Dynamic Response of Zener-Modelled Linearly Viscoelastic Systems under Harmonic Excitation

Abstract

:1. Introduction

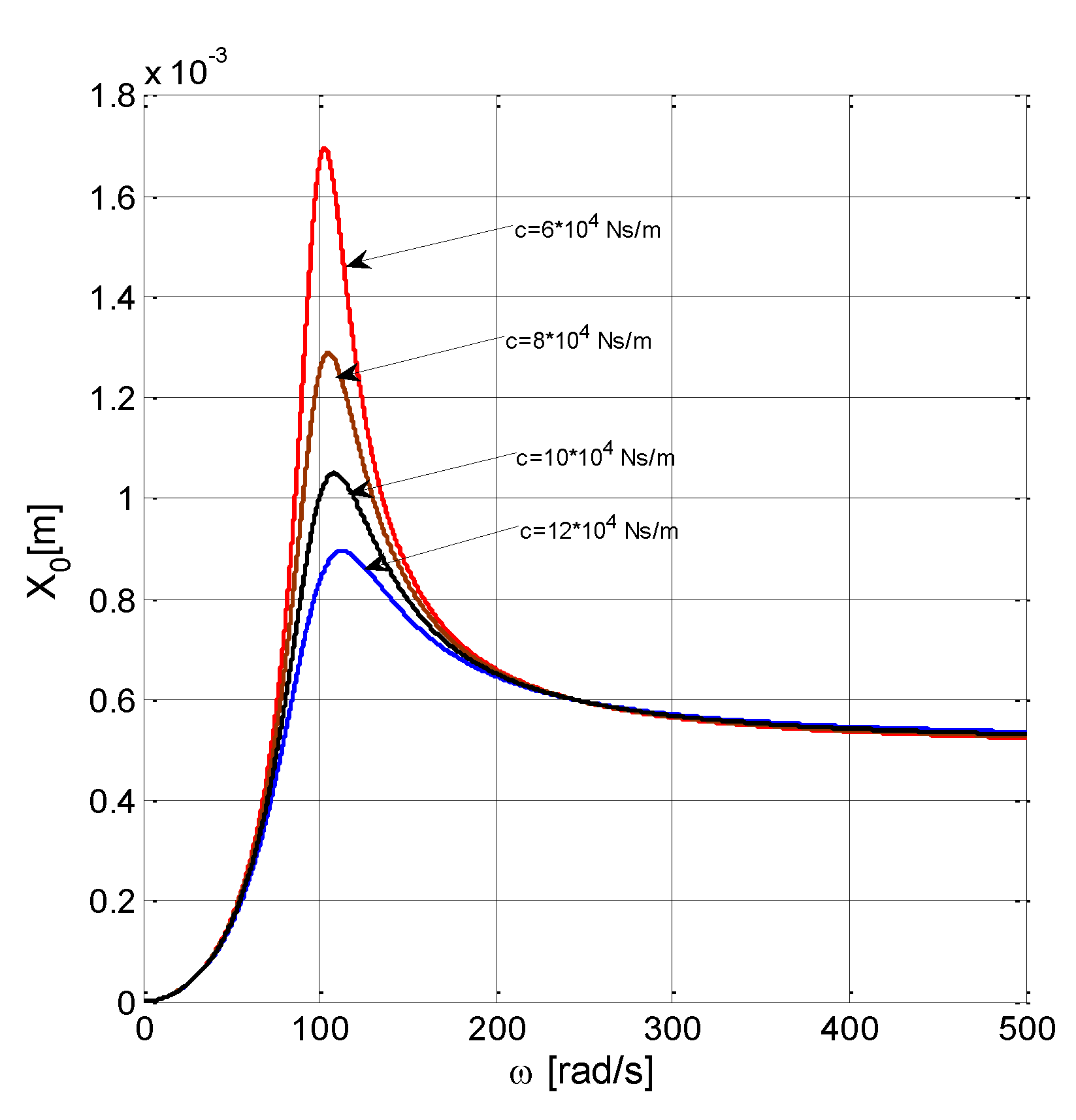

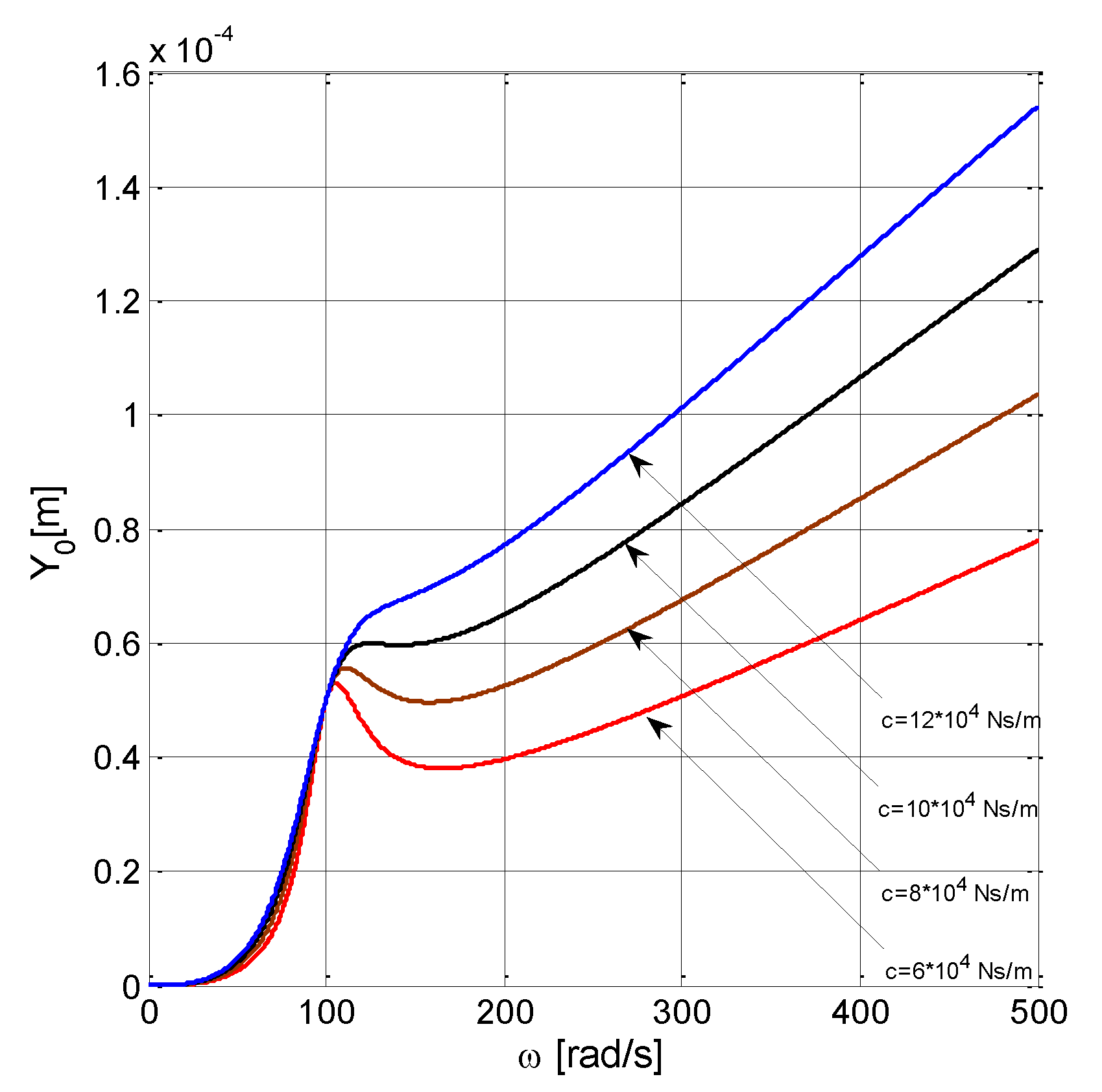

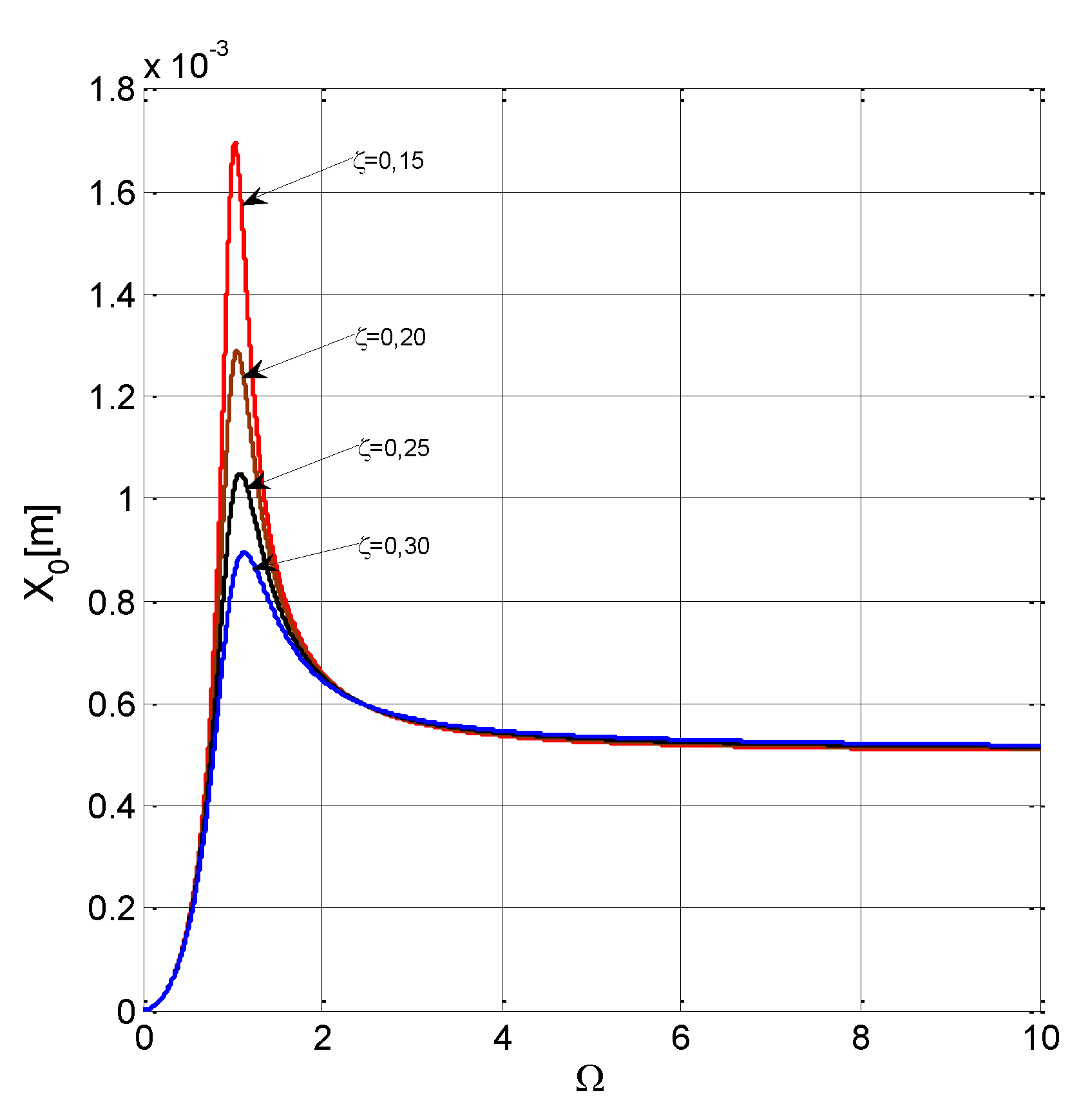

2. Dynamic Response with Respect to Displacements

Variation of Displacement Amplitudes and

