Meso-Damage Mechanism of Strength and Deformation Characteristics of Typical Sandstone in Xinwen Coalfield

Abstract

:1. Introduction

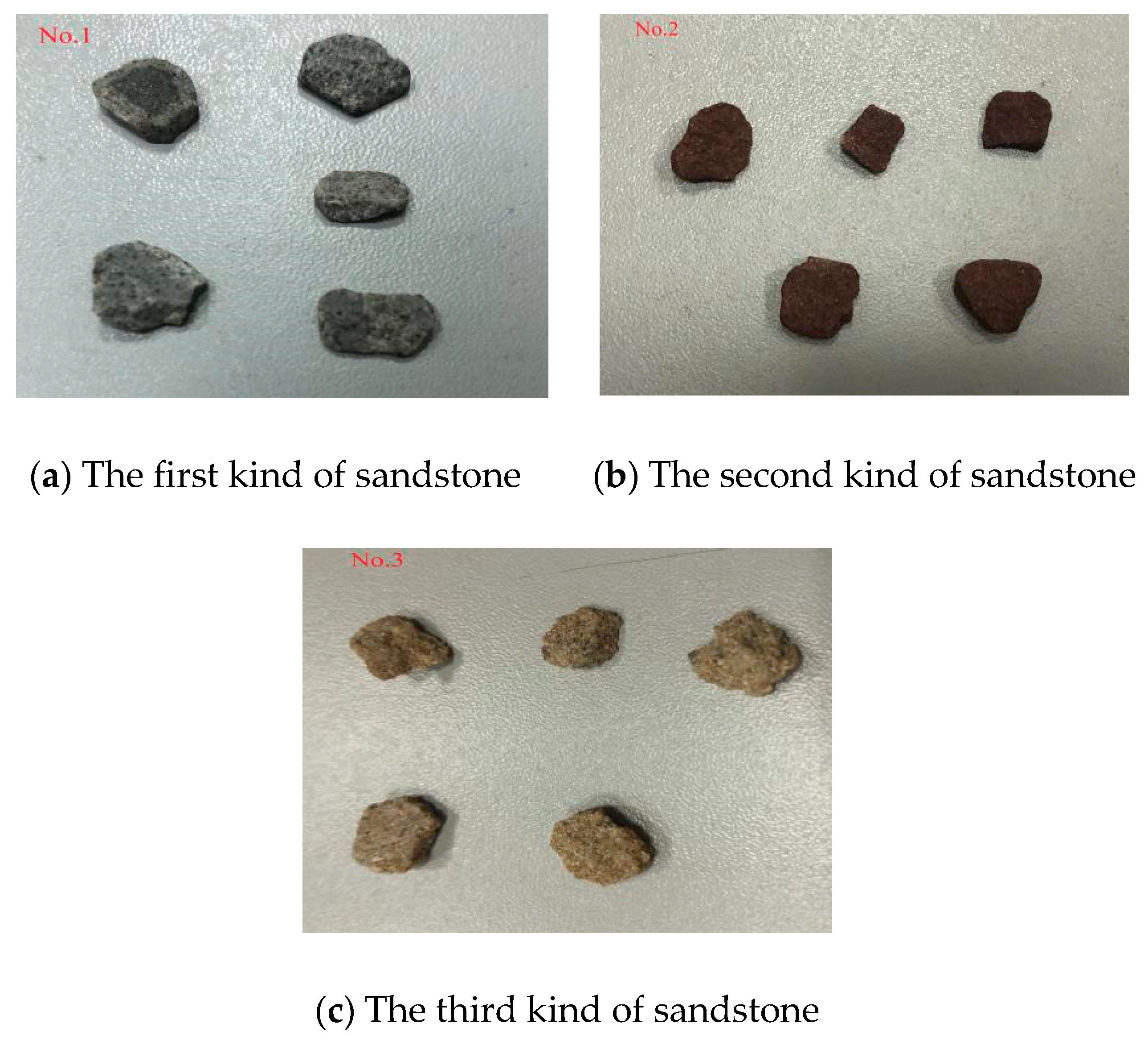

2. Typical Sandstone and Sample Preparation

2.1. Typical Sandstone Geological Conditions

2.2. Rock Sample Preparation

