Heat Transfer Enhancement in a Novel Annular Tube with Outer Straight and Inner Twisted Oval Tubes

Abstract

:1. Introduction

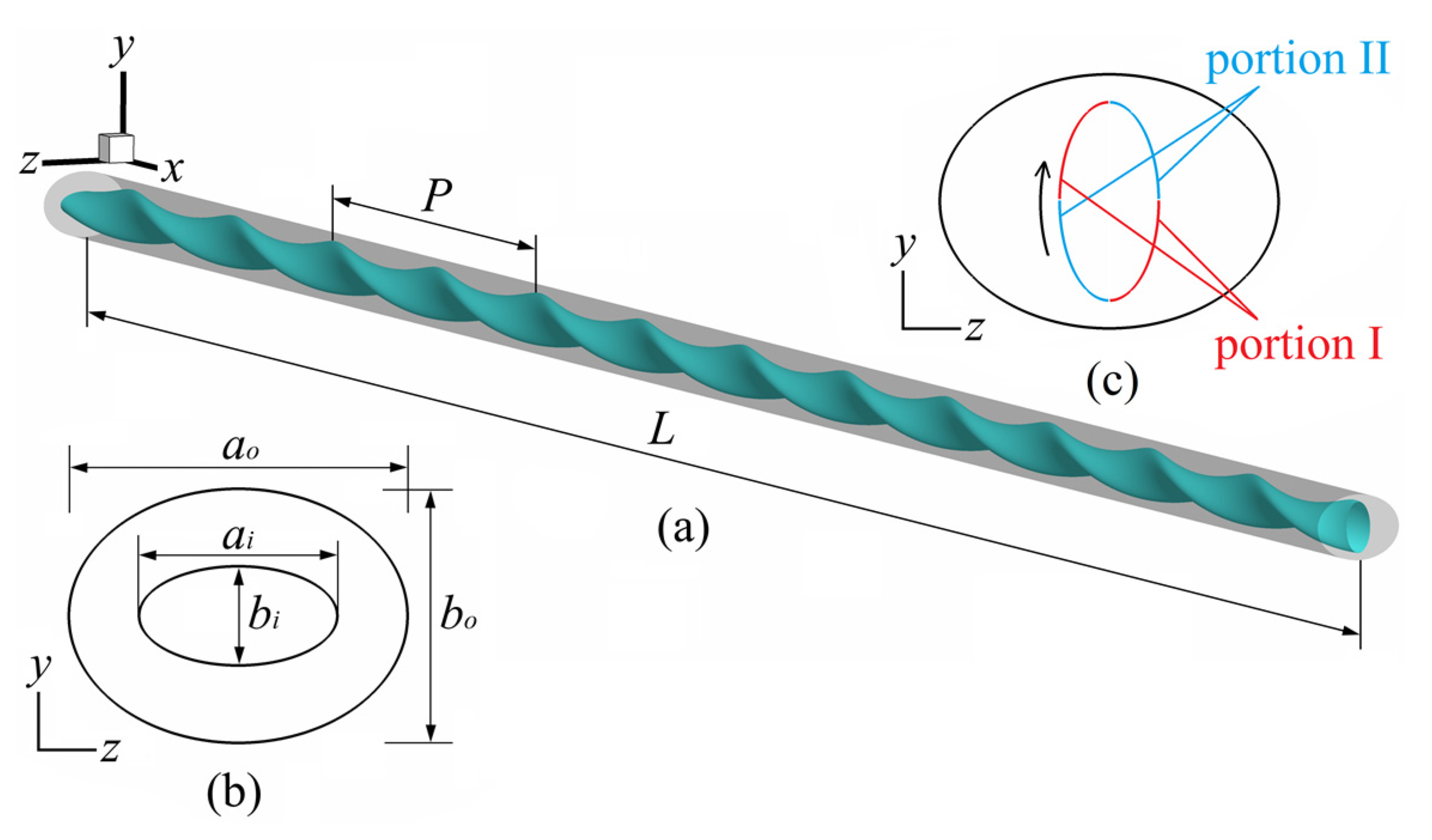

2. Physical Model and Numerical Method

- (a)

- A uniform velocity uin and constant temperature (Tin = 293K) are adopted at the inlet.

