Abstract

The global dairy sector produces upwards of 900 million tonnes of milk each year, resulting in 2.25 billion tonnes of wastewater being generated. This is significant in the South African context as a large percentage of the population lives without reliable access to clean, reliable water. The treatment of dairy wastewater (DWW) in this context would help alleviate the unavailability for many people in this country. DWW has a high fat content along with a high chemical oxygen demand (COD), which makes it problematic to dispose of. Biological treatment processes have shown great success in the remediation of this water. However, these are not without their shortfalls. A variety of biological processes have been listed here as well as suggestions to improve their effectiveness. To improve the treatment efficiency, there are two main lines of thinking: First, to optimise the process through the manipulation of the physical parameters of the systems (e.g., temperature, pH, hydraulic retention time (HRT), agitation, etc.). Second, to add either pre-treatment or post-treatment processes to the main process to increase the effectiveness of the entire process overall. These different options have been discussed, with suggestions being made on the way forward.

1. Introduction

Globally, the dairy sector is a substantial industry amounting to 900 million tonnes of milk being produced annually [1]. However, this large-scale production raises concerns about the resulting wastewater. It is estimated that the volume of wastewater generated during milk processing is 2.5 times greater than the volume of milk processed, amounting to a staggering 2.25 billion tonnes of dairy wastewater produced annually [2].

In South Africa, 40% of the population live in rural areas. According to recent estimates, 74% of the rural population rely on groundwater to meet their water needs. However, 19% of the rural population lack access to reliable water, and 33% lack basic sanitation. Inadequate water access is also a problem for 26% of all schools and 45% of clinics [3]. Water scarcity is a significant issue in South Africa, where the agricultural industry uses 60% of the available water. This poses a challenge as a large portion of the population lack reliable access to water [4]. To exacerbate the problem, the dairy refinement industry alone consumes around 7 million tonnes of water per year [5]. However, there is an opportunity to address this issue by implementing dairy wastewater (DWW) treatment strategies. By doing so, a substantial amount of water can be recovered and reintroduced into the water grid, thereby aiding in reducing the water shortage experienced by many South Africans.

The disposal of wastewater is a topic of great importance as improper disposal may lead to a detrimental effect on the lives of people as well as the degradation of the environment. Many laws and regulations have been put in place to ensure that the wastewater being released from various industrial processes meets a minimum standard of safety [6]. Different industries release varying quantities of wastewater with different types of contamination. The release of DWW into water systems without proper treatment causes an array of environmental issues due to its high organic content. The decomposition of DWW in a water source causes the dissolved oxygen (O2) inside the water body to drop as the microbes (especially algae) flourish in the nutrient-rich environment. This results in a hypoxic environment which is unsuitable for aquatic animal and plant life. The increased algal growth produces elevated levels of CO2 which lowers the pH of the body of water, which in turn slows the growth of fish and shellfish. The addition of DWW into fresh water also provides a breeding ground for various insects, which can upset the balance of the surrounding ecosystem. The degradation of casein also causes the formation of a sludge which is harmful to aquatic organisms [7]. This impacts the health of aquatic life and the potential for fishing which has a negative economic impact. In addition to these environmental implications, the processing of dairy products and the release of DWW can lead to several social impacts. These stem from two main sources, namely, the discharge of untreated or partially treated wastewater into nearby water bodies and the odour produced by the plant and effluents. The contamination caused by the release of DWW can promote the spread of bacteria such as Salmonella and E. coli, which can cause illness in humans and animals which use the water sources. Once contracted, these illnesses can easily be spread throughout the community.

The unique characteristics of dairy wastewater make it a challenging and complex category of industrial wastewater, namely, the high fat content and high levels of COD, which can be seen on Table 1. Within the dairy industry, different types of wastewaters are produced depending on the part of the process from which the water is sampled and the product being made. However, the contaminants contained in DWW which are of most relevance during treatment can be captured by the following parameters: BOD5 (biological oxygen demand over 5 days), COD (chemical oxygen demand), FOG (fats, oils, grease), TSS (total suspended solids), TP (total phosphorous) and TN (total nitrogen). Table 2 shows information on the typical characteristics of effluents from different dairy products. In addition to elevated levels of problematic compounds, dairy wastewater is also warmer (17–25 °C) than municipal water (10–20 °C) [8]. This causes increased biological degradation rates, which can promote eutrophication if disposed of into water bodies. These warm temperatures can also negatively impact the growth of plants and organisms in these water bodies.

Table 1.

Characteristics of types of wastewaters produced by various dairy products.

Due to the large variation in the characteristics of DWW, the choice of appropriate technology is crucial for achieving an effective treatment of different types of wastewater. This review highlights different biological treatment methods which can be applied to DWW, along with their strengths and weaknesses. It also considers possibilities to optimize the various types of processes by altering parameters or adding additional process steps. Most experimental studies focus on the effects of certain parameters on methane production during the anaerobic treatment of DWW. The effects of various parameters on the processes, specifically for the reduction of COD, BOD5 and FOGs, have not been thoroughly investigated. Therefore, this review considers various optimization options that can be implemented and the predicted effects on process efficiency.

2. Treatment Options

Biological treatments have been highly effective in reducing the organic load in various types of wastewaters. The nature of microbial systems allows for biological treatment methods to be versatile with respect to the type of wastewater being remediated. However, the physical conditions of the system, such as pH, temperature, and O2 levels, need to be carefully controlled to avoid damaging the microbial consortia. It is also necessary to ensure that certain compounds do not exceed the microbes’ tolerance, as an excess would kill them. One of the downsides to biological treatment methods is that there are certain substances (such as heavy metals) which cannot be processed as they would poison the microbial colonies. There are two main types of biological treatment methods: aerobic and anaerobic treatment. Anaerobic and aerobic treatments are commonly used in conjunction with one another as they each treat different components of the DWW. A combination of aerobic and anaerobic is a suitable solution for treating different components of DWW, replacing traditional one-phase biological systems [21]. A summary of the below treatment options can be seen on Table 1.

Table 2.

Summary of the removal percentages of the previously mentioned biological systems.

Table 2.

