Drinking Water Network as a Potential Pathway for Micro- and Nanoplastics Exposure to Human: A Mini Review

Abstract

1. Introduction

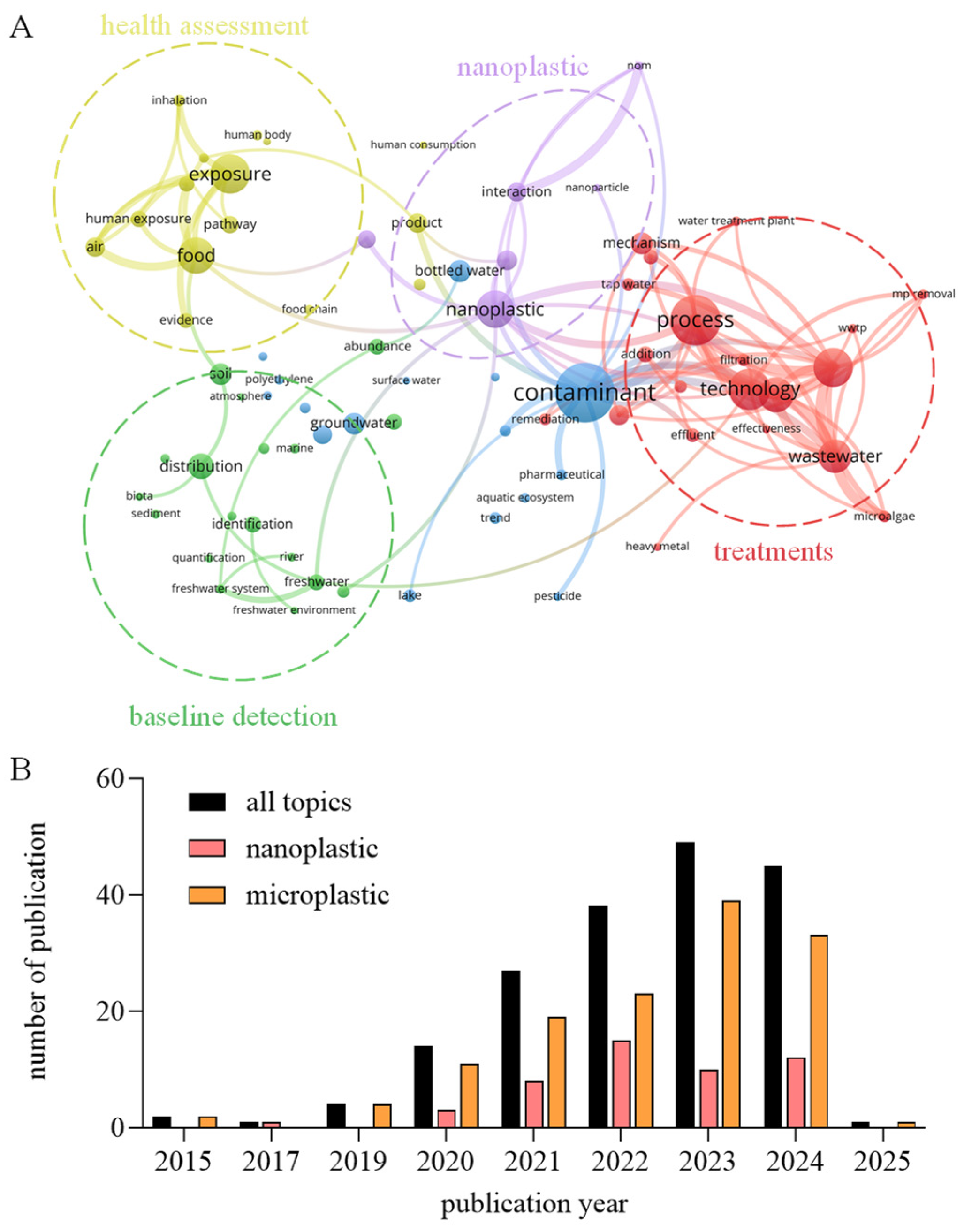

2. Bibliometric Analysis Based on Published Reviews

3. Descriptions of Monitoring Frame and Methodologies

3.1. Spatial Distribution of DWN Monitoring

3.2. Monitoring Sections and Methodologies Used in DWN Monitoring

4. The Abundance and Characteristics of MNPs

4.1. The Abundance of MNPs

| Area (Type) | Estimation Method a | Mean Abundance (Items/L) | Primary Shape Composition (%) | Primary Polymer Composition c | Reference |

|---|---|---|---|---|---|

| Chongqing (Rural), China | indirect | 1.4 | non-fiber (55.0) | PET, PE | [55] |

| fiber (45.0) | |||||

| Tianjin (Urban), China | direct | 679.5 (scales) b | non-fiber (83.3) | PVC, PE, PP | [56] |

| Zahedan (Urban), Iran | indirect | 0.17 | non-fiber (>50.0) | PS, rubber, PA | [57] |

| Poland (mutiple) | direct | 4.5 × 107 (debris) b | non-fiber (no data) | PE, PET, PA | [53] |

