Research on Operation and Maintenance Management of Subsurface Drip Irrigation System in the North China Plain: A Case Study in the Heilonggang Region

Abstract

:1. Introduction

2. Materials and Methods

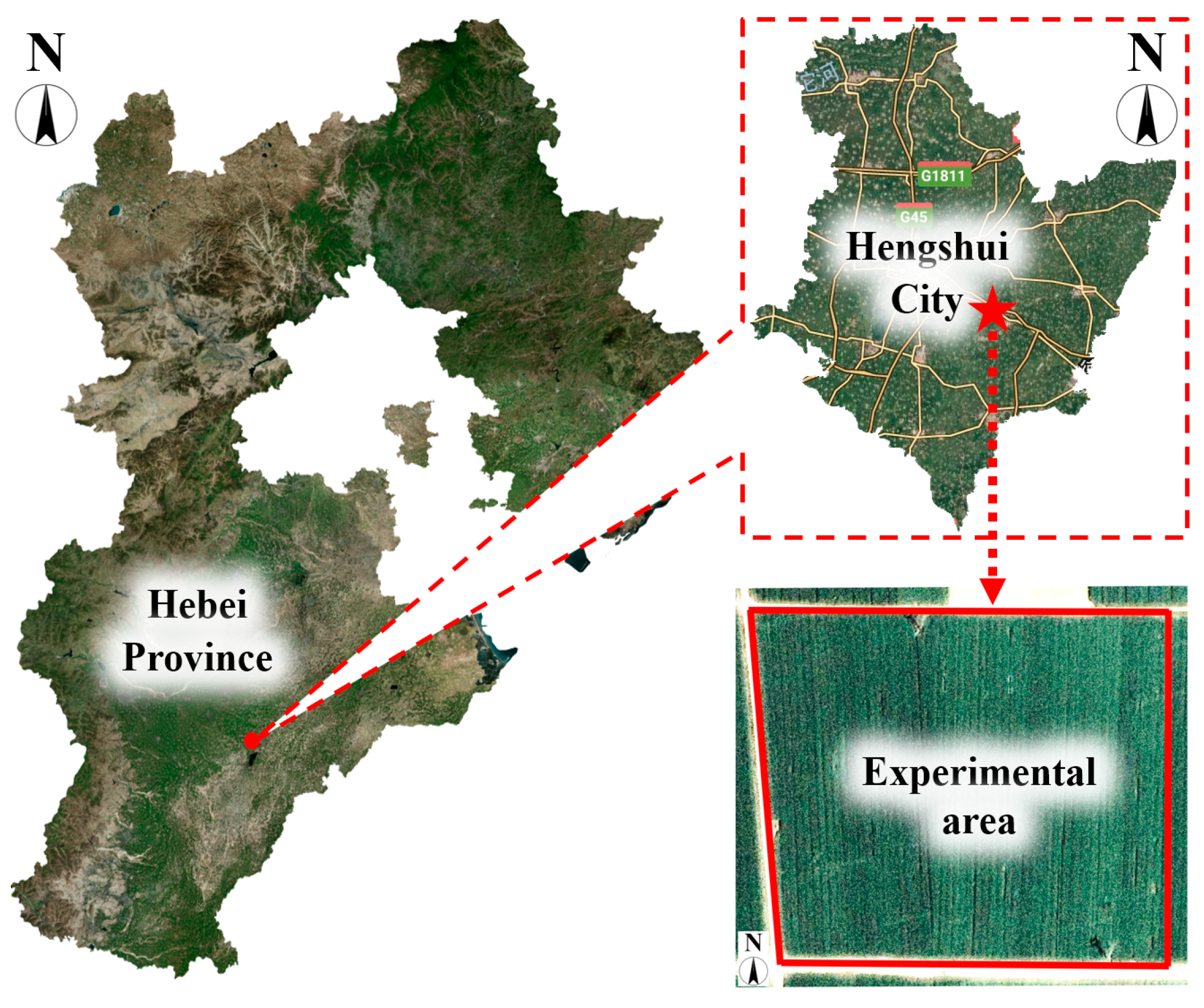

2.1. Experimental Site

2.2. Experimental Materials

2.3. Experimental Design

2.4. Data Analysis

3. Results

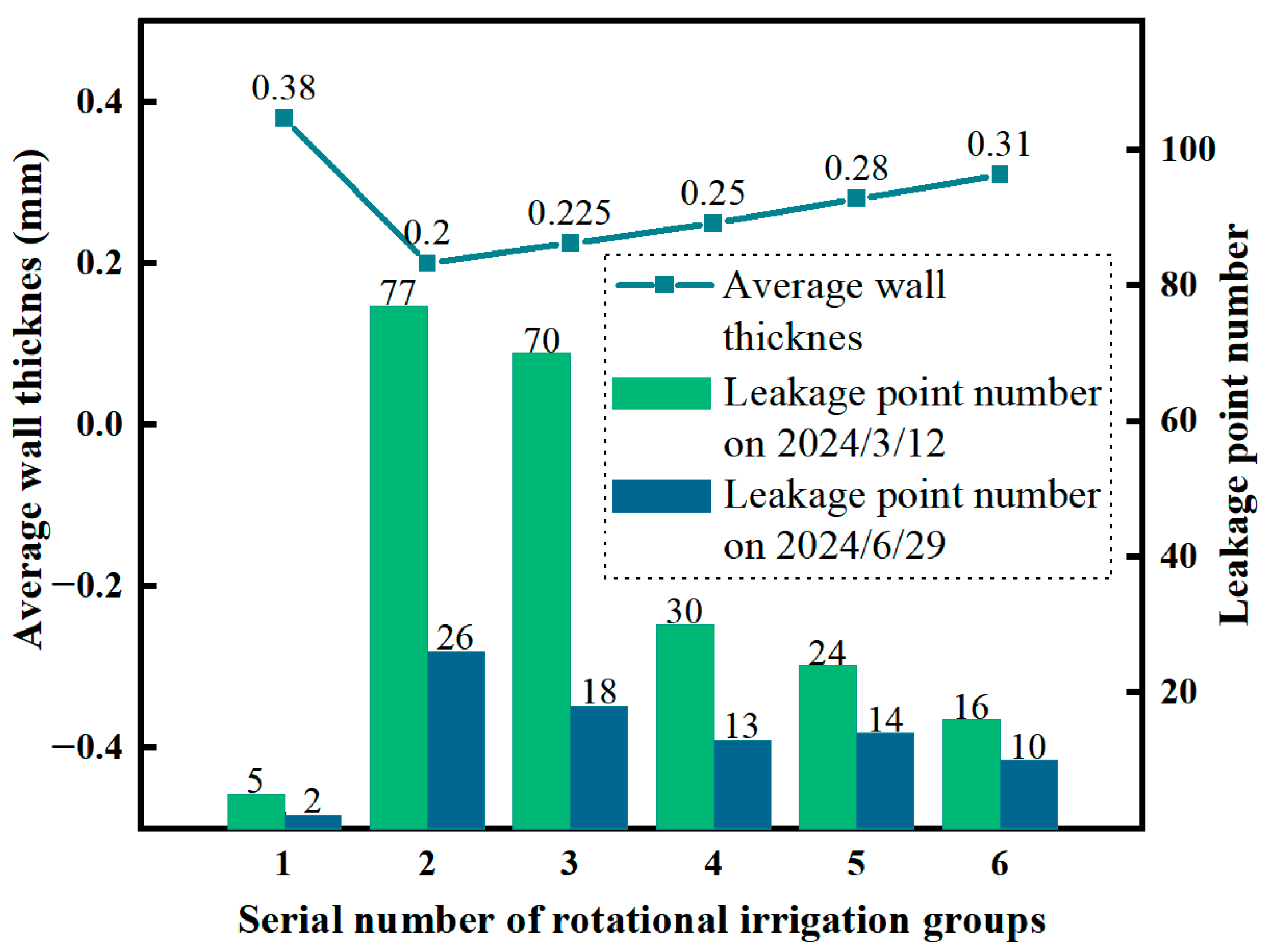

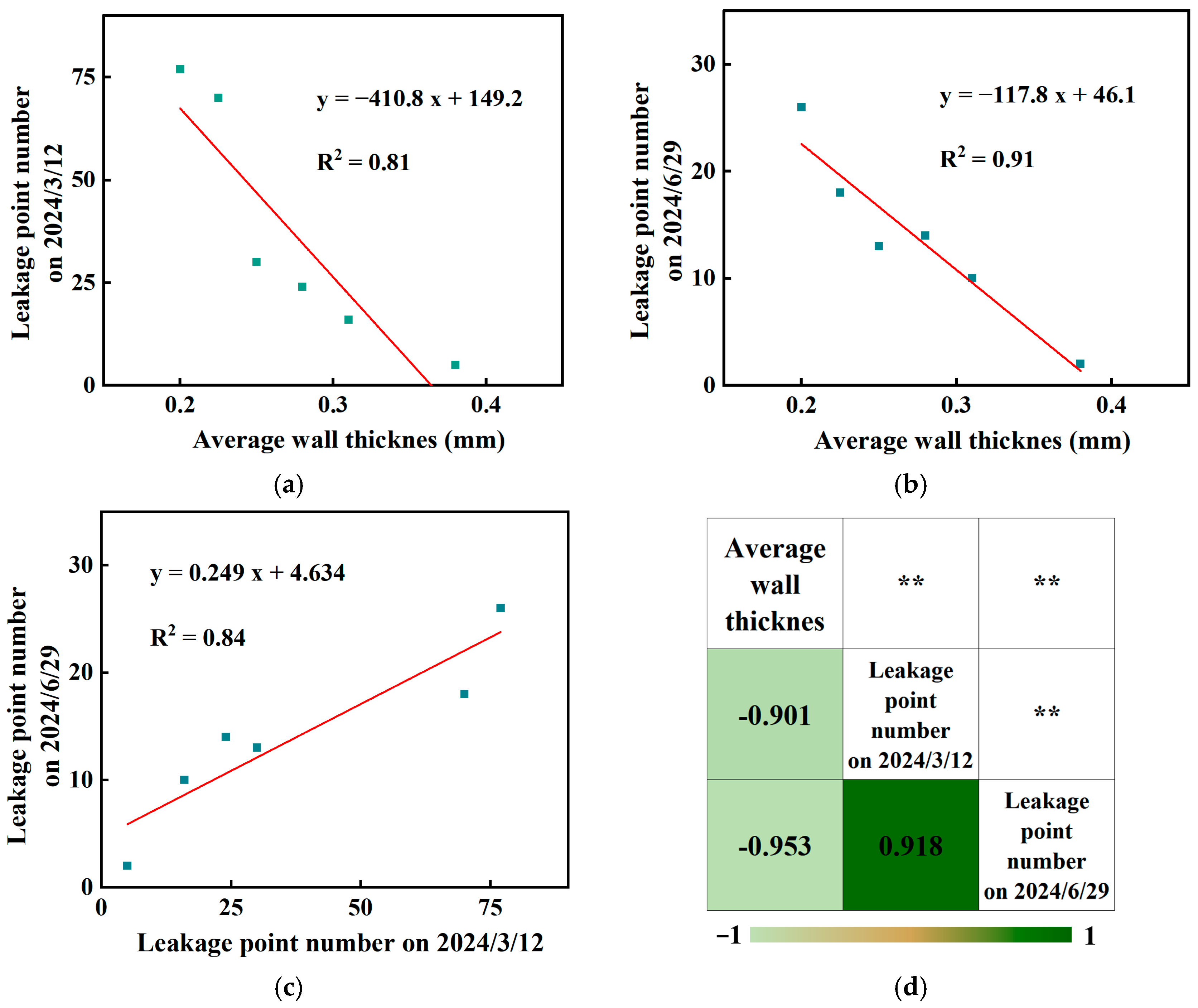

3.1. Effect of Drip Belt Wall Thickness on Irrigation System Operation

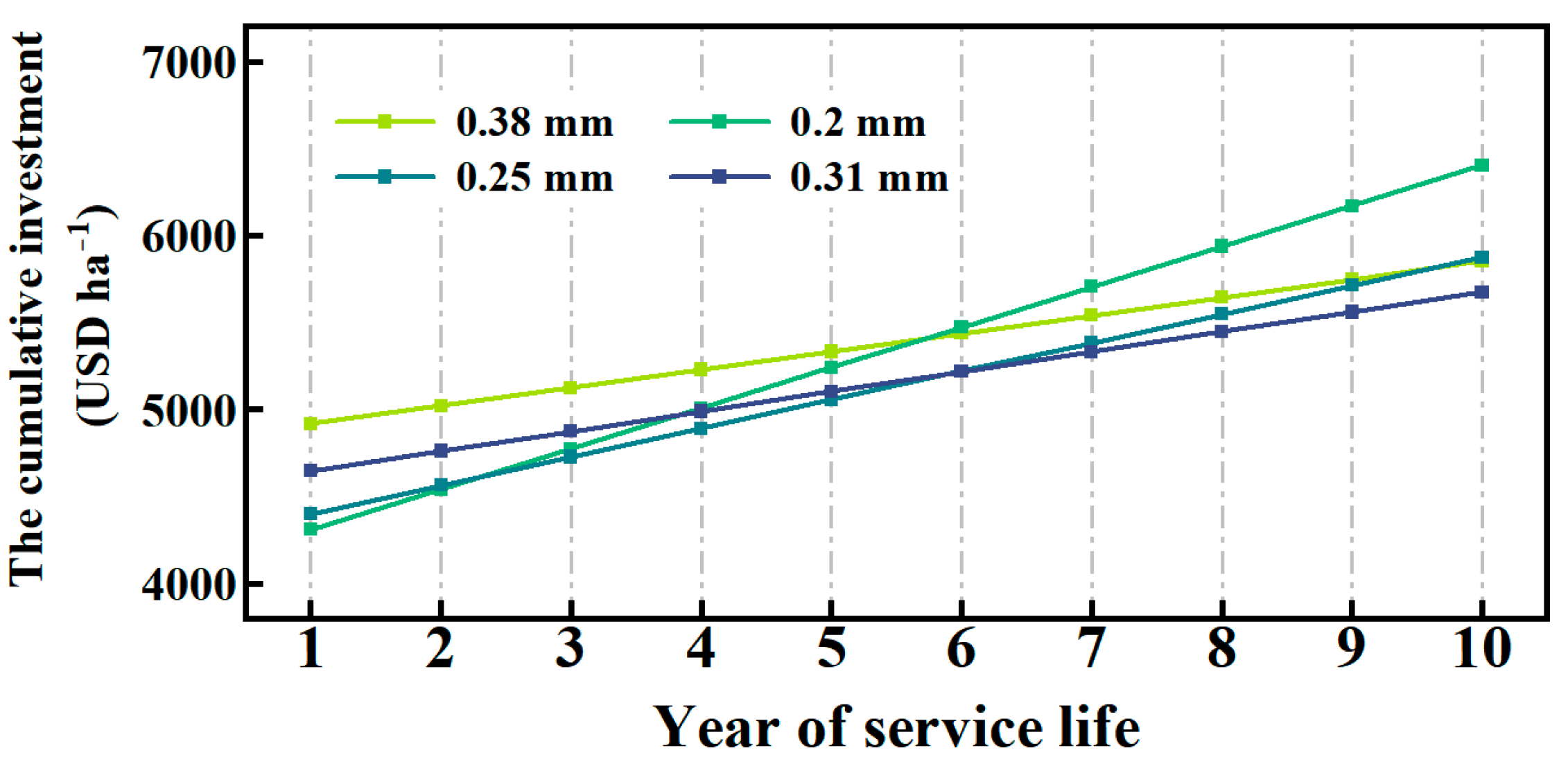

3.2. The Costs of System Construction and Maintenance

4. Discussion

4.1. Protecting Drip Tapes from Field Pests

4.2. Cost Input and Economic Benefit

4.3. Research Prospects