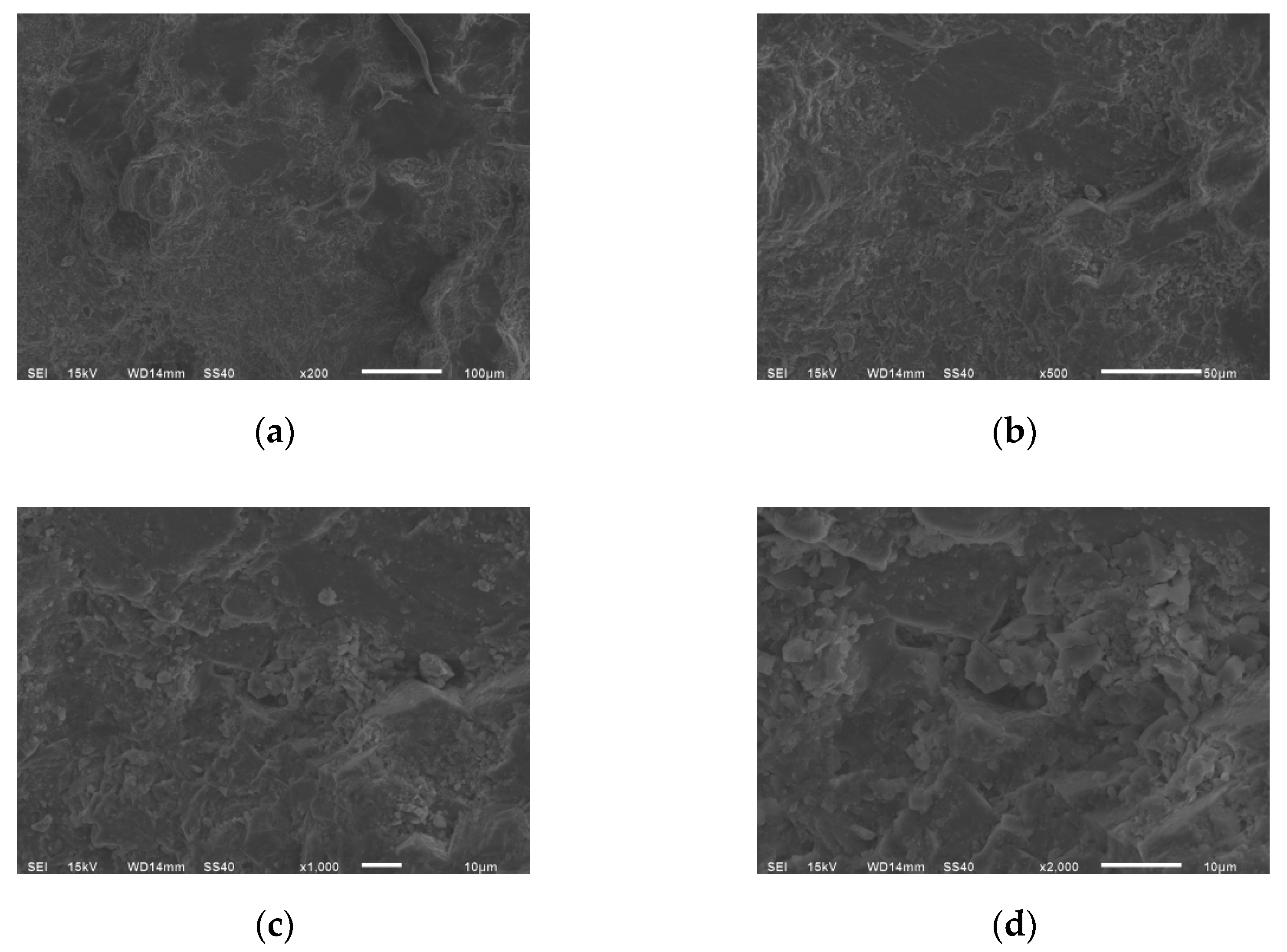

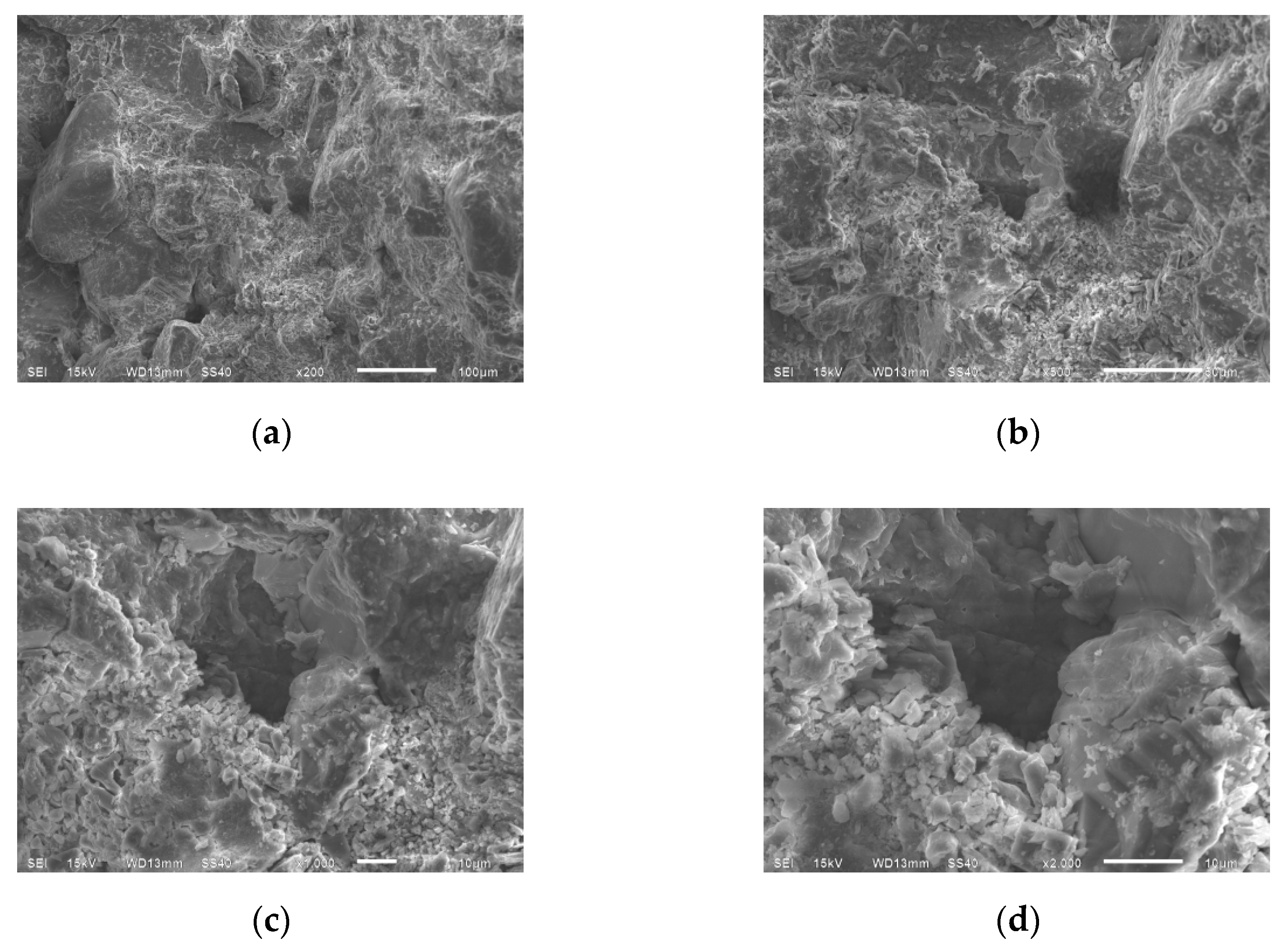

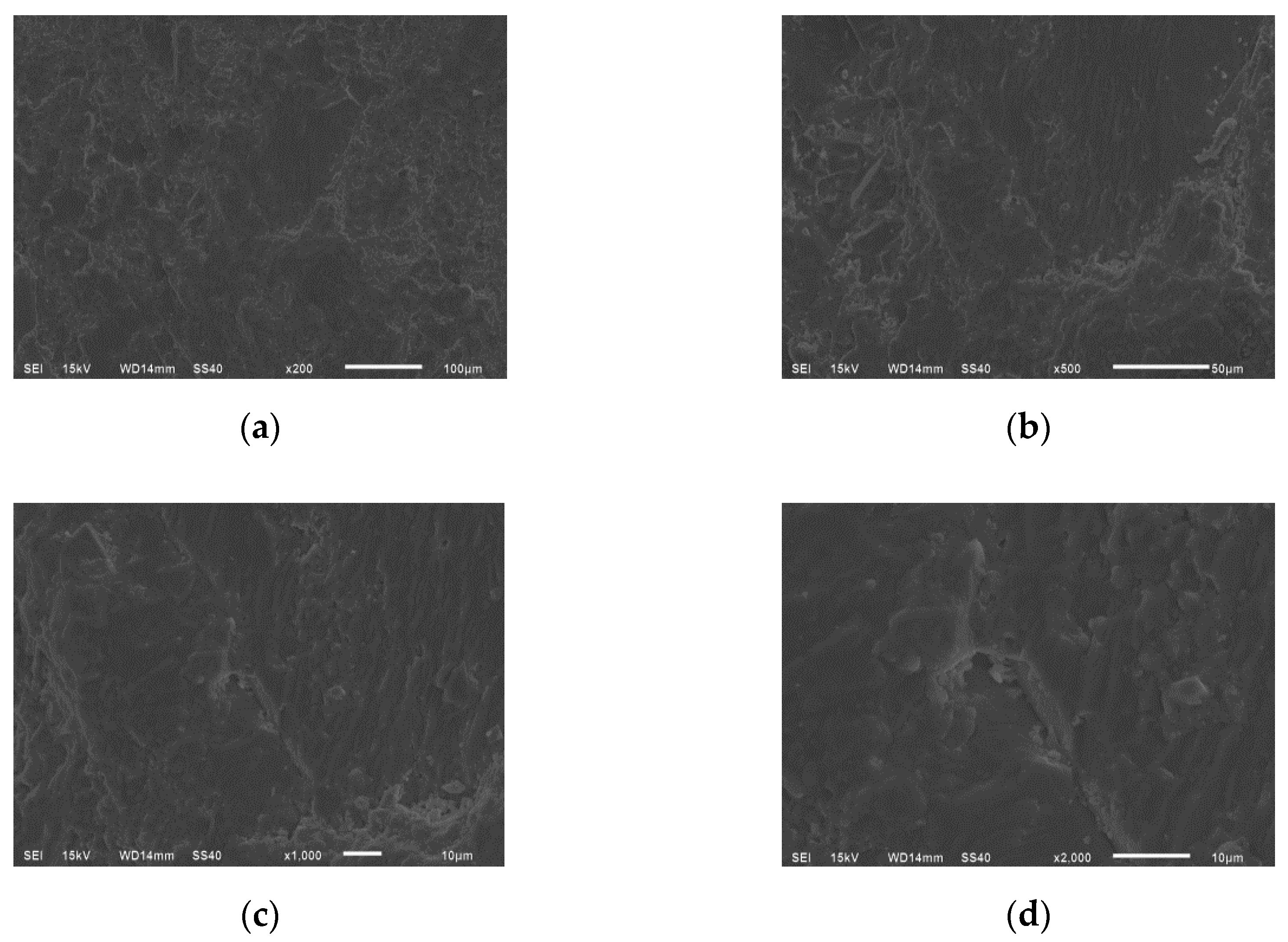

3. Meso Structural Characteristics of Rock Mass

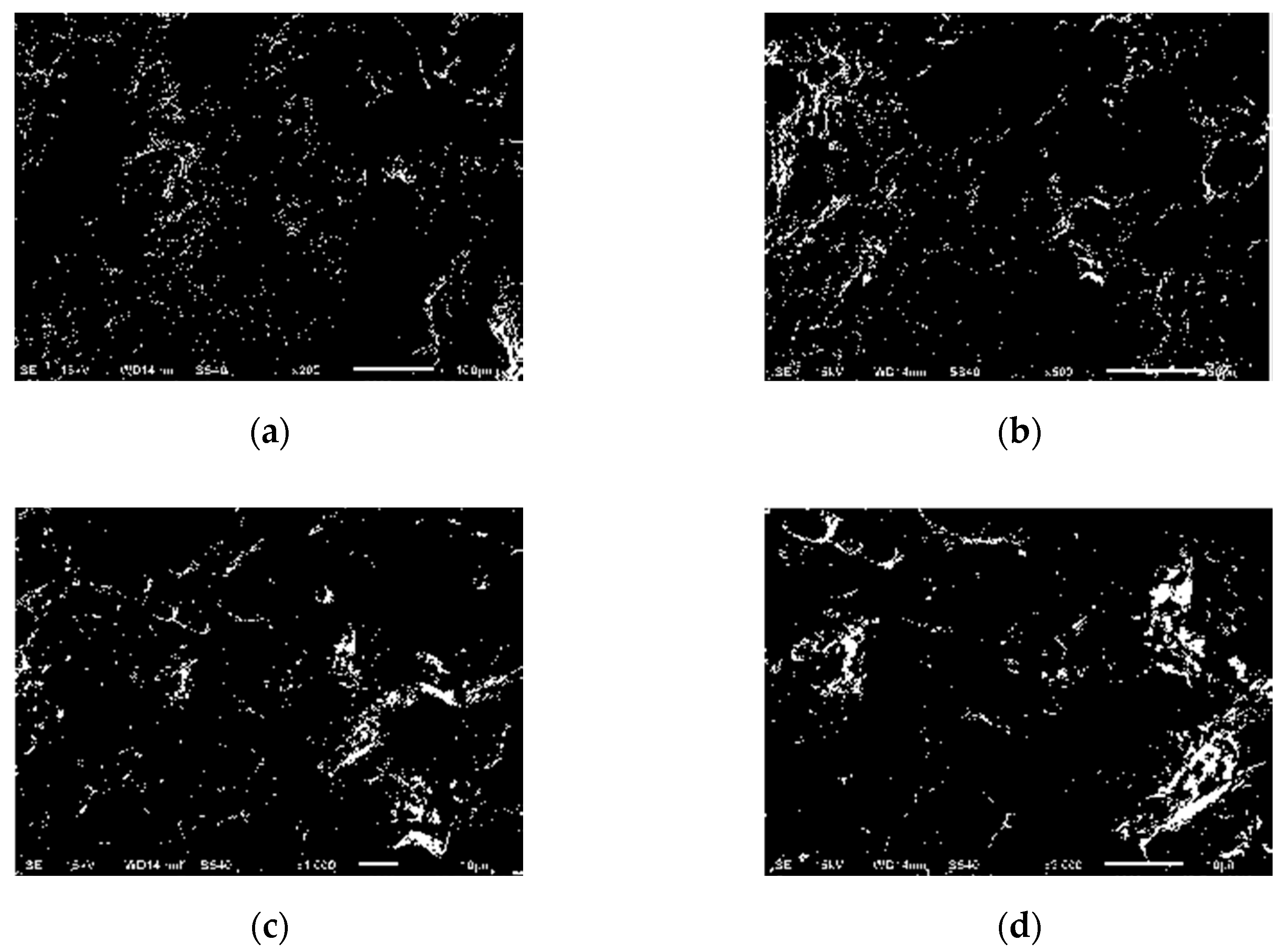

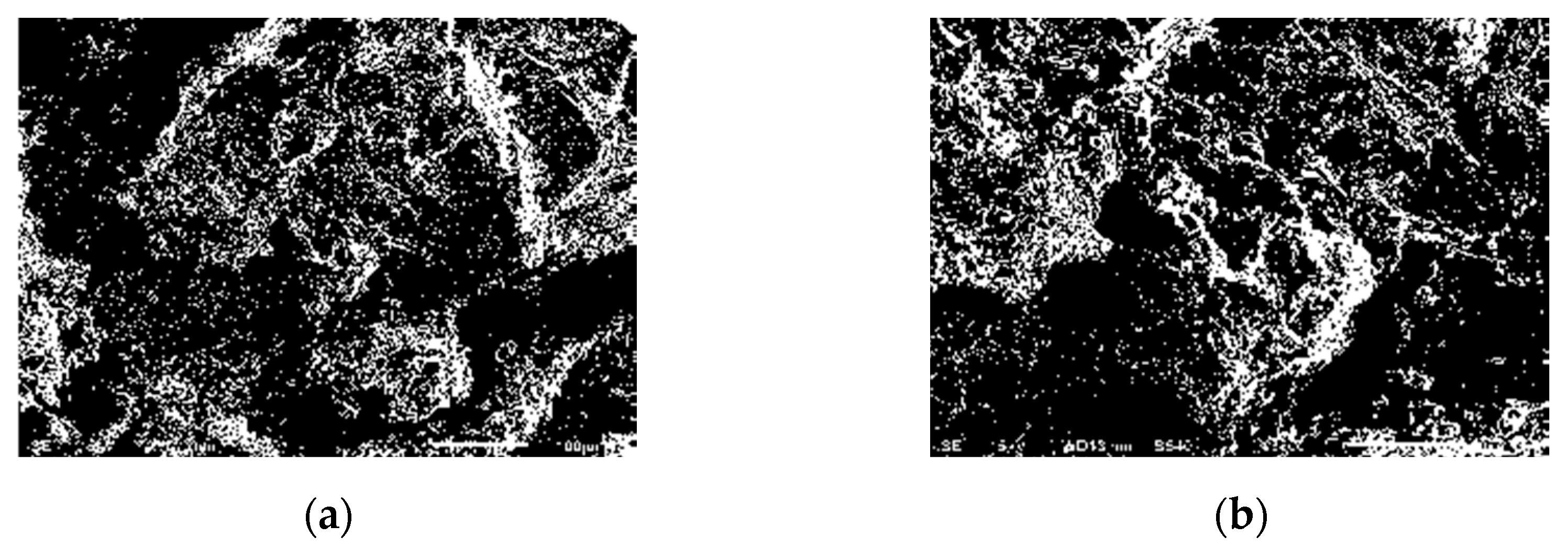

