Carbon Emission Accounting and Reduction Evaluation in Sponge City Residential Areas

Abstract

:1. Introduction

2. Research Methodology

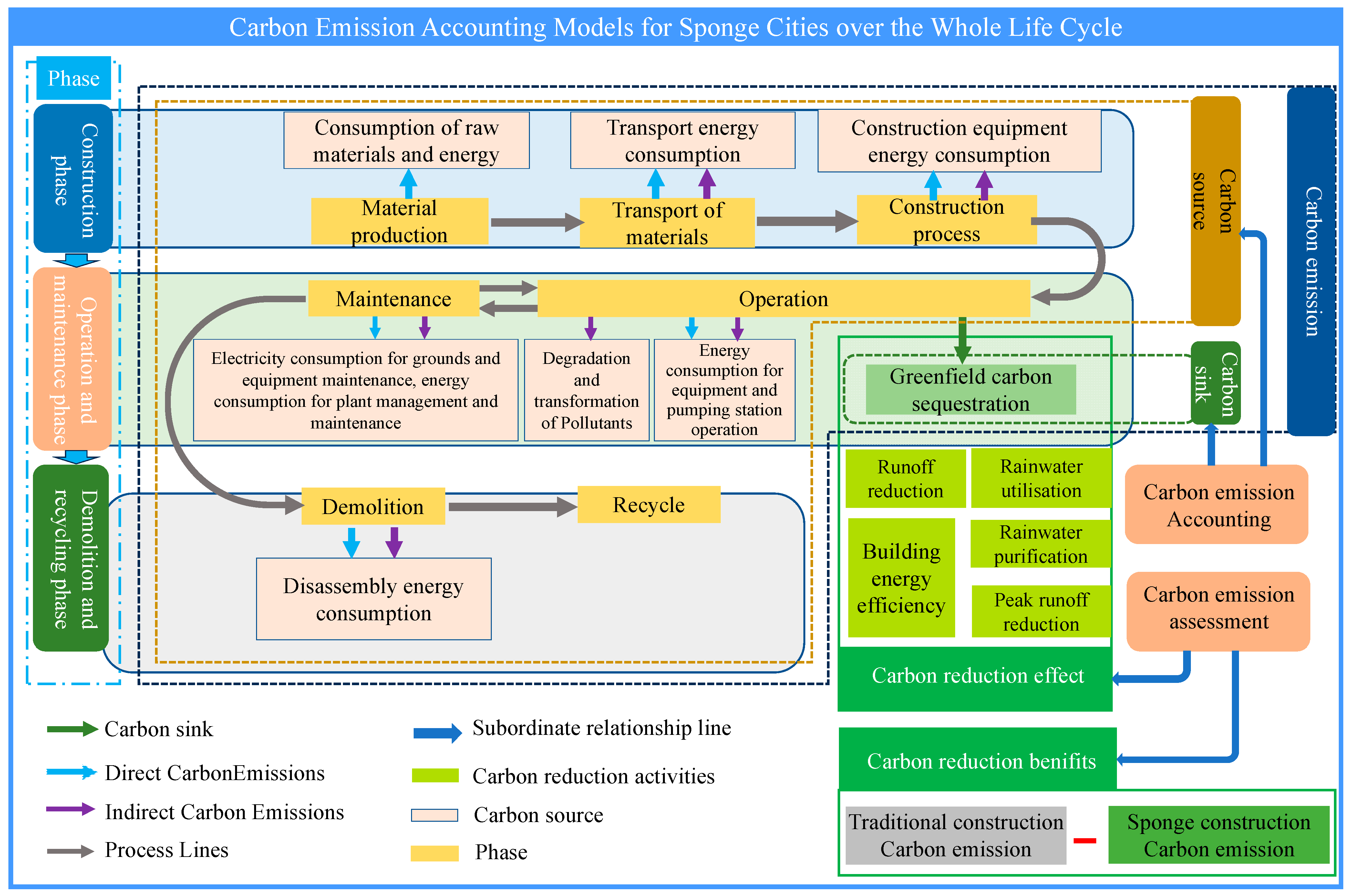

2.1. Carbon Emission Accounting Modelling

2.1.1. Model and Boundary Conditions

- (1)

- Construction Phase: All processes before the facility’s official operation and commissioning, including material production, material transportation, and construction stages.

