Change in the Microstructure and Fractal Characteristics of Intact and Compacted Loess Due to Its Collapsibility

Abstract

:1. Introduction

2. Test Design and Methods

2.1. Test Material

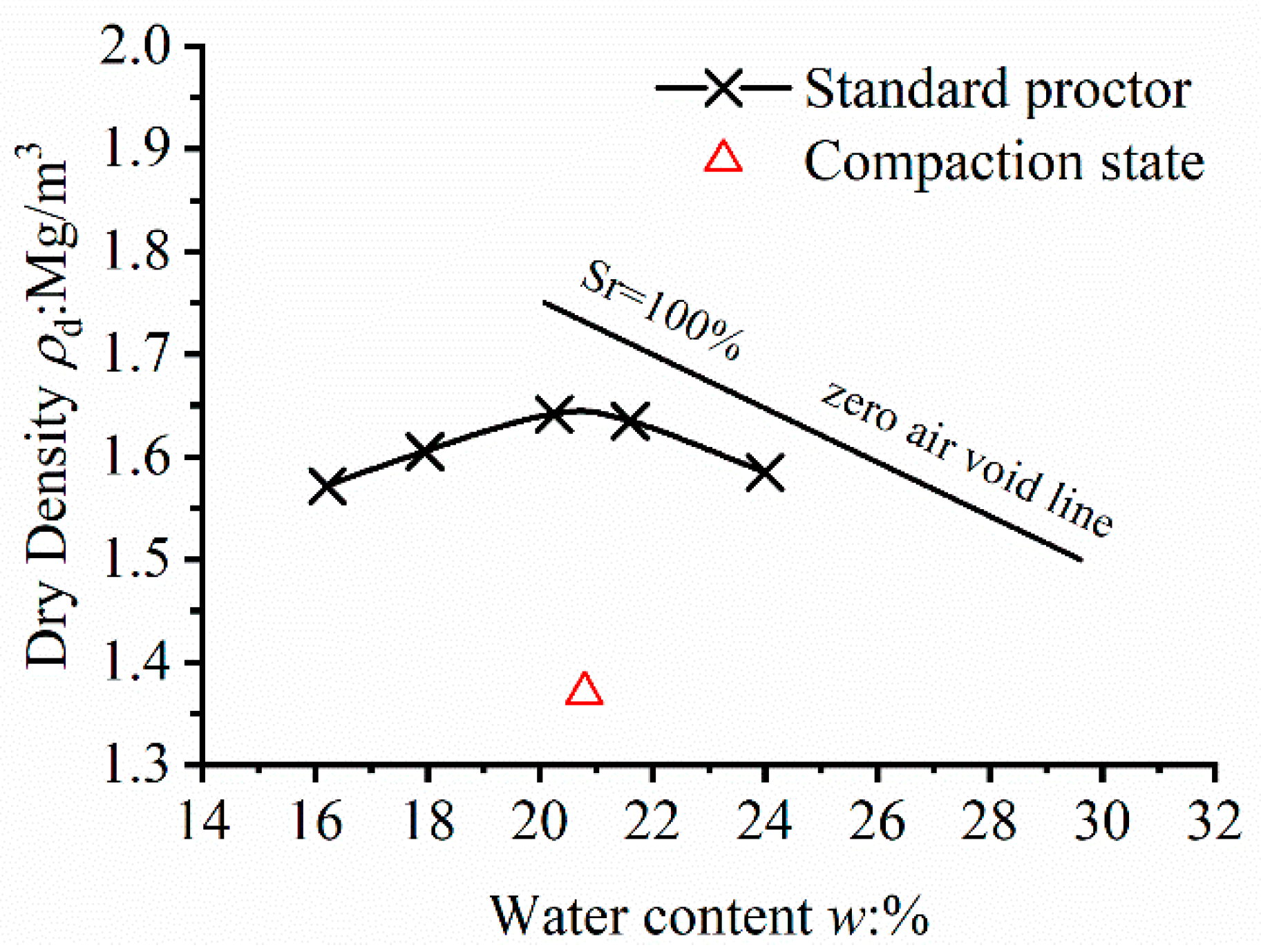

2.2. Preparation of Specimens

2.3. Oedometer Tests

2.4. MIP Tests

3. Models for Determining the Fractal Dimension of Loess

3.1. Capillary Pressure Model

3.2. Menger Sponge Model

3.3. Thermodynamic Law-Based Model

4. Results and Analysis

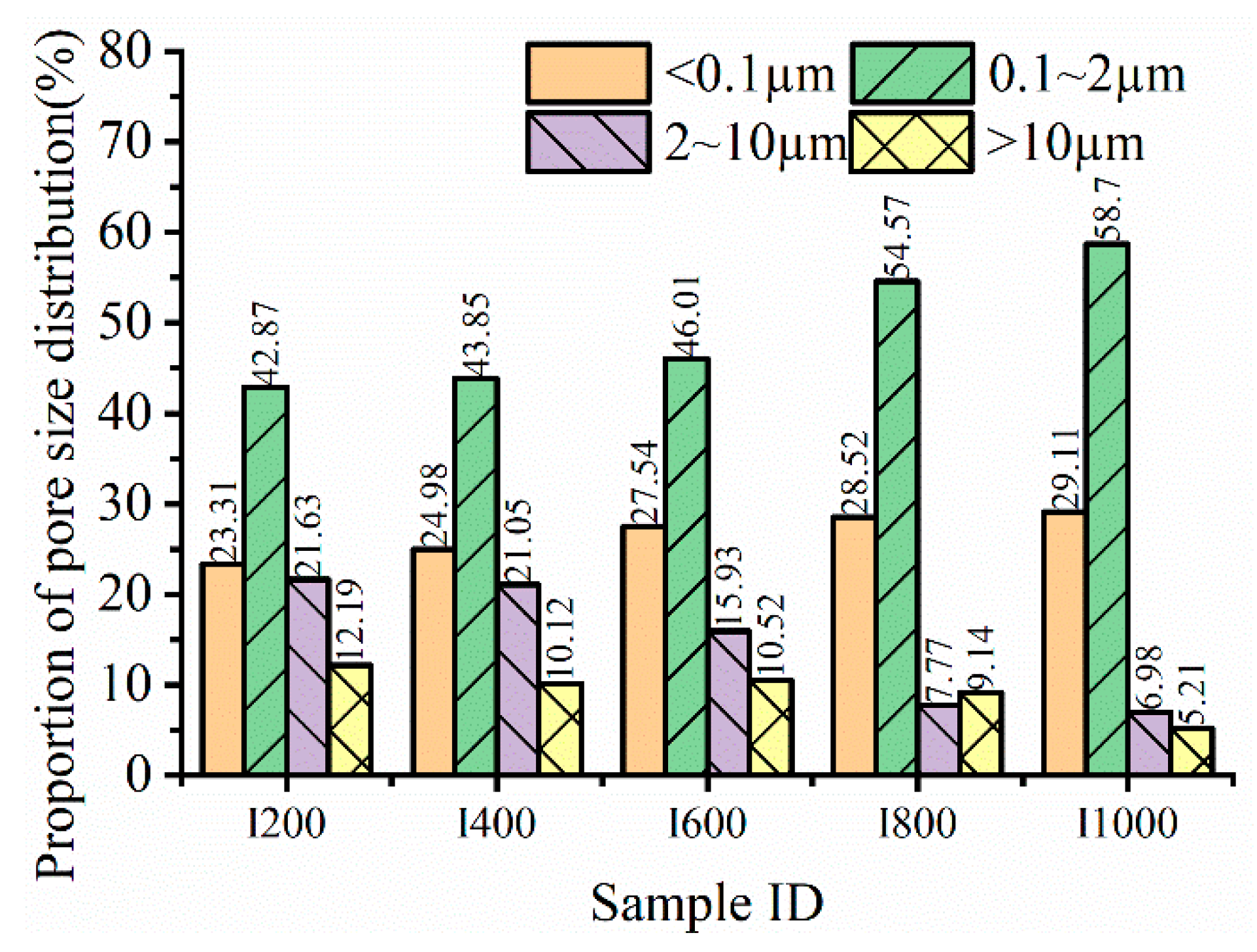

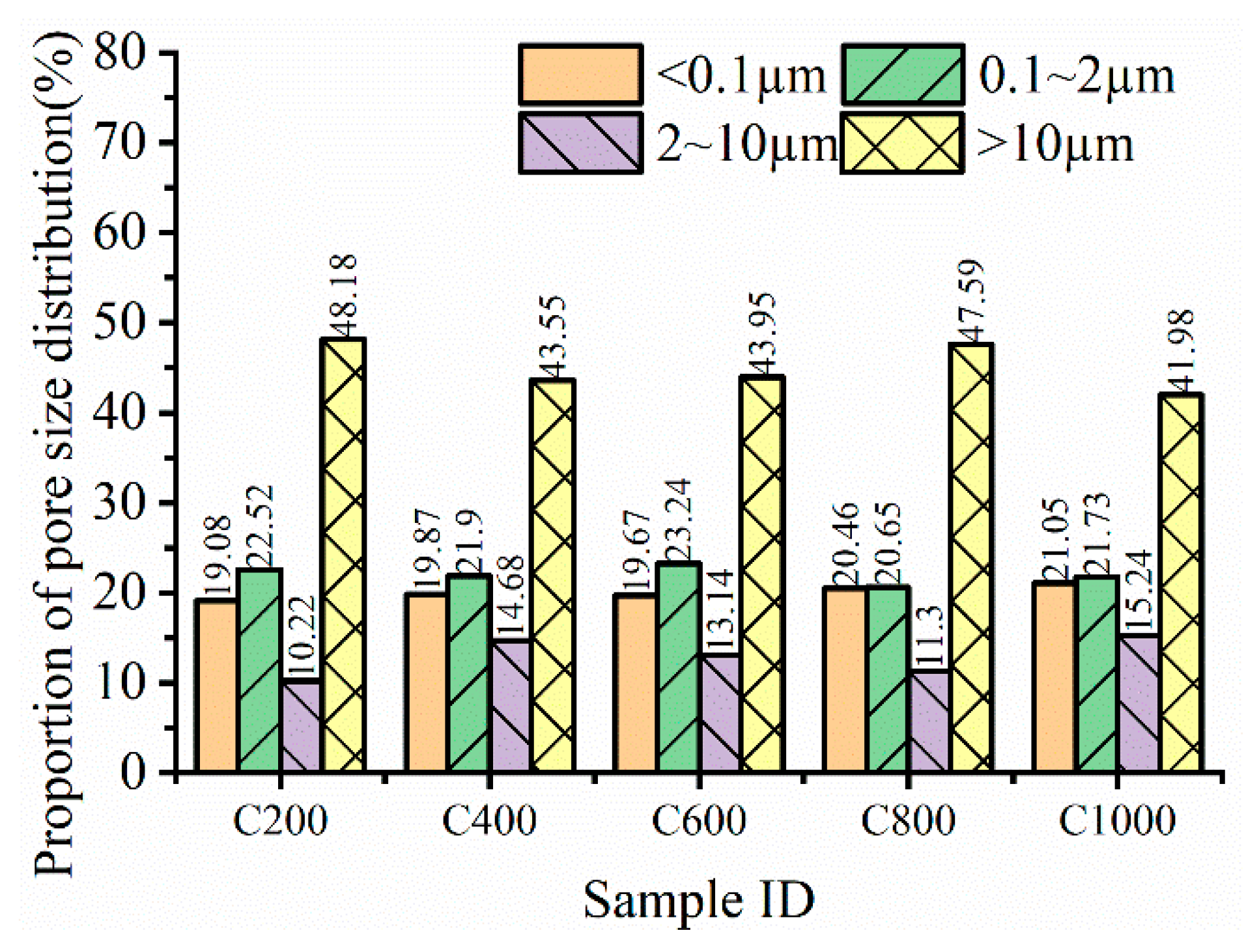

4.1. Pore Distribution Characteristics

