.X. Potential for mine water disposal in coal seam goaf: Investigation of storage coefficients in the Shendong mining area. J. Clean. Prod. 2020, 244, 15. [Google Scholar] [CrossRef]

- Fang, J.; Song, H.Q.; Xu, J.J.; Yang, L.Z.; Li, Z.Y. Storage coefficient calculation model of coal mine underground reservoir considering effect of effective stress. J. China Coal Soc. 2019, 44, 3750–3759. (In Chinese) [Google Scholar]

- Pang, Y.H.; Li, Q.S.; Cao, G.M.; Zhou, B.J. Analysis and calculation method of underground reservoir water storage space composition. J. China Coal Soc. 2019, 44, 557–566. (In Chinese) [Google Scholar]

- Wen, Z.J.; Jiang, P.F.; Song, Z.Q.; Jiang, Y.J.; Wen, J.H.; Jing, S.L. Structural model and capacity determination of underground reservoir in goaf: A case study of Shendong mining area in China. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 18. [Google Scholar] [CrossRef]

- Zhang, C.H.; Luo, B.; Xu, Z.M.; Sun, Y.J.; Feng, L. Research on the Capacity of Underground Reservoirs in Coal Mines to Protect the Groundwater Resources: A Case of Zhangshuanglou Coal Mine in Xuzhou, China. Water 2023, 15, 14. [Google Scholar] [CrossRef]

- Wang, B.F.; Zhou, D.; Jiang, J.Q.; Liang, B. Storage coefficient calculation model of coal mine underground reservoir considering the effects of coal mine water velocity and time. J. Min. Saf. Eng. 2019, 1–12. (In Chinese) [Google Scholar]

- Qin, X.; Cao, Z.G.; Wei, L.C.; Li, P.; Sun, H. Spatial Structure Characteristics of Underground Reservoir Water Storage Space in Coal Mines Considering Shape Characteristics of Crushed Rock. Processes 2023, 11, 17. [Google Scholar] [CrossRef]

- Li, Y.M. Research on Reservoir Dam Structure Stability and Anti-seepage Technology in Mined-out Area. Master’s Thesis, Inner Mongolia University of Science & Technology, Baotou, China, 2020. (In Chinese). [Google Scholar]

- Wu, B.Y. Reasonable Arrangement Mode About Coal Pillar Dam of Distributed Groundwater Reservoir in Coal Mine. Saf. Coal Mines 2018, 49, 68–72+78. (In Chinese) [Google Scholar]

- Wang, M. Study on Damage Mechanism and Time-Dependent Stability of Coal Pillar in Coal Mine Underground Reservoir. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2022. (In Chinese). [Google Scholar]

- Xie, H.X.; Yao, Q.L.; Yu, L.Q.; Shan, C.H. Study on Damage Characteristics of Water-Bearing Coal Samples under Cyclic Loading-Unloading. Sustainability 2022, 14, 16. [Google Scholar] [CrossRef]

- Liu, X.S.; Song, S.L.; Wu, B.Y.; Li, X.B.; Yang, K. Study on Deformation and Fracture Evolution of Underground Reservoir Coal Pillar Dam under Different Mining Conditions. Geofluids 2022, 2022, 11. [Google Scholar]

- He, Q.Y.; Li, Y.C.; Li, D.Q.; Zhang, C.G. Microcrack fracturing of coal specimens under quasi-static combined compression-shear loading. J. Rock. Mech. Geotech. Eng. 2020, 12, 1014–1026. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, X.J.; Han, P.H.; Bai, Q.S.; Chen, J.H. Failure analysis of residual coal pillar under the coupling of mining stress and water immersion in the goaf underground water reservoir. Environ. Earth Sci. 2023, 82, 19. [Google Scholar] [CrossRef]

- Zhi, G.J.; Liu, R.; Yang, R.G.; Cao, Z.G.; Ning, S.; Zhang, C.P.; Ju, J.F. Research on Optimization of Cutting Parameters for Structuring Artificial Dam around Underground Reservoir in Coal Mine. Coal Technol. 2022, 41, 18–22. (In Chinese) [Google Scholar]

- Chi, M.B.; Li, P.; Cao, Z.G.; Wu, Y.; Zhang, Y.; Li, H.X.; Wu, B.Y. Seismic performance analysis of flat artificial dam of underground reservoir in coal mine. J. China Coal Soc. 2023, 48, 1179–1191. (In Chinese) [Google Scholar]

