A Geophysical-Drilling-Hydrochemical Coupled Method for Accurate Detection of Concealed Water-Conducting Faults in Coal Mines

Abstract

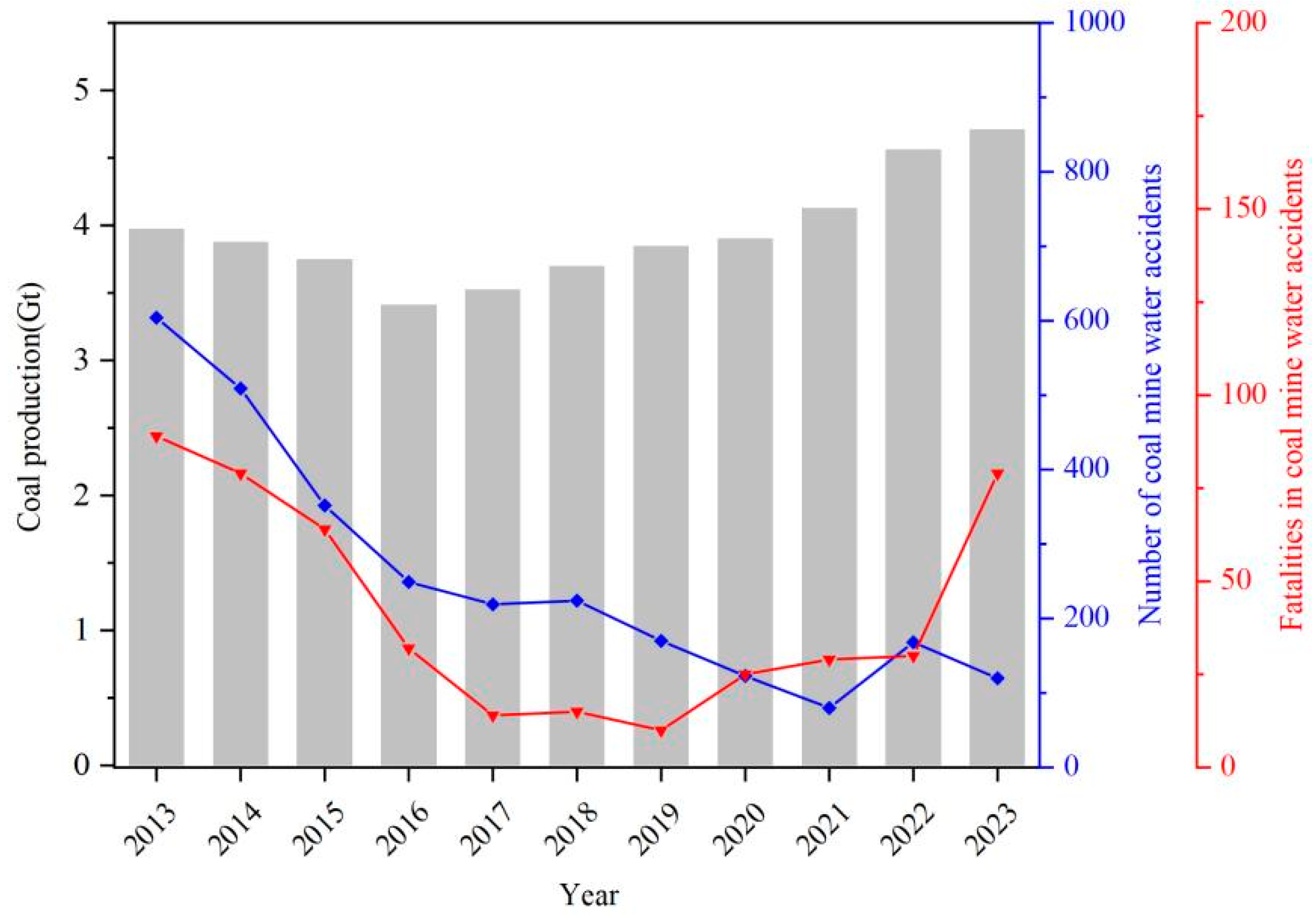

:1. Introduction

2. Proposal of a Geophysical-Drilling-Geochemical Coupled Method

- (1)

- Prediction of potential concealed water-conducting structures through data analysis aided by surface exploration

- (2)

- Detection of the location and water abundance of water-conducing structures by integrated geophysical exploration (IGE)

- (3)

- Verification of the location and parameters of geological structures by hydrogeological drilling