4.2. Fractal Dimension (Ds) Determined by the Capillary Pressure Model

4.3. The Fractal Dimension (Dm) Determined by the Menger Sponge Model

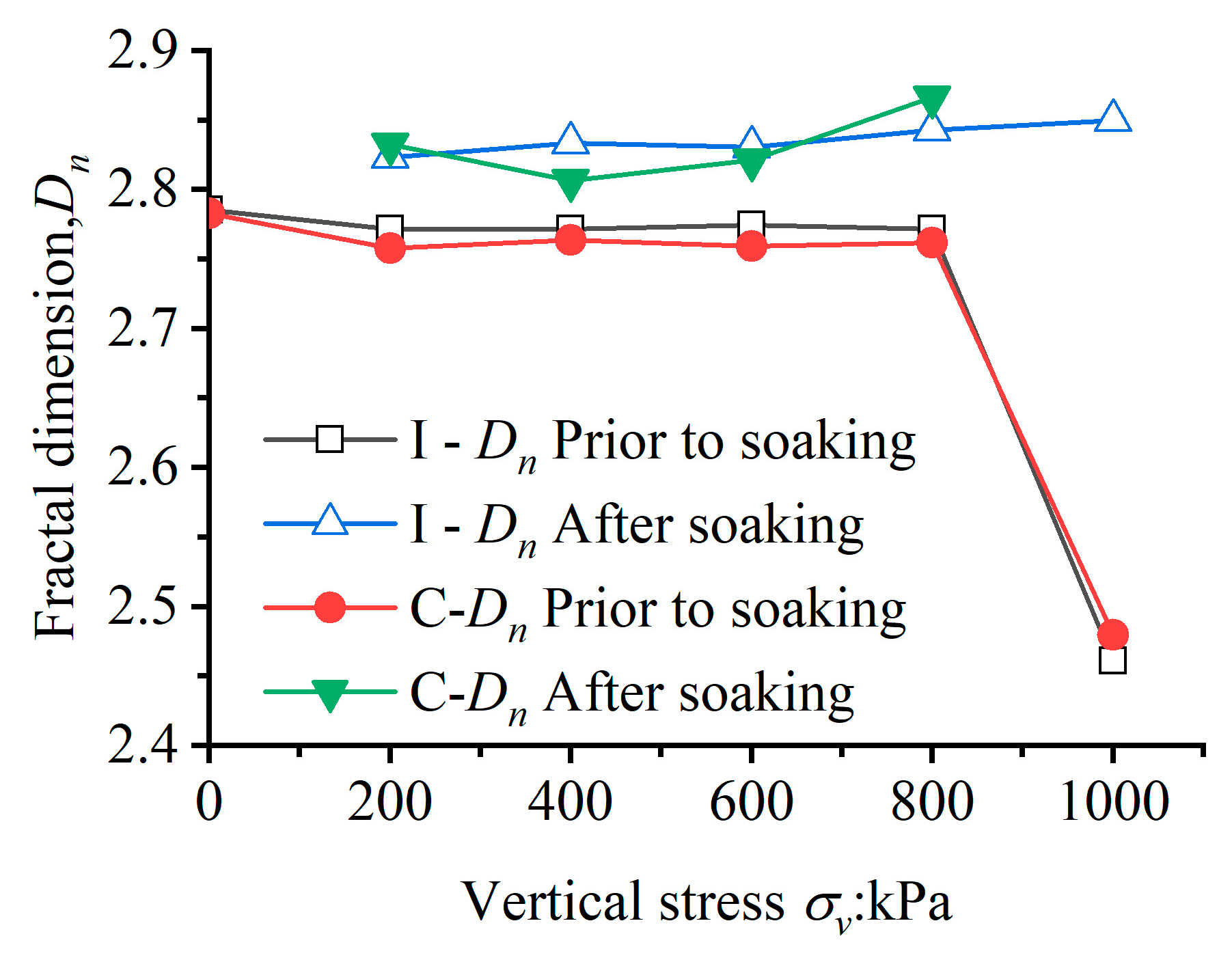

4.4. The Fractal Dimension (Dn) Determined by the Thermodynamic Law-Based Model

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Derbyshire, E.; Mellors, T.W. Geological and Geotechnical Characteristics of Some Loess and Loessic Soils from China and Britain: A Comparison. Eng. Geol. 1988, 25, 135–175. [Google Scholar] [CrossRef]

- Gao, L.; Shao, M. The Interpolation Accuracy for Seven Soil Properties at Various Sampling Scales on the Loess Plateau, China. J. Soils Sediments 2012, 12, 128–142. [Google Scholar] [CrossRef]