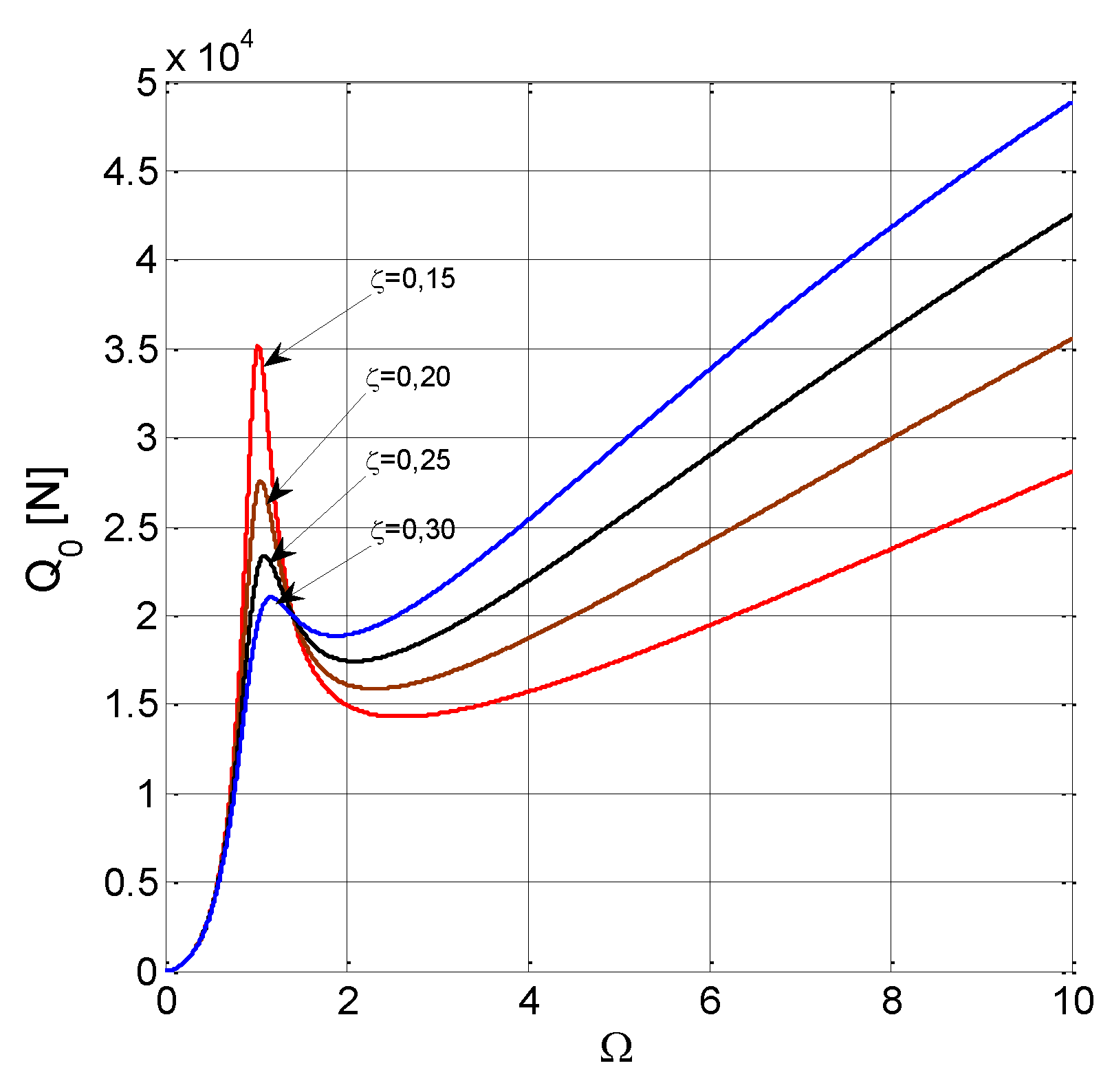

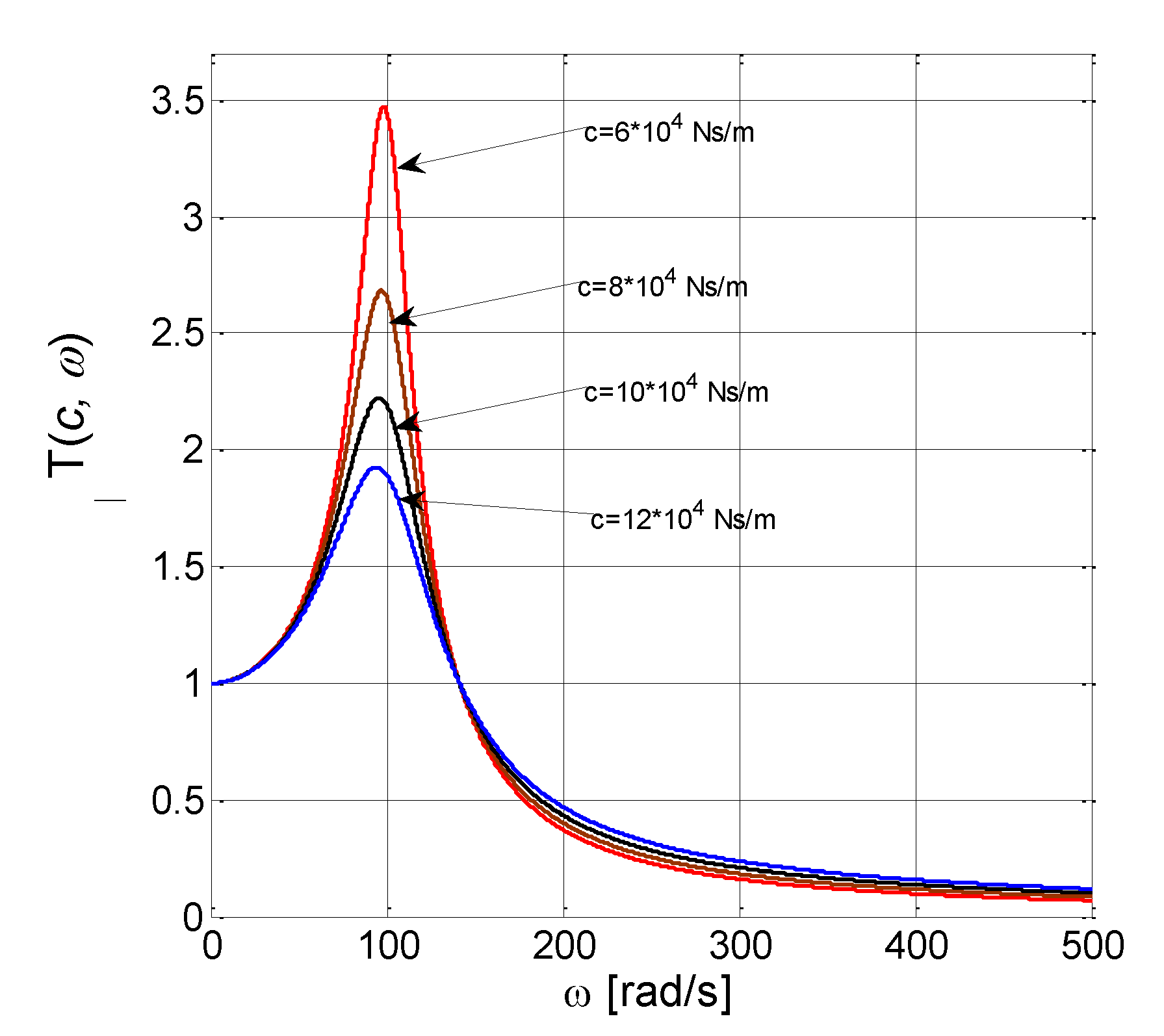

3. Transmitted Dynamic Force

Variation of transmitted force amplitude

4. The Capacity of Dynamic Insulation

Variation of Force Transmissibility

5. Amplitude of Instantaneous Deformation for a Linearly Viscous Buffer.