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xuexiu, J.; Yan, Y.; Chunyan, Z.; Xue, B.; Mengting, H.; Gang, W. Review of Analysis and Evaluation Methods for Regional Water Resource Pressure. J. Nat. Resour. 2016, 31, 1783–1791. [Google Scholar]

- Haishu, L. Analysis of the Current Situation of Water Resources in China and Research on Sustainable Development Countermeasures. Sci. Technol. Innov. 2017, 243. [Google Scholar] [CrossRef]

- National Bureau of Statistics. Statistical Bulletin on National Economic and Social Development of the People’s Republic of China in 2021. Xinhua Digest, 28 February 2022; pp. 46–57.

- Cao, D.; Wu, X.; Hong, X. Spatial distribution of water deficit of winter wheat and summer maize in North China Plain. Rural. Water Conserv. Hydropower China 2020, 6. [Google Scholar]

- Umair, M.; Hussain, T.; Jiang, H.; Ahmad, A.; Yao, J.; Qi, Y.; Zhang, Y.; Min, L.; Shen, Y. Water-Saving Potential of Subsurface Drip Irrigation for Winter Wheat. Sustainability 2019, 11, 2978. [Google Scholar] [CrossRef]

- Liu, Z. Effects of Irrigation Methods on Water Use Efficiency and Yield of Wheat. Master’s Thesis, The Agricultural University of Hebei, Baoding, China, 2023. [Google Scholar]

- Bei, L.; Jiusheng, L. Effects of Drip Irrigation Tape Depth on Soil Water and Nitrogen Distribution and Spring Corn Yield in the Field. J. China Acad. Water Resour. Hydropower Res. 2009, 7, 222–226. [Google Scholar]

- Orta, A.H.; Todorovic, M.; Ahi, Y. Cool-and warm-season turfgrass irrigation with subsurface drip and sprinkler methods using different water management strategies and tools. Water 2023, 15, 272. [Google Scholar] [CrossRef]

- Metwally, I.; Geries, L.; Saudy, H. Interactive effect of soil mulching and irrigation regime on yield, irrigation water use efficiency and weeds of trickle–irrigated onion. Arch. Agron. Soil Sci. 2022, 68, 1103–1116. [Google Scholar] [CrossRef]

- Muleke, A.; Harrison, M.T.; Eisner, R.; de Voil, P.; Yanotti, M.; Liu, K.; Monjardino, M.; Yin, X.; Wang, W.; Nie, J.; et al. Sustainable intensification with irrigation raises farm profit despite climate emergency. Plants People Planet 2023, 5, 368–385. [Google Scholar] [CrossRef]

