Abstract

The European Union (EU) is the largest shrimp consumer market in the world in terms of requirements for shrimp product imports. Therefore, other enterprises that export frozen shrimp to the EU must consider many criteria when choosing suppliers of raw shrimp. The difficulty of choosing suppliers of raw shrimp makes selecting raw material suppliers in the fisheries sector a multi-criteria decision-making problem. In such problems, the decision makers must review and evaluate many criteria—including qualitative and quantitative factors—to achieve an optimal result. While there have been multiple multi-criteria decision making models developed to support supplier selection processes in different industries, none of these have been developed to solve the particular problems facing the shrimp industry, especially as it concerns a fuzzy decision-making environment. In this research, the authors propose a Multi-Criteria Decision Making model (MCDM) including the Fuzzy Analytical Network Process (FANP) and Weighted Aggregated Sum Product Assessment (WASPAS) for the evaluation and selection process of shrimp suppliers in the fisheries industry. The model is applied to a real-world case study and the results show that Supplier 3 (SA3) is the most optimal supplier of raw shrimp. The contribution of this work is the employment of FANP and WASPAS to propose an MCDM for ranking potential suppliers in the fisheries industry in a fuzzy environment. The proposed approach can also be modified to support complex decision-making processes in fuzzy environments in different industries.

1. Introduction

The European–Vietnam Free Trade Agreement (EVFTA) ensures that seafood enterprises have more advantages in tax rates and more favorable legal procedures related to Europe (EU) [1]. The EU is currently the fourth largest shrimp consumer market purchasing from Vietnam, after the US, Japan, and China. The EU accounts for 13.3% of the total value of Vietnam’s shrimp exports [2]. However, the EU has strict requirements for shrimp products imported from other countries [3]. To meet the above requirements, frozen shrimp exporters must improve production systems, improve product quality, and optimally select suitable raw suppliers.

While the production and export volume of Vietnam shrimp has constantly increased in recent years, there are many concerns about the sustainability of current farming practices [4]. Vietnam is among the most heavily impacted countries by climate change and the country’s coastal aquatic ecosystems are extremely vulnerable to overfishing and environmental phenomena. As a result, the shrimp farming industry, which provides the livelihood of many rural communities, is also seriously threatened. As the consumers and governments become increasingly concerned with the sustainability of products, it is extremely important for exporters to identify optimal frozen shrimp suppliers who can satisfy the requirements of EU importers. Therefore, the frozen shrimp supplier evaluation and selection process is a decision-making process that involves multiple criteria, which can be quantitative or qualitative in nature.

Multi-criteria decision making processes can be supported using MCDM methods such as a Combined Compromise Solution (CoCoSo), Data Envelopment Analysis (DEA), or Multi-criteria Optimization and Compromise Solution (VIKOR). In many cases, the selection criteria may consist not only of quantitative, but also qualitative, criteria. In these cases, fuzzy theory [5] is integrated into the MCDM method to create fuzzy MCDM models to support the decision-making processes within uncertain decision-making environments. While there have been multiple MCDM models developed to support supplier selection processes in different industries, none of these are developed to solve the problem in the shrimp industry, especially in a fuzzy decision-making environment. This study aims to develop an MCDM model based on Fuzzy Analytical Network Process (FANP) and Weighted Aggregated Sum Product Assessment (WASPAS) to support the frozen shrimp supplier evaluation and selection process within a fuzzy environment.

The rest of this paper is structured as follows. Relevant literatures of MCDM methods and their applications, the applications of MCDM models in supplier selection problems, and related researches to the supplier selection problem in the frozen shrimp industry, are described in Section 2. The research process and the proposed model based on FANP and WASPAS methods are shown in Section 3. In Section 4, the proposed model is applied to a real-world case study to demonstrate its feasibility. The conclusion of the paper is shown in Section 5.

2. Literature Review

In the past few decades literature has analyzed and employed MCDM models to support supplier evaluation and selection processes in different industries to address criteria in both quantitative and qualitative forms [6,7,8,9,10]. Each of these models are unique and different from each other as each model uses a unique set of criteria or uses distinct MCDM methods. In some instances, these MCDM methods are applied in combination with fuzzy set theory to solve decision-making problems with qualitative criteria.

MCDM methods are frequently employed in different decision-making problems in different industries and sectors. Alizadeh et al. [11] developed an AHP integrated Geographical Information System (GIS) for the Seismic Vulnerability Assessment (SVA) process in the construction industry. The model was utilized to choose the most suitable place for urban residential building projects in Tabriz City, Iran. Padmanathan et al. [12] introduced an AHP based MCDM model to evaluate the performance of solar PV systems regarding economic performance and Life Cycle Cost Analysis (LCCA). Tzeng et al. [13] introduced an approach to evaluate intertwined effects in e-learning programs based on MCDM methods. The proposed model was built using Fuzzy AHP and DEMATEL. Mousavi et al. [14] developed an MCDM tool for the artificial reefs site selection problems. The proposed approached is a combined MCDM integrated GIS model based on Weighted Linear Combination (WLC) and AHP. Villacreses et al. [15] developed an MCDM integrated GIS model to solve the location selection problem of wind farm projects in Ecuador. Peng et al. [16] developed an MCDM model for assessing regional earthquake vulnerability. The proposed model was built based on six MCDM methods (TOPSIS, GRA, PROMETHEE II, VIKOR, ELECTRE III, and WSM) and eleven criteria. The MIVES multi-criteria analysis network which combined multi-attribute utility theory (MAUT) and MDCM is also applied in different decision-making problems such as public investment projects evaluation and selection problem [17] and assessment process of urban-pavement conditions [18]. Mallick [19] used a combination of Fuzzy AHP method and Geoinformation Techniques to support the location evaluation and selection process of municipal solid waste landfill. The proposed model is applied to the Asir Region of Saudi Arabia and shows that 38.14% of the total evaluated area are very suitable place for a solid waste landfill. Miranda-Ackerman et al. [20] developed a green supplier selection model in agro-food industry supply chains based on TOPSIS method in combination with a multi-objective decision-making model. The proposed model is applied to an orange juice supply chain. Alamanos et al. [21] employed four MCDM techniques—multi attribute utility theory (MAUT), AHP, TOPSIS and ELECTRE—to create a multi-criteria analysis tool to support the water resource management strategies evaluation process. Karacan et al. [22] introduced a novel approach to the chickpea cultivars selection problem under stress conditions using FAHP and goal programming technique. Mostafaeipour [23] et al. developed a MCDM based approached support the analysis of potential geothermal project location in Afghanistan. The authors utilized stepwise weight assessment ratio analysis (SWARA) and the additive ratio assessment (ARAS) methods to develop the MCDM model. The proposed model result shows that the Ghazni province is the most optimal location for new geothermal projects. Ulutaş et al. [24] introduced a novel MCDM model to support the equipment selection problem in the field of logistics. The proposed model used the correlation coefficient and the standard deviation (CCSD) in combination with the indifference threshold-based attribute ratio analysis method (ITARA) to calculate the equipment selection criteria weights, while the compromise solution method (MARCOS) was employed to rank the alternatives. Wu and Abdul-Nour [25] performed a comparative evaluation of four MCDM techniques—AHP, ELECTRE III, TOPSIS, and PROMETHEE II—in their ability to solve the urban sewer network plan selection problem. The authors suggested that PROMETHEE II is the optimal MCDM technique to solve the problem.