Summary of the removal percentages of the previously mentioned biological systems.

| Process | Process Type | %Removal | Merits and Demerits | Reference |

|---|---|---|---|---|

| Activated sludge | Aerobic | BOD5: 95% |

| [22] |

| SBR | Aerobic & Anaerobic | COD: 95–98% TS: 60% TN: 40% NH3: >90% TP: >90% |

| [8,23] |

| MBR | Aerobic & Membrane filtration | COD: 95% BOD5: 95–99% TN: 96% NH4: 99.9% TP: 80% |

| [24,25] |

| PBR | Anaerobic | COD: 96% BOD5: 93% VSS: 90% |

| [7] |

| AFs | Anaerobic | COD: 90% FOG: 47% |

| [26,27] |

| UASBR | Anaerobic | COD: 96.3% |

| [28] |

| AF + SBR | Aerobic & Anaerobic | COD: 90% | [27] | |

| UASBR + Aerobic Denitrification | Aerobic & Anaerobic | COD: 95% | [20] |

2.1. Aerobic Treatment Processes

Aerobic treatment occurs when the microbes are exposed to air and thus oxygen whilst anaerobic occurs without the presence of air. Aerobic treatment is effectively used to reduce the BOD5 as well as the phosphorous and nitrogen content in dairy wastewater. Aerobic processes are additionally more cost-effective than anaerobic ones for the removal of fats from DWW [21]. Importantly, the removal of nitrogen is largely associated with the oxidation of ammonia into nitrates, which in turn reduces the odour of the DWW. Aerobic systems are associated with high biomass growth and are susceptible to clogging if solely used to treat DWW [5]. Additionally, aerobic treatments suffer from the high energy demand due to aeration. The following are aerobic treatment methods which have been used to treat DWW, both in a lab setting and on an industrial scale.

2.2. Activated Sludge

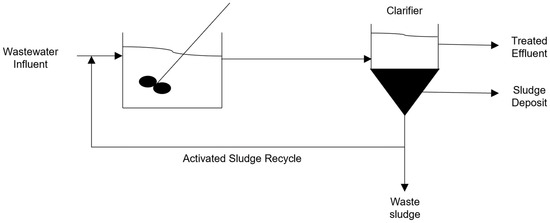

Activated sludge treatment methods are processes which introduce microbes into the wastewater stream to both treat the water and stimulate the growth of microbes. The microbial colonies are then separated from the bulk stream using a clarifier or filter, with a portion of the sludge being reintroduced to the reactor. A schematic representation of an activated sludge system can be seen in Figure 1. These methods are preferred for the removal of carbon, nitrates, and ammonia [4]. The constant recirculation of sludge allows for the microbes to acclimatize to the waste stream composition and increases the performance of the system, the longer it is operated for. These systems are also effective at breaking down complicated compounds such as lactose, FOG, and proteins [29]. Studies have shown a reduction of BOD5 in DWW of up to 95%, using activated sludge [22], demonstrating its effectiveness at reducing organic compounds. Activated sludge processes tend to suffer from low resistance to environmental shocks and a build-up of toxins. In addition, sludge settling can be problematic, which reduces the recovery of biomass. These shortfalls have been overcome using granular sludge, i.e., a type of sludge which forms solid spherical granules from microorganisms and flocs. These granules have a higher resistance to shocks and better settling properties [30]. Another downside to activated sludge processes is the disposal of sludge. This can be somewhat mitigated by reusing the sludge as fertilizer or as part of an animal feedstock.

Figure 1.

Schematic diagram of an activated sludge process.

2.3. Sequencing Batch Reactors

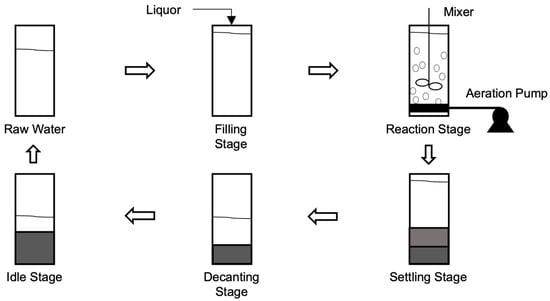

Sequencing batch reactors (SBRs) comprise a series of process steps within a single bioreactor. These steps occur in the sequence of filling, reacting, settling, decanting, and idling. The filling stage is the addition of the DWW and liquor, which contains microbes. The reaction stage can consist of cycles of aerobic and anaerobic phases. This can be achieved by alternating between periods of aerating and no aeration. For the settling stage, the aeration and mixing are stopped for the suspended solids to settle and be easily separated from the treated water. The decanting stage involves the removal of the supernatant fluid (treated wastewater). The idle stage is mostly needed for multi-reactor systems where there is a time delay between the filling stage in between units [21]. A schematic representation of a SBR system can be seen in Figure 2. SBRs have been observed to reduce COD by up to 95%, total solids by up to 60%, and up to 40% of the total nitrogen [8] from DWW. These systems do suffer from relatively low removal rates for phosphorous, nitrogen, and limited solid removal. A study [23] utilizing a hybrid up-flow–downflow reactor was able to achieve a stable treatment of DWW with an average organic loading rate of 10,000 mgCOD/L/day. This system demonstrates the flexibility of an SBR system as it contains both downflow pre-acidification chambers and up-flow methanation chambers. It achieved a COD conversion into biogas of 98%, with an additional removal of NH3 and TP of over 90% [29]. Studies have also been carried out with an SBR coupled with membrane filtration to remedy these limitations. However, the inclusion of a membrane brings the new challenge of membrane fouling, which requires additional strategies to mitigate this risk. SBRs also have the drawback of being a batch system, which necessitates the loading and unloading of the reactors along with cleaning for each batch. This results in lower productivity than that of a continuous system.

Figure 2.

Schematic of an SBR treatment system.

2.4. Membrane Bioreactor

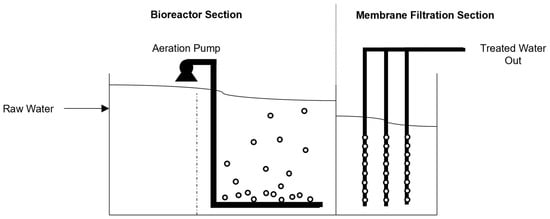

Membrane bioreactors (MBR) incorporate the principle of membrane filtration with a bioreactor. A schematic representation of an MBR can be seen in Figure 3.There are two main configurations of MBR, one where the membrane is submerged within the reactor and one where the membrane is located externally with a recycle back into the reactor. MBRs with submerged membranes are more popular as they are compact and have low energy usage [31]. One of the downsides of submerged membranes is that they are more prone to fouling than the external configuration. This is an issue that must be dealt with for most membrane systems. However, with an MBR, soluble microbial products add to the risk of fouling. This can be somewhat mitigated by treating the membranes with sodium metabisulfite to prevent microbial growth on the membrane [32]. In lab-scale operations, when treating DWW, an aerobic MBR has been observed to decrease the BOD5 level by up to 99% and the ammonium levels by up to 99.9% [24]. Another study, treating high-strength ice-cream wastewater (13,300 mgCOD/L & 6500 mgBOD5/L), was able to achieve a COD and BOD5 reduction of over 95%, TP by 80% and TN by over 96% [25].