- Wang, J.; Tian, Z.; Yang, T.; Li, X.; He, Q.; Wang, D.; Chen, R. Characteristics of limited flow and soil water infiltration boundary of a subsurface drip irrigation emitter in silty loam soil. Agric. Water Manag. 2024, 291, 108636. [Google Scholar] [CrossRef]

- Zhang, S.; Li, H.; Zheng, H.; Cao, X.; Wang, J. Experimental study on soil moisture movement law of buried drip irrigation point source infiltration. Water Sav. Irrig. 2017, 1, 25–27. [Google Scholar]

- Sagi, G. Adi Dripper Resistance to Clogging with Use of Effluent Water—A Case Study. Int. Water Irrig. 2006, 26, 42–43. [Google Scholar]

- Sabine, C.; Edlich, H.N.; Stolter, C.; Baldwin, R.A.; Motro, Y.; Jacob, J. The effect of herbal repellents in five rodent pest species. In Proceedings of the International Plant Protection Congress (IPPC), Berlin, Germany, 24–27 August 2015. [Google Scholar]

- Hansen, S.C.; Jacob, J. Herbal Repellents against Agricultural Rodent Pest Species. In Proceedings of the Vertebrate Pest Conference, Newport Beach, CA, USA, 7–10 March 2016; University of California: Davis, CA, USA, 2016; Volume 27. [Google Scholar]

- NETAFIM USA. Rodent Management Strategies—Managing Rodents in Subsurface Drip Irrigated Fields. 2016. Available online: https://www.netafimusa.com/bynder/3129CC87-47EA-4021-BA60FA0D59264187-a011-rodent-management.pdf (accessed on 8 November 2024).

- Ayars, J.; Phene, C.; Hutmacher, R.; Davis, K.; Schoneman, R.; Vail, S.; Mead, R. Subsurface drip irrigation of row crops: A review of 15 years of research at the Water Management Research Laboratory. Agric. Water Manag. 1999, 42, 1–27. [Google Scholar] [CrossRef]

- Daoxi, L.; Jinyao, L. Research and Progress of Underground Drip Irrigation Technology. China Rural. Water Resour. Hydropower 2003, 4. [Google Scholar]

- Lamm, F.R. In Ksu results from twenty nine years of irrigation and fertigation studies using SDI. In Proceedings of the 30th Annual Central Plains Irrigation Conference, Colby, KS, USA, 20–21 February 2018. [Google Scholar]

- Letey, J.; Dinar, A.; Woodring, C.; Oster, J.D. An economic analysis of irrigation systems. Irrig. Sci. 1990, 11, 37–43. [Google Scholar] [CrossRef]

- Valentín, F.; Nortes, P.A.; Domínguez, A.; Sánchez, J.M.; Intrigliolo, D.S.; Alarcón, J.J.; López-Urrea, R. Comparing evapotranspiration and yield performance of maize under sprinkler, superficial and subsurface drip irrigation in a semi-arid environment. Irrig. Sci. 2020, 38, 105–115. [Google Scholar] [CrossRef]

- Wang, J.; He, Q.; Song, X.; Niu, W. Effect of Soil Moisture Distribution under Subsurface Drip Irrigation on Soil CH4 Flux in Facility Farmland. Res. Environ. Sci. 2023, 36, 1368–1378. [Google Scholar]

- Wang, D.; Li, G.; Mo, Y.; Zhang, D.; Xu, X.; Wilkerson, C.J.; Hoogenboom, G. Evaluation of subsurface, mulched and non-mulched surface drip irrigation for maize pro-duction and economic benefits in northeast China. Irrig. Sci. 2021, 39, 159–171. [Google Scholar] [CrossRef]

- Romero, P.; García, J.; Botía, P. Cost–benefit analysis of a regulated deficit-irrigated almond orchard under subsurface drip irrigation conditions in Southeastern Spain. Irrig. Sci. 2006, 24, 175–184. [Google Scholar] [CrossRef]

- Tunc, T.; Sahin, U.; Evren, S.; Dasci, E.; Guney, E.; Aslantas, R. The deficit irrigation productivity and economy in strawberry in the different drip irrigation practices in a high plain with semi-arid climate. Sci. Horti-Cult. 2019, 245, 47–56. [Google Scholar] [CrossRef]

- Bozkurt Çolak, Y.; Yazar, A.; Yıldız, M.; Tekin, S.; Gönen, E.; Alghawry, A. Assessment of crop water stress index and net bene-fit for surface- and subsurface-drip irrigated bell pepper to various deficit irrigation strategies. J. Agri-Cult. Sci. 2023, 161, 254–271. [Google Scholar]