- (2)

- Operation and Maintenance Phase: All processes from the facility’s commissioning to the end of its operation.

- (3)

- Dismantling and Recycling Phase: All processes in which the facility is used for other purposes or completely removed after the end of operation.

2.1.2. Methods of Accounting

2.2. Definition and Accounting Methods for Carbon Reduction Benefits

2.3. Definition and Accounting Methods for Carbon Emission Reduction Effect

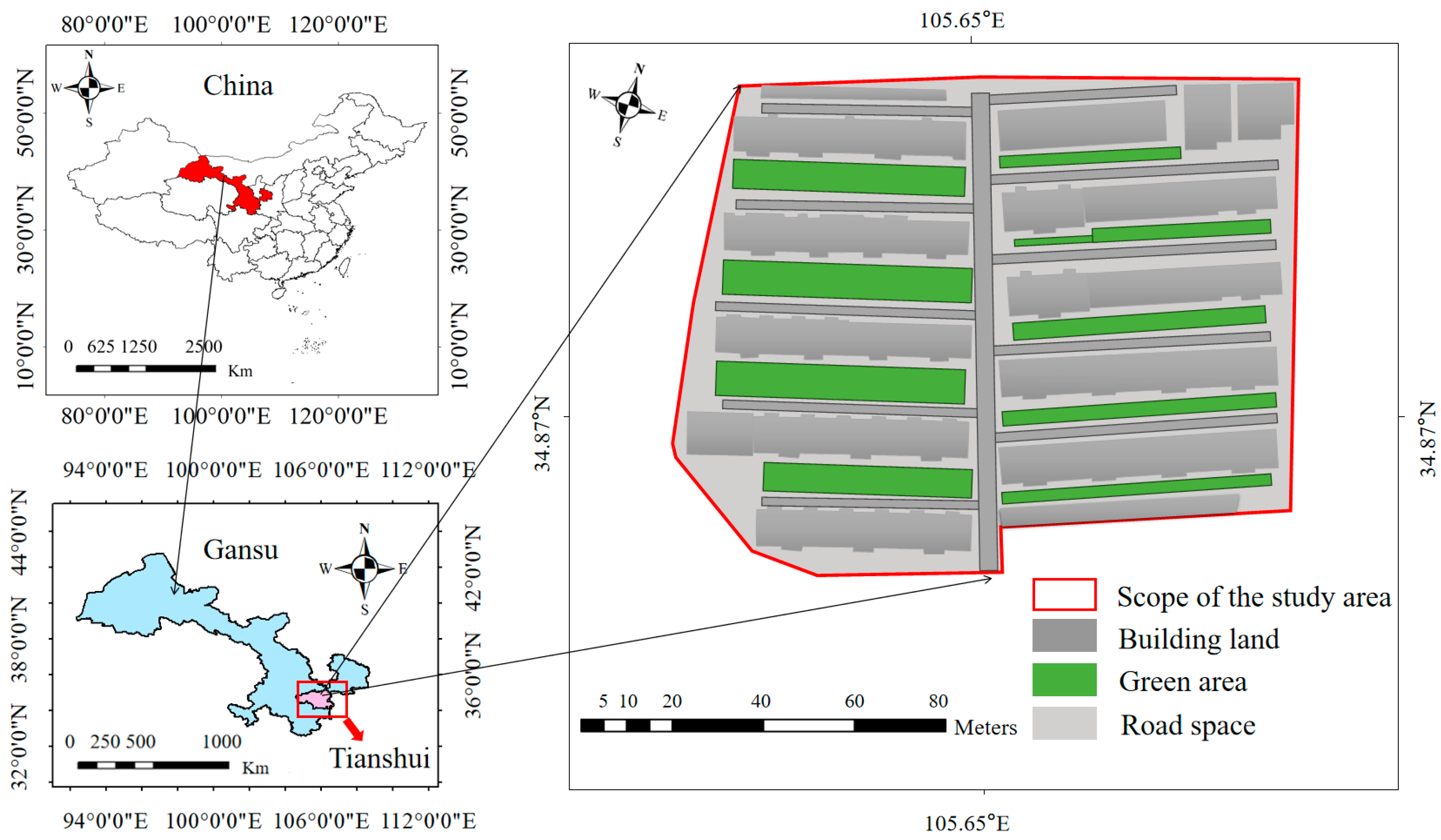

2.4. Case Overview