- Yao, X.; Fu, B.; Lü, Y.; Chang, R.; Wang, S.; Wang, Y.; Su, C. The Multi-Scale Spatial Variance of Soil Moisture in the Semi-Arid Loess Plateau of China. J. Soils Sediments 2012, 12, 694–703. [Google Scholar] [CrossRef]

- Xie, W.; Li, P.; Zhang, M.; Cheng, T.; Wang, Y. Collapse Behavior and Microstructural Evolution of Loess Soils from the Loess Plateau of China. J. Mt. Sci. 2018, 15, 1642–1657. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Z.; Xue, Z. A New Method of Assessing the Collapse Sensitivity of Loess. Bull. Eng. Geol. Environ. 2018, 77, 1287–1298. [Google Scholar] [CrossRef]

- Wang, L.; Shao, S.; She, F. A New Method for Evaluating Loess Collapsibility and Its Application. Eng. Geol. 2020, 264, 105376. [Google Scholar] [CrossRef]

- Leng, Y.; Peng, J.; Wang, S.; Lu, F. Development of Water Sensitivity Index of Loess from Its Mechanical Properties. Eng. Geol. 2021, 280, 105918. [Google Scholar] [CrossRef]

- Ge, M.; Pineda, J.A.; Sheng, D.; Burton, G.J.; Li, N. Microstructural Effects on the Wetting-Induced Collapse in Compacted Loess. Comput. Geotech. 2021, 138, 104359. [Google Scholar] [CrossRef]