- Tong, X.; Wu, P.; Zhang, L.; Wang, Z. Optimizing wolfberry crop productivity and economic sustaina-bility using subsurface irrigation with ceramic emitters for smallholders: A four-year study. Eur. J. Agron. 2024, 159, 127293. [Google Scholar] [CrossRef]

- Payero, J.O.; Yonts, C.D.; Suat, I.; Tarkalson, D. Advantages and disadvantages of subsurface drip irrigation. In Proceedings of the International Meeting on Advances in Drip/Micro Irrigation, Puerto de La Cruz, Spain, 2–5 December 2002. [Google Scholar]

- Irmak, S. Maize response to different subsurface drip irrigation management strategies: Yield, production functions, basal and crop evapotranspiration. Agric. Water Manag. 2024, 300, 108927. [Google Scholar] [CrossRef]

- Liu, C. Water Resources Problems and Countermeasures in Heilonggang Area in the New Era. Geogr. Geogr. Inf. Sci. 2007, 23, 4. [Google Scholar]

- Wang, B.; Zhang, F.; Cheng, Y.; Chen, L.; Guo, X. Evaluation of Water and Soil Resource Quality and Underground Drip Irrigation Water saving Experiment in Heilonggang Area. Jiangsu Agric. Sci. 2011, 4. [Google Scholar]

- Qiao, J.; Ma, Z.; Wang, W.; Zhang, L.; Liu, H.; Hao, X.; Ji, Y. Soil Enzyme and Fertility Characteristics of High Yield Summer Corn Fields in Hebei Province. Jiangsu Agric. Sci. 2016, 44, 484–487. [Google Scholar]

- Camp, C.R.; Bauer, P.J.; Hunt, P.G.; Busscher, W.J.; Sadler, E.J. Subsurface drip irrigation for agronomic crops. In Proceedings of the Irrigation–Association Technical Conference Intl. Irrigation–Association Technical Conference, San Diego, CA, USA, 1–3 November 1998. [Google Scholar]

- He, Z. Natural Color Atlas of Agricultural Pests in Northern China; Liaoning Science and Technology Press: Shenyang, China, 1997. [Google Scholar]

- Li, Y.; Li, J.; Li, B. Effects of drip irrigation system operation mode and fertilization frequency on soil nitrogen dynamics in tomato root zone. J. Water Resour. 2007, 857–864. [Google Scholar]

- Obrien, D.M.; Rogers, D.H.; Lamm, F.R.; Clark, G.A. An economic comparison of subsurface drip and center pivot sprinkler irrigation systems. Appl. Eng. Agric. 1998, 14, 391–398. [Google Scholar] [CrossRef]

- Jun, Y. Issues to be noted in the design and management of underground drip irrigation. Inn. Mong. Water Resour. 2009, 2. [Google Scholar]

- Ren, X.; Xu, H.; Cui, M.; Wang, P. Integrated control of crop diseases and insect pests in farmland. J. Agron. 2004, 17–18. [Google Scholar]

- Hu, X.; Shen, L.; Hu, Z.; Xu, J. Research progress on pollution-free pest control of cultivated ginseng in farmland. Chin. Mod. Tradit. Med. 2020, 22, 9. [Google Scholar]

- Zhao, Y. Pests and control of ginseng. Ginseng Res. 1998, 2. [Google Scholar]

- Xu, L.; Ji, Y.; Li, X.; Li, Y.; Luo, Z.; Lu, D.; Zou, Y.; Cheng, J. Study on population dynamics and control strategy of farmland pests in Sanjiang plain. South. Agric. 2018, 12, 2. [Google Scholar]

- Dai, L. Underground pest population survey and control strategy in Pingliang. Mod. Hortic. 2014, 3. [Google Scholar]

- Guo, L.; Liu, H.; Jiang, G. Restoration of balance of nature and creation of pest-free farmland environment. Green Leaves 2014, 7. [Google Scholar]

- Hong, G. Discussion on the Problems in the Application of Underground Drip Irrigation. Water Sci. Eng. Technol. 2012, 3. [Google Scholar]

- Guo, Y.; Wang, D.; Shi, D. Occurrence and control technology progress of agricultural rat pest in our country. Plant Prot. 2013, 39, 8. [Google Scholar]

- Feng, X.; Peng, X.; Li, D.; Shi, Y.; Liu, J. Occurrence and control of rodent pests in agricultural areas of Jingzhou. Hubei Plant Prot. 2023, 71–74. [Google Scholar]