2.5. Data Collection and Model Applicability

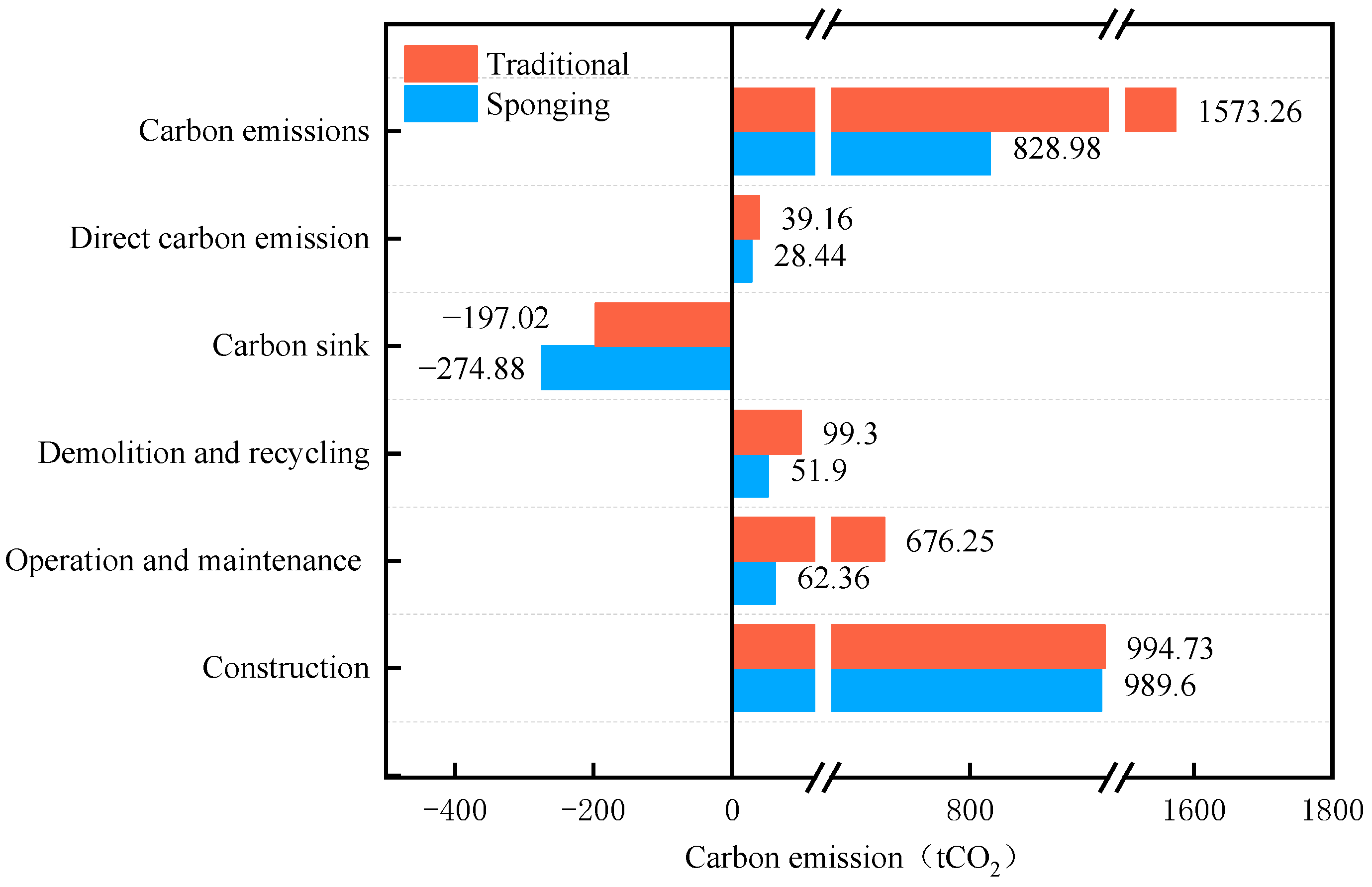

3. Result

3.1. Carbon Emission Accounting

3.1.1. Carbon Emissions during the Construction Phase

- (1)

- Carbon emissions from material production

- (2)

- Carbon emissions from transport of materials

- (3)

- Carbon emissions from construction

3.1.2. Carbon Emissions during the Operation and Maintenance Phase

3.1.3. Carbon Emissions from Demolition and Recycling

3.2. Carbon Reduction Benefits

3.3. Carbon Emission Reduction Effect

- (1)