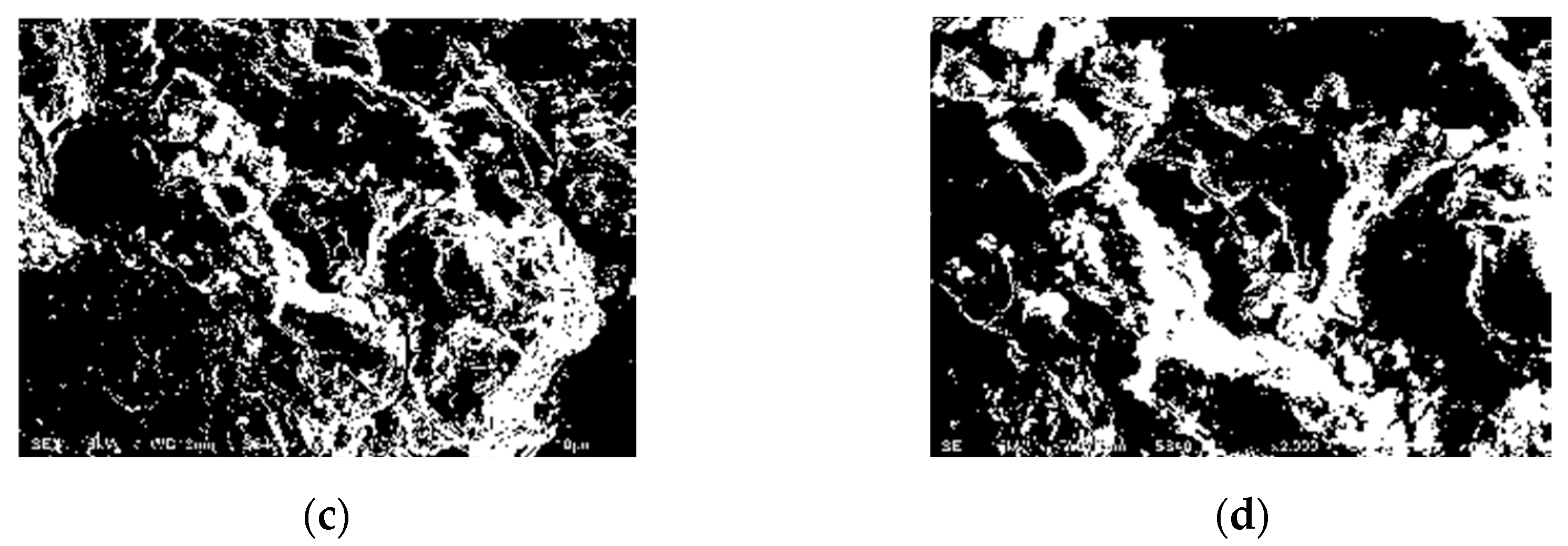

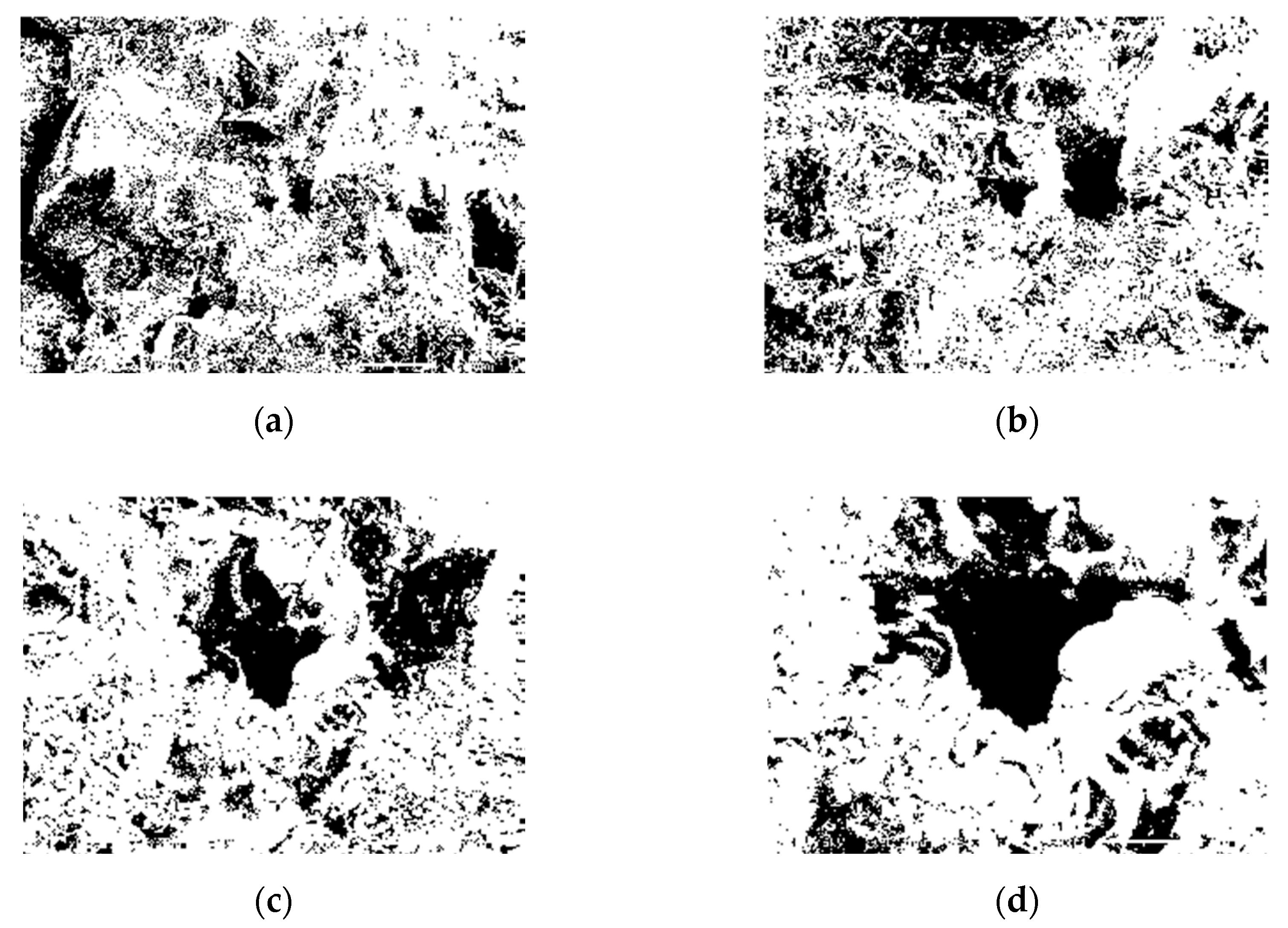

3.1. Micropores and Distribution Characteristics of Sandstone

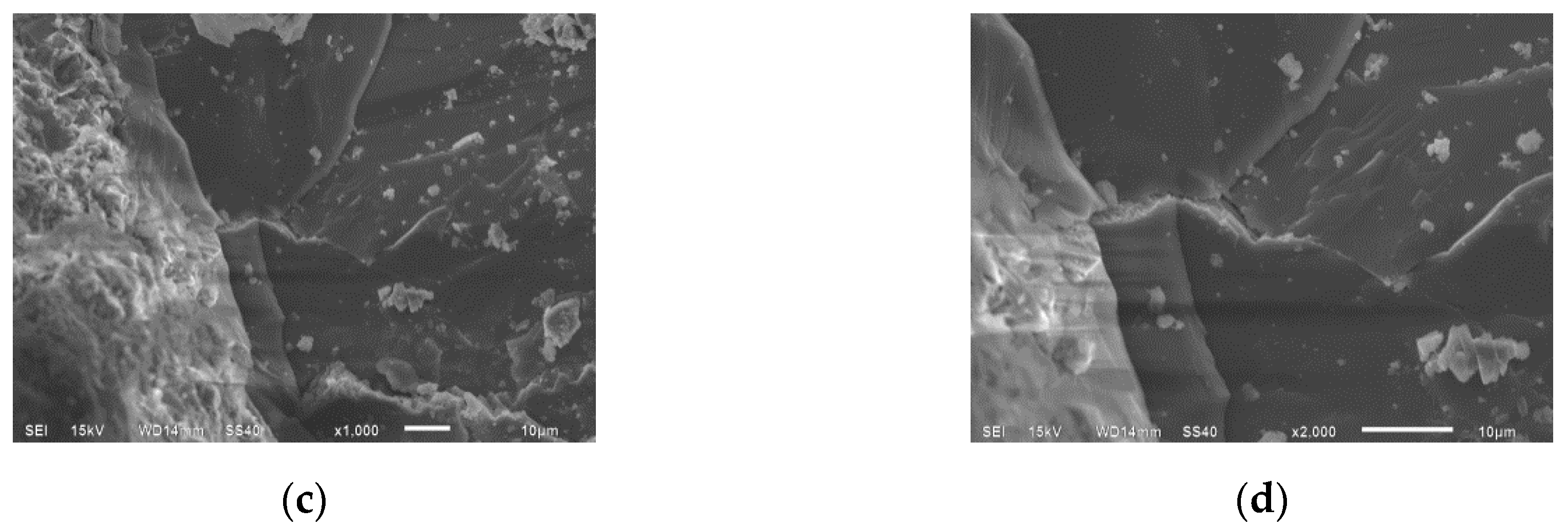

3.2. Microfractures Characteristics of Sandstone

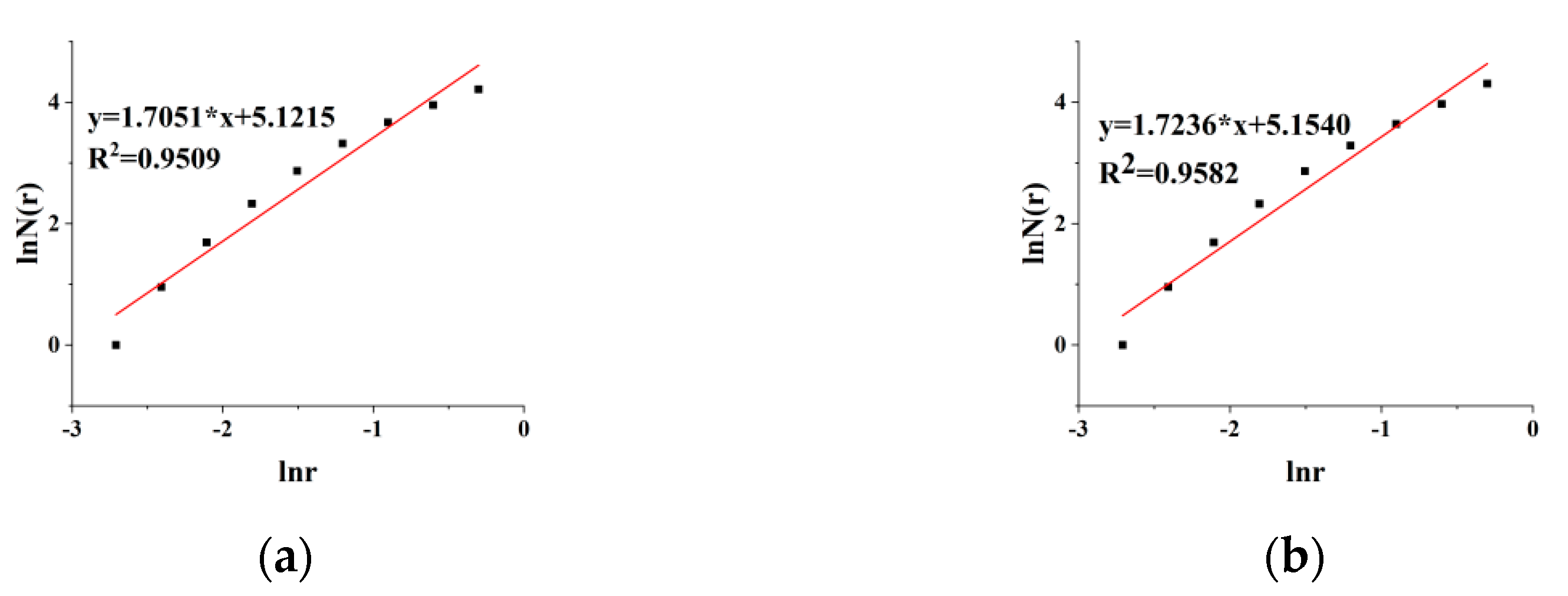