| China (Urban) | direct | 0.67 d | fiber (28.0) | PET, PA, PU | [58] |

| South Africa (Rural) | direct | 0.22 | not available | not available | [30] |

| Barcelona (Urban), Spain | direct | 0.01 | fiber (58.0) | PET, PP, PA | [59] |

| Britain (mutiple) | direct | 0.02 | not available | PP, PET, PS | [28] |

4.2. Shape Size and Polymer Compositions

5. The Mechanisms Involved in the Release of MNPs from Pipes

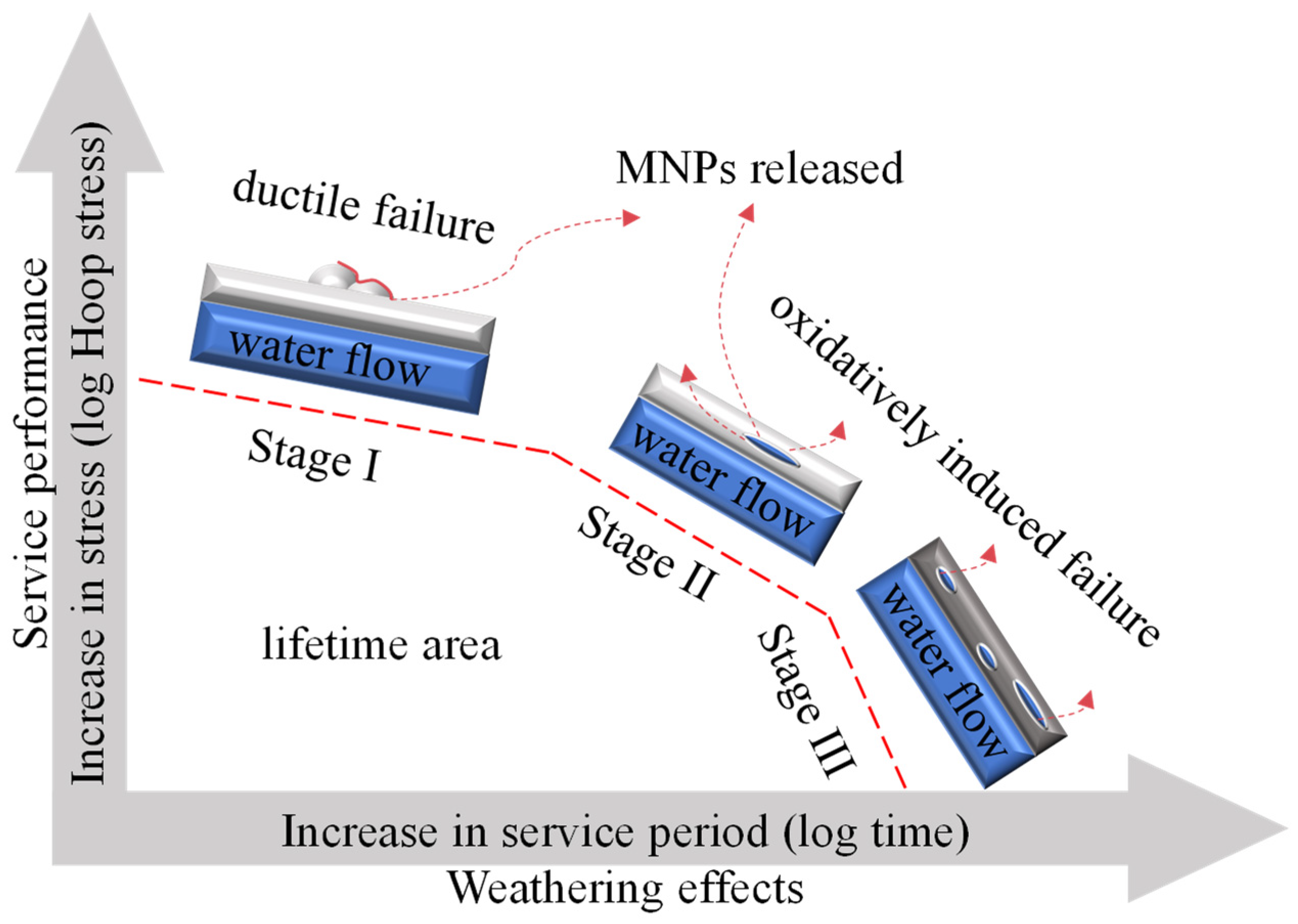

5.1. Physical Mechanisms

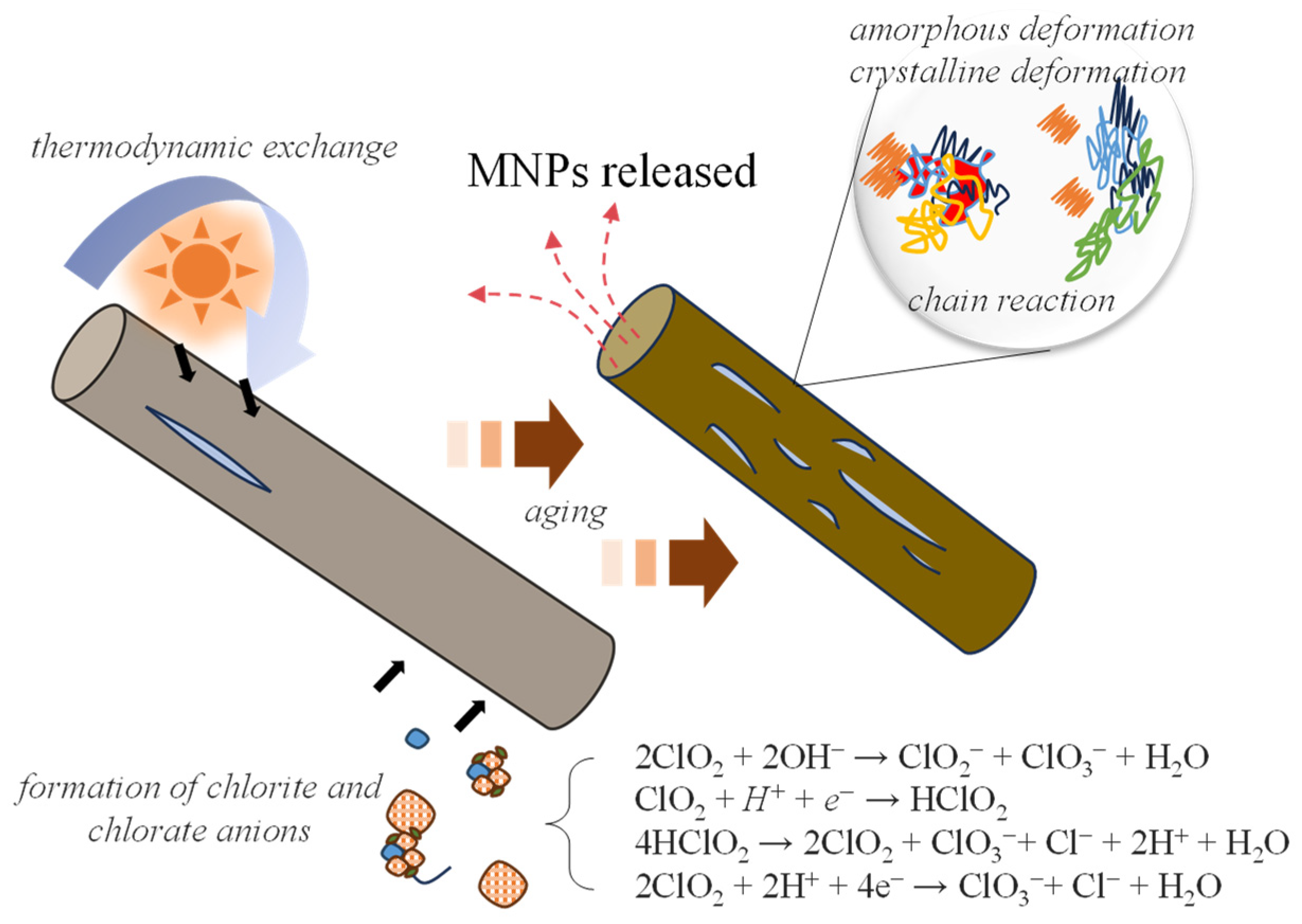

5.2. Chemical Aging and Weathering Effects

6. Conclusions and Perspective

- Standardization of sampling protocol and pipe monitoring

- Incorporating nanoplastics into DWN monitoring

- Incorporating AI and big data into DWN monitoring

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Eze, C.G.; Nwankwo, C.E.; Dey, S.; Sundaramurthy, S.; Okeke, E.S. Food chain microplastics contamination and impact on human health: A review. Environ. Chem. Lett. 2024, 22, 1889–1927. [Google Scholar] [CrossRef]

- Yu, R.-S.; Singh, S. Microplastic Pollution: Threats and Impacts on Global Marine Ecosystems. Sustainability 2023, 15, 13252. [Google Scholar] [CrossRef]

- Enyoh, C.E.; Devi, A.; Kadono, H.; Wang, Q.; Rabin, M.H. The Plastic Within: Microplastics Invading Human Organs and Bodily Fluids Systems. Environments 2023, 10, 194. [Google Scholar] [CrossRef]

- Krause, S.; Ouellet, V.; Allen, D.; Allen, S.; Moss, K.; Nel, H.A.; Manaseki-Holland, S.; Lynch, I. The potential of micro- and nanoplastics to exacerbate the health impacts and global burden of non-communicable diseases. Cell Rep. Med. 2024, 5, 101581. [Google Scholar] [CrossRef]

- Preda, O.-T.; Vlasceanu, A.-M.; Andreescu, C.V.; Tsatsakis, A.; Mezhuev, Y.; Negrei, C.; Baconi, D.L. Health Implications of Widespread Micro- and Nanoplastic Exposure: Environmental Prevalence, Mechanisms, and Biological Impact on Humans. Toxics 2024, 12, 730. [Google Scholar] [CrossRef]

