Study on the Performance Evaluation Method and Application of Drainage Nonwoven Geotextile in the Yellow River Sediment Filling Reclamation Area

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.1.1. Geotextiles

2.1.2. The Yellow River Sediment

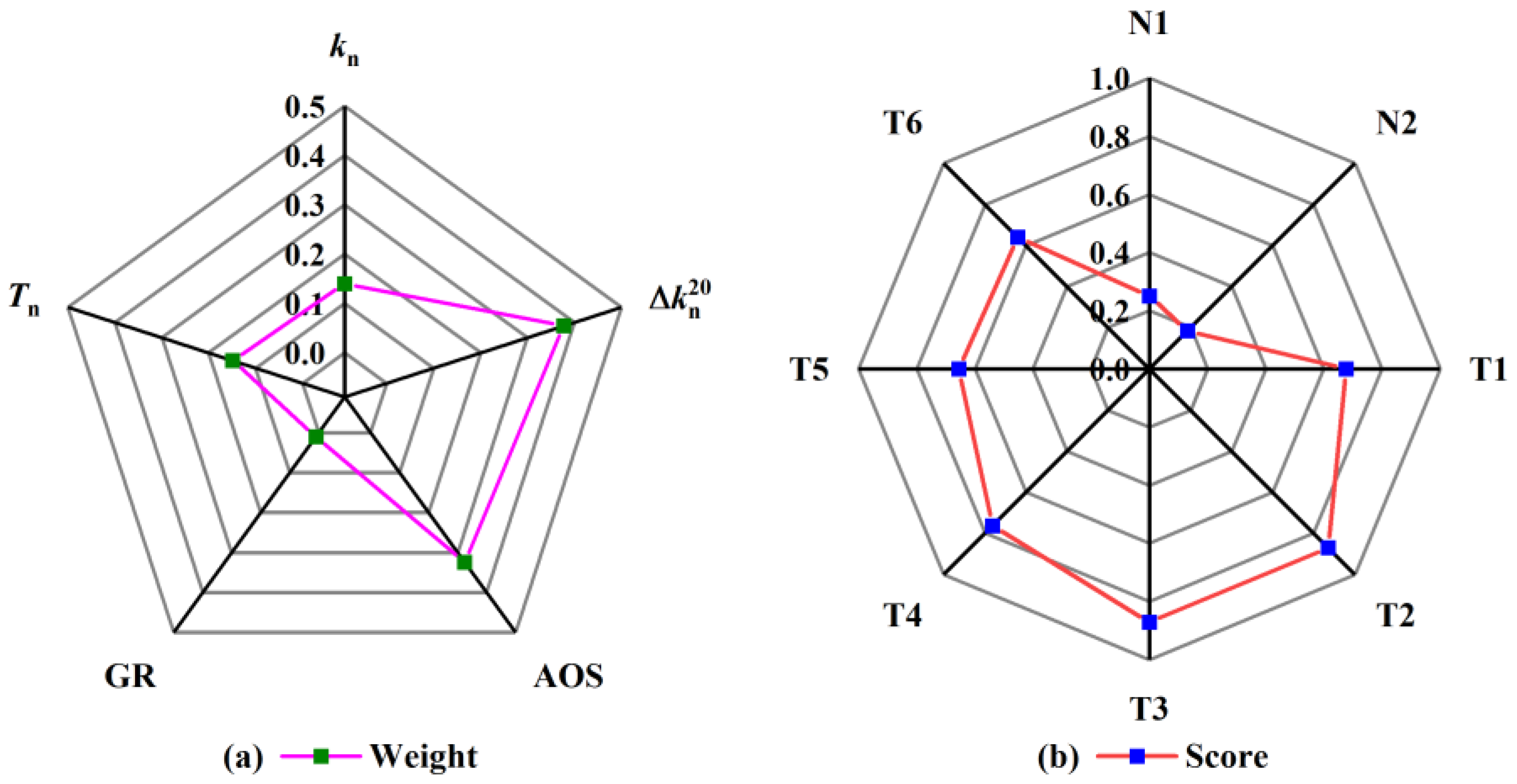

2.2. Geotextiles Performance Evaluation Method

- (1)

- Construction of the evaluation index system: Based on the three fundamental criteria of permeability, soil conservation, and blockage prevention capability, a multilevel evaluation index system was established (Table 2).