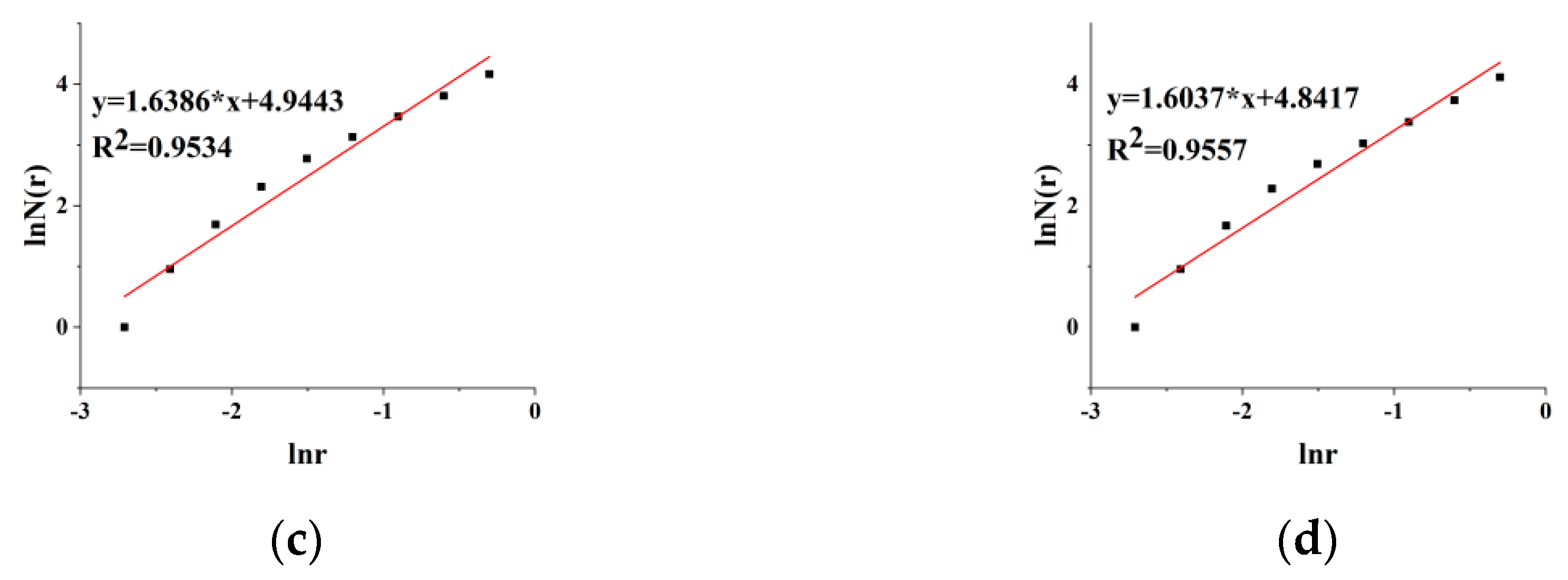

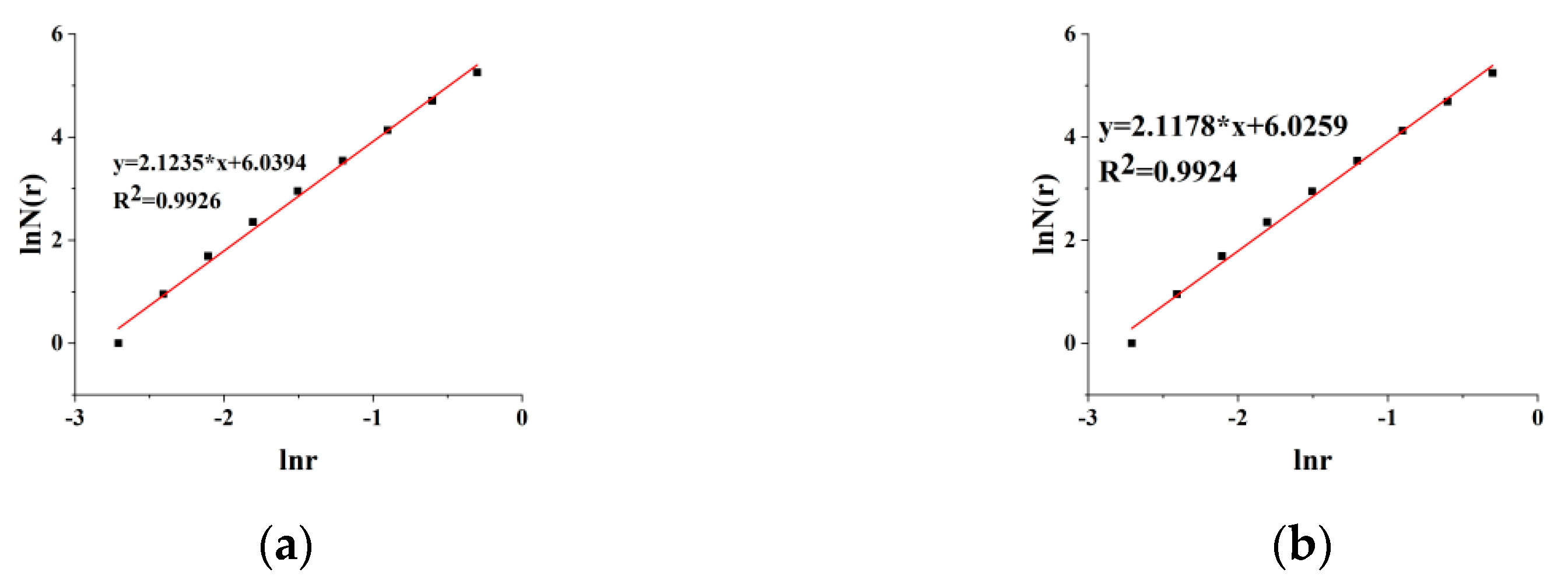

3.3. Fractal Characteristics of Sandstone Micropores

4. Relationship between Fractal Dimension and Mechanical Properties of Sandstone

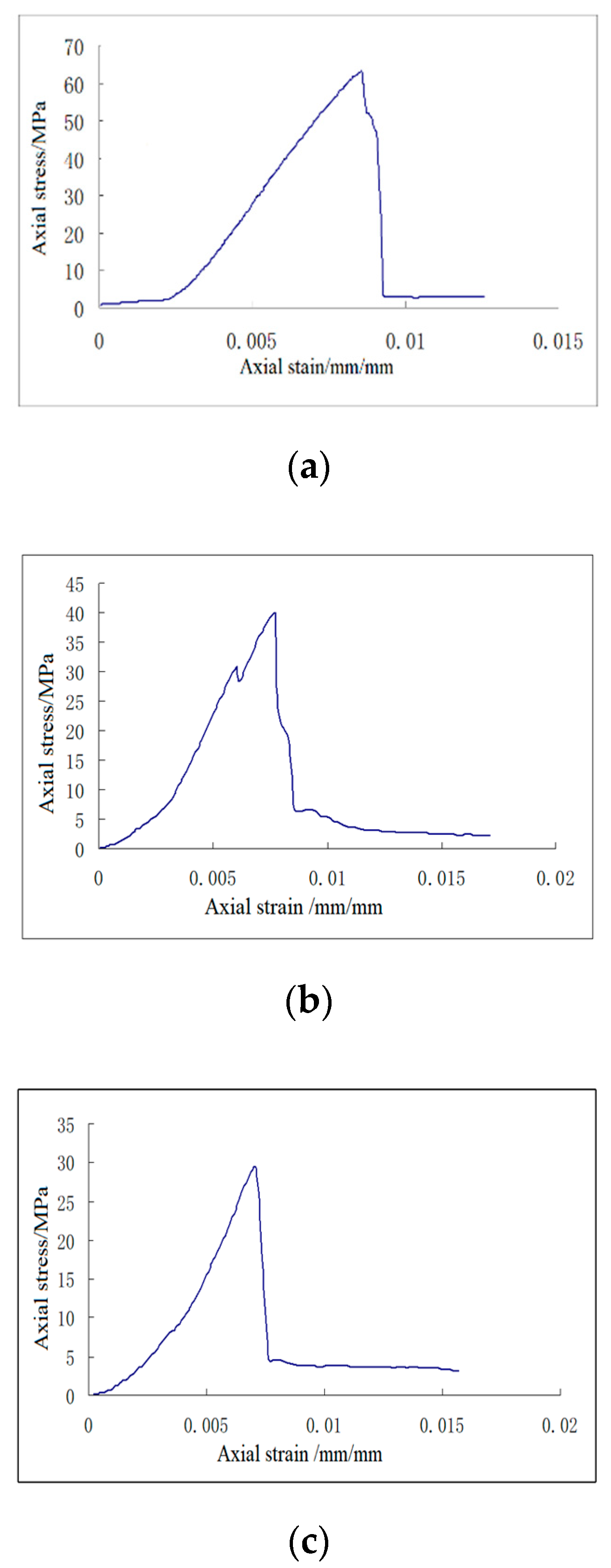

4.1. Strength Characteristics of Sandstone

