Geochemical Characterization and Prediction of Water Accumulation in the Goaf under Extra-Thick Fully Mechanized Top-Coal-Caving Mining

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area

2.2. Sampling and Testing

2.3. Calculation Method of Accumulated Water in Goaf

3. Results

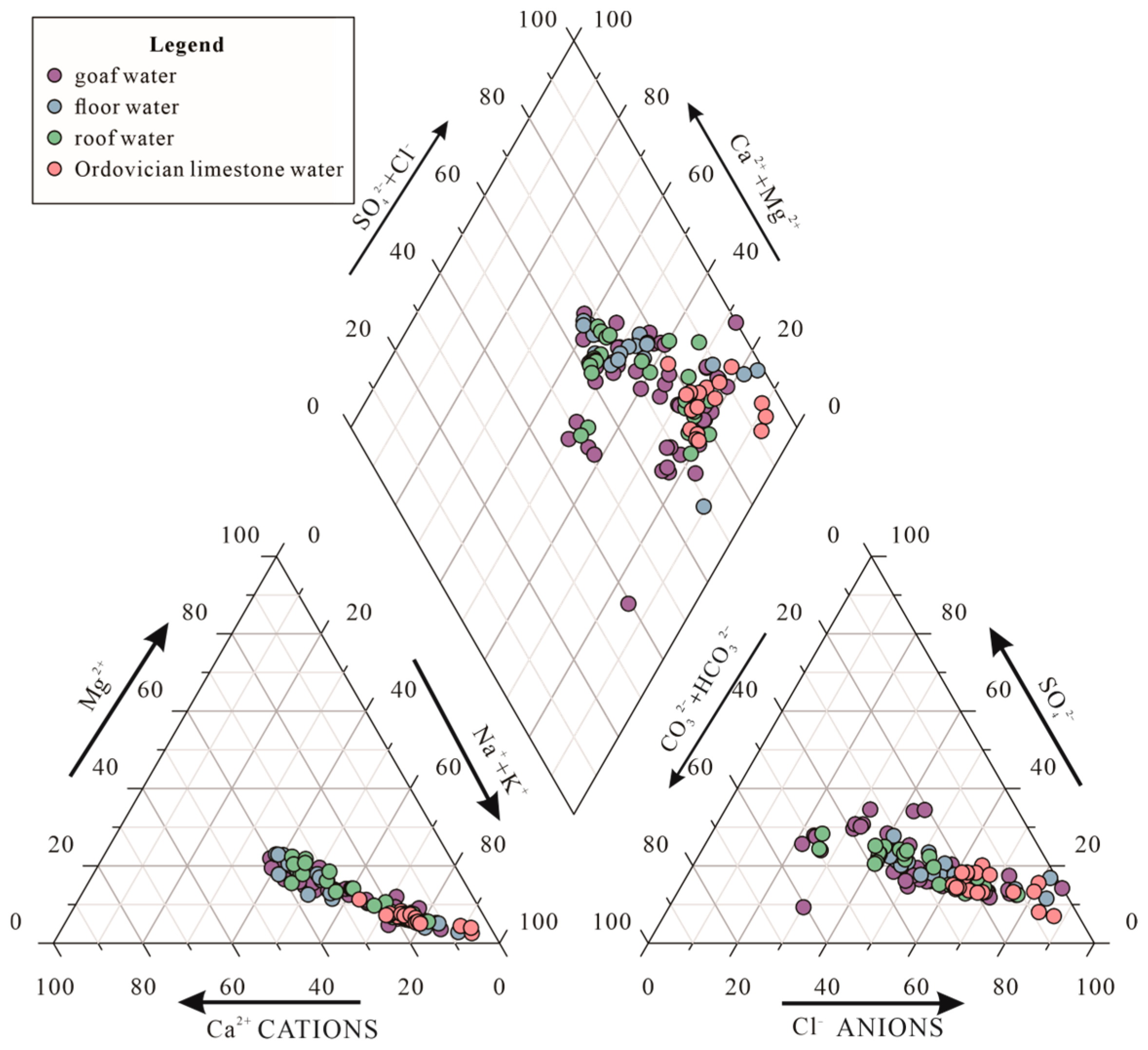

3.1. General Hydrochemical Analysis

3.2. The Hydraulic Connection between Goaf Water and Aquifers