- Luo, Y.; Xu, X.; Yin, Q.; Liu, S.; Xing, M.; Jin, X.; Shu, L.; Jiang, Z.; Cai, Y.; Ouyang, D.; et al. Mapping micro(nano)plastics in various organ systems: Their emerging links to human diseases? Trends Anal. Chem. 2025, 183, 118114. [Google Scholar] [CrossRef]

- Marfella, R.; Prattichizzo, F.; Sardu, C.; Fulgenzi, G.; Graciotti, L.; Spadoni, T.; D’Onofrio, N.; Scisciola, L.; La Grotta, R.; Frigé, C.; et al. Microplastics and Nanoplastics in Atheromas and Cardiovascular Events. N. Engl. J. Med. 2024, 390, 900–910. [Google Scholar] [CrossRef]

- Yu, Y.; Craig, N.; Su, L. A Hidden Pathway for Human Exposure to Micro- and Nanoplastics—The Mechanical Fragmentation of Plastic Products during Daily Use. Toxics 2023, 11, 774. [Google Scholar] [CrossRef] [PubMed]

- Free, C.M.; Jensen, O.P.; Mason, S.A.; Eriksen, M.; Williamson, N.J.; Boldgiv, B. High-levels of microplastic pollution in a large, remote, mountain lake. Mar. Pollut. Bull. 2014, 85, 156–163. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, E.G.; Li, J.; Chen, Q.; Ma, L.; Zeng, E.Y.; Shi, H. A Review of Microplastics in Table Salt, Drinking Water, and Air: Direct Human Exposure. Environ. Sci. Technol. 2020, 54, 3740–3751. [Google Scholar] [CrossRef]

- Hamid, F.S.; Bhatti, M.S.; Anuar, N.; Anuar, N.; Mohan, P.; Periathamby, A. Worldwide distribution and abundance of microplastic: How dire is the situation? Waste Manag. Res. 2018, 36, 873–897. [Google Scholar] [CrossRef] [PubMed]

- Xie, D.; Fang, H.; Zhao, X.; Lin, Y.; Su, Z. Identification of microplastics and nanoplastics in environmental water by AFM-IR. Anal. Chim. Acta. 2025, 1354, 343992. [Google Scholar] [CrossRef]

- Talbot, R.; Chang, H. Microplastics in freshwater: A global review of factors affecting spatial and temporal variations*. Environ. Pollut. 2022, 292, 118393. [Google Scholar] [CrossRef] [PubMed]

- Su, L.; Xue, Y.; Li, L.; Yang, D.; Kolandhasamy, P.; Li, D.; Shi, H. Microplastics in Taihu Lake, China. Environ. Pollut. 2016, 216, 711–719. [Google Scholar] [CrossRef]