Figure 3.

Schematic diagram of a membrane bioreactor.

2.5. Anaerobic Processes

Anaerobic treatment processes are primarily aimed at reducing the organic content of wastewater and are suited for the remediation of wastewater with high organic loads [5]. Anaerobic systems are also effective at decreasing the nitrites and nitrates by reducing them into nitrogen gas. These systems are, however, less effective at removing the FOGs, ammonia, and phosphorous [4] and may require further downstream treatment or a suitable pre-treatment method to meet discharge standards. FOGs and other complex polymeric compounds are difficult to break down using anaerobic consortia and usually require a hydrolysis or oxidation step to break them down into smaller, soluble molecules such as short-chain fatty acids and alcohols [33]. Hydrolysis is the process whereby a complex polymeric organic compound is broken down into smaller soluble compounds in the presence of water [34]. This process can be catalysed by the addition of acids or enzymes to the solution. This is relevant for anaerobic processes as the lipid content is usually a limiting factor for performance [35]. Anaerobic treatment also has the potential of methane production from organic-rich wastewater. Common uses of anaerobic technology include anaerobic filters, sludge blanket reactors, and packed bed digestors.

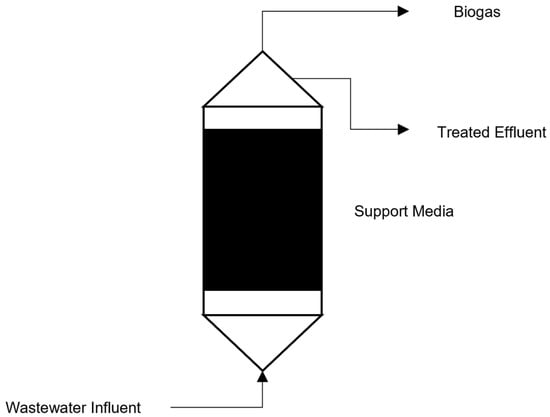

2.6. Anaerobic Filters

Anaerobic filters (AFs) are reactors that are packed with a porous support media with biomass in the packing void. AF reactors contain at least two filtration chambers within the system, with the filter media used to prevent biomass from passing through. A side effect of these filtration chambers is enhanced solid removal, which can be observed [7]. A schematic representation of an AF system can be seen in Figure 4. This treatment method is most appropriate for wastewater with low organic loading and struggles with high-strength wastewater streams [36]. As the organic material in the wastewater stream degrades, it adheres to the support media, which acts as a physical barrier. The selection of media is an important aspect of the AF system, as the characteristics of the media will affect the microbial activity and, ultimately, the performance of the system. Studies have shown that a reduction in COD of up to 90% can be achieved when treating a DWW stream [26]. However, it is not effective at dealing with high-fat DWW, showing low FOG removal rates of around 47% [27]. This highlights the need for the further downstream treatment of the effluent and sludge produced by AF systems when treating wastewater with high organic loading. Alternatively, appropriate pre-treatment systems can be implemented to overcome these difficulties. This has been successfully implemented by the addition of an SBR to remedy the low FOG removal, where a 99% overall FOG removal was achieved [27].

Figure 4.

Schematic diagram of an anaerobic filter.

2.7. Anaerobic Packed Bed Reactors

Anaerobic packed bed reactors (APBRs) utilize sludge which has been immobilized, through which the wastewater is pumped either in an up-flow or downflow configuration. This reactor uses a packing material at the top and/or bottom to fix the biomass in place. This packing material is intended to support biofilm formation and not to act as a physical barrier for the solids contained within the DWW. This is a very similar configuration to that of an anaerobic filter; however, there are no filtration chambers present within the APBR configuration. An issue with this technology is that it can be prone to clogging due to the accumulation of biomass. This issue can be bypassed by allowing biomass to flow out of the reactor with the effluent stream, necessitating further downstream treatment. This solution also raises another issue of low biomass retention within the system. A remedy to this would be to use granulated sludge within the reactor body. The benefits of using granulated sludge would be higher shock resistance, higher toxicity resistance, and higher retention within the reactor. Packed bed reactors were highly effective at reducing COD, BOD5, and volatile suspended solids content of up to 96%, 93%, and 90%, respectively [7].

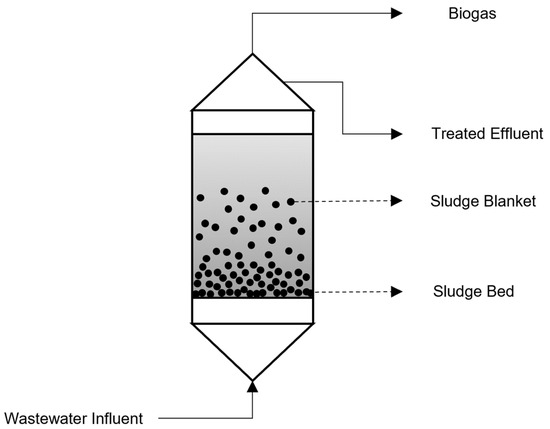

2.8. Up-Flow Anaerobic Sludge Blanket Reactors

Up-flow anaerobic sludge blanket reactors (UASBRs) are some of the most used systems for the treatment of DWW. These types of reactors are fed wastewater through the bottom of a reactor column which is packed with anaerobic sludge granules that have been somewhat fixed in place. The treated effluent is then extracted from the top end of the reactor, with the methane being siphoned off through a vent at the top of the reactor. A schematic representation of an UASBR can be seen in Figure 5. UASB reactors are highly suited for treating wastewater streams which have a high COD content of up to 40,000 mg/L [28], making them an ideal choice for treating DWW. They have been observed to achieve a COD reduction of up to 96.3% with a hydraulic retention time (HRT) of 3 h [37]. A common issue experienced with ASB reactors is the accumulation of organic material in the sludge blanket, possibly due to the difficulties in the breakdown of the FOG of anaerobic bacteria. This problem can be resolved by implementing a hydrolysis stage before the reactor or by increasing the HRT of the reactor [37].

Figure 5.

Schematic diagram of an up-flow Anaerobic Sludge Blanket Reactor (UASBR).