- (2)

- Normalization of indicators: Data standardization was performed to eliminate dimensional differences among various indicators. The raw indicator values were converted into dimensionless values via a standardization formula (Equation (1)).

- (3)

- Determination of indicator weights: The entropy weight method was employed to objectively determine the weights of each indicator based on the amount of information in the data (Equations (2)–(4)).

- (4)

- Calculation of comprehensive scores: By combining the weights obtained from the entropy weight method, the comprehensive performance scores for each type of geotextile were calculated (Equation (5)). The geotextiles were then ranked based on these scores, with an average of five degrees from 0 to 1. A higher score indicates better overall performance, making the geotextile more suitable for the Yellow River sediment filling reclamation drainage projects.

| Criterion Layer | Indicator Layer | Properties |

|---|---|---|

| Permeability | Permeability coefficient ( | Positive |

| Change of at 20 kPa ( | Negative | |

| Soil conservation | Apparent opening size (AOS) | Intermediate |

| Blockage prevention | Gradient ratio (GR) | Negative |

| Sediment retention rate ( | Negative |

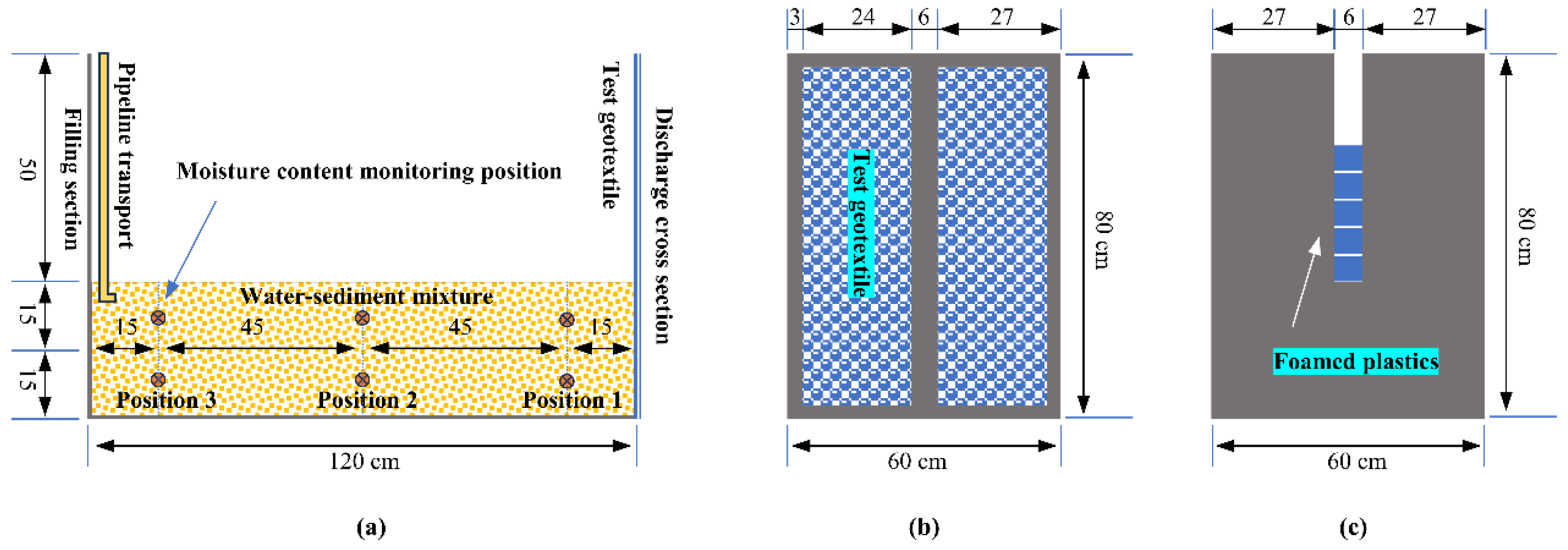

2.3. Indoor Flume Filing and Drainage Experiment

2.4. Statistical Analysis

3. Results

3.1. Evaluation of Geotextile Drainage Performance

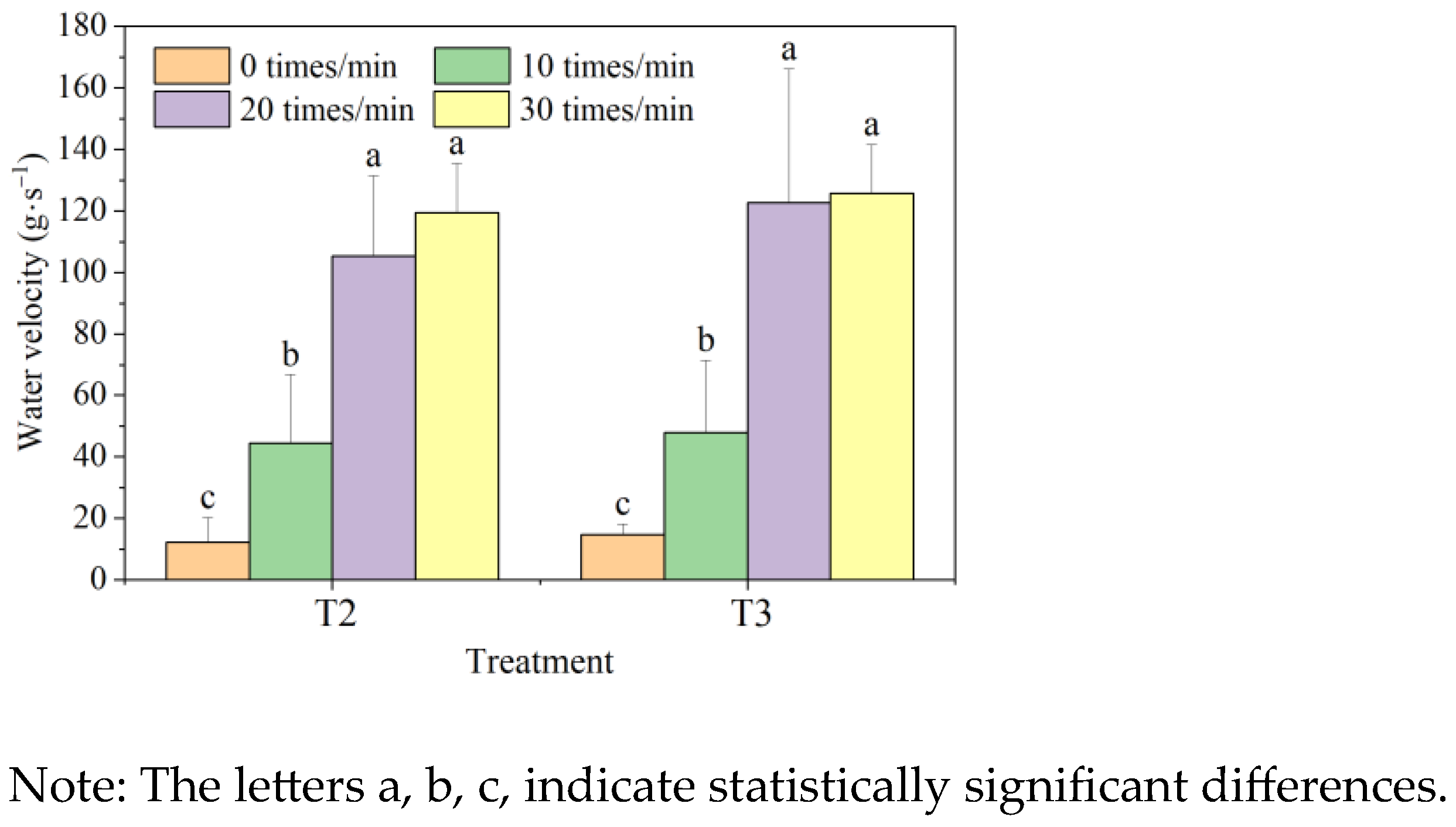

3.2. Indoor Flume Filing and Drainage

