Solution Behavior Near Very Rough Walls under Axial Symmetry: An Exact Solution for Anisotropic Rigid/Plastic Material

Abstract

1. Introduction

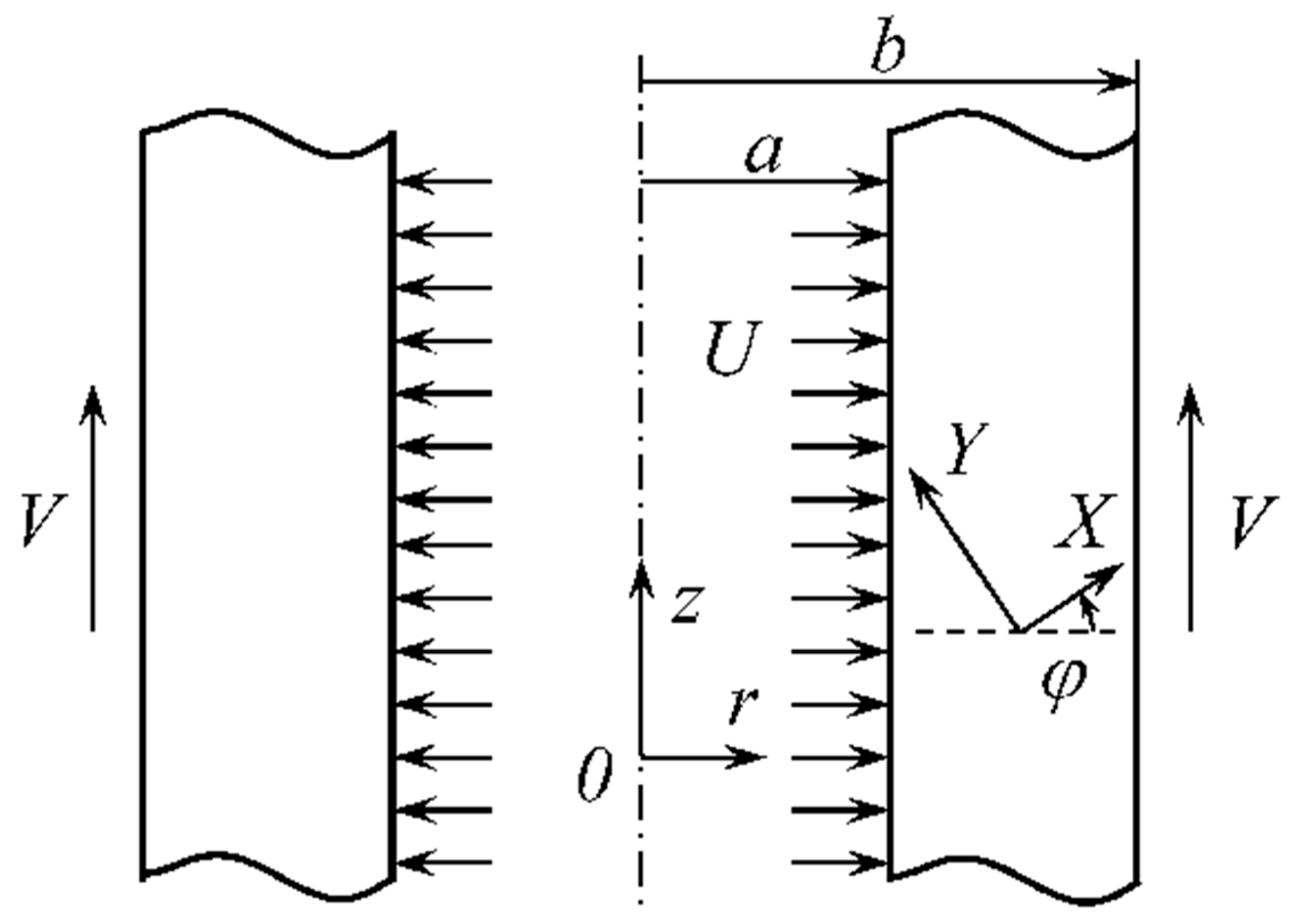

2. Statement of the Problem

2.1. Material Model

2.2. Boundary Value Problem

3. General Solution

4. Analysis of the General Solution

4.1. Special Case

4.2. Special Case

4.3. General Case

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kacem, A.; Krichen, A.; Manach, P.-Y. Occurrence and effect of ironing in the hole-flanging process. J. Mater. Process. Technol. 2011, 211, 1606–1613. [Google Scholar] [CrossRef]