- (b)

- The turbulence intensity (I) of the inlet is obtained by I = 0.16Re−1/8.

- (c)

- All of the tube walls are no-slip.

- (d)

- A constant temperature (Tw = 363K) and adiabatic condition are adopted at the inner wall and outer wall, respectively.

- (e)

- Outlet: an outflow boundary condition is applied, i.e., .

3. Results

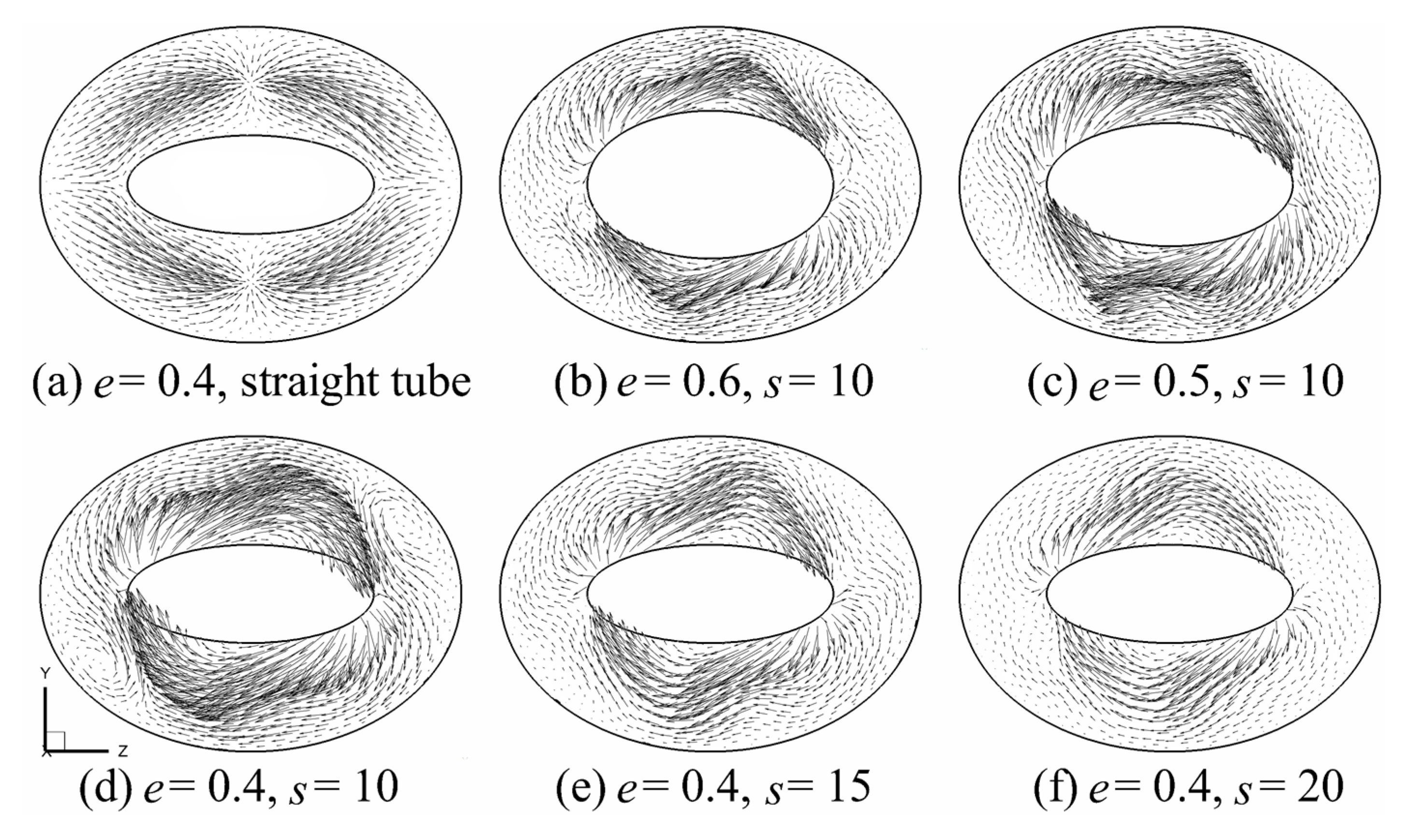