- Paray, B.A.; Yu, J.; Sultana, S.; Banik, P.; Nur, A.-A.U.; Haque, M.R.; Rahman, M.M.; Arai, T.; Yan, L.; Hossain, M.B. Contamination, morphological and chemical characterization, and hazard risk analyses of microplastics in drinking water sourced from groundwater in a developing nation. Front. Environ. Sci. 2024, 12, 1379311. [Google Scholar] [CrossRef]

- Panno, S.V.; Kelly, W.R.; Scott, J.; Zheng, W.; McNeish, R.E.; Holm, N.; Hoellein, T.J.; Baranski, E.L. Microplastic Contamination in Karst Groundwater Systems. Groundwater 2019, 57, 189–196. [Google Scholar] [CrossRef]

- Guo, X.; Ji, X.; Liu, Z.; Feng, Z.; Zhang, Z.; Du, S.; Li, X.; Ma, J.; Sun, Z. Complex impact of metals on the fate of disinfection by-products in drinking water pipelines: A systematic review. Water Res. 2024, 261, 121991. [Google Scholar] [CrossRef]

- Lee, E.J.; Schwab, K.J. Deficiencies in drinking water distribution systems in developing countries. J. Water Health 2005, 3, 109–127. [Google Scholar] [CrossRef]

- Lehtola, M.J.; Miettinen, I.T.; Keinänen, M.M.; Kekki, T.K.; Laine, O.; Hirvonen, A.; Vartiainen, T.; Martikainen, P.J. Microbiology, chemistry and biofilm development in a pilot drinking water distribution system with copper and plastic pipes. Water Res. 2004, 38, 3769–3779. [Google Scholar] [CrossRef]

- Świetlik, J.; Magnucka, M. Aging of drinking water transmission pipes during long-term operation as a potential source of nano- and microplastics. Int. J. Hyg. Environ. Health 2025, 263, 114467. [Google Scholar] [CrossRef]

- Li, C.-G.; Liu, C.; Xu, W.-H.; Shan, M.-G.; Wu, H.-X. Formation mechanisms and supervisory prediction of scaling in water supply pipelines: A review. Water Res. 2022, 222, 118922. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Zhang, Y.; Knibbe, W.-J.; Feng, C.; Liu, W.; Medema, G.; van der Meer, W. Potential impacts of changing supply-water quality on drinking water distribution: A review. Water Res. 2017, 116, 135–148. [Google Scholar] [CrossRef]

- Barton, N.A.; Farewell, T.S.; Hallett, S.H.; Acland, T.F. Improving pipe failure predictions: Factors affecting pipe failure in drinking water networks. Water Res. 2019, 164, 114926. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Li, Z. Research on Failure Pressure Prediction of Water Supply Pipe Based on GA-BP Neural Network. Water 2024, 16, 2659. [Google Scholar] [CrossRef]

- Su, L.; Dong, X.; Peng, J.; Cheng, H.; Craig, N.J.; Hu, B.; Li, J.-Y. Segmentation of beach plastic fragments’ contours based on self-organizing map and multi-shape descriptors: A rapid indication of fragmentation and wearing types. J. Hazard. Mater. 2024, 478, 135564. [Google Scholar] [CrossRef]

- Deng, H.; Su, L.; Zheng, Y.; Du, F.; Liu, Q.-X.; Zheng, J.; Zhou, Z.; Shi, H. Crack Patterns of Environmental Plastic Fragments. Environ. Sci. Technol. 2022, 56, 6399–6414. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Zhang, Y.; Tang, Y. Fragmentation of microplastics in the drinking water treatment process-A case study in Yangtze River region, China. Sci. Total Environ. 2022, 806, 150545. [Google Scholar] [CrossRef]

- Adediran, G.A.; Cox, R.; Jurgens, M.D.; Morel, E.; Cross, R.; Carter, H.; Pereira, M.G.; Read, D.S.; Johnson, A.C. Fate and behaviour of Microplastics (>25 μm) within the water distribution network, from water treatment works to service reservoirs and customer taps. Water Res. 2024, 255, 121508. [Google Scholar] [CrossRef]

- Sun, J.; Dai, X.; Wang, Q.; van Loosdrecht, M.C.M.; Ni, B.-J. Microplastics in wastewater treatment plants: Detection, occurrence and removal. Water Res. 2019, 152, 21–37. [Google Scholar] [CrossRef]

- Swanepoel, A.; du Preez, H.; Bouwman, H.; Verster, C. A baseline study on the prevalence of microplastics in South African drinking water: From source to distribution. Water SA 2023, 49, 320–326. [Google Scholar] [CrossRef]

- Qiana, N.; Gaoa, X.; Lang, X.; Deng, H.; Bratu, T.M.; Chen, Q.; Stapleton, P.; Yan, B.; Min, W. Rapid single-particle chemical imaging of nanoplastics by SRS microscopy. Proc. Natl. Acad. Sci. USA 2024, 121, e2300582121. [Google Scholar] [CrossRef] [PubMed]

- Carnevale Miino, M.; Galafassi, S.; Zullo, R.; Torretta, V.; Rada, E.C. Microplastics removal in wastewater treatment plants: A review of the different approaches to limit their release in the environment. Sci. Total Environ. 2024, 930, 172675. [Google Scholar] [CrossRef] [PubMed]

- Ta, A.T.; Promchan, N. Microplastics in wastewater from developing countries: A comprehensive review and methodology suggestions. TrAC Trends Anal. Chem. 2024, 171, 117537. [Google Scholar] [CrossRef]

- Han, Z.; Jiang, J.; Xia, J.; Yan, C.; Cui, C. Occurrence and fate of microplastics from a water source to two different drinking water treatment plants in a megacity in eastern China. Environ. Pollut. 2024, 346, 123546. [Google Scholar] [CrossRef]

