Influence of Mach Number of Main Flow on Film Cooling Characteristics under Supersonic Condition

Abstract

:1. Introduction

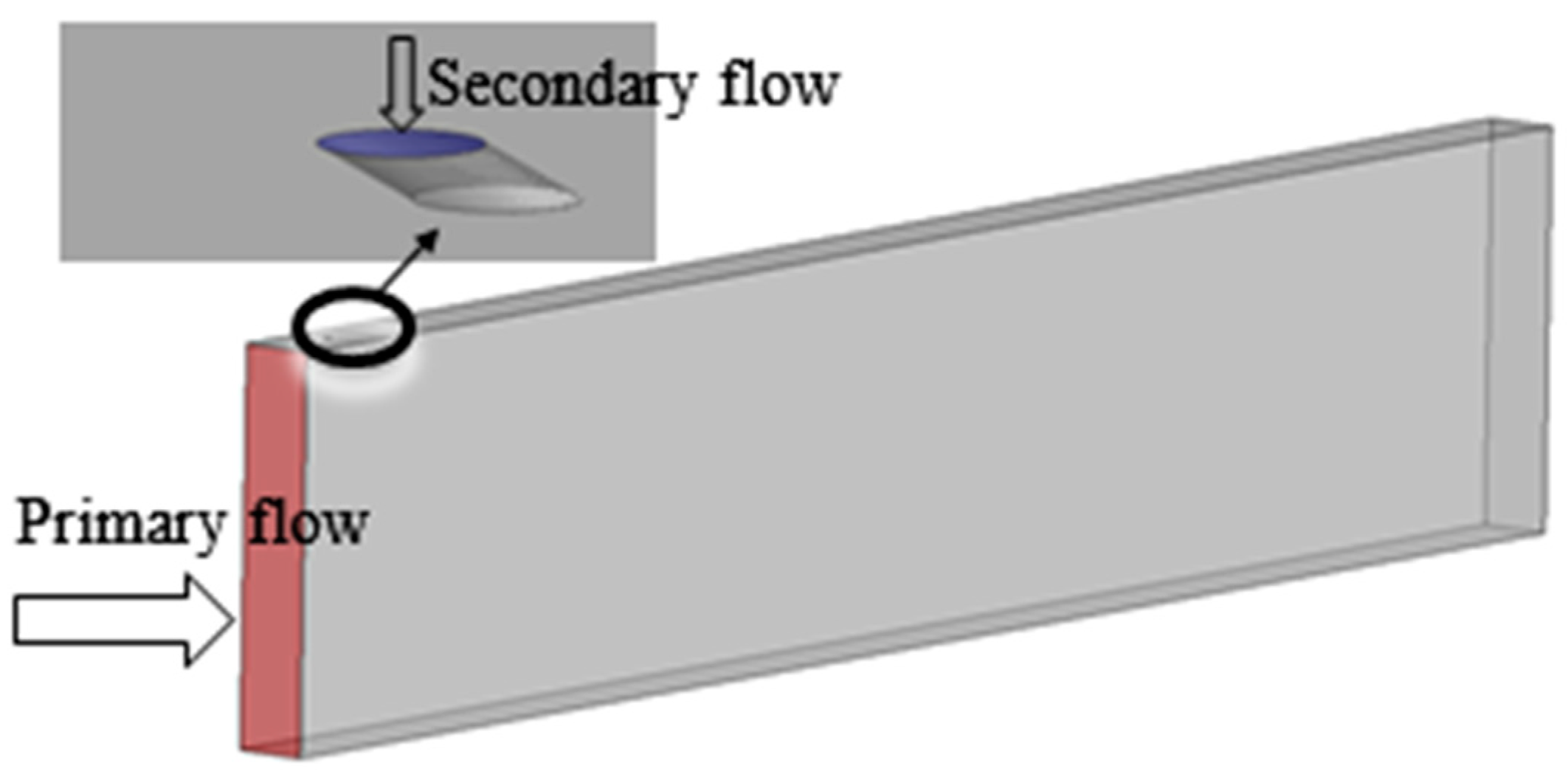

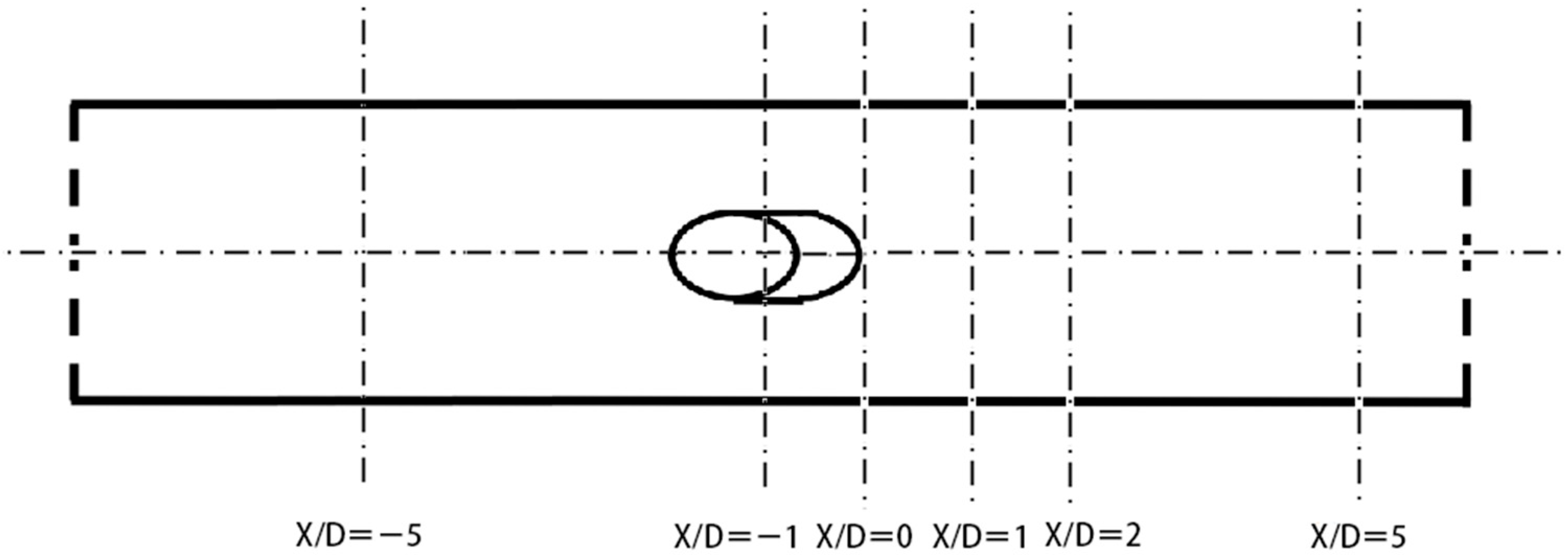

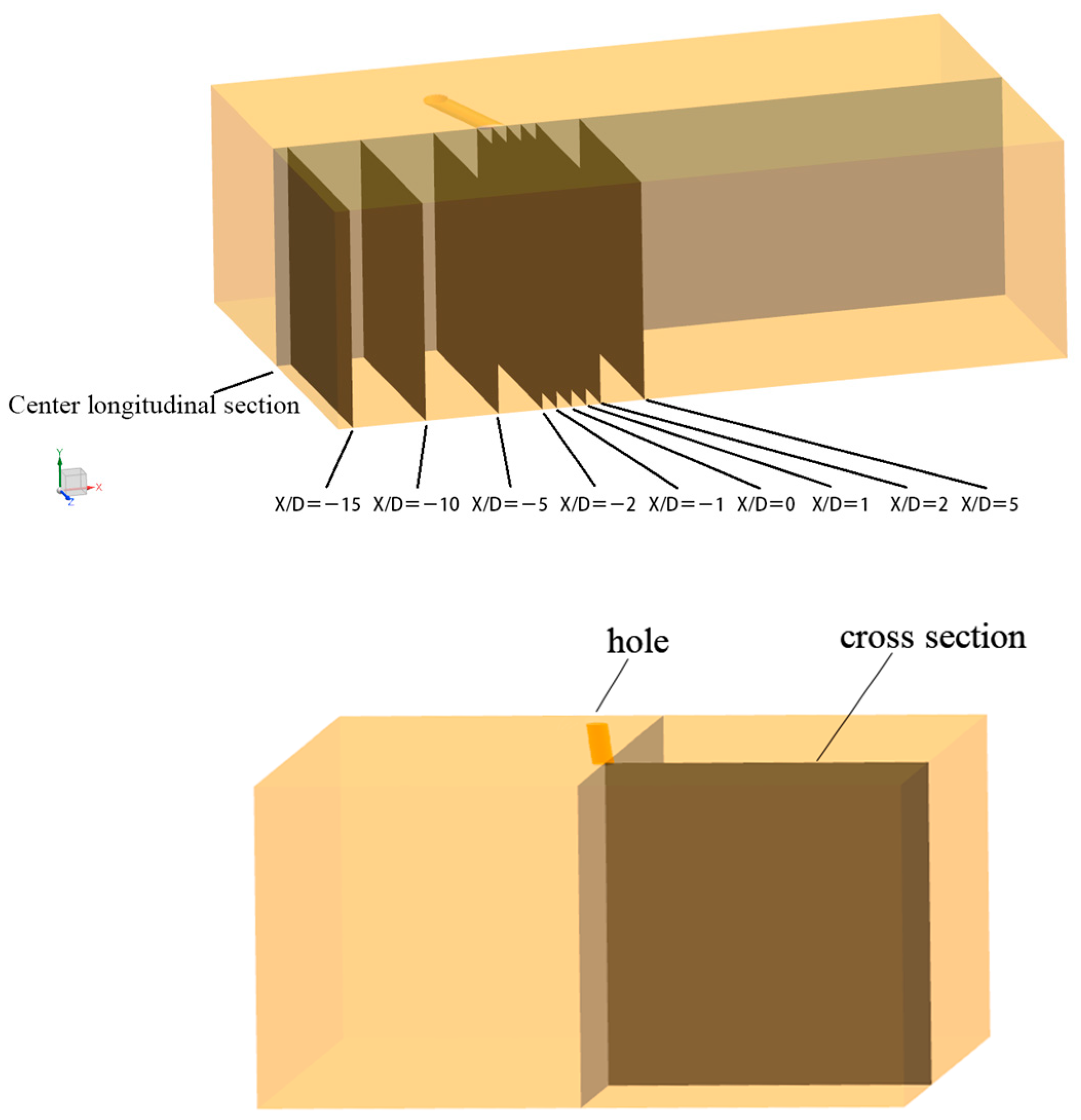