3.1. Secondary Flow in the Annulus

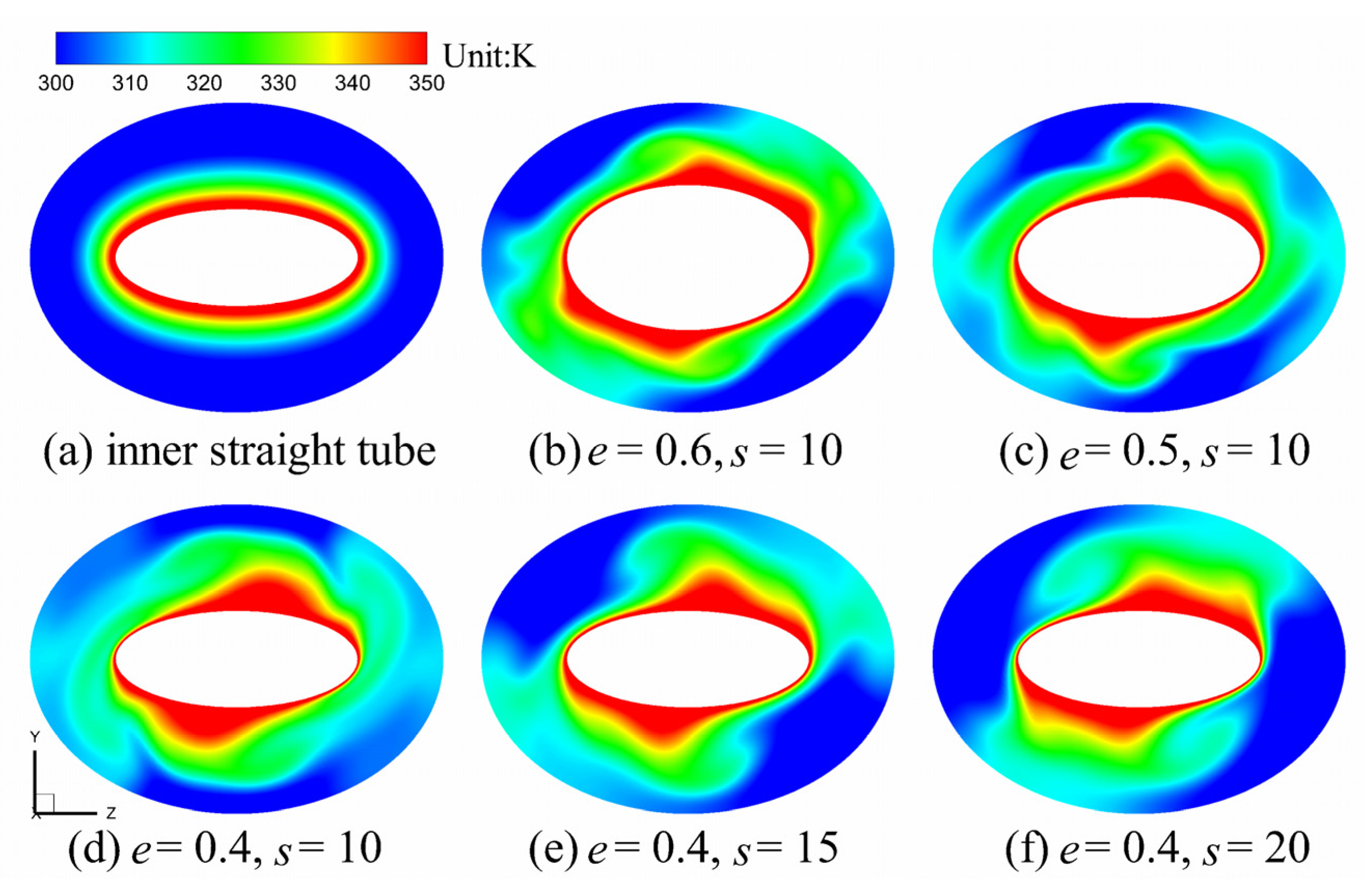

3.2. Temperature in the Annular Space

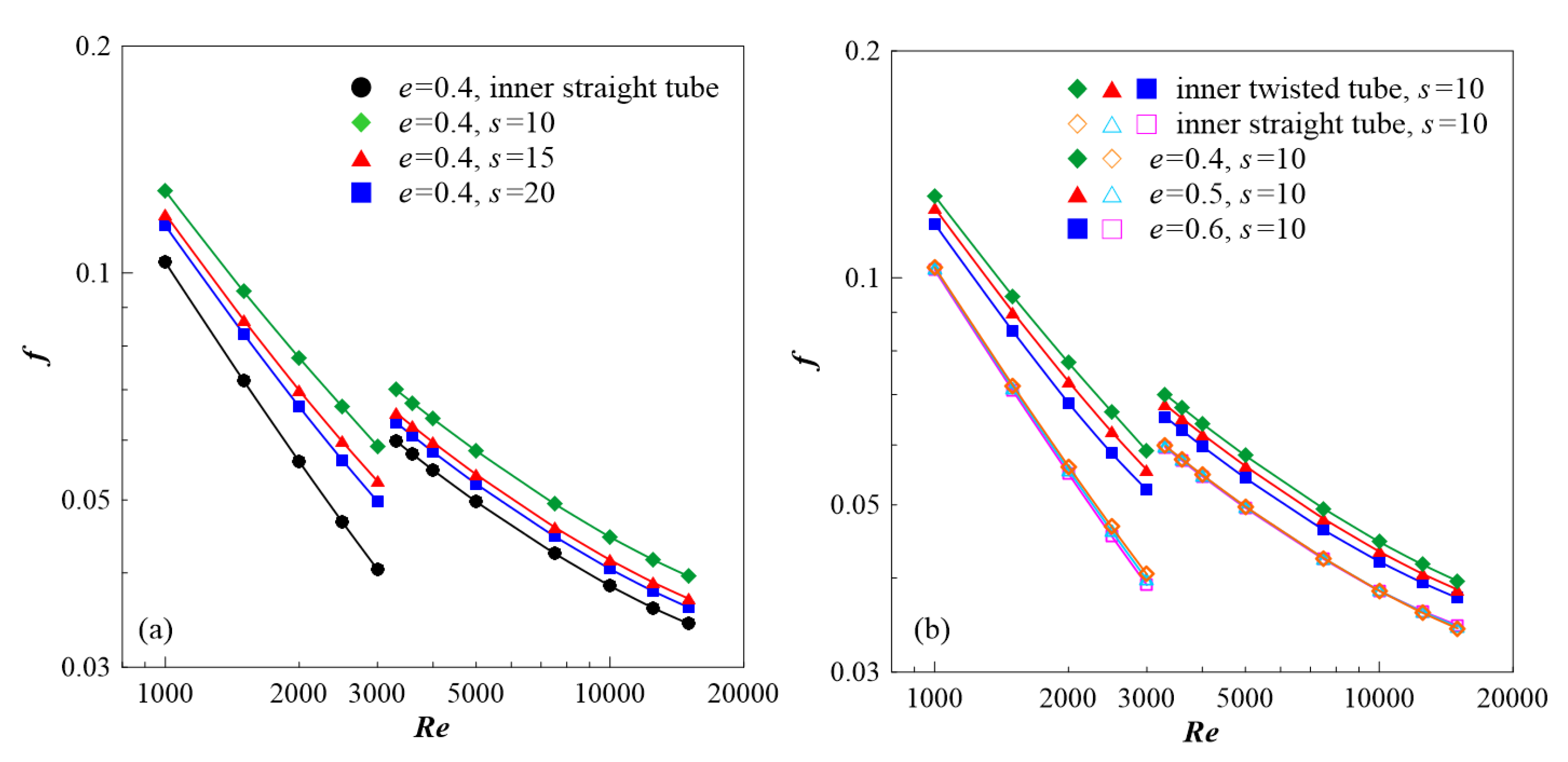

3.3. Effects of s and e on Nu and f

3.4. Effects of s and e on JF

3.5. Correlations

4. Conclusions

- (1)

- The fluid mixing in the annulus is obviously improved by the inner twisted oval tube.

- (2)

- Nu and f increase as both the aspect ratio and twist ratio decrease. The largest relative increments of Nu and f are 35% and 13% between different aspect ratios, and 26% and 18% between different twist ratios.

- (3)

- The inner twisted oval tube yields 116% and 46% increases in Nu and f, respectively, compared with the inner straight tube.