- Foglia, A.; Pittura, L.; Vivani, V.; Sgroi, M.; De Simoni, L.; Eusebi, A.L.; Gorbi, S.; Regoli, F.; Fatone, F. Microplastics in urban water cycles: Looking for a more scientific approach for sampling and characterization in wastewater and drinking water treatment plants. Sci. Total Environ. 2024, 952, 175919. [Google Scholar] [CrossRef]

- Liu, Y.; Nie, Z.; Meng, Y.; Liu, G.; Chen, Y.; Chai, G. Influence of meteorological conditions on atmospheric microplastic transport and deposition. Environ. Res. 2025, 265, 120460. [Google Scholar] [CrossRef]

- Fox, S.; Stefánsson, H.; Peternell, M.; Zlotskiy, E.; Ásbjörnsson, E.J.; Sturkell, E.; Wanner, P.; Konrad-Schmolke, M. Physical characteristics of microplastic particles and potential for global atmospheric transport: A meta-analysis. Environ. Pollut. 2024, 342, 122938. [Google Scholar] [CrossRef]

- Fok, L.; Lam, T.W.L.; Li, H.-X.; Xu, X.-R. A meta-analysis of methodologies adopted by microplastic studies in China. Sci. Total Environ. 2020, 718, 135371. [Google Scholar] [CrossRef] [PubMed]

- He, D.; Luo, Y.; Lu, S.; Liu, M.; Song, Y.; Lei, L. Microplastics in soils: Analytical methods, pollution characteristics and ecological risks. Trends Anal. Chem. 2018, 109, 163–172. [Google Scholar] [CrossRef]

- Narwal, N.; Kakakhel, M.A. Assessing microplastics in aquatic ecosystem: Sources, effects, and nature-based solution. A review. Reg. Stud. Mar. Sci. 2025, 82, 104030. [Google Scholar] [CrossRef]

- Swietlik, J.; Magnucka, M. Chemical and microbiological safety of drinking water in distribution networks made of plastic pipes. Wiley Interdiscip. Rev. Water 2024, 11, e1704. [Google Scholar] [CrossRef]

- Liu, Q.; Yu, H.; Zhu, G.-C.; Wang, P.-B.; Song, S.-Y. Investigation on leakage cause of oil pipeline in the west oilfield of China. Eng. Fail. Anal. 2020, 113, 104552. [Google Scholar] [CrossRef]

- Piri, B.; Amini, R.; Asadinia, E.; Vardak, S.; Mehdilouee, R.; Mojarrad, A. Investigation of failure mechanisms and remaining life prediction of firewater pipelines used in industrial applications. Eng. Fail. Anal. 2021, 124, 105301. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, T.; Chen, W. Occurrence and removal of microplastics in an advanced drinking water treatment plant (ADWTP). Sci. Total Environ. 2020, 700, 134520. [Google Scholar] [CrossRef]

- Chen, L.; Zhou, S.; Su, B.; Qiu, Y.; Li, Y. Microplastic pollution in Taihu Lake: Spatial distribution from the lake inlet to the lake centre and vertical stratification in the water column. Environ. Pollut. 2024, 363, 125102. [Google Scholar] [CrossRef]

- Koelmans, A.A.; Redondo-Hasselerharm, P.E.; Mohamed Nor, N.H.; Gouin, T. On the probability of ecological risks from microplastics in the Laurentian Great lakes. Environ. Pollut. 2023, 325, 121445. [Google Scholar] [CrossRef] [PubMed]

- Nirmala, K.; Rangasamy, G.; Ramya, M.; Shankar, V.U.; Rajesh, G. A critical review on recent research progress on microplastic pollutants in drinking water. Environ. Res. 2023, 222, 115312. [Google Scholar] [CrossRef]

- Ali, N.; Khan, M.H.; Ali, M.; Sidra; Ahmad, S.; Khan, A.; Nabi, G.; Ali, F.; Bououdina, M.; Kyzas, G.Z. Insight into microplastics in the aquatic ecosystem: Properties, sources, threats and mitigation strategies. Sci. Total Environ. 2024, 913, 169489. [Google Scholar] [CrossRef]

- He, L.; Ou, Z.; Fan, J.; Zeng, B.; Guan, W. Research on the non-point source pollution of microplastics. Front. Chem. 2022, 10, 956547. [Google Scholar] [CrossRef]

- He, Y.-Q.; McDonough, L.K.; Zainab, S.M.; Guo, Z.-F.; Chen, C.; Xu, Y.-Y. Microplastic accumulation in groundwater: Data-scaled insights and future research. Water Res. 2024, 258, 121808. [Google Scholar] [CrossRef]

- Muhib, M.I.; Uddin, M.K.; Rahman, M.M.; Malafaia, G. Occurrence of microplastics in tap and bottled water, and food packaging: A narrative review on current knowledge. Sci. Total Environ. 2023, 865, 161274. [Google Scholar] [CrossRef] [PubMed]

- Singh, T. Generation of microplastics from the opening and closing of disposable plastic water bottles. J. Water Health 2021, 19, 488–498. [Google Scholar] [CrossRef]

- Marta, M.; Joanna, Ś.; Agata, L.; Piotr, N.; Lilla, F. Occurrence and identification of microplastics retained in corrosion deposits of drinking water transmission pipes. Water Emerg. Contam. Nanoplastics 2024, 3, 17. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, M.; Lian, E.; Xia, L.; Asimakopoulos, A.G.; Luo, S.; Wang, L. Identification of Poly(ethylene terephthalate) Nanoplastics in Commercially Bottled Drinking Water Using Surface-Enhanced Raman Spectroscopy. Environ. Sci. Technol. 2023, 57, 8365–8372. [Google Scholar] [CrossRef]

- Zhou, G.; Wu, Q.; Wei, X.-F.; Chen, C.; Ma, J.; Crittenden, J.C.; Liu, B. Tracing microplastics in rural drinking water in Chongqing, China: Their presence and pathways from source to tap. J. Hazard. Mater. 2023, 459, 132206. [Google Scholar] [CrossRef]