2. Physical Model

3. Computational Domain and Boundary Conditions

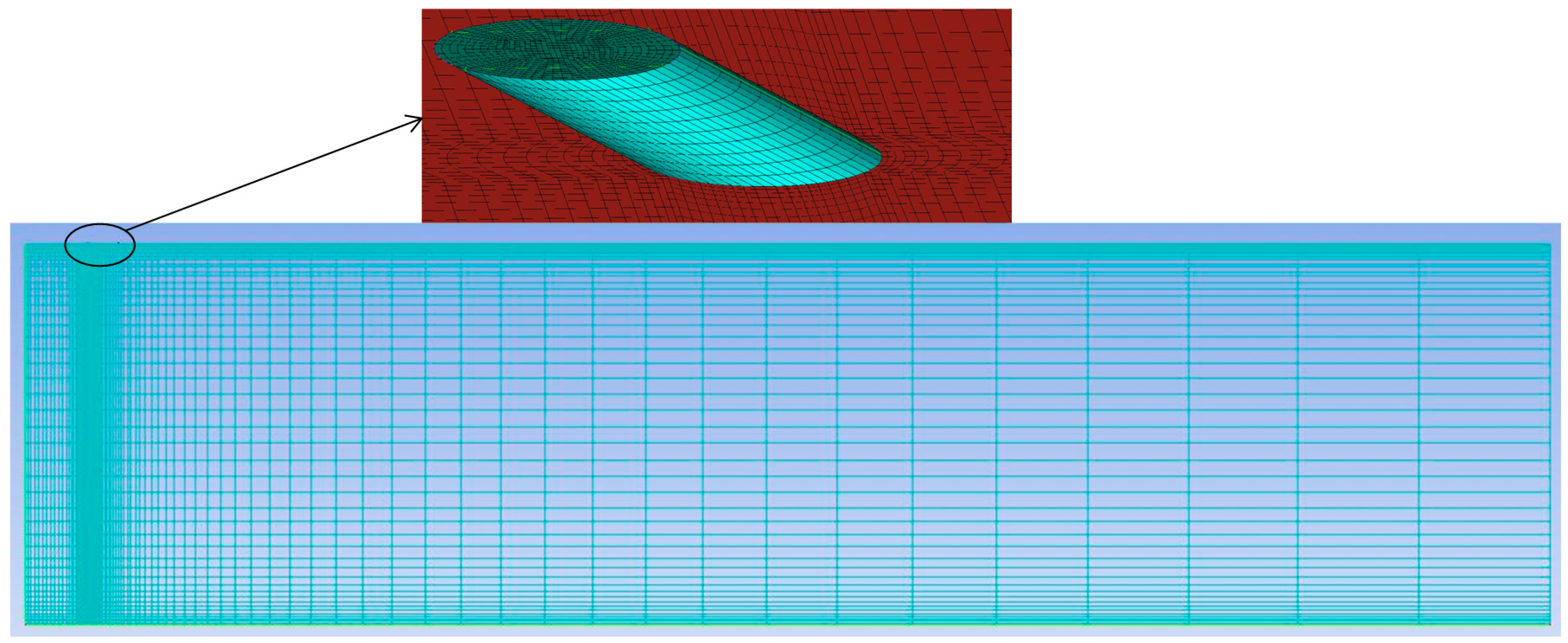

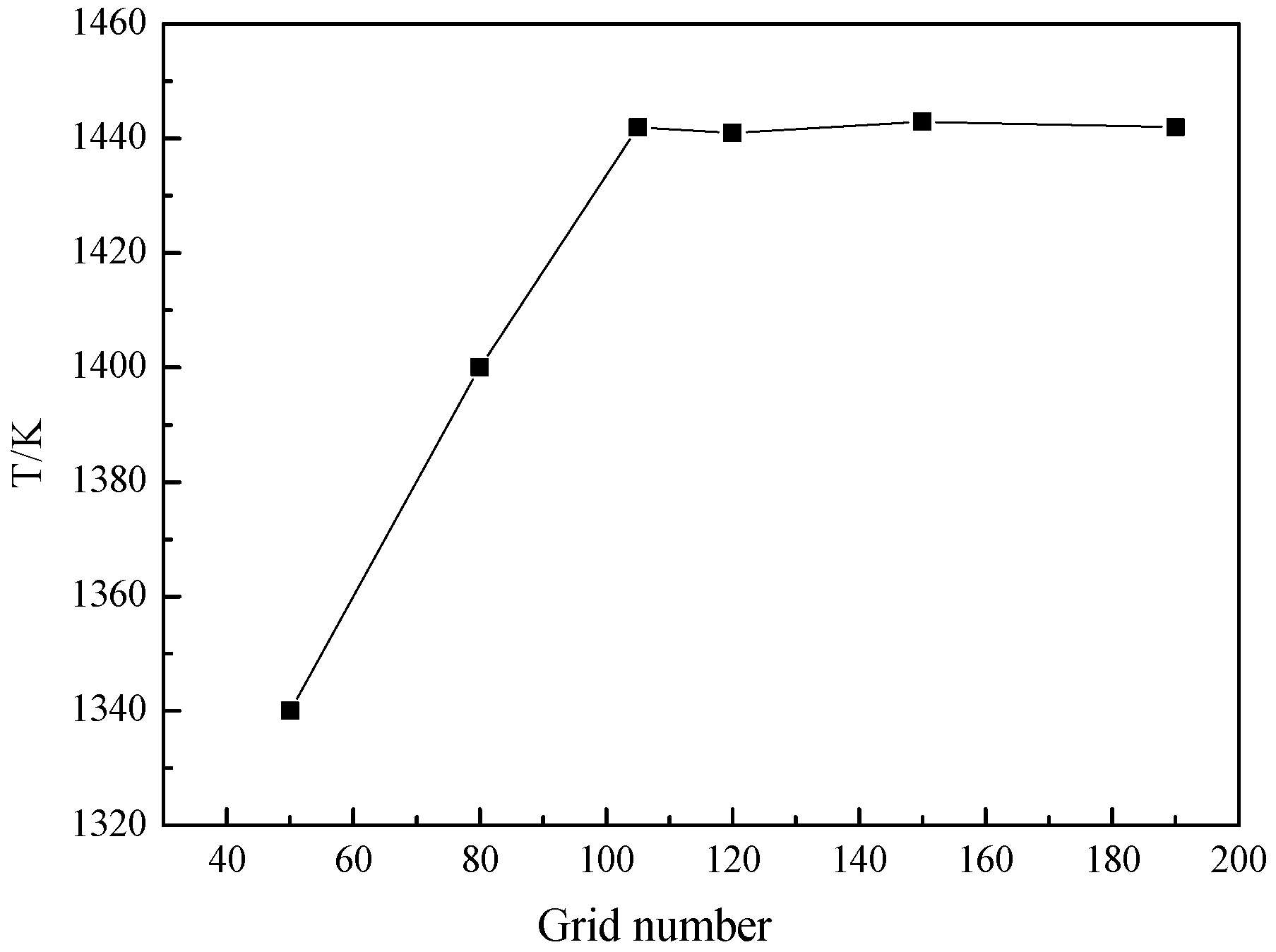

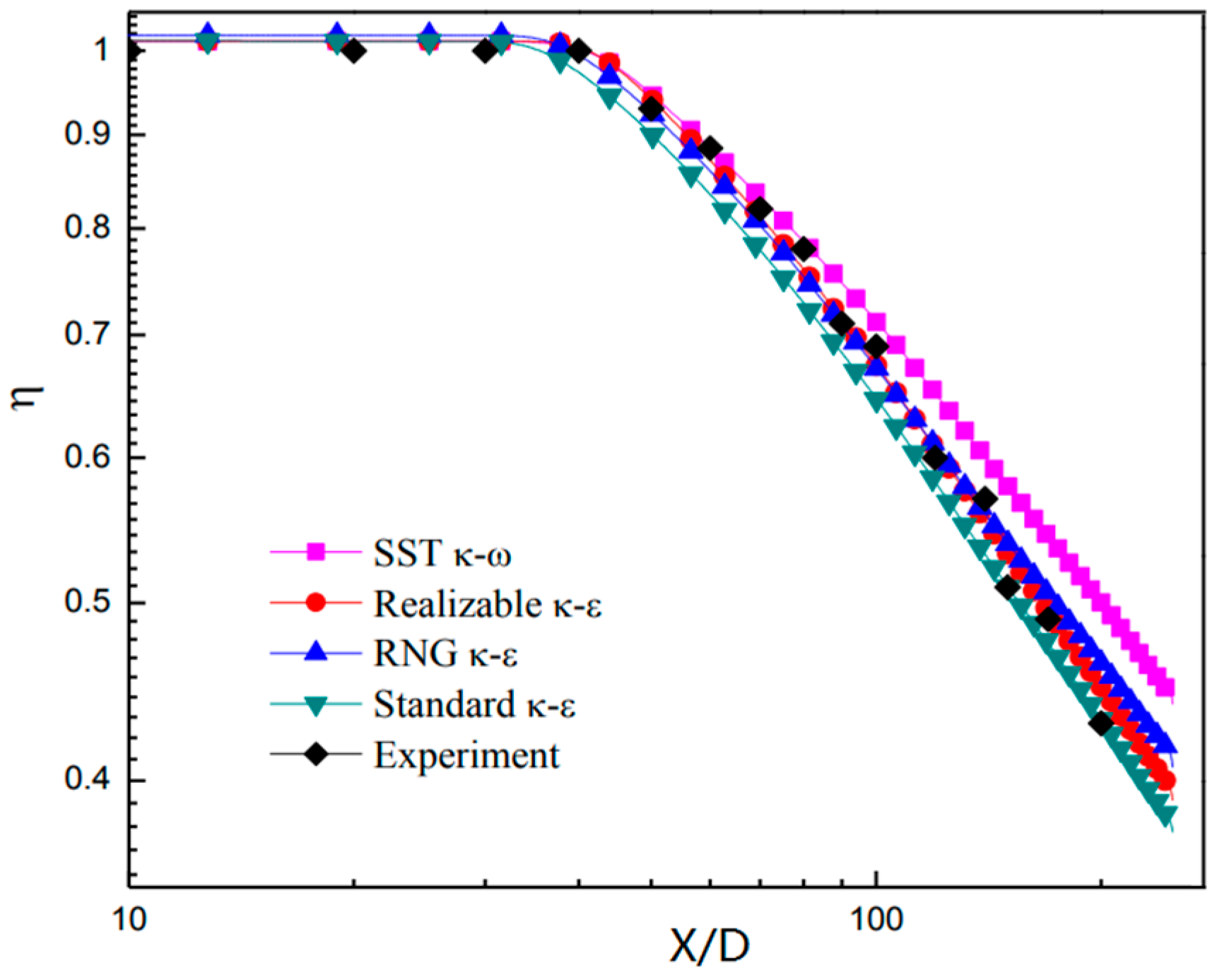

4. Division of Grids and Verification of Grid Independence