2.9. Aerobic–Anaerobic Systems

Aerobic–anaerobic systems have been widely investigated for various wastewaters with high organic contents. The combination of these two technologies allows for a more complete remediation of DWW as each stage focuses on different pollutants within the wastewater. The aerobic stage effectively reduces the ammonia, phosphorous, H2S, and BOD5 content, whereas the anaerobic stage reduces the COD and nitrate content of the water [21]. In theory, it should be possible to achieve removal yields from a two-stage system similar to the yields that can be achieved by the individual processes. This is due to the different pollutants that are being processed by each individual system. In a practical study of an anaerobic filter combined with an aerobic one, an SBR was able to achieve a COD removal of 90% from a high-strength dairy stream with an influent COD content of approximately 8000 g/L [27]. Another study achieved a COD removal of 95%, in a full-scale plant, using an up-flow anaerobic sludge bracket reactor followed by aerobic denitrification [20]. These systems are highly versatile as the selection of reactor configurations is not limited to those found in the literature and can be evaluated on a case-to-case basis. This ultimately depends on the strength of wastewater being treated and the discharge standards to be met. One of the main benefits of using aerobic–anaerobic systems is that a more complete remediation of the wastewater can be achieved. This means that the treated wastewater has the potential to be used for a larger variety of applications when compared to standalone aerobic or anaerobic systems.

3. The Effects of Experimental Parameters on the Performance of Biological Treatment Systems

Certain shortfalls that occur with the biological systems outlined above can be resolved by manipulating various physical parameters. However, this is not a straightforward task when dealing with microbial colonies as they have a complex makeup and can sometimes express unwanted behaviour if taken out of their ideal conditions. Conversely, microbial systems can be highly adaptable to sustained changes in their environments and can therefore be manipulated to perform in a more favourable way through the changes in physical parameters. The following parameters are considered as critical as they can have significant effects on the performance of a biological system without inherently changing the feed characteristics.

3.1. pH Adjustment

There are three main groups of microorganisms which are found in AD: acidogenic (acid producing), acetogenic (acetate-producing), and methanogenic (methane-producing). Each of these has a pH range which it prefers. Acidogens have an optimal pH range between 5.2 and 6.5; acetogens from 6.6 to 7.6; and methanogens from 7.5 to 8.5 [38]. The pH of the system should be carefully controlled because an imbalance, either too high or too low, can lead to an overproduction or accumulation of certain compounds, which can then result in digestor failure [39]. It is important to select an appropriate pH based on the specific need of the system. However, the reactions which occur during the remediation of DWW produce volatile fatty acids (VFAs) from the breakdown of FOGs, which alter the pH as the process occurs. This necessitates the need for constant pH adjustment throughout the process in order to remain at an optimal pH whilst VFAs are being produced.

3.2. Dissolved O2 Levels

Aerobic digestion is enhanced by higher levels of dissolved O2; it therefore follows that anaerobic digestion will be enhanced by the removal of dissolved O2 from the wastewater. One straightforward approach to eliminate dissolved oxygen is to pass another gas through the wastewater. Some potential deoxygenating agents for anaerobic digestion are nitrogen or biogas. Biogas is a convenient option as an amount of CO2 and methane is produced by anaerobic digestion. However, the use of biogas poses an environmental issue due to methane being a greenhouse gas. Nitrogen gas is a suitable gas to use as it is non-reactive and does not pose any inherent environmental risks [39]. Another method of deoxygenation is to increase the temperature of the wastewater. The heating of the water decreases the solubility factor between oxygen and water and allows for the dissolved gas to escape. Pressure is another factor which has an inversely proportional effect on the solubility factor between oxygen and water, which is described by Henry’s Law. In other words, the lower the pressure of the system, the less dissolved oxygen will be present within the wastewater. However, both changing the temperature and the pressure within a system can be energy-intensive and costly to run on a large scale. The use of deoxygenating agents is not energy-intensive; however, it may increase the operating costs as large quantities of gas may be needed when implemented in a real-world scenario.

3.3. Hydraulic Retention Time

Hydraulic retention time (HRT) refers to the average time that a liquid substrate will spend within a reactor. HRT is largely dependent on the type of reactor being used and the organic load of the wastewater being treated. A small HRT can sometimes result in high biomass washout, whereas a long HRT can require large reactor volumes [39]. The growth of the various groups of microorganisms used in AD are favoured by different HRTs. Methanogens prefer a longer HRT period as opposed to acidogenic bacteria, which prefer low HRTs. The determination of optimal hydraulic retention time (HRT) is a complex decision that requires the consideration of both the process and the desired outcomes, and it should be evaluated on a case-by-case basis. As previously mentioned, increasing the HRT improved the ability of an ASB reactor to better metabolize FOGs, which is the prevailing shortfall of anaerobic systems. A higher HRT usually results in greater reactor performance in terms of removal efficiency and has been observed to do so for an SBR with dairy wastewater influent COD levels between 10,000 mg/L and 20,000 mg/L [40]. This system was shown to increase the removal efficiencies of all major components of interest in the wastewater for longer HRT periods. However, there is a point of diminishing returns for a system where increasing the HRT will yield either minimal increases in removal efficiency or efficiencies that have exceeded the levels which are required for the system. HRT is an easily manipulated variable, which can produce significant results when optimised according to the needs of the system.

3.4. Aeration and Agitation

An important factor in aerobic treatments is the aeration which is introduced into the system. It is the driving force behind the reactions which aerobic digestion is utilized for, namely, the oxidation of ammonia and the breakdown of complex organic compounds. Therefore, an optimal aeration regime is essential for the performance of any treatment method used. At lower aeration levels, it was observed that there was a significant decrease in COD removal efficiency and an even more drastic decrease in the efficiency of ammonia removal [40]. This indicates that the available oxygen is being used to oxidise the carbon substrates in the wastewater as opposed to the ammonia. The most likely explanation is that ammonia requires a larger amount of O2 when compared to the organic components. The same study also observed that there was a decrease in biodiversity at lower aeration levels, likely due to the difficulty of certain species of microbes to adapt to prolonged anoxic conditions [41]. This could result in a decrease in the removal of certain components as the microbes best suited for their breakdown would no longer be present in the colonies. Higher levels of aeration were seen to improve the removal of both ammonia and COD, with the highest levels showing the greatest performance. Aeration has the additional effect of dislodging a certain percentage of dissolved gasses, which is also the principle behind using nitrogen gas to reduce the DO content in the wastewater.

Agitation or physical mixing within an aerobic bioreactor has been seen to increase both cell growth and enzymatic activity. This is due to the agitation facilitating the efficient dispersion of macromolecules within the medium [42]. High agitation can negatively affect both the growth and enzymatic activity of the microbes due to the shearing effect [43]. This can prevent larger colonies of biomass from forming due to the lack of fluid stability. Similar to aeration, agitation has the benefit of allowing some of the dissolved gas, which is produced by the treatment process, to escape from the water.

