Comprehensive View of Topological Optimization Scooter Frame Design and Manufacturing

Abstract

:1. Introduction

- Presenting a typical framework for fabricating topologically optimized products;

- Reporting arising technical issues and practical solutions at each stage of the process;

- Showcasing how TO and AM can be combined to deliver a futuristic and functional product, as well as the pros and cons in comparison with conventional manufacturing methods;

- Suggesting possible improvements that can be introduced for better fabricating TO components with AM utilizing existing numerical and manufacturing tools.

2. Materials and Methods

2.1. Load Case Definition and Experiments

2.1.1. Normal Operation

2.1.2. Drop

2.1.3. Braking

2.1.4. Torsional Stiffness

2.2. Topology Optimization (TO)

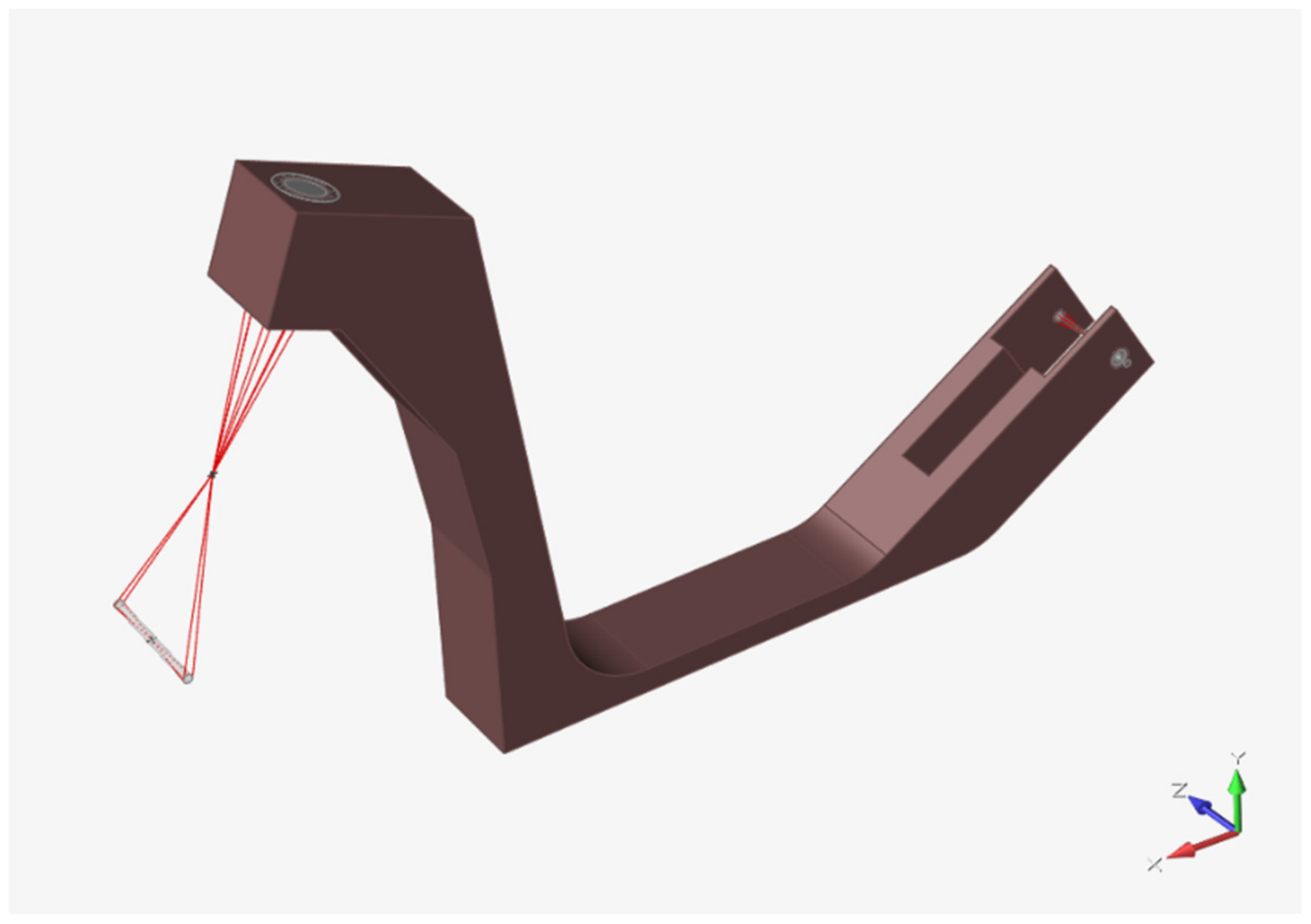

2.2.1. Design Space

2.2.2. Materials and TO Objectives

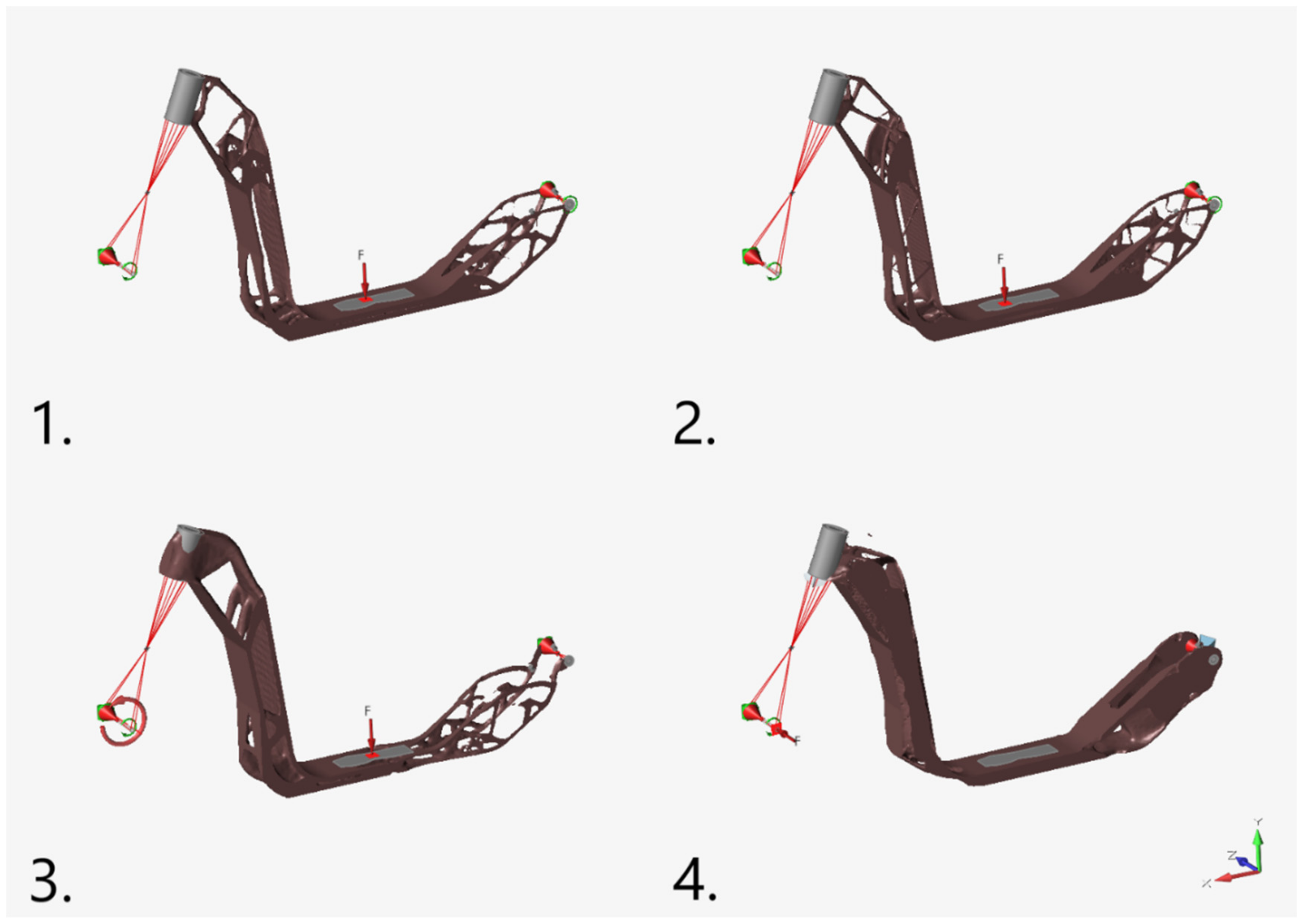

2.2.3. TO Results

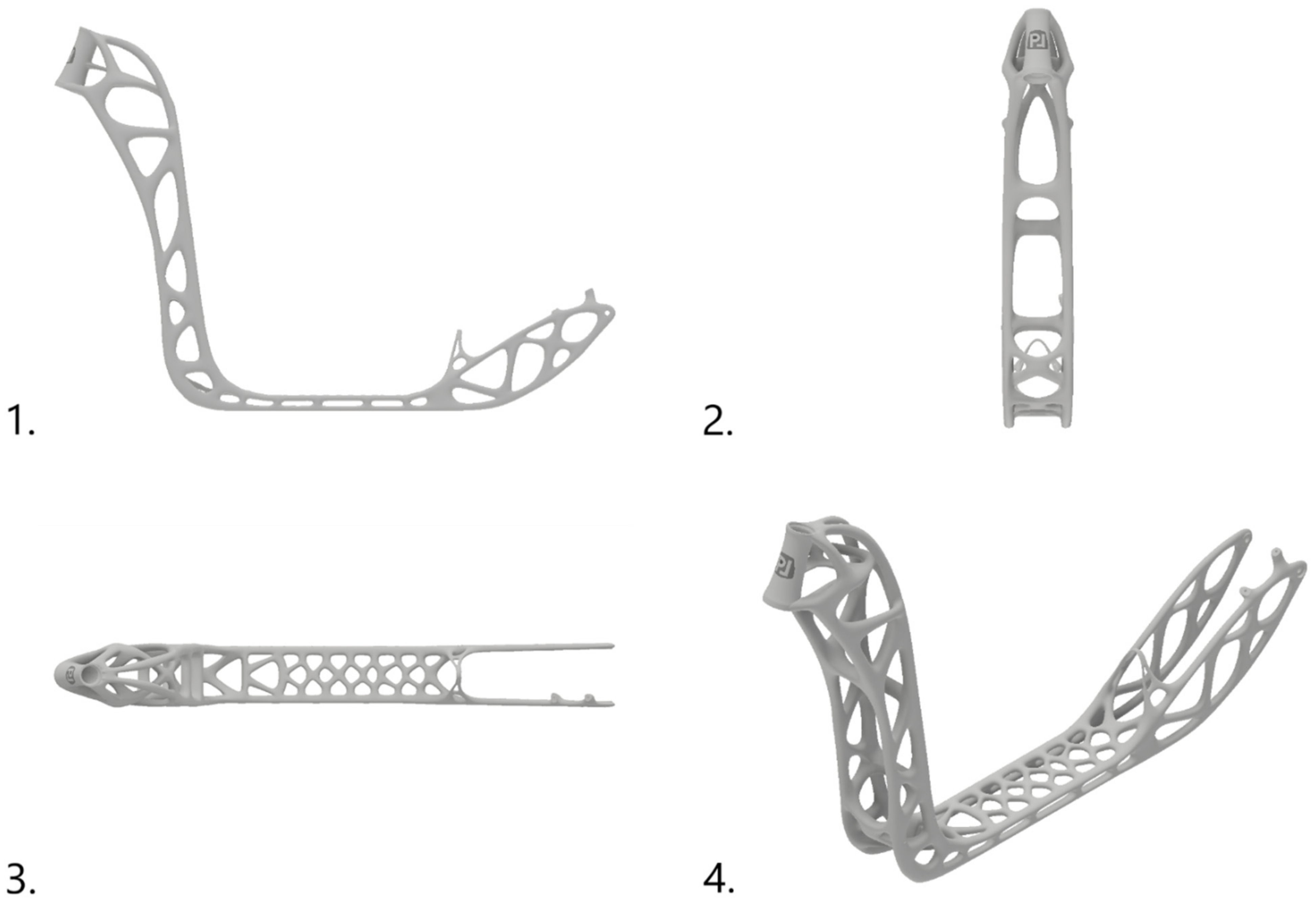

2.3. Summary of TO Results for Redesign

2.3.1. Solid Model

2.3.2. Sectioned and Hollowed Model

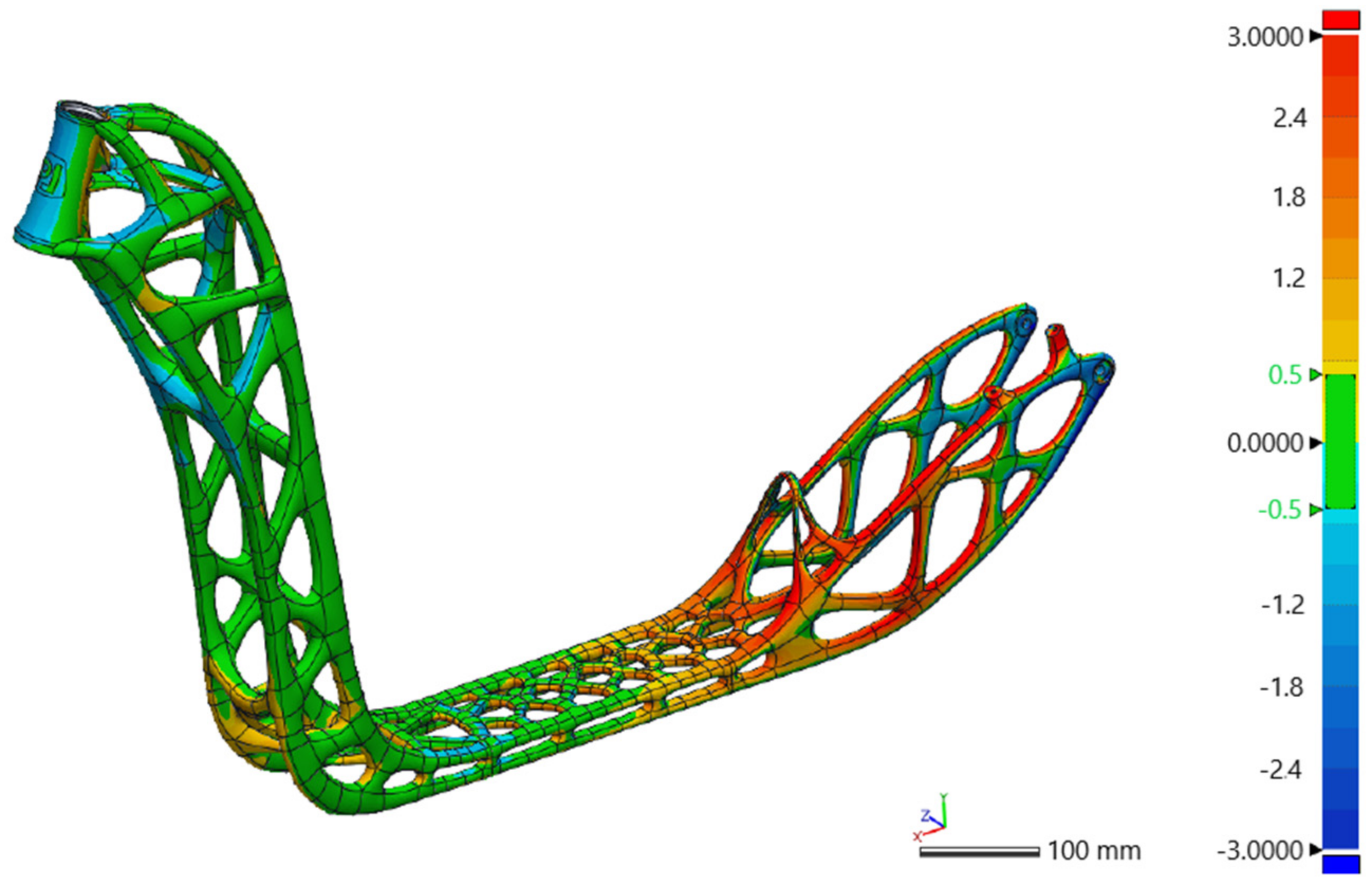

2.4. Finite Element Analysis (FEA)

2.5. Manufacturing

2.5.1. 3D Printing

2.5.2. Welding

2.6. Geometric Inspection

2.7. Comparison with the Conventional Frame

2.8. Fully Assembled TO Frame