- Cong, L.; Luo, C.; Guo, Y.; Liu, X.; Wang, Y.; Wang, D. Preliminary study on the control effect of high-placed large-capacity poison bait station on rodents in northeast farmland. Plant Prot. 2018, 44, 4. [Google Scholar]

- Bosch, D.J.; Powell, N.L.; Wright, F.S. An Economic Comparison of Subsurface Microirrigation with Center Pivot Sprinkler Irrigation. J. Prod. Agric. 1992, 5, 431. [Google Scholar] [CrossRef]

- Wang, D.; Qin, M.; Guo, Y.W. Achievements and challenges of rodent control in rural areas of China from 2011 to 2020. Chin. Guide Plant Prot. 2022, 42, 24–29. [Google Scholar]

- Shao, Y. Control techniques of farmland rat pest. Shaanxi Agric. Sci. 2011, 57, 279–280. [Google Scholar]

- Li, H.; Wie, X.; Chen, J. Popularization and application of rodent control techniques. Guangdong Agric. Sci. 2009, 2. [Google Scholar]

- Darouich, H.M.; Pedras, C.M.; Gonçalves, J.M.; Pereira, L.S. Drip vs. surface irrigation: A comparison focusing on water saving and economic returns using multicriteria analysis applied to cotton. Biosyst. Eng. 2014, 122, 74–90. [Google Scholar] [CrossRef]

- Lamm, F.R.; Manges, H.L.; Stone, L.R.; Khan, A.H.; Rogers, D.H. Water requirement of subsurface drip-irrigated corn in southwest Kansas. Trans. ASAE 1995, 38, 441–448. [Google Scholar] [CrossRef]

- Dhuyvetter, K.C.; Lamm, F.R.; Rogers, D.H. Subsurface Drip Irrigation for Field Corn: An Economic Analysis; Irrigation Management Series Publication, L-909; Kansas State Univ. Research and Extension Service: Manhattan, KS, USA, 1994. [Google Scholar]

- Ezra, D.; Ovadia, A. Control of Mal secco disease in lemon by drip irrigation with fungicide. Phytoparasitica 2024, 52, 68. [Google Scholar] [CrossRef]

- Wang, Z.; Li, J.; Li, Y. Effects of drip irrigation system uniformity and nitrogen applied on deep percolation and nitrate leaching during growing seasons of spring maize in semi-humid region. Irrig. Sci. 2014, 32, 221–236. [Google Scholar] [CrossRef]

- Li, J.S.; Zhang, J.J.; Rao, M.J. Wetting patterns and nitrogen distributions as affected by fertigation strategies from a surface point source. Agric. Water Manag. 2004, 67, 89–104. [Google Scholar] [CrossRef]

- Lamm, F.R.; Colaizzi, P.D.; Sorensen, R.B.; Bordovsky, J.P.; Dougherty, M.; Balkcom, K.; Zaccaria, D.; Bali, K.M.; Rudnick, D.R.; Peters, R.T. A 2020 Vision of Subsurface Drip Irrigation in the U. S. Trans. ASABE 2021, 64, 1319–1343. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, B.; Yang, P. Research progress on emitter clogging mechanism and control method in drip irrigation system. Acta Hydraul. Sin. 2018, 49, 103–114. [Google Scholar]

- Xia, T.; Tian, J.; Fei, W. Experimental Study on the Performance of a Sand Filtration Method and Device by Using Natural Soils and Subsurface PVC Drainage Pipes. J. Irrig. Drain. Eng. 2021, 147, 4021004. [Google Scholar] [CrossRef]

- Wang, R.; Gong, S.; Yu, J.; Wang, J.; Yu, Y. Research progress on resistance to root invasion and clogging in subsurface drip irrigation. Water-Sav. Irrig. 2012, 61–63. [Google Scholar]

- Song, P.; Li, Y.; Li, J.; Pei, Y. Control of emitter clogging in drip irrigation system with reclaimed water by chlorination and lateral flushing. Agric. Eng. 2017, 33, 80–86. [Google Scholar]

- Eroglu, S.; Sahin, U.; Tunc, T.; Sahin, F. Bacterial application increased the flow rate of CaCO3 clogged emitters of drip irrigation system. J. Environ. Manag. 2012, 98, 37–42. [Google Scholar] [CrossRef]

| Treatment Number | Irrigated Area (m3) | Drip Tape Parameters of TYPPHOON PLUS Series | ||

|---|---|---|---|---|

| Diameter (mm) | Wall Thickness (mm) | Flow Rate (L·h−1) | ||

| 1 | 6733 | 22 | 0.380 | 1.0 |

| 2 | 8333 | 16 | 0.200 | 0.7 |

| 3 | 10,333 | 16 | 0.225 | 0.7 |

| 4 | 10,333 | 16 | 0.250 | 0.7 |

| 5 | 10,333 | 16 | 0.280 | 0.7 |

| 6 | 10,333 | 16 | 0.310 | 0.7 |

| Damage Reasons | Rotational Irrigation Group | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| Insects | 5 | 100 | 87 | 43 | 37 | 24 |

