Application of the JDL Model for Care and Management of Greenhouse Banana Cultivation

Abstract

1. Introduction

2. Materials and Methods

2.1. The Approach

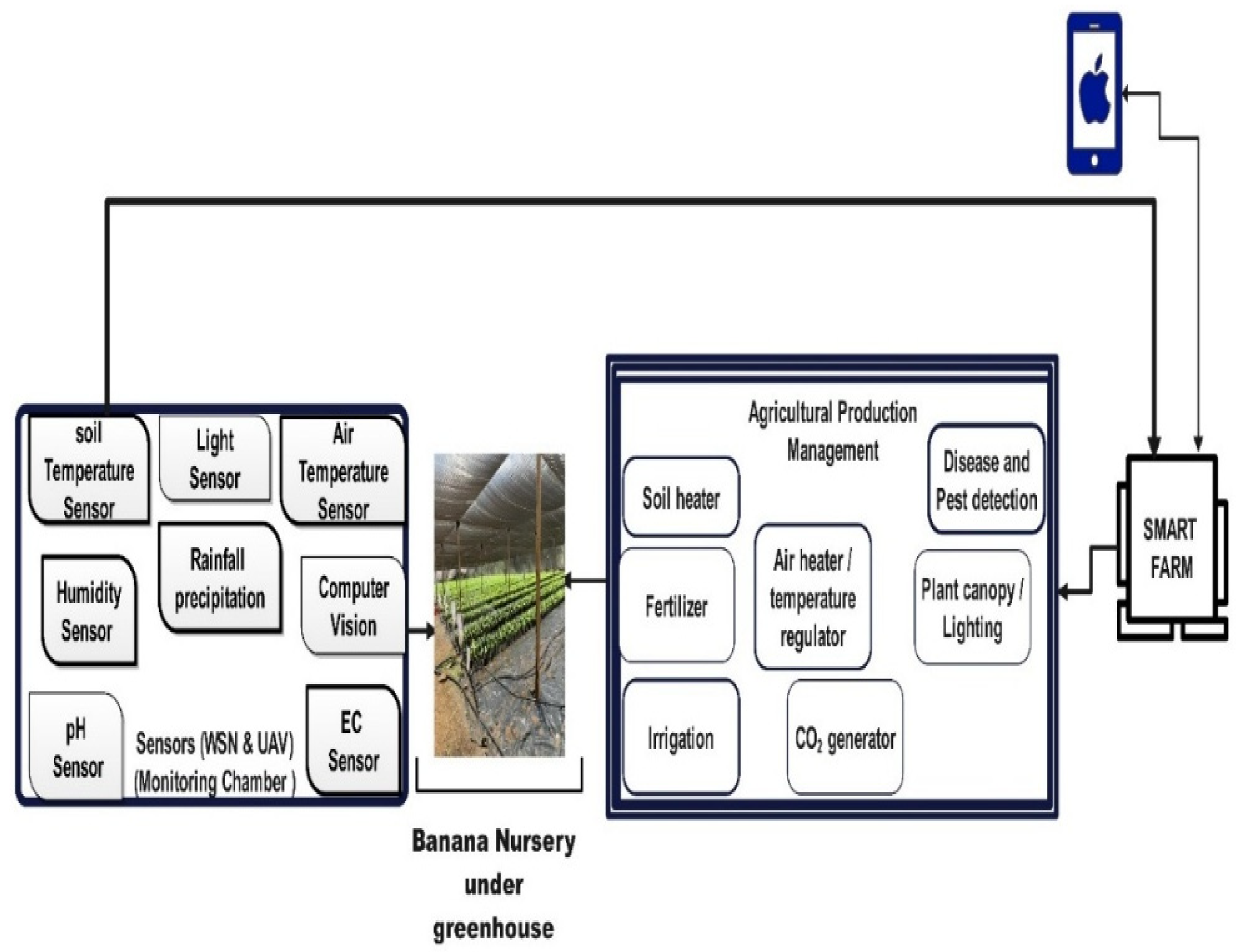

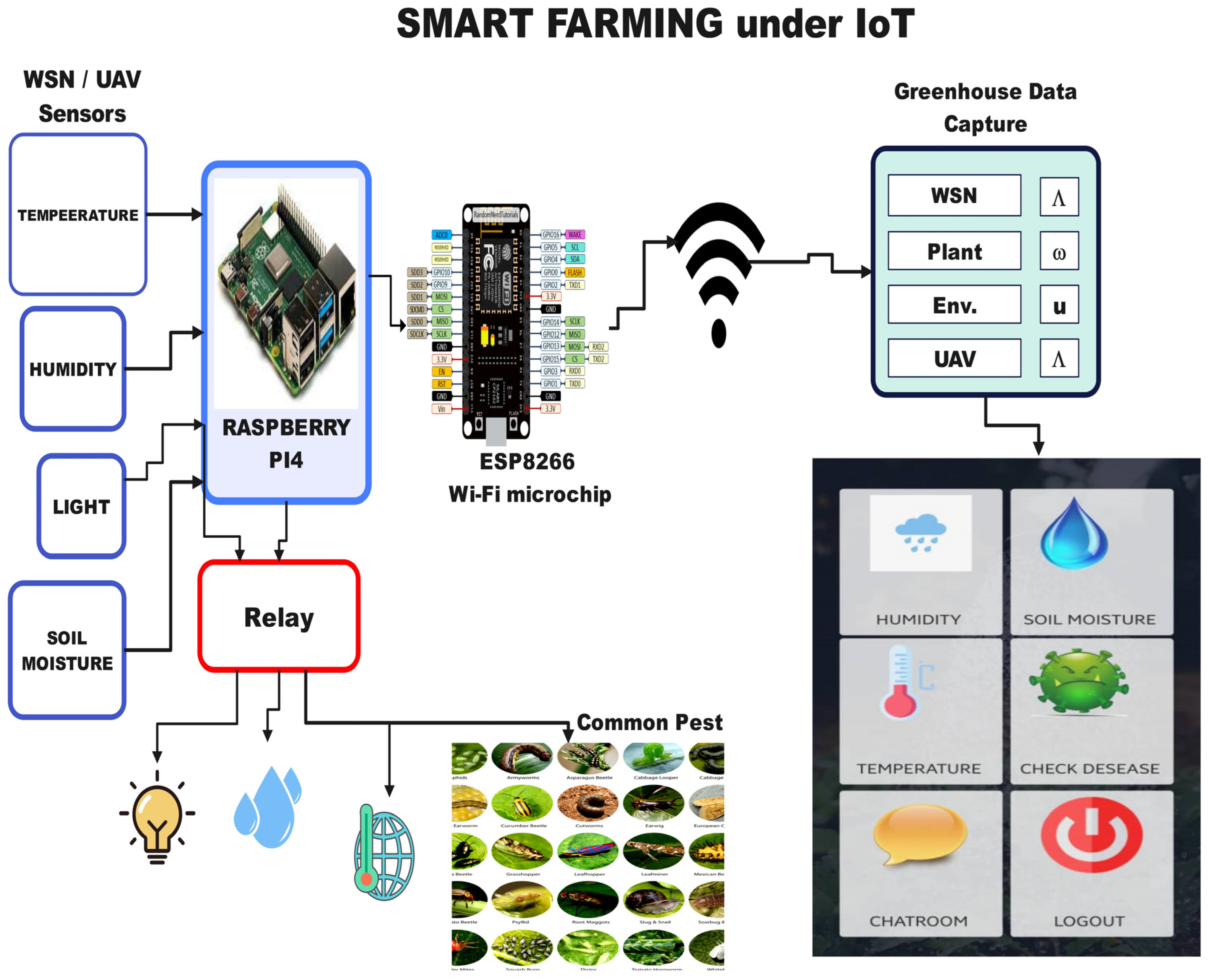

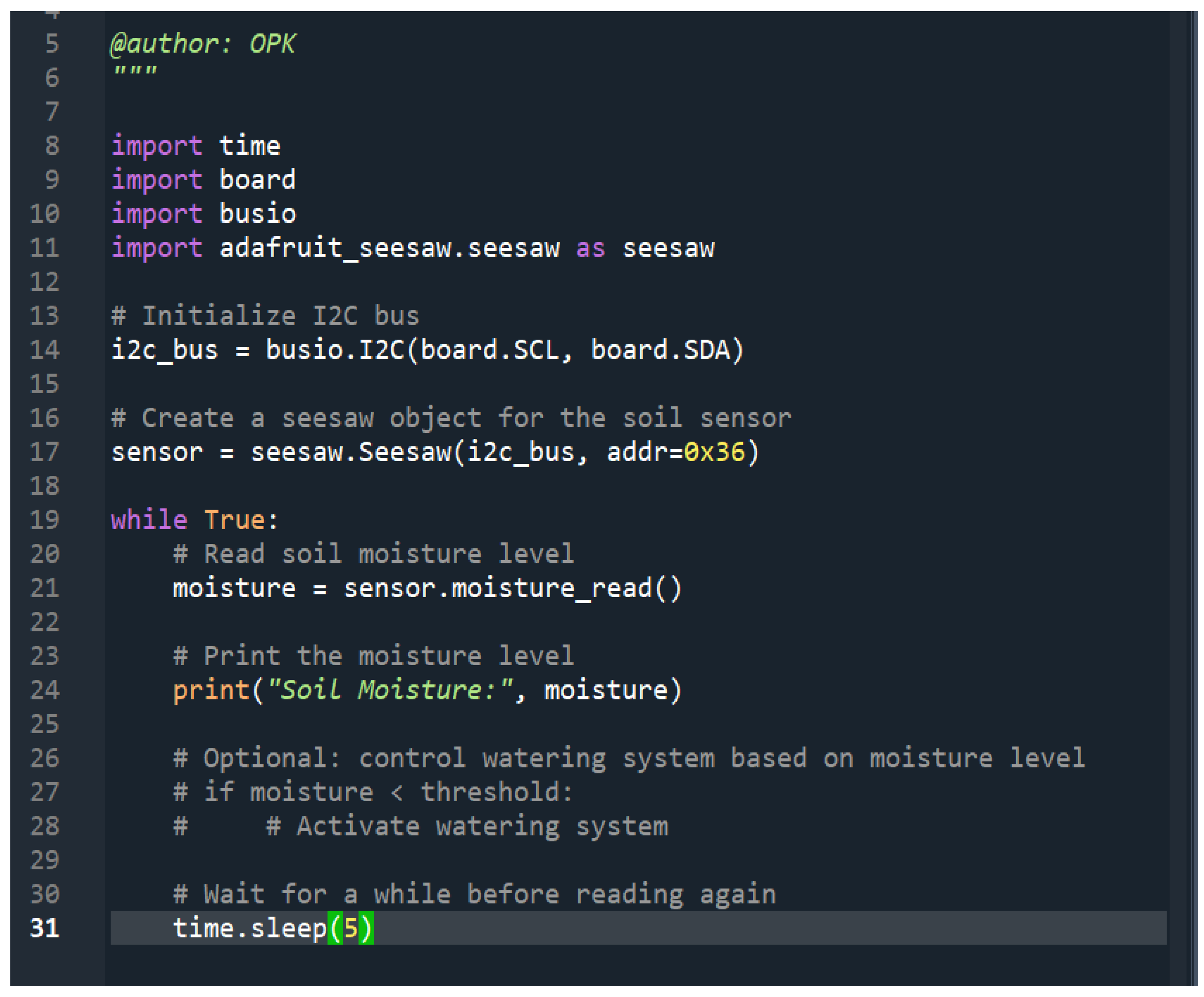

2.2. Technical Details of the SMART FARM Model

- (1)

- Articulating the uncertainty inherent in observations and in the models of the phenomena that produce these observations.

- (2)

- Integrating disparate information (e.g., unique characteristics in imagery, weather elements, and signals).

- (3)

- Managing and processing the vast array of potential associations and interpretations of numerous observations across multiple entities, i.e., UAV and WSN.