3.5. Temperature

The temperature plays a critical role in the reactions involved in wastewater remediation. Different temperature ranges can have both favourable and unfavourable effects on the performance of a bioreactor. High temperatures can cause the denaturation of proteins within the microbes, causing them to lose their enzymatic activity and die. Low temperatures can cause the microbes to become dormant, inactive, or die. It is, therefore, essential that the temperatures within a bioreactor are carefully controlled and are not allowed to go beyond the range within which the microbes are able to thrive. However, choosing an optimal temperature for which to run a system at depends on the specific microorganisms used within it. Most anaerobic digesters used for wastewater treatment typically operate at mesophilic conditions, between 35 °C and 37 °C. Temperature needs to be carefully controlled as large fluctuations can be detrimental for these processes [44].

An important effect which temperature has on DWW has to do with the physical properties of the fats found within the wastewater. The main lipids found in milk are known as triglycerides, with the main fatty acids being long-chain fatty acids, accounting for around 67%, and with the remainder being short-chain fatty acids. This results in milk fats having a melting point temperature of 37 °C [44], which is significant as it means that the fatty solids in DWW can be easily removed from the wastewater through physical methods, namely, reducing the temperature of the wastewater followed by passing the water through a strainer to remove the larger solid particles.

4. Accessory Treatment Options

Another route for overcoming the shortfalls of certain biological systems is the addition of either pre-treatment or post-treatment systems to compensate for the weaknesses in the main treatment process. This can sometimes be easier than manipulating system parameters to obtain a better performance, as the accessory processes can be specifically tailored for the main system and can be implemented without too much trouble. The downside is that this is usually a more costly option. The following are processes which can be integrated into biological systems smoothly, as they do not utilize harsh chemicals or change the feed characteristics in a way that would interfere with the main biological system. A summary of the below accessory treatment options can be seen in Table 3.

4.1. Hydrolysis

Anaerobic systems generally have difficulty in degrading FOGs and ammonia, as these are oxidation reactions which occur. High concentrations of FOGs can contribute to clogging within the reactor as they are poorly broken down through AD. An effective solution to these problems is a hydrolysis stage before the anaerobic digestor. An up-flow ASB reactor (UASB) was observed to be able to effectively treat wastewaters with high FOG contents which had been hydrolysed before treatment. It was noted that when fed unhydrolyzed wastewater, the UASB showed unstable COD removal and a tendency to accumulate some of the fats within the sludge [45]. This suggests that the inclusion of a separate hydrolysis stage can mitigate the risk of clogging within the reactor. Additionally, studies show that DWW that has been hydrolysed increases the production of methane when compared to unhydrolyzed DWW [35]. This can be attributed to the oxidation degradation of the complex organic molecules into more easily digested compounds.

One study, using an up-flow anaerobic sludge bracket reactor, observed that the inclusion of a hydrolysis pre-treatment stage showed small improvements in the COD removal of the reactor, with an average of 90% COD removal compared to the 82% which was observed using unhydrolyzed wastewater. However, it was also seen that utilizing high-strength unhydrolyzed wastewater (1000 mgFOG/L) caused FOG build-up in the reactor and resulted in sludge with 25% higher FOG content than that observed from the reactor utilizing hydrolysed wastewater [45]. Additionally, the FOG content of the effluent stream from the reactor using the high-strength (1000 mgFOG/L) hydrolysed wastewater was observed to be between 100 and 200 mgFOG/L. This is significantly lower than the FOG content of the unhydrolyzed effluent stream, which was observed to be in the region of 700 mgFOG/L [45]. Another study showed a COD removal of 90% and a biogas production of 4710 mL using pre-hydrolysed wastewater, compared with a COD removal of 66% and biogas production of 2330 mL when using unhydrolyzed wastewater of the same initial FOG content [46]. These studies highlight the weakness of single-stage anaerobic digestion when it comes to processing high FOG-content wastewater. The addition of an enzymatic pre-hydrolysis treatment stage has been seen to improve the efficiency of single-stage anaerobic digestors in processing high-strength DWW by increasing both the COD and FOG removal efficiency which results in a more complete remediation of the wastewater. An important effect of reducing the FOG content before anaerobic digestion is that the risk of clogging is reduced within the system. This is an essential factor when considering the real-world operation of a continuous process as it results in a more stable system with less unwanted stoppages.

4.2. Coagulation

Coagulation/Flocculation are currently the most commonly used processes for the removal of suspended and dissolved solids, colloids, and organic components in industrial wastewater [47]. There are two types of coagulants commonly used in wastewater treatment, namely, inorganic and organic coagulants. Inorganic coagulants are usually metal-based salts, usually containing aluminium or iron. The use of Alum (X × Al(SO4)2 × 12H2O, where X is a metal ion such as potassium or sodium) as a coagulant in the treatment of DWW was observed to reduce the turbidity of the water by 95% and reduce COD by 68% [48]. This was further enhanced by the addition of polymeric coagulants, resulting in a reduction in COD by 85%. However, inorganic coagulants produce large amounts of metal-rich floc, which must be further treated before it is disposed of. They can also alter the pH of the water requiring pH control and corrosion-resistant equipment. When trying to integrate inorganic coagulants with biological systems, it is important to evaluate whether the microbial colonies will be able to function unhindered.

Organic coagulants can either be polymeric or natural coagulants. Polymeric coagulants produce longer polymer chains without any metals or hydroxides and produce smaller volumes of floc. They also do not impact the pH of the water. They also produce low-density floc, which does not always settle well. Natural coagulants are being investigated widely and there have been many studies which show their effectiveness in the treatment of wastewater. An extract made from the bark of Guazuma ulmifolia was used as a coagulant for DWW (3037 mgCOD/L & 1283 mgBOD5/L) and was observed to remove 95.8% of the turbidity, 76% of the COD and 81.2% of the BOD5 [49]. Natural coagulants’ low cost and eco-friendliness make them a suitable alternative to the more commonly used synthetic coagulants. Another benefit of natural coagulants is that they are easier to integrate with biological systems as they do not have an impact on the pH of the resulting effluent and are not introducing any potentially harmful substances into the system.

4.3. Membrane Filtration

Membrane filtration methods such as microfiltration are effective at significantly reducing the TSS within the wastewater. However, it has little effect on the TN, COD, and BOD5 content and is commonly used as a pre-treatment step in a wastewater treatment process. Reverse osmosis (RO) is a viable option for dairy wastewater treatment and has been observed to reduce the TN and TOC by 94% and 84%, respectively [50]. Nanofiltration has been observed to be effective at reducing COD and TSS levels but does not remove all ions of interest, such as phosphates and nitrates, from the wastewater stream [51]. There have been some applications of nanofiltration and RO being used in conjunction with a bioreactor, which was observed to greatly improve the overall ion removal in addition to enhancing the reduction in COD and TSS. There are issues associated with RO and membrane filtration, which affect the long-term uses of this type of system. RO is an extremely energy-intensive process and is sometimes impractical to operate at the specifications required [52]. The replacement of this technology can be costly in the event of physical damage or fouling. In addition, this process produces a highly concentrated retentate which needs to be disposed of. This is a major concern as the disposal of the concentrate that is formed is more problematic than that of the wastewater itself. However, this downside can be somewhat mitigated when used in conjunction with a biological treatment system, as the water to be processed will contain already reduced amounts of TN, COD, and TS. This application can be observed in an MBR.

