An Automated Smart EPQ-Based Inventory Model for Technology-Dependent Products under Stochastic Failure and Repair Rate

Abstract

:1. Introduction

2. Literature Review

2.1. Manufacturing Unreliability

2.2. Smart Production System

2.3. Technology Dependent Demand

2.4. Research Gap

3. Problem Statement, Notation, and Assumptions

3.1. Problem Statement

- The cost component is the cost of raw material which increases linearly with increasing failure rate.

- The component represents the manufacturing costs, i.e., energy and lobar, and as the production rate increases, the manufacturing cost is equally distributed over a large number of the produced unit. Consequently the per unit manufacturing cost decreases with high production rates.

- The next cost component is , which represents the manufacturing yield loss. As the failure rate increases, the downtime increases and the overall costs of system increases. However, with higher production rates, the unit yield loss cost decreases.

- The last cost component is referred to as the tool/die cost, and it is directly proportional to production rate.

3.2. Assumptions

- -

- An automated smart integrated production maintenance policy for an unreliable manufacturing system is considered.

- -

- The unreliability of a manufacturing system is modeled through a system performance-quality parameter which follows a stochastic process as discussed in [33].

- -

- The quality performance parameter of manufacturing system is expressed as a design variable, where it is represented as , and manufacturing quality performance can be increased through investment in advanced production technology and resources.

- -

- During production up-time system failure may occurs randomly, a single-machine and single-product type environment is considered.

- -

- Random failure rate and random repair rate is considered with generalized distributions.

- -

- On manufacturing system failure, corrective repair is started immediately. After corrective repair, manufacturing system is restored back to the same initial operational condition with an extra cost .

- -

- Upon manufacturing system breakdown, market demand is fulfilled from on-hand inventory, accumulated during production up-time.

- -

- The demand is technology dependent as , where a is the potential market demand, is a shape parameter and it shows the effectiveness of product technology , whereas is a scale parameter. Moreover per unit technology investment is a decision variable and .

- -

- If the on-hand inventory is sufficient to met market demand, then new production cycle is started after complete inventory consumption.

- -

- Market demand is a variable parameter and depend on technology investment , where is a decision variable.

- -

- The production rate of smart manufacturing system is a controllable variable and can be varied within given limits . Moreover, the variable production rate is always greater than the variable demand rate as .

- -

- Unit smart production cost is a function of manufacturing quality performance parameter , manufacturing yield Y and variable production rate .

- -

- The raw material cost linearly depends on the manufacturing quality performance parameter variable , i.e., ().

- -

- As the manufacturing quality performance parameter decreases, the manufacturing yield loss increases, such that higher downtime increases system costs.

- -

- A shortage cost is considered for lost sales due to longer repair times.