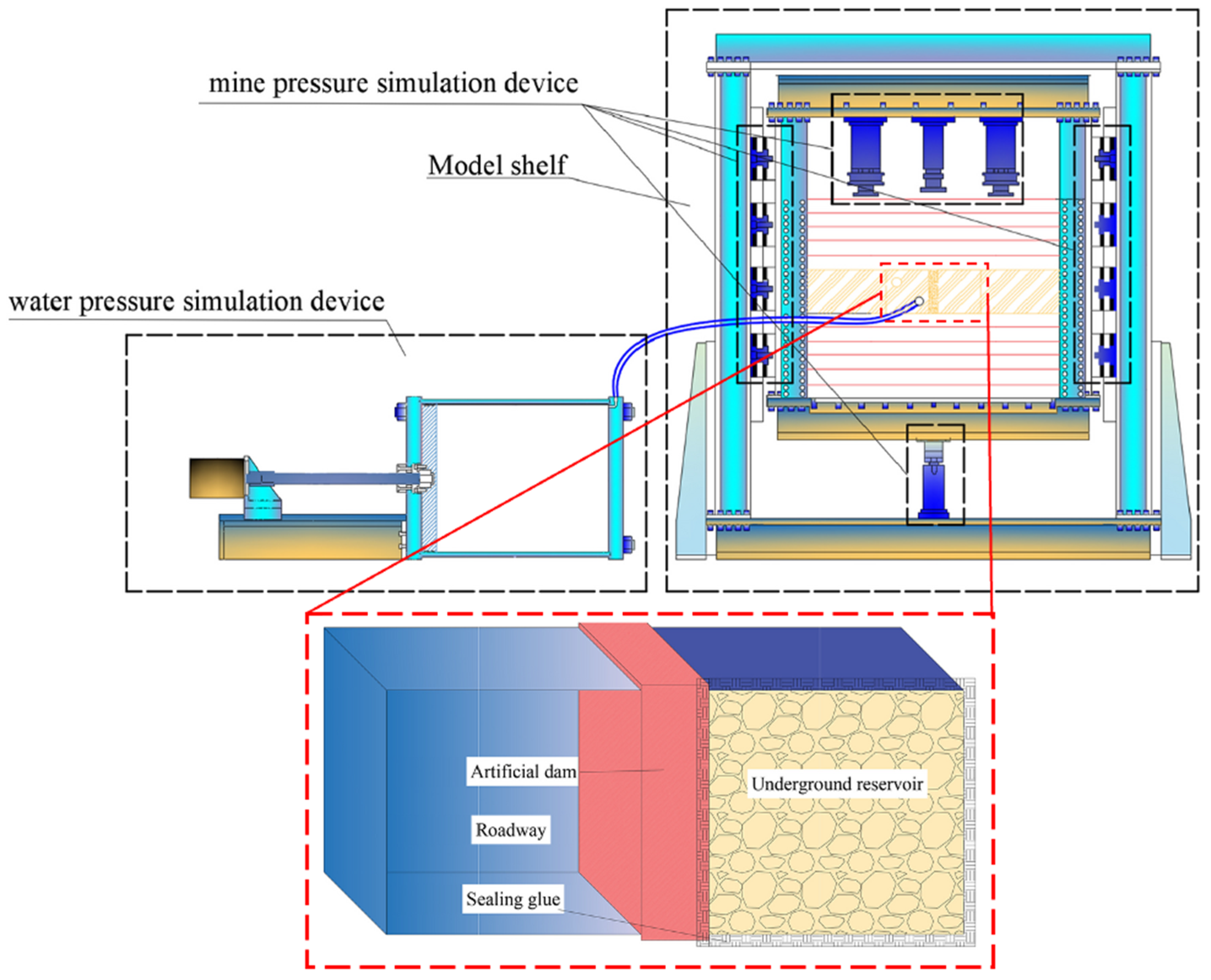

- Kong, X.S.; Huang, J.W.; Shan, R.L.; Yang, W.; Fang, J. Elaboration and application of the nested multi-coupling model test system for an artificial dam seepage simulation under combined action of dynamic and static loads. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 16. [Google Scholar] [CrossRef]