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing; Springer: New York, NY, USA, 2010; 459p, ISBN 1441911200. [Google Scholar]

- Červinek, O.; Werner, B.; Koutný, D.; Vaverka, O.; Pantělejev, L.; Paloušek, D. Computational Approaches of Quasi-Static Compression Loading of SS316L Lattice Structures Made by Selective Laser Melting. Materials 2021, 14, 2462. [Google Scholar] [CrossRef] [PubMed]

- Podroužek, J.; Marcon, M.; Ninčević, K.; Wan-Wendner, R. Bio-Inspired 3D Infill Patterns for Additive Manufacturing and Structural Applications. Materials 2019, 12, 499. [Google Scholar] [CrossRef] [Green Version]

- Pokorný, P.; Václav, Š.; Petru, J.; Kritikos, M. Porosity Analysis of Additive Manufactured Parts Using CAQ Technology. Materials 2021, 14, 1142. [Google Scholar] [CrossRef]

- Gogolewski, D.; Bartkowiak, T.; Kozior, T.; Zmarzły, P. Multiscale Analysis of Surface Texture Quality of Models Manufactured by Laser Powder-Bed Fusion Technology and Machining from 316L Steel. Materials 2021, 14, 2794. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Halama, R.; Aldabash, T.; Mesicek, J.; Jancar, L.; Jansa, J. Prediction of model distortion by FEM in 3D printing via the selective laser melting of stainless steel AISI 316l. Appl. Sci. 2021, 11, 1656. [Google Scholar] [CrossRef]

- Nickels, L. 3D printing the world’s first metal bicycle frame. Met. Powder Rep. 2014, 69, 38–40. [Google Scholar] [CrossRef]

- Abdi, M.; Ashcroft, I.; Wildman, R. Design optimisation for an additively manufactured automotive component. Int. J. Powertrains 2018, 7, 142. [Google Scholar] [CrossRef]

- Ferro, C.G.; Varetti, S.; De Pasquale, G.; Maggiore, P. Lattice structured impact absorber with embedded anti-icing system for aircraft wings fabricated with additive SLM process. Mater. Today Commun. 2018, 15, 185–189. [Google Scholar] [CrossRef]

- Hodonou, C.; Balazinski, M.; Brochu, M.; Mascle, C. Material-design-process selection methodology for aircraft structural components: Application to additive vs subtractive manufacturing processes. Int. J. Adv. Manuf. Technol. 2019, 103, 1509–1517. [Google Scholar] [CrossRef]