4. Mathematical Model

4.1. Model 1: Random Production Rate Model with Breakdown

4.1.1. Case 1 ( Repair Time Lies within )

4.1.2. Case 2 (Repair Time Exceeds )

4.2. Model 2: Random Production Rate Model without Breakdown

4.3. Integration of the EPQ Models with/without Failure

4.4. Solution Methodology

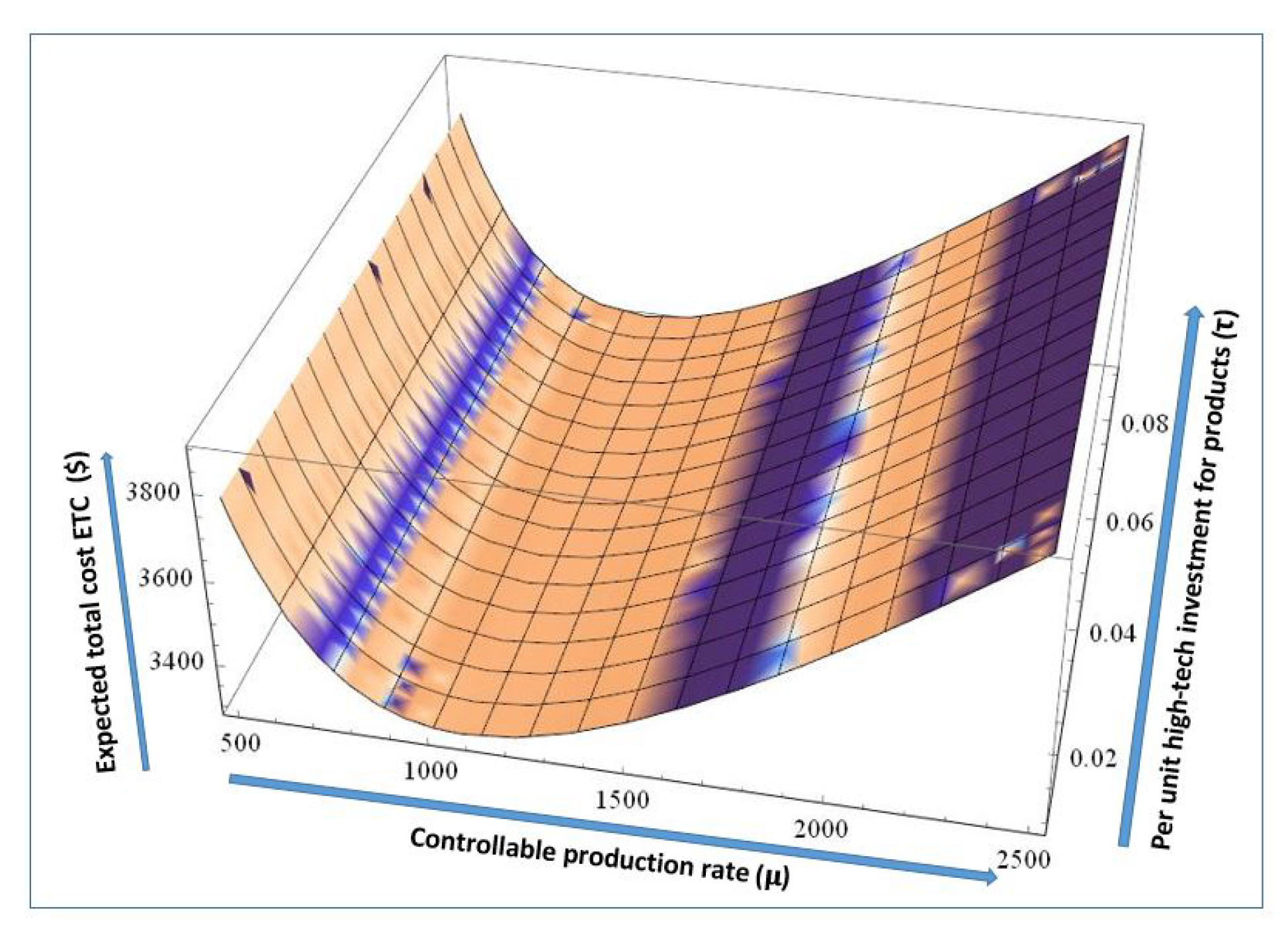

5. Numerical Experiment

5.1. Sensitivity Analysis

5.1.1. Comparative Study

5.1.2. Managerial Insights

- The major insight for the industrial management is to assess uncertain production capacity for automated smart production planning. In a real world production environment, productivity and manufacturing efficiency is compromised generally because of an unreliable and limited production capacity system. Therefore, we provide comprehensive details for the influence of the reliability parameter on production rates and production capacity for optimal production planning.

- As the study is considered for a smart production inventory model, random breakdowns and random repair time is considered, therefore a production manager can easily do the calculations for optimal production quantity and optimal controllable production rates based on random system breakdowns in production planning.

- The unreliable manufacturing system provides optimum values for all decision variables, and if the manufacturing unit is producing smart products, for example high-tech products/electronic products, then our model provides the insight to choose investment options based on manufacturing system reliability.

6. Conclusions

- -

- Rather than fixed designed production rates, the model considers a controllable production rate-based automated smart manufacturing system which reduces the per unit production cost. Along with the production rate , the per unit production cost also depends on the manufacturing reliability and productivity parameter .

- -

- The manufacturing system productivity and reliability can be increased with an investment in advanced technology, and the smart production technology investment is not a constant parameter. Rather, it depends on the failure rate of manufacturing system.

- -

- Concerning product innovation and ever-changing technology advancements, much existing research is considering the approach of remanufacturing and recycling used products to gain two important industrial goals:The problem that all these researchers lack in answering these questions is what are the economical and environmental implications of these growing technological implications on production systems and production efficiency, as production setup and technological development costs are the biggest parts of any production system. Moreover, issues regarding production reliability are currently one of the most important parameters for maintaining an adequate level of access to high-tech products. However, no existing research has considered the influence of smart product innovation and production reliability on manufacturing policies. Therefore, this study investigates the need for considering technological improvement/advancements in the production process and corresponding costs for product innovation. This study outperforms the work of [6] as it considers the demand variability for technology innovation for an unreliable production system, and limits the per-unit technology investment for products as ( ) of the smart production technology development investment .

- -

- Due to the stochastic nature of breakdowns and repair times, the study extended the production inventory model to an integrated smart production maintenance model. The study infers the importance of performance quality parameter for per-unit technological investment for products , as even a 10% increase in gives infeasible results for the proposed unreliable production model.

