1. Introduction

The coupled thermoelasticity theory was expressed by Biot [

1] to dispense with the contradiction intrinsic in the classical uncoupled model that deformation variations have no influence on the field of temperature. The heat conduction equations for coupled and uncoupled models are of the diffusion kind expecting unlimited speeds of spread for thermal waves inconsistent with physical phenomena. The coupled thermoelasticity theory is connecting with the theory of Lord and Shulman (LS) [

2] as well as Green and Lindsay (GL) [

3] by including the temperature relaxing up time in the foundational relations.

Nanotechnology is now considered one of the greatest encouraging advanced technologies to be studied. This important modern technology will have major impacts on many sciences such as human health, space, civil structures, defense industries, mechanical devices, and others. Many endeavors have been committed to constructing nanogadgets with superior physical, electromechanical, and chemical properties. From the point of functionality, the nanodevices could generally be categorized as nanowires, nanorods, nanotubes, nanoplates, and nanoshells. Many efforts have been paid to building nanoscale devices with superior electromechanical, physical, and chemical properties. Nanoscale devices can generally be classified as nanowires, nanotubes, nanorods, and nanopanels [

4,

5,

6,

7,

8,

9].

Microscale and nanomechanical resonators (M/NEMS) that have a quick response and also high sensitivity are generally utilized as modulators and sensors. M/NEMS have suitable significant notice lately due to many significant industrial applications. Careful analysis of different consequences of resonator features, for instance, resonant frequencies and quality factors, is vital to designing the component’s high performance. Several authors have studied the process of heat transfer and the behavior of vibrations of microbeams [

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21].

The nonlocal microbeam models got increasing regard in the previous few years. In 1972, Eringen [

22,

23] has proposed the idea of nonlocal continuum mechanics to deal with problems of small-scale structural materials. Eringen and Edelen [

24] constructed a constitutive relation to the nonlocal stress at any point in an integral form depending on the complete assumption that the stress at any point is a function of the strains at the same point. The presented nonlocal theory depends on the strengths amongst atoms and the inside length scale, which are taken into consideration in the constitutive equations like a material parameter. The nonlocal principle of elasticity has been used to investigate the applications inclusive of lattice dispersion of elastic waves, nanomechanics, wave spread in composites, fracture mechanics, surface strain fluids, and decoupling mechanics [

25].

Recently, some contradictory results and some inconsistencies in the non-local elasticity approaches have been observed through some recent studies. These observations and paradoxical results have motivated researchers in this field to discuss and deal with these contradictory results. It has been shown through studies in this field that these non-local paradoxes can appear when comparing the results of models based on non-local differentials under different loading boundary conditions. Recently, Romano et al. [

26] have introduced some new concepts, including the concept of constitutive boundary conditions, and through the study, they demonstrated that achieving these boundary conditions is a necessary condition for non-local beam models. In order to address the shortcomings of the previous theory and overcome these paradoxes, many studies have been presented and many efforts were made [

27,

28,

29,

30,

31].

State-space strategies are the basis of the novel theory of control. The important advantage of state-space techniques is the characterization of approaches of importance through differential equations in favoring transport functions. This may appear to be a return to the previous primitive period where the differential equations likewise formed a way to represent the method of dynamic operations. However, in the previous duration, the processes were easy and sufficient to them with only one differential equation for a reasonably low order. The potential function technique is frequently employed to solve some problems of thermoelasticity theory. However, this has various shortcomings as described in [

32,

33].

Sherief and Anwar [

34] treated a generalized thermoelastic problem based on LS theory without heat sources. Additionally, Zenkour and Abouelregal [

35] investigated the response of nanobeams of temperature-dependent thermal conductivity subjected to sine wave heating.

The size effect can be circumvented by higher-order continuum theories. In this study, Euler–Bernoulli microbeams are analyzed with modified strain gradient theory (MSGT) and modified couple stress theory (MCST). A few models are considered for small scale and nanostructures, including strain gradient and couple stress models. The modified couple-stress (MCS) theory can be observed as an exceptional instance of the strain gradient model [

36]. The MCS theory considers the revolutions as a variable to delineate curvature, while the strain inclination model considers the strains as a variable to pronounce curvature. Different investigations about these theories have been available in the scientific literatures [

37,

38,

39,

40,

41,

42].