- (4)

- Identification of water source and potential volume through hydrochemical tests

3. Application of the GDH Method

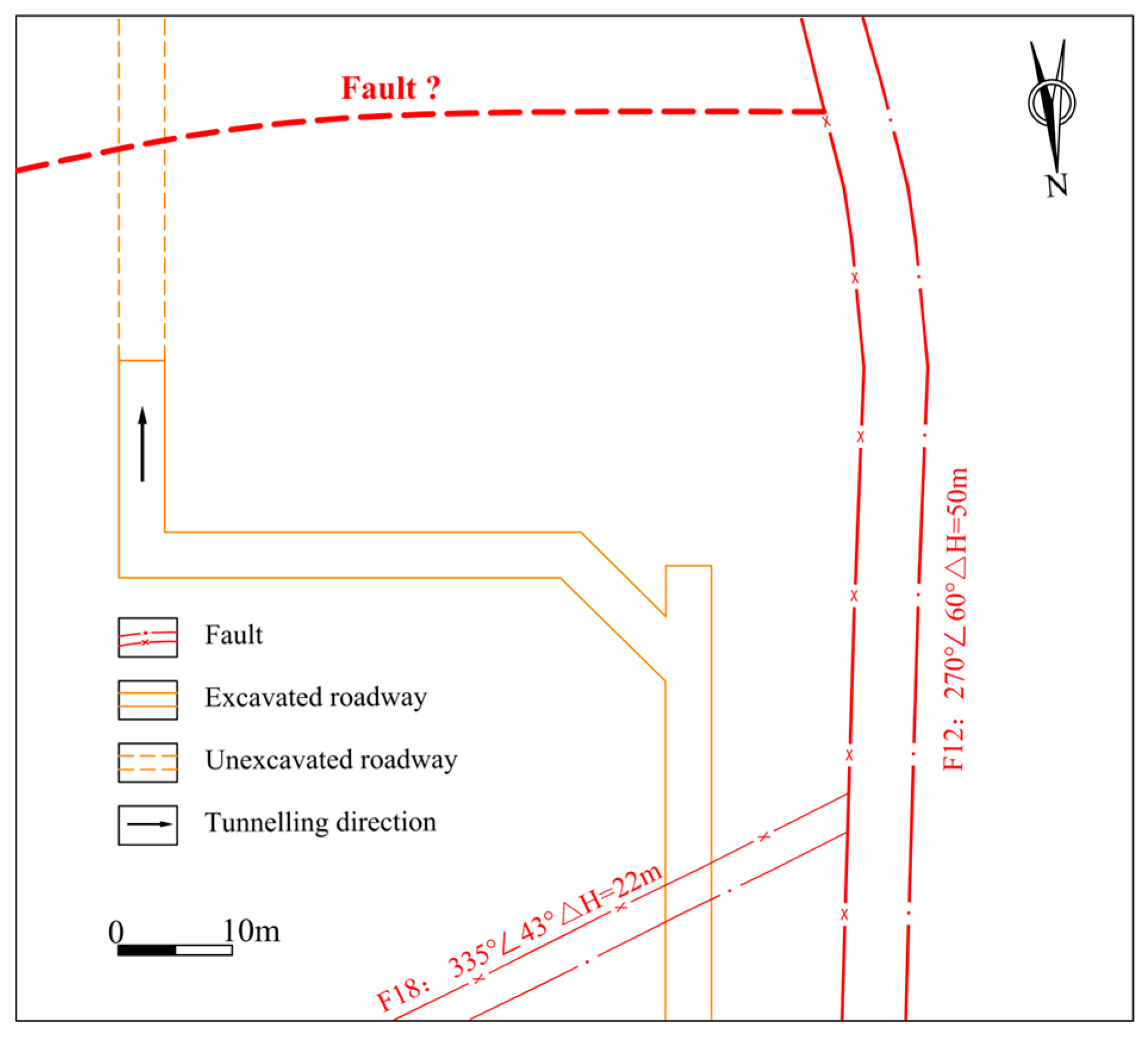

3.1. Background Information

3.2. Accurate Detection Using GDH Method

3.2.1. Integrated Geophysical Method

- (1)

- Mine seismic exploration

- (2)

