Optimizing Trapezoidal Labyrinth Weir Design for Enhanced Scour Mitigation in Straight Channels

Abstract

1. Introduction

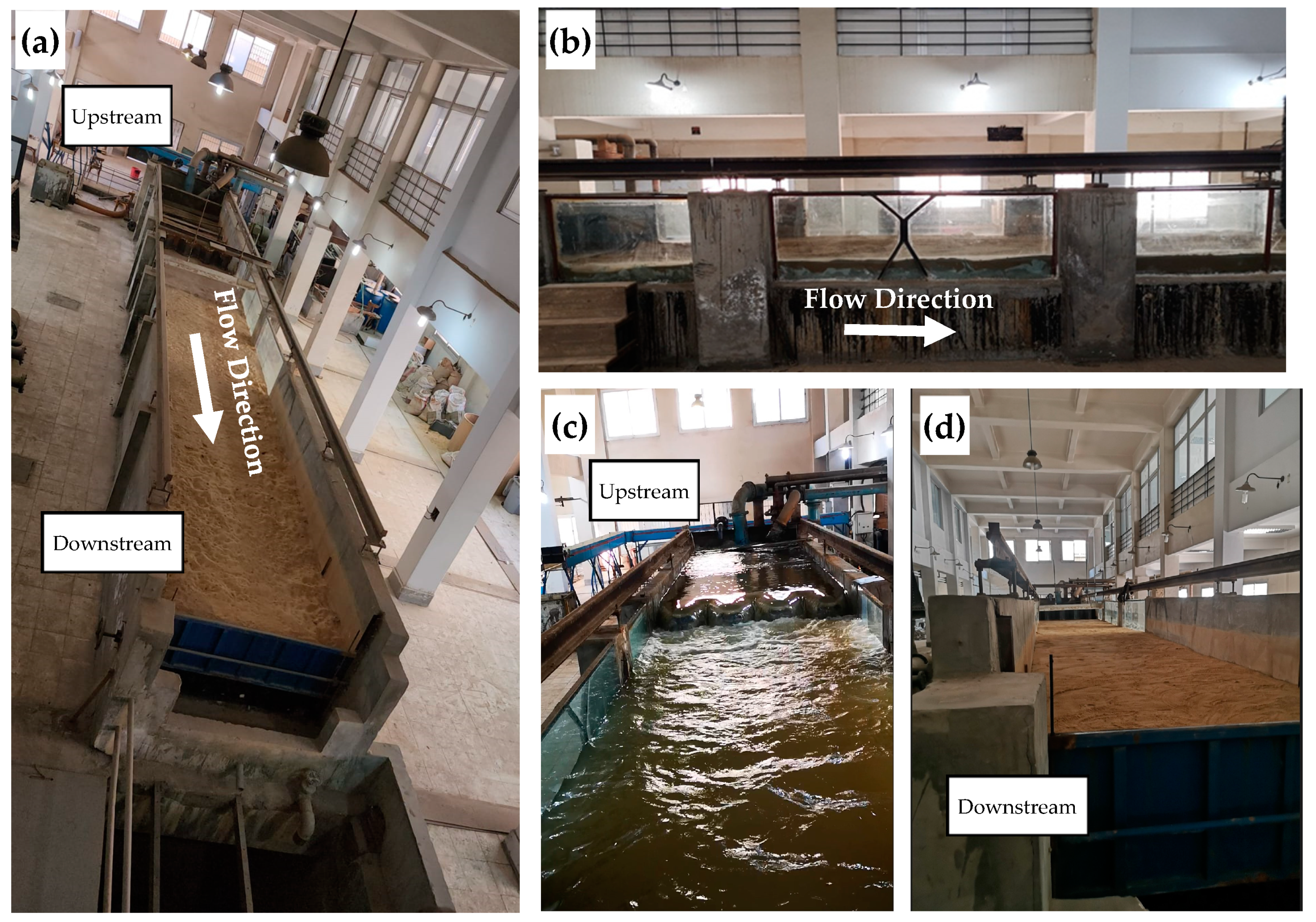

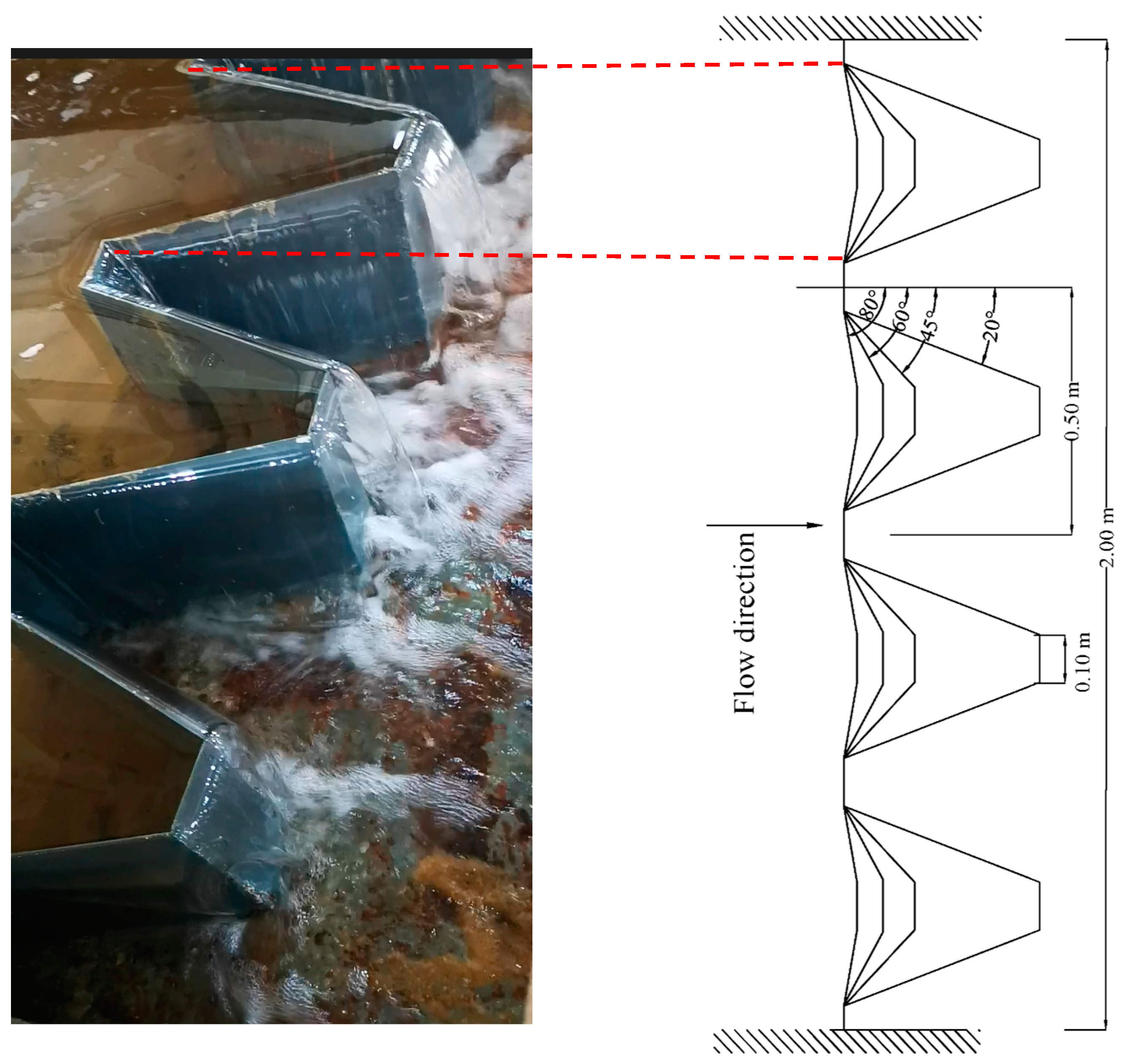

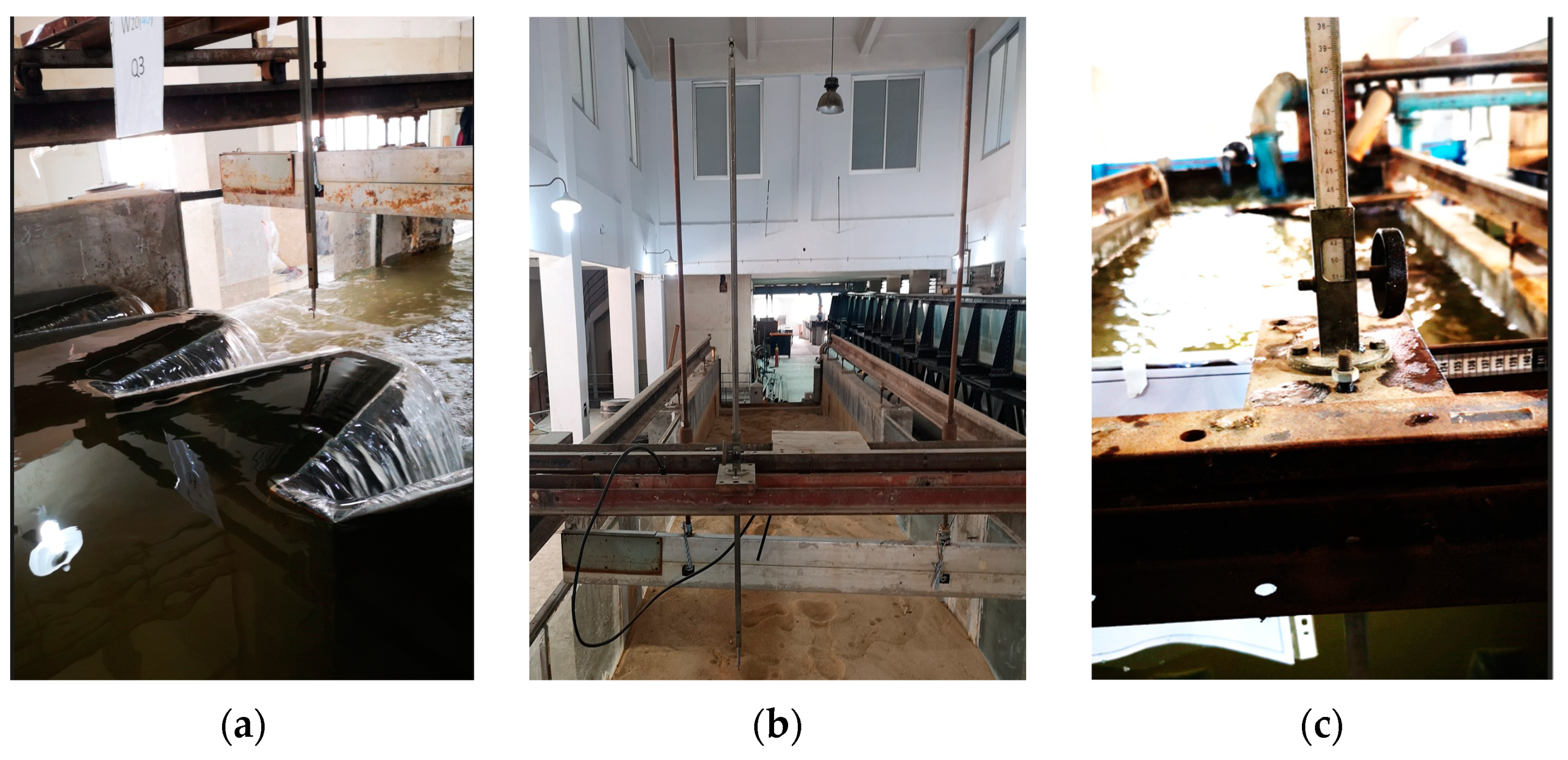

2. Materials and Methods

2.1. Model Setup

2.2. Justification of Experimental Parameters and Assumptions

- The weirs were constructed from 5 mm thick metal sheets. This thickness was chosen as an optimal balance between structural integrity and practicality. Thinner sheets (<5 mm) led to deformations, particularly for taller weirs (40 cm) under high discharge. On the other hand, thicker sheets increased costs and posed handling difficulties during installation.