- Fang, J. Study on Deformation Failure Mechanism and Stability Evaluation of Artificial Dam of Underground Reservoir in Coal Mine. Ph.D. Thesis, China University of Mining & Technology-Beijing, Beijing, China, 2020. (In Chinese). [Google Scholar]

- Wang, Z.B.; Sun, P.; Zuo, J.P.; Liu, C.; Han, Y.D.; Zhang, Z.S. Long-term properties and microstructure change of engineered cementitious composites subjected to high sulfate coal mine water in drying-wetting cycles. Mater. Des. 2021, 203, 13. [Google Scholar] [CrossRef]

- Fang, Z.Y.; Ju, J.F.; Cao, Z.G.; Wang, X.Z.; Xu, J.L. Structural optimization of artificial dam body in coal mine underground reservoir based on orthotropic plate model. J. China Coal Soc. 2020, 45, 1375–1384. (In Chinese) [Google Scholar]

- Xu, Q.; Yao, Q.L.; Yu, L.Q.; Zhu, L.; Chong, Z.H.; Li, Y.H.; Li, X.H. Mechanical properties and damage constitutive model of coal specimen with different moisture under uniaxial loading. Int. J. Damage Mech. 2023, 32, 462–481. [Google Scholar] [CrossRef]

- Yu, L.Q.; Yao, Q.L.; Chong, Z.H.; Li, Y.H.; Xu, Q.; Xie, H.X.; Ye, P.Y. Mechanical and micro-structural damage mechanisms of coal samples treated with dry-wet cycles. Eng. Geol. 2022, 304, 14. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, D.S.; Yao, N.; Wang, L.; Fan, G.W.; Wang, X.F.; Zhang, W. Coupling Influence of Inclination Angle and Moisture Content on Mechanical Properties and Microcrack Fracture of Coal Specimens. Lithosphere 2021, 2021, 23. [Google Scholar] [CrossRef]

- Wang, F.T.; Liang, N.N.; Li, G. Damage and Failure Evolution Mechanism for Coal Pillar Dams Affected by Water Immersion in Underground Reservoirs. Geofluids 2019, 2019, 2985691. [Google Scholar] [CrossRef]