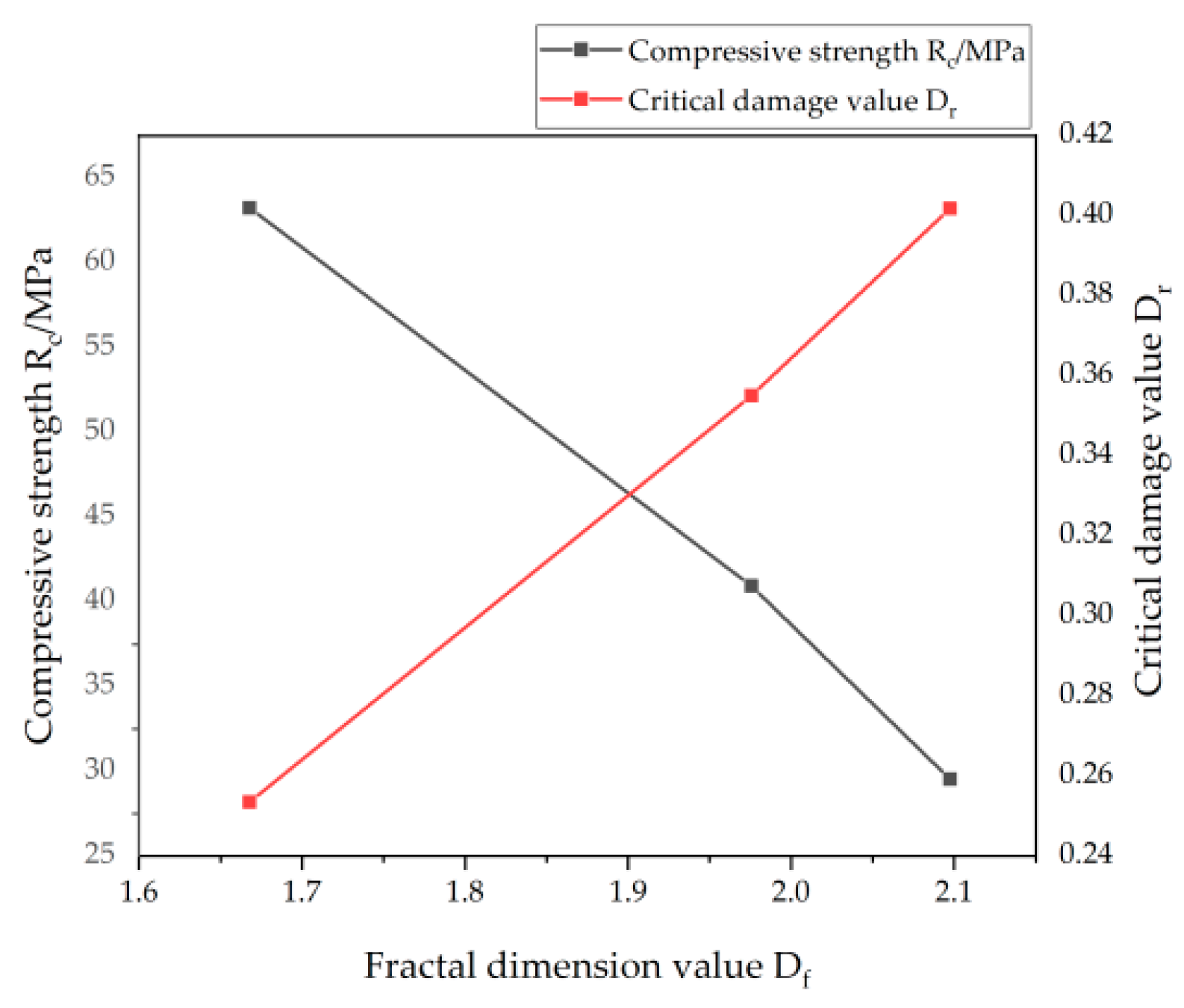

4.2. Damage Mechanics Analysis of Sandstone

5. Conclusions

- (1)

- The study of micro-damage to sandstone can analyze its macro mechanical characteristics in depth. According to the observation of SEM, there are many micropores and microcracks in the three kinds of sandstones, the overall structure is undulating, and there are many particles on the surface, which are typical materials with original damage. The macroscopic mechanical properties of sandstone can be analyzed according to its meso-structure;

- (2)