Micromorphic mechanics is currently a very active field of research both from theoretical and applied perspectives. Therefore, it is possible to reflect on concerning the foundations of the current state of the art and checking the requirements of essential mechanical well-posedness. Romano et al. [

43] investigated the kinematics of generalized continuity and made the main points regarding the definition of a tangential strain measure in general. Barbagallo et al. [

44] and Neff et al. [

45] studied the anisotropic classes of the fourth-tiered elastic tensors of the relaxed micromorphic model and also introducing their second-order counterpart Voigt-type vector notation.

In the present paper we introduce a generalized thermoelastic model for nanobeams when thermal conductivity is variable depending on the model of nonlocal elasticity and thermoelasticity. The technique of Laplace transform can be applied to get the distributions of the displacement, temperature, deflection, and the stress of the nanobeam. The influences of nonlocal parameter (size effect), the thermal conductivity variation, and the term of the modified couple-stress model will be considered and represented graphically. In addition, numerical results for different boundary conditions, different engineering parameters, and non-local parameter values are presented to explain in detail the effects of each of them on different fields of the nanobeam.

2. Mathematical Modeling for Nonlocal Beam Theory

Despite previous studies in the non-local field, it has also been proven that the fully non-local constitutive laws and the local/non-local mixture represent the same non-local constitutive model, but with different degrees of singularity. Additionally, some results demonstrated that the ill-posedness of Eringen’s could not be eliminated since homogeneous parts of the non-local fields could not be formed correctly using the non-local constitutive model.

In this paper, we used the theory of nonlocal elasticity, proposed by Eringen [

22,

23,

24]. In this model, the constitutive relations can be written as

where

and

are respectively, nonlocal and stress tensors,

is the Laplacian operator, and

is the small scale coefficient. The parameter

is the interior characteristic length and

is a constant suitable to each material and obtained by experiment. We can also note that when the parameter

is ignored

Equation (1) reduces to constitutive equations in elasticity theory.

The stress–strain–temperature relations can be written as

where

is the of temperature,

is the temperature distribution and

is the environmental temperature,

are the classical Cauchy relations at a point

in the body,

and

are the Lamé’s constants,

,

is the coefficient of thermal expansion,

denotes the Young’s modulus,

being the Poisson’s ratio, and

is the Kronecker delta function. The Lamé constants

and

can be expressed as

and

.

The classical Cauchy relations are given by

where

are the displacement vector components.

Based on the MSC theory, the

deviatoric part of the couple stress (CS) tensor and

the homogeneous part of the curvature tensor satisfy the relations [

46,

47]:

where

denotes the length scale parameter and

is the rotation vector, which is given by [

47]:

The generalized Fourier law supplanted by the Maxwell-Cattaneo can be written as

where

is the vector of the heat flux,

denotes the temperature-dependent thermal conductivity, and

is the relaxation time. Based on Equation (7), the generalized heat conduction corresponding to LS model can be expressed as [

2]

where

is the temperature-dependent specific heat,

is the heat source, and

is the volumetric strain.

3. Formulation of the Problem

Figure 1 illustrates a thermoelastic Euler–Bernoulli nanobeam isotropic nanobeam. As shown in the Figure the nanobeam has the length

, width

, thickness

, Young’s modulus

and cross-sectional area

. Upon the Euler–Bernoulli beams model and considering that the problem is one-dimensional, the displacement field and the axial strain of the beam can be presented as [

47]

where

is the lateral deflection (displacement in the

direction).

The components of rotation vector are expressed as:

Additionally, putting Equation (10) in Equation (5), we obtained the curvature tensor components as:

Considering conditions of the plane stress, the local constitutive relations along the

-axis has only the nonzero components

As indicated by Eringen theory [

22], the constitutive equations (nonlocal) can be presented as:

where

is the nonlocal couple stress and

.

The motion equation for transverse vibration of nanobeams can be rewritten as

where

is the resultant shear force and

is bending moment of the nanobeam.

From Equations (15) and (16), we get:

Depending on the MCS model and Euler–Bernoulli nanobeam theories, the stress

and couple stress

resultants can be presented as [

46,

47]

The total resultant nonlocal bending moment

of the nanobeam on the

direction can be calculated using the relation [

47]:

If the thermal moment

is defined as

then the equation of bending moment

given in Equation (19) after using Equations (13), (14), and (18) reduces to

where

and

are respectively, the inertia moment of the cross-section and the flexural rigidity.