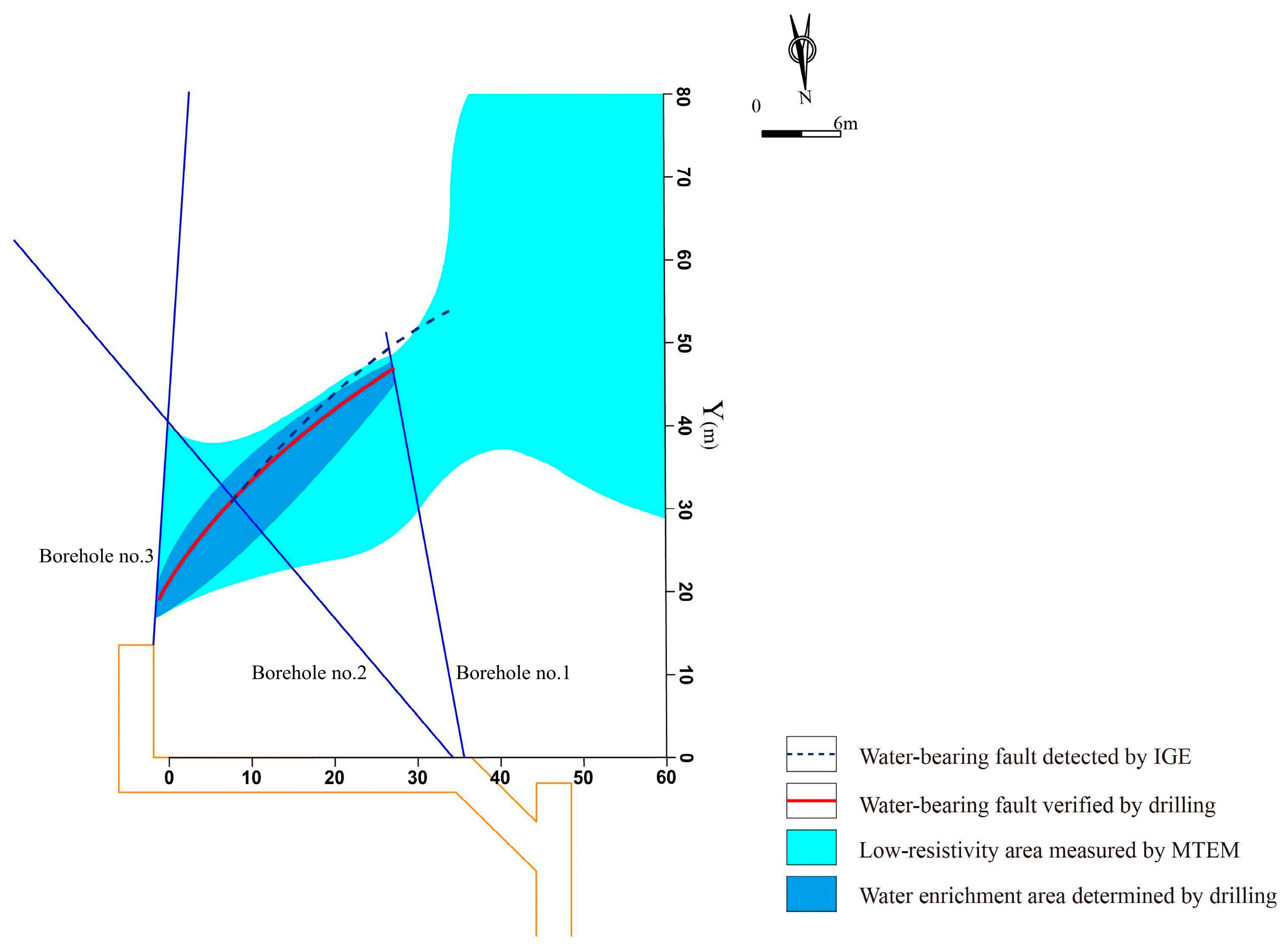

- Mine transient electromagnetic method

3.2.2. Hydrogeological Drilling

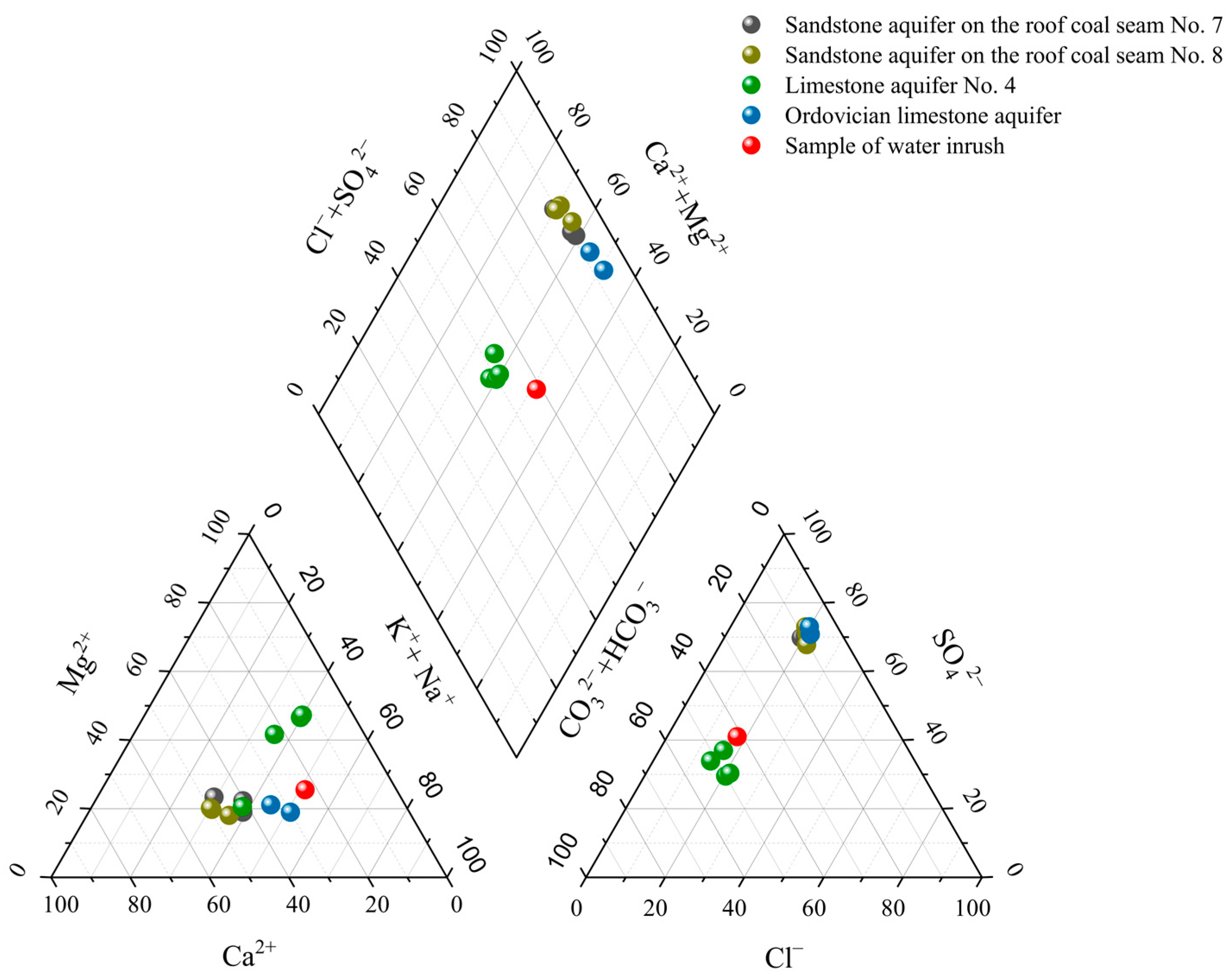

3.2.3. Hydrochemical Analysis

4. Discussion

5. Conclusions

- (1)

- The integrated geophysical method, combining seismic exploration and electrical prospecting, accurately detected the location and water content of concealed geological structures. The results of the geophysical exploration provided a target area for hydrological drilling, thereby making the drilling work more efficient and focused.

- (2)

- Hydrogeological drilling provided rock characteristics and hydrogeological features for both the analysis of the properties of concealed water-conducting structures and the verification of geophysical prospecting results. Meanwhile, it directly exposed the groundwater and obtained water samples for hydrochemical analysis.