5. Computational Method

6. Results and Analysis

6.1. Wall Cooling Efficiency and Wall Temperature Distribution

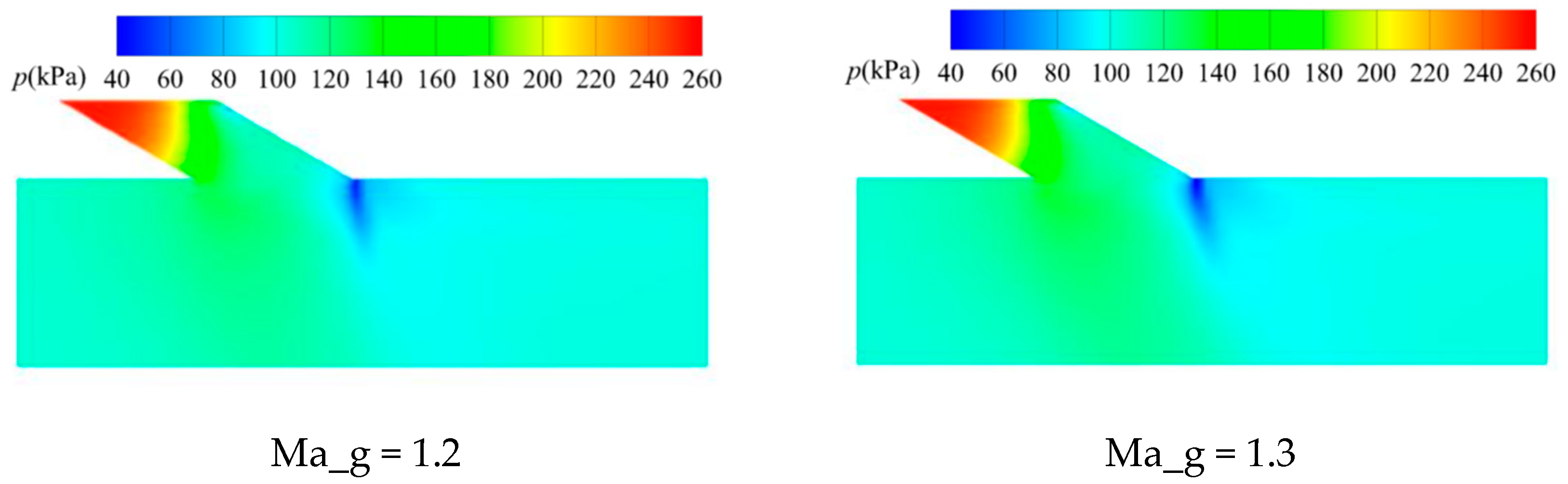

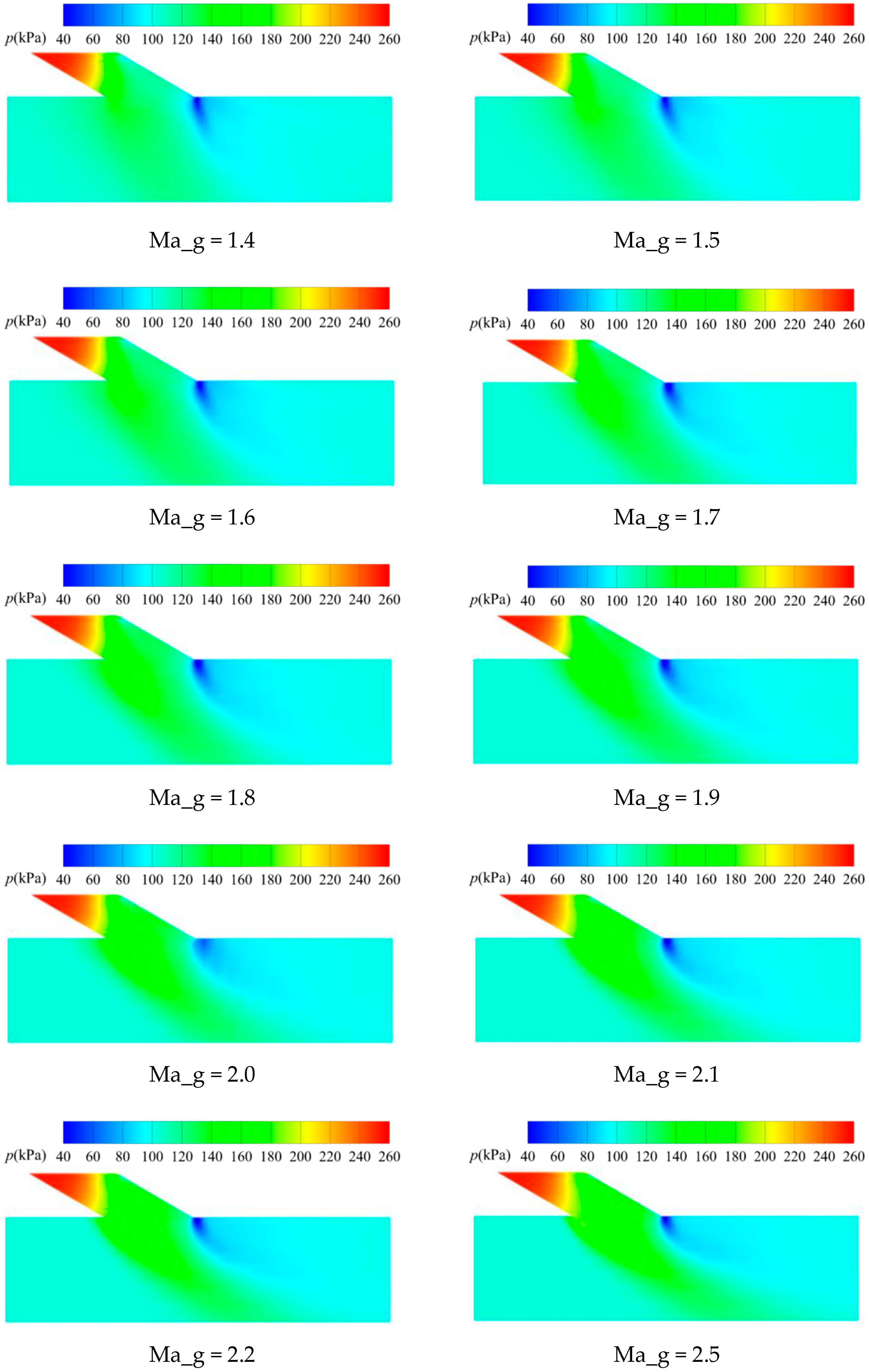

6.2. Longitudinal Cross-Section Flow Field at Incident Position

