1. Introduction

Water distribution networks (WDNs) should be able to deliver a required quantity of water at sufficient pressure under different design and operational situations. The majority of the hydraulic models for WDNs developed for design and management generally account for customer demands as water withdrawal concentrated in nodes and assume that these demands are fixed

a priori in the model [

1], independent of nodal heads, and are fully supplied (demand-driven analysis). In fact, in demand-driven simulation methods, the available discharge in demand nodes is always equal to the required discharge, and the network is assumed to be able to provide the required demand under any circumstances due to the assumed independence between flow and pressure in the node.

However, as is known, the discharge of any node is proportional to its head, and demand-driven analysis is unable to fully account for the relationship between nodal outflows and pressure variations. The evaluation of the discharge on the basis of the population connected to the network, which is related to the per capita consumption (PCC) value, can be considered a good estimate of the discharge at each node only when the hydraulic pressures at the nodes themselves are adequate for the demands, whereas under pressure-deficient conditions, the actual flow supplied to the consumers might decrease and some nodes might not be able to supply any discharge [

2]. Therefore, although a demand-driven analysis may be satisfactory under normal working conditions, it becomes inadequate when the network operates under pressure-deficient conditions (which may be due to its improper design or insufficient water supply from water sources, unplanned pipe outages or unexpected pipe breaks, valve failures, pump breakdowns or excessive consumption [

3]). Under such conditions, the demand-driven formulation leads to unrealistic solutions for the hydraulic analysis of WDNs, and the simulation model has to incorporate a nodal outflow discharge model (head-driven analysis) [

1].

According to the head-driven simulation method, different outflow-pressure relationships can be considered for controlled (as well as uncontrolled) consumptions, fully consistent with the pressure at all nodes.

Over the past three decades, various relationships have been proposed to link the available discharge to the nodal pressure. These relationships are divided into two categories: discontinuous and continuous ones. The analysis of hydraulic networks assuming that the demands are dependent on the head/pressure status began with Bhave [

4], who defined the minimum required nodal head value for normal working conditions and suggested a relationship that falls in the former category. This relationship admits that full demand is available for heads with a higher than the minimum required value: a binary concept is used to express the pressure-outflow relation in which there is no discharge below the minimum required head in each node and in which the full demand is available for heads with a higher than the minimum required value. Tabesh

et al. [

5] stated that this relation similarly cannot be a good estimator of the relationship between the outflow discharge and pressure at a demand node.

On the other hand, continuous laws attempt to consider the link between pressure and outflow discharge for the entire variation domain continuously. Several authors (see [

2,

6,

7,

8,

9,

10,

11,

12,

13,

14]) proposed a number of pressure/discharge relations in an attempt to represent the relationship between flow and pressure at a model node.

These formulations can take into account the pressure distribution in the water network, but cannot be used when the service pipe fills a roof tank or a basement tank. In many situations, when the network does not operate under normal conditions and when water supplies are inadequate to meet consumers’ continuous demands, an unequal distribution of water resulting from the pressure head distribution being different from the designed distribution may cause serious disadvantages in terms of users’ supply. This problem is more severe in the presence of water shortages or intermittent distribution (see [

15,

16]). When users experience water resource rationing due to water shortages, a common strategy adapted by users is to install private tanks to meet their own needs when the network operates under pressure conditions. The local private storage (e.g., a roof tank or a basement tank) interposed between the water meter and the users delivers water to customers via gravity or pumping systems, according to the position of the water storage,

i.e., on the roof or in the basement, respectively. Such local water storage volumes are indeed very common in countries (e.g., in the Mediterranean area) where the water supply is seasonally intermittent. In this operative scheme, the water demand of the customers is supplied by the tank, which is subject to filling/emptying cycles, connected to the hydraulic system.