- (3)

- Hydrochemical analysis was employed to analyze the inrush water sources and runoff conditions. According to the spatial relations between the source aquifer and mining spaces, the vertical extension range of the concealed water-conducting structures was roughly estimated.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zeng, Y.; Wu, Q.; Zhao, S.; Miao, Y.; Zhang, Y.; Mei, A.; Meng, S.; Liu, X. Characteristics, causes, and prevention measures of coal mine water hazard accidents in China. Coal Sci. Technol. 2023, 51, 1–14. [Google Scholar]

- Song, Z.; Hao, J.; Shang, J.; Dan, Y. Study on water inrush from fault’s prevention and control theory. J. China Coal Soc. 2013, 38, 1511–1515. [Google Scholar]

- Wu, Q. Progress, problems and prospects of prevention and control technology of mine water and reutilization in China. J. China Coal Soc. 2014, 39, 795–805. [Google Scholar]

- Hu, W.; Tian, G. Mine water disaster type and prevention and control countermeasures in China. Coal Sci. Technol. 2010, 38, 92–96. [Google Scholar]

- Xu, Y.; Zhang, E.; Luo, Y.; Yi, K. Mechanism of Water Inrush and Controlling Techniques for Fault-Traversing Roadways with Floor Heave Above Highly Confned Aquifers. Mine Water Environ. 2020, 39, 320–330. [Google Scholar] [CrossRef]

- Gu, H.; Lai, X.; Tao, M.; Momeni, A.; Zhang, Q. Dynamic mechanical mechanism and optimization approach of roadway surrounding coal water infusion for dynamic disaster prevention. Measurement 2023, 223, 113639. [Google Scholar] [CrossRef]

- Zhang, Z.; Gao, Y.; Wu, Q.; Wei, S. Discussion on the technical system of solid prevention and control on mine flooding. J. China Coal Soc. 2013, 38, 378–383. [Google Scholar]

- Chudy, K. Mine Water as Geothermal Resource in Nowa Ruda Region (SW Poland). Water 2022, 14, 136. [Google Scholar] [CrossRef]

- Jin, D.; Zhao, C.; Duan, J.; Qiao, W.; Lu, J.; Li, P.; Zhou, Z.; Li, D. Research on 3D monitoring and intelligent early warning system for water hazard of coal seam floor. J. Chna Coal Soc. 2020, 45, 2256–2264. [Google Scholar] [CrossRef]

- Rey, J.; Martínez, J.; Hidalgo, M.; Mendoza, R.; Sandoval, S. Assessment of Tailings Ponds by a Combination of Electrical (ERT and IP) and Hydrochemical Techniques (Linares, Southern Spain). Mine Water Environ. 2021, 40, 298–307. [Google Scholar] [CrossRef]

- Ding, B. Features and prevention countermeasures of major disasters occurred in China coal mine. Coal Sci. Technol. 2017, 45, 109–114. [Google Scholar]

- Diamond, R.; Staden, C.; Dippenaa, M. Tracing Mine Water Flows in a Dolomite Quarry, South Africa, Using Hydrochemistry and Stable Isotopes. Mine Water Environ. 2024, 43, 278–293. [Google Scholar] [CrossRef]

- Han, D.; Li, D.; Cheng, J. DC method of advanced detecting disastrous water-conducting or water-bearing geological structures along same layer. J. China Coal Soc. 2010, 35, 635–639. [Google Scholar]

- Teixeira, F.; Chew, W. Finite-Difference computation of transient electromagnetic waves for cylindrical Geometries in complex media. IEEE Trans. Geosci. Remote Sens. 2000, 38, 1530–1543. [Google Scholar] [CrossRef]

- Yu, J.; Liu, Z.; Liu, S. Theoretical analysis of mine transient electromagnetic method and its application in detecting water burst structures in deep coal stope. J. China Coal Soc. 2007, 32, 818–821. [Google Scholar]

- Danielson, J.; Auken, E.; Jorgensen, F. The application of the transient electromagnetic method in hydro-geophysical surveys. J. Appl. Geophys. 2003, 53, 181–198. [Google Scholar] [CrossRef]

- Bohlen, T.; Borm, G.; Giese, R.; Klose, C.; Mielitz, S.; Otto, P. ISIS-integrated seismic imaging system for the geological prediction ahead of underground construction. Eur. Assoc. Geosci. Eng. 2003, cp-6-00209. [Google Scholar] [CrossRef]

- Otto, R.; Button, E.; Bretterebner, H.; Schwab, P. The application of TRT-True Reflection Tomography-at the Unterwald tunnel. Felsbau 2002, 20, 51–56. [Google Scholar]

- Sattel, G.; Frey, P.; Amberg, R. Prediction ahead of the tunnel face by seismic methods-pilot project in Centovalli Tunnel, Locarno, Switzerland. First Break 1992, 10, 19–25. [Google Scholar] [CrossRef]