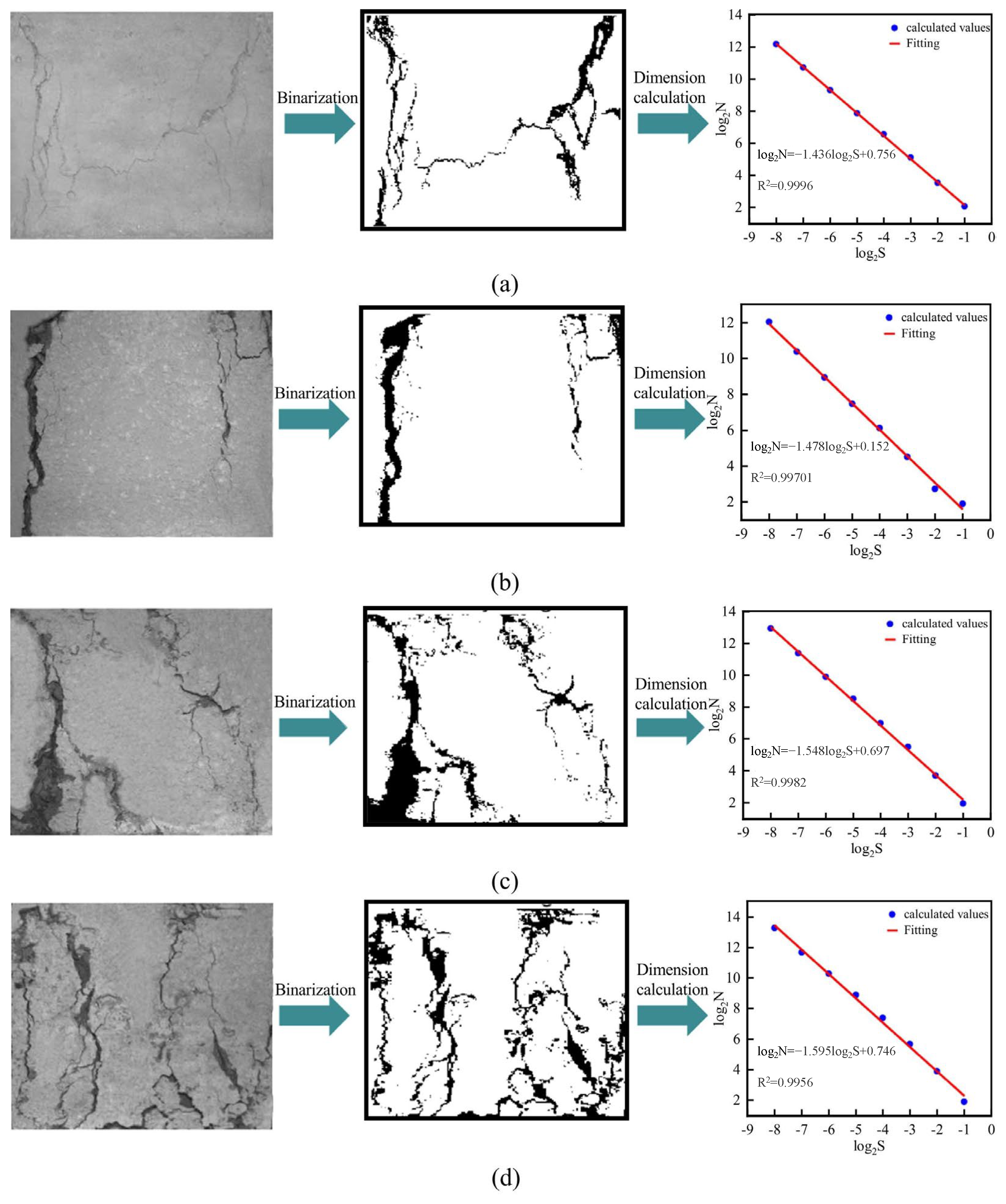

- Tang, C.J.; Yao, Q.L.; Xu, Q.; Shan, C.H.; Xu, J.M.; Han, H.; Guo, H.T. Mechanical Failure Modes and Fractal Characteristics of Coal Samples under Repeated Drying-Saturation Conditions. Nat. Resour. Res. 2021, 30, 4439–4456. [Google Scholar] [CrossRef]

- Yang, P. Study on Strength Damage Mechanism of Coal Pillar Dam in Coal Mine Groundwater Reservoir. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2019. (In Chinese). [Google Scholar]

- Wang, B.F.; Zhou, D.; Zhang, J.; Liang, B. Study on the strength deterioration characteristic and damage model of coal pillar dams with repeated water immersion in underground reservoirs. Sci. Rep. 2024, 14, 19. [Google Scholar] [CrossRef] [PubMed]

- Yao, Q.L.; Hao, Q.; Chen, X.Y.; Zhou, B.J.; Fang, J. Design on the width of coal pillar dam in coal mine groundwater reservoir. J. China Coal Soc. 2019, 44, 891–899. (In Chinese) [Google Scholar]

- Wu, Y.; Yao, Q.L.; Wu, B.Y.; Xie, H.X.; Yu, L.Q.; Li, Y.H.; Wang, L.J. Strength Damage and Acoustic Emission Characteristics of Water-Bearing Coal Pillar Dam Samples from Shangwan Mine, China. Energies 2023, 16, 20. [Google Scholar] [CrossRef]

- Tang, C.J.; Yao, Q.L.; Chen, T.; Shan, C.H.; Li, J. Effects of water content on mechanical failure behaviors of coal samples. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 17. [Google Scholar] [CrossRef]

- Chen, N. Study on Damage Characteristics of Coal Pillar Dam Body of Groundwater Reservoir under Dynamic and Static Load. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2020. (In Chinese). [Google Scholar]

- Li, J.H. Experimental Study of Water Storage Soaking of Coal Mine Underground Reservoir to Coal Pillar Dam Body Strength. Coal Min. Technol. 2018, 23, 15–17+19. (In Chinese) [Google Scholar]

- Yao, Q.L.; Chen, T.; Tang, C.J.; Sedighi, M.; Wang, S.W.; Huang, Q.X. Influence of moisture on crack propagation in coal and its failure modes. Eng. Geol. 2019, 258, 12. [Google Scholar] [CrossRef]