- Yan, S.N.; Li, B.; Hong, J. Bionic design and verification of high-precision machine tool structures. Int. J. Adv. Manuf. Technol. 2015, 81, 73–85. [Google Scholar] [CrossRef]

- Liu, J.; Ou, H.; He, J.; Wen, G. Topological Design of a Lightweight Sandwich Aircraft Spoiler. Materials 2019, 12, 3225. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Y.; Xin, X.; Bin, Z.; Wei, Z.; Yidi, W. Bionic design for the aerodynamic shape of a stratospheric airship. Aerosp. Sci. Technol. 2020, 98, 105664. [Google Scholar] [CrossRef]

- Kong, D.; Ni, X.; Dong, C.; Lei, X.; Zhang, L.; Man, C.; Yao, J.; Cheng, X.; Li, X. Bio-functional and anti-corrosive 3D printing 316L stainless steel fabricated by selective laser melting. Mater. Des. 2018, 152, 88–101. [Google Scholar] [CrossRef]

- Hlinka, J.; Kraus, M.; Hajnys, J.; Pagac, M.; Petru, J.; Brytan, Z.; Tanski, T. Complex corrosion properties of AISI 316L steel prepared by 3D printing technology for possible implant applications. Materials 2020, 13, 1527. [Google Scholar] [CrossRef] [Green Version]

- Bendsoe, M.P.; Sigmund, O. Topology Optimization: Theory, Methods and Applications; Springer: Berlin/Heidelberg, Germany, 2003; ISBN 3-540-42992-1. [Google Scholar]

- Liu, Y.; Li, Z.; Wei, P.; Chen, S. Generating support structures for additive manufacturing with continuum topology optimization methods. Rapid Prototyp. J. 2019, 25, 232–246. [Google Scholar] [CrossRef]

- Jiang, L.; Ye, H.; Zhou, C.; Chen, S. Parametric Topology Optimization Toward Rational Design and Efficient Prefabrication for Additive Manufacturing. J. Manuf. Sci. Eng. Trans. ASME 2019, 141, 041007. [Google Scholar]

- Jiang, D.; Hoglund, R.; Smith, D.E. Continuous Fiber Angle Topology Optimization for Polymer Composite Deposition Additive Manufacturing Applications. Fibers 2019, 7, 14. [Google Scholar] [CrossRef] [Green Version]

- Zhu, D.; Zhan, W.; Wu, F.; Simeone, A. Topology Optimization of Spatially Compliant Mechanisms with an Isomorphic Matrix of a 3-UPC Type Parallel Prototype Manipulator. Micromachines 2018, 9, 184. [Google Scholar] [CrossRef] [Green Version]

- Garaigordobil, A.; Ansola, R.; Veguería, E.; Fernandez, I. Overhang constraint for topology optimization of self-supported compliant mechanisms considering additive manufacturing. Comput. Aided Des. 2019, 110, 33–48. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, H.; Wang, C.; Zhou, L.; Yuan, S.; Zhang, W. A review of topology optimization for additive manufacturing: Status and challenges. Chin. J. Aeronaut. 2021, 34, 91–110. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Sigmund, O. Topology optimization by distribution of isotropic material. In Topology Optimization; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar] [CrossRef]

- Junk, S.; Klerch, B.; Nasdala, L.; Hochberg, U. Topology optimization for additive manufacturing using a component of a humanoid robot. Procedia CIRP 2018, 70, 102–107. [Google Scholar] [CrossRef]

- Orme, M.; Madera, I.; Gschweitl, M.; Ferrari, M. Topology optimization for additive manufacturing as an enabler for light weight flight hardware. Designs 2018, 2, 51. [Google Scholar] [CrossRef] [Green Version]

- Sadri, M.; Kavandi, M.; Jozepiri, A.; Teimouri, S.; Abbasi, F. Bionic Architecture, Forms and Constructions. Res. J. Recent Sci. 2014, 3, 93–98. [Google Scholar]