In supply chain management, MCDM models are commonly employed in decision support systems [26,27,28,29,30]. One of the common use cases of these systems is to solve supplier selection problems. Rezaeisaray et al. [31] introduced a novel MCDM model to solve the outsourcing supplier selection problem in pipe manufacturing. The proposed model is created using DEMATEL, Fuzzy ANP, and Data Envelopment Analysis (DEA) methods. Liu et al. [32] proposed an integrated MCDM model based on Best-worst method (BWM) and Alternative Queuing Method (AQM) to support solving the supplier selection problem under fuzzy environment. Wang Chen et al. [33] support the green supplier selection process using a fuzzy MCDM model. In this model, Fuzzy AHP and Fuzzy TOPSIS were employed in combination with economic and environmental criteria. Hamdan and Cheaitou [34] introduced an approach to the supplier selection and order allocation (SS/OA) problem which is based on a combination of AHP, Fuzzy TOPSIS, and multi-objective optimization methods. Wang et al. [35] proposed multicriteria decision-making (MCDM), including a fuzzy analytic network process (FANP) and technique for order preference by similarity of an ideal solution (TOPSIS) for NPP location selection in Vietnam. Wang et al. [36] proposed an MCDM model using a combination of SCOR metrics with an AHP-TOPSIS approach to support the supplier selection process. Wang et al. [37] introduced a FANP-DEA-based approach to the supplier selection processes in the rice supply chains. Pang et al. [38] utilized fuzzy preference programming (FPP) method in combination with the ANP method to develop a MCDM model to support wind turbine supplier evaluation and selection process. The proposed model was applied to a real-world case study in China and Goldwind was identified as the optimal supplier. Hoseini et al. [39] developed an MCDM model to support the sustainable supplier selection process using fuzzy best-worst method (Fuzzy BWM) and fuzzy inference system model. Zhang et al. [40] introduced a DEMATEL-Fuzzy VIKOR based MCDM model to solve sustainable supplier selection problem. The proposed approach takes the interaction between criteria and the uncertain nature of the decision-making environment into consider which allows a more effective and accurate supplier selection process. Wang et al. [41] introduced a FAHP-DEA-based approach to sustainable supplier selection problems in edible oil production industry. Malek et al. [42] employed grey relational analysis method (GRA) to develop a novel hybrid GRA model for green supply network assessment problem.

While there have been multiple MCDM models introduced to support supplier selection problems, none of these is developed for the frozen shrimp industry, especially under uncertain decision-making environment. Martinez-Cordero [43] developed a MCDM model to evaluate and select sustainable shrimp farming method. Gangadharan et al. [44] employed an AHP-based decision-making support model for the ground water vulnerability assessment process of shrimp farming area. This research study’s goal is to develop a robust and effective supplier selection decision support tool for frozen shrimp exporters under fuzzy environment by combining FANP and WASPAS methods. The FANP method is chosen due to its advantages over FAHP in complex decision-making problems where there is dependency between criteria. Furthermore, FANP and WAPAS methods are also easy-to-understand and readily available in many decision support software, which increase the proposed model usability.