2.3. Information Accumulation Principle

2.4. Development of JDL and Attributes from the Fused Data for Greenhouse

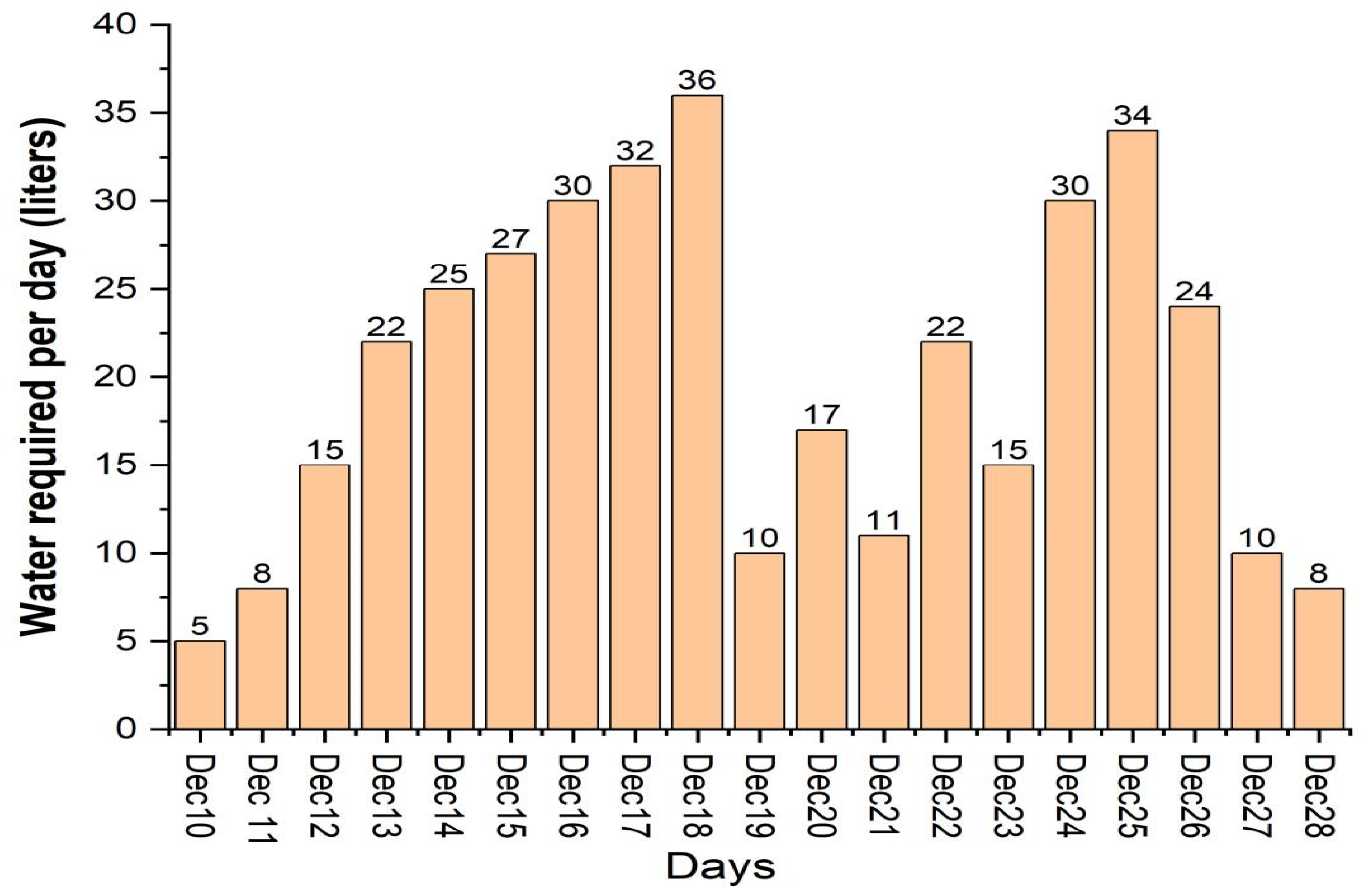

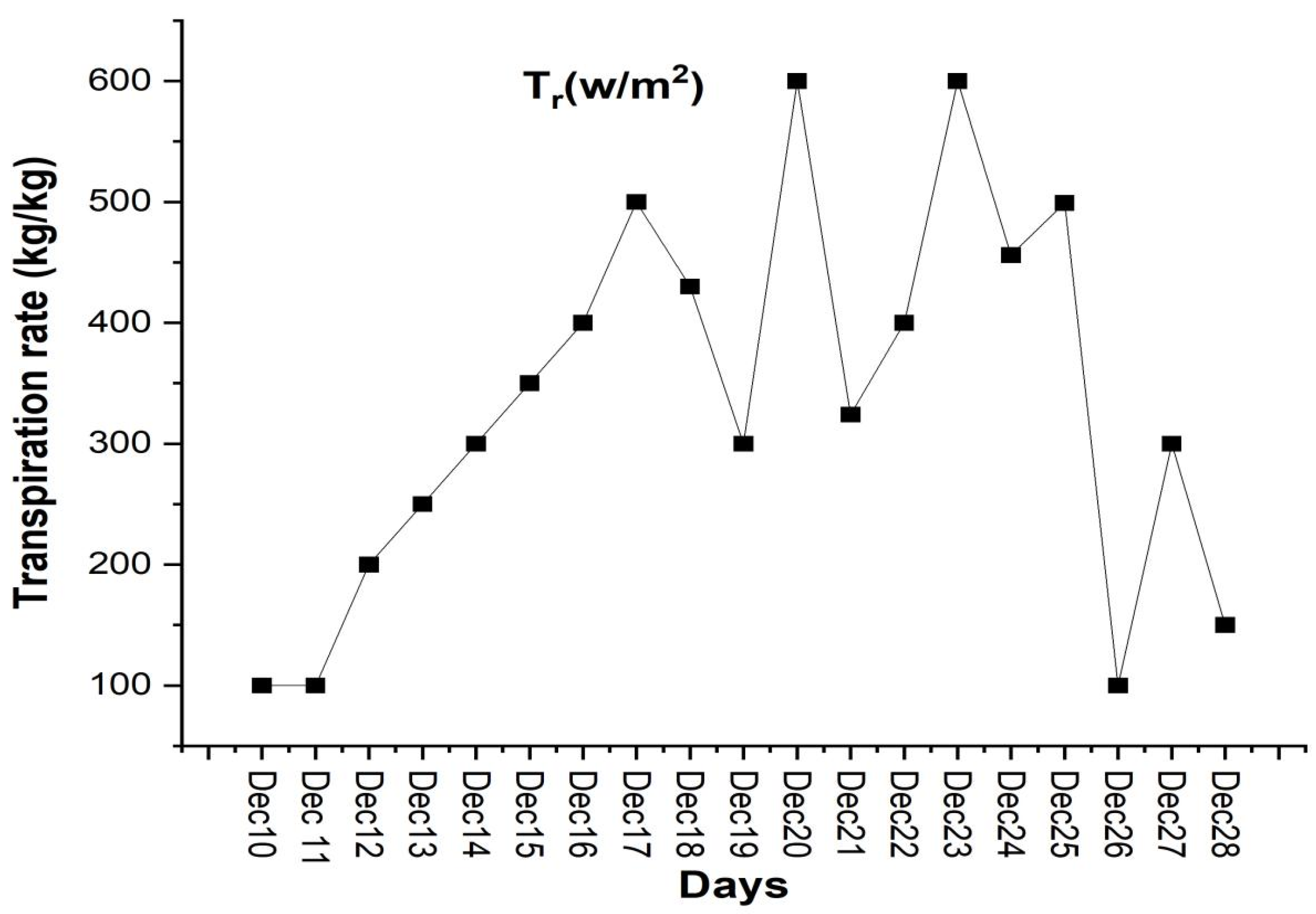

2.5. Rules for Irrigation Activation

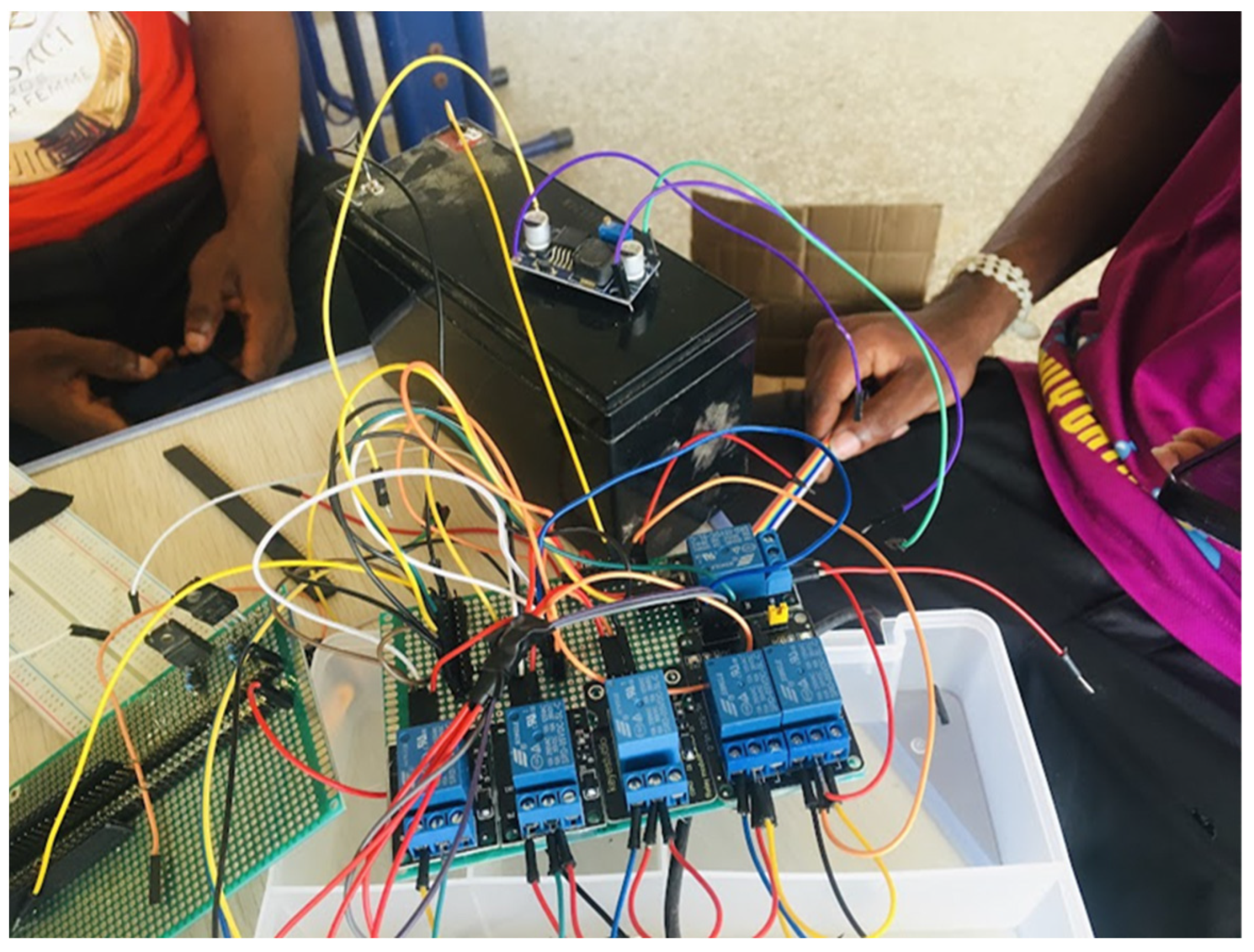

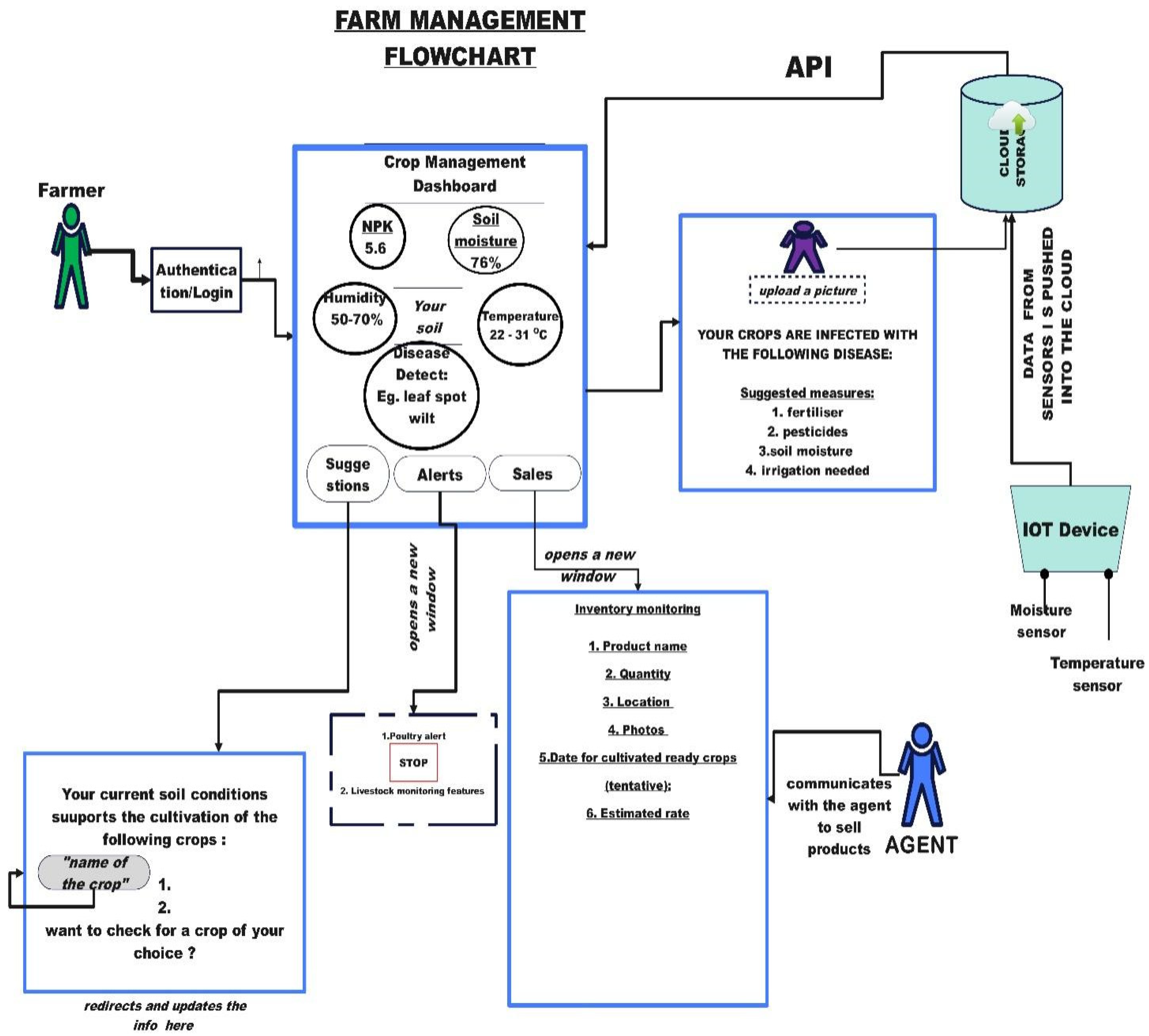

2.6. Building a Prototype and Crop Management Flow

3. Results

3.1. Operation of the Model and the System

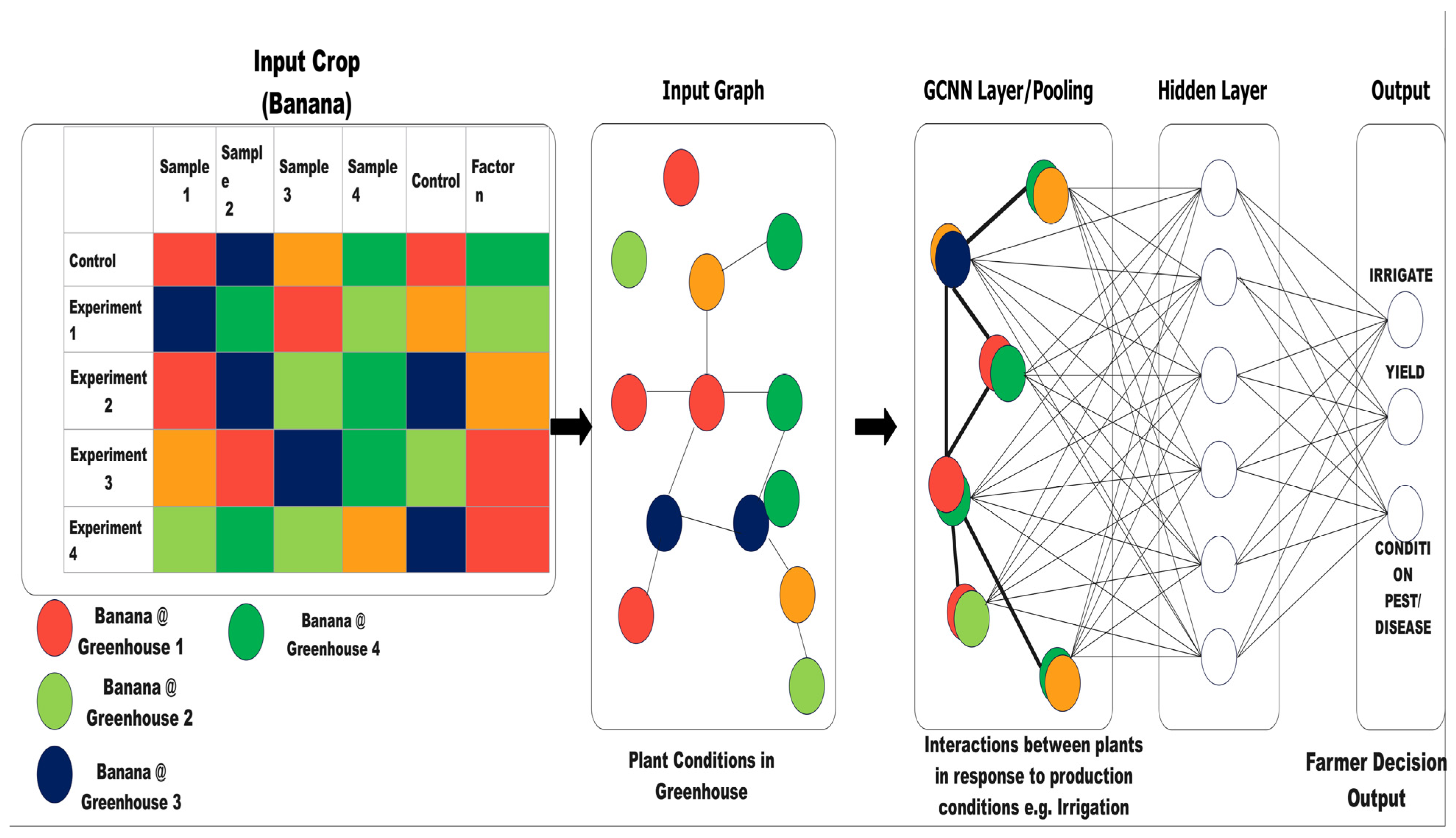

3.2. JDL Network for Banana via Morphological Image Processing

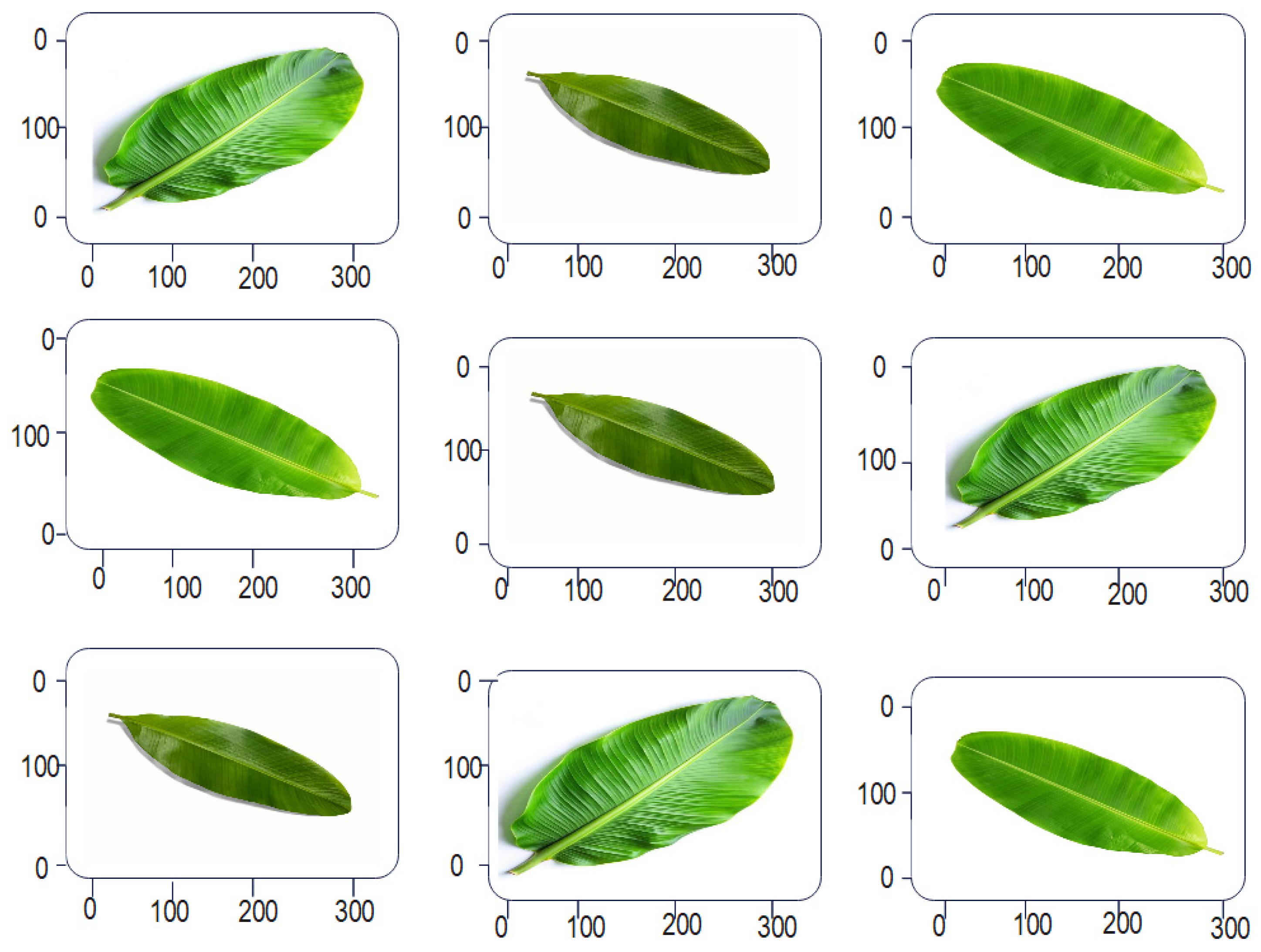

3.3. Image Processing for the CNN Model, Banana Leaf, and Canopy Analysis

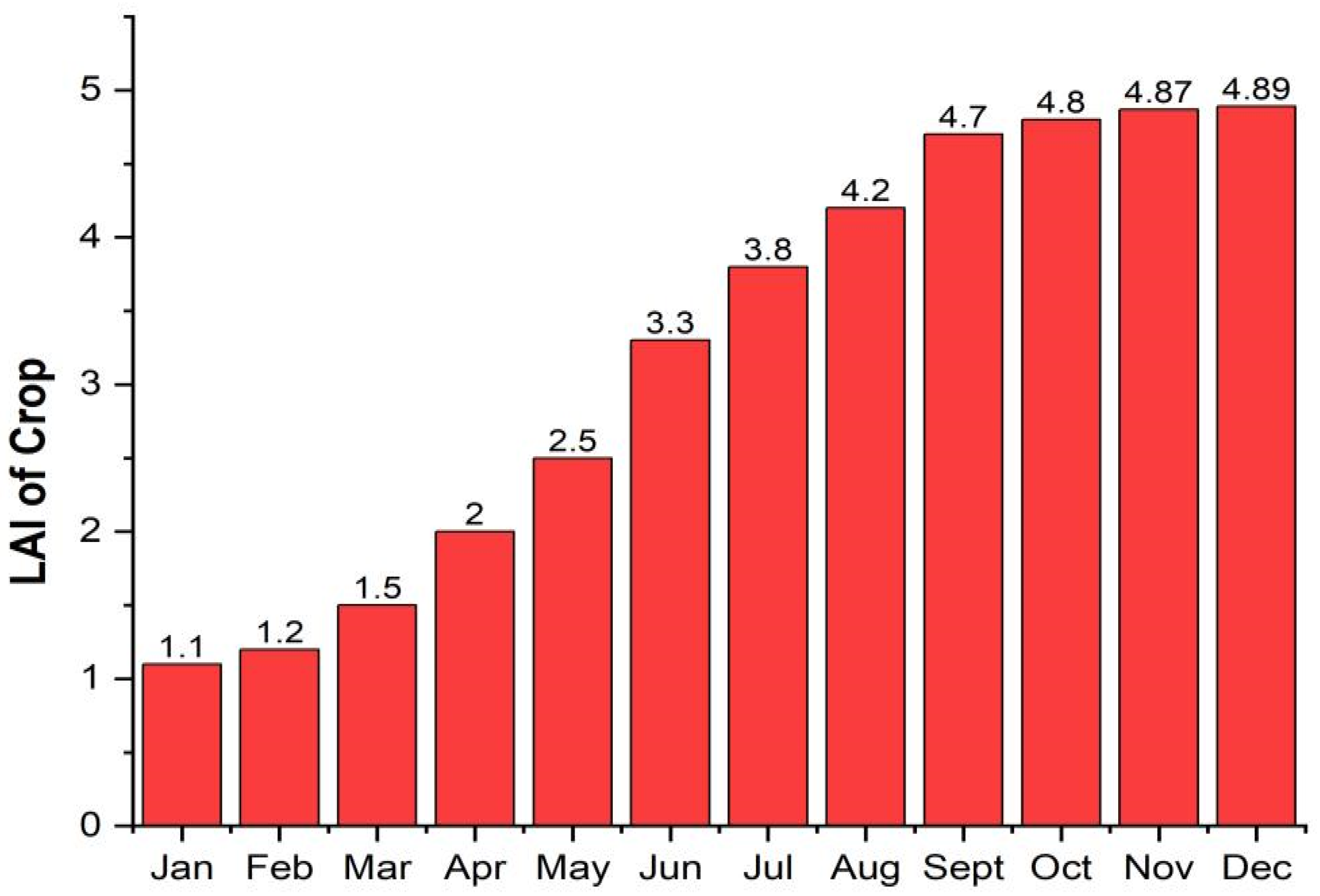

3.4. Overall Banana Growth Trend in the Greenhouse

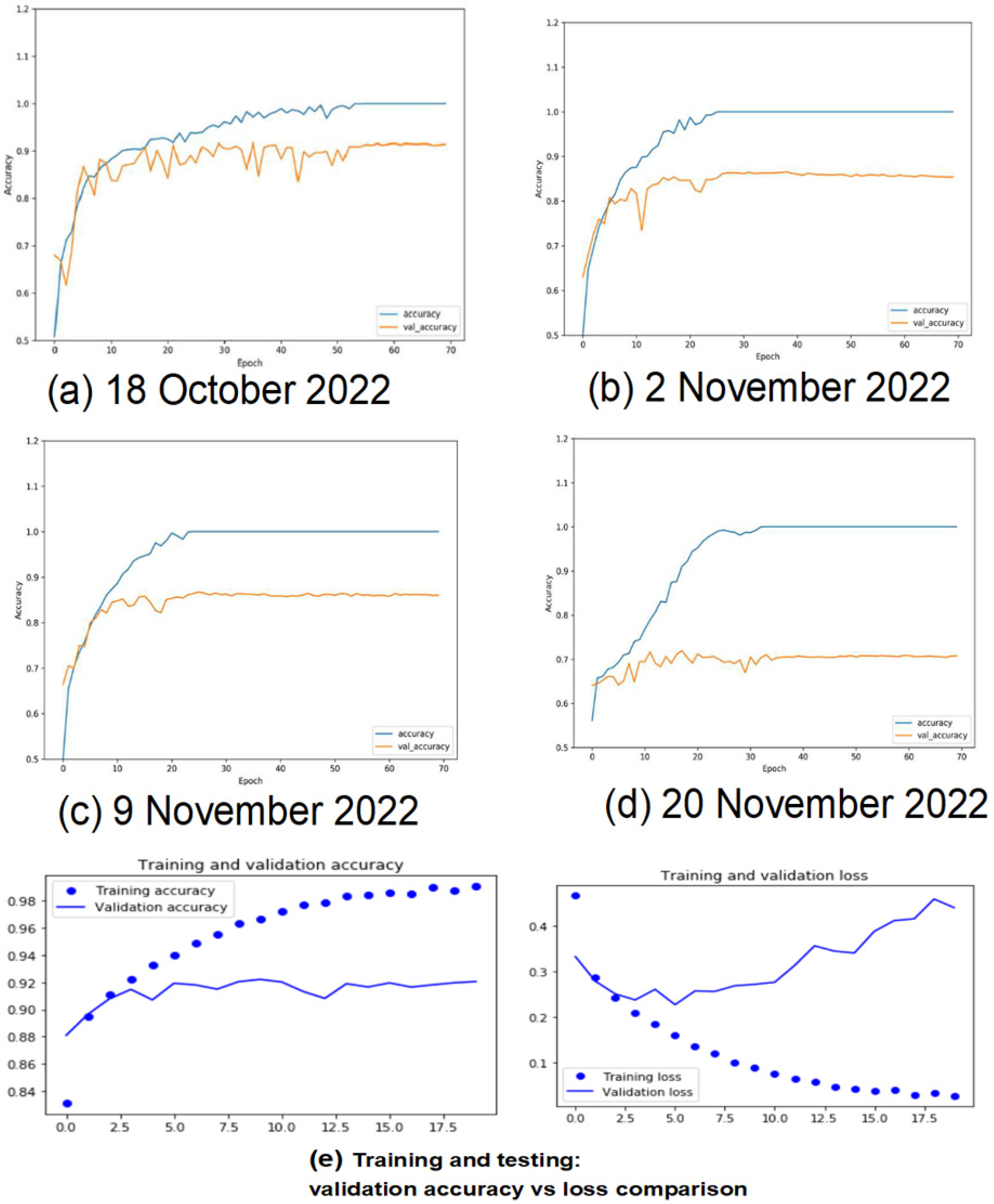

3.5. The CNN Model’s Performance

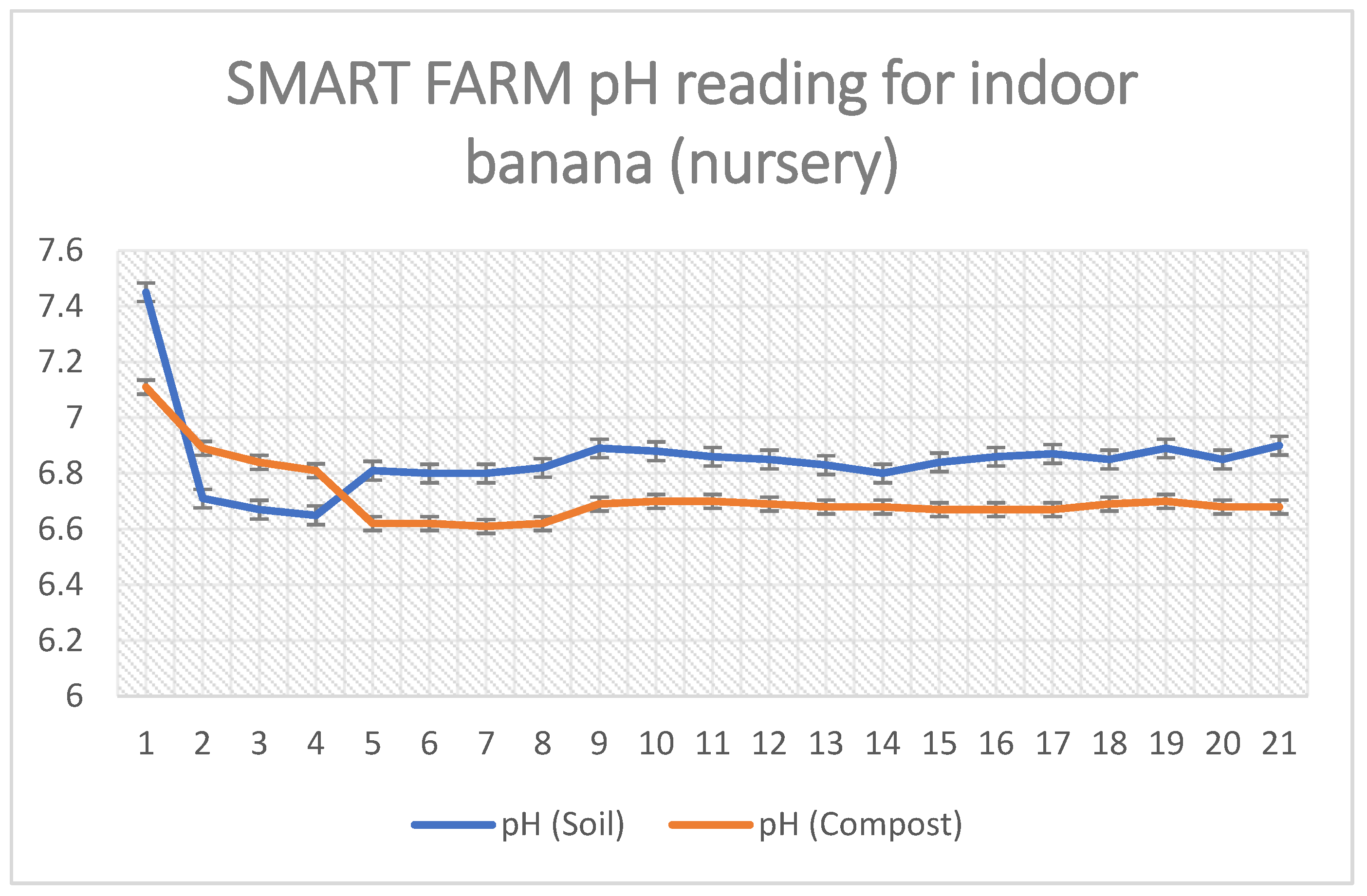

3.6. The SMART FARM pH Reading Based on the JDL Algorithms and the CNN

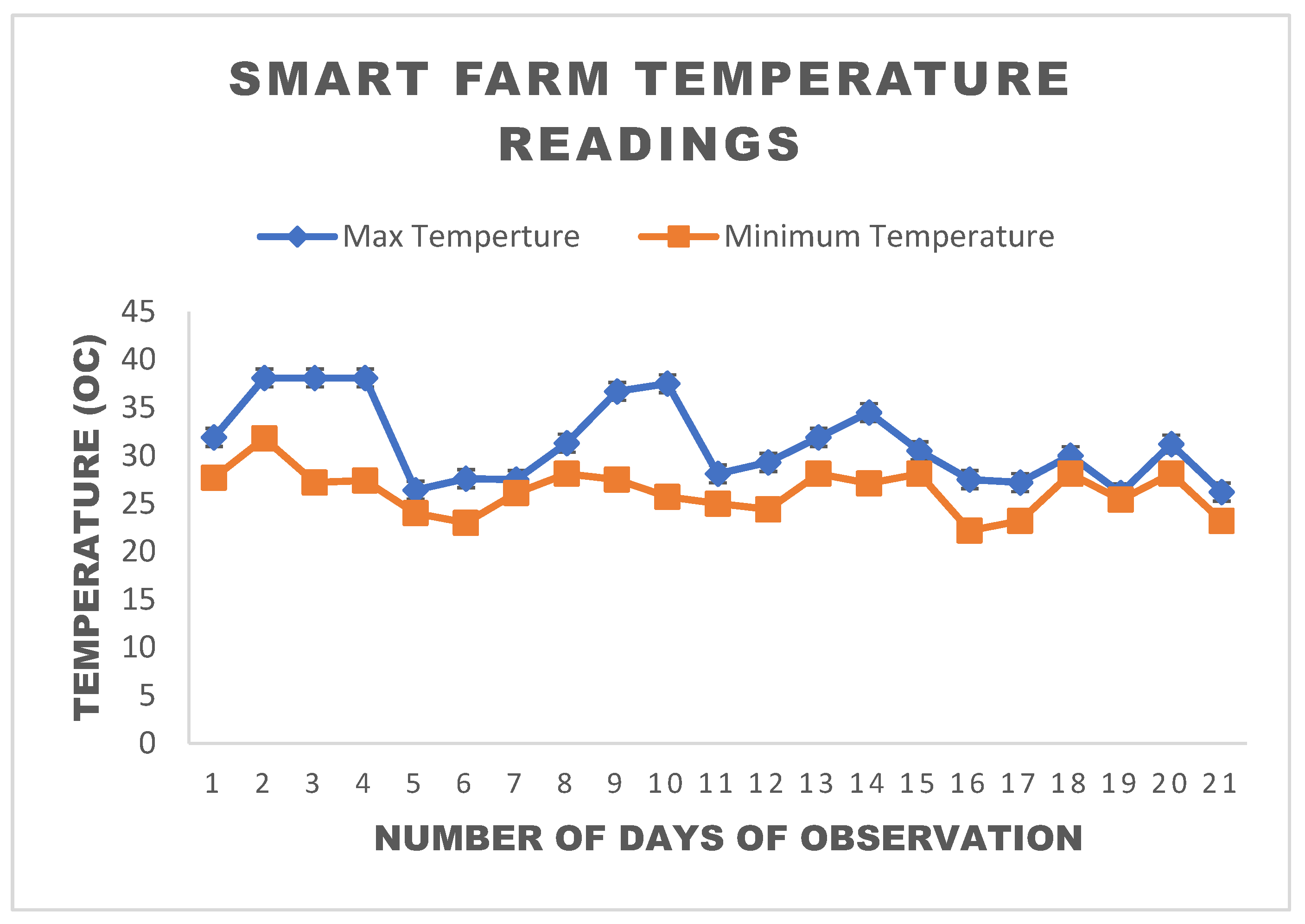

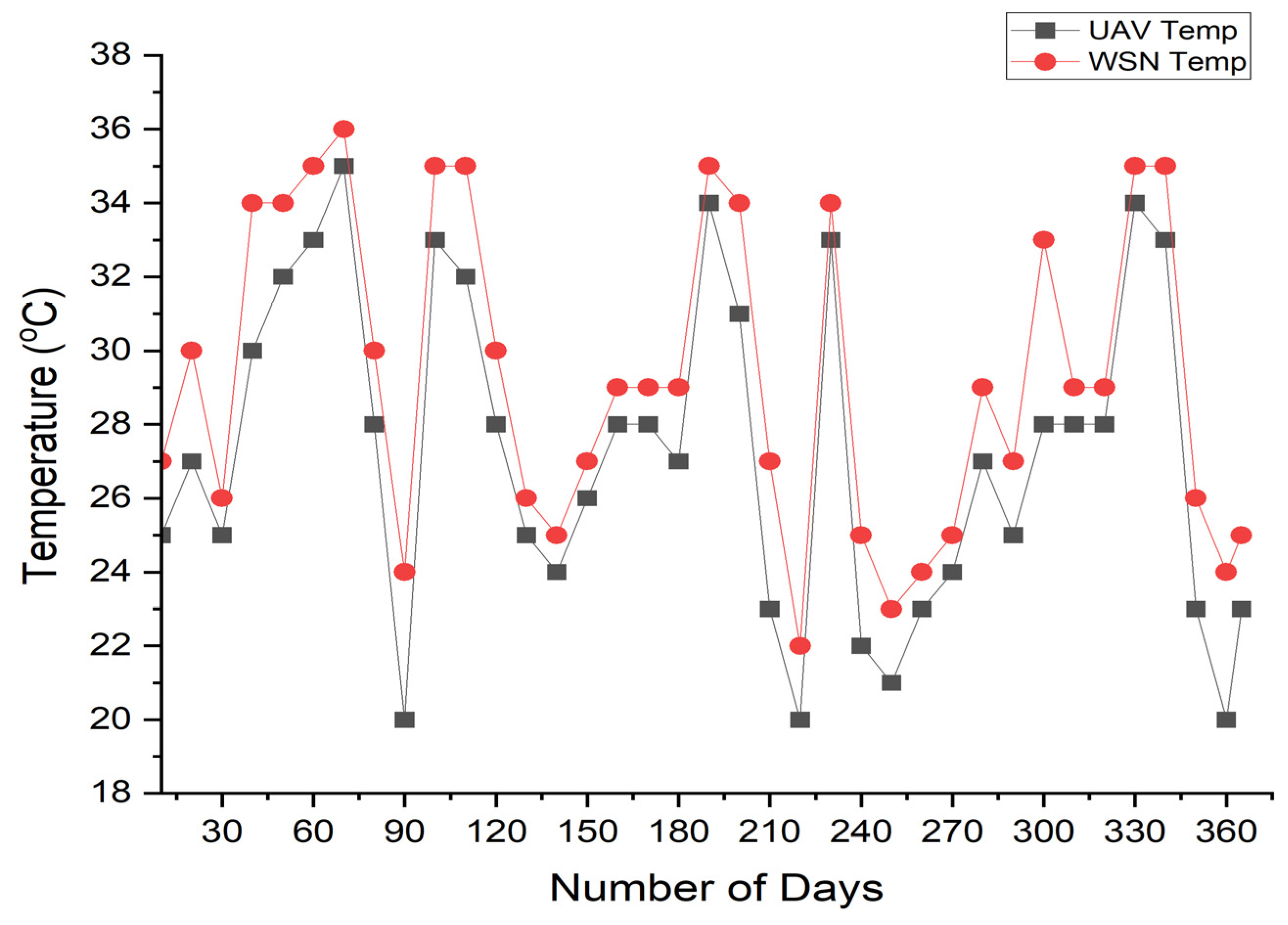