3.3. Groundwater-Hydrochemistry Formation Mechanisms

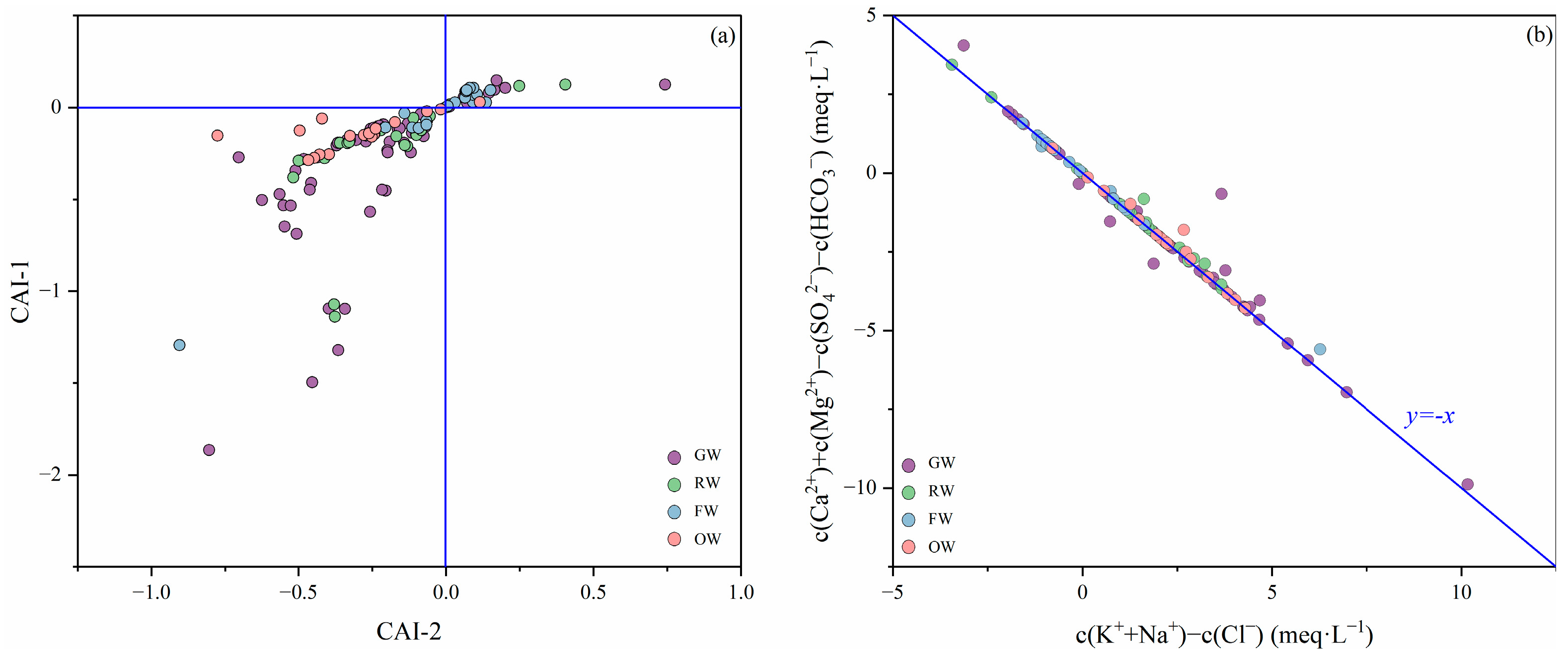

3.3.1. Cation Exchange Action

3.3.2. Desulfurization Action

3.3.3. Leaching Action

3.4. Calculation of Accumulated Water in the Goaf That Can Be Drained from Each Working Face

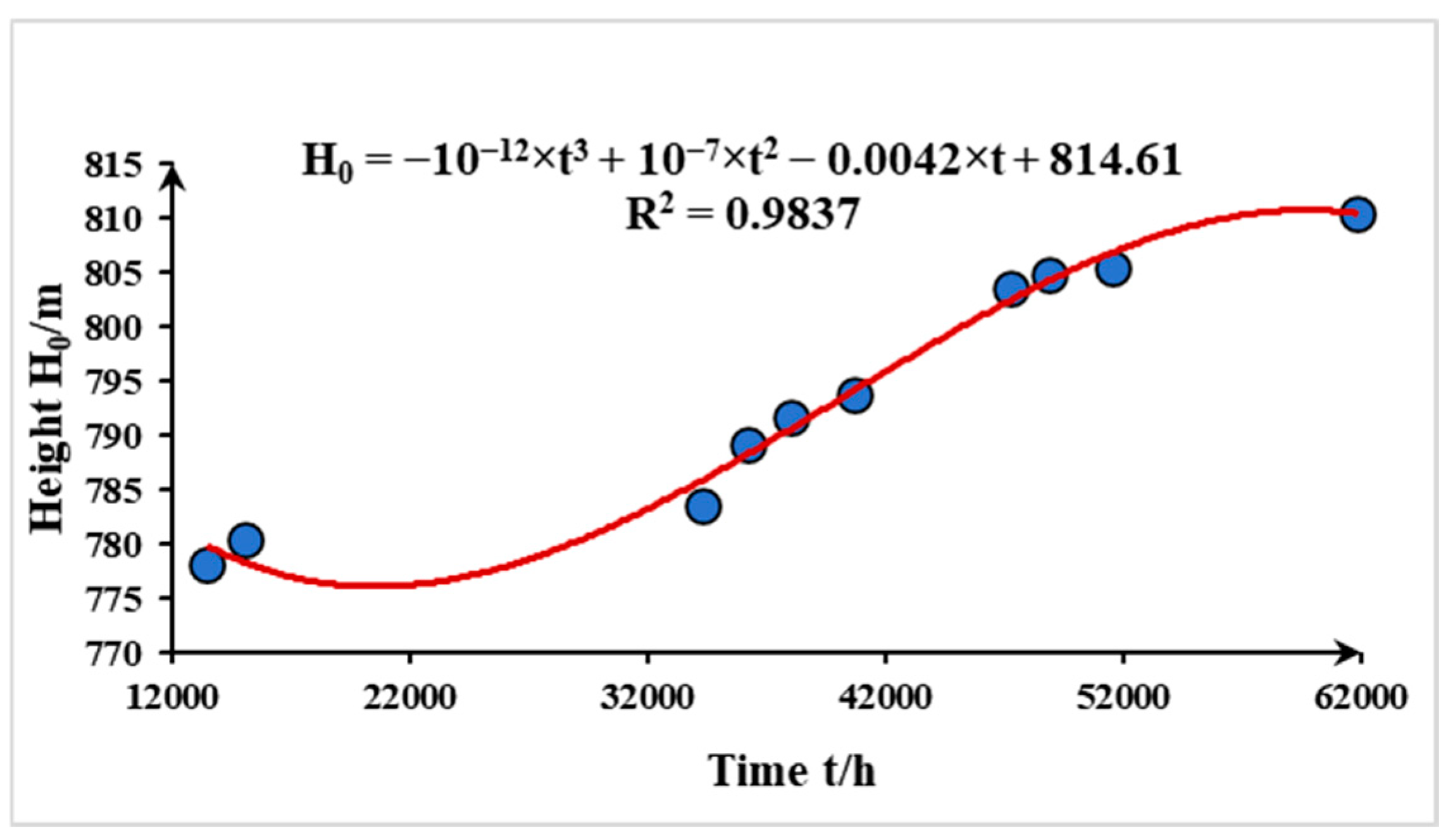

3.5. Calculation Results of Speed of Water Accumulation in Goaf

3.6. Prediction of Water Accumulation in Goaf

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yuan, S.; Sui, W.; Han, G.; Duan, W. An Optimized Combination of Mine Water Control, Treatment, Utilization, and Reinjection for Environmentally Sustainable Mining: A Case Study. Mine Water Environ. 2022, 41, 828–839. [Google Scholar] [CrossRef]

- Acharya, B.S.; Kharel, G. Acid Mine Drainage from Coal Mining in the United States—An Overview. J. Hydrol. 2020, 588, 125061. [Google Scholar] [CrossRef]