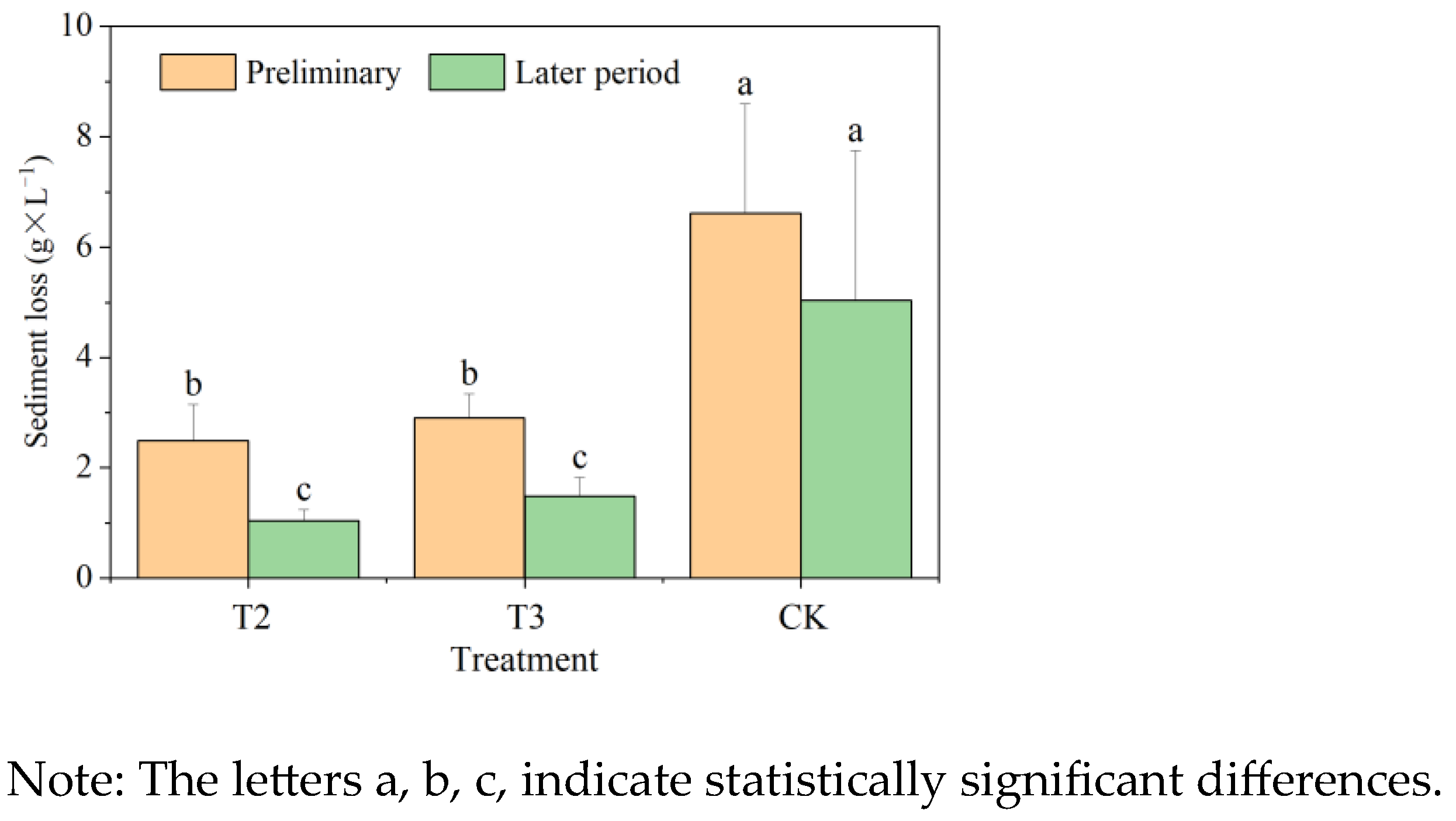

3.2.1. Sediment Content in Drainage Water

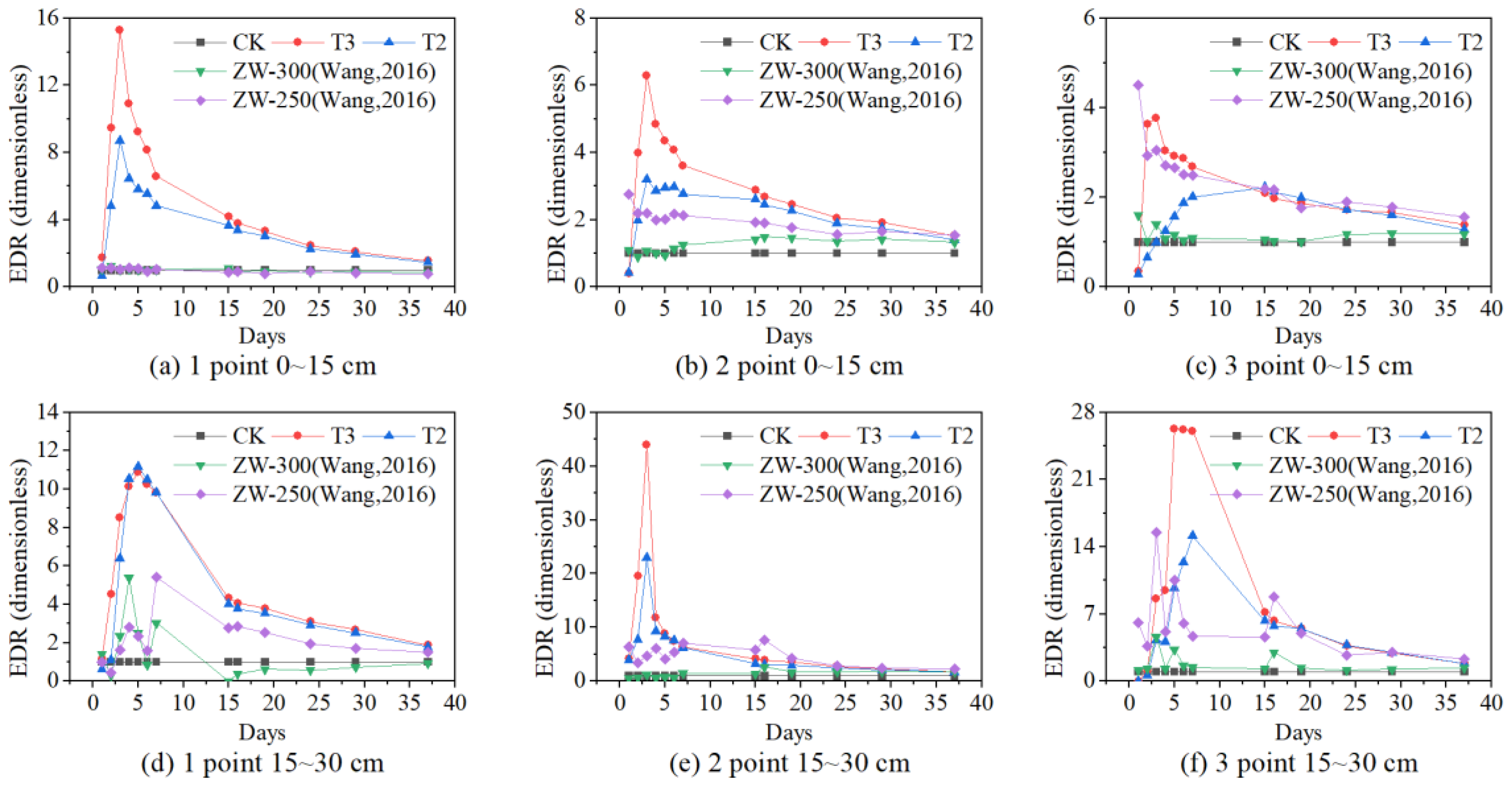

3.2.2. Moisture Content of Infill Sediment

4. Discussion

4.1. Evaluation and Comparison of Basic Drainage Performance of Nonwoven Geotextiles

4.1.1. Enhancing the Efficacy of Evaluation Methods

4.1.2. Superiority of Drainage Performance

4.2. Engineering Application Methods of Drainage Geotextiles

4.3. Implications and Future Prospects

5. Conclusions

- (1)

- An evaluation index system for geotextile performance suitable for the Yellow River sediment filling reclamation drainage was established. This system includes indicators such as permeability coefficient, changes in permeability coefficient under 20 kPa pressure, apparent opening size, gradient ratio, and soil retention rate. The entropy weight method was used to determine the weights of these indicators, identifying two specifications of thermal-bonded nonwoven geotextiles (250 g·m−2 (T2) and 200 g·m−2 (T3)) with an optimal drainage performance under the Yellow River sediment filling reclamation conditions.

- (2)

- Laboratory flume drainage tests demonstrated that both the T2 and T3 geotextiles effectively reduced the moisture content of the drained sediment. Compared to untreated sediment (CK), geotextile treatments significantly enhanced the lateral drainage, validating the reliability of the evaluation model for the Yellow River sediment filling reclamation drainage conditions.