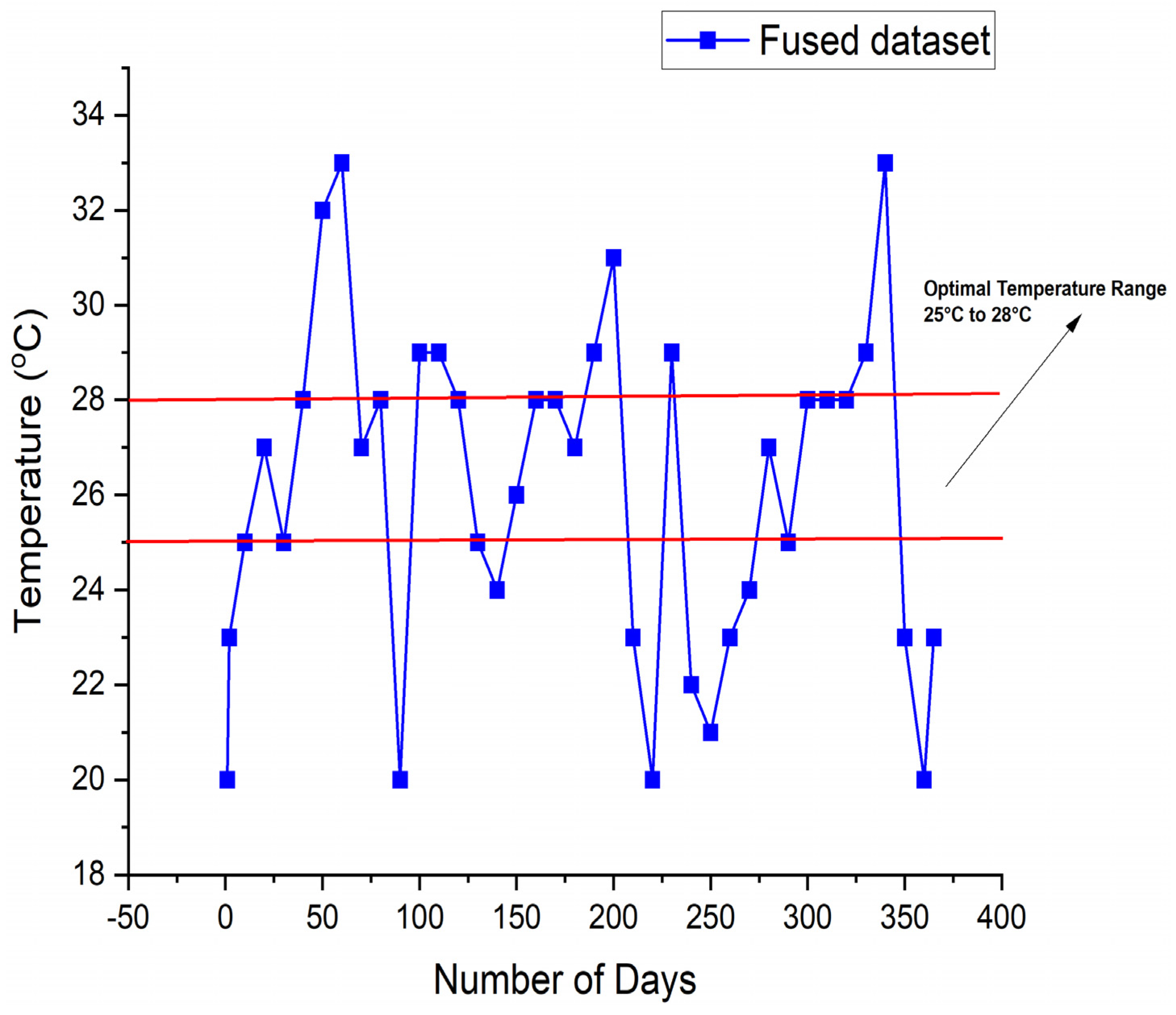

3.7. Temperature and Humidity Based on JDL Algorithms and the CNN

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bolfe, É.L.; Jorge, L.A.d.C.; Sanches, I.D.A.; Luchiari Júnior, A.; da Costa, C.C.; Victoria, D.d.C.; Inamasu, R.Y.; Grego, C.R.; Ferreira, V.R.; Ramirez, A.R. Precision and digital agriculture: Adoption of technologies and perception of Brazilian farmers. Agriculture 2020, 10, 653. [Google Scholar] [CrossRef]

- Escotet, M.Á. The optimistic future of Artificial Intelligence in higher education. Prospects 2023, 1–10. [Google Scholar] [CrossRef]

- Miine, L.K.; Akorsu, A.D.; Boampong, O.; Bukari, S. Digital agriculture and decent working conditions of smallholder farmers and farmworkers in Ghana. Discov. Food 2024, 4, 173. [Google Scholar] [CrossRef]

- Lajoie-O’Malley, A.; Bronson, K.; van der Burg, S.; Klerkx, L. The future (s) of digital agriculture and sustainable food systems: An analysis of high-level policy documents. Ecosyst. Serv. 2020, 45, 101183. [Google Scholar] [CrossRef]