Therefore, private tanks modify the demand profile of normal domestic users. The replenishment of the tank is controlled by proportional float valves that open partially or completely as a function of the water level (under the assumption that the node required pressure is sufficient to supply the tank). During periods of low consumption and when the tank is full, the water level does not fall enough to induce the valve to open completely, and it dampens the instantaneous water demand; consequently, the flow rate passing through the meter is considerably lower than the user’s demand. To correctly model the actual water flows from the network to the users’ systems when water roof tanks are present in the network, it is necessary to evaluate the pressure-consumption law taking into account the hydraulic behavior of the reservoir governed by the ball valve.

In WDNs characterized by the presence of several private tanks, in which the classic head/discharge relationships cannot be employed, specific models need to be developed to correctly simulate the operation of the WDN while accounting for reservoirs located between the hydraulic network and the users [

17]. Modeling the inflow/outflow process of the tank needs to consider the occurrence of a pressure-dependent water demand at the node (classic head/discharge relationship) when the tank is not full and when the valve is completely open, as well as the closure of the orifice when the tank is completely filled. Recently, Giustolisi

et al. [

17] considered two different valve controls: ON/OFF and a linear opening of the orifice with volume.

In fact, the orifice feeding inline tanks are controlled by floating valves that follow a nonlinear behavior depending on the valve type; therefore, to correctly analyze the effects of inline private tanks in WDN models, an accurate discharge law is needed. A mathematical model capable of reproducing the tank emptying/filling cycles has been developed by Criminisi

et al. [

18], which combines a tank continuity equation with a float valve emitter law. This tank model has recently been validated against experimental data [

19], showing that although the emitter law well reproduces the experimental data, some deviations are observed at the start of valve opening and closing.

This work proposes a modified version of the emitter law of Criminisi

et al. [

18]. This new formulation is able to reproduce the entire experimental dataset. The mathematical model of the new emitter law is validated for two different valve branches, thus achieving a formula that can be used irrespective of the tank and valve geometry. The developed model can easily be implemented in hydrodynamic models to take private tanks into account.

2. Overview of the Head-Discharge Relationship

Since the early 1980s, many researchers have realized that the nodal discharge cannot be considered constant and that it is necessary to apply a relationship between nodal head and nodal discharge. Bhave [

4] was probably the first to consider the relationship between nodal flows and heads. He introduced the concept of nodal availability, which assumes the following:

where

represents the available total head at demand node

j,

represents the pressure head below which service at demand node

j is unsatisfactory and therefore unacceptable,

is the outflow at node

j and

is the required discharge at the node itself.

Reddy and Elango [

8] proposed a head-dependent analysis assuming uncontrolled outlets completely dependent on residual heads according to:

where

is a node constant.

None of these approaches properly depict the deficient network performance for reliability purposes. Equation (

1) disregards a partial flow (

) available at a node, whereas Equation (

2) provides unrestricted flow at a node, such that

may be greater than

.

Germanopoulos [

6] proposed the following formula for calculating the available outflows at demand nodes:

If the head at a node

is equal to or less than the minimum pressure head value

, there will be no discharge; for heads lower than

, the desired/required at the node

j, the network is not able to fully supply the required demand; if

, then

= 0.932, if the empirical coefficients

and

are equal to 10 and five, respectively; and

is different from the expected value

[

20].

Comparison between the head/discharge relations shows that the relationship proposed by Wagner

et al. [

7] and Chandapillai [

2] is the most suitable one for computing the head-dependent discharge, as noted by Gupta and Bhave [

10] and Tabesh

et al. [

5].

The relationship of Wagner

et al. [

7] arises from the general orifice formulation:

where

is the resistance coefficient for node

j, whose value depends on the characteristics of the service connection at that node, and

n is the head exponent, which is considered to be between 1.5 and two [

5], although more accurate values for each node may be determined by calibration. When

=

(the demand),

=

and:

substituting in Equation (

4):

This relationship is a continuous function, with upper and lower bounds consistent with the real behavior of a WDN.

Gupta and Bhave [

10] presented a comprehensive comparison of the head-discharge formulations developed by various researchers ([

2,

4,

7,

21]), introducing the equation:

Tanyimboh and Tabesh [

22] and Tabesh [

23] showed that this correction addresses some weaknesses of Germanopoulos’s equation; however, when

, a small change in the value of

might decrease the value of

in comparison with

.