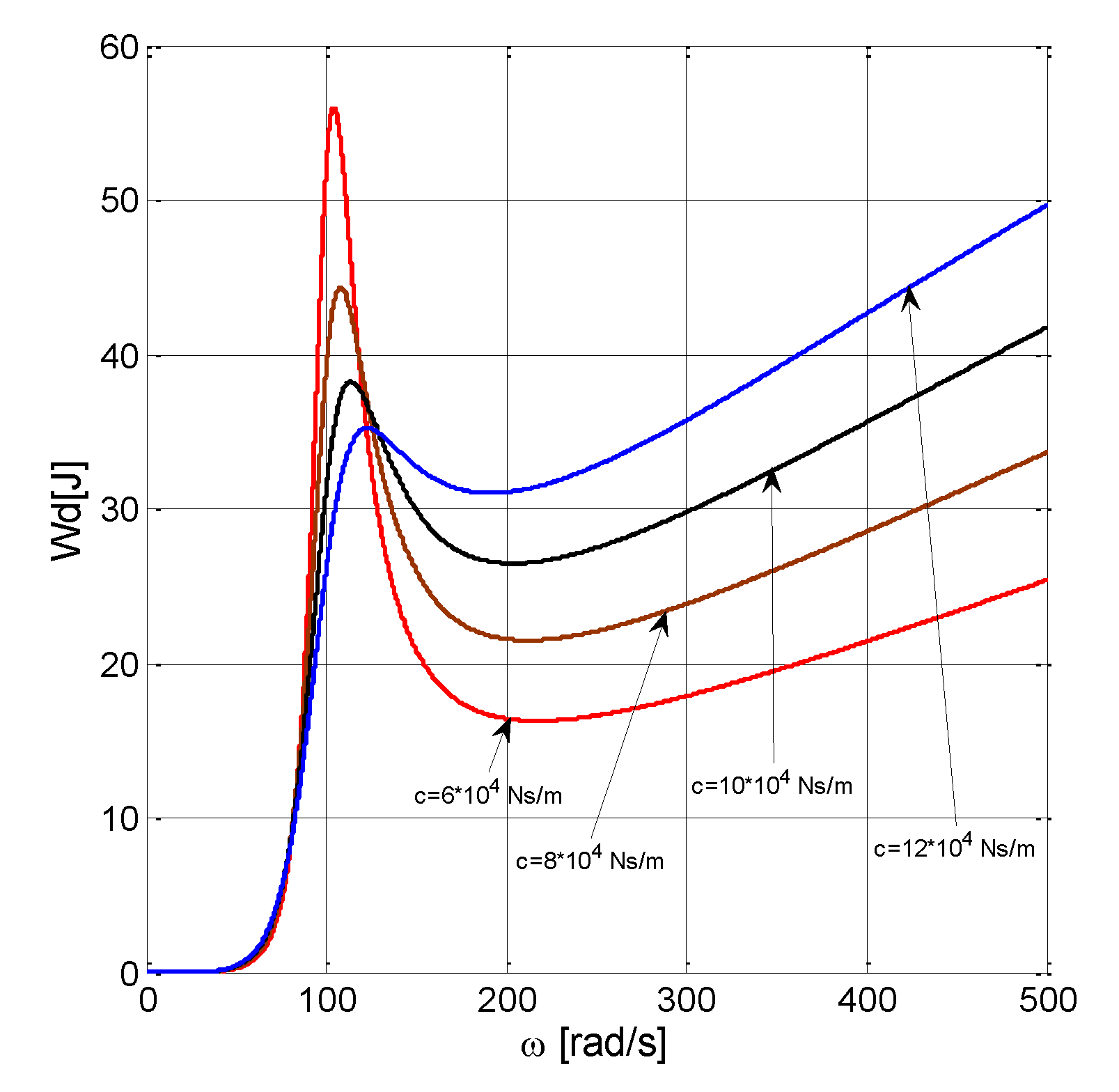

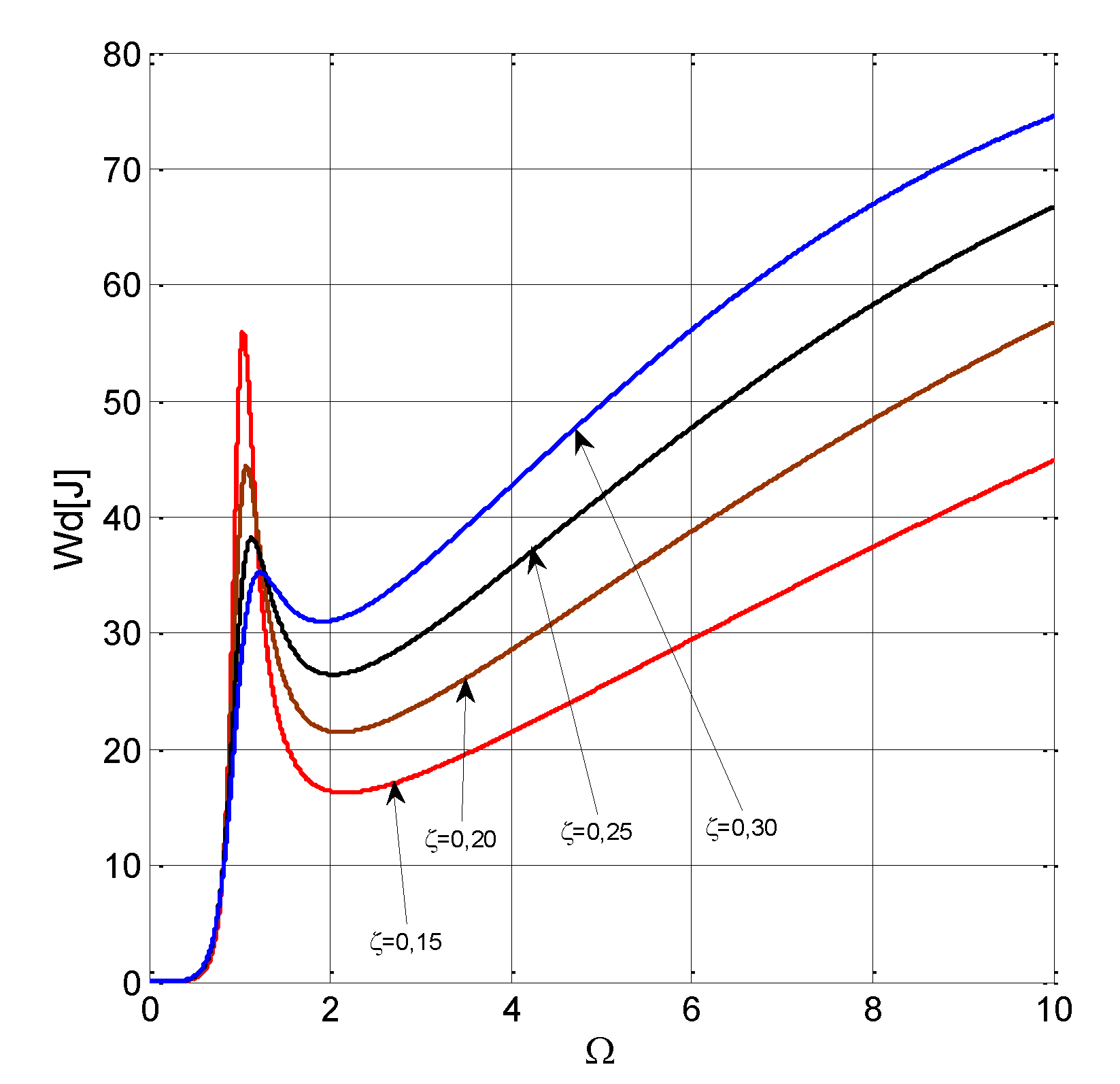

6. Dissipated Energy

7. Conclusions

- (a)

- The analytical model and parametric curves lead to the following conclusions:

- (b)

- (c)

- (d)

- The maximal dynamic transmitted force Q0 in the post-resonance field for ω >> ωn