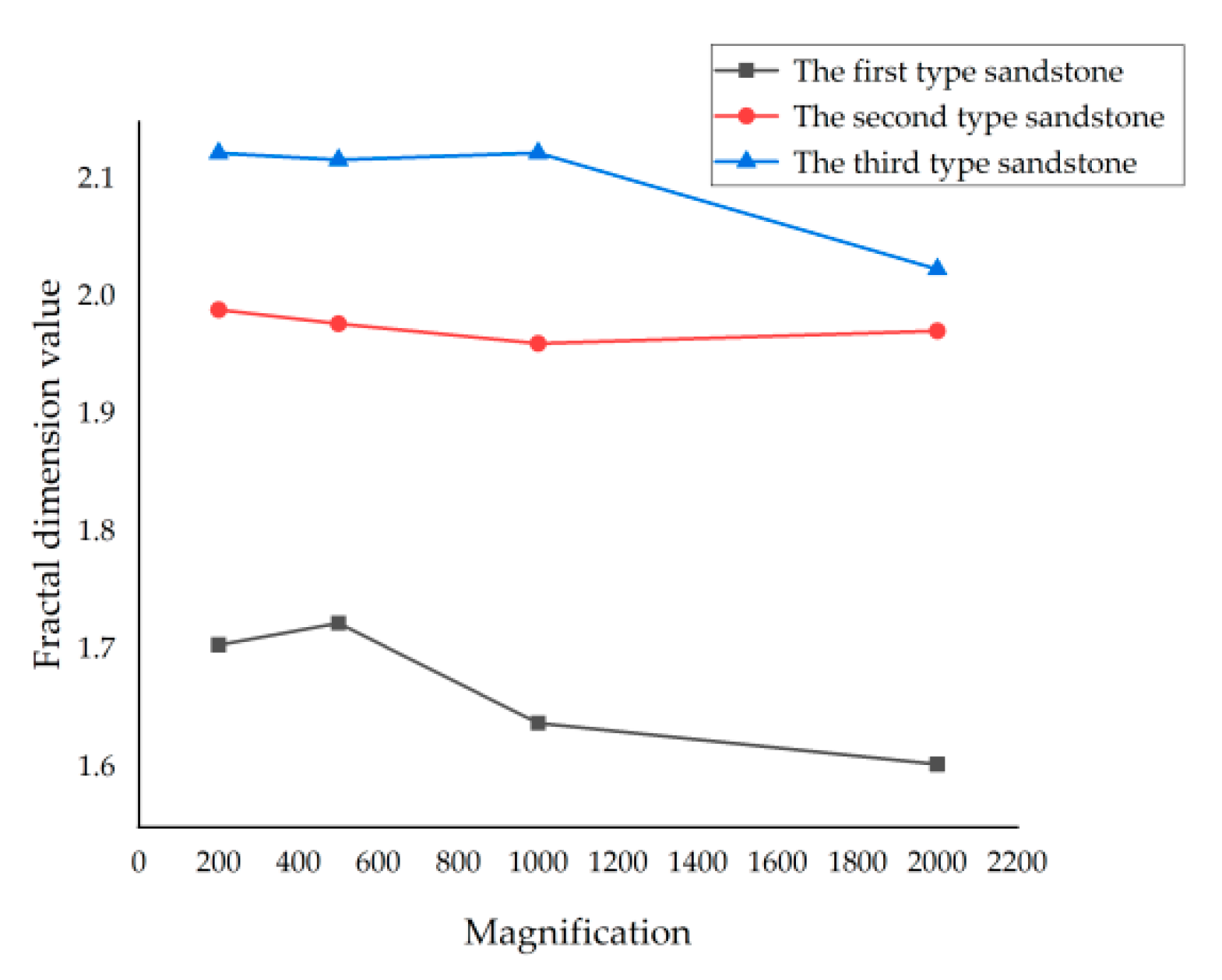

- Matlab is used to calculate the fractal dimension. In order to exclude the particularity, the average value of fractal dimension is selected as the final fractal dimension value. The average fractal dimensions of the three kinds of sandstones are 1.6678, 1.9756 and 2.0974, the micro-morphology of different sandstones varies greatly. The more obvious the micro-fractures and micropores are, the larger the fractal dimension is. Therefore, it is appropriate to use the fractal dimension to describe the characteristics of sandstone. The fractal dimension decreases with the increase in magnification;

- (3)

- According to the results of uniaxial compression test, the compressive strength of the three sandstones are 63.25, 40.93 and 29.54 Mpa, and the elastic modulus are 9.97, 8.46 and 7.06 GPa. The strength characteristics of sandstone are inversely proportional to the fractal dimension. The larger the uniaxial compressive strength and elastic modulus are, the smaller the fractal dimension is;

- (4)

- Based on the damage mechanics theory, the relationship between the critical damage value, compressive strength and fractal dimension is studied. It is found that the critical damage values of the three sandstones are in direct proportion to their fractal dimensions. The larger the fractal dimension of sandstone is, the more micropores and microcracks there are, and the more serious the damage is, the lower the compressive strength is. This shows that the strength and deformation characteristics of sandstone are directly related to its meso-damage, which is consistent with the actual situation.

Author Contributions

Funding

Conflicts of Interest

References

- Fan, P.K. Study on Microstructural Evolution and Strength Model of Cemented Backfill. Ph.D. Thesis, North China University of Science and Technology, Qinhuangdao, China, 2019; pp. 3–8. [Google Scholar]

- Chen, L.J.; Zhang, M. Numerical simulation of hydraulic fracturing of brittle rock with three-dimensional deep crack. Hydropower 2019, 45, 34–38. [Google Scholar]

- Yin, Y.C.; Zhao, T.B.; Tan, Y.L.; Yu, F.H. Rock meso model reconstruction and numerical experiment based on Otsu image processing. Geotech. Mech. 2015, 36, 2532–2540. [Google Scholar]

- Wetzel, M.; Kempka, T.; Kuhn, M. Predicting macroscopic elastic rock properties requires detailed information on microstructure. Energy Procedia 2017, 125, 561–570. [Google Scholar] [CrossRef]

- Zhu, F.; Hu, W.; Cao, J.; Sun, F.; Liu, Y.; Sun, Z. Micro/nanoscale pore structure and fractal characteristics of tight gas sandstone: A case study from the Yuanba area, northeast Sichuan Basin, China. Mar. Pet. Geol. 2018, 98, 116–132. [Google Scholar] [CrossRef]

- Hammes, D.M.; Peternell, M. FAME: Software for analysing rock microstructures. Comput. Geosci. 2016, 90, 24–33. [Google Scholar] [CrossRef]

- ASabatakakis, N.; Tsiambaos, G.; Ktena, S.; Bouboukas, S. The effect of microstructure on mi strength parameter variation of common rock types. Bull. Eng. Geol. Environ. 2018, 77, 1673–1688. [Google Scholar] [CrossRef]

- Regnet, J.B.; David, C.; Robion, P.; Menéndez, B. Microstructures and physical properties in carbonate rocks: A comprehensive review. Mar. Pet. Geol. 2019, 103, 366–376. [Google Scholar] [CrossRef]

- Jeng, F.S.; Weng, M.C.; Lin, M.L.; Huang, T.H. Influence of petrographic parameters on geotechnical properties of tertiary sandstones from Taiwan. Eng. Geol. 2004, 73, 71–91. [Google Scholar] [CrossRef]

- Stück, H.; Koch, R.; Siegesmund, S. Petrographical and petrophysical properties of sandstones: Statistical analysis as an approach to predict material behaviour and construction suitability. Environ. Earth Sci. 2013, 69, 1299–1332. [Google Scholar] [CrossRef] [Green Version]

- Strzałkowski, P.; Kaźmierczak, U.; Wolny, M. Assessment of the method for abrasion resistance determination of sandstones on Böhme abrasion test apparatus. Bull. Eng. Geol. Environ. 2020, 79, 4947–4956. [Google Scholar] [CrossRef]

- Ulusay, R.; Türeli, K.; Ider, M.H. Prediction of engineering properties of a selected litharenite sandstone from its petrographic characteristics using correlation and multivariate statistical techniques. Eng. Geol. 1994, 38, 135–157. [Google Scholar] [CrossRef]

- Niu, S.; Ge, S.; Yang, D.; Dang, Y. Mechanical properties and energy mechanism of saturated sandstones. J. Cent. South Univ. 2019, 25, 1447–1463. [Google Scholar] [CrossRef]

- Liu, H.Y.; Li, J.F.; Pei, X.L. Dynamic damage constitutive model of intermittent jointed rock mass under uniaxial compression. Explos. Impact 2018, 38, 316–323. [Google Scholar]

- Li, K. Study on Fracture Characteristics and Damage Model of Rock Mass with Discontinuous Joints; China University of Geosciences: Beijing, China, 2018. [Google Scholar]

- Gooya, R.; Bruns, S.; Muter, D.; Moaddel, A.; Harti, R.P.; Stipp, S.L.S.; Sørensen, H.O. Effect of tomography resolution on the calculated microscopic properties of porous materials: Comparison of sandstone and carbonate rocks. Appl. Phys. Lett. 2016, 109, 104102. [Google Scholar] [CrossRef] [Green Version]

- Xie, C. Study on Macro Meso Damage and Failure Characteristics and Numerical Method of Fractured Rock Mass. Ph.D. Thesis, Shandong University, Jinan, China, 2018; pp. 22–38. [Google Scholar]

- Zhang, P.; Chen, C. Damage constitutive model of rock mass considering mechanical properties of intermittent joints. Highw. Automob. Transp. 2017, 04, 180–184. [Google Scholar]

- Zhang, S.; Liu, W.; Lv, H. Creep energy damage model of rock graded loading. Results Phys. 2019, 12, 1119–1125. [Google Scholar] [CrossRef]

- Mohammadi, H.; Pietruszczak, S. Description of damage process in fractured rocks. Int. J. Rock Mech. Min. Sci. 2019, 113, 295–302. [Google Scholar] [CrossRef]

- Zhu, Y. A micromechanics-based damage constitutive model of porous rocks. Int. J. Rock Mech. Min. Sci. 2017, 91, 1–6. [Google Scholar] [CrossRef]