3. Methodology

3.1. Research Graph

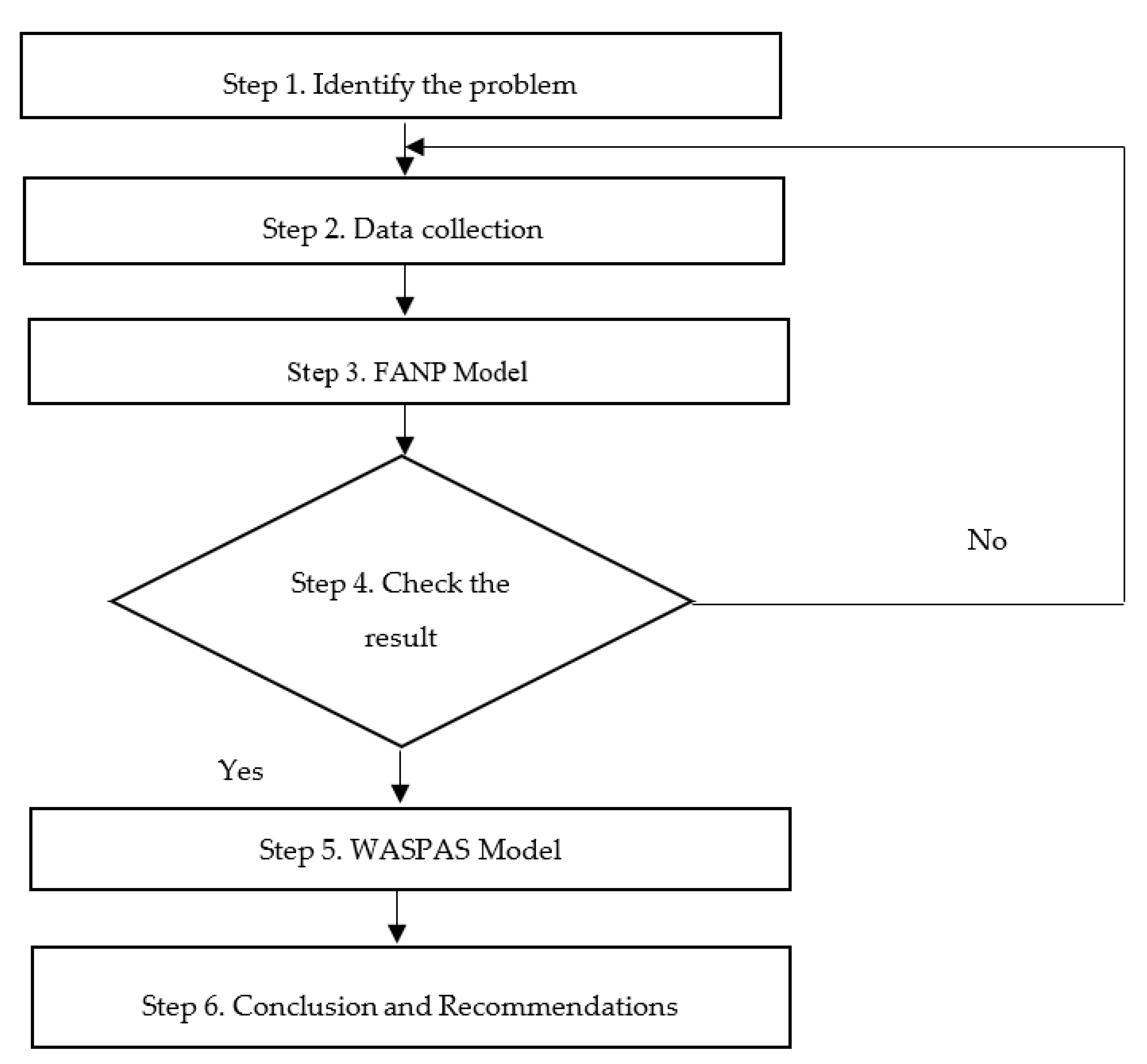

The implementation process of the proposed model consists of six steps as shown in Figure 1.

Figure 1.

Research process.

Step 1: Identify the Problem.

The first step is to learn about the purchasing process as well as the criteria for selecting suppliers at the company through observing the actual operating environment. At the same time, related literature is reviewed in order to identify selection criteria and sub-criteria.

Step 2: Data Collection.

Collect criteria, gather information about suppliers, set up a team of experts or outsource to evaluate criteria.

Step 3: Fuzzy Analysis Network Process (FANP) model.

Apply the FANP method to find the related weights of the criteria and sub-criteria.

Step 4. Check the FANP model’s result.

Check the correctness of the model. If the result is not satisfactory, return to section and re-evaluate the comparison matrix.

Step 5: WASPAS model.

Experts will conduct an initial assessment combined with the weights from the FANP model. Build a new integration model that supports multi decision-making.

Step 6: Conclusions and recommendations.

Analyse and parse the results achieved when conducting the research. Identify issues encountered and unresolved. Provide findings to stakeholders. Develop models in combination with other methods used in other decision-making areas.

3.2. An Integrated Model for Supplier Selection

3.2.1. Fuzzy Analytic Network Process (FANP) Model

While according to Satty [45], the combination of fuzzy theory and AHP/ANP methods is unnecessary, the combination of fuzzy theory and ANP/AHP methods is widely applied in similar decision-making problems. The FANP method is chosen to calculate the criteria weights in this study due to its ability to handle interdependent criteria [46] which is common in supplier selection problems, as well as its ability to represent the uncertain nature of the decision-making process. Furthermore, FANP method is also widely available in different decision-making software which helps improve the proposed method’s usability.

Theoretical weaknesses of the AHP/ANP are primarily: the rank reversal problem, the priorities derivation method, and the comparison scale [47,48]. The rank reversal and priorities derivation method are closely related to each other. The rank reversal because of the formulation of the problem assumes that there is a ranking of alternatives determined with the use of the right eigenvector (preference aggregation method). Solving a reversal problem and performing a preferences aggregation with the use of a left eigenvector method should, as a result, produce a reverse sequence of elements which were pairwise-compared in a matrix. However, this is not always true, in particular in the case of some inconsistencies in the pairwise comparison matrix [49,50]. Therefore, it is important to check the consistency of the pairwise comparison matrix to ensure that the model can perform adequately.

As such, the FANP model is applied to calculate the weights of the selection criteria and sub criteria through four steps as follows:

Step 1: Building the FANP model structure.