- Jaspers, S.S.; Dautzenberg, J. Material behaviour in conditions similar to metal cutting: Flow stress in the primary shear zone. J. Mater. Process. Technol. 2002, 122, 322–330. [Google Scholar] [CrossRef]

- Alexandrov, S.; Richmond, O. Singular plastic flow fields near surfaces of maximum friction stress. Int. J. Non-Linear Mech. 2001, 36, 1–11. [Google Scholar] [CrossRef]

- Alexandrov, S.; Jeng, Y.-R. Singular rigid/plastic solutions in anisotropic plasticity under plane strain conditions. Contin. Mech. Thermodyn. 2013, 25, 685–689. [Google Scholar] [CrossRef]

- Rice, J.R. Plane strain slip line theory for anisotropic rigid/plastic materials. J. Mech. Phys. Solids 1973, 21, 63–74. [Google Scholar] [CrossRef]

- Gottschalk, H.P.; Eisner, E.; Hosalkar, H.S. Medial epicondyle fractures in the pediatric population. J. Am. Acad. Orthop. Surg. 2012, 20, 223–232. [Google Scholar] [CrossRef] [PubMed]

- Collins, I.F.; Meguid, S.A. On the Influence of Hardening and Anisotropy on the Plane-Strain Compression of Thin Metal Strip. J. Appl. Mech. 1977, 44, 271–278. [Google Scholar] [CrossRef]

- Wang, Y.; Alexandrov, S.; Lyamina, E. Solution Behavior in the Vicinity of Characteristic Envelopes for the Double Slip and Rotation Model. Appl. Sci. 2020, 10, 3220. [Google Scholar] [CrossRef]

- Harris, D. A hyperbolic augmented elasto-plastic model for pressure-dependent yield. Acta Mech. 2014, 225, 2277–2299. [Google Scholar] [CrossRef]

- Alexandrov, S.; Richmond, O. Couette flows of rigid/plastic solids: Analytical examples of the interaction of constitutive and frictional laws. Int. J. Mech. Sci. 2001, 43, 653–665. [Google Scholar] [CrossRef]

- Chen, J.-S.; Pan, C.; Roque, C.M.O.L.; Wang, H.-P. A Lagrangian reproducing kernel particle method for metal forming analysis. Comput. Mech. 1998, 22, 289–307. [Google Scholar] [CrossRef]

- Facchinetti, M.; Mishuris, G. Analysis of the maximum friction condition for green body forming in an ANSYS environment. J. Eur. Ceram. Soc. 2016, 36, 2295–2302. [Google Scholar] [CrossRef]

- Fries, T.; Belytschko, T. The extended/generalized finite element method: An overview of the method and its applications. Int. J. Numer. Methods Eng. 2010, 84, 253–304. [Google Scholar] [CrossRef]

- Sasaki, T.; Morris, R.; Thompson, G.B.; Syarif, Y.; Fox, D. Formation of ultra-fine copper grains in copper-clad aluminum wire. Scr. Mater. 2010, 63, 488–491. [Google Scholar] [CrossRef]

- Stolyarov, A.; Polyakova, M.; Atangulova, G.; Alexandrov, S. Effect of Die Angle and Frictional Conditions on Fine Grain Layer Generation in Multipass Drawing of High Carbon Steel Wire. Metals 2020, 10, 1462. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alexandrov, S.; Lyamina, E.; Manach, P.-Y. Solution Behavior Near Very Rough Walls under Axial Symmetry: An Exact Solution for Anisotropic Rigid/Plastic Material. Symmetry 2021, 13, 184. https://doi.org/10.3390/sym13020184

Alexandrov S, Lyamina E, Manach P-Y. Solution Behavior Near Very Rough Walls under Axial Symmetry: An Exact Solution for Anisotropic Rigid/Plastic Material. Symmetry. 2021; 13(2):184. https://doi.org/10.3390/sym13020184

Chicago/Turabian StyleAlexandrov, Sergei, Elena Lyamina, and Pierre-Yves Manach. 2021. "Solution Behavior Near Very Rough Walls under Axial Symmetry: An Exact Solution for Anisotropic Rigid/Plastic Material" Symmetry 13, no. 2: 184. https://doi.org/10.3390/sym13020184

APA StyleAlexandrov, S., Lyamina, E., & Manach, P.-Y. (2021). Solution Behavior Near Very Rough Walls under Axial Symmetry: An Exact Solution for Anisotropic Rigid/Plastic Material. Symmetry, 13(2), 184. https://doi.org/10.3390/sym13020184