- The weir heights were selected between 30 and 40 cm. This range was determined after observing that taller weirs caused complete bed material removal under high discharge, while shorter weirs failed to produce noticeable bed configurations under low discharge.

- The weir apex angles ranged between 20° and 80°. The angles below 20° showed poor energy dissipation performance, while angles exceeding 80° caused the trapezoidal labyrinth weir to behave similarly to a classical sharp-crested weir, negating the benefits of the labyrinth design.

- Discharges between 50 and 200 L/s were tested. The flows below 50 L/s did not produce significant bed material development for shorter weirs, while discharges exceeding 200 L/s resulted in complete bed material movement, limiting the ability to study the scour patterns.

- The run time duration was set to 4 h, during which the quasi-equilibrium state was reached, and no further appreciable bed movement was recorded. Consequently, extending the run time duration beyond this period was useless with respect to bed configurations.

2.3. Dimensional Analysis

3. Results and Discussion

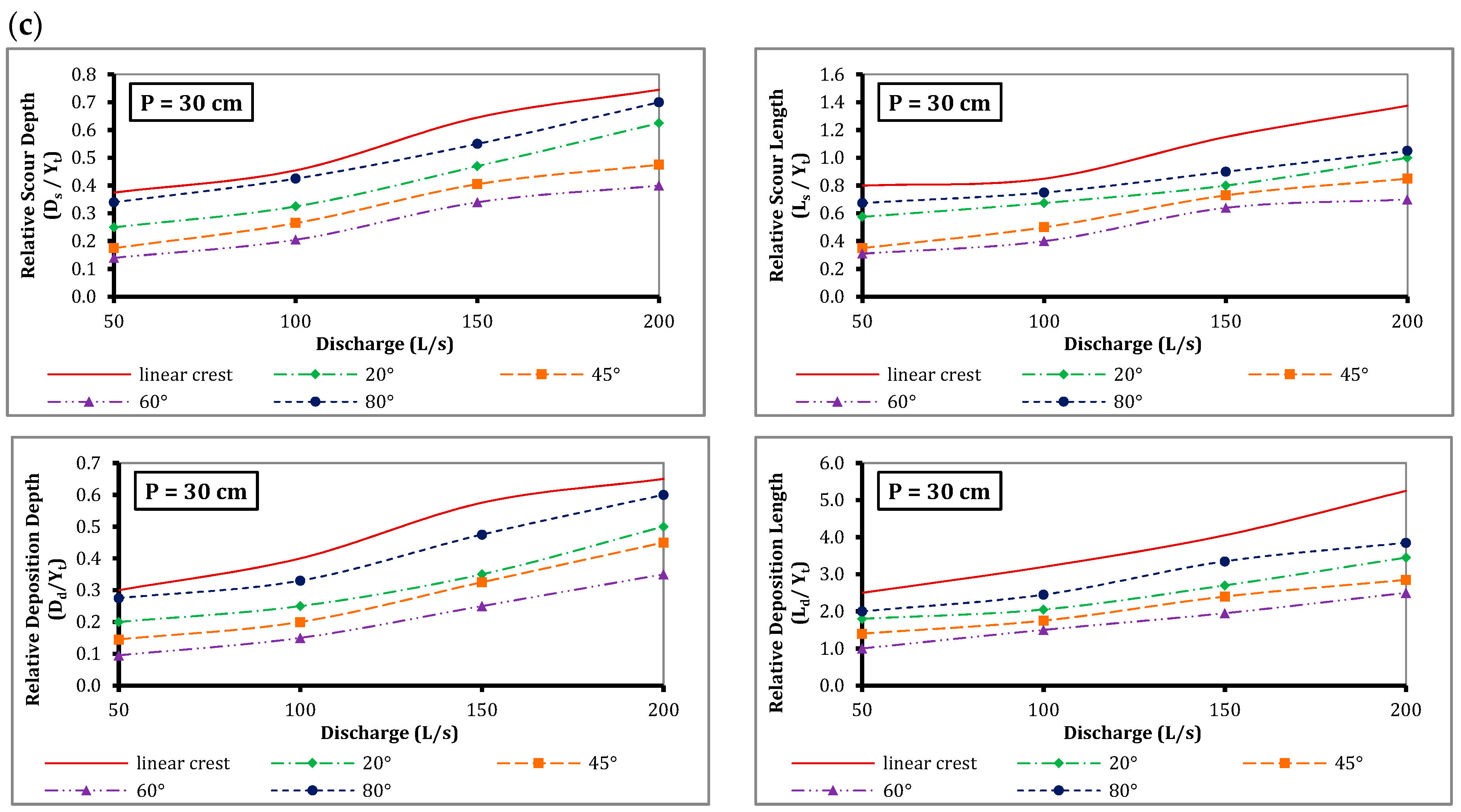

3.1. Effect of Labyrinth Weir Apex Angle on Scour and Deposition Parameters

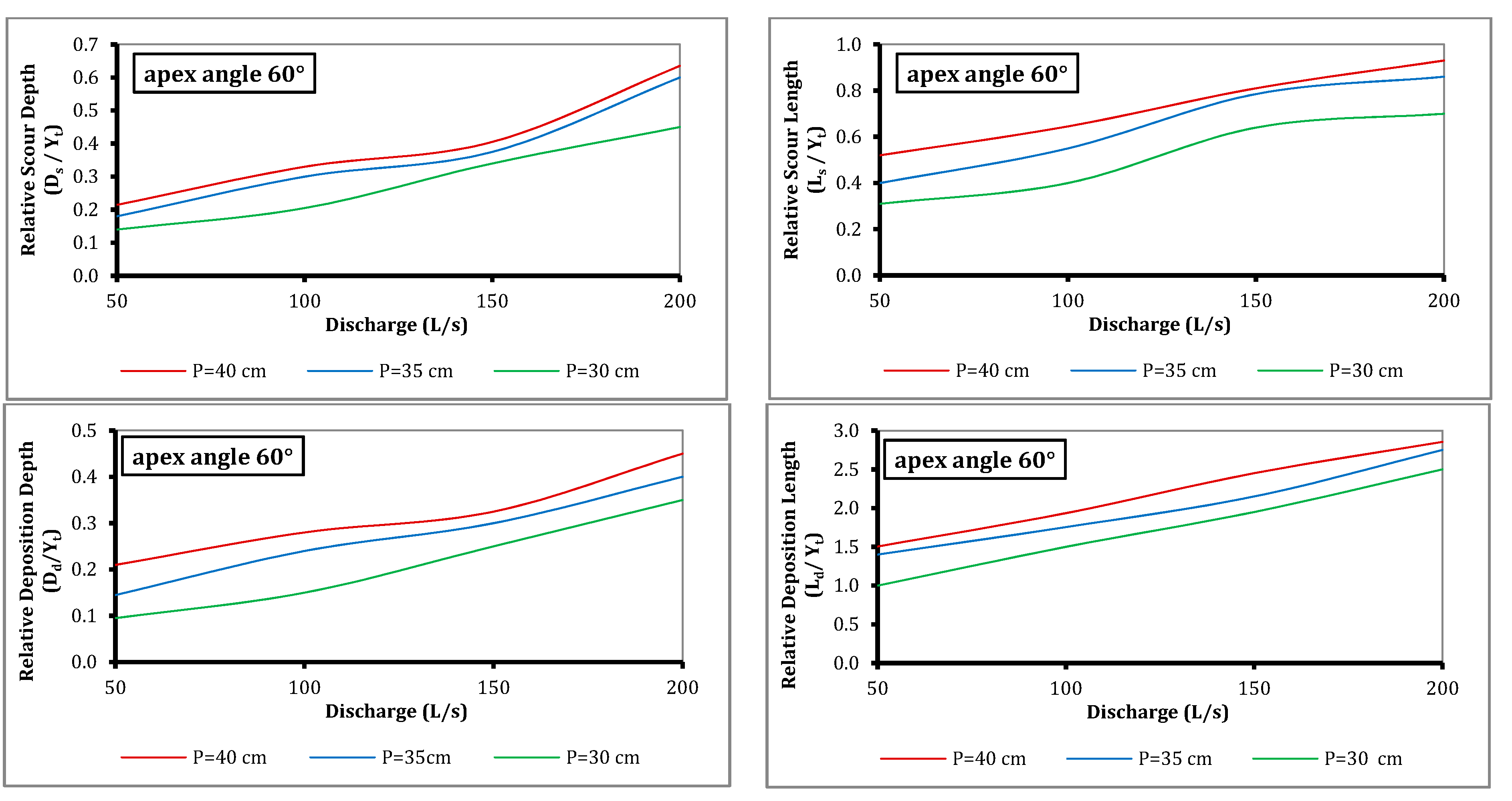

3.2. Effect of Labyrinth Weir Height on Scour and Deposition Parameters

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Döll, P. Impact of Climate Change and Variability on Irrigation Requirements: A Global Perspective. Clim. Chang. 2002, 54, 269–293. [Google Scholar] [CrossRef]

- Oki, T.; Kanae, S. Global Hydrological Cycles and World Water Resources. Science 2006, 313, 1068–1072. [Google Scholar] [CrossRef] [PubMed]

- Ghaderi, A.; Daneshfaraz, R.; Dasineh, M.; Di Francesco, S. Energy Dissipation and Hydraulics of Flow over Trapezoidal–Triangular Labyrinth Weirs. Water 2020, 12, 1992. [Google Scholar] [CrossRef]

- Falvey, H.T. Hydraulic Design of Labyrinth Weirs; ASCE Press (American Society of Civil Engineers): Reston, VA, USA, 2003; ISBN 0784406316. [Google Scholar]

- Sah, S.; Kumar, M.; Singh, D.; Sah, S.; Kumar, M.; Singh, D. Study of Flow Characteristic of Trapezoidal Labyrinth Weir. River Hydraul. Hydraul. Water Resour. Coast. Eng. 2022, 2, 241–248. [Google Scholar] [CrossRef]