Later, Tucciarelli

et al. [

11], Ackley [

12], Tanyimboh

et al. [

13], Tanyimboh

et al. [

14] and Tanyimboh and Templeman [

24] proposed new expressions that are able to improve precision. In particular, Tanyimboh and Templeman [

24] proposed the following relationship:

where the parameters

and

can be determined via calibration of relevant field data. Tanyimboh and Templeman [

24] proposed two equations to calculate

and

, given by:

Bhave [

4], Reddy and Elango [

8], Germanopoulos [

6], Wagner

et al. [

7], Gupta and Bhave [

10], Tabesh [

23] and many others studied the relationship between head and discharge only up to

, but they did not present any relationship for values greater than the minimum required head pressure. To overcome this deficiency, Wu

et al. [

25] presented the following formula:

where

α is the exponent of the pressure demand relationship,

is the available pressure at node

j,

is the minimum required pressure at the node and

is the threshold pressure (for values greater than this, the nodal demand is fully supplied, and the discharge no longer increases and remains constant). The pressure threshold must be greater than or equal to the reference pressure at which the target demand is met. When the nodal pressure drops to or falls below zero, the demand is virtually zero. When the nodal pressure reaches the minimum required value, the demand is fully supplied, and when increasing the nodal pressure over the required value, the nodal discharge does not remain constant, but increases, reaching its maximum value when the nodal pressure reaches the threshold. This threshold exists for most types of consumptions, but in certain cases, such as leakage, there is no such threshold, and the discharge always increases with pressure [

1].

Finally, in the paper recently reported by Tabesh

et al. [

1], starting from Wagner

et al. [

7], they considered nodal discharge under four conditions:

in which

is the threshold head,

is the volumetric portion of the available discharge and

is the head-dependent portion of the available discharge, with

and

[

5]. In their study, Tabesh

et al. [

5] assumed that c = 2. The second condition is for head values between the minimum required value and the threshold value, in which the available discharge increases and passes the required discharge. This available discharge is categorized into two groups: volumetric discharge and head-dependent discharge.

3. The Mathematical Models to Estimate the Flow Rate in Inline Tanks

The pressure-discharge relation used in the WDN continuity equation is one of the most important components of hydraulic models based on head-driven simulation methods. This work proposes a demand model that takes into account the interposition of local storage supplying water to customers, describing the effect of the floating valve on the demand profile. A modified version of Criminisi

et al. [

18] is described below. The proposed model is able to represent tank inflow process taking into account the float valve characteristics as a function of the tank water level. The model is based on the combination of the tank continuity equation:

and the float valve emitter law, consistent with the Torricelli law (the kinetic component is considered to be negligible):

where

D and

are the user water demand and the discharge, respectively,

t is the time and

V is the storage volume with area

A and variable water depth

h.

is the float valve emitter coefficient;

is the valve discharge area;

H the hydraulic head over the distribution network;

is the height of the floating valve; and

g is the acceleration due to gravity. Both the float valve emitter coefficient and the discharge area are dependent on the floater position, that is on the water level in the tank.

Criminisi

et al. [

18] proposed an exponential law for the float valve emitter coefficient, which is given by:

where

and

are the water depths when the valve is fully open and fully closed, respectively.

is the emitter coefficient of the fully open valve, and

m is a shape coefficient that generally ranges between 0.5 and two, which is experimentally estimated. The authors also proposed a similar law for the discharge area

:

where

is the effective area of the fully-open valve; the coefficient

n, similar to the coefficient

m, has to be determined experimentally. However, to reduce the number of equations, the discharge area can be kept constant and equal to

.

