A Gradient-Free Topology Optimization Strategy for Continuum Structures with Design-Dependent Boundary Loads

Abstract

:1. Introduction

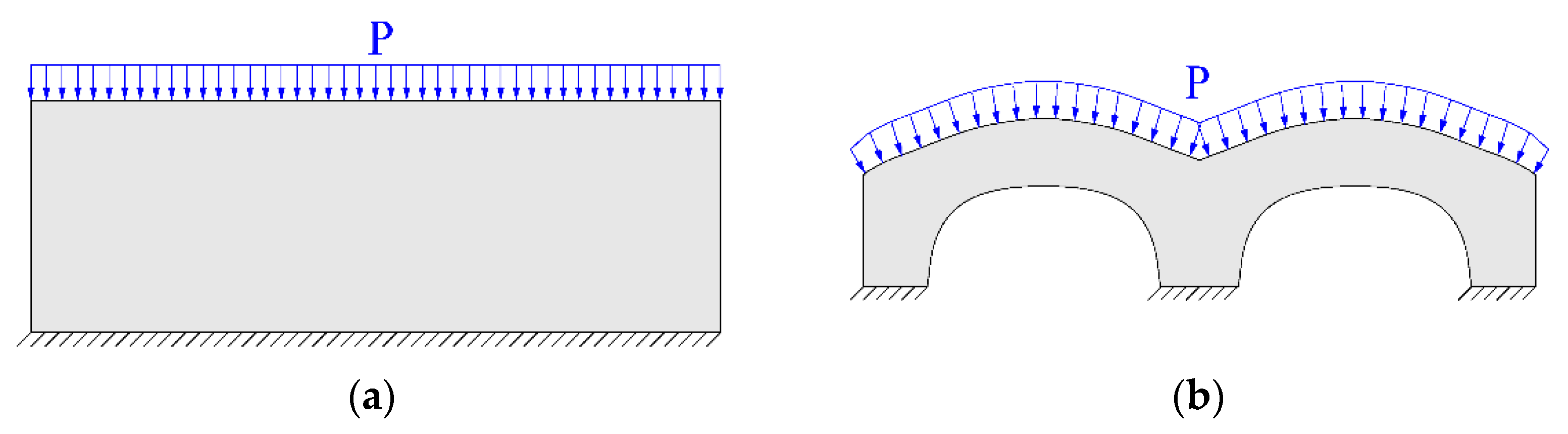

2. Minimum Compliance Design Problem of the Structures with Design-Dependent Loads

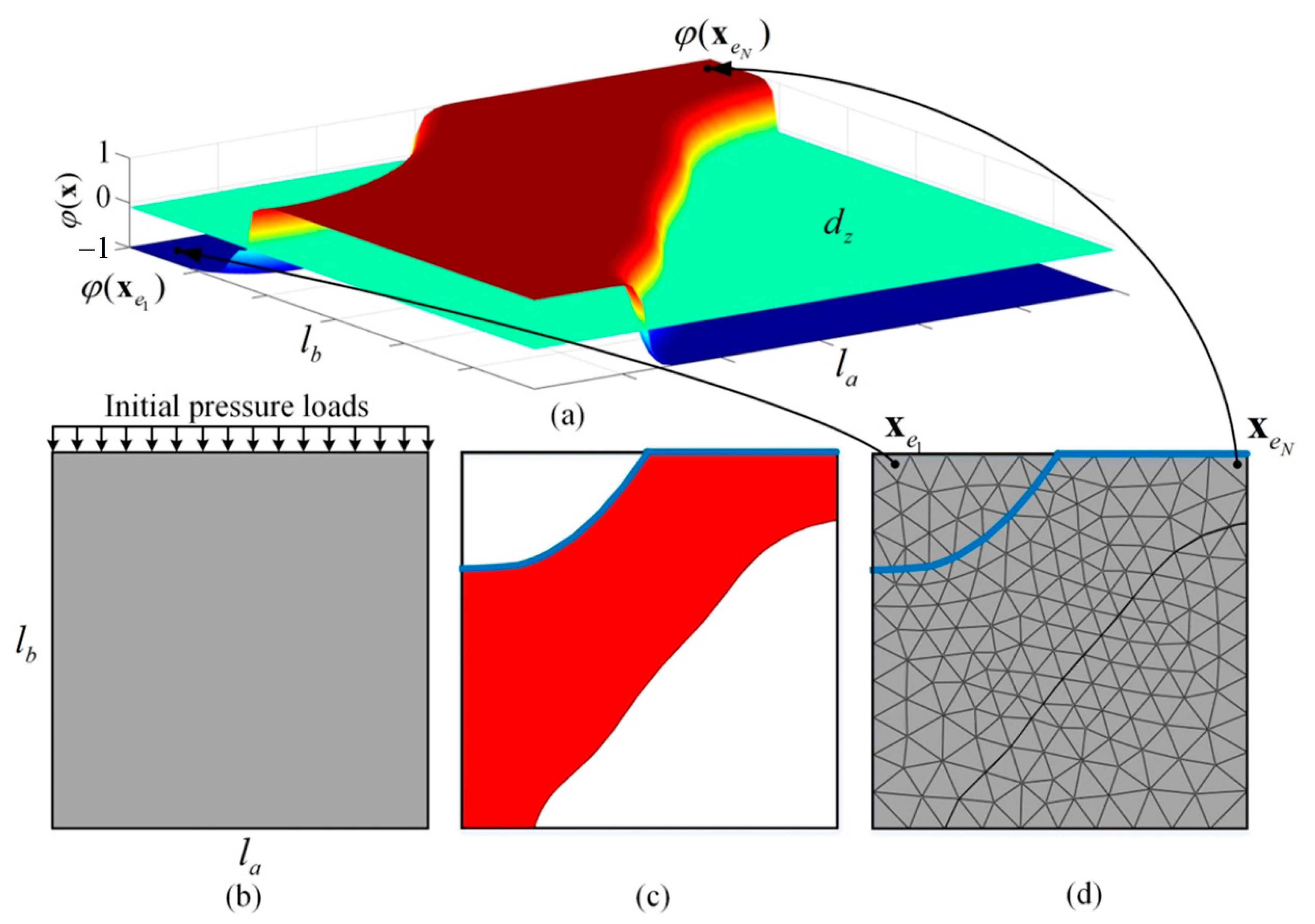

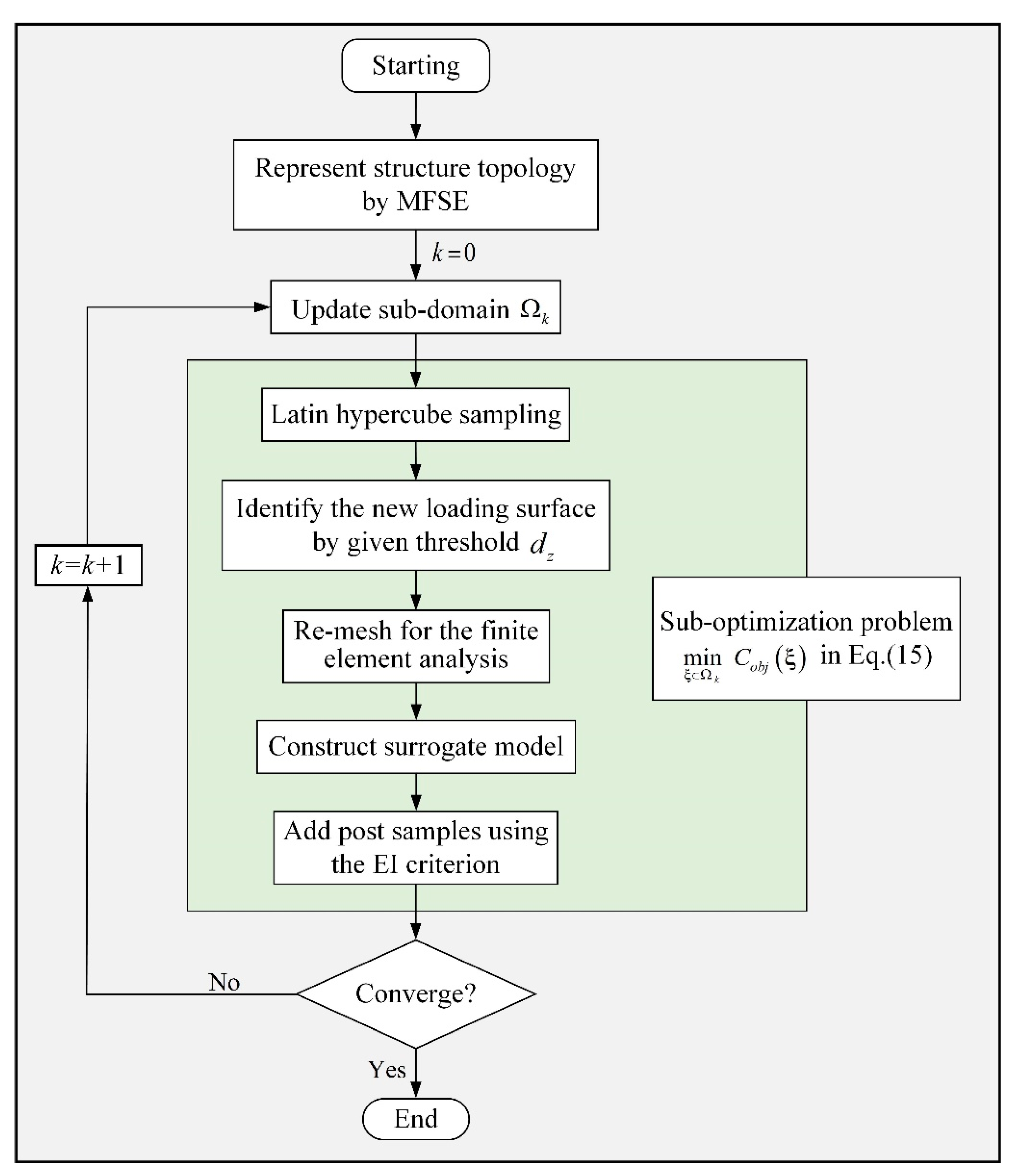

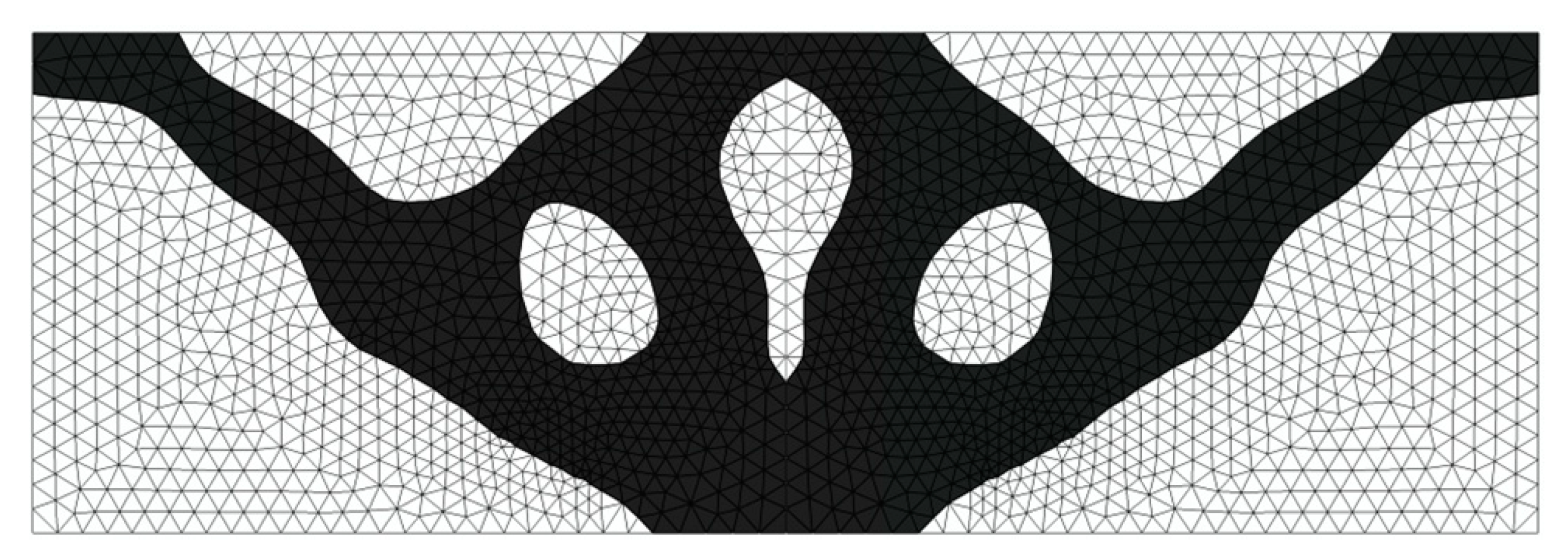