- Liu, S.; Liu, J.; Yue, J. Development status and key problems of Chinese mining geophysical technology. J. China Coal Soc. 2014, 39, 19–25. [Google Scholar]

- Lu, T.; Liu, S.; Wang, B.; Wu, R.; Hu, X. A Review of Geophysical Exploration Technology for Mine Water Disaster in China: Applications and Trends. Mine Water Environ. 2017, 36, 331–340. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, T. The seismic reflection method predicting tunnel geological hazards. Prog. Geophys. 2006, 21, 643–649. [Google Scholar]

- Dong, D.; Zhang, J. Discrimination Methods of Mine Inrush Water Source. Water 2023, 15, 3237. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Y.; Xu, Z.; Zhang, G.; Liu, Y.; Ding, J. Analysis of composition of mine inflow from complicated multi-aquifer affecting safety production in coal mine. J. Min. Saf. Eng. 2010, 3, 433–437. [Google Scholar]

- Wei, W.; Lu, X.; Shi, L. Identification method of multi-water source of mine water inrush. J. China Coal Soc. 2010, 5, 811–815. [Google Scholar]

- Yin, S.; Xu, B.; Yin, H.; Cao, M.; Ding, Y.; Liang, M. Basic structure and connotation of mine water prevention and control discipline. Coal Sci. Technol. 2023, 51, 24–35. [Google Scholar]

| Borehole No. | Azimuth (°) | Dip (°) | Diameter (mm) | Depth (m) | Maximum Water Inrush (m3/h) |

|---|---|---|---|---|---|

| 1 | 174 | −0.5 | 75 | 60 | 30 |

| 2 | 144 | 12 | 75 | 120 | 70 |

| 3 | 188 | 17 | 75 | 150 | 50 |

| Water Aquifer | Sample Number | Concentration (mg/L) | |||||

|---|---|---|---|---|---|---|---|

| Ca2+ | Mg2+ | Na+ + K+ | HCO3− | Cl− | SO42− | ||

| Sandstone aquifer in the roof of coal seam No. 7 | 1 | 290.20 | 86.92 | 216.42 | 201.97 | 212.90 | 1029 |

| 2 | 306.21 | 84.03 | 326.83 | 211.13 | 264.80 | 1223.28 | |

| 3 | 252.90 | 86.79 | 268.41 | 180.61 | 226.64 | 1061.52 | |

| Sandstone aquifer in the roof of coal seam No. 8 | 1 | 372.94 | 90.32 | 264.96 | 200.75 | 270.45 | 1280.9 |

| 2 | 328.05 | 80.84 | 229.54 | 206.85 | 256.72 | 1075.31 | |

| 3 | 357.35 | 92.5 | 333.73 | 211.13 | 271.42 | 1425.78 | |

| Limestone aquifer No. 4 | 1 | 88.38 | 26.62 | 101.75 | 319.12 | 52.34 | 165.87 |

| 2 | 25.53 | 52.28 | 92.28 | 295.84 | 59.72 | 183.99 | |

| 3 | 23.57 | 52.28 | 90.87 | 270.11 | 68.74 | 132.54 | |

| 4 | 47.13 | 52.28 | 90.87 | 270.11 | 68.74 | 132.54 | |

| Ordovician limestone aquifer | 1 | 335.23 | 126.44 | 509.29 | 237.17 | 373.25 | 1674.39 |

| 2 | 290.66 | 108.13 | 604.39 | 195.32 | 335.72 | 1677.68 | |

| Sample of water inrush | 27.25 | 38.45 | 146.97 | 299.24 | 74.56 | 233.79 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, T.; Liu, H.; Jia, H.; Wang, B. A Geophysical-Drilling-Hydrochemical Coupled Method for Accurate Detection of Concealed Water-Conducting Faults in Coal Mines. Water 2024, 16, 2619. https://doi.org/10.3390/w16182619

Lu T, Liu H, Jia H, Wang B. A Geophysical-Drilling-Hydrochemical Coupled Method for Accurate Detection of Concealed Water-Conducting Faults in Coal Mines. Water. 2024; 16(18):2619. https://doi.org/10.3390/w16182619

Chicago/Turabian StyleLu, Tuo, Haodong Liu, Hailiang Jia, and Bo Wang. 2024. "A Geophysical-Drilling-Hydrochemical Coupled Method for Accurate Detection of Concealed Water-Conducting Faults in Coal Mines" Water 16, no. 18: 2619. https://doi.org/10.3390/w16182619