- Chu, X.; Zheng, B.; Li, Z.; Cai, C.; Peng, Z.; Zhao, P.; Tian, Y. Occurrence and distribution of microplastics in water supply systems: In water and pipe scales. Sci. Total Environ. 2022, 803, 150004. [Google Scholar] [CrossRef] [PubMed]

- Taghipour, H.; Ghayebzadeh, M.; Ganji, F.; Mousavi, S.; Azizi, N. Tracking microplastics contamination in drinking water in Zahedan, Iran: From source to consumption taps. Sci. Total Environ. 2023, 872, 162121. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Xu, X.; Zhou, Y.; Yao, Y.; Shen, C.; Liu, J. Longitudinal and vertical distribution of microplastics in various pipe scales in an operating drinking water distribution system. J. Hazard. Mater. 2023, 459, 132108. [Google Scholar] [CrossRef]

- Dalmau-Soler, J.; Ballesteros-Cano, R.; Ferrer, N.; Boleda, M.R.; Lacorte, S. Microplastics throughout a tap water supply network. Water Environ. J. 2022, 36, 292–298. [Google Scholar] [CrossRef]

- Li, C.; Busquets, R.; Campos, L.C. Assessment of microplastics in freshwater systems: A review. Sci. Total Environ. 2020, 707, 135578. [Google Scholar] [CrossRef]

- Wu, F.; Ha, X.; Wang, S.; Li, J.; Gao, Y. Microplastic occurrences, transport, and quantification and associated effects on primary productivity and carbon cycling processes in freshwater ecosystems. Trends Anal. Chem. 2024, 172, 117611. [Google Scholar] [CrossRef]

- Akdogan, Z.; Guven, B. Microplastics in the environment: A critical review of current understanding and identification of future research needs. Environ. Pollut. 2019, 254, 113011. [Google Scholar] [CrossRef]

- Ivar do Sul, J.A.; Costa, M.F. The present and future of microplastic pollution in the marine environment. Environ. Pollut. 2014, 185, 352–364. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Yang, F.; Kazmi, S.S.U.H.; Zhao, Y.; Chen, M.; Wang, J. A review of microplastic pollution in seawater, sediments and organisms of the Chinese coastal and marginal seas. Chemosphere 2022, 286, 131677. [Google Scholar] [CrossRef] [PubMed]

- Barbier, J.-S.; Dris, R.; Lecarpentier, C.; Raymond, V.; Delabre, K.; Thibert, S.; Tassin, B.; Gasperi, J. Microplastic occurrence after conventional and nanofiltration processes at drinking water treatment plants: Preliminary results. Front. Water 2022, 4, 886703. [Google Scholar] [CrossRef]

- Staroverov, O.; Mugatarov, A.; Kuchukov, A.; Strungar, E.; Chebotareva, E.; Sivtseva, A.; Wildemann, V. Influence of proportional multiaxial fatigue loading on the residual mechanical properties of glass-reinforced plastic pipes. Eng. Fail. Anal. 2024, 163, 108586. [Google Scholar] [CrossRef]

- Ghoochani, S.; Hadiuzzaman, M.; Mirza, N.; Brown, S.P.; Salehi, M. Effects of water chemistry and flow on lead release from plastic pipes versus copper pipes, implications for plumbing decontamination. Environ. Pollut. 2023, 337, 122520. [Google Scholar] [CrossRef]

- Mager, S.; Knopick, M.; Oddy, G. The concentration and prevalence of asbestos fibres in Christchurch, New Zealand’s drinking water supply. Water Supply 2022, 22, 4445–4456. [Google Scholar] [CrossRef]

- Della Rovere, C.A.; Silva, R.; Moretti, C.; Kuri, S.E. Corrosion failure analysis of galvanized steel pipes in a water irrigation system. Eng. Fail. Anal. 2013, 33, 381–386. [Google Scholar] [CrossRef]

- Espejo, E. Analysis of Premature Failure of a PVC Water Pipe. J. Fail. Anal. Prev. 2023, 23, 1491–1497. [Google Scholar] [CrossRef]

- Tang, P.; Hu, S.; Lu, C.; He, Z.; Shan, C. Burst failure analysis of PVC-UH pipes with axial surface crack based on multiple methodologies. Eng. Fail. Anal. 2024, 166, 108841. [Google Scholar] [CrossRef]

- El-Sayed, M.H. Flow enhanced corrosion of water injection pipelines. Eng. Fail. Anal. 2015, 50, 1–6. [Google Scholar] [CrossRef]

- He, B.; Han, P.; Lu, C.; Bai, X. Effect of soil particle size on the corrosion behavior of natural gas pipeline. Eng. Fail. Anal. 2015, 58, 19–30. [Google Scholar] [CrossRef]

- Singh, J.; Singh, S.; Singh, J.P. Investigation on wall thickness reduction of hydropower pipeline underwent to erosion-corrosion process. Eng. Fail. Anal. 2021, 127, 105504. [Google Scholar] [CrossRef]

- Akbulut, S.; Akman, P.K.; Tornuk, F.; Yetim, H. Microplastic Release from Single-Use Plastic Beverage Cups. Foods 2024, 13, 1564. [Google Scholar] [CrossRef] [PubMed]

- Chang, M.; Sun, P.; Zhang, L.; Liu, Y.; Chen, L.; Ren, H.; Wu, B. Changes in characteristics and risk of freshwater microplastics under global warming. Water Res. 2024, 260, 121960. [Google Scholar] [CrossRef]

- Rahman, A.M.N.A.A.; Rusli, A.; Abdullah, M.K.; Shuib, R.K.; Hamid, Z.A.A.; Ku Ishak, K.M.; Mohd Zaini Makhtar, M.; Jaafar, M.; Shafiq, M.D. A review of microplastic surface interactions in water and potential capturing methods. Water Sci. Eng. 2024, 17, 361–370. [Google Scholar] [CrossRef]