- Green field Carbon Sequestration

- (2)

- Rainwater Utilization

- (3)

- Peak Runoff Reduction

- (4)

- Rainwater Purification

- (5)

- Building Energy Efficiency

4. Discussion

4.1. Carbon Emission Analysis

4.1.1. Carbon Source Analysis for Sponging Communities

4.1.2. Analysis of Carbon Emissions from LID Facilities

4.2. Carbon Reduction Benefit Analysis

4.2.1. The Whole Life Cycle Carbon Emissions Analysis

4.2.2. Study on the Benefits of Carbon Emission Reduction

4.3. Analysis of Carbon Reduction Effects

4.3.1. Calculation of Carbon Emission Reduction for Different Typical Years of Sponging Construction

4.3.2. Analysis of Carbon Emission Reduction Effect of Sponging

4.3.3. Correlation Analysis between Carbon Reduction Effect and Annual Rainfall

4.3.4. Study on Carbon Emission Reduction Effect

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, C.; Lin, W.; Zhu, Y.; Zhang, B.; Wang, Z.; Jia, H. A macro-level life cycle environmental-economic impact and benefit assessment of sponge cities in China. Resour. Conserv. Recycl. 2024, 211, 107859. [Google Scholar] [CrossRef]

- Lawrence, A.; Marsalek, J.; Ellis, J.; Urbonas, B. Stormwater detention & BMPs. J. Hydraul. Res. 1996, 34, 799–813. [Google Scholar]

- Pugliese, F.; Gerundo, C.; De Paola, F.; Caroppi, G.; Giugni, M. Enhancing the urban resilience to flood risk through a decision support tool for the LID-BMPs optimal design. Water Resour. Manag. 2022, 36, 5633–5654. [Google Scholar] [CrossRef]

- Zhao, L.; Li, J.; Zhang, T.; Feng, P.; Wang, X.; Shen, J. Multi-method combined analysis of urban flood risks and its influencing factors under low impact development. J. Hydrol. 2024, 632, 130927. [Google Scholar] [CrossRef]

- Schulze, J.; Gehrmann, S.; Somvanshi, A.; Rudolph-Cleff, A. From District to City Scale: The Potential of Water-Sensitive Urban Design (WSUD). Water 2024, 16, 582. [Google Scholar] [CrossRef]

- Gimenez-Maranges, M.; Breuste, J.; Hof, A. Sustainable Drainage Systems for transitioning to sustainable urban flood management in the European Union: A review. J. Clean. Prod. 2020, 255, 120191. [Google Scholar] [CrossRef]

- Lim, H.S.; Lu, X.X. Sustainable urban stormwater management in the tropics: An evaluation of Singapore’s ABC Waters Program. J. Hydrol. 2016, 538, 842–862. [Google Scholar] [CrossRef]

- Xu, H.; Randall, M.; Fryd, O. Urban stormwater management at the meso-level: A review of trends, challenges and approaches. J. Environ. Manag. 2023, 331, 117255. [Google Scholar] [CrossRef]

- Griffiths, J.; Chan, F.K.S.; Shao, M.; Zhu, F.; Higgitt, D.L. Interpretation and application of Sponge City guidelines in China. Philos. Trans. R. Soc. A 2020, 378, 20190222. [Google Scholar] [CrossRef]

- Li, J.; Huang, X.; Chuai, X.; Yang, H. The impact of land urbanization on carbon dioxide emissions in the Yangtze River Delta, China: A multiscale perspective. Cities 2021, 116, 103275. [Google Scholar] [CrossRef]

- Su, X.; Shao, W.; Liu, J.; Jiang, Y.; Wang, J.; Yang, Z.; Wang, N. How does sponge city construction affect carbon emission from integrated urban drainage system? J. Clean. Prod. 2022, 363, 132595. [Google Scholar] [CrossRef]

- Pohl, J.; Hilty, L.M.; Finkbeiner, M. How LCA contributes to the environmental assessment of higher order effects of ICT application: A review of different approaches. J. Clean. Prod. 2019, 219, 698–712. [Google Scholar] [CrossRef]