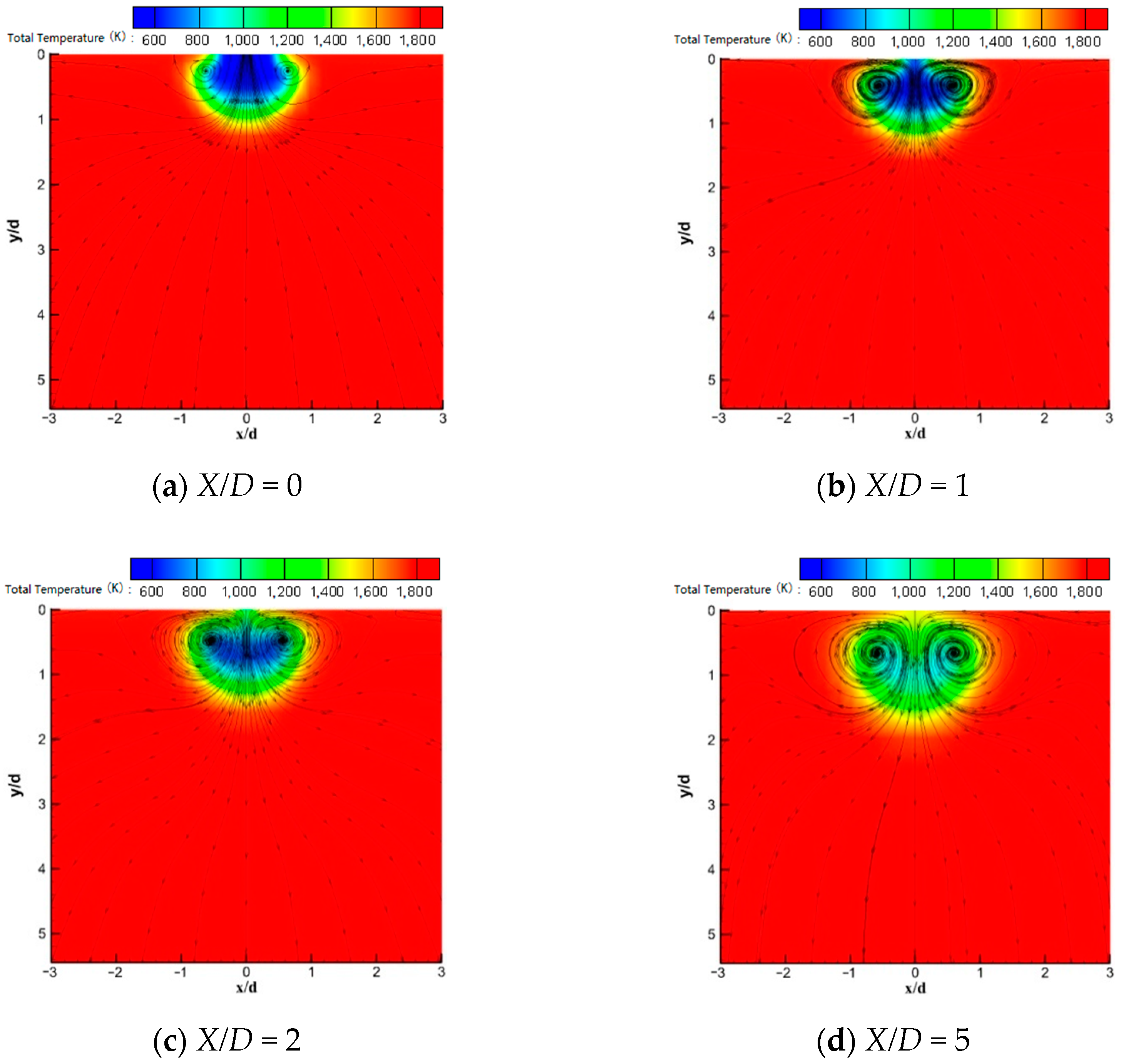

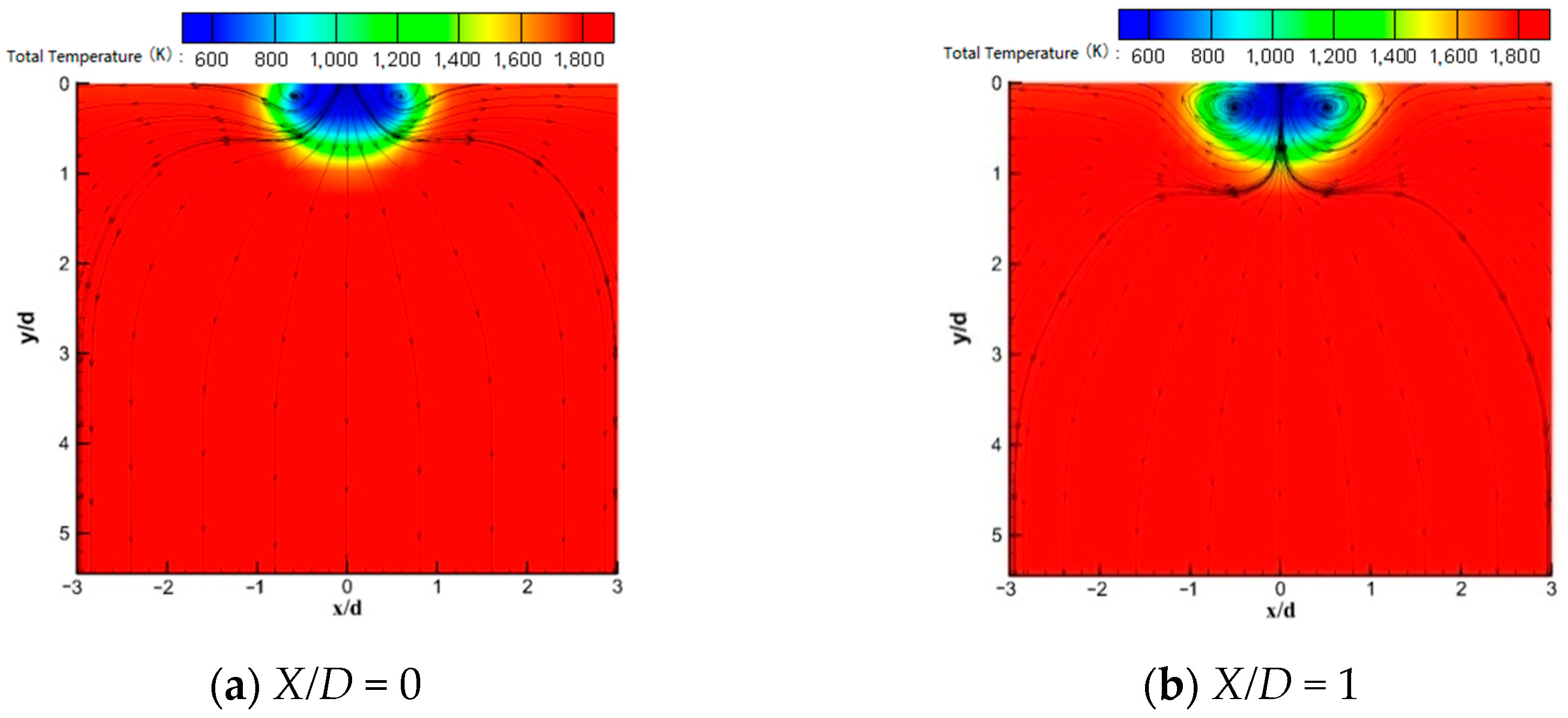

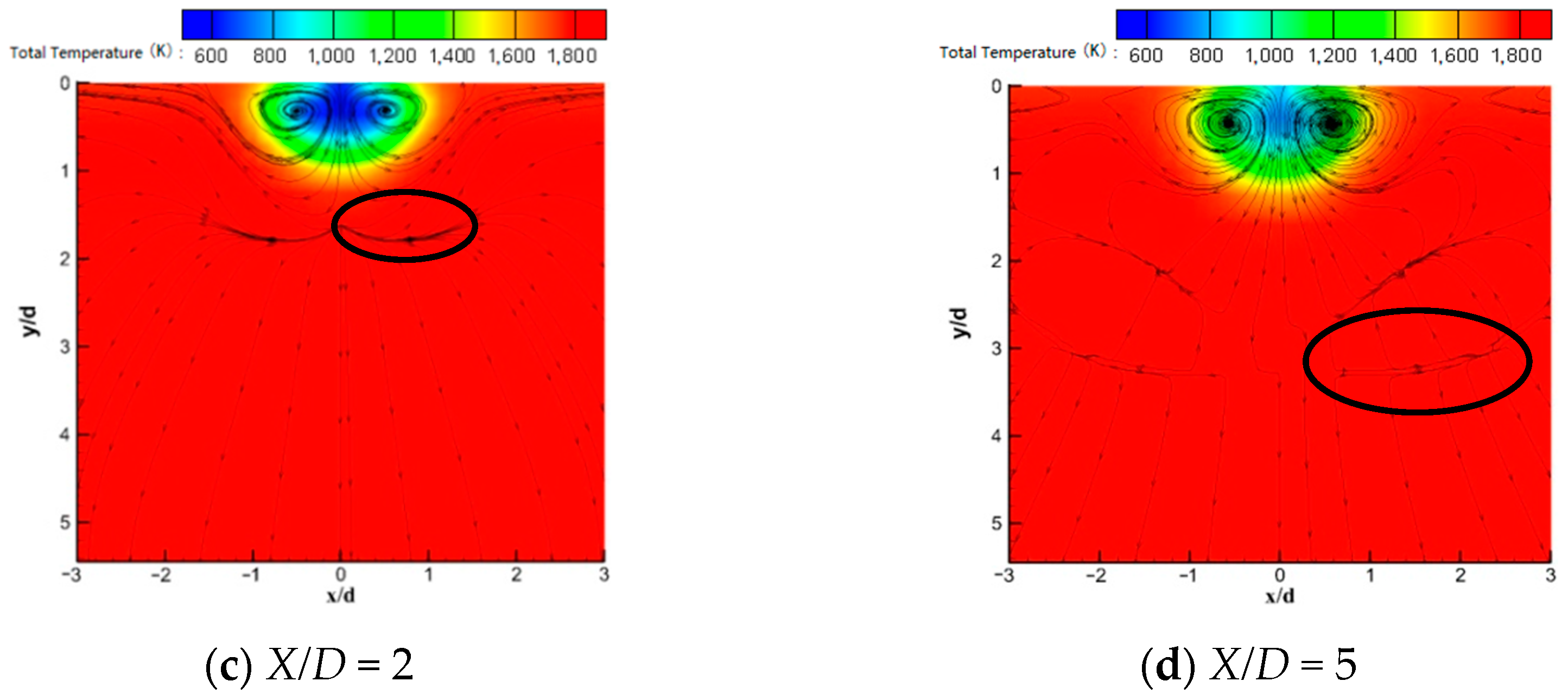

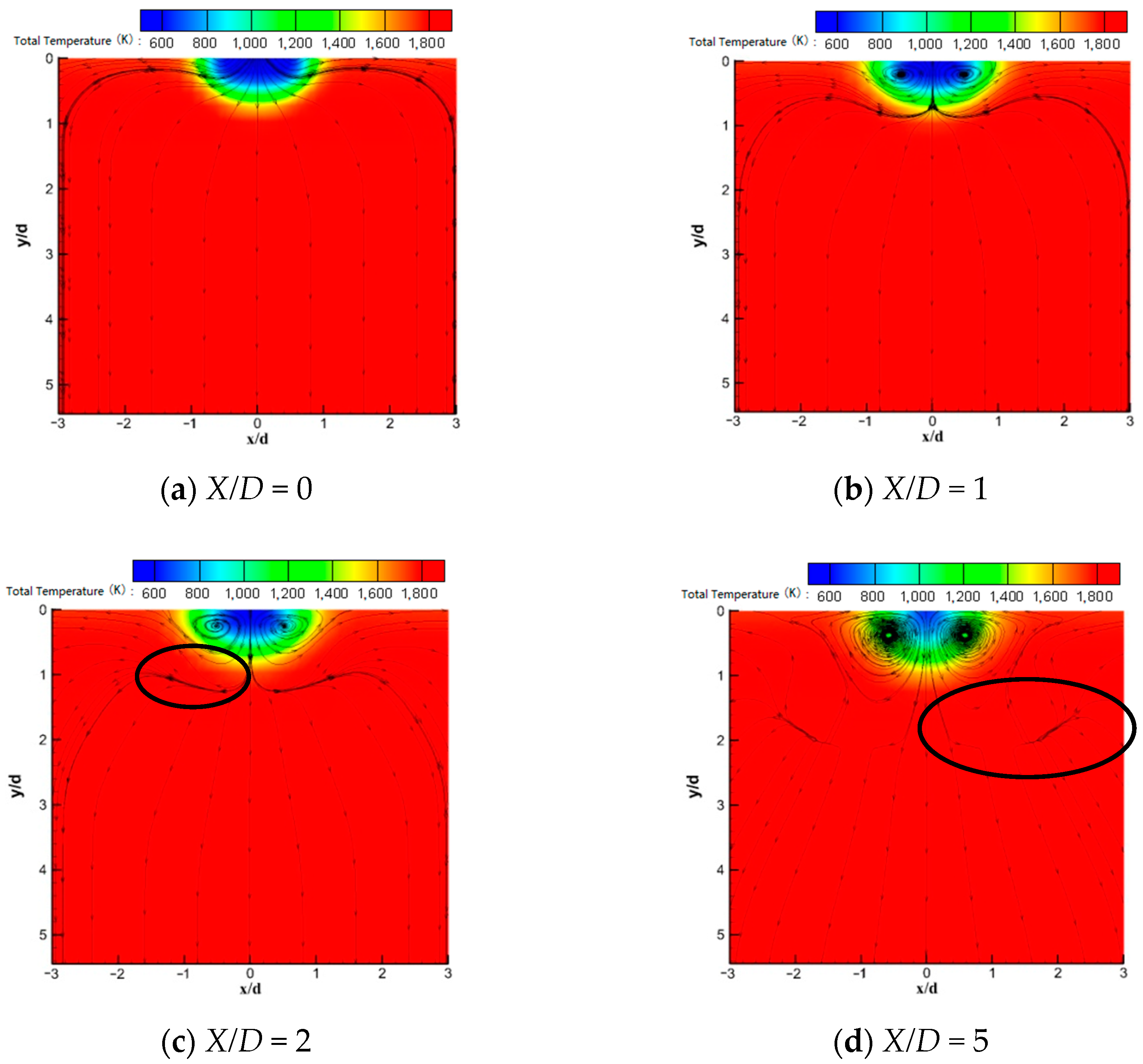

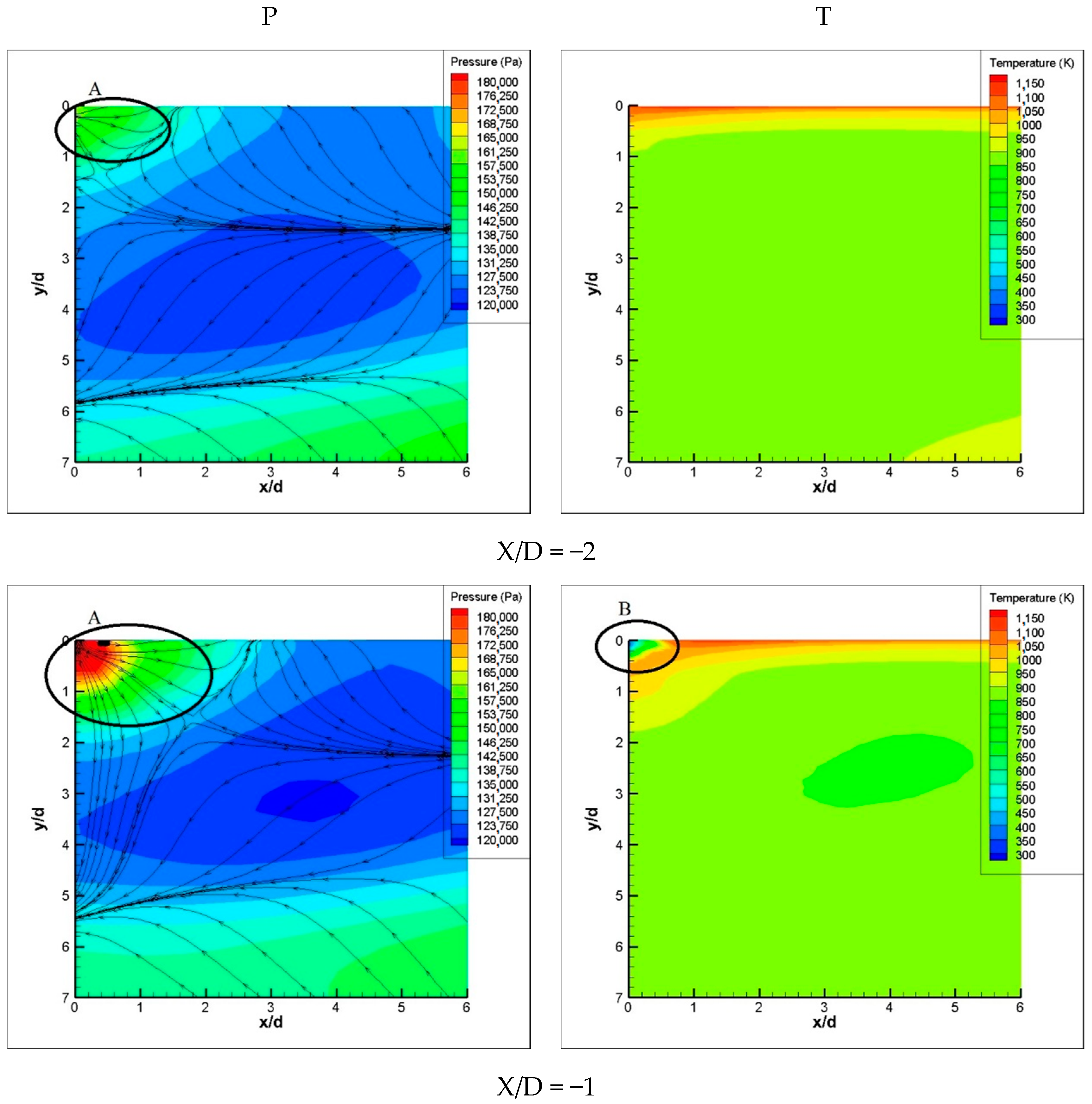