- Yao, Q.L.; Zheng, C.K.; Tang, C.J.; Xu, Q.; Chong, Z.H.; Li, X.H. Experimental Investigation of the Mechanical Failure Behavior of Coal Specimens with Water Intrusion. Front. Earth Sci. 2020, 7, 13. [Google Scholar] [CrossRef]

- Yao, Q.L.; Zheng, C.K.; Shang, X.B.; Yan, L.; Shan, C.H.; Wang, W. Evolution of Mechanical and Acoustic Emission Characteristics of Coal Samples under Different Immersion Heights. Nat. Resour. Res. 2023, 32, 2273–2288. [Google Scholar] [CrossRef]

- Wang, L.; Wu, P.; Li, M.; Mao, X.B.; Chen, L. Mechanical Properties and Acoustic Emission Characteristics of Water-Bearing Coal Specimens under a Coupled Compression-Shear Load. Minerals 2022, 12, 22. [Google Scholar] [CrossRef]

- Yao, Q.L.; Tang, C.J.; Xia, Z.; Liu, X.L.; Zhu, L.; Chong, Z.H.; Hui, X.D. Mechanisms of failure in coal samples from underground water reservoir. Eng. Geol. 2020, 267, 10. [Google Scholar] [CrossRef]

- Wang, F.T.; Wei, X.Q.; Shao, D.L.; Zhang, C. The progressive failure mechanism for coal pillars under the coupling of mining stress and water immersion in underground reservoirs. Bull. Eng. Geol. Environ. 2023, 82, 13. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, T.; Pan, H.; Wu, J. Experimental investigation of the creep damage evolution of coal rock around gas extraction boreholes at different water contents. PLoS ONE 2023, 18, 18. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.Q.; Yao, Q.L.; Chong, Z.H.; Li, Y.H.; Xu, Q.; Liu, Z.C. Experimental study on the moisture migration and triaxial mechanical damage mechanisms of water-bearing coal samples. Int. J. Rock Mech. Min. Sci. 2022, 160, 13. [Google Scholar] [CrossRef]

- Li, G.; Wanyan, Q.; Li, Z.S.; Yi, H.Y.; Ren, F.F.; Chen, Z.; Liu, Y. A Fractional-Order Creep Model of Water-Immersed Coal. Appl. Sci. 2023, 13, 16. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, P.; Wang, L.; Li, M.; Mao, X.B.; Chen, L. Influence of Moisture Content on Creep Mechanical Characteristic and Mic-Fracture Behavior of Water-Bearing Coal Specimen. Geofluids 2022, 2022, 17. [Google Scholar] [CrossRef]

- Wang, M.; Guo, Q.F.; Tian, Y.K.; Dai, B. Physical and Mechanical Properties Evolution of Coal Subjected to Salty Solution and a Damage Constitutive Model under Uniaxial Compression. Mathematics 2021, 9, 19. [Google Scholar] [CrossRef]

- Wang, M.; Xi, X.; Guo, Q.F. Deterioration Mechanism and Constitutive Model of Coal Subjected to Drying-Wetting Cycles of Salty Mine Water. Lithosphere 2022, 2022, 12. [Google Scholar] [CrossRef]

- Shan, C.H.; Yao, Q.L.; Cao, S.G.; Xie, H.X.; Xu, Q.; Zheng, C.K.; Chen, X.Y. Measurement of fracture development evolution of coal samples under acid-alkaline by three-dimensional reconstruction and AE time-frequency characteristic analysis. Measurement 2023, 217, 23. [Google Scholar] [CrossRef]

- Yao, Q.L.; Yu, L.Q.; Chen, N.; Wang, W.N.; Xu, Q. Experimental Study on Damage and Failure of Coal-Pillar Dams in Coal Mine Underground Reservoir under Dynamic Load. Geofluids 2021, 2021, 18. [Google Scholar] [CrossRef]

- Wang, K.; Feng, G.R.; Bai, J.W.; Guo, J.; Shi, X.D.; Cui, B.Q.; Song, C. Dynamic behaviour and failure mechanism of coal subjected to coupled water-static-dynamic loads. Soil Dyn. Earthq. Eng. 2022, 153, 13. [Google Scholar] [CrossRef]

- Bai, L.W.; Wu, D.; Tang, Z.X.; Wang, Y.; ZHao, R.K. Study on the Stability of Coal Mine Underground Reservoir Dam under the Coupling Action of Stress and Seepage. China Mine Eng. 2021, 50, 1–6. (In Chinese) [Google Scholar]