- Bundschuh, J.; Schneider, J.; Alam, M.A.; Niazi, N.K.; Herath, I.; Parvez, F.; Tomaszewska, B.; Guilherme, L.R.G.; Maity, J.P.; López, D.L.; et al. Seven Potential Sources of Arsenic Pollution in Latin America and Their Environmental and Health Impacts. Sci. Total Environ. 2021, 780, 146274. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Gao, X.; Hou, B.; Zhang, S.; Zhang, J.; Li, C.; Wang, W. Occurrence and Environmental Impact of Coal Mine Goaf Water in Karst Areas in China. J. Clean. Prod. 2020, 275, 123813. [Google Scholar] [CrossRef]

- Raj, D.; Kumar, A.; Maiti, S.K. Evaluation of Toxic Metal(Loid)s Concentration in Soils around an Open-Cast Coal Mine (Eastern India). Environ. Earth Sci. 2019, 78, 645. [Google Scholar] [CrossRef]

- Gui, H.; Qiu, H.; Qiu, W.; Tong, S.; Zhang, H. Overview of Goaf Water Hazards Control in China Coalmines. Arab. J. Geosci. 2018, 11, 49. [Google Scholar] [CrossRef]

- Li, P.; Ma, L.; Wu, Y.; Zhang, L.; Hao, Y. Concurrent Mining During Construction and Water-Filling of a Goaf Groundwater Reservoir in a Coal Mine. Mine Water Environ. 2018, 37, 763–773. [Google Scholar] [CrossRef]

- Niu, X.; Feng, G.; Liu, Q.; Han, Y.; Qian, R. Numerical Investigation on Mechanism and Fluid Flow Behavior of Goaf Water Inrush: A Case Study of Dongyu Coal Mine. Nat. Hazards 2022, 113, 1783–1802. [Google Scholar] [CrossRef]

- Wang, N.; Wang, Z.; Sun, Q.; Hui, J. Coal Mine Goaf Interpretation: Survey, Passive Electromagnetic Methods and Case Study. Minerals 2023, 13, 422. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, P.; Lu, L.; Wang, S.; Wang, H. Evaluation of Compressive Geophysical Prospecting Method for the Identification of the Abandoned Goaf at the Tengzhou Section of China’s Mu Shi Expressway. Sustainability 2022, 14, 13785. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, Y.; Wang, Y.; Li, P.; Zhang, Y.; Shen, C. Study on the Law and Risk of Spontaneous Combustion of Residual Coal during Water Drainage in Goaf. Energies 2022, 15, 8896. [Google Scholar] [CrossRef]

- Zhu, L.; Gu, W.; Ouyang, Y.; Qiu, F. Grouting Mechanism and Experimental Study of Goaf Considering Filtration Effect. PLoS ONE 2023, 18, e0282190. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Yao, Q.; Wang, F.; Xiao, L.; Ma, J.; Kong, F.; Shang, X. Tracer Test Method to Confirm Hydraulic Connectivity Between Goafs in a Coal Mine. Mine Water Environ. 2024, 43, 104–116. [Google Scholar] [CrossRef]

- Yan, S.; Xue, G.-Q.; Qiu, W.-Z.; Li, H.; Zhong, H.-S. Feasibility of Central Loop TEM Method for Prospecting Multilayer Water-Filled Goaf. Appl. Geophys. 2016, 13, 587–597. [Google Scholar] [CrossRef]

- Moser, B.; Cook, P.G.; Miller, A.D.; Dogramaci, S.; Wallis, I. The Hydraulic Evolution of Groundwater-Fed Pit Lakes After Mine Closure. Groundwater 2024. [Google Scholar] [CrossRef] [PubMed]

- Roy, D.K.; Paul, C.R.; Munmun, T.H.; Datta, B. An Automatic Model Selection-Based Machine Learning Approach to Predict Seawater Intrusion into Coastal Aquifers. Environ. Earth Sci. 2024, 83, 287. [Google Scholar] [CrossRef]

- Brodic, B.; Malehmir, A.; Pacheco, N.; Juhlin, C.; Carvalho, J.; Dynesius, L.; van den Berg, J.; de Kunder, R.; Donoso, G.; Sjolund, T.; et al. Innovative Seismic Imaging of Volcanogenic Massive Sulfide Deposits, Neves-Corvo, Portugal–Part 1: In-Mine Array. Geophysics 2021, 86, B165–B179. [Google Scholar] [CrossRef]