- Wang, D.; Liu, X.; Li, H.; Chen, H.; Wang, X.; Li, W.; Cao, L.; Liu, J.; Zhang, T.; Wei, B. The Carbon Emission Intensity of Rainwater Bioretention Facilities. Water 2024, 16, 183. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, C.; Xie, H.; Li, Y.; Zhu, C.; Liu, M. Carbon Accounting and Carbon Emission Reduction Potential Analysis of Sponge Cities Based on Life Cycle Assessment. Water 2023, 15, 3565. [Google Scholar] [CrossRef]

- Lin, X.; Ren, J.; Xu, J.; Zheng, T.; Cheng, W.; Qiao, J.; Huang, J.; Li, G. Prediction of life cycle carbon emissions of sponge city projects: A case study in Shanghai, China. Sustainability 2018, 10, 3978. [Google Scholar] [CrossRef]

- Jiang, C.; Zhang, Y.; Zhang, X.; Han, Q.; Xiao, Y. Research on the carbon profit and loss correlation mechanism of sponge city construction life cycle in urban built up areas. Ecohydrol. Hydrobiol. 2024. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, X.; Wang, S.; Chen, L.; Shen, Z. Simulation and comprehensive evaluation of the multidimensional environmental benefits of sponge cities. Water 2023, 15, 2590. [Google Scholar] [CrossRef]

- Kavehei, E.; Jenkins, G.; Adame, M.; Lemckert, C. Carbon sequestration potential for mitigating the carbon footprint of green stormwater infrastructure. Renew. Sustain. Energy Rev. 2018, 94, 1179–1191. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, J.; Han, S.; Ding, L.; Zhao, X.; Liu, X.; Deng, H. A Study on Plant Selection for Low-Carbon Rain Gardens Based on an AHP-TOPSIS Model. Sustainability 2024, 16, 2097. [Google Scholar] [CrossRef]

- Li, Q.; Zhu, Y.; Zhu, Z. Calculation and optimization of the carbon sink benefits of green space plants in residential areas: A case study of Suojin Village in Nanjing. Sustainability 2022, 15, 607. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Zhang, L.; Li, Q.; Chen, J. Annual carbon emission calculation and green technology exploration of the green campus based on comprehensive energy. J. Phys. Conf. Ser. 2024, 2826, 012006. [Google Scholar] [CrossRef]

- Association, C.U.W. Guidelines for Carbon Accounting and EmissionReduction in the Urban Water Sector; China Architecture & Building Press: Beijing, China, 2022; Volume 202. [Google Scholar]

- Peng, Y.; Wang, Y.; Chen, H.; Wang, L.; Luo, B.; Tong, H.; Zou, Y.; Lei, Z.; Chen, S. Carbon reduction potential of a rain garden: A cradle-to-grave life cycle carbon footprint assessment. J. Clean. Prod. 2024, 434, 139806. [Google Scholar] [CrossRef]

- Wei, Y.; Cao, X.; Li, J.; Chang, Y. Greenhouse gas, water, and economic implications of permeable pavements: Quantification for pilot sponge cities in China. J. Clean. Prod. 2024, 471, 143424. [Google Scholar] [CrossRef]

- Cai, Y.; Zhao, Y.; Wei, T.; Fu, W.; Tang, C.; Yuan, Y.; Yin, Q.; Wang, C. Utilization of constructed wetland technology in China’s sponge city scheme under carbon neutral vision. J. Water Process Eng. 2023, 53, 103828. [Google Scholar] [CrossRef]

- Lu, Y.; Zhou, Y.; Zeng, S. Understanding the link between industrial stimulation effect and environmental impact of sponge city: With a focus on the construction phase. J. Clean. Prod. 2023, 389, 136113. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Toro-Huertas, E.I.; Güereca, L.P. Lifecycle sustainability assessment for the comparison of traditional and sustainable drainage systems. Sci. Total Environ. 2022, 817, 152959. [Google Scholar] [CrossRef]

- Dong, X.; Yi, W.; Yuan, P.; Song, Y. Optimization and trade-off framework for coupled green-grey infrastructure considering environmental performance. J. Environ. Manag. 2023, 329, 117041. [Google Scholar] [CrossRef]

- She, L.; Wei, M.; You, X.-y. Multi-objective layout optimization for sponge city by annealing algorithm and its environmental benefits analysis. Sustain. Cities Soc. 2021, 66, 102706. [Google Scholar] [CrossRef]