- Wang, H.; Ni, W.; Liu, H.; Huang, M.; Yuan, K.; Li, L.; Li, X. Study of the Repeated Collapsibility of Undisturbed Loess in Guyuan, China. Bull. Eng. Geol. Environ. 2021, 80, 6321–6330. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, J.; Chen, C.; Wang, S. The Compression and Collapse Behaviour of Intact Loess in Suction-Monitored Triaxial Apparatus. Acta Geotech. 2020, 15, 529–548. [Google Scholar] [CrossRef]

- Mu, Q.Y.; Zhou, C.; Ng, C.W.W. Compression and Wetting Induced Volumetric Behavior of Loess: Macro- and Micro-Investigations. Transp. Geotech. 2020, 23, 100345. [Google Scholar] [CrossRef]

- Wang, J.-D.; Li, P.; Ma, Y.; Vanapalli, S.K.; Wang, X.-G. Change in Pore-Size Distribution of Collapsible Loess Due to Loading and Inundating. Acta Geotech. 2020, 15, 1081–1094. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, F.; Ma, F.; Wang, M.; Bai, X.; Zheng, Y.; Yin, H.; Zhang, G. Collapsibility, Composition, and Microstructure of Loess in China. Can. Geotech. J. 2016, 53, 673–686. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Sadeghi, H.; Hossen, S.B.; Chiu, C.-K.; Alonso, E.; Baghbanrezvan, S. Water Retention and Volumetric Characteristics of Intact and Re-Compacted Loess. Can. Geotech. J. 2016, 53, 1258–1269. [Google Scholar] [CrossRef]

- Shao, X.; Zhang, H.; Tan, Y. Collapse Behavior and Microstructural Alteration of Remolded Loess under Graded Wetting Tests. Eng. Geol. 2018, 233, 11–22. [Google Scholar] [CrossRef]

- Delage, P.; Audiguier, M.; Cui, Y.-J.; Howat, M.D. Microstructure of a Compacted Silt. Can. Geotech. J. 1996, 33, 150–158. [Google Scholar] [CrossRef]

- Rogers, C.D.F.; Dijkstra, T.A.; Smalley, I.J. Hydroconsolidation and Subsidence of Loess: Studies from China, Russia, North America and Europe. Eng. Geol. 1994, 37, 83–113. [Google Scholar] [CrossRef]

- Jiang, M.; Zhang, F.; Hu, H.; Cui, Y.; Peng, J. Structural Characterization of Natural Loess and Remolded Loess under Triaxial Tests. Eng. Geol. 2014, 181, 249–260. [Google Scholar] [CrossRef]

- Li, P.; Shao, S.; Vanapalli, S.K. Characterizing and Modeling the Pore-Size Distribution Evolution of a Compacted Loess during Consolidation and Shearing. J. Soils Sediments 2020, 20, 2855–2867. [Google Scholar] [CrossRef]

- Sun, H.; Mašín, D.; Najser, J.; Neděla, V.; Navrátilová, E. Fractal Characteristics of Pore Structure of Compacted Bentonite Studied by ESEM and MIP Methods. Acta Geotech. 2020, 15, 1655–1671. [Google Scholar] [CrossRef]

- Luo, H.; Wu, F.; Chang, J.; Xu, J. Microstructural Constraints on Geotechnical Properties of Malan Loess: A Case Study from Zhaojiaan Landslide in Shaanxi Province, China. Eng. Geol. 2018, 236, 60–69. [Google Scholar] [CrossRef]

- ASTM D1557; ASTM Standard Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2006.

- Delage, P.; Marcial, D.; Cui, Y.J.; Ruiz, X. Ageing Effects in a Compacted Bentonite: A Microstructure Approach. Géotechnique 2006, 56, 291–304. [Google Scholar] [CrossRef]

- Monroy, R.; Zdravkovic, L.; Ridley, A. Evolution of Microstructure in Compacted London Clay during Wetting and Loading. Géotechnique 2010, 60, 105–119. [Google Scholar] [CrossRef]

- Diamond, S. Pore Size Distributions in Clays. Clays Clay Miner. 1970, 18, 7–23. [Google Scholar] [CrossRef]

- Wang, J.-D.; Li, P.; Ma, Y.; Vanapalli, S.K. Evolution of Pore-Size Distribution of Intact Loess and Remolded Loess Due to Consolidation. J. Soils Sediments 2019, 19, 1226–1238. [Google Scholar] [CrossRef]

- Mandelbrot, B.B.; Aizenman, M. Fractals: Form, Chance, and Dimension. Phys. Today 1979, 32, 65–66. [Google Scholar] [CrossRef]