- Donoso, G.A.; Malehmir, A.; Pacheco, N.; Araujo, V.; Penney, M.; Carvalho, J.; Spicer, B.; Beach, S. Potential of Legacy 2D Seismic Data for Deep Targeting and Structural Imaging at the Neves-Corvo Massive Sulphide-Bearing Deposit, Portugal. Geophys. Prospect. 2020, 68, 44–61. [Google Scholar] [CrossRef]

- Malehmir, A.; Durrheim, R.; Bellefleur, G.; Urosevic, M.; Juhlin, C.; White, D.J.; Milkereit, B.; Campbell, G. Seismic Methods in Mineral Exploration and Mine Planning: A General Overview of Past and Present Case Histories and a Look into the Future. Geophysics 2012, 77, WC173–WC190. [Google Scholar] [CrossRef]

- Jena, M.R.; Tripathy, J.K.; Sahoo, D.; Sahu, P. Geochemical Evaluation of Groundwater Quality in the Coastal Aquifers of Kujang Block, Jagatsinghpur District, Eastern Odisha, India. Water Air Soil. Pollut. 2024, 235, 349. [Google Scholar] [CrossRef]

- Kumar, G.; Kothandaraman, S.; Karuppanan, K.; Hussain, S. Groundwater Quality and Suitability Assessment in Tirupur Region, Tamil Nadu, India. J. Chem. 2024, 2024, 6083772. [Google Scholar] [CrossRef]

- Ahmad, S.; Singh, N.; Mazhar, S.N. Hydrochemical Characteristics of the Groundwater in Trans-Yamuna Alluvial Aquifer, Palwal District, Haryana, India. Appl. Water Sci. 2020, 10, 75. [Google Scholar] [CrossRef]

- Azari, T.; Tabari, M.M.R. An Integrated Approach Based on HFE-D, GIS Techniques, GQISWI, and Statistical Analysis for the Assessment of Potential Seawater Intrusion: Coastal Multilayered Aquifer of Ghaemshahr-Juybar (Mazandaran, Iran). Environ. Sci. Pollut. Res. 2024, 31, 13335–13371. [Google Scholar] [CrossRef] [PubMed]

- Molla, S.H.; Rukhsana; Ul Hasan, M.S. Deployment of Entropy Information Theory in the Indian Sundarban Region Using Hydrogeochemical Parameters and GIS for Assessment of Irrigation Suitability. Environ. Monit. Assess. 2023, 195, 1277. [Google Scholar] [CrossRef]

- Sadeghi-Lari, A.; Bahrami, M.; Dastandaz, T. Temporal and Spatial Variations of Groundwater Quantity and Quality for Drinking and Irrigation Purposes in the Arid and Hot Weather of Southern Iran. Phys. Chem. Earth 2024, 134, 103582. [Google Scholar] [CrossRef]

- Iddrisu, U.F.; Armah, E.K.; Amedorme, B.S.; Mbatchou, V.C. Assessing the Groundwater Quality in Ghana’s Nanton District: Comprehensive Evaluation and Implications for Sustainable Management. AQUA Water Infrastruct. Ecosyst. Soc. 2024, 73, 34–56. [Google Scholar] [CrossRef]

- Selmani, Y.; Chihi, L.; Kadri, A.; Hatira, N.; Regaya, K. Identifying Sub-Surface Triassic Salt Diapirs under Domal Structures in the Tunisian Atlas: Exploration Targets for Potential Mineralization. Carbonates Evaporites 2024, 39, 28. [Google Scholar] [CrossRef]

- Jiang, C.; Wang, L.; Yu, X.; Lv, W.; Yang, X. A New Method of Monitoring 3D Mining-Induced Deformation in Mountainous Areas Based on Single-Track InSAR. KSCE J. Civ. Eng. 2022, 26, 2392–2407. [Google Scholar] [CrossRef]

- Zhang, D.; Cen, X.; Wang, W.; Deng, J.; Wen, H.; Xiao, Y.; Shu, C.-M. The Graded Warning Method of Coal Spontaneous Combustion in Tangjiahui Mine. Fuel 2021, 288, 119635. [Google Scholar] [CrossRef]

- Sun, B.; Zhang, P.; Wu, R.; Fu, M.; Ou, Y. Research on the Overburden Deformation and Migration Law in Deep and Extra-Thick Coal Seam Mining. J. Appl. Geophys. 2021, 190, 104337. [Google Scholar] [CrossRef]