- Li, J.; Wang, H.; Li, H. Research progress of carbon emission accounting for urban stormwater systems based on content analysis method. Water Conserv. 2024, 40, 33–43. (In Chinese) [Google Scholar]

- Dos Santos, M.F.N.; Barbassa, A.P.; Vasconcelos, A.F.; Ometto, A.R. Stormwater management for highly urbanized areas in the tropics: Life cycle assessment of low impact development practices. J. Hydrol. 2021, 598, 126409. [Google Scholar] [CrossRef]

- Bledsoe, R.B.; Bean, E.Z.; Austin, S.S.; Peralta, A.L. A microbial perspective on balancing trade-offs in ecosystem functions in a constructed stormwater wetland. Ecol. Eng. 2020, 158, 106000. [Google Scholar] [CrossRef]

- Fan, L.; Wang, J.; Liu, X.; Luo, H.; Zhang, K.; Fu, X.; Li, M.; Li, X.; Jiang, B.; Chen, J. Whether the carbon emission from green roofs can be effectively mitigated by recycling waste building material as green roof substrate during five-year operation? Environ. Sci. Pollut. Res. 2020, 27, 40893–40906. [Google Scholar] [CrossRef]

- Teng, Y.; Li, C.Z.; Shen, G.Q.; Yang, Q.; Peng, Z. The impact of life cycle assessment database selection on embodied carbon estimation of buildings. Build. Environ. 2023, 243, 110648. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Wu, L.; She, N. Study on Carbon Reduction Capacity of Sponge City Facilities. In ICCREM 2022; ASCE: Preston, VA, USA, 2022; pp. 37–46. [Google Scholar]

- Ma, J. Carbon Source Analysis and Carbon Emission Study of Typical Measures for Sponge City Construction. Master’s Thesis, Shanxi Agricultural University, Jinzhong, China, 2018. (In Chinese). [Google Scholar]

- Lu, L. Life Cycle Assessment of Two Typical Low Impact Development Technology. Master’s Thesis, Beijing University of Civil Engineering and Architecture, Beijing, China, 2013. (In Chinese). [Google Scholar]

- Zhu, Y.; Shao, W.; Yang, Z. Carbon emission accounting for whole life cycle of sponge facilities. Water Conserv. 2023, 39, 32–38. (In Chinese) [Google Scholar]

- Zheng, T. Estimation of carbon emission during sponge city recoSnstruction of residential community. China Water Wastewater 2021, 37, 112–119. (In Chinese) [Google Scholar]

- Jia, Y. Study on Low Impact Development Technology Allocation Optimization and Carbon Emission Reduction in Sponge City Construction. Master’s Thesis, Tianjin University, Tianjin, China, 2017. (In Chinese). [Google Scholar]

- Li, J.; Zhang, X.; Li, H. Study on carbon emission accounting in construction and operation of a sponge city in Beijing. Water Resour. Prot. 2023, 39, 86–93. (In Chinese) [Google Scholar]

- Wang, Y.; Li, H.; Abdelhady, A.; Harvey, J. Initial evaluation methodology and case studies for life cycle impact of permeability of permeable pavements. Int. J. Transp. Sci. Technol. 2018, 7, 169–178. [Google Scholar] [CrossRef]

- Hu, F.L.Y.; Zhou, X.; Li, Y.; Yu, L.; Zhang, S. Assessment of Carbon Emission Reduction Benefits of Sponge City Construction in Typical Old District. China Water Supply Drain. 2024, 40, 130–136. (In Chinese) [Google Scholar]

- Zhai, M.; Huang, D.; She, X. China’s Energy Development from the BP Statistical Yearbook of World Energy. Energy Environ. 2014, 6, 16–17. (In Chinese) [Google Scholar]

- Tian, P.C.S.; Mao, B.; Zhou, Q.; Huang, J.; Tong, R. Impact of new energy vehicles on carbon emissions of private cars in China. J. Chang. Univ. (Nat. Sci. Ed.) 2023, 43, 88–98. (In Chinese) [Google Scholar]