3. Topology Optimization Based on Material-Field Series Expansion Model and Adaptive Body-Fitted Mesh

3.1. Bounded Material Field Definition

3.2. Reduced Series Expansion of the Material Field

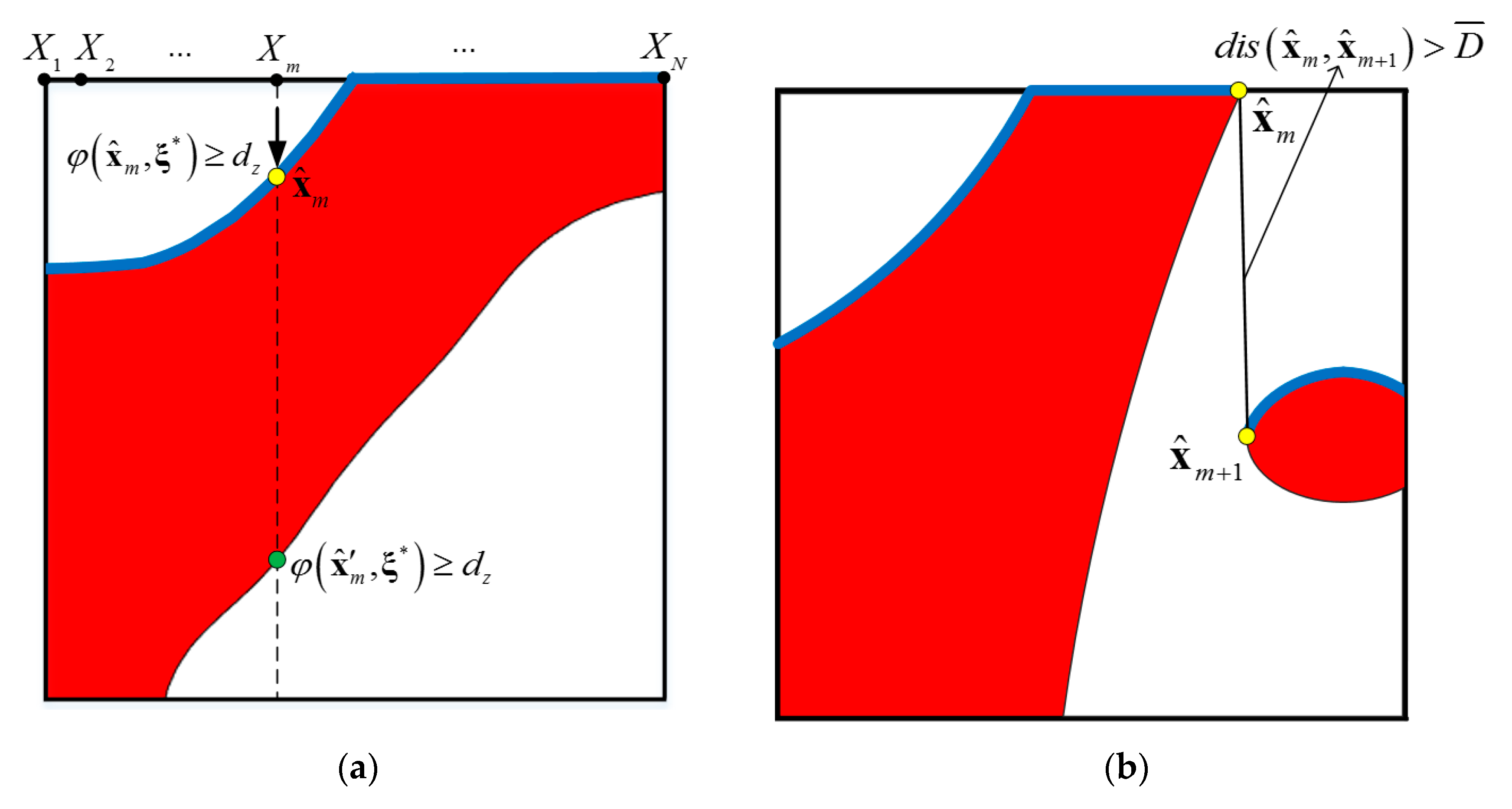

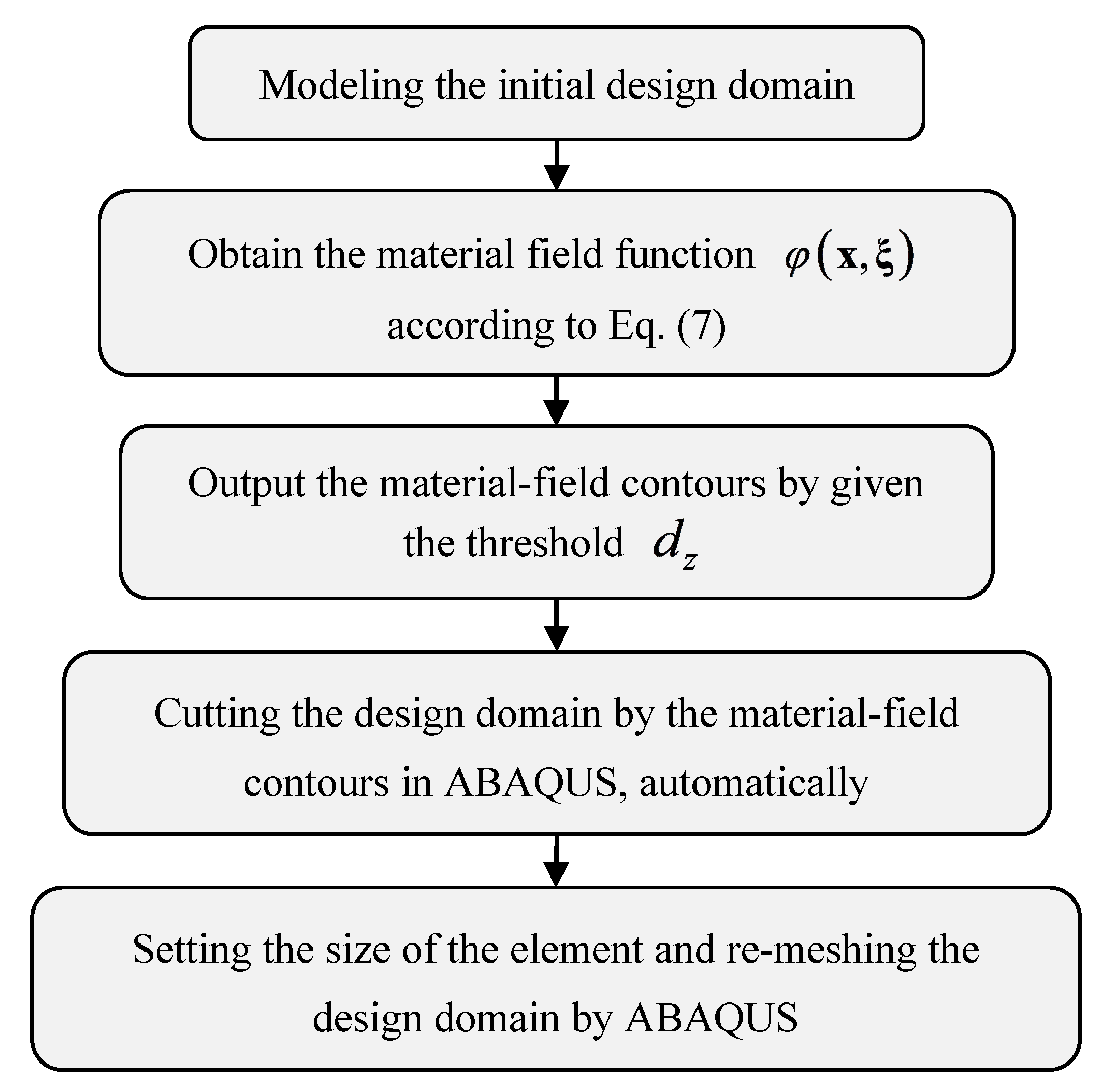

3.3. Identification of the Loading Surface

- Step 1:

- Represent the Material-Field Function Using Series Expansion

- Step 2:

- Determine the Load-Carrying Parts and Update the Loading Surface

- Step 3:

- Apply the Pressure Loads and Re-Meshing for the Finite Element Analysis

3.4. Topology Optimization Formulation for the Structures with Design-Dependent Boundary Loads

4. Sequential Kriging-Based Optimization Algorithm

5. Numerical Examples

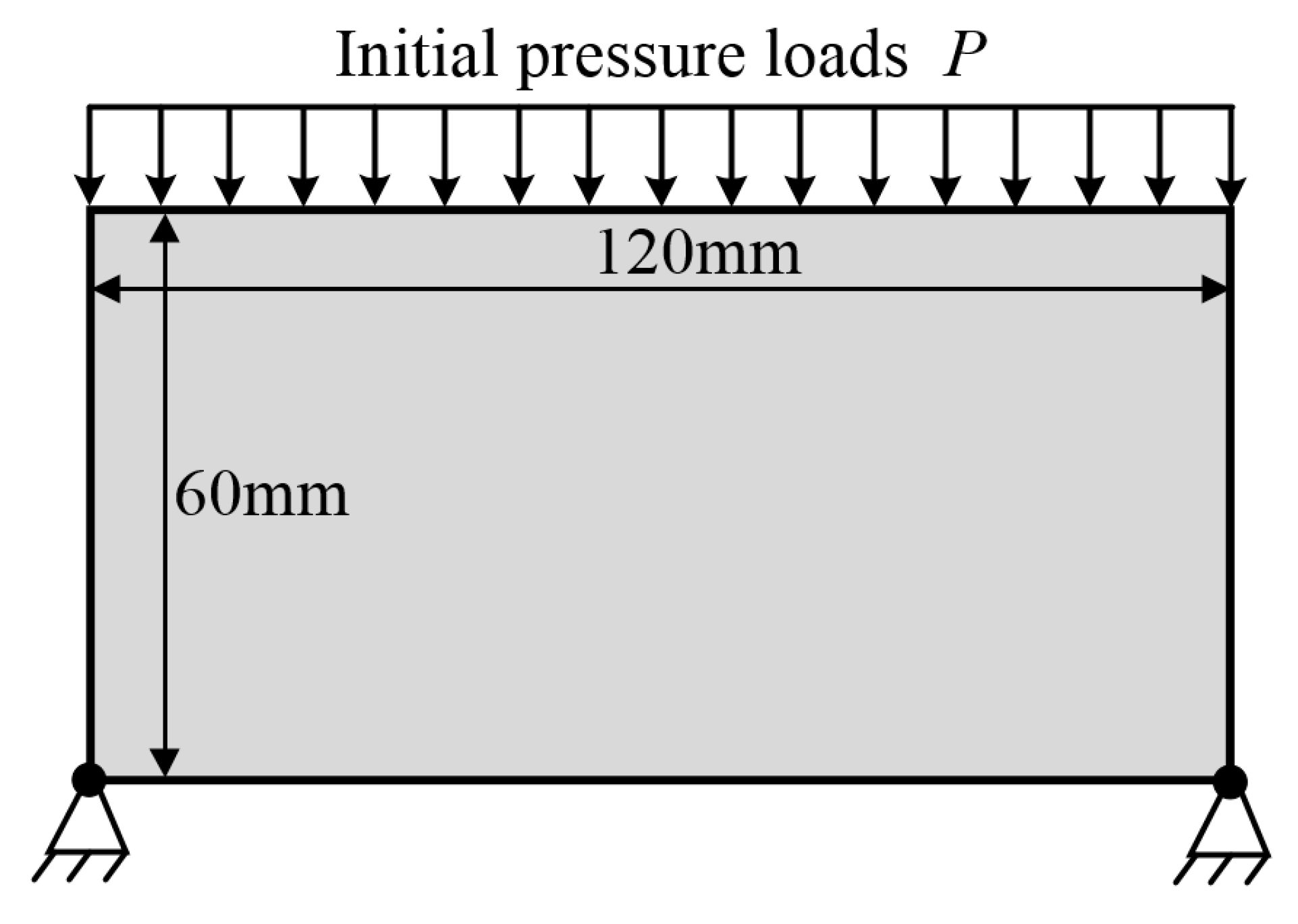

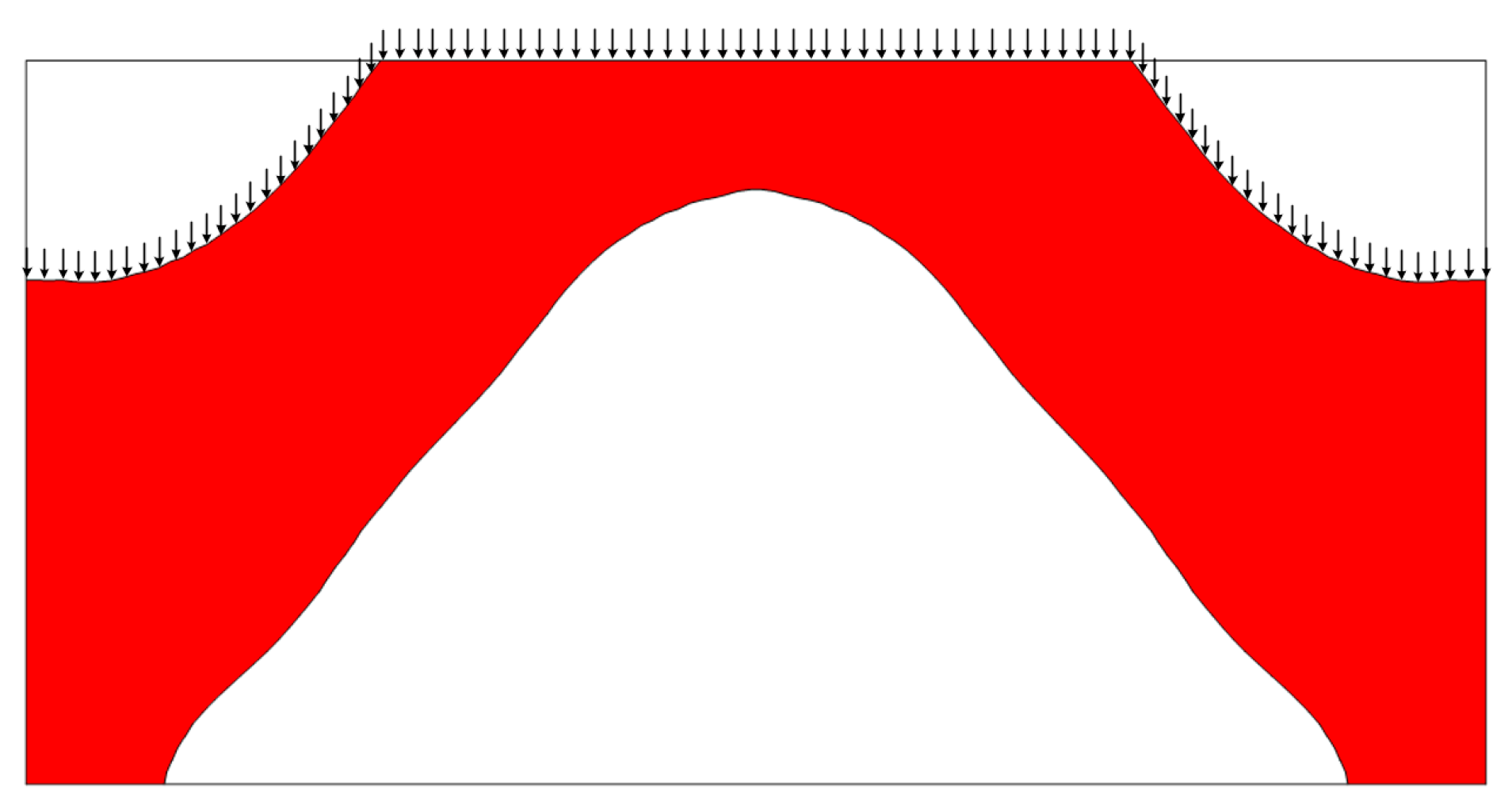

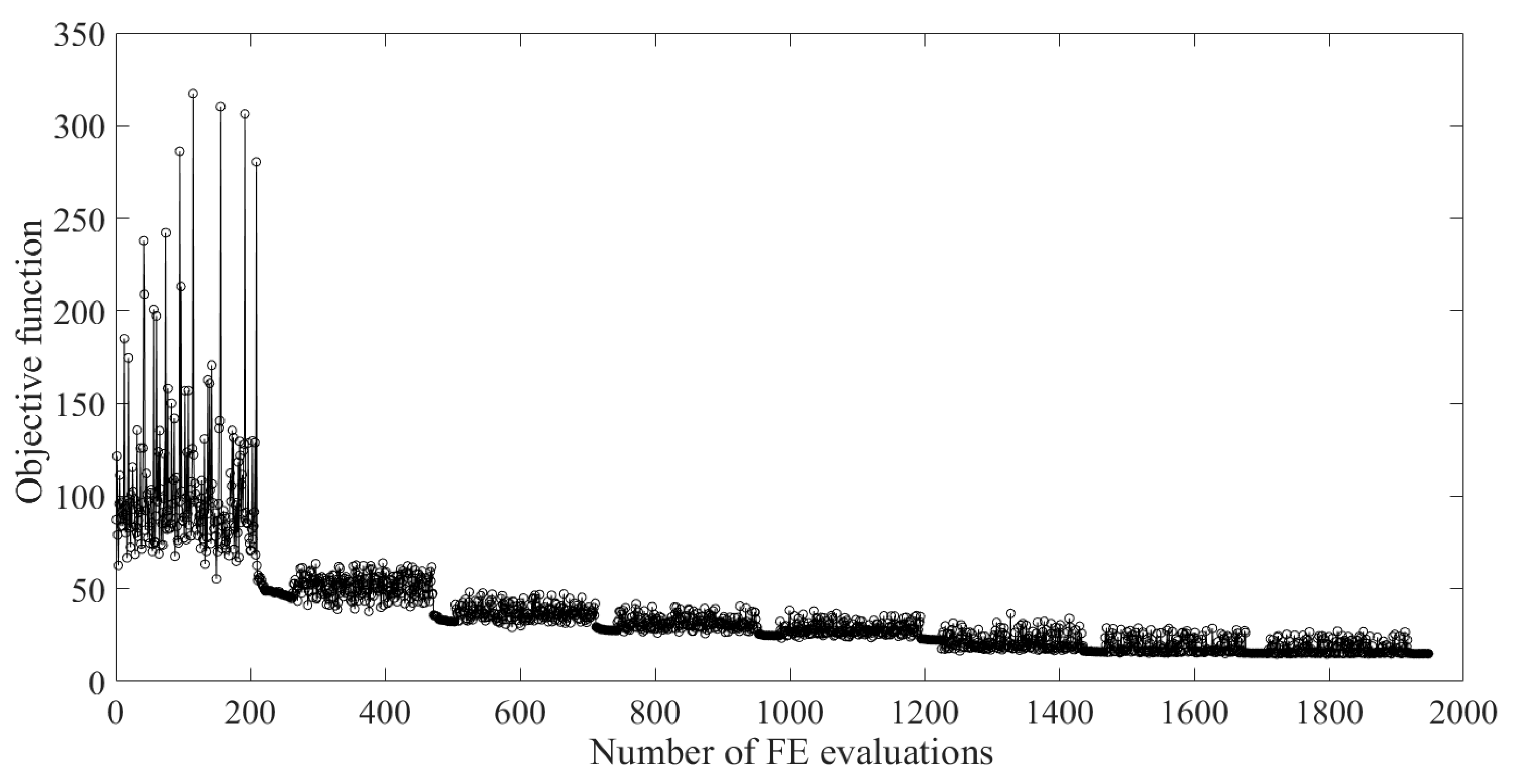

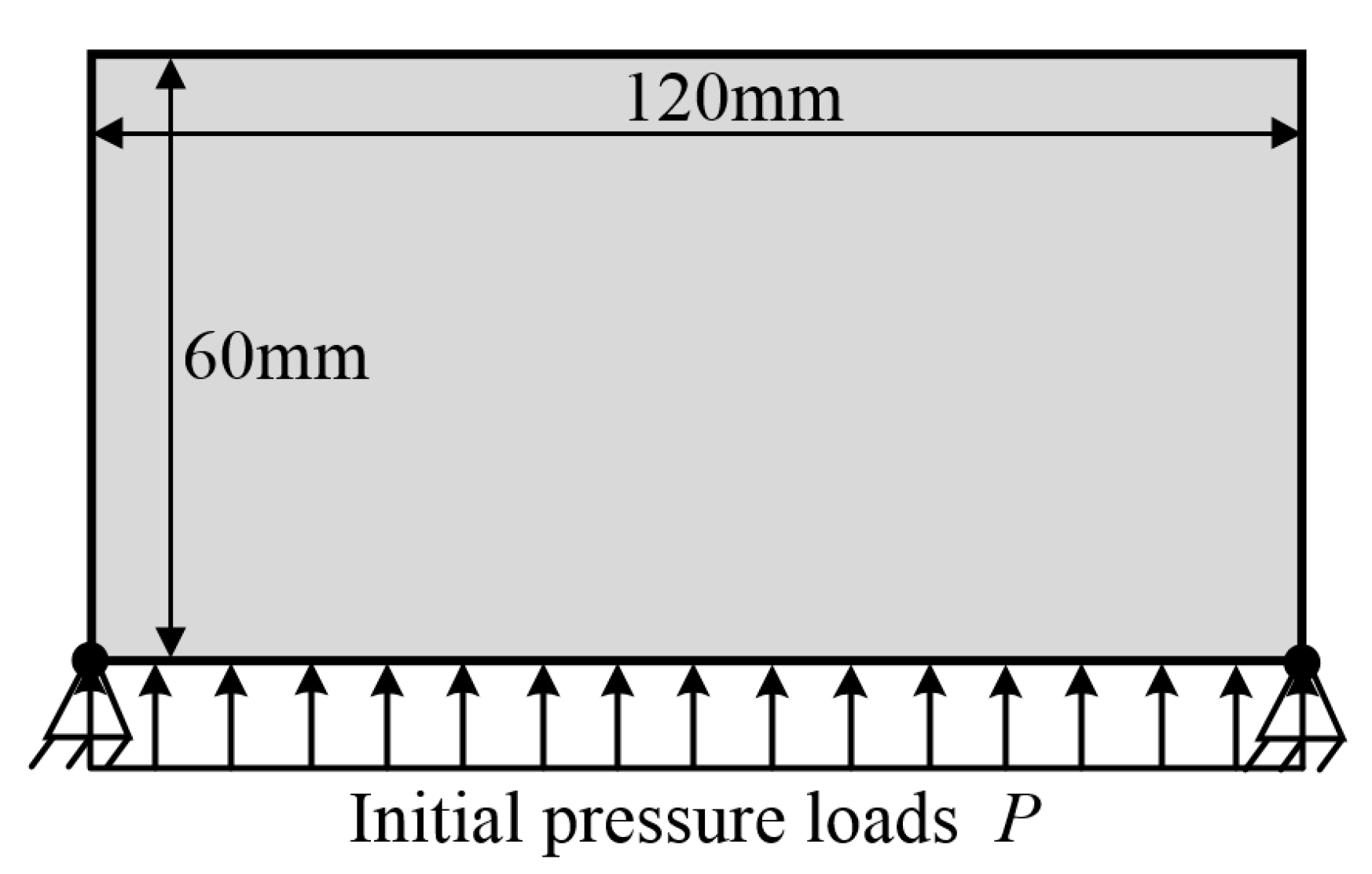

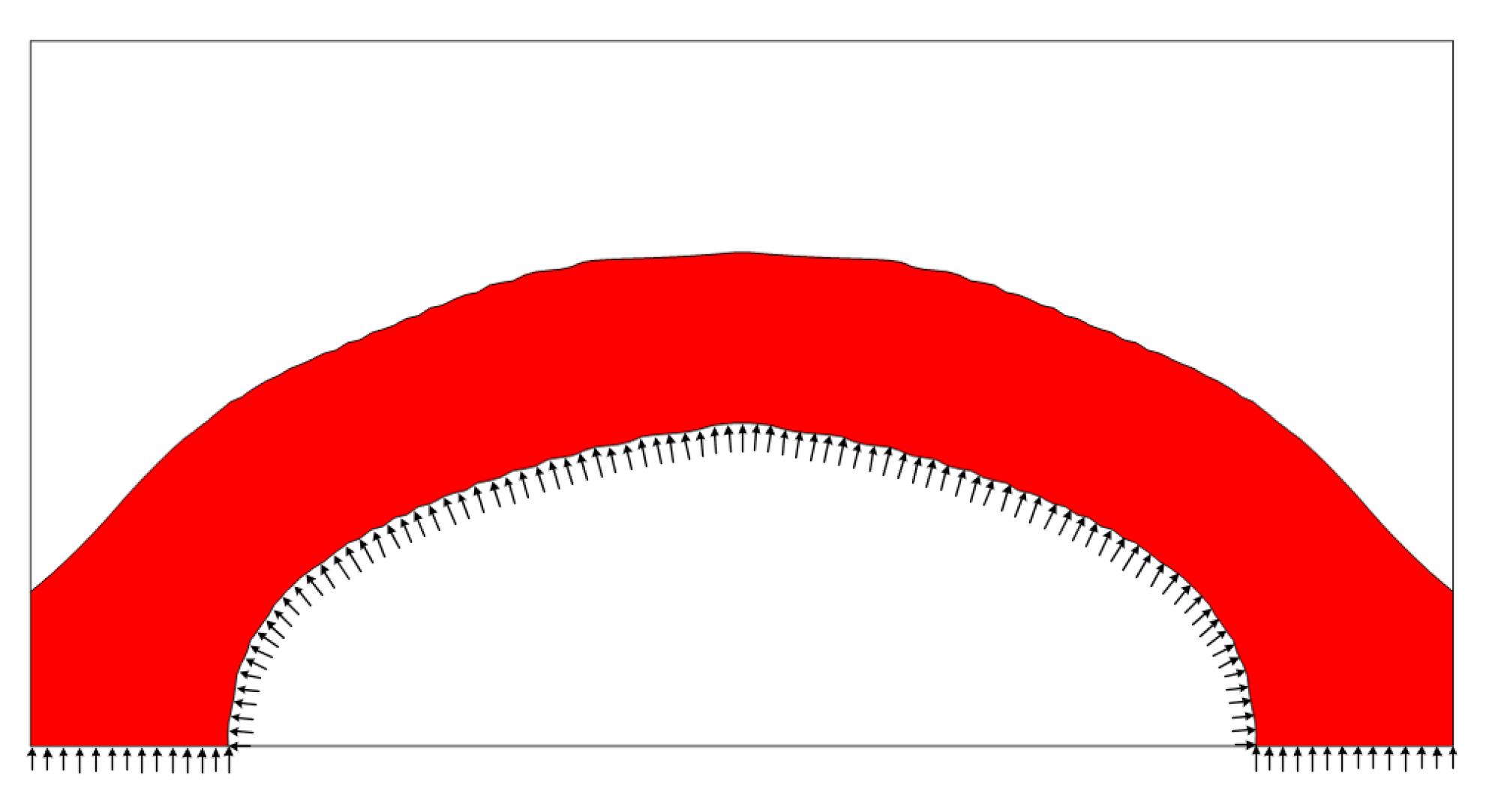

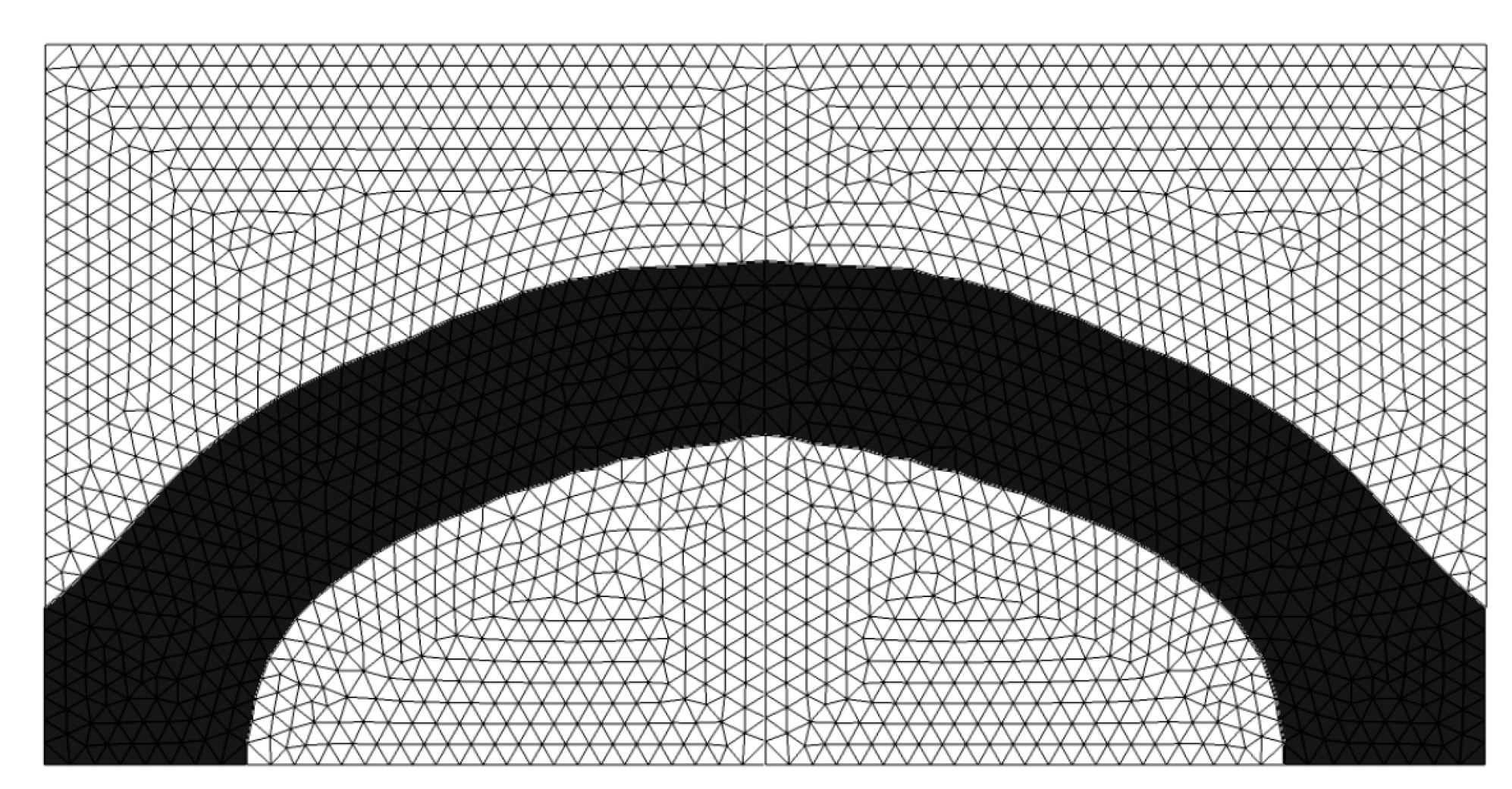