- Ding, Y.; Zhou, Z.; Wang, Z.; Liu, H.; Wang, K. Bionic Stiffener Layout Optimization with a Flexible Plate in Solar-Powered UAV Surface Structure Design. Appl. Sci. 2019, 9, 5196. [Google Scholar] [CrossRef] [Green Version]

- Warguła, Ł.; Wojtkowiak, D.; Kukla, M.; Talaśka, K. Symmetric Nature of Stress Distribution in the Elastic-Plastic Range of Pinus, L. Pine Wood Samples Determined Experimentally and Using the Finite Element Method (FEM). Symmetry 2021, 13, 39. [Google Scholar] [CrossRef]

- Christiansen, A.N.; Bærentzen, J.A.; Nobel-Jørgensen, M.; Aage, N.; Sigmund, O. Combined shape and topology optimization of 3D structures. Comput. Graph. 2015, 46, 25–35. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Du, W.; He, P.; Yang, M. Topology Optimization and 3D Printing of Three-Branch Joints in Treelike Structures. J. Struct. Eng. 2020, 146, 04019167. [Google Scholar] [CrossRef]

- Primo, T.; Calabrese, M.; Del Prete, A.; Anglani, A. Additive manufacturing integration with topology optimization methodology for innovative product design. Int. J. Adv. Manuf. Technol. 2017, 93, 467–479. [Google Scholar] [CrossRef]

- Li, C.; Liu, J.F.; Guo, Y.B. Prediction of Residual Stress and Part Distortion in Selective Laser Melting. Procedia CIRP 2016, 45, 171–174. [Google Scholar] [CrossRef] [Green Version]

- Williams, R.; Catrin, J.; Davies, M.; Hooper, P.A. A pragmatic part scale model for residual stress and distortion prediction in powder bed fusion. Addit. Manuf. 2018, 22, 416–425. [Google Scholar] [CrossRef]

- The Project. Available online: http://www.3i-print.com/ (accessed on 28 June 2021).

- Significant Weight Reduction by Using Topology Optimization in Volkswagen Design Development. Available online: https://www.altair.com/resource/significant-weight-reduction-by-using-topology-optimization-in-volkswagen-design-development (accessed on 28 June 2021).

- BMW 3D Printing Superbike Components at the Track|3D-Prints. Available online: https://3d-prints.com/2020/11/04/bmw-3d-printing-superbike-components-at-the-track/ (accessed on 28 June 2021).

- Airbus APWorks Launches the ‘Light Rider’: The World’s First 3D-Printed Motorcycle. Available online: https://www.airbus.com/newsroom/press-releases/en/2016/05/APWorks-Launch-Light-Rider.html (accessed on 28 June 2021).

- Topology Optimization of Aircraft Wing Box Ribs. Available online: https://www.altair.com/resource/topology-optimization-of-aircraft-wing-box-ribs (accessed on 28 June 2021).

- Relativity Space. Available online: https://www.relativityspace.com/rockets (accessed on 28 June 2021).

- Hajnys, J.; Pagac, M.; Kotera, O.; Petru, J.; Scholz, S. Influence of basic process parameters on mechanical and internal properties of 316l steel in SLM process for RENISHAW AM400. MM Sci. J. 2019, 2019, 2790–2794. [Google Scholar] [CrossRef] [Green Version]

- Inspire 2018—Why Use PolyNURBS? Available online: https://www.altair.com/training/inspire_2018/content/polynurbs/why_polynurbs.htm (accessed on 7 May 2021).