- Yu, C.; Ma, J.; Xue, J. Simulation and Analysis of the Transient Electromagnetic Method Response in Double-Layer Water-Filled Goaf in Coal Mines. J. Geophys. Eng. 2024, 21, 782–795. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, S.; Chen, Y. Study on Water Inrush Risk of Overlying Old Goaf Water in Fully Mechanized Caving Mining of Lower Coal Group. Q. J. Eng. Geol. Hydrogeol. 2024, 57, qjegh2023-064. [Google Scholar] [CrossRef]

- Yi, S.; Zhang, Y.; Yi, H.; Li, X.; Wang, X.; Wang, Y.; Chu, T. Study on the Instability Activation Mechanism and Deformation Law of Surrounding Rock Affected by Water Immersion in Goafs. Water 2022, 14, 3250. [Google Scholar] [CrossRef]

- Chang, J.; Su, B.; Malekian, R.; Xing, X. Detection of Water-Filled Mining Goaf Using Mining Transient Electromagnetic Method. IEEE Trans. Ind. Inform. 2020, 16, 2977–2984. [Google Scholar] [CrossRef]

- Luo, P.; Zhang, M.; Zhou, S. Research on the Reconstruction of Aquatic Vegetation Landscape in Coal Mining Subsidence Wetlands Based on Ecological Water Level. Water 2024, 16, 1339. [Google Scholar] [CrossRef]

| Aquifers | Statistics | Mass Concentration (meq/L) | |||||

|---|---|---|---|---|---|---|---|

| Ca2+ | K++Na+ | Mg2+ | Cl− | SO42− | HCO3− | ||

| GW (n = 60) | Min. | 2.04 | 5.60 | 0.66 | 2.67 | 1.68 | 0.03 |

| Max. | 8.57 | 25.98 | 4.90 | 25.59 | 5.15 | 10.95 | |

| Mean | 5.08 | 14.96 | 2.26 | 12.94 | 3.92 | 5.37 | |

| Standard deviation | 1.63 | 5.81 | 0.94 | 6.49 | 0.66 | 1.58 | |

| C.V | 0.32 | 0.39 | 0.42 | 0.50 | 0.17 | 0.29 | |

| RW (n = 30) | Min. | 84.00 | 2.65 | 6.23 | 1.02 | 3.01 | 2.81 |

| Max. | 113.00 | 8.41 | 24.27 | 4.85 | 27.71 | 5.41 | |

| Mean | 98.50 | 5.62 | 13.43 | 2.80 | 11.97 | 4.05 | |

| Standard deviation | 8.80 | 1.80 | 4.42 | 1.26 | 4.92 | 0.82 | |

| C.V | 0.09 | 0.32 | 0.33 | 0.45 | 0.41 | 0.20 | |

| FW (n = 23) | Min. | 61.00 | 0.97 | 7.85 | 0.36 | 4.84 | 3.11 |

| Max. | 83.00 | 8.77 | 28.75 | 4.79 | 29.54 | 5.20 | |

| Mean | 72.00 | 6.93 | 13.60 | 3.30 | 13.53 | 4.49 | |

| Standard deviation | 6.78 | 1.98 | 5.53 | 1.26 | 5.81 | 0.51 | |

| C.V | 0.09 | 0.29 | 0.41 | 0.38 | 0.43 | 0.11 | |

| OW (n = 19) | Min. | 114.00 | 1.07 | 13.33 | 0.56 | 12.96 | 1.68 |

| Max. | 132.00 | 6.12 | 27.55 | 2.40 | 27.15 | 4.79 | |

| Mean | 123.00 | 4.04 | 19.34 | 1.62 | 17.17 | 3.68 | |

| Standard deviation | 5.63 | 1.41 | 3.70 | 0.45 | 4.26 | 0.87 | |

| C.V | 0.05 | 0.35 | 0.19 | 0.28 | 0.25 | 0.24 | |

| Working Face | Length (m) | Width (m) | Elevation (m) | Dip Angle (°) | Average Thickness (m) | Volume (m3) |