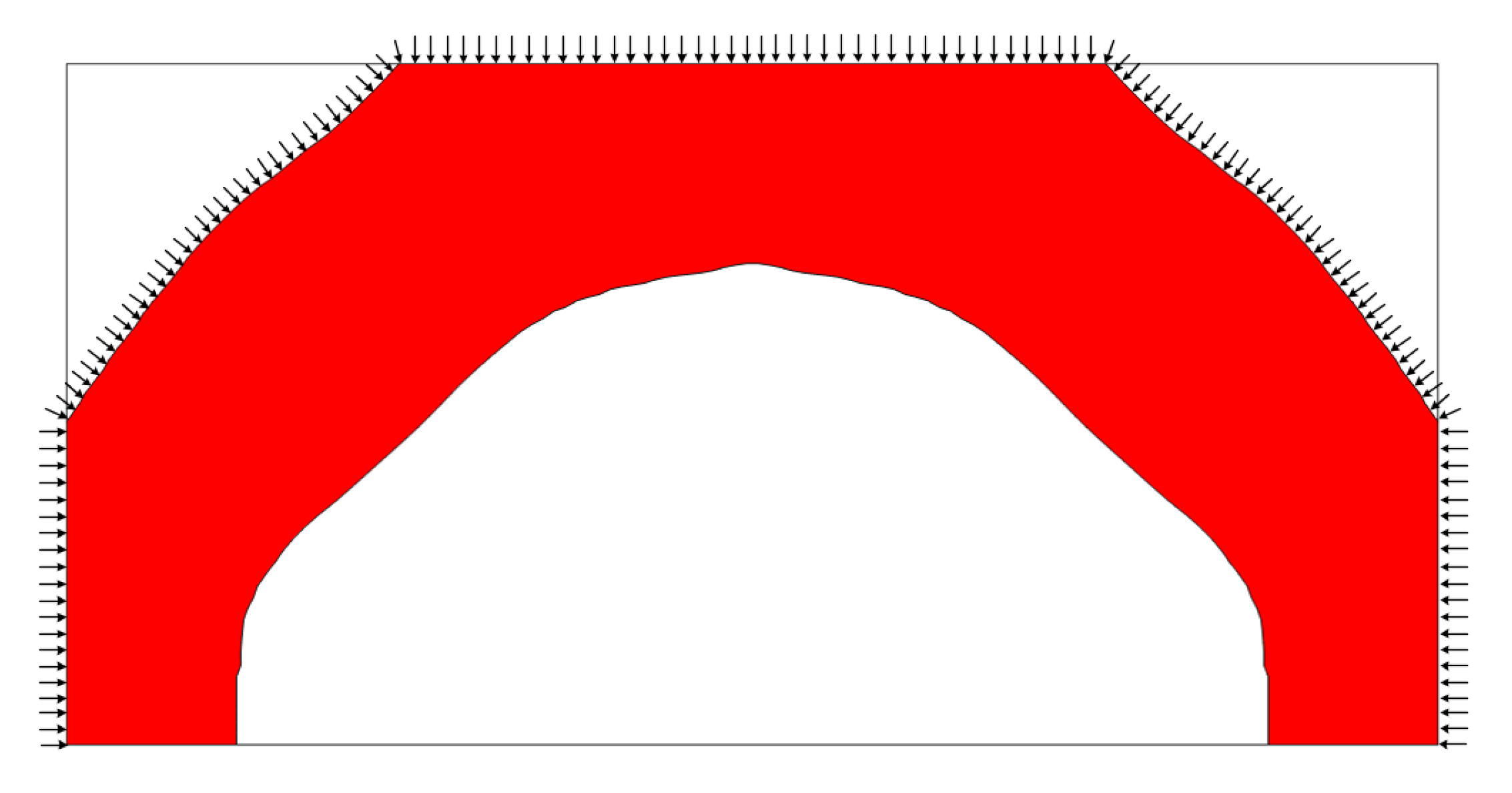

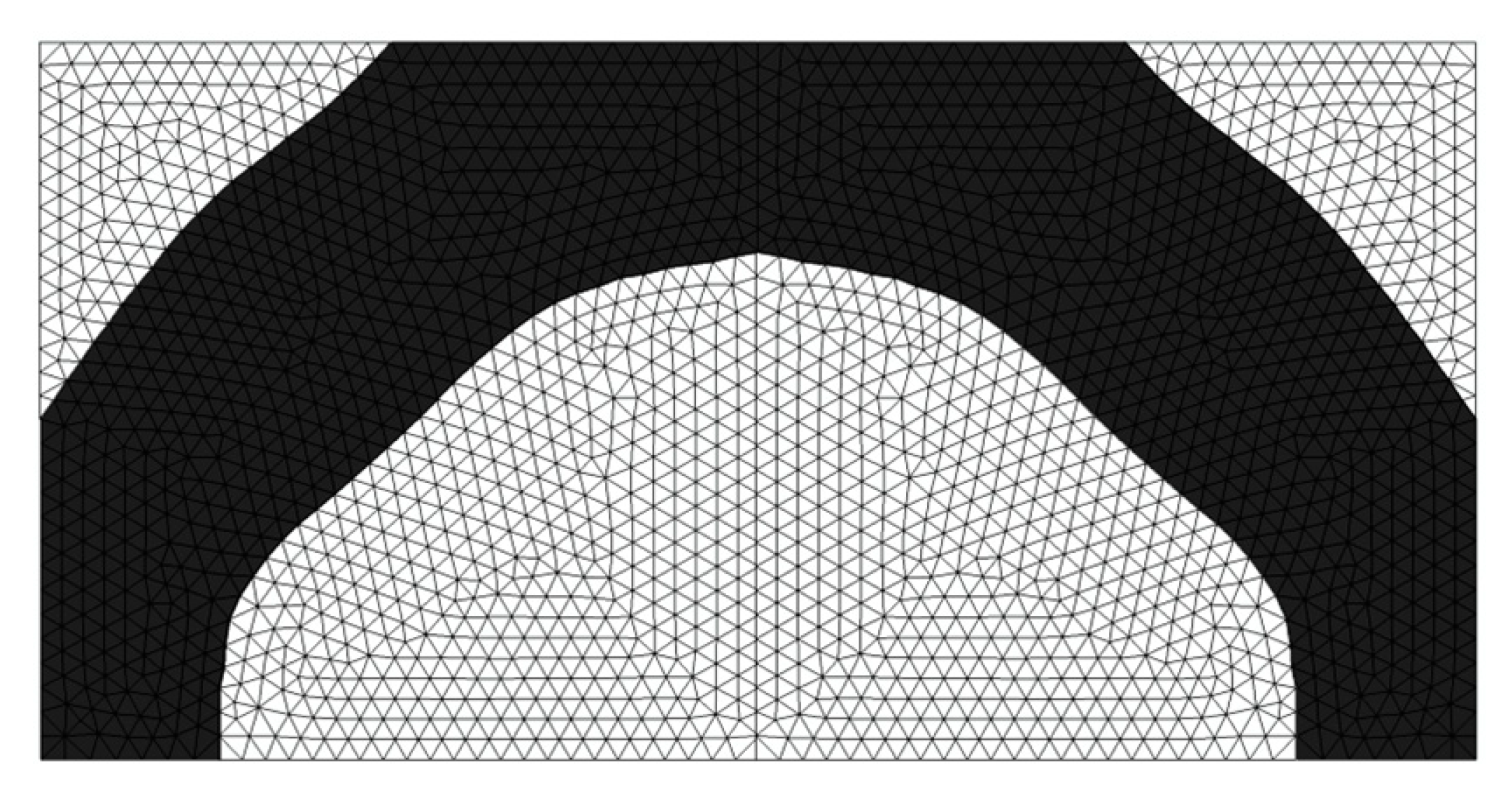

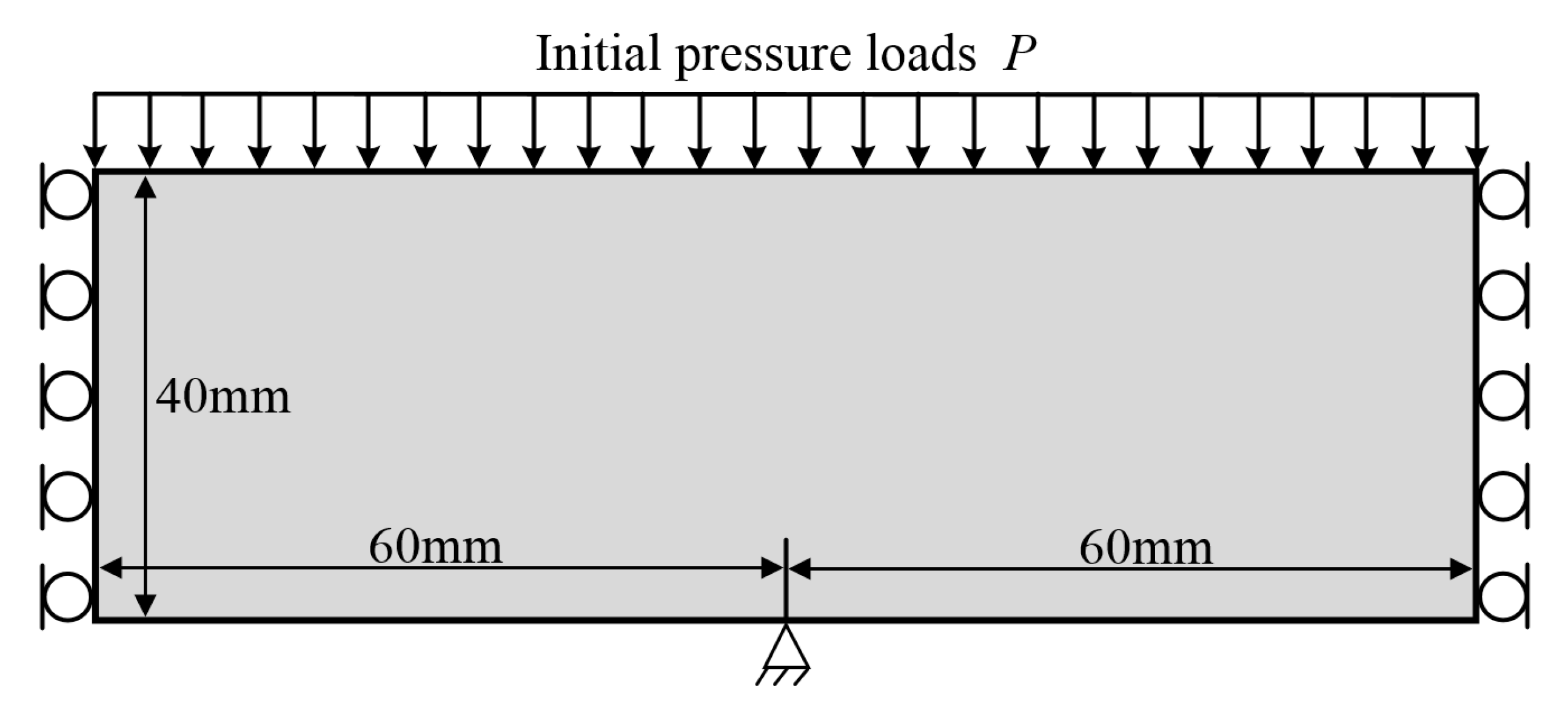

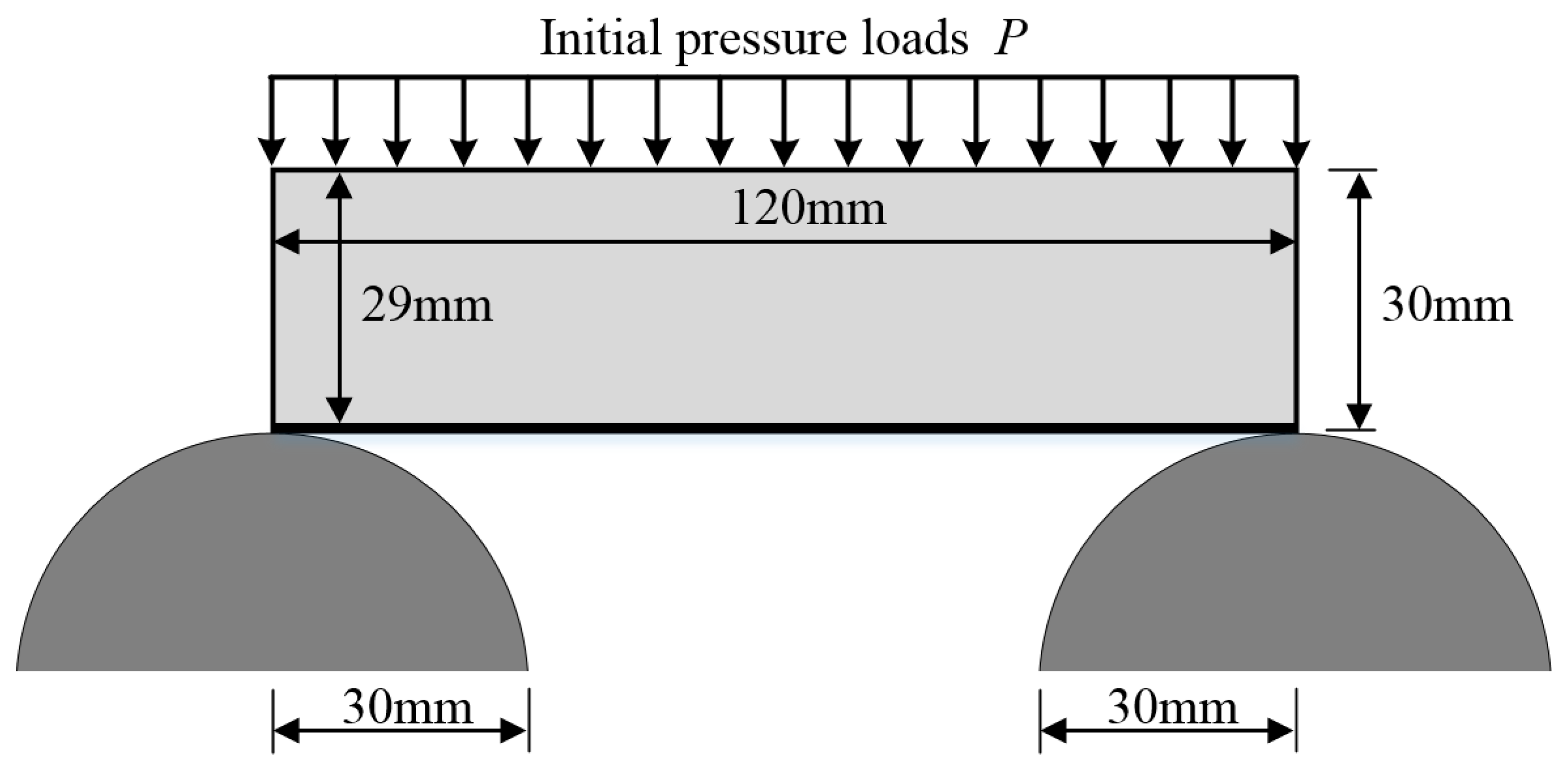

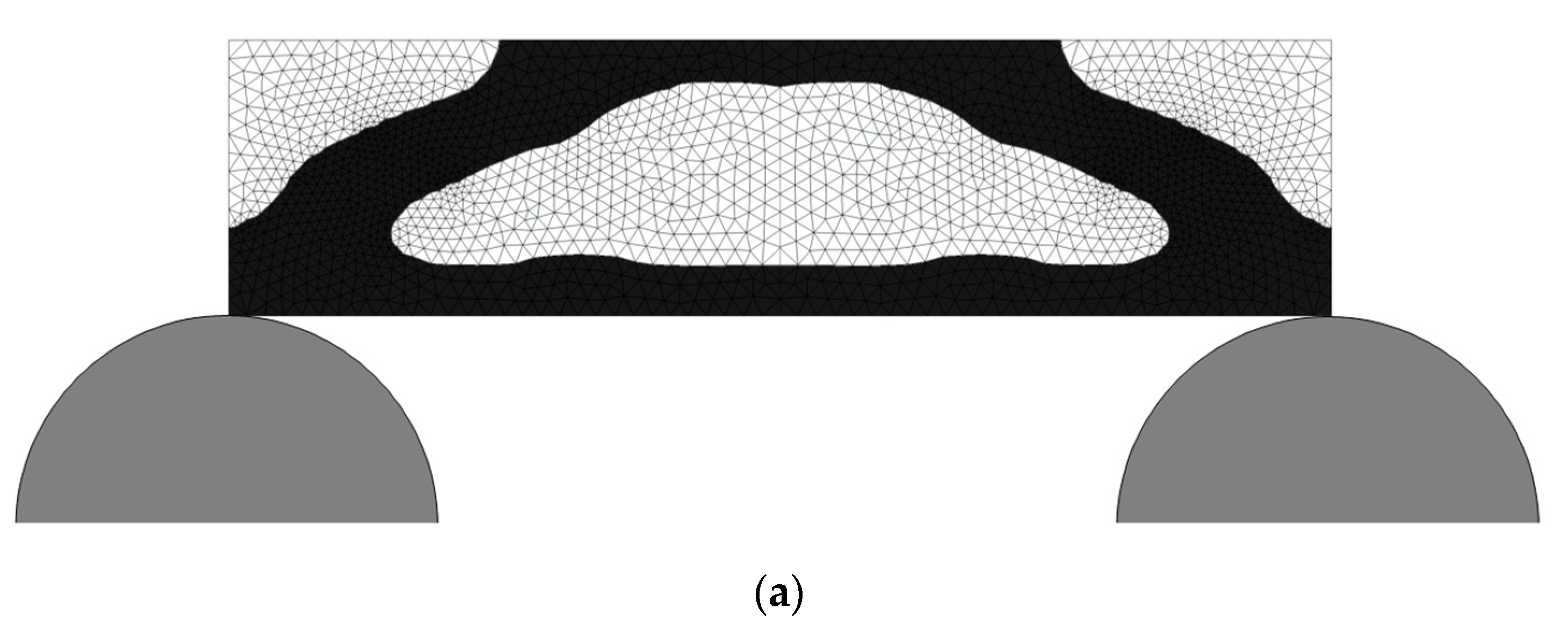

5.1. Example 1