As recently observed by De Marchis

et al. [

19], although the system of Equations (

13) and (

14) is able to capture the valve-closing phase, some deviations are observed, particularly at the beginning and at the end of the valve closure. Aiming to reduce the inaccuracy level of the float valve model, a simple mathematical model is proposed here to reproduce the supply system in water tanks. Specifically, a new formulation of the emitter coefficient is proposed, as follows:

Equation (

16) was obtained through the best fit to the laboratory measurements, used to compare the proposed pressure-discharge relationship for demands, when a tank is present. Introducing Equation (

16) into Equation (

13), it is obtained:

Following Criminisi

et al. [

18], the system of Equation (

16) was integrated considering a specific equation for the discharge area

. Similar to Equation (

16), a hyperbolic tangent law has been considered:

The coefficient

n of Equation (

18) was calibrated through laboratory experiments. Adding Equation (

18) into Equation (

17), the equation for the flow rate discharging into the water tank reads:

4. Experimental Setup

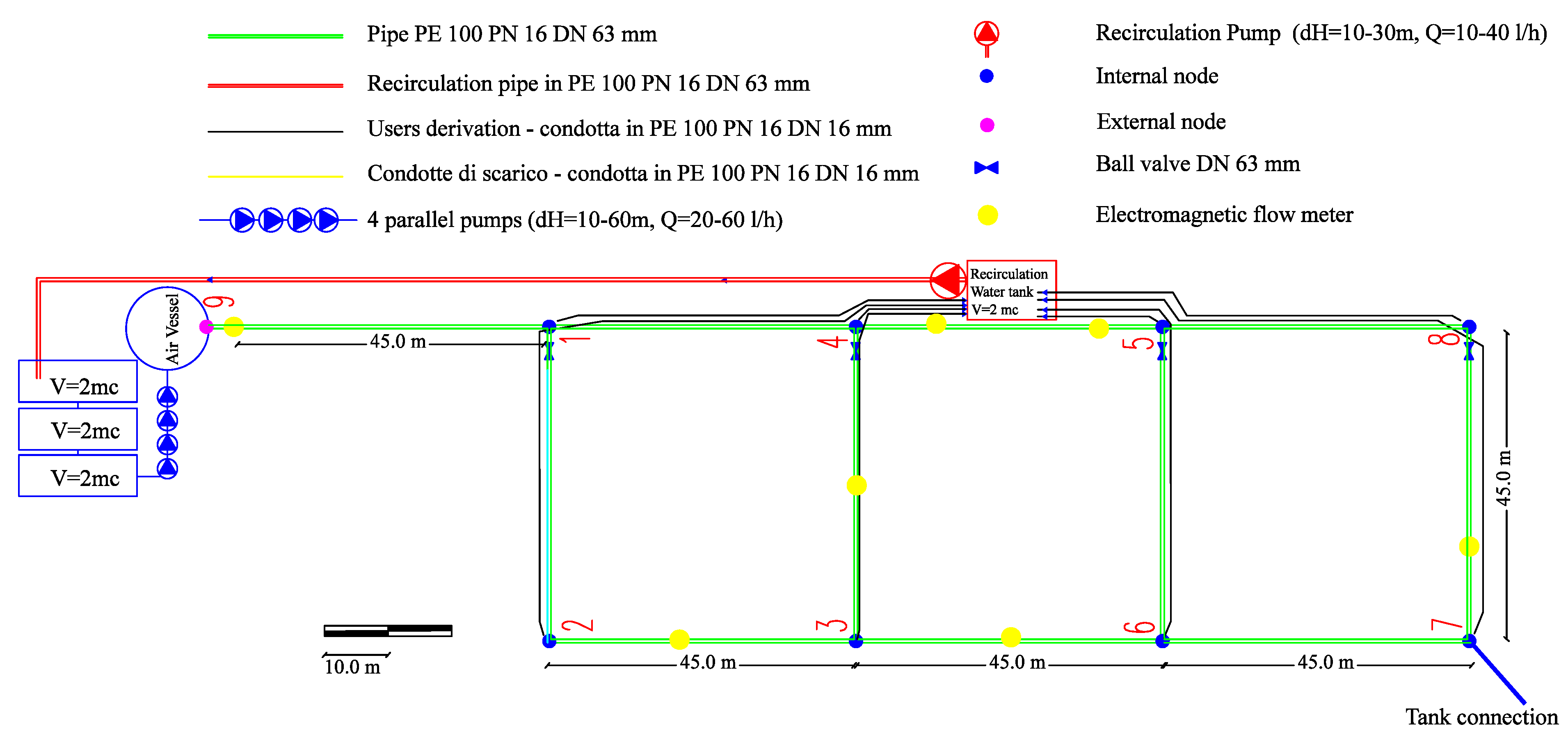

The experiments were conducted at the Environmental Hydraulic Laboratory of the University of Enna (Italy). The flow facility is composed of a water distribution network of high-density polyethylene (HDPE 100 PN16) pipes, designed with three main loops (M = 3), eight internal nodes (N = 8), one external node (S = 1) and eleven pipes (L = 11) with a diameter (DN) of 63 mm. In

Figure 1 is plotted a schematic representation of the network. All pipes are enveloped in concentric circles, with a mean diameter of approximately 2 m (as shown in

Figure 2a, where a picture of the laboratory is reported), thus achieving a length of approximately 45 m. Four ball valves are located in four different pipes, thereby enabling simulations of networks having one, two or three loops, as well as an inline pipe of approximately 500 m.

Figure 1 presents a schematic representation of the water distribution network. The network is fed by four pumps (P), which operate in parallel, connected to three water tanks having a capacity of 2 m

each. All of the pumps are equipped with an inverter, thereby enabling changes in the speed rotation and variations in the water head in a range from 10 to 60 m. The system is monitored by 7 electromagnetic flow meters located in Pipes 9–1, 4–5, 3–6, 2–3, 3–6 and 7–8 of the network. Pressure cells and multi-jet water meters are distributed over the entire network at each node position. The network is designed to model the effect of real losses and of apparent losses. The apparent loss are analyzed through a private tank, which is located on the roof of the laboratory at approximately 17.5 m above the network level and is connected to the system through a high-density polyethylene (HDPE 100 PN16) pipe that is 30 m long with a diameter of 12.7 mm. The tank filling process is governed by a float ball valve, BS 1212 type.