- (4)

- The thermal performance enhancement is more significant in the laminar regime. The largest JF = 1.9 is obtained for aspect ratio 0.4 and twist ratio 10 at Re = 3000, which is the largest Re in the laminar regime.

- (5)

- The deviations for Nu and f of the correlations are within ±5% and ±4%, respectively.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ao | long-axis length of outer tube, m |

| ai | long-axis length of inner tube, m |

| A | cross-sectional area, m2 |

| bo | short-axis length of outer tube, m |

| bi | short-axis length of inner tube, m |

| Dh | hydraulic diameter, m |

| e | aspect ratio |

| f | friction factor |

| Gk | turbulent kinetic energy due to mean velocity gradient, J/kg |

| hi | heat transfer coefficient, W/(m2 K) |

| JF | thermal performance factor |

| k | turbulent kinetic energy, J/kg |

| L | length of the annular domain, m |

| LP | wetted perimeter, m |

| Nu | Nusselt number |

| Δp | pressure loss, Pa |

| P | length of twisted pitch, m |

| q | wall heat flux, W/m2 |

| Re | Reynolds number |

| s | twist ratio |

| S | fin surface area, m2 |

| T | temperature, K |

| Ts | bulk temperature, K |

| u, v, w | components of velocity vector, m/s |

| X | non-dimensional distance |

| x, y, z | coordinates, m |

| Greek symbols | |

| ε | turbulent dissipation rate, J/(kg s) |

| λ | thermal conductivity, W/(m K) |

| μ | dynamic viscosity, kg/(m s) |

| ρ | density, kg/m3 |

| Subscripts | |

| 0 | straight inner and outer oval tubes |

| in | inlet |

| t | turbulent |

| w | wall surface |

References

- Omidi, M.; Farhadi, M.; Jafari, M. A comprehensive review on double pipe heat exchangers. Appl. Therm. Eng. 2017, 110, 1075–1090. [Google Scholar] [CrossRef]

- Setareh, M.; Saffar-Avval, M.; Abdullah, A. Experimental and numerical study on heat transfer enhancement using ultrasonic vibration in a double-pipe heat exchanger. Appl. Therm. Eng. 2019, 159, 113867. [Google Scholar] [CrossRef]

- Bahiraei, M.; Hangi, M. Investigating the efficacy of magnetic nanofluid as a coolant in double-pipe heat exchanger in the presence of magnetic field. Energy Convers. Manag. 2013, 76, 1125–1133. [Google Scholar] [CrossRef]

- Mousavi, S.V.; Sheikholeslami, M.; Bandpy, M.G.; Gerdroodbary, M.B. The Influence of magnetic field on heat transfer of magnetic nanofluid in a sinusoidal double pipe heat exchanger. Chem. Eng. Res. Des. 2016, 113, 112–124. [Google Scholar] [CrossRef]

- Bezaatpour, M.; Goharkhah, M. Convective heat transfer enhancement in a double pipe mini heat exchanger by magnetic field induced swirling flow. Appl. Therm. Eng. 2020, 167, 114801. [Google Scholar] [CrossRef]

- Zhang, S.J.; Lu, L.; Dong, C.S.; Cha, S.H. Thermal characteristics of perforated self-rotating twisted tapes in a double-pipe heat exchanger. Appl. Therm. Eng. 2019, 162, 114296. [Google Scholar] [CrossRef]

- Mashoofi, N.; Pourahmad, S.; Pesteei, S.M. Study the effect of axially perforated twisted tapes on the thermal performance enhancement factor of a double tube heat exchanger. Case Stud. Therm. Eng. 2017, 10, 161–168. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Ganji, D.D. Heat transfer improvement in a double pipe heat exchanger by means of perforated turbulators. Energy Convers. Manag. 2016, 127, 112–123. [Google Scholar] [CrossRef]

- Song, K.W.; Tagawa, T. The optimal arrangement of vortex generators for best heat transfer enhancement in flat-tube-fin heat exchanger. Int. J. Therm. Sci. 2018, 132, 355–367. [Google Scholar] [CrossRef]

- Song, K.W.; Xi, Z.P.; Su, M.; Wang, L.C.; Wu, X.; Wang, L.B. Effect of geometric size of curved delta winglet vortex generators and tube pitch on heat transfer characteristics of fin-tube heat exchanger. Exp. Therm. Fluid Sci. 2017, 82, 8–18. [Google Scholar] [CrossRef]