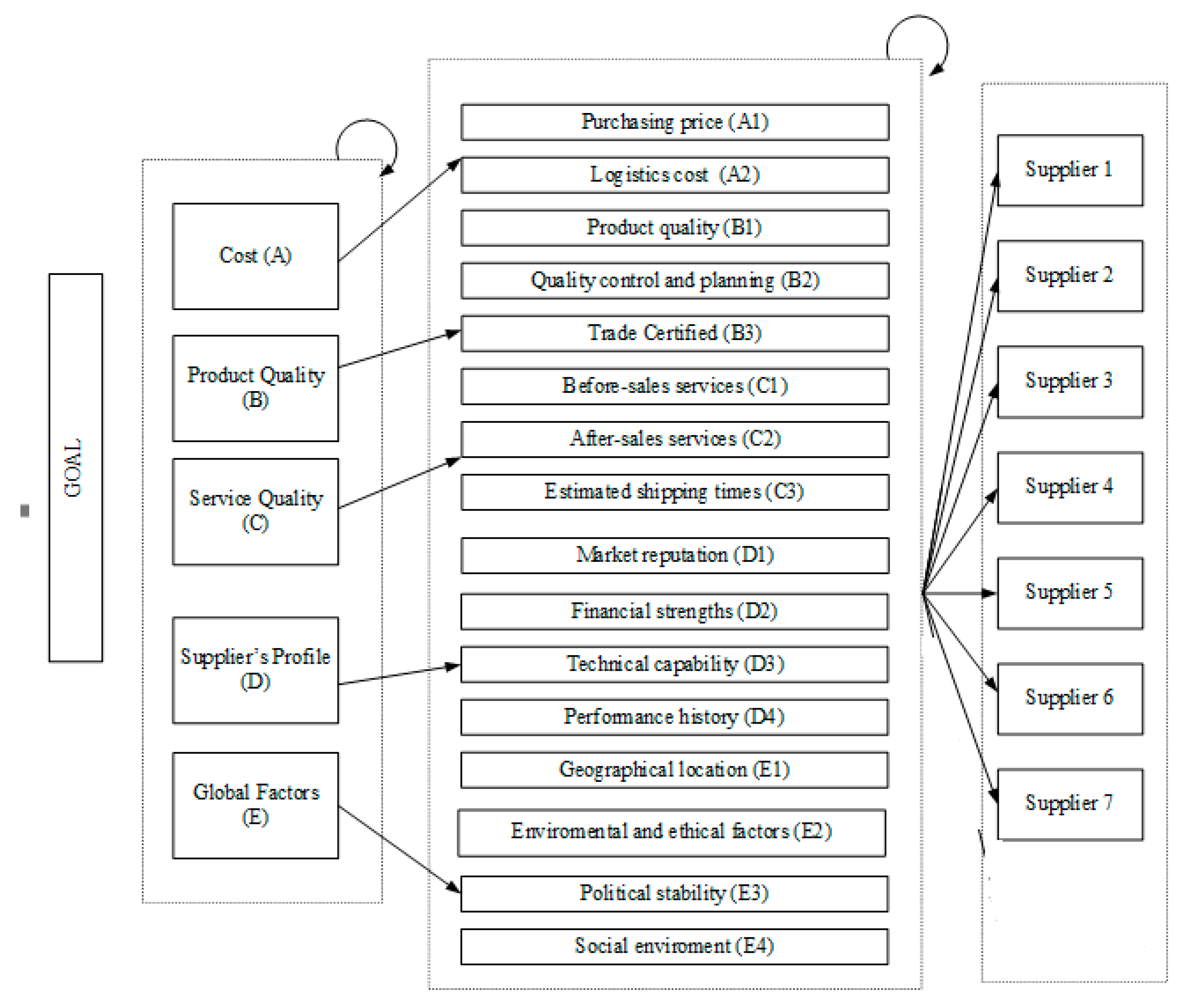

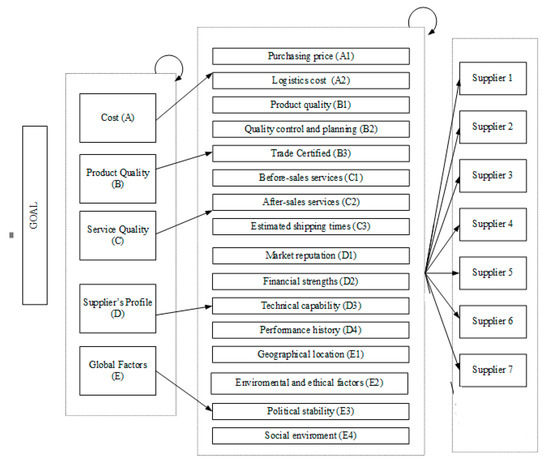

The relationships between the selection criteria and the suppliers are shown on Figure 2:

Figure 2.

The Fuzzy Analytic Network Process (FANP) model.

Step 2: Calculate the pairwise comparison matrix.

A fuzzy pairwise comparison matrix is employed to carry out the pairwise comparison between the criteria. The matrix is defined as follows:

where:

is the fuzzy pairwise comparison matrix.

is the triangular fuzzy mean value of the pairwise priority comparison result between the criteria.

The triangular fuzzy trigonometric method is applied to convert the fuzzy elements of the fuzzy pairwise comparison matrix into real numbers [51]:

where:

When matching the diagonal matrix, we have:

After the conversion of the fuzzy pairwise comparison matrix’s elements into real numbers, a comparison matrix with real numbers (N) is obtained as follows:

Step 3: Determine the maximum individual value.

The Lambda Max method, proposed by Saaty [52,53], is applied in this step to calculate the maximum specific value of the indicator as follows:

where:

: the maximum value of the matrix.

I: unit matrix with the same level of matrix N.

Step 4: Examine the consistency ratio of the model.

The Consistency Ratio (CR) is calculated as:

where CI is the Consistency Index and RI is the Random Index. The Consistency index is calculated as:

where:

is the maximum value of the matrix.

n is the number of criteria.

The Random Index is determined based on the number of criteria (n) as shown in Table 1 below:

Table 1.

Randomized Index Values [54].

If CR ≤ 0.1 then the result of the model is satisfactory, otherwise the comparison matrix must be re-evaluated.

3.2.2. Weighted Aggregated Sum Product Assessment (WASPAS)

The WASPAS method is applied to calculate the ranking of the alternatives due to the method’s simplicity and easy-to-understand nature which adds to the proposed model’s applicability. WASPAS is also a well-known method which is available in decision-making software [55]. In the WASPAS method, each alternative ranking score is the product of the scale rating of each criterion of strength by the criterion’s significance weight [56].

The WASPAS method application steps are presented as follows:

Step 1: Normalization of the decision matrix.

The approach to normalizing the decision matrix depends on whether the decision criteria are beneficial or not. For beneficial decision criteria the decision matrix is normalized using Equation (10) as follows:

For non-beneficial decision criteria as shown in Equation (11):

Step 2: Determine the relative importance of the ith alternative, based on the Weighted Sum Model as follows:

Step 3: The performance index of the ith alternative is evaluated by Weighted Product Model as given in Equation (13):

Step 4: With the combination of Equations (12) and (13), we create a WASPAS model to calculate the total relative importance.

The general criterion of the weighted synthesis of the addition and multiplication methods (the sum of relative importance) is calculated as follows:

with λ as the coefficient where λ ∈ [0,1]. When decision-makers have no preference in relation to the coefficient, its value is set to λ = 0.5.

The alternatives are ranked based on an index of performance, and the optimal supplier will have the highest score.

4. Case Study

4.1. Data Collection

From the reference documents and expert analysis, the authors identified a list of criteria. In this case study five main criteria with 16 sub-criteria and seven potential suppliers are identified (Table 2 and Table 3).

Table 2.

List of supplier selection criteria.

Table 3.

List of suppliers.

4.2. FANP Model

After the supplier selection criteria and potential suppliers are identified, the decision-makers compare the attributes related to the criterion. Then, the pairwise comparison matrix (Table 4) is constructed, and the weight vector of each matrix is determined. All properties are compared against each individual criterion by following the sample procedure shown as follows.

Table 4.

Pair-wise comparison matrix of main criteria.

The fuzzy pairwise comparison matrix between main criteria is calculated. The results are shown in Table 5.

Table 5.

Fuzzy pairwise comparison matrix between main criteria.

In the next step the fuzzy pairwise comparison matrix between the main criteria is converted into crisp numbers using the triangular fuzzy number method. In this process of defuzzification, the coefficients values are α = 0.5 and β = 0.5, where α represents the uncertainty of the environment and β represents the fairness of the assessment. A sample calculation of the defuzzification process is shown as follows:

f0.5(LE,B) = (4 − 3) × 0.5 + 3 = 3.5

f0.5(UE,B) = 5 − (5 − 4) × 0.5 = 4.5

The real number priority matrix after the defuzzification process is shown in Table 6:

Table 6.

Real number priority matrix.