- Cheng, Y.; Liu, J.; Zhang, J. Fractal Estimation of Soil Water Retention Curves Using CT Images. Acta Agric. Scand. Sect. B—Soil Plant Sci. 2013, 63, 442–452. [Google Scholar] [CrossRef]

- Sun, Z.-X.; Jiang, Y.-Y.; Wang, Q.-B.; Owens, P.R. A Fractal Evaluation of Particle Size Distributions in an Eolian Loess-Paleosol Sequence and the Linkage with Pedogenesis. CATENA 2018, 165, 80–91. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, X.; Lin, J.; Zhao, D.; Jiang, F.; Wang, M.-K.; Ge, H.; Huang, Y. Effects of Fractal Dimension and Water Content on the Shear Strength of Red Soil in the Hilly Granitic Region of Southern China. Geomorphology 2020, 351, 106956. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, T.; Lin, C. Pore Structure Evaluation of Low Permeability Reservoir Based on Pore Fractal Features. Lithol. Reserv. 2013, 25, 40–45. [Google Scholar]

- Friesen, W.I.; Mikula, R.J. Fractal Dimensions of Coal Particles. J. Colloid Interface Sci. 1987, 120, 263–271. [Google Scholar] [CrossRef]

- Zhang, B.; Li, S. Determination of the Surface Fractal Dimension for Porous Media by Mercury Porosimetry. Ind. Eng. Chem. Res. 1995, 34, 1383–1386. [Google Scholar] [CrossRef]

- Li, P.; Xie, W.; Pak, R.Y.S.; Vanapalli, S.K. Microstructural Evolution of Loess Soils from the Loess Plateau of China. CATENA 2019, 173, 276–288. [Google Scholar] [CrossRef]

- Zhao, J.; Luo, X.; Ma, Y.; Shao, T.; Yue, Y. Soil Characteristics and New Formation Model of Loess on the Chinese Loess Plateau. Geosci. J. 2017, 21, 607–616. [Google Scholar] [CrossRef]

- Pineda, J.A.; Suwal, L.P.; Kelly, R.B.; Bates, L.; Sloan, S.W. Characterisation of Ballina Clay. Géotechnique 2016, 66, 556–577. [Google Scholar] [CrossRef]

- Sloan, S.W.; Kelly, R.B. Newcastle Symposium for the Prediction of Embankment Behaviour on Soft Soil. Comput. Geotech. 2018, 93, 1–2. [Google Scholar] [CrossRef]

- Liu, K.; Ye, W.; Gao, H.; Dong, Q. Multi-Scale Effects of Mechanical Property Degradation of Expansive Soils under Drying-Wetting Environments. Chin. J. Rock Mech. Eng. 2020, 39, 2148–2159. [Google Scholar] [CrossRef]

- Liu, Y.; An, C.; Lai, H.; Wang, G.; Xie, M. Experimental Research on Strength and Microstructure Evolution of Q2 Undisturbed Loess Under Different Wetting-Drying Cycle Paths. China J. Highw. Transp. 2022, 35, 168–180. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Hammes, U. Spectrum of Pore Types and Networks in Mudrocks and a Descriptive Classification for Matrix-Related Mudrock Pores. Bulletin 2012, 96, 1071–1098. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, J. Fractal Approach to Measuring Soil Porosity. J. Southeast Univ. (Nat. Sci. Ed.) 1997, 27, 129–132. [Google Scholar]

- Hou, X.; Vanapalli, S.K.; Li, T. Wetting-Induced Collapse Behavior Associated with Infiltration: A Case Study. Eng. Geol. 2019, 258, 105146. [Google Scholar] [CrossRef]

- Li, P.; Zheng, M.; Bi, H.; Wu, S.; Wang, X. Pore Throat Structure and Fractal Characteristics of Tight Oil Sandstone: A Case Study in the Ordos Basin, China. J. Pet. Sci. Eng. 2017, 149, 665–674. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, W.; Liu, X. Scale-Dependent Nature of the Surface Fractal Dimension for Bi- and Multi-Disperse Porous Solids by Mercury Porosimetry. Appl. Surf. Sci. 2006, 253, 1349–1355. [Google Scholar] [CrossRef]

- Collins, K.; McGown, A. The Form and Function of Microfabric Features in a Variety of Natural Soils. Géotechnique 1974, 24, 223–254. [Google Scholar] [CrossRef]

- Pfeifer, P.; Avnir, D. Chemistry in Noninteger Dimensions between Two and Three. I. Fractal Theory of Heterogeneous Surfaces. J. Chem. Phys. 1983, 79, 3558–3565, Erratum in J. Chem. Phys. 1984, 80, 4573. [Google Scholar] [CrossRef]