Author Contributions

Conflicts of Interest

Abbreviations

| EOQ | Economic ordering quantity |

| EPQ | Economic production quantity |

| EMQ | Economic manufacturing quantity |

| OPT | Optimum production technology |

| AR | Abort/Resume |

| NR | No-resumption |

| OSE | Overall system effectiveness |

| VMI | Vendor managed inventory |

| JMI | Jointly managed inventory |

| IT | Information technology |

| Decision variables | |

| Technology investment for high-techs products ($/unit) | |

| The manufacturing quality performance parameter, where | |

| Q | Production quantity (units) |

| Variable rate of smart production, where (units/unit time) | |

| Model Parameters | |

| Z | Time horizon (years) |

| S | Manufacturing setup cost ($/setup) |

| Technology dependent demand rate (units/unit time) | |

| Unit smart production cost, a function of manufacturing quality performance parameter and varia-ble production rate ($/unit/unit time) | |

| Raw material cost ($/unit) | |

| Raw material increment cost due to low manufacturing quality performance parameter ($/unit) | |

| Y | Unit manufacturing yield loss cost due to low manufacturing quality performance parameter ($/unit/unit time) |

| Tool/die cost ($/unit) | |

| Inventory carrying cost ($/unit/unit time) | |

| System repair cost ($/unit/unit time) | |

| Manufacturing technology development cost ($) | |

| Advanced manufacturing technology investment ($) | |

| Manufacturing quality performance scale parameter (non-negative) | |

| Manufacturing quality performance constant (non-negative) | |

| System restoration cost ($/setup) | |

| Shortage cost ($/unit/unit time) | |

| Stochastic variable indicating manufacturing system failure time (non-negative) | |

| Stochastic repair rate (number of repairs/unit time) | |

| Stochastic variable indicating repair time upon manufacturing system breakdown (non-negative) | |

| Probability density function of manufacturing system failure time | |

| Cumulative density function of manufacturing system failure time | |

| Probability density function of manufacturing system repair time | |

| Cumulative density function of manufacturing system repair time | |

| Expected total cost of system with high manufacturing quality performance variable () | |

| Expected total cost of system with low manufacturing quality performance variable () | |

| Expected cycle length with high quality performance variable () | |

| Expected cycle length with low quality performance variable () | |

| Expected cycle length of manufacturing system () | |

| Expected total cost per unit of time with high manufacturing quality performance variable ($) | |

| Expected total cost per unit of time with low manufacturing quality performance variable ($) | |

| Expected total cost per unit time of manufacturing system ($) | |

Appendix A

References

- Kang, C.W.; Ramzan, M.B.; Sarkar, B.; Imran, M. Effect of inspection performance in smart manufacturing system based on human quality control system. Int. J. Adv. Manuf. Technol. 2018, 94, 4351–4364. [Google Scholar] [CrossRef]

- Sarkar, M.; Sarkar, B. Optimization of safety stock under controllable production rate and energy consumption in an automated smart production management. Energies 2019, 12, 2059. [Google Scholar] [CrossRef] [Green Version]

- Sarkar, M.; Sarkar, B.; Iqbal, M. Effect of energy and failure rate in a multi-item smart production system. Energies 2018, 11, 2958. [Google Scholar] [CrossRef] [Green Version]

- Wu, S.D.; Erkoc, M.; Karabuk, S. Managing capacity in the high-tech industry: A review of literature. Eng. Econ. 2005, 50, 125–158. [Google Scholar] [CrossRef]

- Chakraborty, T.; Giri, B.C.; Chaudhuri, K. Production lot sizing with process deterioration and machine breakdown. Eur. J. Oper. Res. 2008, 185, 606–618. [Google Scholar] [CrossRef]

- Asghar, I.; Sarkar, B.; Kim, S.j. Economic Analysis of an Integrated Production–Inventory System under Stochastic Production Capacity and Energy Consumption. Energies 2019, 12, 3179. [Google Scholar] [CrossRef] [Green Version]

- Marchi, B.; Zanoni, S.; Jaber, M.Y. Economic production quantity model with learning in production, quality, reliability and energy efficiency. Comput. Ind. Eng. 2019, 129, 502–511. [Google Scholar] [CrossRef]

- Lopes, R. Integrated model of quality inspection, preventive maintenance and buffer stock in an imperfect production system. Comput. Ind. Eng. 2018, 126, 650–656. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Zavanella, L.; Jaber, M. Supply chain models with greenhouse gases emissions, energy usage, imperfect process under different coordination decisions. Int. J. Prod. Econ. 2019, 211, 145–153. [Google Scholar] [CrossRef]

- Chakraborty, T.; Giri, B.; Chaudhuri, K. Production lot sizing with process deterioration and machine breakdown under inspection schedule. Omega 2009, 37, 257–271. [Google Scholar] [CrossRef]

- Kang, K.; Subramaniam, V. Joint control of dynamic maintenance and production in a failure-prone manufacturing system subjected to deterioration. Comput. Ind. Eng. 2018, 119, 309–320. [Google Scholar] [CrossRef]

- Bhunia, A.K.; Shaikh, A.A.; Cárdenas-Barrón, L.E. A partially integrated production-inventory model with interval valued inventory costs, variable demand and flexible reliability. Appl. Soft Comput. 2017, 55, 491–502. [Google Scholar] [CrossRef]

- Ouaret, S.; Kenné, J.P.; Gharbi, A. Production and replacement policies for a deteriorating manufacturing system under random demand and quality. Eur. J. Oper. Res. 2018, 264, 623–636. [Google Scholar] [CrossRef]