- Haddad-Martim, P.M.; Carranza, E.J.M.; De Souza Filho, C.R. The fractal nature of structural controls on ore formation: The Case of the Iron oxide copper-gold deposits in the carajás mineral province, Brazilian amazon. Econ. Geol. 2018, 113, 1499–1524. [Google Scholar] [CrossRef]

- Gao, D.S. Application of Fractal Models to Research Mineral Particles Surface Morphology: Magnetite in Luoyang iron Deposit of Fujian Province; China University of Geosciences: Beijing, China, 2020. [Google Scholar]

- Du, G.S. Brazilian Splitting Test of Rock Based on the Characteristics of Micro Fabric; Inner Mongolia University of Science&Technology: Baotou, China, 2020. [Google Scholar]

- Jin, P.H.; Hu, Y.Q.; Shao, J.X.; Liu, Z.J.; Feng, G.; Song, S. Influence of Temperature on the Structure of Pore—Fracture of Sandstone. Rock Mech. Rock Eng. 2020, 53, 1–12. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.W.; Wang, Z.Y.; Chen, J.; Pang, X.J.; Wang, S.C.; Zhou, Z.L.; He, Z.B.; Qin, Z.Q.; Fan, X.Q. A review on pore structure characterization in tight sandstones. Earth Sci. Rev. 2018, 177, 436–457. [Google Scholar] [CrossRef]

- Kuzmin, V.A. Microstructural Effects in Electron-Microscopic Studies of Carbonate Rocks. J. Surf. Investig. X-Ray Synchrotron Neutron Tech. 2018, 12, 953–956. [Google Scholar] [CrossRef]

- Pedrosa, E.T.; Boeck, L.; Putnis, C.V.; Putnis, A. The replacement of a carbonate rock by fluorite: Kinetics and microstructure. Am. Mineral. 2017, 102, 126–134. [Google Scholar] [CrossRef]

- Chen, T.X.; Chen, Y.; Sha, Y.B.; Bai, W.S.; Wu, Z.H.; Wang, T.T. Microstructure and fractal characteristics of red clay particles in existing foundation based on SEM images. Carsologica Sin. 2019, 38, 635–642. [Google Scholar]

- Zhou, L.; Du, W.W.; Han, X.; Li, C.F. Fractal characteristics of micro pore structure of clay minerals. J. Heilongjiang Univ. Sci. Technol. 2009, 19, 94–96, 120. [Google Scholar]

- Lu, C.; Mai, Y.W.; Xie, H. A sudden drop of fractal dimension: A likely precursor of catastrophic failure in disordered media. Philos. Mag. Lett. 2005, 85, 33–40. [Google Scholar] [CrossRef]

- Li, D.J.; Wang, G.L.; Han, L.Q.; Liu, P.Y.; He, M.C.; Yang, G.X.; Tai, Q.M. Analysis of microscopic pore structures of rocks before and after water absorption. Min. Sci. Technol. 2011, 21, 287–293. [Google Scholar]

- Chen, C.X.; Liu, X.M.; Liu, C.C. Application of digital image technology in rock micromechanics. Geotech. Mech. 2010, 31, 53–60. [Google Scholar]

- Yin, S.; Dong, L.; Yang, X.; Wang, R.Y. Experimental investigation of the petrophysical properties, minerals, elements and pore structures in tight sandstones. J. Nat. Gas Sci. Eng. 2020, 76, 103189. [Google Scholar] [CrossRef]

- Liang, C.Y.; Wu, S.R.; Li, X. Study on the micro and micro fracture characteristics of granite under uniaxial compression in the range of low and medium strain rates. J. Rock Mech. Eng. 2015, 34, 2977–2986. [Google Scholar]

- Zhang, K.X.; Lai, J.; Bai, G.P.; Pang, X.J.; Ma, X.Q.; Qin, Z.Q.; Zhang, X.S.; Fan, X.C. Comparison of fractal models using NMR and CT analysis in low permeability sandstones. Mar. Pet. Geol. 2020, 112, 104069. [Google Scholar] [CrossRef]

- Huang, D.M.; Chang, X.K.; Tan, Y.L.; Fang, K.; Yin, Y.C. From rock microstructure to macromechanical properties based on fractal dimensions. Adv. Mech. Eng. 2019, 11, 3. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.X.; Jiang, J.Q.; Liu, F.S.; Wang, S.H. Fractal study of scale effect in microscopic, mesoscopic and macroscopic states for fracture mechanism of rock materials. Rock Soil Mech. 2008, 29, 2619–2622. [Google Scholar]

- Huang, D.M.; Chang, X.K.; Lin, X.F.; Fu, Y.X. Fractal characteristics of rock fracture cracks under uniaxial compression. J. Shandong Univ. Sci. Technol. 2014, 33, 58–62. [Google Scholar]

- Alfonso, I.; Beltrán, A.; Abatal, M.; Castro, I.; Fuentes, A.; Vázquez, L.; Garcia, A. Fractal Dimension Determination of Rock Pores by Multi-Scale Analysis of Images Obtained Using OM, SEM and XCT. Fractals 2018, 26, 1850067. [Google Scholar] [CrossRef]

- Holgado, M.A.; Fernandez-Hervas, M.J.; Rabasco, A.M.; Fini, A. Characterization study of a diclofenac salt by means of SEM and fractal analysis. Int. J. Pharm. 1995, 120, 157–167. [Google Scholar] [CrossRef]

- Zhao, D.L.; Zuo, S.Y.; Huang, C.; Wang, S.; Yang, C. Experimental study on anisotropic damage mechanical characteristics of layered rock mass. Hydropower Energy Sci. 2019, 37, 144–147. [Google Scholar]

- Zhao, X.; Ma, S.Q. Theoretical analysis and numerical simulation of coal micro damage. J. North China Univ. Sci. Technol. 2016, 13, 53–57, 61. [Google Scholar]

- Yang, Y.J.; Wang, D.C.; Wang, K.; Huang, D.M. Micromechanical damage mechanism of coal and rock strength and deformation characteristics. J. Beijing Univ. Sci. Technol. 2011, 33, 653–657. [Google Scholar]

- Wu, Z.; Zhang, C.J. Damage model and mechanical properties of rock under uniaxial loading. Acta Petromech. Eng. 1996, 15, 55–61. [Google Scholar]

| Sandstone Type | Fractal Dimension Values Under Different Magnification | Average Fractal Dimension | |||

|---|---|---|---|---|---|

| ×200 | ×500 | ×1000 | ×2000 | ||

| 1 | 1.7051 | 1.7236 | 1.6386 | 1.6037 | 1.6678 |

| 2 | 1.9902 | 1.9784 | 1.9615 | 1.9722 | 1.9756 |

| 3 | 2.1235 | 2.1178 | 2.1237 | 2.0247 | 2.0974 |

| Sandstone Type | Compressive Strength Rc/MPa | Elastic Modulus E/GPa | Poisson’s Ratio μ | Fractal Dimension Value Df |

|---|---|---|---|---|

| 1 | 63.25 | 9.97 | 0.04 | 1.6678 |

| 2 | 40.93 | 8.46 | 0.16 | 1.9756 |

| 3 | 29.54 | 7.06 | 0.18 | 2.0974 |

| Sandstone Type | Critical Damage Value Dr | Compressive Strength Rc/MPa | Fractal Dimension Value Df |

|---|---|---|---|

| 1 | 25.35% | 63.25 | 1.6678 |

| 2 | 35.50% | 40.93 | 1.9756 |

| 3 | 40.18% | 29.54 | 2.0974 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, C.; Huang, D.; Chang, X.; Xi, H. Meso-Damage Mechanism of Strength and Deformation Characteristics of Typical Sandstone in Xinwen Coalfield. Symmetry 2020, 12, 1815. https://doi.org/10.3390/sym12111815

Gao C, Huang D, Chang X, Xi H. Meso-Damage Mechanism of Strength and Deformation Characteristics of Typical Sandstone in Xinwen Coalfield. Symmetry. 2020; 12(11):1815. https://doi.org/10.3390/sym12111815

Chicago/Turabian StyleGao, Chunjing, Dongmei Huang, Xikun Chang, and Han Xi. 2020. "Meso-Damage Mechanism of Strength and Deformation Characteristics of Typical Sandstone in Xinwen Coalfield" Symmetry 12, no. 11: 1815. https://doi.org/10.3390/sym12111815