- Hu, W.; Cheng, W.-C.; Wang, L.; Xue, Z.-F. Micro-Structural Characteristics Deterioration of Intact Loess under Acid and Saline Solutions and Resultant Macro-Mechanical Properties. Soil Tillage Res. 2022, 220, 105382. [Google Scholar] [CrossRef]

- Xiao, T.; Li, P.; Shao, S. Fractal Dimension and Its Variation of Intact and Compacted Loess. Powder Technol. 2022, 395, 476–490. [Google Scholar] [CrossRef]

- Haeri, S.M.; Khosravi, A.; Ghaizadeh, S.; Garakani, A.A.; Meehan, C.L. Characterization of the Effect of Disturbance on the Hydro-Mechanical Behavior of a Highly Collapsible Loessial Soil. In Proceedings of the 6th International Conference on Unsaturated Soils, UNSAT 2014, Sydney, Australia, 2–4 July 2014; Taylor and Francis—Balkema: Sydney, NSW, Australia, 2014; Volume 1, pp. 261–266. [Google Scholar]

- Pan, L.; Zhu, J.-G.; Zhang, Y.-F. Evaluation of Structural Strength and Parameters of Collapsible Loess. Int. J. Geomech. 2021, 21, 04021066. [Google Scholar] [CrossRef]

- Khoshghalb, A.; Pasha, A.Y.; Khalili, N. A Fractal Model for Volume Change Dependency of the Water Retention Curve. Géotechnique 2015, 65, 141–146. [Google Scholar] [CrossRef]

- Romero, E.; Della Vecchia, G.; Jommi, C. An Insight into the Water Retention Properties of Compacted Clayey Soils. Géotechnique 2011, 61, 313–328. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Specific gravity | 2.71 |

| Initial moist bulk density (g/cm3) | 1.37 |

| Maximum dry density, ρdmax (g/cm3) | 1.65 |

| Initial water content (%) | 14.3 |

| optimum water content (%) | 20.8 |

| Void ratio | 0.9721 |

| Atterberg limits | |

| wI (%) | 30.2 |

| wp (%) | 20.5 |

| Ip | 9.7 |

| Particle size distribution | |

| Gravel content (≥2 mm) | 0 |

| Sand 0.075~2 mm (%) | 0.1 |

| Silt 0.002~0.075 mm (%) | 72.3 |

| Clay < 0.002 mm | 27.6 |

| Unified Soil Classification System | CL |

| Main minerals | |

| Quartz (%) | 35.8 |

| Feldspar (%) | 12.5 |

| albite (%) | 21.4 |

| Calcite (%) | 19.6 |

| Dolomite (%) | 2.3 |

| Chlorite (%) | 1.2 |

| Illite (%) | 7.2 |

| Sample ID | Type of Specimens | Vertical Stress | Initial State | Final State | Time Point | ||

|---|---|---|---|---|---|---|---|

| kPa | Void Ratio | Degree of Saturation | Void Ratio | Degree of Saturation | |||