- Droste, N.; May, W.; Clough, Y.; Börjesson, G.; Brady, M.; Hedlund, K. Soil carbon insures arable crop production against increasing adverse weather due to climate change. Environ. Res. Lett. 2020, 15, 124034. [Google Scholar] [CrossRef]

- Corejova, T.; Chinoracky, R. Assessing the Potential for Digital Transformation. Sustainability 2021, 13, 11040. [Google Scholar] [CrossRef]

- Yamini, B.; Pradeep, G.; Kalaiyarasi, D.; Jayaprakash, M.; Janani, G.; Uthayakumar, G.S. Theoretical study and analysis of advanced wireless sensor network techniques in Internet of Things (IoT). Meas. Sens. 2024, 33, 101098. [Google Scholar] [CrossRef]

- Naeem, M.; Jamal, T.; Diaz-Martinez, J.; Butt, S.A.; Montesano, N.; Tariq, M.I.; De-la-Hoz-Franco, E.; De-La-Hoz-Valdiris, E. Trends and future perspective challenges in big data. In The Advances in Intelligent Data Analysis and Applications, Proceeding of the Sixth Euro-China Conference on Intelligent Data Analysis and Applications, Arad, Romania, 15–18 October 2019; Springer: Singapore, 2022; pp. 309–325. [Google Scholar]