- Shen, M.; Li, Y.; Qin, L.; Chen, X.; Ao, T.; Liang, X.; Jin, K.; Dou, Y.; Li, J.; Duan, X. Distribution and risk assessment of microplastics in a source water reservoir, Central China. Sci. Rep. 2025, 15, 468. [Google Scholar] [CrossRef]

- Deng, H.; Fu, Q.; Li, D.; Zhang, Y.; He, J.; Feng, D.; Zhao, Y.; Du, G.; Yu, H.; Ge, C. Microplastic-associated biofilm in an intensive mariculture pond: Temporal dynamics of microbial communities, extracellular polymeric substances and impacts on microplastics properties. J. Clean. Prod. 2021, 319, 128774. [Google Scholar] [CrossRef]

- Saharan, B.S.; Beniwal, N.; Duhan, J.S. From formulation to function: A detailed review of microbial biofilms and their polymer-based extracellular substances. Microbe 2024, 5, 100194. [Google Scholar] [CrossRef]

- Huang, H.; Zeng, S.; Luo, C.; Long, T. Separate effect of turbulent pulsation on internal mass transfer in porous biofilms. Environ. Res. 2023, 217, 114972. [Google Scholar] [CrossRef]

- Zou, L.; Qiao, Y.; Wu, X.-S.; Li, C.M. Tailoring hierarchically porous graphene architecture by carbon nanotube to accelerate extracellular electron transfer of anodic biofilm in microbial fuel cells. J. Power Sources 2016, 328, 143–150. [Google Scholar] [CrossRef]

- Mou, Y.; Lian, Z.; Sang, P.; Yu, H.; Zhang, Q.; Li, R. Study on water hammer effect on defective tubing failure in high pressure deep gas well. Eng. Fail. Anal. 2019, 106, 104154. [Google Scholar] [CrossRef]

- Kandil, M.; El-Sayed, T.A.; Kamal, A.M. Unveiling the impact of pipe materials on water hammer in pressure pipelines: An experimental and numerical study. Sci. Rep. 2024, 14, 30599. [Google Scholar] [CrossRef] [PubMed]

- Cancemi, S.A.; Lo Frano, R. Preliminary Analysis of Long-Term Performance of a Piping: Aging and Creep Effects. Materials 2021, 14, 1703. [Google Scholar] [CrossRef] [PubMed]

- Maliwan, T.; Hu, J. Release of microplastics from polymeric ultrafiltration membrane system for drinking water treatment under different operating conditions. Water Res. 2025, 274, 123047. [Google Scholar] [CrossRef]

- Ding, H.; Zhang, J.; He, H.; Zhu, Y.; Dionysiou, D.D.; Liu, Z.; Zhao, C. Do membrane filtration systems in drinking water treatment plants release nano/microplastics? Sci. Total Environ. 2021, 755, 142658. [Google Scholar] [CrossRef]

- Sheraz, M.; Sun, X.-F.; Siddiqui, A.; Hu, S.; Song, Z. Research Advances in Natural Polymers for Environmental Remediation. Polymers 2025, 17, 559. [Google Scholar] [CrossRef]

- Zhu, Y.; Yang, S.; Gustavsson, M.; Huang, W.; Gao, S.; Wang, R. Investigation of Removal Efficiency of Microplastics at Different Process Stages of a Wastewater Treatment Plant in the Textile Industry in Southern China. Water 2025, 17, 574. [Google Scholar] [CrossRef]

- Lancioni, N.; Parlapiano, M.; Sgroi, M.; Giorgi, L.; Fusi, V.; Darvini, G.; Soldini, L.; Szeląg, B.; Eusebi, A.L.; Fatone, F. Polyethylene pipes exposed to chlorine dioxide in drinking water supply system: A critical review of degradation mechanisms and accelerated aging methods. Water Res. 2023, 238, 120030. [Google Scholar] [CrossRef]

- Makris, K.F.; Langeveld, J.; Clemens, F.H.L.R. A review on the durability of PVC sewer pipes: Research vs. practice. Struct. Infrastruct. Eng. 2020, 16, 880–897. [Google Scholar] [CrossRef]

- Tang, M.; Triantafyllidou, S.; Edwards, M. In situ remediation of leaks in potable water supply systems. Corros. Rev. 2013, 31, 105–122. [Google Scholar] [CrossRef]

- Colin, X. Humid and Thermal Oxidative Ageing of Radiation Cured Polymers-A Brief Overview. Front. Chem. 2022, 9, 797335. [Google Scholar] [CrossRef]

- Ge, J.; Wang, M.; Liu, P.; Zhang, Z.; Peng, J.; Guo, X. A systematic review on the aging of microplastics and the effects of typical factors in various environmental media. Trends Anal. Chem. 2023, 162, 117025. [Google Scholar] [CrossRef]

- Wang, H.; Gao, Z.; Zhu, Q.; Wang, C.; Cao, Y.; Chen, L.; Liu, J.; Zhu, J. Overview of the environmental risks of microplastics and their controlled degradation from the perspective of free radicals. Environ. Pollut. 2024, 355, 124227. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Jiang, Y.; Gu, Y.; Chen, C.; Yu, J.; Wang, C.; Shi, C.; Pan, R.; Chen, H. Environmentally persistent free radicals on photoaging microplastics shortens longevity via inducing oxidative stress in Caenorhabditis elegans. Chemosphere 2024, 361, 142560. [Google Scholar] [CrossRef]

- Chen, G.; Yang, Y.; Zhou, C.; Zhou, Z.; Yan, D. Thermal-oxidative aging performance and life prediction of polyethylene pipe under cyclic and constant internal pressure. J. Appl. Polym. Sci. 2019, 136, 47766. [Google Scholar] [CrossRef]

- Vega, A.; Yarahmadi, N.; Sällström, J.H.; Jakubowicz, I. Effects of cyclic mechanical loads and thermal ageing on district heating pipes. Polym. Degrad. Stab. 2020, 182, 109385. [Google Scholar] [CrossRef]