Table 3.

Summary of Accessory Treatment Options.

Table 3.

Summary of Accessory Treatment Options.

| Process | Examples | Merits & Demerits | Reference |

|---|---|---|---|

| Hydrolysis |

|

| [35,39,46,53,54] |

| Coagulation |

|

| [46,47,48,55] |

| Membrane Filtration |

|

| [49,50,51] |

5. The Way Forward and Conclusions

The treatment of DWW is an essential part of an ever-expanding dairy industry, with advancements in these processes not only affecting this industry but all industries processing high-strength organic wastewater. The potential to reclaim water that would otherwise be discarded is vital in South Africa due to the water shortages experienced by a large portion of the population. Much of the waste produced from the processing of dairy products has the potential to be remediated using biological methods. Biological treatment methods have been proven to be highly effective in the remediation of dairy wastewater from all sources and strengths. Apart from the versatility of these systems, they are also more environmentally friendly than many chemical-based processes and physical treatment methods.

The two categories of biological treatment, aerobic and anaerobic, each have their own advantages and disadvantages when it comes to the bioremediation of DWW. Aerobic treatment is effectively used to reduce the BOD5, the phosphorous and nitrogen content as well as the odour of the DWW. Aerobic processes are additionally more cost-effective than anaerobic ones for the removal of fats from DWW. On the other hand, aerobic treatments suffer from high energy utilization due to the aeration required. Anaerobic treatments are primarily aimed at reducing the organic content of wastewater and are suited for the remediation of wastewater with high organic loads. Additionally, these systems also have the potential of methane production from organic-rich wastewater. Anaerobic systems are, however, less effective at removing the FOGs, ammonia, nitrates, and phosphorous and may require further downstream treatment or a suitable pre-treatment method to meet discharge standards. Biological processes have several factors to which they are sensitive, such as pH, temperature, hydraulic retention time, agitation, and the dissolved O2 levels in the wastewater.

The optimization of these parameters has not been fully explored when investigated simultaneously to establish whether any synergistic effects exist or not. Some further aspects which need to be considered for the real-life implementation of these technologies are highlighted below.

- The effects that various parameters have on the efficiency of aerobic and anaerobic digestion must be examined. It is important to examine and understand the effects that changes in multiple parameters will have collectively, and possible synergistic effects between these parameters, as this will aid in developing better control strategies for optimal DWW treatment.

- The optimal operating conditions for each of these parameters based on the discharge standards to be met and the varying characteristics of different DWWs must be determined.

- Future work must consider developing a more complete understanding of the reactions taking place in both aerobic and anaerobic digestion to be able to better optimize each process individually and together. This would be a big step in understanding the synergies between the two processes when used in a multi-stage system for the improved efficacy of DWW treatment processes.

- Considerations must be made into optimizing pre-treatments that can be used in conjunction with a biological treatment system, and to evaluate the effects that this will have on the remediation efficiency of the process. This will be primarily aimed at treating the wastewater and not at the production of biogas or methane.

- The viability of accessory treatment options must be made a key consideration and evaluated for the purposes of overcoming the various shortfalls of certain biological processes.

Author Contributions

Conceptualization, J.R. and M.B.; investigation, J.R.; writing—original draft preparation, J.R.; writing—review and editing, J.R., L.G., W.B.A., M.B. and M.S.M.; supervision, M.B. and M.S.M.; project administration, M.B.; funding acquisition, M.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received funding from the National Research Foundation of SA—Thuthuka Funding (Grant No.138173) as well as Building Research Active Academic Staff (BRAAS) funding from the University of Cape Town. Any opinions, findings, conclusions, or recommendations expressed in any publication generated by NRF supported research is that of the authors, and the NRF accepts no liability whatsoever in this regard. The APC was funded by the University of Cape Town.

Conflicts of Interest

The author declares no conflict of interest.

References

- United States Department of Agriculture. Dairy: World Markets and Trade; United States Department of Agriculture: Washington, DC, USA, 2022.

- Dogan, O.B.; Meneses, Y.E.; Flores, R.A.; Wang, B. Risk-based assessment and criteria specification of the microbial safety of wastewater reuse in food processing: Managing Listeria monocytogenes contamination in pasteurized fluid milk. Water Res. 2020, 171, 115466. [Google Scholar] [CrossRef]

- 2016-06-SA’s Farmers Can Benefit by Reducing Their Water Use–Wits University. Available online: https://www.wits.ac.za/news/latest-news/in-their-own-words/2016/2016-06/sas-farmers-can-benefit-by-reducing-their-water-use.html (accessed on 2 May 2023).

- Water Access in South Africa|Water for All. Available online: http://www.12.000.scripts.mit.edu/mission2017/case-studies/water-access-in-south-africa/ (accessed on 2 May 2023).

- Van Heerdan, B. Suid-Afrikaanse Melkprosesseer South African Milk Processors’ Organisation dersorganisasie A Milk SA publication compiled by the Milk Producers’ Organisation. 2022. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwiu5OLrtNWBAxXTWEEAHaPiAYYQFnoECBQQAQ&url=https%3A%2F%2Fmilksa.co.za%2Fsites%2Fdefault%2Ffiles%2F2018-09%2FLAC004%2520Nov%25202017.pdf&usg=AOvVaw07hNM16NuvQXnHrUDjHDjB&opi=89978449 (accessed on 10 July 2023).