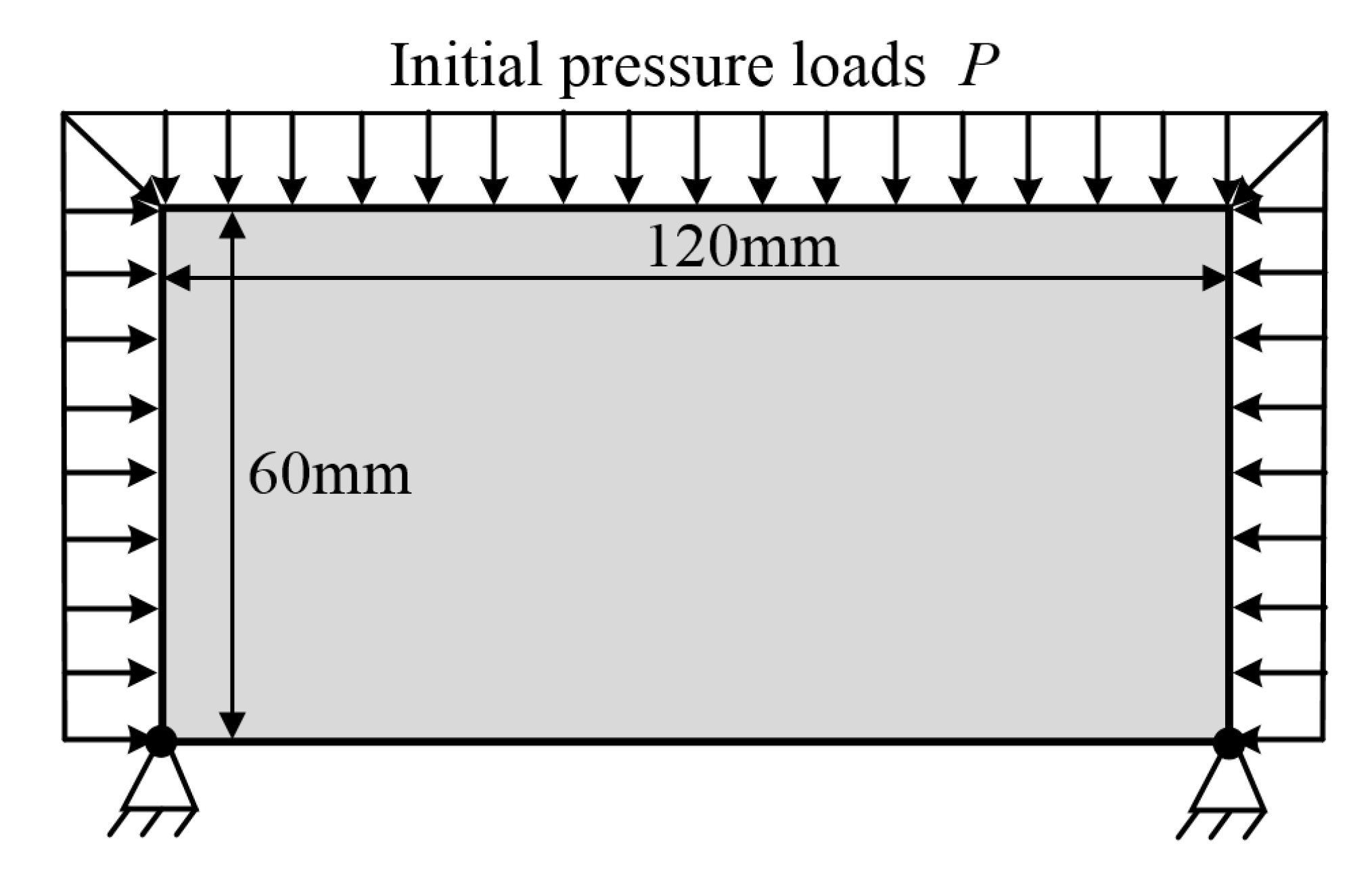

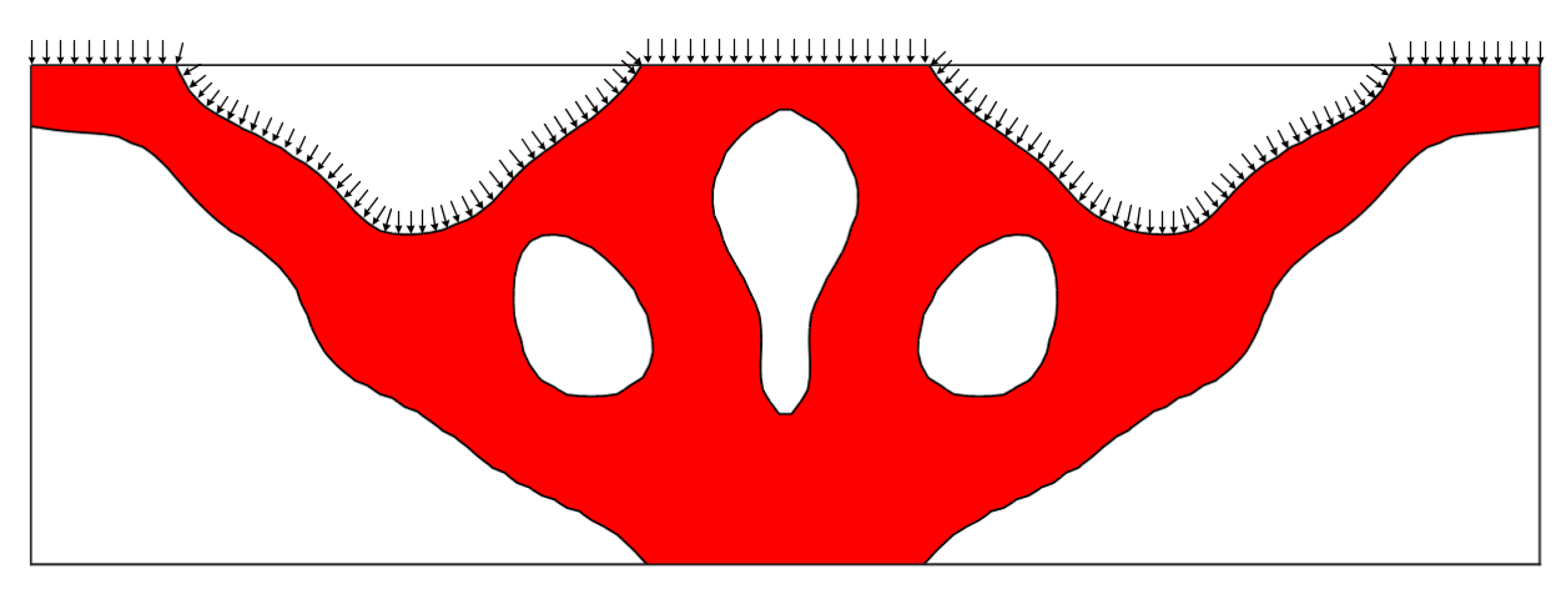

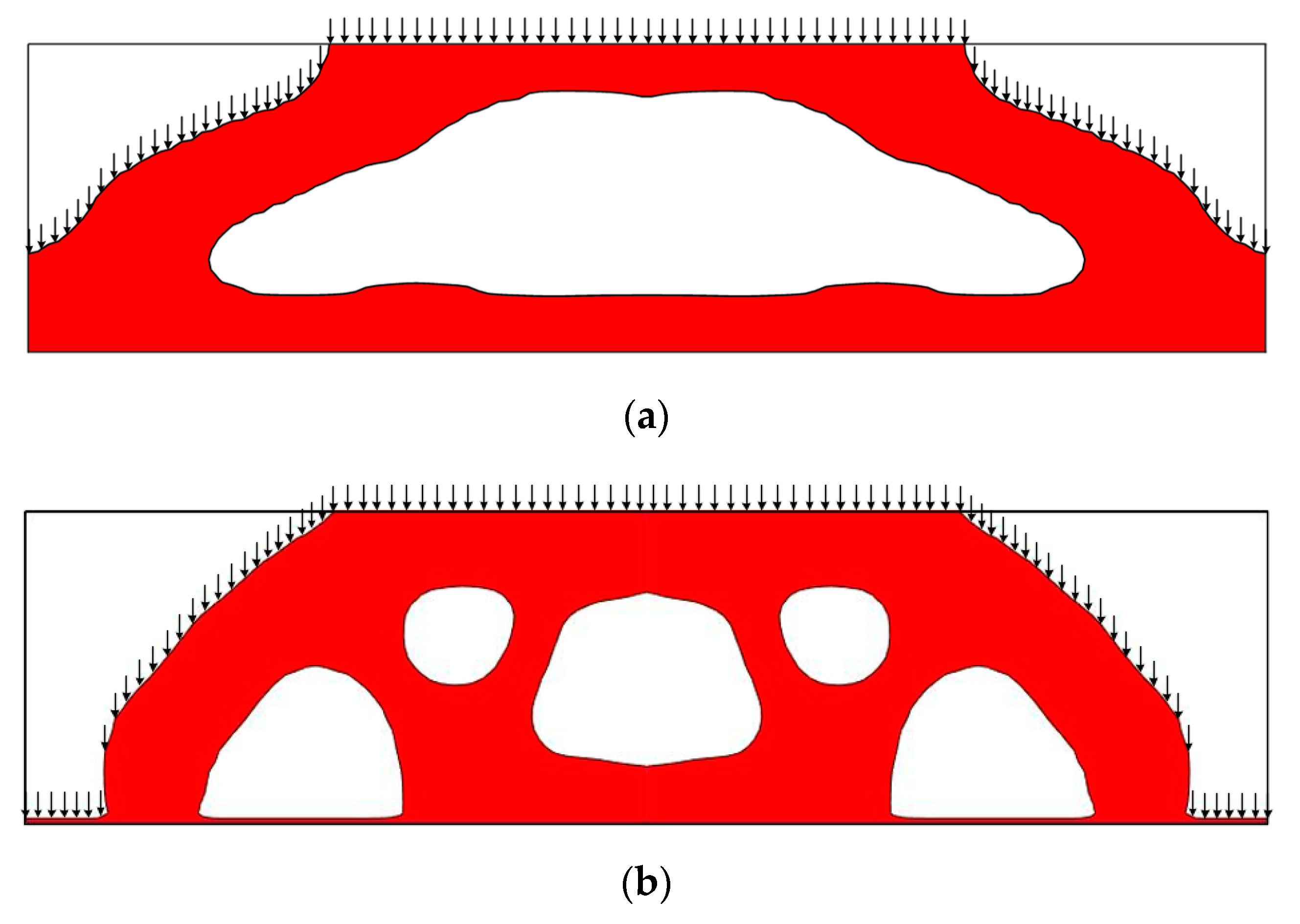

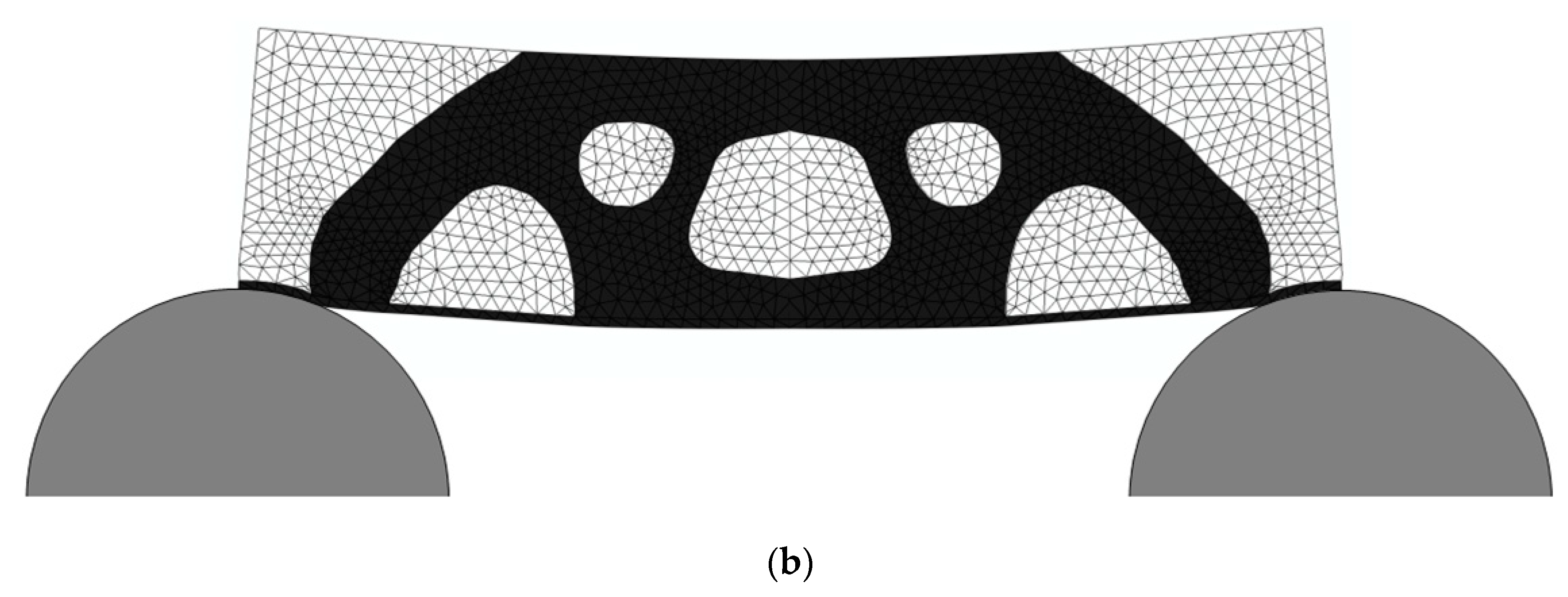

5.2. Example 2

5.3. Example 3

5.4. Example 4

5.5. Example 5

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Bendsøe, M.P.; Kikuchi, N. Generating optimal topologies in structural design using a homogenization method. Comput. Methods Appl. Mech. Eng. 1988, 71, 197–224. [Google Scholar] [CrossRef]