- Wang, L.J.; Cao, Z.G.; Cheng, J.C.; Liu, S.G.; Zhou, H.W.; Wu, Y.; Wang, J.G.; Ouyang, D.; Xue, D.J. Failure analysis of rock strata between upper and lower coals under underground reservoir in coal mine and its critical percolation model of jumping permeability. J. China Coal Soc. 2023, 48, 1192–1208. (In Chinese) [Google Scholar]

- Wen, Z.J.; Jiang, P.F.; Jing, S.L.; Cao, Z.G.; Guan, Y.T. Development and verification of simulation testing system for floor seepage in coal mine underground reservoir. J. China Coal Soc. 2021, 46, 1487–1497. (In Chinese) [Google Scholar]

- Chi, M.B.; Wu, B.Y.; Cao, Z.G.; Li, P.; Liu, X.Q.; Li, H.X.; Zhang, Y.; Yang, Y. Research on Instability Mechanism and Precursory Information of Coal Pillar Dam of Underground Reservoir in Coal Mine. Coal Sci. Technol. 2023, 51, 36–49. (In Chinese) [Google Scholar]

- Zhang, C.; Bai, Q.S.; Han, P.H.; Wang, L.; Wang, X.J.; Wang, F.T. Strength weakening and its micromechanism in water-rock interaction, a short review in laboratory tests. Int. J. Coal Sci. Technol. 2023, 10, 15. [Google Scholar] [CrossRef]

- Han, P.H.; Zhang, C.; Wang, W. Failure analysis of coal pillars and gateroads in longwall faces under the mining-water invasion coupling effect. Eng. Fail. Anal. 2022, 131, 23. [Google Scholar] [CrossRef]

- Fan, J.Y.; Li, Z.; Feng, G.R.; Zhang, H.D.; Qi, C.E.; Zhang, J.Y. Failure analysis of coal pillars and overburden from underground water reservoir under the mining-water invasion coupling effect. Eng. Fail. Anal. 2023, 151, 19. [Google Scholar] [CrossRef]

- Wang, P.T.; Qi, Z.W.; Ma, C.; Cai, M.F. Anisotropic behavior of the seepage-stress coupling mechanical model of coal pillars of underground reservoirs. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 20. [Google Scholar] [CrossRef]

- Chen, Z.H.; Zhao, X.D.; Han, Z.; Ji, Y.; Qiao, Z.J. Reasonable Size Design and Influencing Factors Analysis of the Coal Pillar Dam of an Underground Reservoir in Daliuta Mine. Processes 2023, 11, 13. [Google Scholar] [CrossRef]

- Zhang, B.; Ni, W.; Hao, X.Q.; Li, H.Q.; Shen, Y.P. A Study on the Development and Evolution of Fractures in the Coal Pillar Dams of Underground Reservoirs in Coal Mines and Their Optimum Size. Processes 2023, 11, 21. [Google Scholar] [CrossRef]

- Zhi, G.J.; Liu, R.; Yang, R.G.; Qin, W.; Ju, J.F. Study on hydraulic connection and seepage law of adjacent goaf of underground reservoir in coal mine. Min. Saf. Environ. Prot. 2022, 49, 9–15. (In Chinese) [Google Scholar]

- Bai, D.Y. Stability Analysis of Underground Reservoir Dam in Li Jiahao Mine. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2018. (In Chinese). [Google Scholar]

- Bai, D.Y.; Ju, J.F.; Xu, J.L.; Li, J.H. Stability analysis of mine underground reservoir artificial dam in Lijiahao Mine. J. China Coal Soc. 2017, 42, 1839–1845. (In Chinese) [Google Scholar]

- Shan, C.H.; Yao, Q.L.; Zheng, C.K.; Xie, H.X.; Xu, Q.; Xia, Z.; Zou, S. Strength Degradation and Fracture Propagation of Repeatedly Immersed Artificial Dam Samples under Uniaxial Cyclic Loading-Unloading. ACS Omega 2023, 8, 2538–2555. [Google Scholar] [CrossRef]