- Song, K.W.; Wang, L.; Hu, Y.J.; Liu, Q. Flow symmetry and heat transfer characteristics of winglet vortex generators arranged in common flow up configuration. Symmetry 2020, 12, 247. [Google Scholar] [CrossRef] [Green Version]

- Bhadouriya, R.; Agrawal, A.; Prabhu, S.V. Experimental and numerical study of fluid flow and heat transfer in a twisted square duct. Int. J. Heat Mass Transf. 2015, 82, 143–158. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, L.; Xu, H. Experimental study on convective heat transfer and flow resistance characteristics of water flow in twisted elliptical tubes. Appl. Therm. Eng. 2011, 31, 2981–2991. [Google Scholar] [CrossRef]

- Cheng, J.L.; Qian, Z.Q.; Wang, Q. Analysis of heat transfer and flow resistance of twisted oval tube in low Reynolds number flow. Int. J. Heat Mass Transf. 2017, 109, 761–777. [Google Scholar] [CrossRef]

- Song, K.W.; Wang, L.B. Relationship between heat transfer intensity and absolute vorticity flux intensity in flat tube bank fin channels with Vortex Generators. Prog. Comput. Fluid Dyn. Int. J. 2008, 8, 496–502. [Google Scholar] [CrossRef]

- Song, K.W.; Wang, L.B. The effectiveness of secondary flow produced by vortex generators mounted on both surfaces of the fin to enhance heat transfer in a flat tube bank fin heat exchanger. J. Heat Transf. 2013, 135, 041902. [Google Scholar] [CrossRef]

- Hu, W.L.; Song, K.W.; Guan, Y.; Chang, L.M.; Liu, S.; Wang, L.B. Secondary flow intensity determines Nusselt number on the fin surfaces of circle tube bank fin heat exchanger. Int. J. Heat Mass Transf. 2013, 62, 620–631. [Google Scholar] [CrossRef]

- Song, K.W.; Liu, S.; Wang, L.B. Interaction of counter rotating longitudinal vortices and the effect on fluid flow and heat transfer. Int. J. Heat Mass Transf. 2016, 93, 349–360. [Google Scholar] [CrossRef]

- Song, K.W.; Hu, W.L.; Liu, S.; Wang, L.B. Quantitative relationship between secondary flow intensity and heat transfer intensity in flat-tube-and-fin air heat exchanger with vortex generators. Appl. Therm. Eng. 2016, 103, 1064–1070. [Google Scholar] [CrossRef]

- Esmaeilzadeh, E.; Almohammadi, H.; Nokhosteen, A.; Motezaker, A.; Omrani, A.N. Study on heat transfer and friction factor characteristics of γ-Al2O3/water through circular tube with twisted tape inserts with different thicknesses. Int. J. Therm. Sci. 2014, 82, 72–83. [Google Scholar] [CrossRef]

- Man, C.Z.; Yao, J.Y.; Wang, C. The experimental study on the heat transfer and friction factor characteristics in tube with a new kind of twisted tape insert. Int. Commun. Heat Mass Transf. 2016, 75, 124–129. [Google Scholar] [CrossRef]

- Pourahmad, S.; Pesteei, S.M. Effectiveness-NTU analyses in a double tube heat exchanger equipped with wavy strip considering various angles. Energy Convers. Manag. 2016, 123, 462–469. [Google Scholar] [CrossRef]

- Zhang, Z.; Ding, Y.M.; Guan, C.F.; Yan, H.; Yang, W.M. Heat transfer enhancement in double-pipe heat exchanger by means of rotor-assembled strands. Chem. Eng. Process. Process Intensif. 2012, 60, 26–33. [Google Scholar] [CrossRef]

- Bhadouriya, R.; Agrawal, A.; Prabhu, S.V. Experimental and numerical study of fluid flow and heat transfer in an annulus of inner twisted square duct and outer circular pipe. Int. J. Therm. Sci. 2015, 94, 96–109. [Google Scholar] [CrossRef]

- Bashtani, I.; Esfahani, J.A. ε-NTU analysis of turbulent flow in a corrugated double pipe heat exchanger: A numerical investigation. Appl. Therm. Eng. 2019, 159, 113886. [Google Scholar] [CrossRef]