- (3)

- The study found that striking the geotextile drainage sections with a mallet during sediment filling can stabilize the drainage speed and significantly improve the drainage efficiency. Considering both drainage effectiveness and economic costs, using the 200 g·m−2 thermal-bonded nonwoven geotextile (T3) and installing simple vibration devices during the filling process to achieve stable and optimal drainage effects is recommended.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, Y.; Gao, X.; Zhou, D.; Zhou, R. Changes in Soil Physical and Chemical Properties after a Coal Mine Subsidence Event in a Semi-Arid Climate Region. Pol. J. Environ. Stud. 2022, 31, 2329–2340. [Google Scholar] [CrossRef]

- Zheng, Q.; Wang, C.; Pang, L. Overburden and Surface Subsidence with Slicing Paste Filling Mining in Thick Coal Seams. Front. Earth Sci. 2023, 10, 1027816. [Google Scholar] [CrossRef]

- Han, C.; Gao, Z.; Wu, Z.; Huang, J.; Liu, Z.; Zhang, L.; Zhang, G. Restoration of Damaged Ecosystems in Desert Steppe Open-pit Coal Mines: Effects on Soil Nematode Communities and Functions. Land Degrad. Dev. 2021, 32, 4402–4416. [Google Scholar] [CrossRef]

- Hu, Z.; Li, J.; Zhao, Y. Problems, Reasons and Countermeasures for Environmental Quality and Food Safety in the Overlapped Areas of Crop and Mineral Production. Sci. Technol. Rev. 2006, 24, 21–24. [Google Scholar]

- Xiao, W.; Hu, Z.; Chugh, Y.P.; Zhao, Y. Dynamic Subsidence Simulation and Topsoil Removal Strategy in High Groundwater Table and Underground Coal Mining Area: A Case Study in Shandong Province. Int. J. Min. Reclam. Environ. 2014, 28, 250–263. [Google Scholar] [CrossRef]

- Bednik, M.; Medyńska-Juraszek, A.; Dudek, M.; Kloc, S.; Kręt, A.; Łabaz, B.; Waroszewski, J.; Kumar, D.; Singh, B. The Use of Coal Fly Ash in Sodic Soil Reclamation. Land Degrad. Dev. 2003, 14, 285–299. [Google Scholar] [CrossRef]

- Wang, J.; Qin, Q.; Hu, S.; Wu, K. A Concrete Material with Waste Coal Gangue and Fly Ash Used for Farmland Drainage in High Groundwater Level Areas. J. Clean. Prod. 2016, 112, 631–638. [Google Scholar] [CrossRef]

- Xu, L.; Xu, S.; Yang, X.; Yan, J.; Meuser, H.; Makowsky, L. Study on Distribution Character of Physical and Chemical Properties and Heavy Metals in Reclaimed Land Filled with Fly Ash: A Case Study of Reclaimed Land of Luohe Power Plant in Huainan City. J. Agro-Environ. Sci. 2012, 31, 2352–2360. [Google Scholar]

- Bai, D.; Yang, X.; Lai, J.; Wang, Y.; Zhang, Y.; Luo, X. In Situ Restoration of Soil Ecological Function in a Coal Gangue Reclamation Area after 10 Years of Elm/Poplar Phytoremediation. J. Environ. Manag. 2022, 305, 114400. [Google Scholar] [CrossRef]

- Wang, P.; Shao, F.; Liu, J.; Li, X.; Hu, Z.; Yost, R.S. Simulated experiment on drainage and fine sediment retention effects of geotextiles in land reclamation with Yellow River sediments. Trans. Chin. Soc. Agric. Eng. 2015, 31, 72–80. [Google Scholar] [CrossRef]

- Hu, Z.; Zhao, Y. Principle and Technology of Coordinated Control of Eco⁃environment of Mining Areas and River Sediments in Yellow River Watershed. J. China Coal Soc. 2022, 47, 438–448. [Google Scholar] [CrossRef]

- Wang, P.; Hu, Z.; Shao, F.; Jiang, Z.; Qiao, Z.; Liu, D.; Chen, Y. Experimental Study of the Shear Strength of Soil from the Heifangtai Platform of the Loess Plateau of China. J. China Coal Soc. 2014, 39, 1133–1139. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, P.; Yost, R.S.; Shao, F.; Duo, L. Assessment of Several Typical Physical Properties of Reclaimed Farmland Filled with Yellow River Sediment in Jining, China. Int. J. Coal Sci. Technol. 2018, 5, 36–46. [Google Scholar] [CrossRef]