By substituting Equation (21) into Equation (17), motion Equation (17) can be rewritten in the form

Additionally, substituting Equation (17) into Equation (21) we have:

Using Equation (9), the generalized non-Fourier equation of heat conduction (8) in under LS model [

2] can be given as

In applied engineering problems, the thermal conductivity coefficient depends on the heat in that the numerical estimation of thermal conductivity changes with temperature. Therefore, the equation of heat conduction in this case is a nonlinear equation. The determination of the thermal conductivity is important in numerous thermal management frameworks. Particularly, an exact forecast of the thermal conductivity is important to attain an ideal thermal governor system [

48].

One of our objectives in this paper was to explain the effect of the temperature dependency of thermal conductivity, taking into consideration that the other of the parameters are constant. We assumed that thermoelastic materials have temperature-dependent properties on the formula (Zhang [

48])

where

is the thermal diffusivity. Introducing Equation (25) into Equation (24), the conduction equation can be rewritten as

4. Analytical Solution

Considering the following mapping (Kirchhoff’s transform), which to convert the nonlinear terms of the temperature to be linear, we considered the following mapping [

35]:

where

denotes the temperature-independent thermal conductivity. With the utility of Equation (26), Equation (30) is reduced to the linear partial differential equation

We considered that the top and bottom surfaces of the nanobeam have no heat flow. This means that at

,

. Additionally, we assumed that the variation of the functions

and

are in a sinusoidal variation during the thickness direction given by

This leads to the following equations

Using the previous equation we get Equations (22) and (23) as

where

Substituting Equation (29) into Equation (28) and integrating with respect to

from

to

and with, we get

The following non-dimensional values can be used to convert basic equations in non-dimensional form:

Consequently, Equations (31)–(33) will be in the form (neglecting the dashes)

The constants

, (

in Equations (35)–(37) are

Initial conditions are assumed to be homogeneous in the form

The following mechanical boundary conditions are assumed:

Additionally, we assumed that the surface

is thermally loaded, i.e.,

where

is a constant and

is Heaviside unite step function. Additionally, the thermal conductivity

is considerd to be a linear function of the temperature

as [

35]

where the parameters

and

are constants.

By using the mapping in Equation (17), one gets

Using Equation (41), then one gets

6. Mathematical Method of State-Space Approach

The state space technique of linear frameworks has been utilized widely in several fields of mechanics, for example, the examination of systems control. This method suggests an interesting technique to avert the complications in the classical linear model approach. This methodology aids one to utilize the procedure of advanced model of control in taking care of problems of elasticity and thermoelasticity theories. Bahar and Hetnarski [

32] introduced technique of the state-space approach in the field of thermoelasticity. Their work dealing with the coupled thermoelasticity problems does not including any heat sources.

Taking as a state variables in the

-direction the following functions and gradients

Equations (48)–(50) can be demonstrated in matrix form as

where

indicates the state vector in the transform and

The differential Equation (53) may be integrated using the matrix exponential to give

where

is the exponential transfer matrix and

is given by

We will use Cayley–Hamilton theorem to obtain the formula of

. The characteristic equation corresponding to the matrix

is given by

where

the root of Equation (56) and

The roots

,

and

of Equation (56), satisfy the relations:

The expansion of Taylor series for the matrix

can be expressed as

The Taylor series expansion of the matrix

can be obtaind in the following form based on the Caley–Hamilton theorem

where

are functions of the parameter

and distance

. Using the theorem of Cayley–Hamilton, the roots

of Equation (56) must satisfy Equation (60). Thus, we obtained the system equations:

The solution of the system equations (61) is provided in the

Appendix A.

Therefore,

is given by

where the coefficient of the matrix

are given in

Appendix B.

The boundary conditions Equations (40), (41) and (44) in the Laplace transform domain will be

To get

,

and

, the boundary conditions at

is used as follows:

After using Laplace transform, one gets

Hence, the functions

,

and

are determined by

The final solutions in the transformed domain becomes

Additionally, the displacement after using Equation (68) can be written as

Finally, the solution of the temperature

can be acquired by solving Equation (42)

The bending moment can be obtained after introducing (46), (47), (86), and (86) in Equation (47).