| I0 | Intact | 0 | 0.972 | 0.398 | 0.972 | 0.398 | |

| I200 | 200 | 0.985 | 0.393 | 0.937 | 0.414 | Before soaking | |

| IS200 | 0.972 | 0.398 | 0.867 | 0.981 | After soaking | ||

| I400 | 400 | 0.977 | 0.396 | 0.888 | 0.436 | Before soaking | |

| IS400 | 0.964 | 0.402 | 0.756 | 0.985 | After soaking | ||

| IS600 | 600 | 0.975 | 0.397 | 0.821 | 0.473 | Before soaking | |

| IS600 | 0.974 | 0.397 | 0.732 | 0.983 | After soaking | ||

| I800 | 800 | 0.972 | 0.398 | 0.787 | 0.497 | Before soaking | |

| IS800 | 0.979 | 0.395 | 0.637 | 0.981 | After soaking | ||

| I1000 | 1600 | 0.968 | 0.400 | 0.644 | 0.601 | Before soaking | |

| IS1000 | 0.977 | 0.396 | 0.509 | 0.988 | After soaking | ||

| C0 | Compacted | 0 | 0.972 | 0.398 | 0.972 | 0.398 | |

| C200 | 200 | 0.972 | 0.398 | 0.919 | 0.421 | Before soaking | |

| CS200 | 0.972 | 0.398 | 0.671 | 0.983 | After soaking | ||

| C400 | 400 | 0.972 | 0.398 | 0.900 | 0.430 | Before soaking | |

| CS400 | 0.972 | 0.398 | 0.597 | 0.982 | After soaking | ||

| C600 | 600 | 0.972 | 0.398 | 0.860 | 0.451 | Before soaking | |

| CS600 | 0.972 | 0.398 | 0.540 | 0.985 | After soaking | ||

| C800 | 800 | 0.972 | 0.398 | 0.849 | 0.456 | Before soaking | |

| CS800 | 0.972 | 0.398 | 0.492 | 0.981 | After soaking | ||

| C1000 | 1600 | 0.972 | 0.398 | 0.729 | 0.531 | Before soaking | |

| CS1000 | 0.972 | 0.398 | 0.429 | 0.982 | After soaking | ||

| Sample ID | Ds1 | Ds2 | Ds3 |

|---|---|---|---|

| I0 | 2.9387 | 2.6848 | 1.7285 |

| I200 | 2.9469 | 2.6912 | 1.2503 |

| IS200 | 2.9670 | 2.6928 | 1.3691 |

| I400 | 2.9439 | 2.6920 | 1.7784 |

| IS400 | 2.9722 | 2.7013 | 1.7362 |

| I600 | 2.9631 | 2.6907 | 1.5874 |

| IS600 | 2.9528 | 2.6415 | 1.7083 |

| I800 | 2.9573 | 2.6981 | 1.4838 |

| IS800 | 2.9722 | 2.6326 | 1.4943 |

| I1000 | 2.9651 | 2.7030 | 1.7780 |

| IS1000 | 2.9775 | 2.6031 | 1.4504 |

| C0 | 2.9613 | 2.7635 | 1.6216 |

| C200 | 2.9527 | 2.7924 | 1.7644 |

| CS200 | 2.9763 | 2.7664 | 1.5822 |

| C400 | 2.9631 | 2.7882 | 1.0226 |

| CS400 | 2.9850 | 2.7602 | 0.7546 |

| C600 | 2.9612 | 2.7861 | 0.8536 |

| CS600 | 2.9789 | 2.7553 | 1.6744 |

| C800 | 2.9591 | 2.7942 | 1.6897 |

| CS800 | 2.9858 | 2.6820 | 0.8210 |

| C1000 | 2.9736 | 2.7855 | 1.5240 |

| CS1000 | 2.9843 | 2.6274 | 1.2374 |

| Range | 2.93~2.99 | 2.60~2.80 | 0.75~1.78 |

| Sample ID | Dm1 | R2 | Dm2 | R2 | Dm3 | R2 |

|---|---|---|---|---|---|---|

| I0 | 2.9641 | 0.9453 | - | - | - | - |

| I200 | 3.8745 | 0.1789 | 4.3543 | 0.8162 | 3.6105 | 0.5959 |

| IS200 | 3.048 | 0.9481 | 4.2958 | 0.7607 | 2.5563 | 0.9985 |

| I400 | 3.5407 | 0.6963 | 3.4152 | 0.2828 | 4.2185 | 0.5820 |

| IS400 | 4.2503 | 0.3256 | 3.1154 | 0.8835 | 4.3400 | 0.4647 |

| I600 | 4.1156 | 0.3908 | - | - | - | - |

| IS600 | 4.3366 | 0.4608 | 3.6901 | 0.4478 | 4.4249 | 0.4734 |

| I800 | 3.9102 | 0.0438 | 4.3851 | 0.8131 | 3.5975 | 0.6311 |

| IS800 | 3.9985 | 0.0061 | 4.0125 | 0.2845 | 4.0012 | 0.0009 |

| I1000 | 4.1974 | 0.4852 | 3.7488 | 0.2766 | 3.9248 | 0.0256 |

| IS1000 | 4.5509 | 0.9119 | 3.6861 | 0.6411 | 4.4377 | 0.7187 |

| Range | 2.96~4.56 | 0.17~0.95 | 2.60~2.80 | 0.28~0.82 | 0.75~1.78 | 0.0009~0.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Shao, S.; Shao, S.; Wu, H.; Wang, Z. Change in the Microstructure and Fractal Characteristics of Intact and Compacted Loess Due to Its Collapsibility. Water 2024, 16, 228. https://doi.org/10.3390/w16020228

Zhang S, Shao S, Shao S, Wu H, Wang Z. Change in the Microstructure and Fractal Characteristics of Intact and Compacted Loess Due to Its Collapsibility. Water. 2024; 16(2):228. https://doi.org/10.3390/w16020228

Chicago/Turabian StyleZhang, Shaoying, Shuai Shao, Shengjun Shao, Hao Wu, and Zechi Wang. 2024. "Change in the Microstructure and Fractal Characteristics of Intact and Compacted Loess Due to Its Collapsibility" Water 16, no. 2: 228. https://doi.org/10.3390/w16020228