Experimental Study on the Application of Heat-Treated High-Strength Lattice Girder in Tunnel Engineering

Abstract

:1. Introduction

2. Performance of Heat-Treated High-Strength Rebar and Steel Arch Structure

2.1. Mechanical Property of Heat-Treated High-Strength Rebar

2.2. Structural Characteristics of Steel Arch Frame

2.2.1. Support Stiffness of Steel Arch Frame

2.2.2. Cohesiveness between Steel Arch Frame and Shotcrete

2.2.3. Processing, Transportation, and Installation of Steel Arch Frame

3. Field Test of Heat-Treated High-Strength Lattice Girder

4. Results and Analysis

4.1. Settlement and Convergence

4.2. Surrounding Rock Pressure

4.3. Stress of Steel Arch

5. Conclusions

- (1)

- Heat-treated high-strength rebar has many advantages such as high strength, superior ductility, high yield ratio, excellent welding and cold bending performance, which can effectively reduce the amount of steel bars used in the project. The combination effect of the grille and the sprayed concrete is good, and the construction is convenient. It is not easy to form a void behind the initial support, which makes it easy to ensure the quality of the project.

- (2)

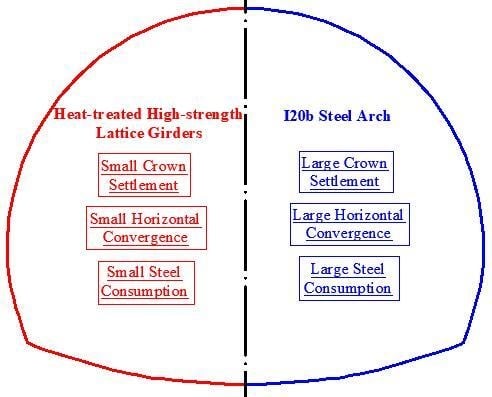

- The deformation monitoring data of the test section show that the crown settlement of the high-strength lattice girder is about 7%~26% smaller than that of the I20b steel arch frame, and the horizontal convergence of high-strength lattice girder is about 12%~30% smaller than that of I20b steel arch frame. The deformation law for both of them is same. In the early stage, the deformation increased rapidly, and it became stable after the invert was enclosing. The main reason for this is that the heat-treated high-strength lattice girders with the same section have relatively large stiffness compared to that of the I20b-shape steel arch frame.

- (3)

- The surrounding rock pressure and distribution of the high-strength steel grid arch section are basically the same as that of the I20b steel arch section, and the surrounding rock pressure of the dome is relatively large. Although the stress of the high-strength steel grid is slightly higher than that of the I20b steel, the stress distribution of the high-strength steel grid is more uniform.

- (4)

- Compared with the I20b steel arch frame, the high-strength lattice girder has more advantages. The main rebar for high-strength lattice girder is Φ 22, the weight per linear meter of which is 64% of that of the I20b steel arch frame, therefore, the high-strength lattice girder will reduce about 36% of the steel consumption, which has remarkable social and economic benefits and popularizing value.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, H.L. Chinese architecture will enter into the era of high-strength rebar. Constr. Architect. 2011, 19, 6–11. (In Chinese) [Google Scholar]

- Gao, C.; Lin, H.; Xu, S.Q. Economic analysis of high-strength bars in railway bridge engineering application. Railw. Stand. Des. 2018, 62, 59–63. (In Chinese) [Google Scholar]

- Du, M.M. Comment on the application of high-strength rebar in concrete structures. Concrete 2012, 9, 121–125. (In Chinese) [Google Scholar]

- Yu, F.C.; Zhang, D.L.; Fang, Q. Experimental study on characteristics of composite support with high-strength reinforcing lattice girders embedded in concrete. China Civ. Eng. J. 2015, 48, 104–111. (In Chinese) [Google Scholar]

- Coro, A.; Abasolo, M.; Aguirrebeitia, J.; López de Lacalle, L.N. Inspection scheduling based on reliability updating of gas turbine welded structures. Adv. Mech. Eng. 2019, 11, 1–20. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Rodríguez, A.; Fernández-Valdivieso, A.; López-Blanco, R.; Fernández, J.; Azkona, I. On the cutting of wood for joinery applications. In Proceedings of the Institution of Mechanical Engineers Part B Journal of Engineering Manufacture, Bilbao, Spain, 20 October 2013. [Google Scholar]

- Guan, B.S. Tunneling by mining method: Lecture IV: Steel arch. Tunn. Constr. 2016, 36, 123–130. (In Chinese) [Google Scholar]

- Qu, H.F.; Zhu, H.H.; Huang, C.Z. Study on selection of section-steel and grid-steel in primary support system of tunnel. Chin. J. Undergr. Space Eng. 2005, 3, 258–262. [Google Scholar]

- Tan, Z.S.; Yu, Y.; Wang, M.N. Comparative tests on section steel and steel grid for loess tunnels with large section. Chin. J. Geotech. Eng. 2009, 31, 628–633. [Google Scholar]

- Chen, Z.X.; Hu, B.W.; Li, X.Z. Study on effect of steel framework in tunnel preliminary bracing. Constr. Technol. 2012, 41, 29–31. [Google Scholar]

- Li, H.Q.; Yang, C.Y.; Xu, M.X. Assessment on safety of lattice girder reinforced shotcrete support for tunnels. Chin. J. Rock Mech. Eng. 2009, 28, 3903–3908. [Google Scholar]