or Ω >> 1 shows the stable values set by the size of the viscous amortization.

- (e)

- Transmissibility decreases at high values of the excitation pulsation once a discrete value is set for amortization.

- (f)

Author Contributions

Funding

Conflicts of Interest

References

- Bratu, P.; Stuparu, A.; Leopa, A.; Popa, S. The dynamic analyse of a construction with the base insulation consisting in anti-seismic devices modeled as a Hooke-Voigt-Kelvin linear rheological system. Acta Tech. Napoc. Ser. Appl. Math. Eng. 2018, 60, 465–472. [Google Scholar]

- Bratu, P.; Stuparu, A.; Popa, S.; Iacob, N.; Voicu, O.; Iacob, N.; Spanu, G. The dynamic isolation performances analysis of the vibrating equipment with elastic links to a fixed base. Acta Tech. Napoc. Ser. Appl. Math. Eng. 2018, 61, 23–28. [Google Scholar]

- Dobrescu, C.F. Highlighting the Change of the Dynamic Response to Discrete Variation of Soil Stiffness in the Process of Dynamic Compaction with Roller Compactors Based on Linear Rheological Modeling. Appl. Mech. Mater. 2015, 801, 242–248. [Google Scholar] [CrossRef]

- Adam, D.; Kopf, F. Theoretical Analysis of Dynamically Loaded Soils, European Workshop: Compaction of Soils and Granular Materials; ETC11 of ISSMGE: Paris, France, 2000. [Google Scholar]