The maximum individual value is calculated as follows:

with five main criteria, the λmax and CI values are calculated as follows:

with RI = 1.12 and N = 5, the CR value is calculated as:

MX1 = (1 × 3 × 6 × 2 × 3)1/5 = 2.55

MX2 = (1/3 × 1 × 4 × 2 × 2)1/5 = 1.4

MX3 = (1/6 × 1/4 × 1 × 1/3 × 1/2)1/5 = 0.37

MX4 = (1/2 × 1/2 × 3 × 1 × 2)1/5 = 1.08

MX5 = (1/3 × 1/2 × 2 × 1/2 × 1)1/5 = 0.7

∑ MX = MX1 + MX2 + MX3 + MX4 + MX5 = 6.1

As the consistency ratio is CR = 0.0821 ≤ 0.1, the result is satisfactory and there is no need to reevaluate the pairwise comparison matrix. The results of the pairwise comparison matrix are presented in Table 7:

Table 7.

The results of the pair-wise comparison matrix.

To calculate the effect between the main criteria, a pairwise comparison matrix between main criteria without criterion A is constructed. The results are presented in Table 8:

Table 8.

Comparison between the main criteria in the absence of A.

The pairwise comparison matrix between main criteria without criterion B is presented in Table 9:

Table 9.

Comparison between the main criteria in the absence of B.

The pairwise comparison matrix between main criteria without criterion C is presented in Table 10:

Table 10.

Comparison between the main criteria in the absence of C.

The pairwise comparison matrix between main criteria without criterion D is presented in Table 11:

Table 11.

Comparison between the main criteria in the absence of D.

The pairwise comparison matrix between main criteria without criterion E is presented in Table 12:

Table 12.

Comparison between the main criteria in the absence of E.

The sub-criteria weights are shown in Table 13.

Table 13.

Weights of sub-criteria.

After weights of the sub-criteria are determined by FANP, how to choose the best supplier WASPAS is developed.

4.3. WASPAS Method

The WASPAS method will be used to select the best supplier after receiving the comparison weights criteria from the FANP model results. Table 14 shows the Weight Normalized Matrix of the criteria among suppliers.

Table 14.

Weighted Normalized Matrix.

Table 15 shows the Exponentially Weighted Matrix of the criteria among suppliers.

Table 15.

Exponentially Weighted Matrix.

Based on Table 14 and Table 15, the relative importance of the alternatives is calculated using Weighted Sum Model () and Weighted Product Model (). The final performance indexes of the potential suppliers are calculated and shown in Table 16. The final ranking of the potential suppliers is obtained based on the final performance indexes which shows Supplier 3 (S3) is the optimal supplier.

Table 16.

Result of supplier selection process.

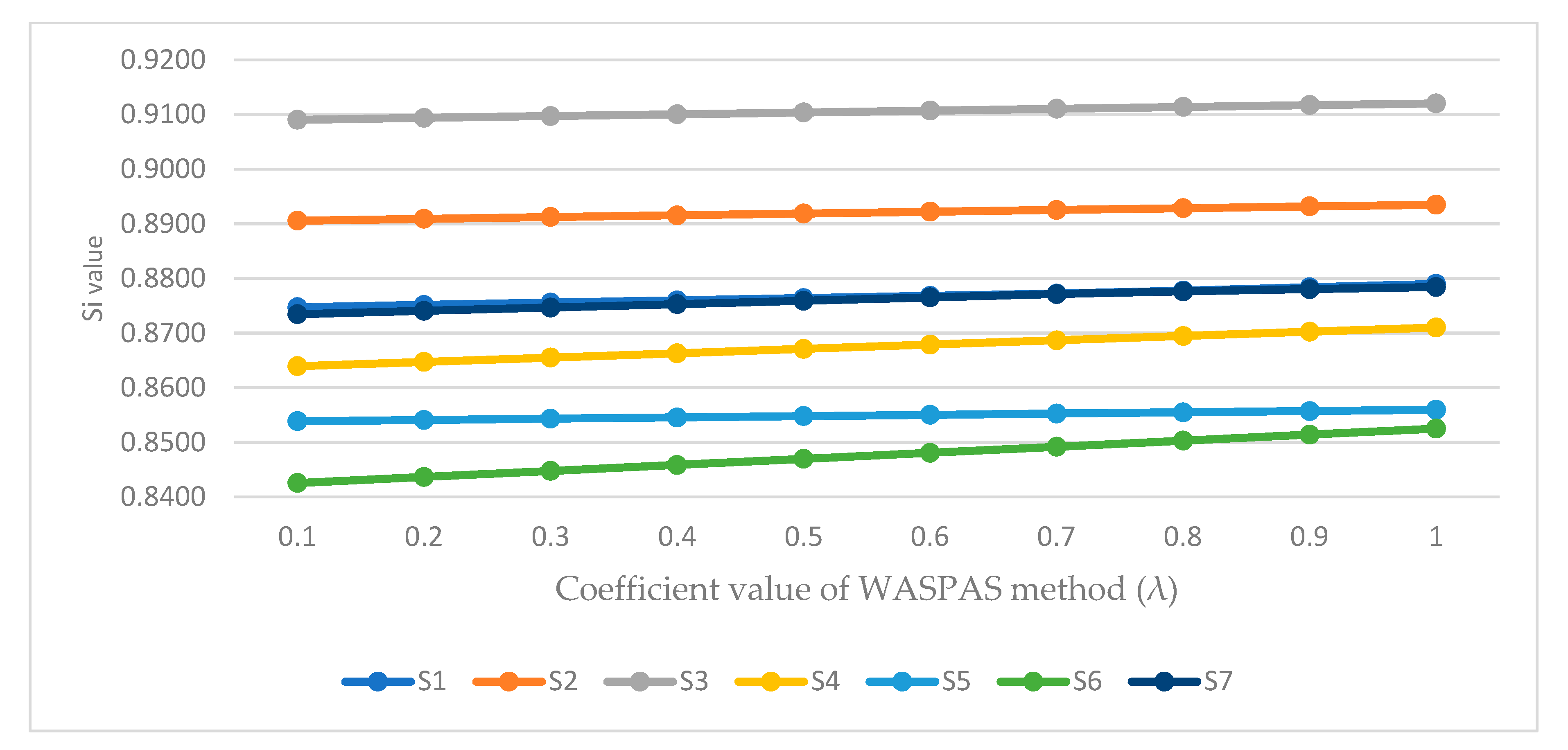

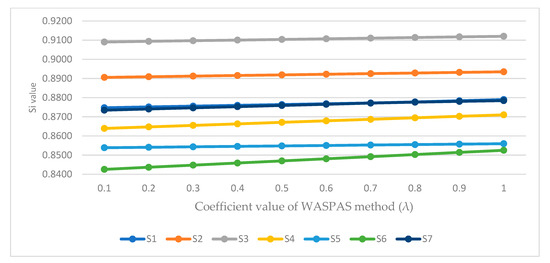

The proposed model’s rationality and stability are verified using the concept of sensitivity analysis. In this case, the resolving coefficient values (λ) are used to test the reliability of the proposed approach between λ = 0.1 and λ = 1.