- Bag, S.; Chakraborty, D.; Roy, A. A production inventory model with fuzzy random demand and with flexibility and reliability considerations. Comput. Ind. Eng. 2009, 56, 411–416. [Google Scholar] [CrossRef]

- AlDurgam, M.; Adegbola, K.; Glock, C.H. A single-vendor single-manufacturer integrated inventory model with stochastic demand and variable production rate. Int. J. Prod. Econ. 2017, 191, 335–350. [Google Scholar] [CrossRef]

- Ouaret, S.; Kenné, J.P.; Gharbi, A. Joint production and replacement planning for an unreliable manufacturing system subject to random demand and quality. IFAC-PapersOnLine 2018, 51, 951–956. [Google Scholar] [CrossRef]

- Manna, A.K.; Dey, J.K.; Mondal, S.K. Imperfect production inventory model with production rate dependent defective rate and advertisement dependent demand. Comput. Ind. Eng. 2017, 104, 9–22. [Google Scholar] [CrossRef]

- Zhu, X.; Jiao, C.; Yuan, T. Optimal decisions on product reliability, sales and promotion under nonrenewable warranties. Reliab. Eng. Syst. Saf. 2018, 192, 106268. [Google Scholar] [CrossRef]

- Shah, N.H.; Vaghela, C.R. Imperfect production inventory model for time and effort dependent demand under inflation and maximum reliability. Int. J. Syst. Sci. Oper. Logist. 2018, 5, 60–68. [Google Scholar] [CrossRef]

- Khara, B.; Dey, J.K.; Mondal, S.K. An inventory model under development cost-dependent imperfect production and reliability-dependent demand. J. Manag. Anal. 2017, 4, 258–275. [Google Scholar] [CrossRef]

- Shah, N.H.; Naik, M.K. Inventory Policies with Development Cost for Imperfect Production and Price-Stock Reliability-Dependent Demand. In Optimization and Inventory Management; Springer: Singapore, 2020; pp. 119–136. [Google Scholar]

- Çanakoğlu, E.; Bilgic, T. Analysis of a two-stage telecommunication supply chain with technology dependent demand. Eur. J. Oper. Res. 2007, 177, 995–1012. [Google Scholar] [CrossRef]

- Rosenblatt, M.J.; Lee, H.L. Economic production cycles with imperfect production processes. IIE Trans. 1986, 18, 48–55. [Google Scholar] [CrossRef]

- Porteus, E.L. Optimal lot sizing, process quality improvement and setup cost reduction. Oper. Res. 1986, 34, 137–144. [Google Scholar] [CrossRef]

- Kim, C.H.; Hong, Y. An optimal production run length in deteriorating production processes. Int. J. Prod. Econ. 1999, 58, 183–189. [Google Scholar]

- Akella, R.; Kumar, P. Optimal control of production rate in a failure prone manufacturing system. IEEE Trans. Autom. Control 1986, 31, 116–126. [Google Scholar] [CrossRef] [Green Version]

- Sharifnia, A. Production control of a manufacturing system with multiple machine states. IEEE Trans. Autom. Control 1988, 33, 620–625. [Google Scholar] [CrossRef]

- Posner, M.; Berg, M. Analysis of a production-inventory system with unreliable production facility. Oper. Res. Lett. 1989, 8, 339–345. [Google Scholar] [CrossRef]

- Boukas, E.K.; Haurie, A. Manufacturing flow control and preventing maintenance: A stochastic control approach. IEEE Trans. Autom. Control 1990, 35, 1024–1031. [Google Scholar] [CrossRef]

- Groenevelt, H.; Pintelon, L.; Seidmann, A. Production batching with machine breakdowns and safety stocks. Oper. Res. 1992, 40, 959–971. [Google Scholar] [CrossRef]

- Groenevelt, H.; Pintelon, L.; Seidmann, A. Production lot sizing with machine breakdowns. Manag. Sci. 1992, 38, 104–123. [Google Scholar] [CrossRef]

- Nodem, F.D.; Kenné, J.P.; Gharbi, A. Hierarchical decision making in production and repair/replacement planning with imperfect repairs under uncertainties. Eur. J. Oper. Res. 2009, 198, 173–189. [Google Scholar] [CrossRef]

- Sarkar, B.; Sana, S.S.; Chaudhuri, K. Optimal reliability, production lotsize and safety stock: An economic manufacturing quantity model. Int. J. Manag. Sci. Eng. Manag. 2010, 5, 192–202. [Google Scholar] [CrossRef]

- Sarkar, B.; Sana, S.S.; Chaudhuri, K. Optimal reliability, production lot size and safety stock in an imperfect production system. Int. J. Math. Oper. Res. 2010, 2, 467–490. [Google Scholar] [CrossRef]

- Bhuniya, S.; Sarkar, B.; Pareek, S. Multi-Product Production System with the Reduced Failure Rate and the Optimum Energy Consumption under Variable Demand. Mathematics 2019, 7, 465. [Google Scholar] [CrossRef] [Green Version]