- Steinberg, A.N.; Bowman, C.L.; White, F.E.; Blasch, E.P.; Llinas, J. Evolution of the JDL model. Perspect. Inf. Fusion 2023, 6, 36–40. [Google Scholar]

- Munkhdalai, L.; Munkhdalai, T.; Pham, V.-H.; Li, M.; Ryu, K.H.; Theera-Umpon, N. Recurrent neural network-augmented locally adaptive interpretable regression for multivariate time-series forecasting. IEEE Access 2022, 10, 11871–11885. [Google Scholar] [CrossRef]

- Wang, M.; Song, G.; Yu, Y.; Zhang, B. The current research status of AI-based network security situational awareness. Electronics 2023, 12, 2309. [Google Scholar] [CrossRef]

- Teixeira, A.V.; Rezende, D.A. A multidimensional information management framework for strategic digital cities: A comparative analysis of Canada and Brazil. Glob. J. Flex. Syst. Manag. 2023, 24, 107–121. [Google Scholar] [CrossRef]

- Huang, J.; Naini, S.S.; Miller, R.; Rizzo, D.; Sebeck, K.; Shurin, S.; Wagner, J. A hybrid electric vehicle motor cooling system—Design, model, and control. IEEE Trans. Veh. Technol. 2019, 68, 4467–4478. [Google Scholar] [CrossRef]

- Peykova, A.; Petrova-Antonova, D.; Karamitov, K. Data Processing and Enrichment of LiDAR-Derived Traffic Data. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2024, 10, 263. [Google Scholar] [CrossRef]

- Vignesh, T.; Gowrishankar, S.; Jishnu, M.; Prithvi, J.K.; Joseph, P.L.; Devi, P.K.D. Influence of telepresence robot using arduino UNO R3 based 20A robot control board. In Proceedings of the 1st International Conference on Frontier of Digital Technology Towards a Sustainable Society, organized by the University, Malaysia, Malaysia, 22 May 2023. [Google Scholar]

- Aboudzadeh, M.A.; Hamzehlou, S. Supramolecular Ionic Networks: Properties. In Supramolecular Assemblies Based on Electrostatic Interactions; Springer: Berlin/Heidelberg, Germany, 2022; pp. 29–54. [Google Scholar]

- Carcaterra, A. Minimum-variance-response and irreversible energy confinement. In The IUTAM Symposium on the Vibration Analysis of Structures with Uncertainties: Proceedings of the IUTAM Symposium on the Vibration Analysis of Structures with Uncertainties Held in St. Petersburg, Russia, July 5–9, 2009; Springer: Dordrecht, The Netherlands, 2011; pp. 215–228. [Google Scholar]

- Mazumder, S. Use of Integrated Crop Management (ICM) Practices by the Farmers of Pirojpur District. Master’s Thesis, Department of Agricultural Extension and Information System, Sher-e-Bangla Agricultural University, Dhaka, Bangladesh, 2018. [Google Scholar]

- Zhang, X.; He, K.; Sima, Q.; Bao, Y. Error-feedback three-phase optimization to configurable convolutional echo state network for time series forecasting. Appl. Soft Comput. 2024, 161, 111715. [Google Scholar] [CrossRef]

- Badamasi, Y.A. The working principle of an Arduino. In Proceedings of the 2014 11th International Conference on Electronics, Computer and Computation (ICECCO), Abuja, Nigeria, 29 September–October 2014; pp. 1–4. [Google Scholar]