- Emin Emiroglu, M.; Cihan Aydin, M.; Kaya, N. Discharge Characteristics of a Trapezoidal Labyrinth Side Weir with One and Two Cycles in Subcritical Flow. J. Irrig. Drain. Eng. 2014, 140, 04014007. [Google Scholar] [CrossRef]

- Idrees, A.K.; Al-Ameri, R. Investigating a New Approach to Enhance the Discharge Capacity of Labyrinth Weirs. J. Hydroinform. 2023, 25, 300–317. [Google Scholar] [CrossRef]

- Hong, S.; Biering, C.; Sturm, T.; Yoon, K.; Gonzalez-Castro, J. Effect of Submergence and Apron Length on Spillway Scour: Case Study. Water 2015, 7, 5378–5395. [Google Scholar] [CrossRef]

- Derakhshanifard, M.; Heidarnejad, M.; Masjedi, A.; Bordbar, A.; Egdernezhad, A. Experimental Study of Effect of Creating an Additional Cycle along the Lateral Crest of the Labyrinth Weirs. Flow Meas. Instrum. 2023, 90, 102306. [Google Scholar] [CrossRef]

- Azmathullah, H.M.D.; Deo, M.C.; Deolalikar, P.B. Estimation of Scour below Spillways Using Neural Networks. J. Hydraul. Res. 2006, 44, 61–69. [Google Scholar] [CrossRef]