- Eschenauer, H.A.; Olhoff, N. Topology optimization of continuum structures: A review. Appl. Mech. Rev. 2001, 54, 1453–1457. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Sigmund, O. Topology Optimization: Theory, Methods and Applications, 2nd ed.; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2003. [Google Scholar]

- Allaire, G.; Jouve, F.; Toader, A. Structural optimization using sensitivity analysis and a level-set method. J. Comput. Phys. 2004, 194, 363–393. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Wang, M.Y.; Guo, D. Structural shape and topology optimization in a level-set-based framework of region representation. Struct. Multidiscip. Optim. 2004, 27, 1–19. [Google Scholar] [CrossRef]

- Sigmund, O.; Maute, K. Topology optimization approaches. Struct. Multidiscip. Optim. 2013, 48, 1031–1055. [Google Scholar] [CrossRef]

- Deaton, J.D.; Grandhi, R.V. A survey of structural and multidisciplinary continuum topology optimization: Post 2000. Struct. Multidiscip. Optim. 2014, 49, 1–38. [Google Scholar] [CrossRef]

- Hammer, V.B.; Olhoff, N. Topology optimization of continuum structures subjected to pressure loading. Struct. Multidiscip. Optim. 2000, 19, 85–92. [Google Scholar] [CrossRef]

- Du, J.; Olhoff, N. Topological optimization of continuum structures with design-dependent surface loading–Part I: New computational approach for 2D problems. Struct. Multidiscip. Optim. 2004, 27, 151–165. [Google Scholar] [CrossRef]

- Fuchs, M.B.; Shemesh, N. Density-based topological design of structures subjected to water pressure using a parametric loading surface. Struct. Multidiscip. Optim. 2004, 28, 11–19. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, X.; Liu, S. A new boundary search scheme for topology optimization of continuum structures with design dependent loads. Struct. Multidiscip. Optim. 2008, 37, 121–129. [Google Scholar] [CrossRef]

- Chen, B.; Kikuchi, N. Topology optimization with design-dependent loads. Finite Elem. Anal. Des. 2001, 37, 57–70. [Google Scholar] [CrossRef]

- Bourdin, B.; Chambolle, A. Design-dependent loads in topology optimization. ESAIM Control Optim. Calc. Var. 2003, 9, 19–48. [Google Scholar] [CrossRef]

- Sigmund, O.; Clausen, P.M. Topology optimization using a mixed formulation: An alternative way to solve pressure load problems. Comput. Methods Appl. Mech. Eng. 2007, 196, 1874–1889. [Google Scholar] [CrossRef] [Green Version]

- Yoon, G.H.; Jensen, J.S.; Sigmund, O. Topology optimization of acoustic-structure problems using a mixed finite element formulation. Int. J. Numer. Methods Eng. 2007, 70, 1049–1075. [Google Scholar] [CrossRef]

- Yoon, G.H. Topology optimization for stationary fluid-structure interaction problems using a new monolithic formulation. Int. J. Numer. Methods Eng. 2010, 82, 591–616. [Google Scholar] [CrossRef]

- Lundgaard, C.; Alexandersen, J.; Zhou, M.; Andreasen, C.; Sigmund, O. Revisiting density-based topology optimization for fluid-structure-interaction problems. Struct. Multidiscip. Optim. 2018, 58, 969–995. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.Y.; Xie, Y.M.; Steven, G.P. Evolutionary methods for topology optimisation of continuous structures with design dependent loads. Comput. Struct. 2005, 83, 956–963. [Google Scholar] [CrossRef]

- Xia, Q.; Wang, M.Y.; Shi, T. Topology optimization with pressure load through a level set method. Comput. Methods Appl. Mech. Eng. 2015, 283, 177–195. [Google Scholar] [CrossRef]

- Shu, L.; Wang, M.Y.; Ma, Z. Level set based topology optimization of vibrating structures for coupled acoustic-structural dynamics. Comput. Struct. 2014, 132, 34–42. [Google Scholar] [CrossRef]

- Emmendoerfer, H.; Fancello, E.; Silva, E. Level set topology optimization for design-dependent pressure load problems. Int. J. Numer. Methods Eng. 2018, 115, 825–848. [Google Scholar] [CrossRef]

- Picelli, R.; Neofytou, A.; Kim, H.A. Topology optimization for design-dependent hydrostatic pressure loading via the level-set method. Struct. Multidiscip. Optim. 2019, 60, 1313–1326. [Google Scholar] [CrossRef] [Green Version]

- Neofytou, A.; Picelli, R.; Huang, T.H.; Chen, J.S.; Kim, H.A. Level set topology optimization for design-dependent pressure loads using the reproducing kernel particle method. Struct. Multidiscip. Optim. 2020, 61, 1805–1820. [Google Scholar] [CrossRef]

- Lohan, D.J.; Dede, E.M.; Allison, J.T. Topology optimization for heat conduction using generative design algorithms. Struct. Multidiscip. Optim. 2015, 55, 1063–1077. [Google Scholar] [CrossRef]

- Yoshimura, M.; Shimoyama, K.; Misaka, T.; Obayashi, S. Topology optimization of fluid problems using genetic algorithm assisted by the Kriging model. Int. J. Numer. Methods Eng. 2016, 109, 514–532. [Google Scholar] [CrossRef] [Green Version]

- Raponi, E.; Bujny, M.; Olhofer, M.; Aulig, N.; Boria, S.; Duddeck, F. Kriging-assisted topology optimization of crash structures. Comput. Methods Appl. Mech. Eng. 2019, 348, 730–752. [Google Scholar] [CrossRef]

- Vimal, J.; Savsani, V.J.; Patel, V.K. Truss topology optimization with static and dynamic constraints using modified subpopulation teaching–learning-based optimization. Eng. Optim. 2016, 48, 1990–2006. [Google Scholar]

- Tejani, G.; Savsani, V. Teaching-learning-based optimization (TLBO) approach to truss structure subjected to static and dynamic constraints. In Proceedings of International Conference on ICT for Sustainable Development; Springer: Singapore, 2016; pp. 63–71. [Google Scholar]

- Tejani, G.G.; Savsani, V.J.; Patel, V.K. Modified sub-population teaching-learning-based optimization for design of truss structures with natural frequency constraints. Mech. Based Des. Struct. Mach. 2016, 44, 495–513. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, P.; Zhang, X.; Luo, Y. Photonic crystal topological design for polarized and polarization-independent band gaps by gradient-free topology optimization. Opt. Express 2021, 29, 24861–24883. [Google Scholar] [CrossRef]

- Zhang, X.; Luo, Y.; Yan, Y.; Liu, P.; Kang, Z. Photonic band gap material topological design at specified target frequency. Adv. Theory Simul. 2021, 4, 2100125. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, X.; Luo, Y. Topological Design of Freely Vibrating Bi-Material Structures to Achieve the Maximum Band Gap Centering at a Specified Frequency. J. Appl. Mech. 2021, 88, 081003. [Google Scholar] [CrossRef]

- Liu, P.; Yan, Y.; Zhang, X.; Luo, Y.; Kang, Z. Topological design of microstructures using periodic material-field series-expansion and gradient-free optimization algorithm. Mater. Des. 2021, 199, 109437. [Google Scholar] [CrossRef]

- Zhang, X.; Xing, J.; Liu, P.; Luo, Y.; Kang, Z. Realization of full and directional band gap design by non-gradient topology optimization in acoustic metamaterials. Extrem. Mech. Lett. 2021, 42, 101126. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Y.; Wang, Y.; Jia, Z.; Luo, Y. Narrow-band filter design of phononic crystals with periodic point defects via topology optimization. Int. J. Mech. Sci. 2021, 212, 106829. [Google Scholar] [CrossRef]

- Liu, P.; Yan, Y.; Zhang, X.; Luo, Y. A MATLAB code for the material-field series-expansion topology optimization method. Front. Mech. Eng. 2021, 16, 607–622. [Google Scholar] [CrossRef]

- Luo, Y.; Xing, J.; Kang, Z. Topology optimization using material-field series expansion and Kriging-based algorithm: An effective non-gradient method. Comput. Methods Appl. Mech. Eng. 2020, 364, 112966. [Google Scholar] [CrossRef]

- Luo, Y.; Zhan, J.; Xing, J.; Kang, Z. Non-probabilistic uncertainty quantification and response analysis of structures with a bounded field model. Comput. Methods Appl. Mech. Eng. 2019, 347, 663–678. [Google Scholar] [CrossRef]

- Luo, Y.; Bao, J. A material-field series-expansion method for topology optimization of continuum structures. Comput. Struct. 2019, 225, 106122. [Google Scholar] [CrossRef]

- Wang, F.; Lazarov, B.S.; Sigmund, O. On projection methods, convergence and robust formulations in topology optimization. Struct. Multidiscip. Optim. 2011, 43, 767–784. [Google Scholar] [CrossRef]

- Joseph, R.V.; Hung, Y. Orthogonal-maximin Latin hypercube designs. Stat. Sin. 2012, 18, 171–186. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, J.; Li, J.; Liu, P.; Luo, Y. A Gradient-Free Topology Optimization Strategy for Continuum Structures with Design-Dependent Boundary Loads. Symmetry 2021, 13, 1976. https://doi.org/10.3390/sym13111976

Zhan J, Li J, Liu P, Luo Y. A Gradient-Free Topology Optimization Strategy for Continuum Structures with Design-Dependent Boundary Loads. Symmetry. 2021; 13(11):1976. https://doi.org/10.3390/sym13111976

Chicago/Turabian StyleZhan, Junjie, Jing Li, Pai Liu, and Yangjun Luo. 2021. "A Gradient-Free Topology Optimization Strategy for Continuum Structures with Design-Dependent Boundary Loads" Symmetry 13, no. 11: 1976. https://doi.org/10.3390/sym13111976

APA StyleZhan, J., Li, J., Liu, P., & Luo, Y. (2021). A Gradient-Free Topology Optimization Strategy for Continuum Structures with Design-Dependent Boundary Loads. Symmetry, 13(11), 1976. https://doi.org/10.3390/sym13111976