From Table 17 and Figure 3 it can be seen that, with changing values of λ the ranking results are the same. Therefore, the ranking results of the proposed model are robust and reliable.

Table 17.

Effect of λ on ranking performance of Weighted Aggregated Sum Product Assessment (WASPAS) method.

Figure 3.

Variation analysis of λ values of each alternative.

According to the results in Table 16 and Figure 3, Supplier 3 (S3) is consistently the best alternative, and the remaining six suppliers are not optimal in any case. The alternatives are ranked as S3 > S2 > S7 > S1 > S4 > S5 > S6. Therefore, it is confirmed that the proposed model can be applied to real-world cases. The research has successfully created a hybrid MCDM model using FANP and WASPAS to assist the supplier evaluation and selection process in the shrimp industry.

5. Conclusions

Selecting suppliers is an important decision-making problem that can boost business and increase profits in the shrimp industry. However, the supplier selection process tends to rely, mostly, on the decision-maker’s experience which creates inaccuracy and ambiguity. While there are various academic studies about the application of MCDM models in supplier selection processes in different industries, the integration of fuzzy theory into these models is recent. However, none of these models are specially developed for the shrimp industry, especially within a fuzzy environment. The aim of this research is to develop an optimal supplier selection model for the shrimp industry within a fuzzy environment. FANP and WASPAS methods are combined in this study to develop a fuzzy MCDM model to support the supplier selection process in the shrimp industry. FANP and WASPAS methods were chosen due to their availability in many decision-making software, which allows the proposed model to be easily applied in practical situations.

The proposed model was developed based on the combination of the FANP method and the WASPAS model. A model test problem concerning supplier selection was performed as follows: evaluation criteria were listed first through the documentary review and interview with experts, and they were used to build a network with five criteria, sixteen sub-criteria, and seven suppliers. After the experts answered the questionnaire, the Fuzzy ANP model was used to calculate the weights of the criteria and sub-criteria and to determine the relative importance of the criteria. The results obtained from the Fuzzy ANP model were then used as input data in conjunction with expert evaluation of the WASPAS model to rank suppliers. The results of ranking suppliers from the WASPAS model showed that Supplier 3 (S3) is the most suitable. From the results of this case study, the proposed model is found to be feasible.

The FANP-WASPAS model can support optimal decision-making because it considers problems based on many criteria and allows the decision-makers to check the correlation between criteria. It also considers the ambiguity, uncertainty, and subjectivity of many different decision makers. Therefore, the model in this study can support companies in the shrimp industry in making optimal decisions regarding supplier selection. Although the study is only applicable to the shrimp industry in Vietnam, the proposed model can be adapted and modified to support other industries in different countries as a resource in solving MCDM problems. A potential application is the development of fuzzy MCDM models based on the proposed method to support the supplier selection processes for different Vietnamese exported aquatic products to the EU market, such as pangasius and tuna. Future research can look into different methods to handle the uncertainty of supplier selection processes, such as the integration of D numbers into MCDM models, and perform a comparative analysis of different models to identify the optimal support tool for the supplier selection problems of supply chains.

Author Contributions

Conceptualization, C.-N.W., V.T.N. (Van Thanh Nguyen), J.-C.K., C.-C.C. and V.T.N. (Viet Tinh Nguyen); Data curation, C.-N.W., V.T.N. (Van Thanh Nguyen), J.-C.K. and C.-C.C.; Formal analysis, C.-N.W., V.T.N. (Van Thanh Nguyen) and V.T.N. (Viet Tinh Nguyen); Funding acquisition, C.-N.W., C.-C.C. and V.T.N. (Viet Tinh Nguyen); Investigation, V.T.N. (Van Thanh Nguyen), J.-C.K. and V.T.N. (Viet Tinh Nguyen); Methodology, V.T.N. (Van Thanh Nguyen), J.-C.K., C.-C.C. and V.T.N. (Viet Tinh Nguyen); Project administration, C.-N.W. and J.-C.K.; Resources, C.-N.W., V.T.N. (Van Thanh Nguyen), J.-C.K. and V.T.N. (Viet Tinh Nguyen); Software, V.T.N. (Van Thanh Nguyen) and C.-C.C.; Validation, C.-N.W.; Visualization, C.-C.C.; Writing—original draft, V.T.N. (Van Thanh Nguyen) and V.T.N. (Viet Tinh Nguyen); Writing—review and editing, C.-N.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Vietnam Investment Review. Vietnam Exports First Batch of Shrimp to EU under EVFTA. 2020. Available online: https://www.vir.com.vn/vietnam-exports-first-batch-of-shrimp-to-eu-under-evfta-79210.html (accessed on 12 November 2020).

- Vietnamnews. Shrimp Exports to EU Surge. 2020. Available online: https://vietnamnews.vn/economy/822040/shrimp-exports-to-eu-surge.html (accessed on 9 November 2020).

- The European Union. How to Export Shrimps to the European Union. 2020. Available online: https://europa.eu/capacity4dev/file/9654/download?token=KV8BYbN_#:~:text=Shrimps%20can%20only%20be%20exported,the%20EU’s%20border%20inspection%20control (accessed on 12 November 2020).