- Li, M.; Bekö, G.; Zannoni, N.; Pugliese, G.; Carrito, M.; Cera, N.; Moura, C.; Wargocki, P.; Vasconcelos, P.; Nobre, P. Human metabolic emissions of carbon dioxide and methane and their implications for carbon emissions. Sci. Total Environ. 2022, 833, 155241. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Ren, Z.; Wang, C.; Zhang, P.; Ma, Z.; Hong, S.; Hong, W.; He, X. Spatiotemporal patterns of urban forest carbon sequestration capacity: Implications for urban CO2 emission mitigation during China’s rapid urbanization. Sci. Total Environ. 2024, 912, 168781. [Google Scholar] [CrossRef] [PubMed]

| Construction Model | Facilities | Materials | Building Materials Usage | Carbon Emission Factor | Carbon Emission (kgCO2) | Total | ||

|---|---|---|---|---|---|---|---|---|

| Unit | Value | Unit | Value | |||||

| Traditional construction | Ordinary impermeable paving | Concrete bricks | m3 | 378.58 | kgCO2/m3 | 334.80 [35] | 126,748.72 | 764,707.61 |

| M10 cement mortar | t | 252.13 | kgCO2/t | 740.60 [35] | 186,730.85 | |||

| C15 concrete | m3 | 688.33 | kgCO2/m3 | 247.65 [35] | 170,464.43 | |||

| gravel | t | 1393.86 | kgCO2/t | 2.18 [35] | 3038.62 | |||

| Green space | Assuming that the vegetation is locally transplanted and the required soils are used nearby, the carbon emissions are negligible | |||||||

| Pipelines | UPVC | t | 17.60 | kgCO2/t | 7930.00 [14] | 139,568.00 | ||

| Reinforced Concrete Pipe | t | 72.11 | kgCO2/t | 1915.92 [14] | 138,156.99 | |||

| Spong city | Permeable pavement | Permeable brick | m3 | 378.58 | kgCO2/m3 | 320.00 [22] | 121,145.73 | 768,208.42 |

| Sands | m3 | 206.50 | kgCO2/m3 | 15 [35] | 3097.48 | |||

| Pervious concrete | m3 | 688.33 | kgCO2/m3 | 360.00 [36] | 247,798.08 | |||

| Graded aggregates | m3 | 1032.49 | kgCO2/m3 | 8.76 [36] | 9044.63 | |||

| Bioretention facility | Bark filler | Assuming that the vegetation is locally transplanted and the required soils are used nearby, the carbon emissions are negligible | ||||||

| Plantation | ||||||||

| Geotextile | m2 | 4093.30 | kgCO2/m2 | 0.16 [36] | 654.93 | |||

| Grit | t | 1361.02 | kgCO2/t | 6.05 [36] | 8234.18 | |||

| HDPE Impermeable membrane (0.5 mm PE–200 g Non-woven Fabric–150 g Woven fabric) | t | 47.71 | kgCO2/t | 2620.00 [22] | 125,000.20 | |||

| Green roof | Paulownia pigment | t | 151.74 | — | — | — | ||

| Long fiber polyester filter cloth | m2 | 5419.26 | kgCO2/m2 | 0.16 [36] | 867.08 | |||

| PVC Drainage and Storage Board | t | 130.92 | kgCO2/t | 1765.00 [22] | 231,073.80 | |||

| High-density polystyrene film (HDPE) | t | 0.23 | kgCO2/t | 2620.00 [22] | 589.50 | |||

| SBS-modified bitumen waterproofing membrane | m2 | 7225.68 | kgCO2/m2 | 2.37 [22] | 17,124.86 | |||

| Rain barrel (0.9 m high) | PE plastic | m3 | 39.96 | kgCO2/m3 | 73.98 [22] | 2956.24 | ||

| Others | PE pipe | m | 875.65 | kgCO2/m | 0.71 [36] | 621.71 | ||

| Construction Model | Building Materials | Weights (t) | Carbon Emission Factor [kgCO2/(t·km)] | Carbon Emission (kgCO2) | Total |

|---|---|---|---|---|---|

| Traditional construction | Concrete block | 946.45 | 0.057 | 9494.80 | 119,687.00 |