- Molewa, B.E. Revision of General Authorisations in Terms of Section 39 of the National Water Act, 1998 (Act No. 36 of 1998) (the Act). In Government Gazette No. 36820; Government Gazette of South Africa: Pretoria, South Africa, 2013. [Google Scholar]

- Joshiba, G.J.; Kumar, P.S.; Femina, C.C.; Jayashree, E.; Racchana, R.; Sivanesan, S. Critical review on biological treatment strategies of dairy wastewater. Desalination Water Treat. 2019, 160, 94–109. [Google Scholar] [CrossRef]

- Slavov, A.K. General characteristics and treatment possibilities of dairy wastewater—A review. Food Technol. Biotechnol. 2017, 55, 14–28. [Google Scholar] [CrossRef] [PubMed]

- Najafpour, G.; Najafpour, G.D.; Hashemiyeh, B.A.; Asadi, M.; Ghasemi, M.B. Biological treatment of dairy wastewater in an upflow anaerobic sludge-fixed film bioreactor. J. Agric. Food Chem. 2008, 4, 251–257. [Google Scholar]

- Demirel, B.; Yenigun, O.; Onay, T.T. Anaerobic treatment of dairy wastewaters: A review. Process. Biochem. 2005, 40, 2583–2595. [Google Scholar] [CrossRef]

- Farizoglu, B.; Keskinler, B.; Yildiz, E.; Nuhoglu, A. Simultaneous removal of C, N, P from cheese whey by jet loop membrane bioreactor (JLMBR). J. Hazard. Mater. 2007, 146, 399–407. [Google Scholar] [CrossRef] [PubMed]

- Janczukowicz, W.; Zieliński, M.; Dębowski, M. Biodegradability evaluation of dairy effluents originated in selected sections of dairy production. Bioresour. Technol. 2008, 99, 4199–4205. [Google Scholar] [CrossRef] [PubMed]

- Watkins, M.; Nash, D. Dairy Factory Wastewaters, Their Use on Land and Possible Environmental Impacts—A Mini Review. Open Agric. J. 2010, 4, 1–9. [Google Scholar] [CrossRef]

- Wang, S.; Rao, N.C.; Qiu, R.; Moletta, R. Performance and kinetic evaluation of anaerobic moving bed biofilm reactor for treating milk permeate from dairy industry. Bioresour. Technol. 2009, 100, 5641–5647. [Google Scholar] [CrossRef]

- Gannoun, H.; Khelifi, E.; Bouallagui, H.; Touhami, Y.; Hamdi, M. Ecological clarification of cheese whey prior to anaerobic digestion in upflow anaerobic filter. Bioresour. Technol. 2008, 99, 6105–6111. [Google Scholar] [CrossRef]

- Yang, P.; Zhang, R.; McGarvey, J.A.; Benemann, J.R. Biohydrogen production from cheese processing wastewater by anaerobic fermentation using mixed microbial communities. Int. J. Hydrogen Energy 2007, 32, 4761–4771. [Google Scholar] [CrossRef]

- Carvalho, F.; Prazeres, A.R.; Rivas, J. Cheese whey wastewater: Characterization and treatment. Sci. Total Environ. 2013, 445–446, 385–396. [Google Scholar] [CrossRef]

- Venetsaneas, N.; Antonopoulou, G.; Stamatelatou, K.; Kornaros, M.; Lyberatos, G. Using cheese whey for hydrogen and methane generation in a two-stage continuous process with alternative pH controlling approaches. Bioresour. Technol. 2009, 100, 3713–3717. [Google Scholar] [CrossRef]

- Geilman, W.G.; Schmidt, D.; Herfurth-Kennedy, C.; Path, J.; Cullor, J. Production of an Electrolyte Beverage from Milk Permeate. J. Dairy Sci. 1992, 75, 2364–2369. [Google Scholar] [CrossRef]

- B Britz, T.J.; van Schalkwyk, C.; Hung, Y.-T. Treatment of Dairy Processing Wastewaters. In Handbook of Industrial and Hazardous Wastes Treatment; CRC Press: Boca Raton, FL, USA, 2004; pp. 673–705. [Google Scholar] [CrossRef]

- Zhao, K.; Wu, Y.W.; Young, S.; Chen, X.J. Biological Treatment of Dairy Wastewater: A Mini Review. J. Environ. Inform. Lett. 2020, 4, 22–31. [Google Scholar] [CrossRef]

- Lateef, S.A.; Beneragama, N.; Yamashiro, T.; Iwasaki, M.; Umetsu, K. Batch anaerobic co-digestion of cow manure and waste milk in two-stage process for hydrogen and methane productions. Bioprocess Biosyst. Eng. 2014, 37, 355–363. [Google Scholar] [CrossRef]

- Malaspina, F.; Stante, L.; Cellamare, C.; Tilche, A. Cheese whey and cheese factory wastewater treatment with a biological anaerobic-aerobic process. Water Sci. Technol. 1995, 32, 59–72. [Google Scholar] [CrossRef]

- Stepanov, S.; Solkina, O.; Stepanov, A. Dairy Wastewater Treatment Using Membrane Bioreactor. IOP Conf. Series: Earth Environ. Sci. 2019, 272, 022249. [Google Scholar] [CrossRef]

- Scott, J.; Smith, K. A bioreactor coupled to a membrane to provide aeration and filtration in ice-cream factory wastewater remediation. Water Res. 1997, 31, 69–74. [Google Scholar] [CrossRef]

- Rajagopal, R.; Torrijos, M.; Kumar, P.; Mehrotra, I. Substrate removal kinetics in high-rate upflow anaerobic filters packed with low-density polyethylene media treating high-strength agro-food wastewaters. J. Environ. Manag. 2013, 116, 101–106. [Google Scholar] [CrossRef] [PubMed]

- Omil, F.; Garrido, J.M.; Arrojo, B.; Méndez, R. Anaerobic filter reactor performance for the treatment of complex dairy wastewater at industrial scale. Water Res. 2003, 37, 4099–4108. [Google Scholar] [CrossRef]

- Buntner, D.; Sánchez, A.; Garrido, J. Feasibility of combined UASB and MBR system in dairy wastewater treatment at ambient temperatures. Chem. Eng. J. 2013, 230, 475–481. [Google Scholar] [CrossRef]

- Bae, T.-H.; Han, S.-S.; Tak, T.-M. Membrane sequencing batch reactor system for the treatment of dairy industry wastewater. Process. Biochem. 2003, 39, 221–231. [Google Scholar] [CrossRef]

- Vashi, H.; Iorhemen, O.T.; Tay, J.H. Aerobic granulation: A recent development on the biological treatment of pulp and paper wastewater. Environ. Technol. Innov. 2018, 9, 265–274. [Google Scholar] [CrossRef]

- Goli, A.; Shamiri, A.; Khosroyar, S.; Talaiekhozani, A.; Sanaye, R.; Azizi, K. A review on different aerobic and anaerobic treatment methods in dairy industry wastewater. J. Environ. Treat. Tech. 2019, 7, 113–141. [Google Scholar]

- Meyo, H.B.; Njoya, M.; Basitere, M.; Ntwampe, S.K.O.; Kaskote, E. Treatment of poultry slaughterhouse wastewater (Psw) using a pretreatment stage, an expanded granular sludge bed reactor (egsb), and a membrane bioreactor (mbr). Membranes 2021, 11, 345. [Google Scholar] [CrossRef]