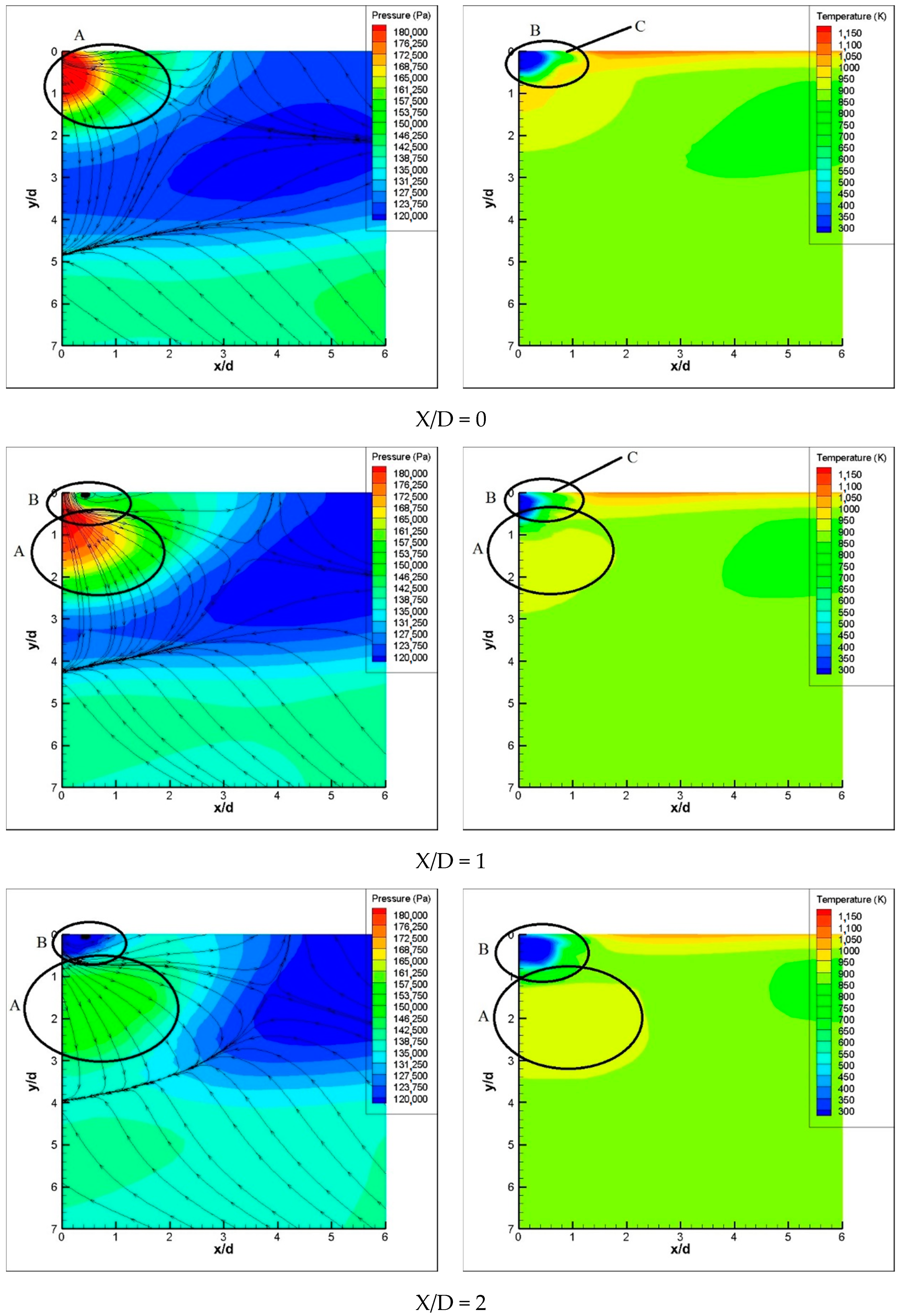

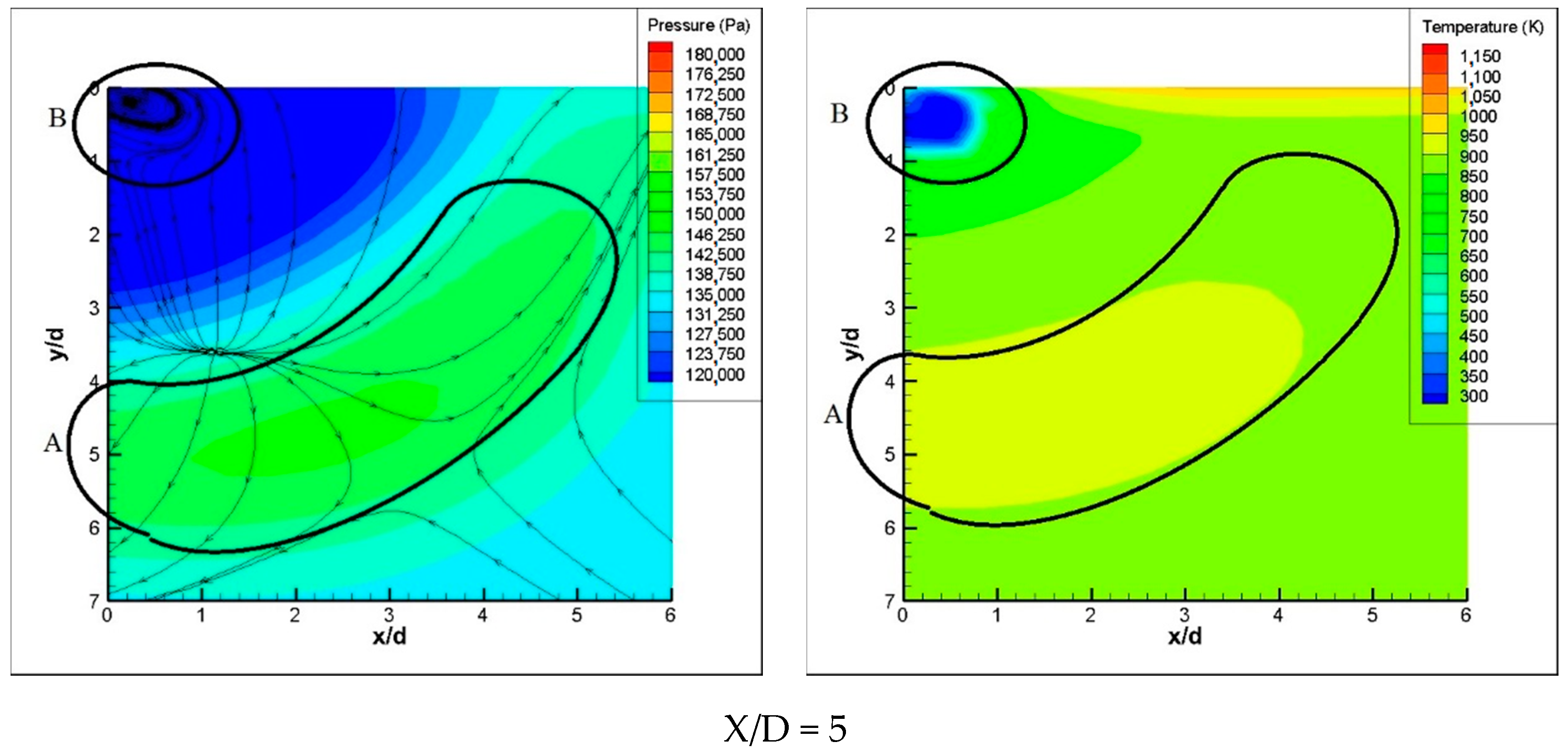

6.3. Vortices Distribution in the Cross Section Downstream

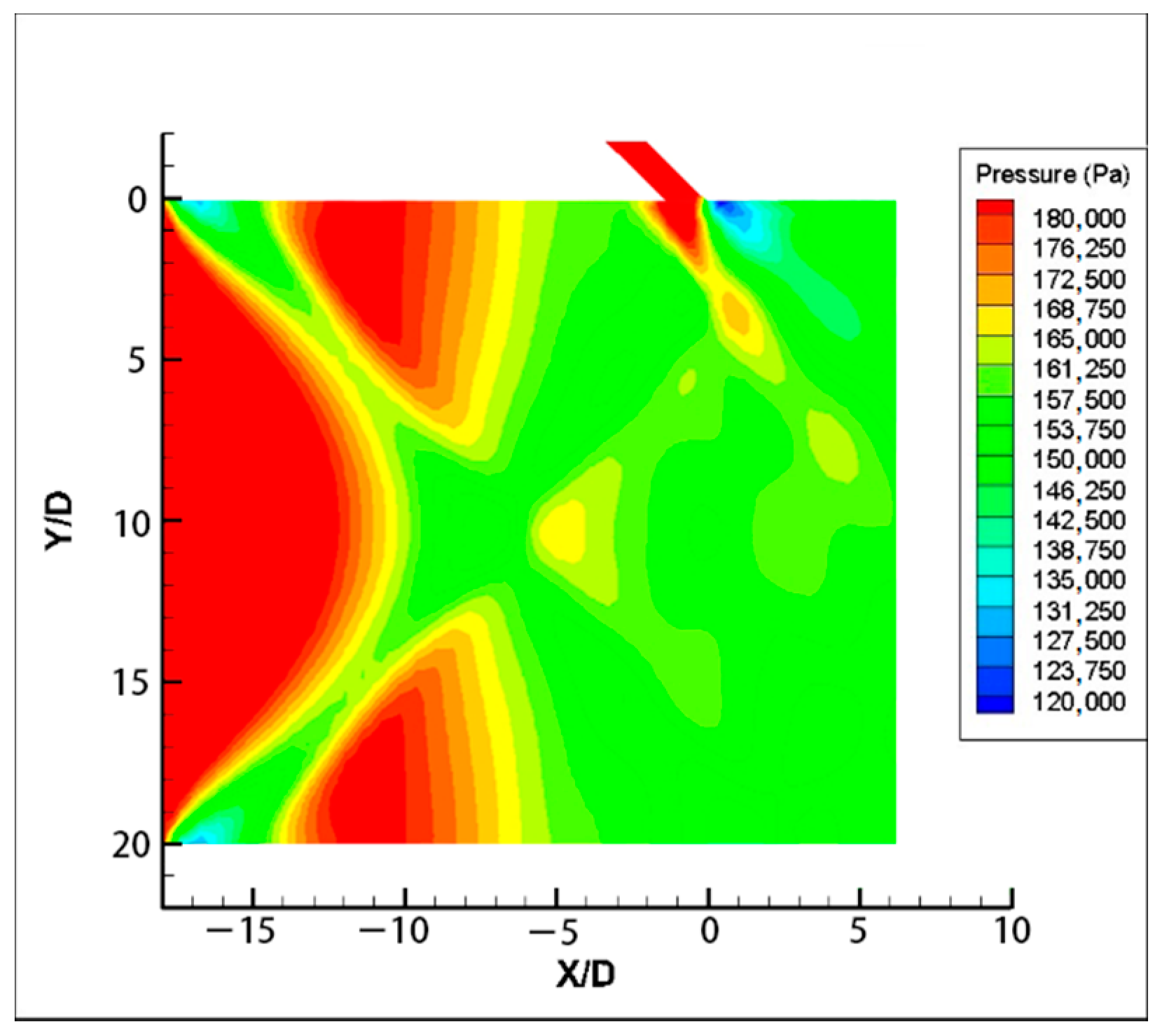

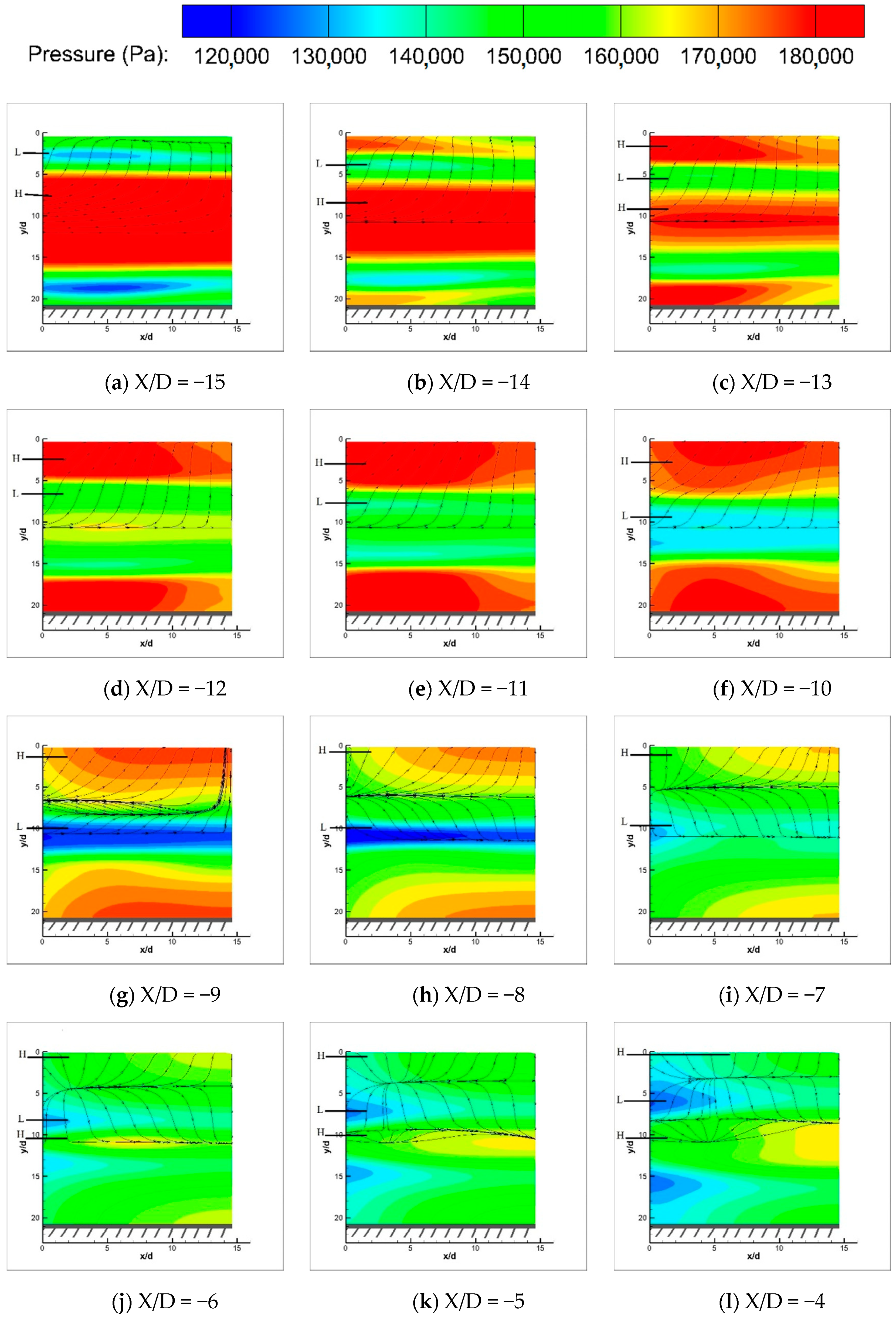