| M10 cement Mortar | 252.13 | 0.286 | 12,691.40 | ||

| C15 concrete | 1651.99 | 0.179 | 52,044.20 | ||

| Crushed | 1393.86 | 0.179 | 43,912.30 | ||

| UPVC | 17.60 | 0.179 | 554.47 | ||

| Reinforced Concrete pipes | 72.11 | 0.078 | 989.93 | ||

| Spong city | Permeable brick | 1892.90 | 0.057 | 18,989.60 | 163,723.00 |

| Sands | 454.30 | 0057 | 12,952.90 | ||

| Pervious concrete | 1789.65 | 0.179 | 56,381.20 | ||

| Graded aggregates | 1600.36 | 0.179 | 50,417.80 | ||

| Geotextile | 0.61 | 0.162 | 17.51 | ||

| HDPE impermeable Membrane | 47.71 | 0.179 | 1503.06 | ||

| Grit | 1361.02 | 0.057 | 13,653.80 | ||

| Paulownia pigment | 151.74 | 0.179 | 4780.39 | ||

| Long Fibre Polyester Filter Cloth | 1.08 | 34.15 | |||

| PVC drainage and Storage board | 130.92 | 4124.50 | |||

| High-density Polystyrene film (HDPE) | 0.23 | 7.09 | |||

| SBS bituminous Waterproofing Membranes | 23.99 | 755.76 | |||

| PE plastics | 1.20 | 37.77 | |||

| PE pipe | 2.36 | 0.162 | 67.28 |

| Carbon Reduction Activities | Carbon Emission Reduction (kgCO2) |

|---|---|

| Green field Carbon Sequestration | 274,877.00 |

| Rainwater Purification | 209,408.13 |

| Rainwater Utilization | 107,138.07 |

| Building Energy Efficiency | 663,100.65 |

| Peak Runoff Reduction | 205,783.30 |

| (Grand) total | 1,460,307.15 |

| Stage | Construction Stage | Operation and Maintenance Stage | Demolition and Recycling Phase | Carbon Sinks | Total | |

|---|---|---|---|---|---|---|

| Facilities | ||||||

| Bioretention facility | 74.51 | 5.16 | 1.51 | −66.77 | 14.41 | |

| Green roof | 75.66 | 2.55 | 3.48 | −10.95 | 70.74 | |

| Permeable Pavement | 81.37 | 0.51 | 5.27 | — | 87.15 | |

| Facilities | Numeric Type | Carbon Emissions per Unit Area at Different Phases | ||||

|---|---|---|---|---|---|---|

| Planning and Construction Stage (kgCO2/m2) | Operation and Maintenance Stage | Demolition and Recycling Phase (kgCO2/m2) | The Whole Life Cycle [kgCO2/(30a·m2)] | |||

| Indirect Carbon Emissions [kgCO2/(a·m2)] | Direct Carbon Emissions | |||||

| Bioretention facility | Ground | 5.34~229.612 | 0.171~2.174 | — | 18.12 | 54.9~98.4 |

| averages | 82.382 | 0.802 | — | — | 71.95 | |

| Green roof | Ground | 8.98~85.588 | 0.234~9.70 | — | 11.659 | 64.20 |

| averages | 59.970 | 4.967 | — | — | — | |

| Permeable pavement | Ground | 31.481~150.14 | 0.01~0.692 | — | — | 86.09~146.2 |

| averages | 82.211 | 0.24 | — | — | 107.81 | |

| Parameters | Greenhouse Gas Emission Reductions Corresponding to Typical Probabilities of Occurrence/(kgCO2) | ||||||

|---|---|---|---|---|---|---|---|

| N | Average Value (kgCO2) | CV | CS/CV | P = 20% | P = 50% | P = 75% | P = 95% |

| 67 | 42,140.90 | 0.05 | 6.4 | 43,873.62 | 42,028.70 | 40,665.22 | 38,877.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Liu, X.; Liu, J.; Du, C.; Liang, M.; Li, W.; Cao, L.; Wang, D.; Wang, H.; Zhang, T.; et al. Carbon Emission Accounting and Reduction Evaluation in Sponge City Residential Areas. Water 2024, 16, 2535. https://doi.org/10.3390/w16172535

Ma Y, Liu X, Liu J, Du C, Liang M, Li W, Cao L, Wang D, Wang H, Zhang T, et al. Carbon Emission Accounting and Reduction Evaluation in Sponge City Residential Areas. Water. 2024; 16(17):2535. https://doi.org/10.3390/w16172535

Chicago/Turabian StyleMa, Yingqiang, Xuefeng Liu, Jianlin Liu, Chengyin Du, Mei Liang, Wei Li, Lianbao Cao, Deqi Wang, Hao Wang, Tingting Zhang, and et al. 2024. "Carbon Emission Accounting and Reduction Evaluation in Sponge City Residential Areas" Water 16, no. 17: 2535. https://doi.org/10.3390/w16172535