- Bejan, S. Analiza Performanței Procesului de Compactare Dinamică Prin Vibrații Pentru Structuri Rutiere. Ph.D. Thesis, “Dunarea de Jos” University of Galati, Galați, Romania, 2015. [Google Scholar]

- Bratu, P. The behavior of nonlinear viscoelastic systems subjected to harmonic dynamic excitation. In Proceedings of the 9th International Congress on Sound and Vibration, University of Central Florida, Orlando, FL, USA, 8–11 July 2002. [Google Scholar]

- Bratu, P.; Debeleac, C. The analysis of vibratory roller motion. In Proceedings of the VII International Triennial Conference Heavy Machinery–HM 2011, Session Earth-moving and transportation machinery, Vrnjačka Banja, Serbia, 29 June–2 July 2011; pp. 23–26, ISBN 978-86-82631-58-3. [Google Scholar]

- Bratu, P.; Stuparu, A.; Popa, S.; Iacob, N.; Voicu, O. The assessment of the dynamic response to seismic excitation for constructions equipped with base isolation systems according to the Newton-Voigt-Kelvin model. Acta Tech. Napoc. Ser. Appl. Math. Eng. 2017, 60, 459–464. [Google Scholar]

- Bratu, P. Dynamic response of nonlinear systems under stationary harmonic excitation, Non-linear acoustics and vibration. In Proceedings of the 11th International Congress on Sound and Vibration, St. Petersburg, Russia, 5–8 July 2004; pp. 2767–2770. [Google Scholar]

- Dobrescu, C.F.; Brăguţă, E. Optimization of Vibro-Compaction Technological Process Considering Rheological Properties. In Springer Proceedings in Physics, Proceedings of the 14th AVMS Conference, Timisoara, Romania, 25–26 May 2017; Herisanu, N., Marinca, V., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 287–293. [Google Scholar] [CrossRef]

- Leopa, A.; Debeleac, C.; Năstac, S. Simulation of Vibration Effects on Ground Produced by Technological Equipments. In Proceedings of the 12th International Multidisciplinary Scientific GeoConference and EXPO-Modern Management of Mine Producing, Geology and Environmental Protection, SGEM 2012, Albena, Bulgaria, 17–23 June 2012; Volume 5, pp. 743–750. [Google Scholar]

- Morariu-Gligor, R.M.; Crisan, A.V.; Şerdean, F.M. Optimal design of an one-way plate compactor. Acta Tech. Napoc. Ser. Appl. Math. Mech Eng. 2017, 60, 557–564. [Google Scholar]

- Pințoi, R.; Bordos, R.; Braguța, E. Vibration Effects in the Process of Dynamic Compaction of Fresh Concrete and Stabilized Earth. J. Vib. Eng. Technol. 2017, 5, 247–254. [Google Scholar]

- Mooney, M.A.; Rinehart, R.V. Field Monitoring of Roller Vibration During Compaction of Subgrade Soil. J. Geotech. Geoenviron. Eng. ASCE 2007, 133, 257–265. [Google Scholar] [CrossRef]

- Mooney, M.A.; Rinehart, R.V. In-Situ Soil Response to Vibratory Loading and Its Relationship to Roller-Measured Soil Stiffness. J. Geotech. Geoenviron. Eng. ASCE 2009, 135, 1022–1031. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bratu, P.; Dobrescu, C. Dynamic Response of Zener-Modelled Linearly Viscoelastic Systems under Harmonic Excitation. Symmetry 2019, 11, 1050. https://doi.org/10.3390/sym11081050

Bratu P, Dobrescu C. Dynamic Response of Zener-Modelled Linearly Viscoelastic Systems under Harmonic Excitation. Symmetry. 2019; 11(8):1050. https://doi.org/10.3390/sym11081050

Chicago/Turabian StyleBratu, Polidor, and Cornelia Dobrescu. 2019. "Dynamic Response of Zener-Modelled Linearly Viscoelastic Systems under Harmonic Excitation" Symmetry 11, no. 8: 1050. https://doi.org/10.3390/sym11081050

APA StyleBratu, P., & Dobrescu, C. (2019). Dynamic Response of Zener-Modelled Linearly Viscoelastic Systems under Harmonic Excitation. Symmetry, 11(8), 1050. https://doi.org/10.3390/sym11081050