- Zambaux, J.A.; Harion, J.L.; Russeil, S.; Bouvier, P. The effect of successive alternating wall deformation on the performance of an annular heat exchanger. Appl. Therm. Eng. 2015, 90, 286–295. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.; Lee, K.S.; Li, B. Optimal design of a double pipe heat exchanger based on the outward helically corrugated tube. Int. J. Heat Mass Transf. 2019, 135, 706–716. [Google Scholar] [CrossRef]

- Gorman, J.M.; Krautbauer, K.R.; Sparrow, E.M. Thermal and fluid flow first-principles numerical design of an enhanced double pipe heat exchanger. Appl. Therm. Eng. 2016, 107, 194–206. [Google Scholar] [CrossRef]

- Qi, C.; Luo, T.; Liu, M.N.; Fan, F.; Yan, Y.Y. Experimental study on the flow and heat transfer characteristics of nanofluids in double-tube heat exchangers based on thermal efficiency assessment. Energy Convers. Manag. 2019, 197, 111877. [Google Scholar] [CrossRef]

- Sadeghianjahromi, A.; Kheradmand, S.; Nemati, H. Developed correlations for heat transfer and flow friction characteristics of louvered finned tube heat exchangers. Int. J. Therm. Sci. 2018, 129, 135–144. [Google Scholar] [CrossRef]

- Luo, C.; Wu, S.; Song, K.W.; Hua, L.; Wang, L.B. Thermo-hydraulic performance optimization of wavy fin heat exchanger by combining delta winglet vortex generators. Appl. Therm. Eng. 2019, 163, 114343. [Google Scholar] [CrossRef]

- Luo, C.; Song, K.W.; Tagawa, T.; Wu, X.; Wang, L.B. Thermal performance of a zig-zag channel formed by two wavy fins mounted with vortex generators. Int. J. Therm. Sci. 2020, 153, 106361. [Google Scholar] [CrossRef]

- Song, K.W.; Shi, W.N.; Wu, X.; Wang, L.B. Characteristics of flow symmetry and heat transfer of winglet pair in common flow down configuration. Symmetry 2020, 12, 209. [Google Scholar] [CrossRef] [Green Version]

- Song, K.W.; Tagawa, T.; Chen, Z.H.; Zhang, Q. Heat transfer characteristics of concave and convex curved vortex generators in the channel of plate heat exchanger under laminar flow. Int. J. Therm. Sci. 2019, 137, 215–228. [Google Scholar] [CrossRef]

- Song, K.W.; Wang, L.B. Effects of longitudinal vortex interaction on periodically developed flow and heat transfer of fin-and-tube heat exchanger. Int. J. Therm. Sci. 2016, 109, 206–216. [Google Scholar] [CrossRef]

| Calculation Model | Laminar, Re = 1000 | RNG k–ε, Re = 11,000 | ||

|---|---|---|---|---|

| fRe | Nu | fRe | Nu | |

| Experiment [24] | 22.7 | 4.41 | 87.4 | 43.31 |

| Present | 21.45 | 4.01 | 97.39 | 38.67 |

| Relative error | 5.5% | 9.1% | 11.4% | 10.7% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, C.; Song, K.; Tagawa, T.; Liu, T. Heat Transfer Enhancement in a Novel Annular Tube with Outer Straight and Inner Twisted Oval Tubes. Symmetry 2020, 12, 1213. https://doi.org/10.3390/sym12081213

Luo C, Song K, Tagawa T, Liu T. Heat Transfer Enhancement in a Novel Annular Tube with Outer Straight and Inner Twisted Oval Tubes. Symmetry. 2020; 12(8):1213. https://doi.org/10.3390/sym12081213

Chicago/Turabian StyleLuo, Chao, KeWei Song, Toshio Tagawa, and TengFei Liu. 2020. "Heat Transfer Enhancement in a Novel Annular Tube with Outer Straight and Inner Twisted Oval Tubes" Symmetry 12, no. 8: 1213. https://doi.org/10.3390/sym12081213

APA StyleLuo, C., Song, K., Tagawa, T., & Liu, T. (2020). Heat Transfer Enhancement in a Novel Annular Tube with Outer Straight and Inner Twisted Oval Tubes. Symmetry, 12(8), 1213. https://doi.org/10.3390/sym12081213