Figure 3 presents a schematic of the water tank and float valve.

Figure 2 shows a view of the laboratory and of the roof tank. Details on the water distribution system can be found in De Marchis

et al. [

19].

Figure 1.

Layout of the water distribution network.

Figure 1.

Layout of the water distribution network.

Experiments

To determine the optimal empirical law to calculate the flow discharging into the local reservoir, two set of experiments were conducted in which the length of the float valve branch was modified. Specifically, in the first set of simulations, a branch with a length of approximately 40 cm was installed (Test Case 1 (TC1)), whereas in the second set of experiments, the float valve was equipped with a branch of approximately 20 cm (TC2); see

Figure 3. In the first test case, the float valve starts to close when the water level inside the tank reaches a depth of

= 0.53 cm, whereas when the water depth is

= 0.65 cm, the valve can be considered completely closed. In contrast, in TC2,

= 0.60 cm. In all cases, the experiments were performed considering that at the beginning of each test, the water tank was empty, and then, the tank is filled considering the daily water supply of the user (350 L per inhabitant per day); this condition simulates a daily intermittent network in which the tank is filled every two days, and it is emptied on the day in which water supply is not guaranteed (see [

15,

26]). For each test case, four scenarios were simulated by changing the pressure from 2 bar to 5 bar, with a step of 0.5 bar. The water volume flowing into the tank was estimated using the electromagnetic flow meter of the ABB IM/WM type (with an accuracy of 0.4%) installed in the inlet pipe, downstream of the pump station. The hydraulic head

H used in Equation (

13) to estimate

was measured using a piezoresistive pressure transducer Gems sensor 3100 series (with an accuracy of 0.1%) located in Node 7. The data were collected using a sampling rate of 1 Hz. Each experiment was repeated twice, and the average value was considered. The experiments were used to calibrate the empirical law proposed in the present study.

Figure 2.

Layout of the water distribution network and view of the roof tank.

Figure 2.

Layout of the water distribution network and view of the roof tank.

Figure 3.

Layout of the water tank and the float valve. Left: short branch; right: long branch.

Figure 3.

Layout of the water tank and the float valve. Left: short branch; right: long branch.