8. Numerical Results

To validate the present results, we compared our results with that of that available in the literature.

For the validation purpose, we considered the following material and geometrical parameters of silicon nanobeam that have been used

Unless otherwise stated herein, we assumed the non-dimensional parameters and satisfies the relations , and . When the non-dimensional scale coefficient is ignored , the governing equation for local Euler–Bernoulli beams can be attained as a special case from the modified couple stress (MCS) theory. The solutions of the studied fields are obtained numerically using the relation (72). The numerical results are displayed graphically along the -axis. The results are discussed in three different cases.

In the first case, the significance of scale coefficient on different field variables has been highlighted. The nonlocal parameter is obtained experimentally for different materials; for example, a conservative estimate of is proposed for a single-walled carbon nanotube. In this study, the non dimensional nonlocal parameter was given by . To clarify the effect of this parameter more clearly, we will introduce a new parameter (). The other effective parameters such as the parameter of the variability of thermal conductivity , scale coefficient , the parameters , and remain constants.

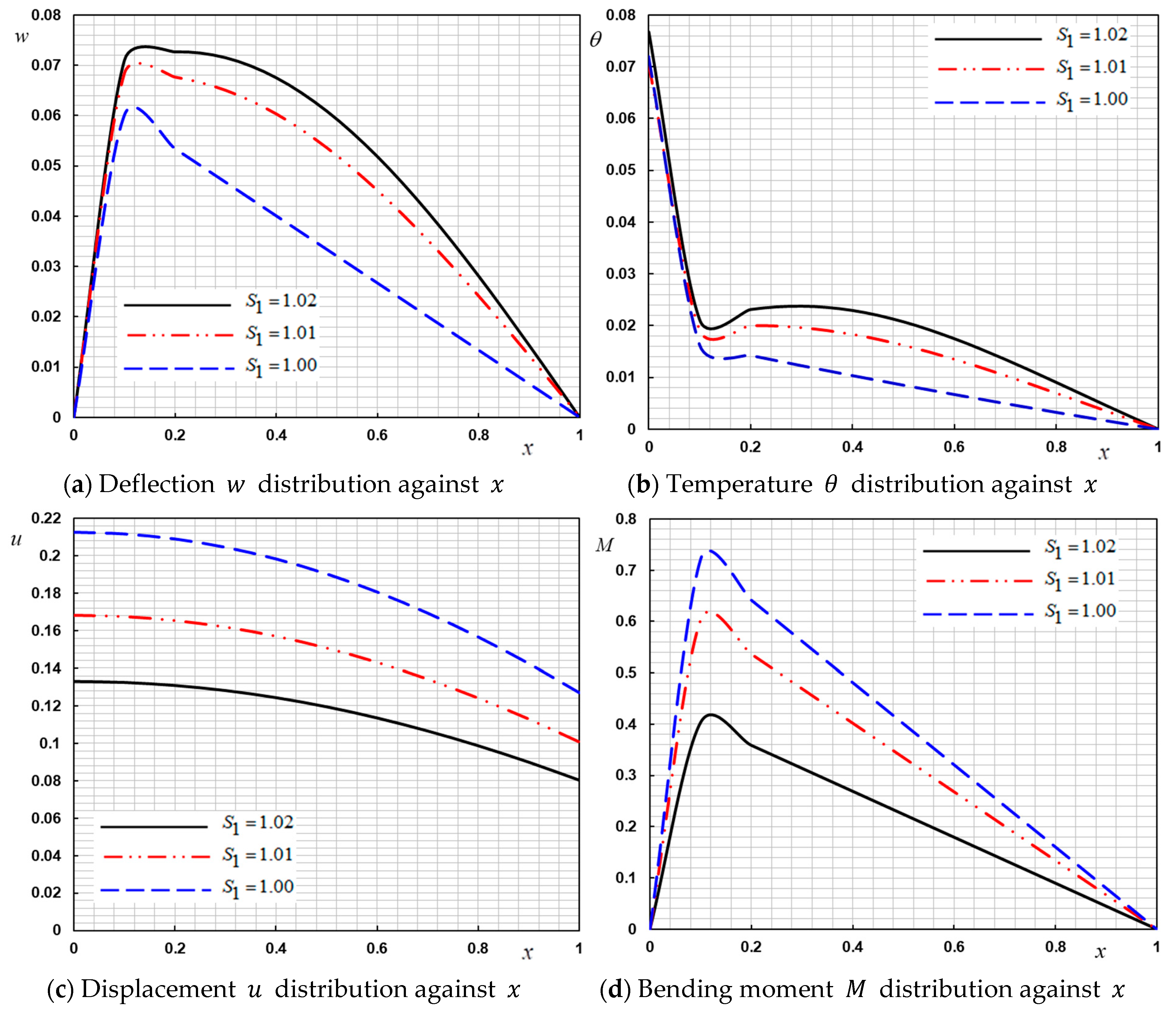

In

Figure 2a–d, the numerical results are shown for various nonlocal parameter coefficients. In the case of the nonlocal model, we took

and

and for the classical one, we put

. The prominent effect of the non-local parameter

can be observed in all areas studied. The displayed figures show that, with the increases in the nonlocal scale parameter, the magnitude of the studied variables

,

,

and

increased.

It can be observed from the figures that there is an excellent agreement between the current results and those in [

19,

25,

50], as it can be seen that this parameter had a clear effect on all the different distributions. It is noted from figures that the peak points of the physical fields increased with the increase in the nonlocal parameter. From

Figure 2a, we can see that the distribution of deflection started from zero and increased gradually until it attained the highest value at position

and then decreased again to zero, which satisfied the conditions of the problem. As shown in

Figure 2b, the temperature distribution decreased with increasing distance

in the direction of the heat wave propagation, which is physically appropriate.

In the second case, the behavior of the field quantities under the influence of thermal conductivity variability was investigated. The parameter is the initial thermal conductivity (when thermal conductivity in independent of temperature) and the parameter is the small negative quantity for measuring the influence of temperature on thermal conductivity. To make comparisons and to study the effect of variability of on different distributions, we will take a third of a different value of the parameter and when parameters , and remain constant.

Numerical values are represented by the