- Wang, P.; Hu, Z.; Yost, R.S.; Shao, F.; Liu, J.; Li, X. Assessment of Chemical Properties of Reclaimed Subsidence Land by the Integrated Technology Using Yellow River Sediment in Jining, China. Environ. Earth Sci. 2016, 75, 1046. [Google Scholar] [CrossRef]

- Hu, Z.; Shao, F.; McSweeney, K. Reclaiming Subsided Land with Yellow River Sediments: Evaluation of Soil-Sediment Columns. Geoderma 2017, 307, 210–219. [Google Scholar] [CrossRef]

- Wang, P. Technique of Filling and Drainage of Water-Sediment Mixture Used to Reclaim Mining Subsidence Land in Eastern China. Ph.D. Dissertation, China University of Mining and Technology-Beijing, Beijing, China, 2016. [Google Scholar]

- Sun, H.; Hu, Z.; Wang, S. A Study of the Physical and Mechanical Properties of Yellow River Sediments and Their Impact on the Reclamation of Coal-Mined Subsided Land. Sustainability 2024, 16, 439. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, P.; Shao, F. Technique for Filling Reclamation of Mining Subsidence Land with Yellow River Sediment. Trans. Chin. Soc. Agric. Eng. 2015, 31, 288–295. [Google Scholar]

- Wu, C.-S.; Hong, Y.-S.; Yan, Y.-W.; Chang, B.-S. Soil-Nonwoven Geotextile Filtration Behavior under Contact with Drainage Materials. Geotext. Geomembr. 2006, 24, 1–10. [Google Scholar] [CrossRef]

- Chen, H.; Chu, J.; Guo, W.; Wu, S. Land Reclamation Using the Horizontal Drainage Enhanced Geotextile Sheet Method. Geotext. Geomembr. 2023, 51, 131–150. [Google Scholar] [CrossRef]

- Palmeira, E.M.; Tatto, J. Behaviour of Geotextile Filters in Armoured Slopes Subjected to the Action of Waves. Geotext. Geomembr. 2015, 43, 46–55. [Google Scholar] [CrossRef]

- Farias, R.J.C.; Palmeira, E.M.; Carvalho, J.C. Performance of Geotextile Silt Fences in Large Flume Tests. Geosynth. Int. 2006, 13, 133–144. [Google Scholar] [CrossRef]

- GB/T 50290-2014; Technical Code for Application of Geosynthetics. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, China Planning Press: Beijing, China, 2014.

- Stuyt, L.C.P.M.; Dierickx, W.; Beltrán, J.M. Materials for Subsurface Land Drainage Systems; Food and Agriculture Organization of the United Nations: Rome, Italy, 2005. [Google Scholar]

- Mao, W.; Kang, S.; Wan, Y.; Sun, Y.; Li, X.; Wang, Y.; Palmeira, E.M.; Gardoni, M.G.; Bessa da Luz, D.W. Soil–Geotextile Filter Interaction under High Stress Levels in the Gradient Ratio Test. Geosynth. Int. 2005, 12, 162–175. [Google Scholar] [CrossRef]

- Hong, Y.-S.; Wu, C.-S. Filtration Behaviour of Soil-Nonwoven Geotextile Combinations Subjected to Various Loads. Geotext. Geomembr. 2011, 29, 102–115. [Google Scholar] [CrossRef]

- Markiewicz, A.; Kiraga, M.; Koda, E. Influence of Physical Clogging on Filtration Performance of Soil-Geotextile Interaction. Geosynth. Int. 2022, 29, 356–368. [Google Scholar] [CrossRef]

- ASTM D 5493; Committee Test Method for Permittivity of Geotextiles Under Load. ASTM International: West Conshohocken, PA, USA, 2023.

- Hufenus, R.; Schrade, U. An Optimized Method to Measure the Hydraulic Conductivity of Geosynthetics under Load. Geotext. Geomembr. 2006, 24, 243–253. [Google Scholar] [CrossRef]

- ASTM D 4751-12; Committee Test Methods for Determining Apparent Opening Size of a Geotextile. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D 5101-12; Committee Test Method for Measuring the Filtration Compatibility of Soil-Geotextile Systems. ASTM International: West Conshohocken, PA, USA, 2017.