| Rodents | 0 | 0 | 0 | 0 | 0 | 1 |

| Overstretched | 0 | 3 | 1 | 0 | 0 | 1 |

| Weak connection | 1 | 0 | 0 | 0 | 1 | 0 |

| Total amount | 7 | 103 | 88 | 43 | 38 | 26 |

| Time | Source | Sum of Squares | df | Mean Square | Significant Level |

|---|---|---|---|---|---|

| 12 March | Between groups | 3088.9 | 5 | 617.8 | ≤0.001 |

| Within groups | 307.9 | 12 | 25.7 | ||

| Total | 3396.8 | 17 | |||

| 29 June | Between groups | 260.9 | 5 | 52.2 | ≤0.001 |

| Within groups | 62.4 | 12 | 5.2 | ||

| Total | 323.4 | 17 |

| Types of Insecticides | Price (USD) | Packaging Quantity | Usage Quantity (ha−1) | Price (USD·ha−1) | Cost (USD·ha−1) |

|---|---|---|---|---|---|

| 40% phoxim | 1.8·Can−1 | 500 mL·Can−1 | 3000 mL | 10.7 | 16.7 |

| 2.5% lambda-cyhalothrin | 0.56·Can−1 | 500 mL·Can−1 | 2250 mL | 2.5 | |

| 70% imidacloprid | 1.2·Bag−1 | 100 g·Bag−1 | 300 g | 3.5 |

| Time | Treatment | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| September | 3.2 | 20.5 | 16.6 | 10.9 | 7.0 | 4.4 |

| November | 1.7 | 14.5 | 9.2 | 8.0 | 7.0 | 2.9 |

| Average | 2.4 | 17.5 | 12.9 | 9.4 | 7.0 | 3.6 |

| annual count | 12.0 | 87.5 | 64.7 | 47.2 | 35.0 | 18.0 |

| Type of Cost | Type of Drip Tape | |||

|---|---|---|---|---|

| 0.20 mm | 0.25 mm | 0.31 mm | 0.38 mm | |

| Maintenance | 149.5 | 80.7 | 30.8 | 20.5 |

| Pesticides | 83.5 | 83.5 | 83.5 | 83.5 |

| Total annual | 232.8 | 164.0 | 114.1 | 103.9 |

| Drip Tape Type | Wall Thickness (mm) | Price (USD·roll−1) | Length (m·roll−1) | Cost (USD·ha−1) |

|---|---|---|---|---|

| Thin-wall | 0.20 | 150.0 | 2500 | 1002.0 |

| 0.25 | 139.7 | 2000 | 1161.9 | |

| Thick-wall | 0.31 | 139.1 | 1600 | 1459.0 |

| 0.38 | 135.5 | 1300 | 1739.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Dang, H.; Hui, X.; Cai, D.; Zhang, H.; Xue, J.; Liu, X.; Ma, J.; Cao, C.; Niu, X.; et al. Research on Operation and Maintenance Management of Subsurface Drip Irrigation System in the North China Plain: A Case Study in the Heilonggang Region. Water 2025, 17, 508. https://doi.org/10.3390/w17040508

Zheng Y, Dang H, Hui X, Cai D, Zhang H, Xue J, Liu X, Ma J, Cao C, Niu X, et al. Research on Operation and Maintenance Management of Subsurface Drip Irrigation System in the North China Plain: A Case Study in the Heilonggang Region. Water. 2025; 17(4):508. https://doi.org/10.3390/w17040508

Chicago/Turabian StyleZheng, Yudong, Hongkai Dang, Xin Hui, Dongyu Cai, Haohui Zhang, Jingyuan Xue, Xuetong Liu, Junyong Ma, Caiyun Cao, Xindong Niu, and et al. 2025. "Research on Operation and Maintenance Management of Subsurface Drip Irrigation System in the North China Plain: A Case Study in the Heilonggang Region" Water 17, no. 4: 508. https://doi.org/10.3390/w17040508

APA StyleZheng, Y., Dang, H., Hui, X., Cai, D., Zhang, H., Xue, J., Liu, X., Ma, J., Cao, C., Niu, X., Zheng, C., & Li, K. (2025). Research on Operation and Maintenance Management of Subsurface Drip Irrigation System in the North China Plain: A Case Study in the Heilonggang Region. Water, 17(4), 508. https://doi.org/10.3390/w17040508