6.4. Phenomenon of Stratified Flow of the Main Flow in Hypersonic Speed

6.4.1. Changes of the Stratified Flow Phenomenon along the Streamwise Flow

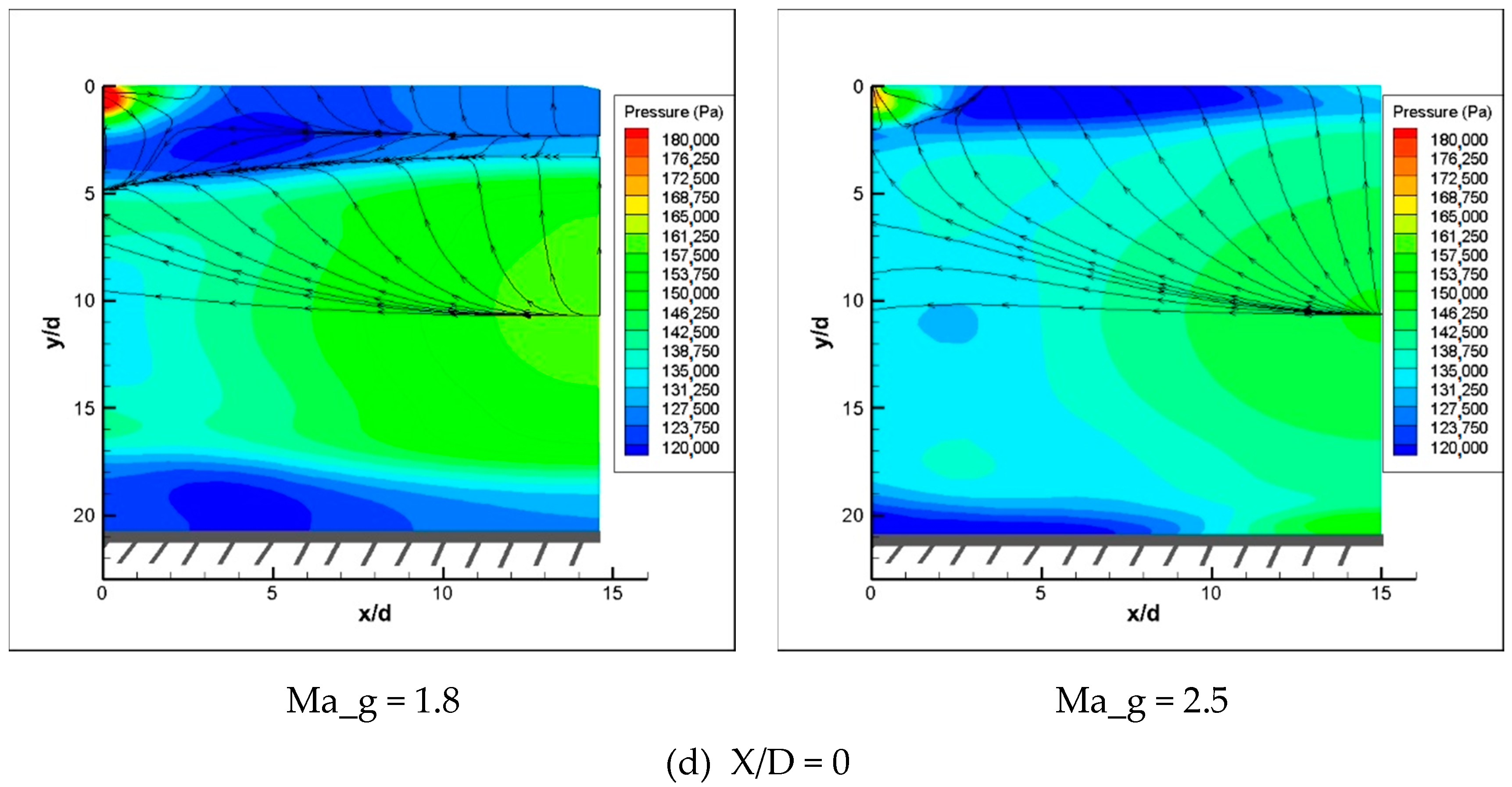

6.4.2. Changes of the Stratified Flow Phenomenon with Ma_g

7. Conclusions

- (1)

- Under supersonic main stream conditions, the increasing of Ma_g always causes the film jet to main flow ratio to decrease. The relatively small amount of film jet weakens its mixing with the main flow, leading to a better attachment of the film.