- Glock, C.H. Batch sizing with controllable production rates. Int. J. Prod. Res. 2010, 48, 5925–5942. [Google Scholar] [CrossRef] [Green Version]

- Glock, C.H. Batch sizing with controllable production rates. Int. J. Prod. Res. 2011, 49, 2455. [Google Scholar] [CrossRef] [Green Version]

- Shepherd, R.W. Theory of Cost and Production Functions; Princeton University Press: Princeton, NJ, USA, 2015. [Google Scholar]

- Sarkar, B.; Majumder, A.; Sarkar, M.; Kim, N.; Ullah, M. Effects of variable production rate on quality of products in a single-vendor multi-buyer supply chain management. Int. J. Adv. Manuf. Technol. 2018, 99, 567–581. [Google Scholar] [CrossRef]

- Khouja, M.; Mehrez, A. Economic production lot size model with variable production rate and imperfect quality. J. Oper. Res. Soc. 1994, 45, 1405–1417. [Google Scholar] [CrossRef]

- Rishel, R. Control of systems with jump Markov disturbances. IEEE Trans. Autom. Control 1975, 20, 241–244. [Google Scholar] [CrossRef]

- Olsder, G.; Suri, R. Time-optimal control of parts-routing in a manufacturing system with failure-prone machines. In Proceedings of the 1980 19th IEEE Conference on Decision and Control including the Symposium on Adaptive Processes, Albuquerque, NM, USA, 10–12 December 1980; pp. 722–727. [Google Scholar]

- Deb, M.; Chaudhuri, K. An EOQ model for items with finite rate of production and variable rate of deterioration. Opsearch 1986, 23, 175–181. [Google Scholar]

- Mandal, B.a.; Phaujdar, S. An inventory model for deteriorating items and stock-dependent consumption rate. J. Oper. Res. Soc. 1989, 40, 483–488. [Google Scholar] [CrossRef]

- Bhunia, A.; Maiti, M. Deterministic inventory model for deteriorating items with finite rate of replenishment dependent on inventory level. Comput. Oper. Res. 1998, 25, 997–1006. [Google Scholar] [CrossRef]

- Abad, P.L. Optimal lot size for a perishable good under conditions of finite production and partial backordering and lost sale. Comput. Ind. Eng. 2000, 38, 457–465. [Google Scholar] [CrossRef]

- Giri, B.C.; Yun, W.; Dohi, T. Optimal design of unreliable production–inventory systems with variable production rate. Eur. J. Oper. Res. 2005, 162, 372–386. [Google Scholar] [CrossRef]

- Larsen, C. The economic production lot size model extended to include more than one production rate. Int. Trans. Oper. Res. 2005, 12, 339–353. [Google Scholar] [CrossRef]

- AlDurgam, M.M.; Duffuaa, S.O. Optimal joint maintenance and operation policies to maximise overall systems effectiveness. Int. J. Prod. Res. 2013, 51, 1319–1330. [Google Scholar] [CrossRef]

- Sarkar, M.; Hur, S.; Sarkar, B. Effects of Variable Production Rate and Time-Dependent Holding Cost for Complementary Products in Supply Chain Model. Math. Probl. Eng. 2017. [Google Scholar] [CrossRef]

- Alfares, H.K.; Ghaithan, A.M. EOQ and EPQ Production-Inventory Models with Variable Holding Cost: State-of-the-Art Review. Arab. J. Sci. Eng. 2019, 44, 1737–1755. [Google Scholar] [CrossRef]

- Dey, B.K.; Sarkar, B.; Pareek, S. A Two-Echelon Supply Chain Management With Setup Time and Cost Reduction, Quality Improvement and Variable Production Rate. Mathematics 2019, 7, 328. [Google Scholar] [CrossRef] [Green Version]

- Bhandari, R.; Sharma, P. The economic production lot-size model with variable cost function. Opsearch 1999, 36, 137–150. [Google Scholar] [CrossRef]

- Khalifehzadeh, S.; Fakhrzad, M. A Modified Firefly Algorithm for optimizing a multi stage supply chain network with stochastic demand and fuzzy production capacity. Comput. Ind. Eng. 2019, 133, 42–56. [Google Scholar] [CrossRef]

- Harris, F.W. Operations and cost. In Factory Management Series; AW Shaw Co.: Chicago, IL, USA, 1915; pp. 48–52. [Google Scholar]

- Wilson, R. A Scientific Routine for Stock Control; Harvard Univ.: Cambridge, MA, USA, 1934. [Google Scholar]

- Cho, D.I. Analysis of optimal production and advertising policies. Int. J. Syst. Sci. 1996, 27, 1297–1305. [Google Scholar] [CrossRef]

- Hazari, S.; Maity, K.; Dey, J.K.; Kar, S. Advertisement policy and reliability dependent imperfect production inventory control problem in bi–fuzzy environment. Int. J. Oper. Res. 2015, 22, 342–365. [Google Scholar] [CrossRef]