- Bal, A.S.; Dhagat, N.N. Upflow anaerobic sludge blanket reactor—A review. Indian J. Environ. Health 2001, 43, 1–82. [Google Scholar] [PubMed]

- Hanrahan, G. Aqueous Chemistry. In Key Concepts in Environmental Chemistry; Academic Press: Cambridge, MA, USA, 2012; pp. 73–106. [Google Scholar] [CrossRef]

- Pascale, N.C.; Chastinet, J.J.; Bila, D.M.; Sant̀anna, G.L.; Quitério, S.L.; Vendramel, S.M.R. Enzymatic hydrolysis of floatable fatty wastes from dairy and meat food-processing industries and further anaerobic digestion. Water Sci. Technol. 2019, 79, 985–992. [Google Scholar] [CrossRef]

- Karadag, D.; Köroğlu, O.E.; Ozkaya, B.; Cakmakci, M. A review on anaerobic biofilm reactors for the treatment of dairy industry wastewater. Process. Biochem. 2015, 50, 262–271. [Google Scholar] [CrossRef]

- Passeggi, M.; López, I.; Borzacconi, L. Modified UASB reactor for dairy industry wastewater: Performance indicators and comparison with the traditional approach. J. Clean. Prod. 2012, 26, 90–94. [Google Scholar] [CrossRef]

- Demirer, G.; Chen, S. Effect of retention time and organic loading rate on anaerobic acidification and biogasification of dairy manure. J. Chem. Technol. Biotechnol. 2004, 79, 1381–1387. [Google Scholar] [CrossRef]

- Bella, K.; Rao, P.V. Anaerobic digestion of dairy wastewater: Effect of different parameters and co-digestion options—A review. Biomass-Convers. Biorefinery 2021, 13, 2527–2552. [Google Scholar] [CrossRef]

- Tocchi, C.; Federici, E.; Fidati, L.; Manzi, R.; Vincigurerra, V.; Petruccioli, M. Aerobic treatment of dairy wastewater in an industrial three-reactor plant: Effect of aeration regime on performances and on protozoan and bacterial communities. Water Res. 2012, 46, 3334–3344. [Google Scholar] [CrossRef] [PubMed]

- Dubber, D.; Gray, N. The effect of anoxia and anaerobia on ciliate community in biological nutrient removal systems using laboratory-scale sequencing batch reactors (SBRs). Water Res. 2011, 45, 2213–2226. [Google Scholar] [CrossRef]

- Feng, Y.; He, Z.; Ong, S.L.; Hu, J.; Zhang, Z.; Ng, W.J. Optimization of agitation, aeration, and temperature conditions for maximum β-mannanase production. Enzym. Microb. Technol. 2003, 32, 282–289. [Google Scholar] [CrossRef]

- Shioya, S.; Morikawa, M.; Kajihara, Y.; Shimizu, H. Optimization of agitation and aeration conditions for maximum virginiamycin production. Appl. Microbiol. Biotechnol. 1999, 51, 164–169. [Google Scholar] [CrossRef] [PubMed]

- Goff, H.D.; Hill, A.; Ferrer, M.A. Milk Lipids-Chemical Properties; Physical Properties; Structure and Fat Globules; Func-tional Properties. In Dairy Science and Technology eBook; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Leal, M.C.; Freire, D.M.; Cammarota, M.C.; Sant’anna, G.L. Effect of enzymatic hydrolysis on anaerobic treatment of dairy wastewater. Process. Biochem. 2006, 41, 1173–1178. [Google Scholar] [CrossRef]

- Mobarak-Qamsari, E.; Kasra-Kermanshahi, R.; Nosrati, M.; Amani, T. Enzymatic Pre-Hydrolysis of high fat Content Dairy Wastewater as a Pretreatment for Anaerobic Digestion. Int. J. Environ. Res. 2012, 6, 475–480. Available online: https://www.SID.ir (accessed on 9 October 2023).

- Mateus, G.A.P.; Formentini-Schmitt, D.M.; Nishi, L.; Fagundes-Klen, M.R.; Gomes, R.G.; Bergamasco, R. Coagulation/Flocculation with Moringa oleifera and Membrane Filtration for Dairy Wastewater Treatment. Water Air Soil Pollut. 2017, 228, 342. [Google Scholar] [CrossRef]

- Loloei, M.; Nekonam, G.; Alidadi, H.; Kor, Y. Study of the coagulation process in wastewater treatment of dairy industries. Int. J. Environ. Health Sci. Eng. 2014, 3, 12. [Google Scholar] [CrossRef]

- Muniz, G.L.; Da Silva, T.C.F.; Borges, A.C. Assessment and optimization of the use of a novel natural coagulant (Guazuma ulmifolia) for dairy wastewater treatment. Sci. Total. Environ. 2020, 744, 140864. [Google Scholar] [CrossRef] [PubMed]

- Bortoluzzi, A.C.; Faitão, J.A.; Di Luccio, M.; Dallago, R.M.; Steffens, J.; Zabot, G.L.; Tres, M.V. Dairy wastewater treatment using integrated membrane systems. J. Environ. Chem. Eng. 2017, 5, 4819–4827. [Google Scholar] [CrossRef]

- Andrade, L.; Mendes, F.; Espindola, J.; Amaral, M. Nanofiltration as tertiary treatment for the reuse of dairy wastewater treated by membrane bioreactor. Sep. Purif. Technol. 2014, 126, 21–29. [Google Scholar] [CrossRef]

- Zhao, S.; Liao, Z.; Fane, A.; Li, J.; Tang, C.; Zheng, C.; Lin, J.; Kong, L. Engineering antifouling reverse osmosis membranes: A review. Desalination 2021, 499, 114857. [Google Scholar] [CrossRef]

- Li, X.; Zhang, R. Aerobic treatment of dairy wastewater with sequencing batch reactor systems. Bioprocess Biosyst. Eng. 2002, 25, 103–109. [Google Scholar] [CrossRef] [PubMed]

- Khorasani, R.; Khodaparasti, M.S.; Tavakoli, O. Hydrogen production from dairy wastewater using catalytic supercritical water gasification: Mechanism and reaction pathway. Int. J. Hydrogen Energy 2021, 46, 22368–22384. [Google Scholar] [CrossRef]

- Justina, M.D.; Muniz, B.R.B.; Bröring, M.M.; Costa, V.J.; Skoronski, E. Using vegetable tannin and polyaluminium chloride as coagulants for dairy wastewater treatment: A comparative study. J. Water Process. Eng. 2018, 25, 173–181. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).