- Prema, R.; Jahnavi, V.; Reddy, S.V. Smart Surveillance System using Python and OpenCV. Int. J. Sci. Res. Eng. Manag. 2023. [Google Scholar]

- Richards, J.A.; Richards, J.A. Remote Sensing Digital Image Analysis; Springer: Berlin/Heidelberg, Germany, 2022; Volume 5. [Google Scholar]

- Sabado-Burlat, C.; Ignacio, M.T.T.; Guihawan, J. Inventory of high value crops using lidar data and gis in lanao del norte philippines. ASEAN Eng. J. 2022, 12, 183–187. [Google Scholar] [CrossRef]

- Dibbo, S.V.; Cheung, W.; Vhaduri, S. On-Phone CNN Model-Based Implicit Authentication to Secure IoT Wearables. In The Fifth International Conference on Safety and Security with IoT; Springer: Cham, Switzerland, 2023. [Google Scholar]

- Agbozo, E.; Balungu, D.M. Liver Disease Classification—An XAI Approach to Biomedical AI. Informatica 2024, 48, 03505596. [Google Scholar] [CrossRef]

- Zheng, K.; Qian, Y.; Yuan, Z.; Peng, F. Centrosymmetric constrained Convolutional Neural Networks. Int. J. Mach. Learn. Cybern. 2024, 15, 2749–2760. [Google Scholar] [CrossRef]

- Patrignani, A.; Ochsner, T.E. Canopeo: A powerful new tool for measuring fractional green canopy cover. Agron. J. 2015, 107, 2312–2320. [Google Scholar] [CrossRef]

- Wilson, J.B. Cover plus: Ways of measuring plant canopies and the terms used for them. J. Veg. Sci. 2011, 22, 197–206. [Google Scholar] [CrossRef]

- Ashapure, A.; Jung, J.; Chang, A.; Oh, S.; Maeda, M.; Landivar, J. A comparative study of RGB and multispectral sensor-based cotton canopy cover modelling using multi-temporal UAS data. Remote Sens. 2019, 11, 2757. [Google Scholar] [CrossRef]

- Kaewchote, J.; Janyong, S.; Limprasert, W. Image recognition method using Local Binary Pattern and the Random Forest classifier to count post larvae shrimp. Agric. Nat. Resour. 2018, 52, 371–376. [Google Scholar] [CrossRef]

- Dale, J.; Burnside, N.G.; Hill-Butler, C.; Berg, M.J.; Strong, C.J.; Burgess, H.M. The use of unmanned aerial vehicles to determine differences in vegetation cover: A tool for monitoring coastal wetland restoration schemes. Remote Sens. 2020, 12, 4022. [Google Scholar] [CrossRef]

- Pereira, L.; Paredes, P.; Jovanovic, N. Soil water balance models for determining crop water and irrigation requirements and irrigation scheduling focusing on the FAO56 method and the dual Kc approach. Agric. Water Manag. 2020, 241, 106357. [Google Scholar] [CrossRef]

- Abdalla, Z.F.; El-Ramady, H. Applications and Challenges of Smart Farming for Developing Sustainable Agriculture. Environ. Biodivers. Soil Secur. 2022, 6, 81–90. [Google Scholar] [CrossRef]

- Fandiño, M.; Cancela, J.; Rey, B.; Martínez, E.; Rosa, R.; Pereira, L. Using the dual-Kc approach to model evapotranspiration of Albariño vineyards (Vitis vinifera L. cv. Albariño) with consideration of active ground cover. Agric. Water Manag. 2012, 112, 75–87. [Google Scholar] [CrossRef]

- Israeli, Y.; Lahav, E. Injuries to banana caused by adverse climate and extreme weather. In Handbook of Diseases of Banana, Abacá and Enset; CAB International: Wallingford, UK, 2019; pp. 487–526. [Google Scholar]

- Ravi, I.; Vaganan, M.M. Abiotic stress tolerance in banana. In Abiotic Stress Physiology of Horticultural Crops; Springer: Berlin/Heidelberg, Germany, 2016; pp. 207–222. [Google Scholar]

- Botín-Sanabria, D.M.; Mihaita, A.-S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.d.J. Digital twin technology challenges and applications: A comprehensive review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Varlamis, I.; Michail, D.; Glykou, F.; Tsantilas, P. A survey on the use of graph convolutional networks for combating fake news. Future Internet 2022, 14, 70. [Google Scholar] [CrossRef]

| Variable | Type | Description | Included in JDL Model |

|---|---|---|---|

| Fused Dataset (‘ꝩ1’)-(Soil water potential) | Target | First-order difference in daily average soil water potential values for a specific plot and year at a specific depth | x |

| Plant Name (Banana) | Static categorical | Plant name differentiates between plants and characteristics | x |

| Soil texture | Static categorical | Texture of the soil | x |

| Pruning treatment | Static categorical | Weather leaves or roots were pruned | x |

| Irrigation treatment | Static categorical | Whether deficit irrigation was applied or not | x |

| Sensor depth | Static real | Depth of the soil moisture sensor in cm | x |

| Soil water potential centre | Static real | Mean of the soil water potential input window | x |

| Soil water potential scale | Static real | Scale of the soil water potential input window | x |

| Measurement year | Static real | Measurement year | x |

| Measurement month | Known categorical | Measurement month | x |

| Relative time index | Known real | Time index (in days) since k | x |

| Precipitation | Known real | Daily total precipitation | x |

| Reference evapotranspiration | Known real | Reference evapotranspiration (ETo), which is the same for all fields here | x |

| ‘ꝩ1’-(Soil water potential) | Historic real | History of the target | x |

| Irrigation amount | Historic real | Amount of irrigation applied to a specific plot | x |

| Humidity | Historic real | Daily Humidity | x |

| Soil temperature | Historic real | Daily mean soil temperature around soil moisture sensor (measured by soil moisture sensor) | x |

| Reference evapotranspiration | Historic real | Reference evapotranspiration (ETo) | x |

| Layer Type | Output Shape | Parameter Numbers |

|---|---|---|

| Conv2D | (None, 62, 62, 32) | 896 |

| MaxPooling2D | (None, 31, 31, 32) | 0 |

| Conv2D | (None, 29, 29, 64) | 18,496 |

| MaxPooling2D | (None, 14, 14, 64) | 0 |

| Conv2D | (None, 12, 12, 64) | 36,928 |

| Flatten | (None, 9216) | 0 |

| Dense | (None, 64) | 589,888 |

| Dense | (None, 4) | 260 |

| Sample Date | Irrigation Treatments | Precision | Recall | F1-Score |

|---|---|---|---|---|

| 18 October | Fully irrigated | 0.92 | 0.93 | 0.93 |

| 18 October | percent deficit | 0.89 | 0.92 | 0.90 |

| 18 October | Irrigation time delay | 0.90 | 0.88 | 0.89 |

| 2 November | Fully irrigated | 0.83 | 0.83 | 0.83 |

| 2 November | percent deficit | 0.82 | 0.84 | 0.83 |

| 2 November | Irrigation time delay | 0.83 | 0.81 | 0.82 |

| 9 November | Fully irrigated | 0.84 | 0.83 | 0.84 |

| 9 November | per cent deficit | 0.84 | 0.85 | 0.84 |

| 9 November | Irrigation time delay | 0.81 | 0.81 | 0.81 |

| 20 November | Fully irrigated | 0.83 | 0.82 | 0.82 |

| 20 November | per cent deficit | 0.60 | 0.63 | 0.62 |

| 20 November | Irrigation time delay | 0.60 | 0.56 | 0.58 |

| Irrigation Treatment | Precision | Recall | F1-Score |

|---|---|---|---|

| Fully irrigated | 0.94 | 0.96 | 0.95 |

| Per cent deficit | 0.93 | 0.90 | 0.92 |

| Irrigation time delay | 0.94 | 0.92 | 0.93 |

| Accuracy | 0.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwabena Oppong, P.; Mao, H.; Nyatuame, M.; Owusu-Manu Kwabena, C.; Nutifafa Yakanu, P.; Kwami Buami, E. Application of the JDL Model for Care and Management of Greenhouse Banana Cultivation. Water 2025, 17, 325. https://doi.org/10.3390/w17030325

Kwabena Oppong P, Mao H, Nyatuame M, Owusu-Manu Kwabena C, Nutifafa Yakanu P, Kwami Buami E. Application of the JDL Model for Care and Management of Greenhouse Banana Cultivation. Water. 2025; 17(3):325. https://doi.org/10.3390/w17030325

Chicago/Turabian StyleKwabena Oppong, Paul, Hanping Mao, Mexoese Nyatuame, Castro Owusu-Manu Kwabena, Pearl Nutifafa Yakanu, and Evans Kwami Buami. 2025. "Application of the JDL Model for Care and Management of Greenhouse Banana Cultivation" Water 17, no. 3: 325. https://doi.org/10.3390/w17030325

APA StyleKwabena Oppong, P., Mao, H., Nyatuame, M., Owusu-Manu Kwabena, C., Nutifafa Yakanu, P., & Kwami Buami, E. (2025). Application of the JDL Model for Care and Management of Greenhouse Banana Cultivation. Water, 17(3), 325. https://doi.org/10.3390/w17030325