- Rivera-Gómez, H.; Gharbi, A.; Kenné, J.P.; Montano-Arango, O.; Hernandez-Gress, E.S. Production control problem integrating overhaul and subcontracting strategies for a quality deteriorating manufacturing system. Int. J. Prod. Econ. 2016, 171, 134–150. [Google Scholar] [CrossRef]

- Yin, K.K.; Liu, H.; Yin, G.G. Stochastic models and numerical solutions for production planning with applications to the paper industry. Comput. Chem. Eng. 2003, 27, 1693–1706. [Google Scholar] [CrossRef]

- Yang, P.; Wee, H.M.; Hsu, P. Collaborative vendor–buyer inventory system with declining market. Comput. Ind. Eng. 2008, 54, 128–139. [Google Scholar] [CrossRef]

- Goyal, M.; Netessine, S. Strategic technology choice and capacity investment under demand uncertainty. Manag. Sci. 2007, 53, 192–207. [Google Scholar] [CrossRef] [Green Version]

- Yuan, X.; Shen, L.; Ashayeri, J. Dynamic simulation assessment of collaboration strategies to manage demand gap in high-tech product diffusion. Robot. Comput.-Integr. Manuf. 2010, 26, 647–657. [Google Scholar] [CrossRef]

- Sana, S.; Chaudhuri, K.; Mahavidyalaya, B. On a volume flexible production policy for a deteriorating item with time-dependent demand and shortages. Adv. Model. Optim. 2004, 6, 57–74. [Google Scholar]

- Ross, S.M. Introduction to Probability Models; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Goyal, S.; Giri, B.C. The production–inventory problem of a product with time varying demand, production and deterioration rates. Eur. J. Oper. Res. 2003, 147, 549–557. [Google Scholar] [CrossRef]

- Malik, A.I.; Kim, B.S. A Constrained Production System Involving Production Flexibility and Carbon Emissions. Mathematics 2020, 8, 275. [Google Scholar] [CrossRef] [Green Version]

- Ullah, M.; Sarkar, B.; Asghar, I. Effects of Preservation Technology Investment on Waste Generation in a Two-Echelon Supply Chain Model. Mathematics 2019, 7, 189. [Google Scholar] [CrossRef] [Green Version]

- Ullah, M.; Sarkar, B. Recovery-channel selection in a hybrid manufacturing-remanufacturing production model with RFID and product quality. Int. J. Prod. Econ. 2020, 219, 360–374. [Google Scholar] [CrossRef]

- Sarkar, B.; Guchhait, R.; Sarkar, M.; Cárdenas-Barrón, L.E. How does an industry manage the optimum cash flow within a smart production system with the carbon footprint and carbon emission under logistics framework? Int. J. Prod. Econ. 2019, 213, 243–257. [Google Scholar] [CrossRef]

- Sarkar, B.; Ullah, M.; Kim, N. Environmental and economic assessment of closed-loop supply chain with remanufacturing and returnable transport items. Comput. Ind. Eng. 2017, 111, 148–163. [Google Scholar] [CrossRef]

- Sarkar, B.; Ullah, M.; Choi, S.B. Joint inventory and pricing policy for an online to offline closed-loop supply chain model with random defective rate and returnable transport items. Mathematics 2019, 7, 497. [Google Scholar] [CrossRef] [Green Version]

- Sarkar, B.; Tayyab, M.; Choi, S.B. Product Channeling in an O2O supply chain management as power transmission in electric power distribution systems. Mathematics 2019, 7, 4. [Google Scholar] [CrossRef] [Green Version]

| Author(s) | Manufacturing Reliability | Repair Rate | Production Rate | Unit Production Cost | Technology Development | Demand Rate |

|---|---|---|---|---|---|---|

| Chakraborty et al. [5] | random | random | constant | NA | NA | constant |

| Asghar et al. [6] | stochastic | stochastic | variable | () | () | constant |

| Marchi et al. [7] | random | NA | variable | () | NA | constant |

| Sarkar et al. [3] | random | NA | variable | () | () | constant |

| Lopes, R. [8] | random | constant | constant | NA | NA | constant |

| Marchi et al. [9] | imperfect | constant | variable | () | NA | constant |

| Chakraborty et al. [10] | random | random | constant | NA | NA | constant |

| Kang et al. [11] | age dependent | constant | random | NA | NA | constant |

| Bhunia et al. [12] | flexible (product quality based) | NA | variable | () | NA | variable (selling price + marketing cost) |

| Ouaret et al. [13] | random | constant | flexible | NA | NA | random |

| Bag et al. [14] | variable | NA | constant | constant | NA | fuzzy random |

| Aldurgam et al. [15] | NA | NA | variable | () | NA | stochastic |

| Ouaret et al. [16] | random | constant | variable | NA | NA | random |

| Manna et al. [17] | production rate dependent | NA | variable | () | NA | advertisement dependent |

| Zhu et al. [18] | NA | NA | constant | () | NA | (product reliability + warranty period) |

| Shah et al. [19] | imperfect | NA | variable | () | NA | time and effort dependent |