- Mohyla, P.; Hajnys, J.; Sternadelová, K.; Krejčí, L.; Pagáč, M.; Konečná, K.; Krpec, P. Analysis of welded joint properties on an AISI316L stainless steel tube manufactured by SLM technology. Materials 2020, 13, 4362. [Google Scholar] [CrossRef] [PubMed]

- Kozior, T.; Bochnia, J.; Zmarzły, P.; Gogolewski, D.; Mathia, T. Waviness of Freeform Surface Characterizations from Austenitic Stainless Steel (316 L) Manufactured by 3D Printing-Selective Laser Melting (SLM) Technology. Materials 2020, 13, 4372. [Google Scholar] [CrossRef]

- Hajnys, J.; Pagáč, M.; Měsíček, J.; Petru, J.; Król, M. Influence of Scanning Strategy Parameters on Residual Stress in the SLM Process According to the Bridge Curvature Method for AISI 316L Stainless Steel. Materials 2020, 13, 1659. [Google Scholar] [CrossRef] [Green Version]

- Chen, N.; Ma, G.; Zhu, W.; Godfrey, A.; Shen, Z.; Wu, G.; Huang, X. Enhancement of an additive-manufactured austenitic stainless steel by post-manufacture heat-treatment. Mater. Sci. Eng. A 2019, 759, 65–69. [Google Scholar] [CrossRef]

- Sotola, M.; Marsalek, P.; Rybansky, D.; Fusek, M.; Gabriel, D. Sensitivity Analysis of Key Formulations of Topology Optimization on an Example of Cantilever Bending Beam. Symmetry 2021, 13, 712. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Density | 7.99 × 10−6 kg·mm−3 |

| Tensile strength | 614 MPa |

| Yield strength (0.2% offset) | 467 MPa |

| Young modulus | 204 GPa |

| Poisson’s ratio | 0.29 |

| Parameter | Value |

|---|---|

| Strategy | Meander |

| Laser power | 200 W |

| Layer thickness | 50 µm |

| Hatch spacing | 0.11 mm |

| Scan speed | 650 mm/s |

| Conventional | TO | % | |||

|---|---|---|---|---|---|

| Simulation | Reality | ||||

| Weight | 4.4 kg | 4.65 kg | 5.10 kg | +0.16 | |

| Normal operation | Deflection | 11 mm | 1.3 mm | 11 mm | 0 |

| VM stress | -- | 127 MPa | -- | -- | |

| Drop | Deflection | -- | 3.8 mm | -- | -- |

| VM stress | -- | 378 MPa | -- | -- | |

| Braking | Deflection | -- | -- | -- | -- |

| VM stress | -- | 115 MPa | -- | ||

| Torsional stiffness | Deflection | 30 mm | 21 mm | 30 mm | 0 |

| VM stress | -- | 153 MPa | -- | -- | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mesicek, J.; Jancar, L.; Ma, Q.-P.; Hajnys, J.; Tanski, T.; Krpec, P.; Pagac, M. Comprehensive View of Topological Optimization Scooter Frame Design and Manufacturing. Symmetry 2021, 13, 1201. https://doi.org/10.3390/sym13071201

Mesicek J, Jancar L, Ma Q-P, Hajnys J, Tanski T, Krpec P, Pagac M. Comprehensive View of Topological Optimization Scooter Frame Design and Manufacturing. Symmetry. 2021; 13(7):1201. https://doi.org/10.3390/sym13071201

Chicago/Turabian StyleMesicek, Jakub, Lukas Jancar, Quoc-Phu Ma, Jiri Hajnys, Tomasz Tanski, Pavel Krpec, and Marek Pagac. 2021. "Comprehensive View of Topological Optimization Scooter Frame Design and Manufacturing" Symmetry 13, no. 7: 1201. https://doi.org/10.3390/sym13071201

APA StyleMesicek, J., Jancar, L., Ma, Q.-P., Hajnys, J., Tanski, T., Krpec, P., & Pagac, M. (2021). Comprehensive View of Topological Optimization Scooter Frame Design and Manufacturing. Symmetry, 13(7), 1201. https://doi.org/10.3390/sym13071201