|---|---|---|---|---|---|---|

| 61,101 | 982 | 220 | 780 | 2 | 17.17 | 124,594.4831 |

| 61,102 | 1013 | 235 | 793.2 | 2 | 18.3 | 137,290.9631 |

| 61,103 | 1048 | 235 | 791.17 | 2 | 18.7 | 142,034.4811 |

| 61,201 | 2100 | 240 | 804.4 | 1 | 16.96 | 223,874.6692 |

| 61,202 | 1907 | 240 | 810 | 2 | 9.9 | 263,952.9857 |

| 61,207 | 1405 | 265 | 805 | 2 | 8.6 | 214,727.0919 |

| 61,208 | 1254 | 264 | 803 | 2 | 7.5 | 190,926.4544 |

| 61,302 | 1897 | 240 | 788.6 | 2 | 14.6 | 262,568.8589 |

| 61,303 | 1797 | 240 | 777.5 | 2 | 23.1 | 248,727.5906 |

| 61,304 | 2154 | 240 | 783 | 2 | 14.1 | 298,140.9183 |

| Working Face | Permeability Coefficient K (m/d) | Water-Level Drawdown S (m) | Water-Column Height H (m) | Aquifer Thickness M (m) | Predicted Area Conversion Radius r0 (m) | Predicted Area Influence Radius R (m) | Water Inflow Q (m3/h) |

|---|---|---|---|---|---|---|---|

| 61,304 | 0.032 | 35.620 | 35.620 | 34.600 | 606.500 | 670.220 | 15.50 |

| 61,303 | 0.029 | 14.680 | 14.680 | 55.890 | 612.914 | 637.913 | 18.50 |

| 61,302 | 0.032 | 222.135 | 222.135 | 58.500 | 390.100 | 786.846 | 136.00 |

| 61,208 | 0.029 | 35.600 | 35.600 | 23.500 | 379.500 | 440.125 | 28.70 |

| 61,207 | 0.037 | 98.840 | 98.840 | 41.100 | 467.865 | 657.473 | 80.61 |

| 61,202 | 0.037 | 40.000 | 40.000 | 17.000 | 408.870 | 485.603 | 25.68 |

| 61,201 | 0.029 | 90.000 | 90.000 | 62.000 | 690.300 | 843.564 | 138.67 |

| 61,103 | 0.029 | 90.000 | 90.000 | 62.000 | 378.485 | 531.749 | 81.78 |

| 61,102 | 0.029 | 25.000 | 42.000 | 25.000 | 368.160 | 410.733 | 51.23 |

| 61,101 | 0.029 | 90.000 | 90.000 | 62.000 | 354.590 | 507.854 | 77.40 |

| Mean | 65.407 |

| Working Face | Water Elevation/H0 (m) | t (h) |

|---|---|---|

| 61,303 | 778.0767195 | 13,444.73463 |

| 61,101 | 780.5767195 | 15,054.44557 |

| 61,304 | 783.5767195 | 34,289.34353 |

| 61,302 | 789.1767195 | 36,219.9969 |

| 61,103 | 791.7467195 | 37,956.76084 |

| 61,102 | 793.7767195 | 40,636.67442 |

| 61,208 | 803.5767195 | 47,289.16412 |

| 61,201 | 804.8441958 | 48,903.57572 |

| 61,207 | 805.5767195 | 51,567.35307 |

| 61,202 | 810.5767195 | 61,845.89612 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wang, H.; Yin, S.; Liao, Q.; Ju, Q.; Chen, K. Geochemical Characterization and Prediction of Water Accumulation in the Goaf under Extra-Thick Fully Mechanized Top-Coal-Caving Mining. Water 2024, 16, 2110. https://doi.org/10.3390/w16152110

Wang J, Wang H, Yin S, Liao Q, Ju Q, Chen K. Geochemical Characterization and Prediction of Water Accumulation in the Goaf under Extra-Thick Fully Mechanized Top-Coal-Caving Mining. Water. 2024; 16(15):2110. https://doi.org/10.3390/w16152110

Chicago/Turabian StyleWang, Jianghong, Hongwei Wang, Shaobo Yin, Qingfa Liao, Qiding Ju, and Kai Chen. 2024. "Geochemical Characterization and Prediction of Water Accumulation in the Goaf under Extra-Thick Fully Mechanized Top-Coal-Caving Mining" Water 16, no. 15: 2110. https://doi.org/10.3390/w16152110