| Khara et al. [20] | imperfect | NA | constant | () | () | selling price + dependent |

| Shah et al. [21] | imperfect | NA | constant | () | () | (, selling price) |

| Ethem Çanakoğlu, Taner Bilgiç. [22] | NA | NA | NA | NA | fixed | technology dependent |

| This study | Stochastic | Stochastic | Variable | () dependent | () dependent | Technology dependent |

| ($/unit) | ($/unit) | ($/setup) |

| ($) | ($) | |

| ($/unit time) | (repairs /unit time) | |

| ($/unit) | ||

| ($) | (units/unit time) | |

| ($/unit/unit time) |

| Parameter | Change | Q | % Change in | |||

|---|---|---|---|---|---|---|

| % | (Units) | (Failures/Unit Time) | (Units/Unit Time) | ($/Unit) | ($/Unit/Unit Time) | |

| −20 | 3424.64 | 0873.26 | −7.92 | |||

| −10 | 3191.81 | 0983.87 | −3.70 | |||

| +10 | 2977.92 | 1149.03 | +3.07 | |||

| +20 | 2946.28 | 1203.95 | +5.02 | |||

| −20 | 3060.56 | 1075.18 | −2.78 | |||

| −10 | 3060.64 | 1075.15 | −1.54 | |||

| +10 | 3061.87 | 1074.71 | +1.20 | |||

| +20 | 3145.10 | 1027.73 | +2.77 | |||

| −20 | 3059.87 | 1075.27 | −0.11 | |||

| −10 | 3061.85 | 1074.72 | −0.02 | |||

| +10 | 3074.20 | 1070.24 | +0.01 | |||

| +20 | 3056.48 | 1075.55 | +0.16 | |||

| Y | −20 | 3059.92 | 1075.42 | −0.02 | ||

| −10 | 3064.73 | 1073.37 | −0.12 | |||

| +10 | 3088.96 | 1081.51 | +0.15 | |||

| +20 | inf | inf | inf | inf | inf | |

| −20 | 3375.97 | 0975.35 | +0.81 | |||

| −10 | 3058.88 | 1075.57 | +0.004 | |||

| +10 | 3059.67 | 1075.51 | −0.09 | |||

| +20 | 3066.45 | 1073.06 | −0.11 | |||

| −20 | 3058.21 | 1075.61 | −0.01 | |||

| −10 | 3059.87 | 1075.43 | −0.01 | |||

| +10 | 3058.48 | 1075.59 | +0.01 | |||

| +20 | 3062.35 | 1074.54 | +0.01 | |||

| −20 | 2917.85 | 1214.58 | −5.25 | |||

| −10 | 2998.08 | 1131.27 | −2.28 | |||

| +10 | 3137.53 | 1019.07 | +2.69 | |||

| +20 | 3214.55 | 0970.72 | +4.65 | |||

| −20 | 3237.36 | 1012.05 | −4.43 | |||

| −10 | 3059.23 | 1075.53 | −0.02 | |||

| +10 | 3060.01 | 1075.48 | +0.004 | |||

| +20 | 3063.44 | 1074.32 | +0.004 | |||

| −20 | 1916.47 | 1161.88 | 0.33 | +2.68 | ||

| −10 | 3063.76 | 1074.20 | +0.13 | |||

| +10 | 3066.49 | 1073.21 | −0.07 | |||

| +20 | inf | inf | inf | inf | inf | |

| −20 | 3060.39 | 1075.25 | −0.03 | |||

| −10 | 3059.60 | 1075.47 | −0.03 | |||

| +10 | 3060.02 | 1075.38 | −0.07 | |||

| +20 | 3062.40 | 1074.52 | −0.07 | |||

| −20 | 2993.77 | 1079.94 | −0.51 | |||

| −10 | 3084.50 | 1056.75 | −0.25 | |||

| +10 | 3093.58 | 1072.82 | +0.24 | |||

| +20 | 3126.98 | 1070.26 | +0.48 | |||

| −20 | 3062.26 | 1074.57 | −0.02 | |||

| −10 | 3059.98 | 1075.39 | −0.01 | |||

| +10 | inf | inf | inf | inf | inf | |

| +20 | inf | inf | inf | inf | inf | |

| −20 | 3384.03 | 1102.44 | −2.85 | |||

| −10 | 3221.49 | 1077.35 | −1.29 | |||

| +10 | 2966.62 | 1043.72 | +1.21 | |||

| +20 | 2198.90 | 1108.43 | 0.04 | +3.13 | ||

| S | −20 | 2809.52 | 1094.69 | −1.87 | ||

| −10 | 2939.03 | 1084.00 | −0.95 | |||

| +10 | 3213.57 | 1061.55 | +0.97 | |||

| +20 | 3356.06 | 1043.57 | +1.93 | |||

| −20 | 3067.79 | 1072.58 | −0.07 | |||

| −10 | 3093.14 | 1063.56 | −0.18 | |||

| +10 | 3062.60 | 1074.45 | +0.003 | |||

