Review on Performance Enhancement of Photovoltaic/Thermal–Thermoelectric Generator Systems with Nanofluid Cooling

Abstract

:1. Introduction

2. Background

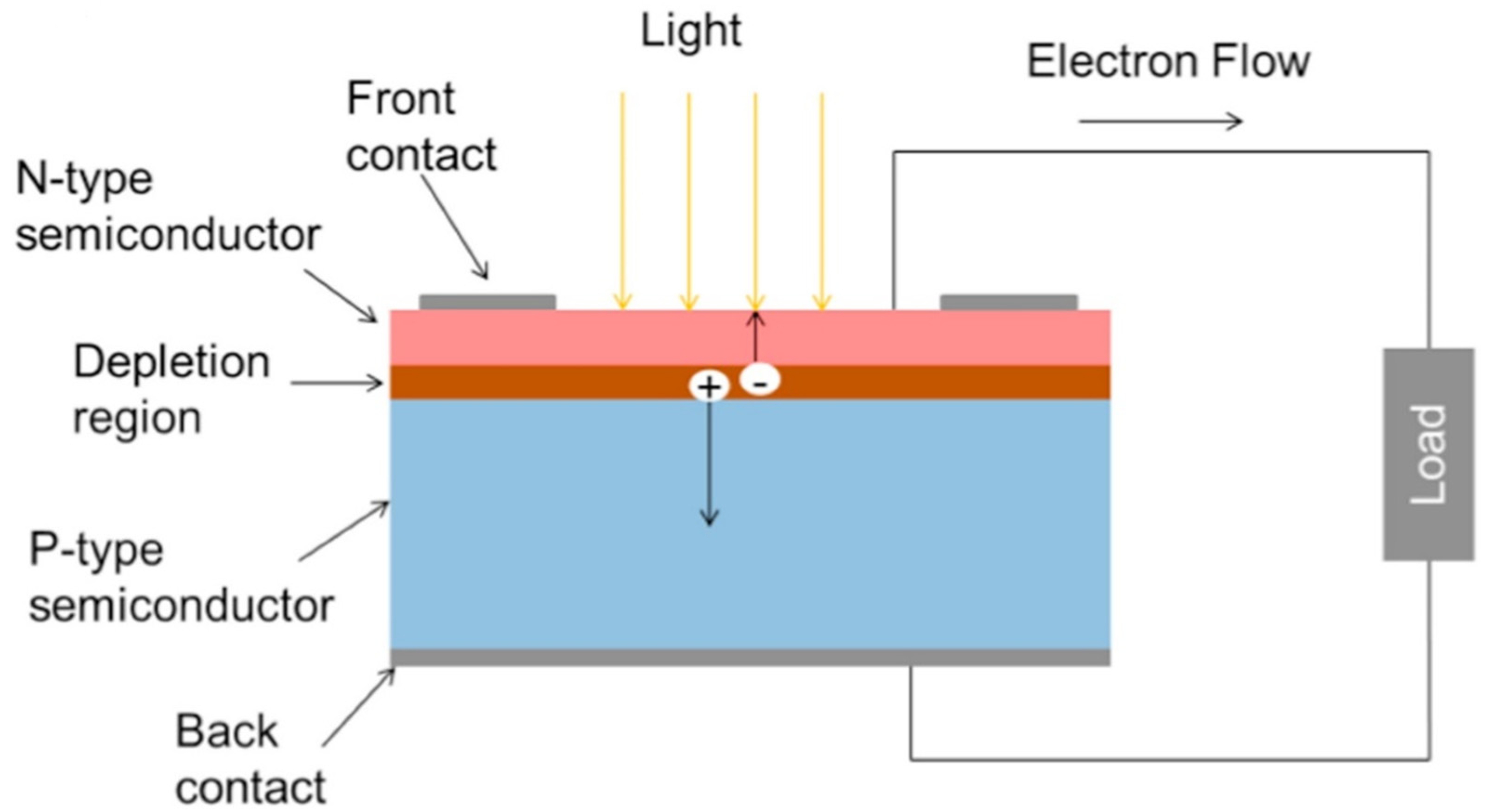

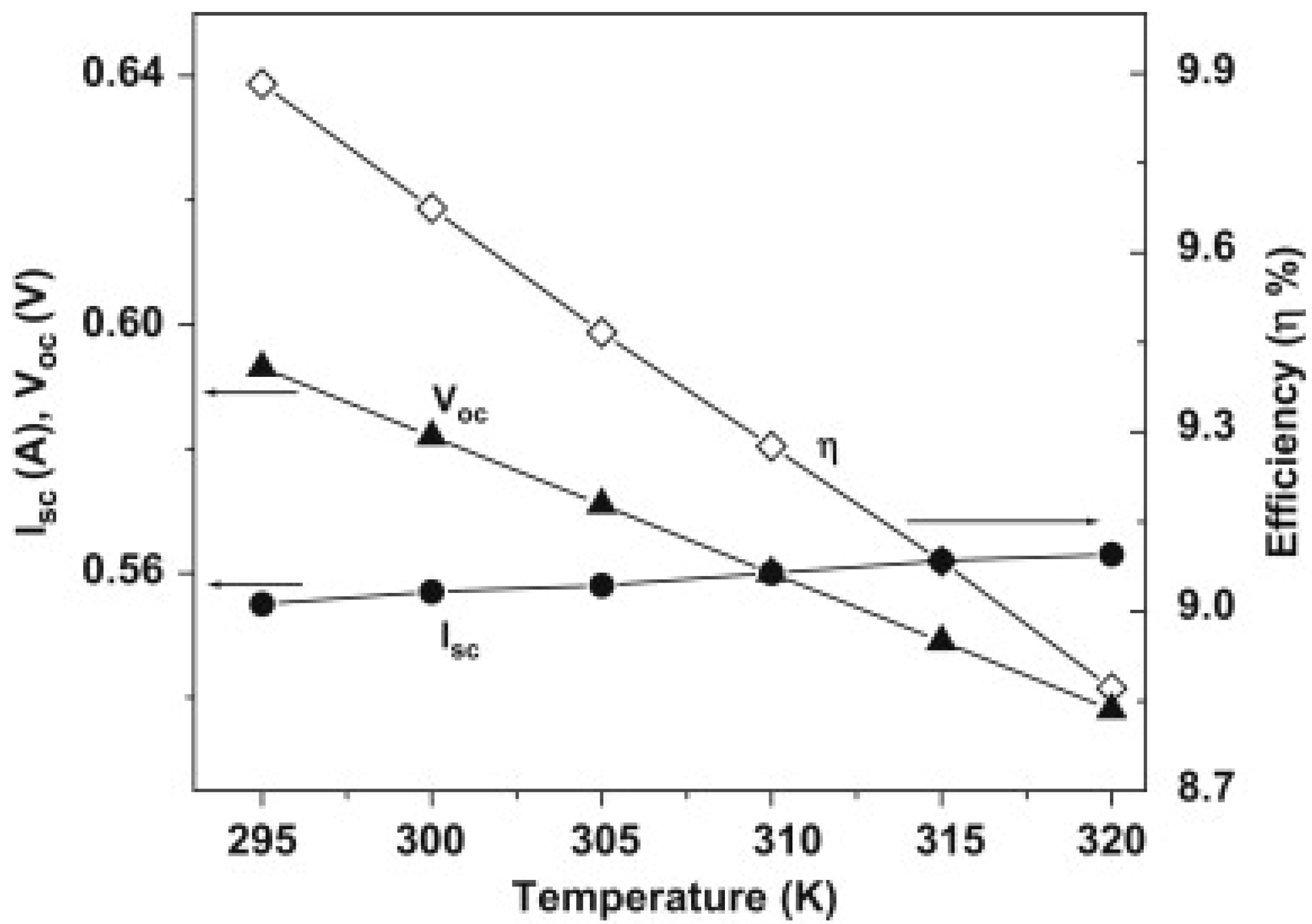

2.1. Photovoltaics