- Goel, A.; Pal, M. Application of Support Vector Machines in Scour Prediction on Grade-Control Structures. Eng. Appl. Artif. Intell. 2009, 22, 216–223. [Google Scholar] [CrossRef]

- Eslinger, K.R.; Crookston, B.M. Energy Dissipation of Type a Piano Key Weirs. Water 2020, 12, 1253. [Google Scholar] [CrossRef]

- Sharafati, A.; Haghbin, M.; Haji Seyed Asadollah, S.B.; Tiwari, N.K.; Al-Ansari, N.; Yaseen, Z.M. Scouring Depth Assessment Downstream of Weirs Using Hybrid Intelligence Models. Appl. Sci. 2020, 10, 3714. [Google Scholar] [CrossRef]

- Rajaei, A.; Esmaeili Varaki, M.; Shafei Sabet, B. Experimental Investigation on Local Scour at the Downstream of Grade Control Structures with Labyrinth Planform. ISH J. Hydraul. Eng. 2020, 26, 457–467. [Google Scholar] [CrossRef]

- Tullis, B.P.; Jorgensen, T.J.; Crookston, B.M. Effects of a Labyrinth Weir with Outlet Ramps on Downstream Steep-Stepped Chute Sidewall Height Requirements. J. Irrig. Drain. Eng. 2021, 147, 04021057. [Google Scholar] [CrossRef]

- Idrees, A.K.; Al-Ameri, R. A Review of Hydraulic Performance and Design Methods of Labyrinth Weirs. Water Supply 2022, 22, 8120–8138. [Google Scholar] [CrossRef]

- Kardan, N.; Hassanzadeh, Y.; Shakooei Bonab, B. Shape Optimization of Trapezoidal Labyrinth Weirs Using Genetic Algorithm. Arab. J. Sci. Eng. 2017, 42, 1219–1229. [Google Scholar] [CrossRef]

- Masoudi, M.H.; Yari, A.; Sadeghian, J.; Norouzi, H. Experimental Investigation of the Discharge Coefficient of the Rectangular and Trapezoidal Labyrinth Weirs Considering Variable Congress Lengths. Model. Earth Syst. Environ. 2024, 10, 2819–2832. [Google Scholar] [CrossRef]

- Elnikhely, E.A.; Fathy, I. Prediction of Scour Downstream of Triangular Labyrinth Weirs. Alex. Eng. J. 2020, 59, 1037–1047. [Google Scholar] [CrossRef]

- Yasi, M.; Azizpour, B. Comparative Experimental Study on Local-Scour Downstream of Labyrinth Weirs with Different Planforms. Iran. J. Sci. Technol. Trans. Civ. Eng. 2023, 48, 2663–2677. [Google Scholar] [CrossRef]

- Ikinciogullari, E.; Emiroglu, M.E.; Aydin, M.C. Comparison of Scour Properties of Classical and Trapezoidal Labyrinth Weirs. Arab. J. Sci. Eng. 2022, 47, 4023–4040. [Google Scholar] [CrossRef]

- Dehghani, H.S.; Varaki, M.E. Experimental Investigation of Upstream Sedimentation and Downstream Bed Levels’ Effects on Discharge Coefficients of Trapezoidal Labyrinth Weirs. Arab. J. Geosci. 2021, 14, 1999. [Google Scholar] [CrossRef]

- Obaida, A.A.M.; Khattab, N.I.; Mohammed, A.Y. Scour Depth Downstream Sharp-Crested Weir. J. Eng. Appl. Sci. 2023, 70, 23. [Google Scholar] [CrossRef]

- Guan, D.; Melville, B.; Friedrich, H. Local Scour at Submerged Weirs in Sand-Bed Channels. J. Hydraul. Res. 2016, 54, 172–184. [Google Scholar] [CrossRef]

- Fathi, A.; Abdi Chooplou, C.; Ghodsian, M. Local Scour Downstream of Type-A Trapezoidal Stepped Piano Key Weir in Sand and Gravel Sediments. ISH J. Hydraul. Eng. 2024, 30, 417–429. [Google Scholar] [CrossRef]