- Nguyen, T.A.T.; Nguyen, K.A.T.; Jolly, C. Is Super-Intensification the Solution to Shrimp Production and Export Sustainability? Sustainability 2019, 11, 5277. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Rigo, P.D.; Rediske, G.; Rosa, C.B.; Gastaldo, N.G.; Michels, L.; Neuenfeldt Júnior, A.L.; Siluk, J.C.M. Renewable Energy Problems: Exploring the Methods to Support the Decision-Making Process. Sustainability 2020, 12, 10195. [Google Scholar] [CrossRef]

- Pons-Valladares, O.; Nikolic, J. Sustainable Design, Construction, Refurbishment and Restoration of Architecture: A Review. Sustainability 2020, 12, 9741. [Google Scholar] [CrossRef]

- Kuo-Ping, L.; Kuo-Chen, H.; Yu-Ting, L.; Yao-Hung, H. Green Suppliers Performance Evaluation in Belt and Road Using Fuzzy Weighted Average with Social Media Information. Sustainability 2017, 10, 5. [Google Scholar]

- Asemi, A.; Asemi, A. Intelligent MCDM Method for Supplier Selection under Fuzzy Environment. Int. J. Inf. Sci. Manag. 2014, 33–40. [Google Scholar]

- Wang, C.-N.; Nguyen, V.T.; Chyou, J.-T.; Lin, T.-F.; Nguyen, T.N. Fuzzy Multicriteria Decision-Making Model (MCDM) for Raw Materials Supplier Selection in Plastics Industry. Mathematics 2019, 7, 981. [Google Scholar] [CrossRef]

- Alizadeh, M.; Hashim, M.; Alizadeh, E.; Shahabi, H.; Karami, M.; Beiranvand Pour, A.; Pradhan, B.; Zabihi, H. Multi-Criteria Decision Making (MCDM) Model For Seismic Vulnerability Assessment (SVA) Of Urban Residential Buildings. ISPRS Int. J. Geo-Inf. 2018, 7, 444. [Google Scholar] [CrossRef]

- Govindarajan, U.; K Ramachandaramurthy, V. Multiple Criteria Decision Making (MCDM) Based Economic Analysis of Solar PV System with Respect to Performance Investigation for Indian Market. Sustainability 2017, 9, 820. [Google Scholar] [CrossRef]

- Tzeng, G.; Chiang, C.; Li, C. Evaluating Intertwined Effects in E-Learning Programs: A Novel Hybrid MCDM Model Based On Factor Analysis And DEMATEL. Expert Syst. Appl. 2007, 32, 1028–1044. [Google Scholar] [CrossRef]

- Mousavi, S.; Danehkar, A.; Shokri, M.; Poorbagher, H.; Azhdari, D. Site Selection For Artificial Reefs Using A New Combine Multi-Criteria Decision-Making (MCDM) Tools For Coral Reefs In The Kish Island–Persian Gulf. Ocean Coast. Manag. 2015, 111, 92–102. [Google Scholar] [CrossRef]

- Villacreses, G.; Gaona, G.; Martínez-Gómez, J.; Jijón, D. Wind Farms Suitability Location Using Geographical Information System (GIS), Based On Multi-Criteria Decision Making (MCDM) Methods: The Case Of Continental Ecuador. Renew. Energy 2017, 109, 275–286. [Google Scholar] [CrossRef]

- Peng, Y. Regional Earthquake Vulnerability Assessment Using a Combination Of MCDM Methods. Ann. Oper. Res. 2012, 234, 95–110. [Google Scholar] [CrossRef]

- Pujadas, P.; Pardo-Bosch, F.; Aguado-Renter, A.; Aguado, A. MIVES Multi-Criteria Approach for the Evaluation, Prioritization, And Selection Of Public Investment Projects. A Case Study in the City Of Barcelona. Land Use Policy 2017, 64, 29–37. [Google Scholar] [CrossRef]

- Pujadas, P.; Cavalaro, S.; Aguado, A. Mives Multicriteria Assessment Of Urban-Pavement Conditions: Application To A Case Study In Barcelona. Road Mater. Pavement Des. 2018, 20, 1827–1843. [Google Scholar] [CrossRef]

- Mallick, J. Municipal Solid Waste Landfill Site Selection Based on Fuzzy-AHP and Geoinformation Techniques in Asir Region Saudi Arabia. Sustainability 2021, 13, 1538. [Google Scholar] [CrossRef]

- Miranda-Ackerman, M.A.; Azzaro-Pantel, C.; Aguilar-Lasserre, A.A.; Bueno-Solano, A.; Arredondo-Soto, K.C. Green Supplier Selection in the Agro-Food Industry with Contract Farming: A Multi-Objective Optimization Approach. Sustainability 2019, 11, 7017. [Google Scholar] [CrossRef]

- Alamanos, A.; Mylopoulos, N.; Loukas, A.; Gaitanaros, D. An Integrated Multicriteria Analysis Tool for Evaluating Water Resource Management Strategies. Water 2018, 10, 1795. [Google Scholar] [CrossRef]

- Karacan, I.; Senvar, O.; Arslan, O.; Ekmekçi, Y.; Bulkan, S. A Novel Approach Integrating Intuitionistic Fuzzy Analytical Hierarchy Process and Goal Programming for Chickpea Cultivar Selection under Stress Conditions. Processes 2020, 8, 1288. [Google Scholar] [CrossRef]

- Mostafaeipour, A.; Hosseini Dehshiri, S.J.; Hosseini Dehshiri, S.S.; Jahangiri, M.; Techato, K. A Thorough Analysis of Potential Geothermal Project Locations in Afghanistan. Sustainability 2020, 12, 8397. [Google Scholar] [CrossRef]

- Ulutaş, A.; Karabasevic, D.; Popovic, G.; Stanujkic, D.; Nguyen, P.T.; Karaköy, Ç. Development of a Novel Integrated CCSD-ITARA-MARCOS Decision-Making Approach for Stackers Selection in a Logistics System. Mathematics 2020, 8, 1672. [Google Scholar] [CrossRef]

- Wu, Z.; Abdul-Nour, G. Comparison of Multi-Criteria Group Decision-Making Methods for Urban Sewer Network Plan Selection. CivilEng 2020, 1, 3. [Google Scholar] [CrossRef]

- Ghodsypour, S.; O’Brien, C. A Decision Support System for Supplier Selection Using an Integrated Analytic Hierarchy Process and Linear Programming. Int. J. Prod. Econ. 1998, 56–57, 199–212. [Google Scholar] [CrossRef]

- Bhutta, K.; Huq, F. Supplier Selection Problem: A Comparison of the Total Cost of Ownership and Analytic Hierarchy Process Approaches. Supply Chain Manag. Int. J. 2002, 7, 126–135. [Google Scholar] [CrossRef]

- Mohanty, R.; Deshmukh, S. Use of Analytic Hierarchic Process for Evaluating Sources of Supply. Int. J. Phys. Distrib. Logist. Manag. 1993, 23, 22–28. [Google Scholar] [CrossRef]

- Narasimhan, R. An Analytical Approach to Supplier Selection. J. Purch. Mater. Manag. 1983, 19, 27–32. [Google Scholar] [CrossRef]

- Nydick, R.; Hill, R. Using the Analytic Hierarchy Process to Structure the Supplier Selection Procedure. Int. J. Purch. Mater. Manag. 1992, 28, 31–36. [Google Scholar] [CrossRef]