- Komselis, C.; Blayney, N.; Hindle, D. The use of lattice girders in the construction of tunnels. Masterbuilder 2012, 14, 88–94. [Google Scholar]

- Kim, S.; Han, T.H.; Baek, J.S. Evaluation of the structural performance of tetragonal lattice girders. Int. J. Steel Struct. 2013, 13, 31–47. [Google Scholar] [CrossRef]

- Nomikos, P.P.; Sofianos, A.I.; Sakkas, K.M. Nonlinear simulation of lattice girder segment tests. Tunn. Undergr. Space Technol. 2013, 38, 180–188. [Google Scholar] [CrossRef]

- Baumann, T.; Betzle, M. Investigation of the performance of lattice girders in tunnelling. Rock Mech. Rock Eng. 1984, 17, 67–81. [Google Scholar] [CrossRef]

- Oreste, P.P. Analysis of structural interaction in tunnels using the convergence-confinement approach. Tunn. Undergr. Space Technol. 2003, 18, 347–363. [Google Scholar] [CrossRef]

- Ding, Y.Z.; Tan, Z.S.; Ma, D.; Fan, M.G.; Huang, H.H. Study on support effect of high-strength steel grille in tunnel with IV grade surrounding rock. China Civ. Eng. J. 2017, 50, 98–103. [Google Scholar]

- Ma, D.; Tan, Z.S.; Ding, Y.Z.; Dong, B.L.; Huang, H.H. Study on support effect of high-strength steel grille in tunnel with V grade surrounding rock. China Civ. Eng. J. 2017, 50, 14–20. [Google Scholar]

- Zhang, F.P.; Wang, X.L.; Liu, Y.M. Effect of heat treatment on microstructure and property of high strength steel bar. Hot Work. Technol. 2014, 43, 169–173. [Google Scholar]

- Wang, M.S. China Tunnel and Underground Engineering Construction Technology; China Communication Press: Beijing, China, 2010. [Google Scholar]

| High-Strength Rebar Grade | Yield Strength ReL/MPa | Ultimate Tensile Strength Rm/MPa | Strength Ratio Rm/ReL/% | Maximum Total Elongation Agt/% |

|---|---|---|---|---|

| CRMG600 | 600 | 750 | 1.25 | 9.0 |

| HTH900 | 900 | 1070 | 1.15 | 3.5 |

| Grades and Types of Rebar | Elastic Modulus E/GPa |

|---|---|

| HPB300Rebar | 210 |

| HRB335, HRB400, HRB500Rebar | 200 |

| HRBF335, HRBF400, HRBF500Rebar | |

| CRMG600, CRMG700, CRMG785, CRMG830Rebar | 200 |

| HTH800, HTH900, HTH1000Rebar |

| Steel Arch Form | Weight per m/kg |

|---|---|

| I16 | 20.5 |

| I18 | 24.1 |

| I20b | 31.1 |

| I22b | 36.5 |

| High-strength steel grille arch (Main Rebar Φ 22) | 19.8 |

| Project Type | Conditions of Surrounding Rock | Steel Frame Type | Tunnel Span/m |

|---|---|---|---|

| Double-track railway tunnel | Limestone with dolomitic limestone; Limestone sand shale | I20b | 13.50 |

| Two-lane road tunnel | Tuff sandstone | I20b | 12.86 |

| Three-lane road tunnel | Fragmented lithified mixed granite | I20b | 16.52 |

| Type | Model | Diameter (mm) | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|

| Main rebar | CRMG600 | Φ 22 | 600 | 750 |

| Stirrup | HTH900 | Φ 10 | 900 | 1070 |

| Squama | HTH900 | Φ 12 | 900 | 1070 |

| Bolt | M20 | / | / | / |

| Measure Point | Types of Steel Arch Frame | Tunnel Type | ||

|---|---|---|---|---|

| Double-Track Railway Tunnel | Two-Lane Highway Tunnel | Three-Lane Highway Tunnel | ||

| Crown settlement/mm | High-strength lattice girder | 35.8 | 11.2 | 12.2 |

| I20b-shape steel arch frame | 43.2 | 15.1 | 13.1 | |

| Difference value | −7.4 | −3.9 | −0.9 | |

| Horizontal convergence/mm | High-strength lattice girder | 24.0 | 12.2 | 12.2 |

| I20b-shape steel arch frame | 34.2 | 15.4 | 13.9 | |

| Difference value | −10.2 | −3.2 | −1.7 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Z.; Han, K. Experimental Study on the Application of Heat-Treated High-Strength Lattice Girder in Tunnel Engineering. Symmetry 2019, 11, 1007. https://doi.org/10.3390/sym11081007

Tan Z, Han K. Experimental Study on the Application of Heat-Treated High-Strength Lattice Girder in Tunnel Engineering. Symmetry. 2019; 11(8):1007. https://doi.org/10.3390/sym11081007

Chicago/Turabian StyleTan, Zhongsheng, and Kaihang Han. 2019. "Experimental Study on the Application of Heat-Treated High-Strength Lattice Girder in Tunnel Engineering" Symmetry 11, no. 8: 1007. https://doi.org/10.3390/sym11081007

APA StyleTan, Z., & Han, K. (2019). Experimental Study on the Application of Heat-Treated High-Strength Lattice Girder in Tunnel Engineering. Symmetry, 11(8), 1007. https://doi.org/10.3390/sym11081007