- (2)

- Multi-interfacial layered structures were formed as the film jet flew across shock waves. At the interfaces of the film jet and shock waves, additional pressure was exerted on the film towards the wall. The pressure increased as the Mach number of main flow increased; this contributed to the increased adhesion of the gas film, which caused the cooling enhancement under supersonic condition.

- (3)

- In the vicinity of the film hole exit, a local low pressure region was formed under the influence of the supersonic main flow. An aerodynamic convergent–divergent state was formed in the film hole, devastating the state of supersonic congestion of the film hole and further enhancing the film cooling effect.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hartnett, J.P.; Birkebak, R.C.; Eckert, E.R.G. Velocity distributions, temperature distributions effectiveness and heat transfer in cooling of a surface with a pressure gradient. Int. Dev. Heat Transf. 1961, 682–689. [Google Scholar] [CrossRef]

- Bergeles, G.; Gosman, A.D.; Launder, B.E. Double-row discrete holes cooling: An experimental and numerical study. ASME J. Eng. Power 1980, 102, 498–503. [Google Scholar] [CrossRef]

- Bons, J.P.; Macarthur, C.D.; Rivir, R.B. The effect of high freestream turbulence on film cooling effectiveness. ASME J. Turbo Mach. 1996, 118, 814–825. [Google Scholar] [CrossRef]

- Jiang, P.X.; Wang, B.X.; Luo, D.A.; Ren, Z.P. Fluid flow and convective heat transfer in a vertical porous annulus. Numer. Heat Transf. 1996, 30, 305–320. [Google Scholar] [CrossRef]

- Goldfield, M.L.; Sargison, J.E. A converging slot-hole file-cooling geometry-part 2: Transonic nozzle guide vane heat transfer and loss. ASME J. Turbo-Mach. 2002, 124, 461–471. [Google Scholar]

- Rozati, A.; Danesh, K.T. Effect of coolant-mainstream blowing ratio on leading edge film cooling flow and heat transfer-LES investigation. Int. J. Heat Fluid Flow 2008, 120, 857–873. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Xie, H.; Yang, C.F. Numerical study of flow and heat transfer characteristics of impingement/effusion cooling. Chin. J. Aeronaut. 2009, 22, 343–348. [Google Scholar]

- Vos, R.; Farokhi, S. Airfoil Aerodynamics. In Introduction to Transonic Aerodynamics; Springer: Dordrecht, The Netherlands, 2015; Volume 110, pp. 367–425. Available online: http://dl.samegp.com/Digital_Liblary/Transonic%20Flow/(Fluid%20Mechanics%20and%20Its%20Applications%20110)%20Roelof%20Vos,%20Saeed%20Farokhi%20(auth.)%20-%20Introduction%20to%20Transonic%20Aerodynamics-Springer%20Netherlands%20(2015).pdf (accessed on 9 December 2020).

- Seddon, J. The Flow Produced by Interaction of a Turbulent Boundary Layer with a Normal Shock Wave of Strength Sufficient to Cause Separation; Her Majesty’s Stationery Office: London, UK, 1967. [Google Scholar]

- Matsuo, K.; Miyazato, Y.; Kim, H.D. Shock train and Pseudo-shock phenomena in internal gas flows. Prog. Aerosp. Sci. 1999, 35, 33–100. [Google Scholar] [CrossRef]

- Pirozzoli, S.; Bernardini, M.; Grasso, F. Direct numerical simulation of transonic shock/boundary layer interaction under conditions of incipient separation. J. Fluid Mech. 2010, 657, 361–393. [Google Scholar] [CrossRef]

- Sirieix, M.; Delery, J.; Stanewsky, E. High-Reynolds Number Boundary-Layer Shock-Wave Interaction in Transonic Flow. In Advances in Fluid Mechanics; Lecture Notes in Physics; Krause, E., Ed.; Springer: Berlin/Heidelberg, Germany, 1981. [Google Scholar]

- Holger, B. Shock Wave Boundary Layer Interactions. In Shock Wave-Boundary-Layer Interactions; Cambridge University Press: Cambridge, UK, 2011; Available online: https://assets.cambridge.org/97805218/48527/frontmatter/9780521848527_frontmatter.pdf (accessed on 9 December 2020).

- Konopka, M.; Meinke, M.; Schröder, W. Large-eddy simulation of shock/cooling-film interaction. AIAA J. 2012, 50, 2102–2111. [Google Scholar] [CrossRef]

- Delery, J.M. Shock Wave/turbulent Boundary Layer Inter- action and Its Control. Progress in Aerospace Sciences 1985, 22, 209–280. [Google Scholar] [CrossRef]

- Dolling, D.S. Fifty years of shock-wave/boundary layer interaction research: What next? AIAA J. 2001, 39, 1517–1531. [Google Scholar] [CrossRef]

- Delery, J.; Dussauge, J.P. Some physical aspects of shock wave/boundary layer interactions. Shock Waves 2009, 19, 453–468. [Google Scholar] [CrossRef]

- Dickmann, D.A.; Lu, F. Jet in Supersonic Crossflow on a Flat Plate. In Proceedings of the 25th AIAA Aerodynamic Measurement Technology and Ground Testing Conference, San Francisco, CA, USA, 5–8 June 2006. [Google Scholar]

- Viti, V.; Neel, R.; Schetz, J.A. Detailed Flow Physics of the Supersonic Jet Interaction Flow Field. Phys. Fluids 2009, 21, 046101. [Google Scholar] [CrossRef]

- Zhu, Y.; Jiang, P. Experimental and numerical investigation of the effect of shock wave characteristics on the ejector performance. Int. J. Refrig. 2014, 40, 31–42. [Google Scholar] [CrossRef]

- Zhu, Y.H.; Cai, W.J.; Wen, C.Y.; Li, Y.Z. Shock circle model for ejector performance evaluation. Energy Convers. Manag. 2007, 48, 2533–2541. [Google Scholar] [CrossRef]

- Zhang, B.; Bai, Y. Numerical investigation of heat transfer in film layer under supersonic condition of convergent-divergent transition. Therm. Sci. 2020, 24, 2279–2288. [Google Scholar] [CrossRef]

- Heufer, K.A.; Olivier, H. Experimental and numerical investigation of film cooling in hypersonic flows. In Shock Waves; Hannemann, K., Seiler, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Alzner, E.; Zakkay, V. Turbulent boundary layer shock interaction with and without injection. AIAA J. 1971, 9, 1769–1776. [Google Scholar] [CrossRef]

- Kanda, T.; Ono, F.; Saito, T. Experimental studies of supersonic film cooling with shock wave interaction. AIAA J. 1996, 34, 265–271. [Google Scholar] [CrossRef]

- Juhany, K.A.; Hunt, M.L. Flow field measurements in supersonic film cooling including the effect of shock-wave interaction. AIAA J. 1994, 32, 578–585. [Google Scholar] [CrossRef]

- Zhang, B.; Lin, L.B. Effect of forward expansion angle on film cooling characteristics of shaped holes. Open Phys. 2020, 18, 302–314. [Google Scholar] [CrossRef]

| Total Temperature of Main Flow, Tt_g | Mach Number of Main Flow, Ma_g | Total Temperature of Film Jet, Tt_c | Total Pressure of Film Jet, Pt_c | Static Pressure at Main Flow Outlet, Pb |

|---|---|---|---|---|

| 1900 K | 1.2–2.5 | 500 K | 0.25 MPa | 101,325 Pa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Chen, Y.-X.; Wang, Z.-g.; Li, J.-Q.; Ji, H.-h. Influence of Mach Number of Main Flow on Film Cooling Characteristics under Supersonic Condition. Symmetry 2021, 13, 127. https://doi.org/10.3390/sym13010127

Zhang B, Chen Y-X, Wang Z-g, Li J-Q, Ji H-h. Influence of Mach Number of Main Flow on Film Cooling Characteristics under Supersonic Condition. Symmetry. 2021; 13(1):127. https://doi.org/10.3390/sym13010127

Chicago/Turabian StyleZhang, Bo, Yuan-Xiang Chen, Zhi-guo Wang, Ji-Quan Li, and Hong-hu Ji. 2021. "Influence of Mach Number of Main Flow on Film Cooling Characteristics under Supersonic Condition" Symmetry 13, no. 1: 127. https://doi.org/10.3390/sym13010127

APA StyleZhang, B., Chen, Y.-X., Wang, Z.-g., Li, J.-Q., & Ji, H.-h. (2021). Influence of Mach Number of Main Flow on Film Cooling Characteristics under Supersonic Condition. Symmetry, 13(1), 127. https://doi.org/10.3390/sym13010127