| +20 | 3195.18 | 1016.47 | +0.53 |

| Parameter | % | % Change in | ||||

|---|---|---|---|---|---|---|

| Change | (Rate) | ($/Unit/Unit Time) | ($/Unit) | ($/Unit/Unit Time) | ||

| −20 | 100 | 4.60 | −7.92 | |||

| −10 | 99 | 4.70 | −3.70 | |||

| +10 | 99 | 5.09 | +3.07 | |||

| +20 | 100 | 5.20 | +5.02 | |||

| −20 | 99 | 4.75 | −2.78 | |||

| −10 | 99 | 4.80 | −1.54 | |||

| +10 | 100 | 5.01 | +1.20 | |||

| +20 | 100 | 5.17 | +2.77 | |||

| −20 | 100 | 4.90 | −0.11 | |||

| −10 | 99 | 4.93 | −0.02 | |||

| +10 | 99 | 4.90 | +0.01 | |||

| +20 | 100 | 4.93 | +0.16 | |||

| Y | −20 | 99 | 4.93 | −0.02 | ||

| −10 | 99 | 4.94 | −0.12 | |||

| +10 | 100 | 4.94 | +0.15 | |||

| +20 | inf | inf | inf | inf | inf | |

| −20 | 100 | 5.03 | +0.81 | |||

| −10 | 99 | 4.94 | +0.004 | |||

| +10 | 100 | 4.93 | −0.09 | |||

| +20 | 100 | 4.94 | −0.11 | |||

| −20 | 100 | 4.94 | −0.01 | |||

| −10 | 99 | 4.94 | −0.01 | |||

| +10 | 100 | 4.94 | +0.01 | |||

| +20 | 100 | 4.94 | +0.01 | |||

| −20 | 100 | 5.00 | −4.43 | |||

| −10 | 99 | 4.94 | −0.02 | |||

| +10 | 99 | 4.94 | +0.004 | |||

| +20 | 99 | 4.94 | +0.004 | |||

| −20 | 99 | 4.89 | 0.33 | +2.68 | ||

| −10 | 100 | 4.93 | +0.13 | |||

| +10 | 100 | 4.94 | −0.07 | |||

| +20 | inf | inf | inf | inf | inf | |

| −20 | 99 | 4.94 | −0.03 | |||

| −10 | 100 | 4.94 | −0.03 | |||

| +10 | 100 | 4.94 | −0.07 | |||

| +20 | 100 | 4.94 | −0.07 | |||

| −20 | 99 | 4.94 | −0.51 | |||

| −10 | 99 | 4.95 | −0.25 | |||

| +10 | 99 | 4.94 | +0.24 | |||

| +20 | 99 | 4.94 | +0.48 | |||

| −20 | 99 | 4.93 | −0.02 | |||

| −10 | 99 | 4.93 | −0.01 | |||

| +10 | inf | inf | inf | inf | inf | |

| +20 | inf | inf | inf | inf | inf | |

| −20 | 100 | 4.92 | −2.85 | |||

| −10 | 100 | 4.94 | −1.29 | |||

| +10 | 100 | 4.96 | +1.21 | |||

| +20 | 99 | 4.91 | 0.04 | +3.13 | ||

| −20 | 99 | 4.52 | −5.25 | |||

| −10 | 99 | 4.75 | −2.28 | |||

| +10 | 99 | 5.13 | +2.69 | |||

| +20 | 99 | 5.32 | +4.65 | |||

| S | −20 | 99 | 4.92 | −1.87 | ||

| −10 | 100 | 4.93 | −0.95 | |||

| +10 | 100 | 4.95 | +0.97 | |||

| +20 | 100 | 4.96 | +1.93 | |||

| −20 | 100 | 4.93 | −0.07 | |||

| −10 | 100 | 4.94 | −0.18 | |||

| +10 | 100 | 4.94 | +0.003 | |||

| +20 | 100 | 4.99 | +0.53 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asghar, I.; Kim, J.S. An Automated Smart EPQ-Based Inventory Model for Technology-Dependent Products under Stochastic Failure and Repair Rate. Symmetry 2020, 12, 388. https://doi.org/10.3390/sym12030388

Asghar I, Kim JS. An Automated Smart EPQ-Based Inventory Model for Technology-Dependent Products under Stochastic Failure and Repair Rate. Symmetry. 2020; 12(3):388. https://doi.org/10.3390/sym12030388

Chicago/Turabian StyleAsghar, Iqra, and Jong Soo Kim. 2020. "An Automated Smart EPQ-Based Inventory Model for Technology-Dependent Products under Stochastic Failure and Repair Rate" Symmetry 12, no. 3: 388. https://doi.org/10.3390/sym12030388

APA StyleAsghar, I., & Kim, J. S. (2020). An Automated Smart EPQ-Based Inventory Model for Technology-Dependent Products under Stochastic Failure and Repair Rate. Symmetry, 12(3), 388. https://doi.org/10.3390/sym12030388