- Yang, H.Z.; Wang, X.R.; Wang, E.Y.; Song, Y.; Chen, D.; Zhang, Y.D.; Liu, W.Z. Macro-micro crack and damage evolution characteristics of concrete: After the action of acidic drying-saturation cycle. Constr. Build. Mater. 2024, 411, 15. [Google Scholar] [CrossRef]

- Yang, H.Z.; Wang, E.Y.; Cheng, D.Q.; Wang, X.R.; Li, B.L.; Song, Y.; Wang, D.M.; Liu, W.Z. Characteristics of energy evolution and acoustic emission response of concrete under the action of acidic drying-saturation processes cycle. J. Build. Eng. 2023, 74, 21. [Google Scholar] [CrossRef]

- Hao, X.J.; Wei, Y.N.; Zhang, T.; Chen, Z.Y.; Zhang, C.; Teng, T. Comparative study of the effects of different nanomaterials on the failure process of saturated concrete in an underground reservoir of a coal mine. Energy Explor. Exploit. 2022, 40, 1788–1805. [Google Scholar] [CrossRef]

- Yan, Y.G. Experimental Study on Seismic Resistance of Underground Reservoir in Level Coal Seam. Master’s Thesis, Tsinghua University, Beijing, China, 2016. (In Chinese). [Google Scholar]

- Zhang, Y.; Cao, Z.G.; Wang, L.J.; Zha, E.R.; Li, S.B.; Chu, Z.F. Seismic Safety Analysis of Interlaminar Rock Mass in the Distributed Underground Reservoir of a Coal Mine. Water 2024, 16, 19. [Google Scholar] [CrossRef]

- Cao, Z.G. Study on aseismic performance of different artificial dam structures of coal mine underground reservoir. Coal Sci. Technol. 2020, 48, 237–243. (In Chinese) [Google Scholar]

- Fan, F.; Liu, C.Y.; Xu, J.S. Stability analysis of artificial dam body in coal mine groundwater reservoir. Coal Eng. 2020, 52, 120–125. (In Chinese) [Google Scholar]

- Ma, J.P.; Zhang, G.C.; Zhou, G.L.; Zhang, Y.; Meng, X.J.; Zhao, Y.Q.; Chen, M. Stability analysis of artificial dam in coal mine underground water reservoir based on the hydro-mechanical damage model. Geomat. Nat. Hazards Risk 2023, 14, 16. [Google Scholar] [CrossRef]

- Kong, X.S.; Xu, Z.Z.; Shan, R.L.; Liu, S.; Xiao, S.C. Investigation on groove depth of artificial dam of underground reservoir in coal mines. Environ. Earth Sci. 2021, 80, 17. [Google Scholar] [CrossRef]

- Kong, X.S.; Fang, J.; Xu, Z.Z.; Wang, S.; Liu, S. Design of Cutting Depth of Artificial Dam of Underground Reservoir in Wulanmulun Mine. In Proceedings of the International Conference on Advances in Civil Engineering, Energy Resources and Environment Engineering (ACCESE), Jilin Jianzhu Univiversity, Coll Civil Engineering, Changchun, China, 28–30 June 2019. [Google Scholar]

- Zhao, R.J. Research on Seepage Flow and Design of Artificial Dam in Lingxin Coal Mine. Master’s Thesis, North China University of Technology, Beijing, China, 2020. (In Chinese). [Google Scholar]

| Yao [65] | Chen [93] | |

|---|---|---|

| LCp | ||

| LHp | ||

| LCe | ||

| L | L = LCp + LHp + LCe | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Liu, F.; Kou, M.; Li, M. A Review of Stability of Dam Structures in Coal Mine Underground Reservoirs. Water 2024, 16, 1856. https://doi.org/10.3390/w16131856

Wang Y, Liu F, Kou M, Li M. A Review of Stability of Dam Structures in Coal Mine Underground Reservoirs. Water. 2024; 16(13):1856. https://doi.org/10.3390/w16131856

Chicago/Turabian StyleWang, Yan, Fei Liu, Miaomiao Kou, and Mingfei Li. 2024. "A Review of Stability of Dam Structures in Coal Mine Underground Reservoirs" Water 16, no. 13: 1856. https://doi.org/10.3390/w16131856

APA StyleWang, Y., Liu, F., Kou, M., & Li, M. (2024). A Review of Stability of Dam Structures in Coal Mine Underground Reservoirs. Water, 16(13), 1856. https://doi.org/10.3390/w16131856