Figure 3a–d. We noticed that there was a noticeable difference in the values of the fields when

compared to the values when

and

. Hence, it is necessary to consider the change of the coefficient of thermal conductivity with the change of temperature when designing devices and machines. From the Figures presented, it can be seen that the curves of the different distributions of the studied functions decrease with the increase of the parameter

which corresponds to [

51,

52].

In the last case, a comparison was investigated between the MCS model and the classical continuum theory. The couple stress theory had two advantages in comparison with other classical theories. The first was that the constitutive relations included only one length scale parameter. The second one was the anti-symmetry of the curvature and the couple stress tensors. Numerical results of the field variables in the context of MCS theory are explained in 4(a–d). In the case of MCS theory, we have

with scale coefficient

and

. Comparisons were made for three different size-scale values

,

and in the absence of the effect of the small scale

(

). Other effective parameters

,

and

are constants. The material scale parameter of the MCS theory had a great influence on the considered fields. It is noted that the current work results were in good agreement with the results of [

47,

53,

54]. Note, for example, that the values of deflection

in the MCS model were higher compared to classical theory. The results depicted in

Figure 4c are expected due to the fact that couple stress theories led to stiffening structural responses in terms of the scale parameter.

9. Conclusions

In this investigation, a thermoelastic new model for Euler–Bernoulli nanobeams was derived based on generalized thermoelasticity, modified couple stress, and nonlocal elasticity theories. Additionally, it was considered that the thermal conductivity was a linear function dependent on the temperature increment. The analysis of the state-space approach was employed to get the analytical expressions for the physical fields based on the Laplace transformations. Discussions and comparisons were made in the presence and absence of the influence of many effective parameters. The strain energy in this theory included only the antisymmetric part of the curvature and couple stress tensors resulting in a simpler form of the strain energy in comparison with other non-classical theories.

According to the results obtained from this study, we found that the effective parameters had a clear effect on thermal and mechanical behaviors. This observation is very important in the industry, especially in the design of precision devices and machines. Additionally, the current model is expected to be extremely effective in analyzing and designing of nanorods, nanotubes, and nanoscale beams under nonlinear geometry and different thermal load conditions. In addition, it can be effective in design procedures for modern nanodevices such as nanosensors and nanoscopes.

In the future, some contradictory results and some inconsistencies in the non-local flexibility approach referred to by some recent studies will be studied.