- Kong, L.; Qi, D.; Li, H.; Ding, N.; Ge, P.; Xu, Y.; Zhang, C.; Pan, C.; Fan, X. Aging of Polyethylene of Raised Temperature Resistance Pipe Liner After a Four-Year Service in a Crude Oil Gathering System. J. Fail. Anal. Prev. 2021, 21, 1323–1330. [Google Scholar] [CrossRef]

- Bachir-Bey, T.; Belhaneche-Bensemra, N. Investigation of Polyethylene Pipeline Behavior after 30 Years of Use in Gas Distribution Network. J. Mater. Eng. Perform. 2020, 29, 6652–6660. [Google Scholar] [CrossRef]

- Leuteritz, A.; Doering, K.-D.; Lampke, T.; Kuehnert, I. Accelerated ageing of plastic jacket pipes for district heating. Polym. Test. 2016, 51, 142–147. [Google Scholar] [CrossRef]

- Sorlini, S.; Biasibetti, M.; Gialdini, F.; Muraca, A. Modeling and analysis of chlorine dioxide, chlorite, and chlorate propagation in a drinking water distribution system. J. Water Supply Res. Technol. Aqua 2016, 65, 597–611. [Google Scholar] [CrossRef]

- Luo, H.; Zeng, Y.; Zhao, Y.; Xiang, Y.; Li, Y.; Pan, X. Effects of advanced oxidation processes on leachates and properties of microplastics. J. Hazard. Mater. 2021, 413, 125342. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wang, H.; Huang, Q.; Yang, C.; Wang, L.; Lou, Z.; Zhou, Q.; Wang, T.; Ning, C. Microplastics in Landfill Leachate: A Comprehensive Review on Characteristics, Detection, and Their Fates during Advanced Oxidation Processes. Water 2023, 15, 252. [Google Scholar] [CrossRef]

- Vertova, A.; Miani, A.; Lesma, G.; Rondinini, S.; Minguzzi, A.; Falciola, L.; Ortenzi, M.A. Chlorine Dioxide Degradation Issues on Metal and Plastic Water Pipes Tested in Parallel in a Semi-Closed System. Int. J. Environ. Res. Public Health 2019, 16, 4582. [Google Scholar] [CrossRef]

- Yu, W.; Azhdar, B.; Andersson, D.; Reitberger, T.; Hassinen, J.; Hjertberg, T.; Gedde, U.W. Deterioration of polyethylene pipes exposed to water containing chlorine dioxide. Polym. Degrad. Stab. 2011, 96, 790–797. [Google Scholar] [CrossRef]

- He, H.; Li, F.; Liu, K.; Zhan, J.; Wang, X.; Lai, C.; Yang, X.; Huang, B.; Pan, X. The disinfectant residues promote the leaching of water contaminants from plastic pipe particles. Environ. Pollut. 2023, 327, 121577. [Google Scholar] [CrossRef]

- Gan, X.; Lin, T.; Jiang, F.; Zhang, X. Impacts on characteristics and effluent safety of PVDF ultrafiltration membranes aged by different chemical cleaning types. J. Membr. Sci. 2021, 640, 119770. [Google Scholar] [CrossRef]

- Castagnetti, D.; Scirè Mammano, G.; Dragoni, E. Effect of chlorinated water on the oxidative resistance and the mechanical strength of polyethylene pipes. Polym. Test. 2011, 30, 277–285. [Google Scholar] [CrossRef]

- Lu, Q.; Tang, D.; Liang, Q.; Wang, S. Biotechnology for the degradation and upcycling of traditional plastics. Environ. Res. 2024, 263, 120140. [Google Scholar] [CrossRef]

- Aydonat, S.; Hergesell, A.H.; Seitzinger, C.L.; Lennarz, R.; Chang, G.; Sievers, C.; Meisner, J.; Vollmer, I.; Göstl, R. Leveraging mechanochemistry for sustainable polymer degradation. Polym. J. 2024, 56, 249–268. [Google Scholar] [CrossRef]

- Campisi, L.; La Motta, C.; Napierska, D. Polyvinyl chloride (PVC), its additives, microplastic and human health: Unresolved and emerging issues. Sci. Total Environ. 2025, 960, 178276. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; He, Y.; Jiang, L.; Shi, Y.; Hao, L.; Huang, L.; Lyu, M.; Wang, S. Plastic additives as a new threat to the global environment: Research status, remediation strategies and perspectives. Environ. Res. 2024, 263, 120007. [Google Scholar] [CrossRef] [PubMed]

- Im, H.R.; Im, S.J.; Nguyen, D.V.; Jeong, S.P.; Jang, A. Real-time diagnosis and monitoring of biofilm and corrosion layer formation on different water pipe materials using non-invasive imaging methods. Chemosphere 2024, 361, 142577. [Google Scholar] [CrossRef]

- Mo, Y.; Bi, L. TR Self-Adaptive Cancellation Based Pipeline Leakage Localization Method Using Piezoceramic Transducers. Sensors 2022, 22, 696. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Wang, Y.; Hu, B.; Su, L. Drinking Water Network as a Potential Pathway for Micro- and Nanoplastics Exposure to Human: A Mini Review. Water 2025, 17, 1188. https://doi.org/10.3390/w17081188

Chen Y, Wang Y, Hu B, Su L. Drinking Water Network as a Potential Pathway for Micro- and Nanoplastics Exposure to Human: A Mini Review. Water. 2025; 17(8):1188. https://doi.org/10.3390/w17081188

Chicago/Turabian StyleChen, Yecang, Yi Wang, Bo Hu, and Lei Su. 2025. "Drinking Water Network as a Potential Pathway for Micro- and Nanoplastics Exposure to Human: A Mini Review" Water 17, no. 8: 1188. https://doi.org/10.3390/w17081188

APA StyleChen, Y., Wang, Y., Hu, B., & Su, L. (2025). Drinking Water Network as a Potential Pathway for Micro- and Nanoplastics Exposure to Human: A Mini Review. Water, 17(8), 1188. https://doi.org/10.3390/w17081188