- Guan, D.; Liu, J.; Chiew, Y.-M.; Zhou, Y. Scour Evolution Downstream of Submerged Weirs in Clear Water Scour Conditions. Water 2019, 11, 1746. [Google Scholar] [CrossRef]

- Abdi Chooplou, C.; Bodaghi, E.; Ghodsian, M.; Vaghefi, M. Temporal Evolution of Scouring Downstream of a Trapezoidal Piano Key Weir. Int. J. River Basin Manag. 2024, 22, 351–364. [Google Scholar] [CrossRef]

- Pagliara, S.; Kurdistani, S.M. Scour Downstream of Cross-Vane Structures. J. Hydro-Environ. Res. 2013, 7, 236–242. [Google Scholar] [CrossRef]

- Najafzadeh, M.; Saberi-Movahed, F.; Sarkamaryan, S. NF-GMDH-Based Self-Organized Systems to Predict Bridge Pier Scour Depth under Debris Flow Effects. Mar. Georesour. Geotechnol. 2018, 36, 589–602. [Google Scholar] [CrossRef]

- Karbasi, M.; Md Azamathulla, H. Prediction of Scour Caused by 2D Horizontal Jets Using Soft Computing Techniques. Ain Shams Eng. J. 2017, 8, 559–570. [Google Scholar] [CrossRef]

| P | weir height | g | the gravity acceleration |

| Ds | maximum scour depth | water density | |

| Ls | soil particle density | ||

| Dd | maximum deposition depth | So | is the flume bed slope |

| Ld | maximum deposition length | d50 | median grain size |

| Q | passing discharge (L/s) | V | the mean flow velocity |

| W | width of the channel | μ | dynamic water viscosity |

| Lb | length of the concrete apron | σ | the surface tension |

| yt | tailwater depth | N | total number of weir cycles |

| α | the labyrinth weir apex angle |

| P = 40 cm | P = 35 cm | P = 30 cm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| α = 80° | α = 45° | α = 20° | Linear | α = 80° | α = 45° | α = 20° | Linear | α = 80° | α = 45° | α = 20° | Linear | |

| Scour depth (Ds/yt) | 33 | 10 | 23 | 41 | 33 | 10 | 23 | 35 | 46 | 18 | 35 | 29 |

| Scour length (Ls/yt) | 36 | 15 | 27 | 50 | 38 | 14 | 26 | 40 | 39 | 16 | 33 | 25 |

| Deposition depth (Dd/yt) | 39 | 14 | 30 | 40 | 42 | 14 | 30 | 40 | 50 | 25 | 35 | 29 |

| Deposition length (Ld/yt) | 35 | 17 | 28 | 50 | 37 | 16 | 29 | 40 | 40 | 17 | 31 | 25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shehata, A.H.; Youssef, T.F.; Hamada, H.A.; M., I.M.; Samy, A. Optimizing Trapezoidal Labyrinth Weir Design for Enhanced Scour Mitigation in Straight Channels. Water 2024, 16, 2443. https://doi.org/10.3390/w16172443

Shehata AH, Youssef TF, Hamada HA, M. IM, Samy A. Optimizing Trapezoidal Labyrinth Weir Design for Enhanced Scour Mitigation in Straight Channels. Water. 2024; 16(17):2443. https://doi.org/10.3390/w16172443

Chicago/Turabian StyleShehata, Ahmed H., Tahani F. Youssef, Hamada A. Hamada, Ibrahim M. M., and Abeer Samy. 2024. "Optimizing Trapezoidal Labyrinth Weir Design for Enhanced Scour Mitigation in Straight Channels" Water 16, no. 17: 2443. https://doi.org/10.3390/w16172443

APA StyleShehata, A. H., Youssef, T. F., Hamada, H. A., M., I. M., & Samy, A. (2024). Optimizing Trapezoidal Labyrinth Weir Design for Enhanced Scour Mitigation in Straight Channels. Water, 16(17), 2443. https://doi.org/10.3390/w16172443