- Rezaeisaray, M.; Ebrahimnejad, S.; Khalili-Damghani, K. A Novel Hybrid MCDM Approach for Outsourcing Supplier Selection. J. Model. Manag. 2016, 11, 536–559. [Google Scholar] [CrossRef]

- Liu, H.; Quan, M.; Li, Z.; Wang, Z. A New Integrated MCDM Model for Sustainable Supplier Selection under Interval-Valued Intuitionistic Uncertain Linguistic Environment. Inf. Sci. 2019, 486, 254–270. [Google Scholar] [CrossRef]

- Wang Chen, H.; Chou, S.; Luu, Q.; Yu, T. A Fuzzy MCDM Approach for Green Supplier Selection from the Economic and Environmental Aspects. Math. Probl. Eng. 2016, 2016, 1–10. [Google Scholar] [CrossRef]

- Hamdan, S.; Cheaitou, A. Supplier Selection And Order Allocation With Green Criteria: An MCDM And Multi-Objective Optimization Approach. Comput. Oper. Res. 2017, 81, 282–304. [Google Scholar] [CrossRef]

- Wang, C.-N.; Su, C.-C.; Nguyen, V.T. Nuclear Power Plant Location Selection in Vietnam under Fuzzy Environment Conditions. Symmetry 2018, 10, 548. [Google Scholar] [CrossRef]

- Wang, C.-N.; Huang, Y.-F.; Cheng, I.F.; Nguyen, V.T. A Multi-Criteria Decision-Making (MCDM) Approach Using Hybrid SCOR Metrics, AHP, and TOPSIS for Supplier Evaluation and Selection in the Gas and Oil Industry. Processes 2018, 6, 252. [Google Scholar] [CrossRef]

- Wang, C.; Nguyen, V.T.; Duong, D.H.; Do, H.T. A Hybrid Fuzzy Analytic Network Process (FANP) and Data Envelopment Analysis (DEA) Approach for Supplier Evaluation and Selection in the Rice Supply Chain. Symmetry 2018, 10, 221. [Google Scholar] [CrossRef]

- Pang, N.; Nan, M.; Meng, Q.; Zhao, S. Selection of Wind Turbine Based on Fuzzy Analytic Network Process: A Case Study in China. Sustainability 2021, 13, 1792. [Google Scholar] [CrossRef]

- Hoseini, S.A.; Fallahpour, A.; Wong, K.Y.; Mahdiyar, A.; Saberi, M.; Durdyev, S. Sustainable Supplier Selection in Construction Industry through Hybrid Fuzzy-Based Approaches. Sustainability 2021, 13, 1413. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, D.; Li, Q.; Lev, B.; Ma, Y. Research on Sustainable Supplier Selection Based on the Rough DEMATEL and FVIKOR Methods. Sustainability 2021, 13, 88. [Google Scholar] [CrossRef]

- Wang, C.-N.; Nguyen, V.T.; Thai, H.T.N.; Tran, N.N.; Tran, T.L.A. Sustainable Supplier Selection Process in Edible Oil Production by a Hybrid Fuzzy Analytical Hierarchy Process and Green Data Envelopment Analysis for the SMEs Food Processing Industry. Mathematics 2018, 6, 302. [Google Scholar] [CrossRef]

- Malek, A.; Ebrahimnejad, S.; Tavakkoli-Moghaddam, R. An Improved Hybrid Grey Relational Analysis Approach for Green Resilient Supply Chain Network Assessment. Sustainability 2017, 9, 1433. [Google Scholar] [CrossRef]

- Martinez-Cordero, F.; Leung, P. Multicriteria Decision Making (MCDM) Model For Regional Sustainable Shrimp Farming Development In Northwest Mexico. Aquac. Econ. Manag. 2004, 8, 179–192. [Google Scholar] [CrossRef]

- Gangadharan, R.; Nila, R.P.; Vinoth, S. Assessment Of Groundwater Vulnerability Mapping Using AHP Method In Coastal Watershed Of Shrimp Farming Area. Arab. J. Geosci. 2016, 9, 107. [Google Scholar]

- Saaty, L.T. The Analytic Hierarchy and Analytic Network Measurement Processes: Applications to Decisions under Risk. Eur. J. Pure Appl. Math. 2008, 1, 122–196. [Google Scholar]

- Ziemba, P. Inter-Criteria Dependencies-Based Decision Support in the Sustainable Wind Energy Management. Energies 2019, 12, 749. [Google Scholar] [CrossRef]

- Ishizaka, A.; Lusti, M. How to Derive Priorities in AHP: A Comparative Study. Cent. Eur. J. Oper. Res. 2006, 14, 387–400. [Google Scholar] [CrossRef]

- Ishizaka, A.; Labib, A. Analytic Hierarchy Process and Expert Choice: Benefits and Limitations. OR Insight 2009, 22, 201–220. [Google Scholar] [CrossRef]

- Ziemba, P.; Wątróbski, J.; Jankowski, J.; Piwowarski, M. Research on the Properties of the AHP In The Environment Of Inaccurate Expert Evaluations. Sel. Issues Exp. Econ. 2016, 227–243. [Google Scholar]

- Ziemba, P.; Wątróbski, J. Selected Issues of Rank Reversal Problem in ANP Method. Sel. Issues Exp. Econ. 2016, 203–225. [Google Scholar]

- Guneri, A.; Cengiz, M.; Seker, S. A Fuzzy ANP Approach to Shipyard Location Selection. Expert Syst. Appl. 2009, 36, 7992–7999. [Google Scholar] [CrossRef]

- Chang, D. Applications of the Extent Analysis Method on Fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Hwang, C.; Yoon, K. Multiple Attribute Decision Making; Springer: Berlin/Heidelberg, Germany, 1981. [Google Scholar]

- Kusumadewi, S.; Hartati, S.; Harjoko, A.; Wardoyo, R. Fuzzy Multi-Attribute Decision Making (Fuzzy MADM). J. Transform. 2006, 14, 78–79. [Google Scholar]

- Singh, R.; Modgil, S. Supplier Selection Using SWARA and WASPAS—A Case Study of Indian Cement Industry. Meas. Bus. Excell. 2020, 24, 243–265. [Google Scholar] [CrossRef]

- Hadi Mousavi-Nasab, S.; Sotoudeh-Anvari, A. An Extension of Best-Worst Method with D Numbers: Application in Evaluation of Renewable Energy Resources. Sustain. Energy Technol. Assess. 2020, 40, 100771. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).