- Faure, Y.H.; Farkouh, B.; Delmas, P.; Nancey, A. Analysis of Geotextile Filter Behaviour after 21 Years in Valcros Dam. Geotext. Geomembr. 1999, 17, 353–370. [Google Scholar] [CrossRef]

- Xu, C.; Du, C.; Yang, Y.; Shen, P.; Li, M. Long-Term Permeability Tests on Clogging and Permeability of Nonwoven Geotextile Filtering Silty Clay. J. Text. Inst. 2023, 114, 1704–1715. [Google Scholar] [CrossRef]

- Du, C.; Xu, C.; Yang, Y.; Wang, J. Filtration Performance of Nonwoven Geotextile Filtering Fine-Grained Soil under Normal Compressive Stresses. Appl. Sci. 2022, 12, 12638. [Google Scholar] [CrossRef]

- Fatema, N.; Bhatia, S.K. Sediment Retention and Clogging of Geotextile with High Water Content Slurries. Int. J. Geosynth. Ground Eng. 2018, 4, 13. [Google Scholar] [CrossRef]

- Zhenqi, H.; Li, Y.; Chen, Y. The Mechanism and Key Technology of the Yellow River Sediment in Ecological Rehabilitation. J. China Univ. Min. Technol. 2022, 51, 1–15. [Google Scholar] [CrossRef]

- Howard, I.L.; Vahedifard, F.; Williams, J.M.; Timpson, C. Geotextile Tubes and Beneficial Reuse of Dredged Soil: Applications near Ports and Harbours. Int. J. Geosynth. Ground Eng. 2018, 171, 244–257. [Google Scholar] [CrossRef]

- Shao, Q.; Gu, W.; Dai, Q.; Makoto, S.; Liu, Y. Effectiveness of Geotextile Mulches for Slope Restoration in Semi-Arid Northern China. Catena 2014, 116, 1–9. [Google Scholar] [CrossRef]

- Kalore, S.A.; Sivakumar Babu, G.L. Improved Design Criteria for Nonwoven Geotextile Filters with Internally Stable and Unstable Soils. Geotext. Geomembr. 2022, 50, 1120–1134. [Google Scholar] [CrossRef]

| Experiment | Gross Weight | AOS | GR | |||

|---|---|---|---|---|---|---|

| g × m−2 | cm × s−1 | cm × s−1 | mm | - | % | |

| N1 | 300 | 9.95 × 10−2 | 5.98 × 10−2 | 1.00 × 10−1 | 9.92 | 9.92 |

| N2 | 200 | 4.62 × 10−2 | 2.78 × 10−2 | 1.03 × 10−1 | 10.67 | 10.67 |

| T1 | 300 | 5.30 × 10−2 | 9.00 × 10−4 | 1.23 × 10−1 | 4.64 | 4.64 |

| T2 | 250 | 5.07 × 10−2 | 9.00 × 10−4 | 1.33 × 10−1 | 4.42 | 4.42 |

| T3 | 200 | 4.65 × 10−2 | 8.00 × 10−4 | 1.47 × 10−1 | 4.07 | 4.07 |

| T4 | 160 | 3.07 × 10−2 | 5.00 × 10−4 | 1.52 × 10−1 | 2.68 | 2.68 |

| T5 | 120 | 2.94 × 10−2 | 5.00 × 10−4 | 1.63 × 10−1 | 3.03 | 3.03 |

| T6 | 100 | 2.72 × 10−2 | 5.00 × 10−4 | 1.74 × 10−1 | 2.63 | 2.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Hu, Z.; Song, D.; Nie, X.; Wang, S. Study on the Performance Evaluation Method and Application of Drainage Nonwoven Geotextile in the Yellow River Sediment Filling Reclamation Area. Land 2024, 13, 1597. https://doi.org/10.3390/land13101597

Sun H, Hu Z, Song D, Nie X, Wang S. Study on the Performance Evaluation Method and Application of Drainage Nonwoven Geotextile in the Yellow River Sediment Filling Reclamation Area. Land. 2024; 13(10):1597. https://doi.org/10.3390/land13101597

Chicago/Turabian StyleSun, Huang, Zhenqi Hu, Deyun Song, Xinran Nie, and Shuai Wang. 2024. "Study on the Performance Evaluation Method and Application of Drainage Nonwoven Geotextile in the Yellow River Sediment Filling Reclamation Area" Land 13, no. 10: 1597. https://doi.org/10.3390/land13101597