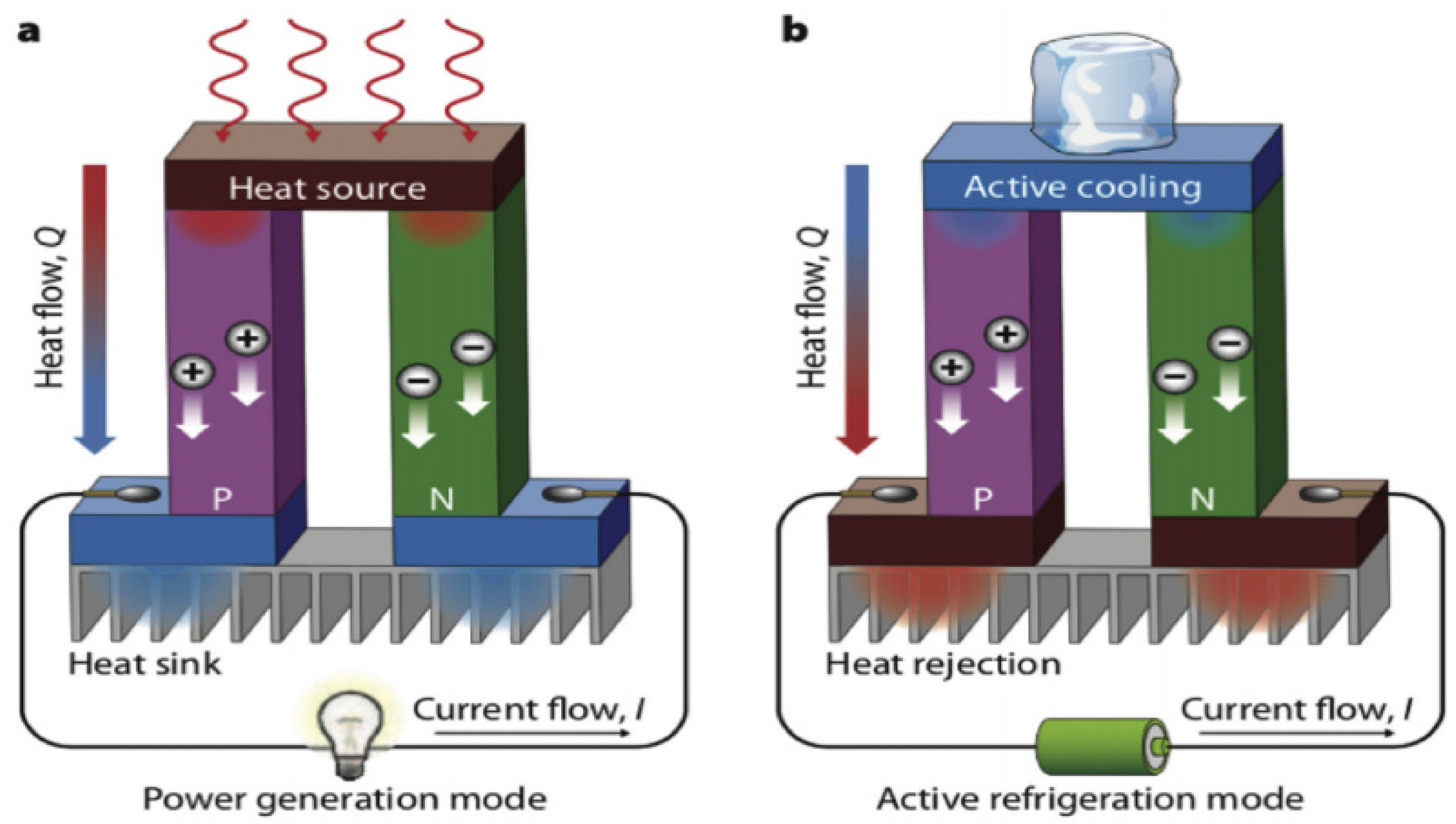

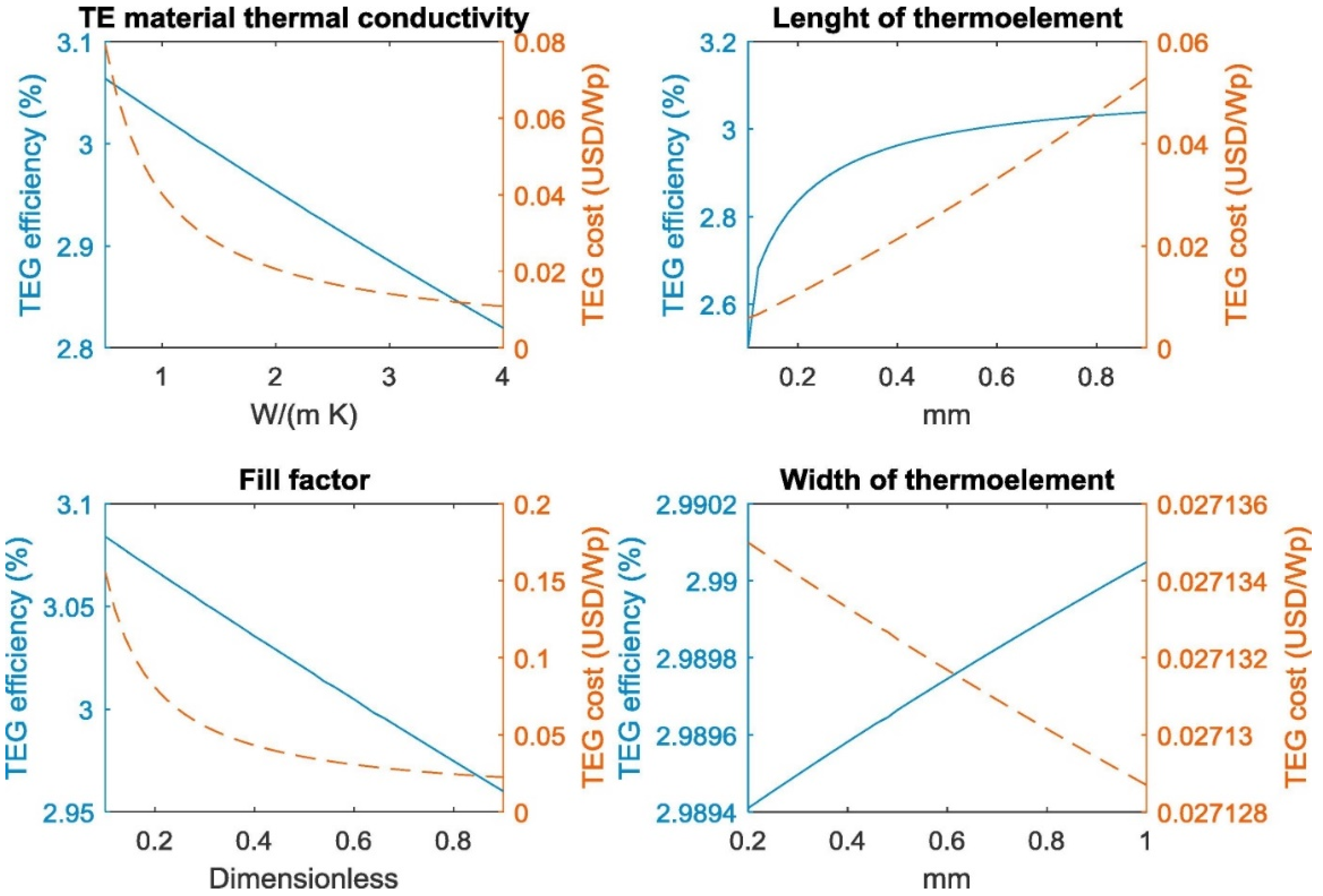

2.2. Thermoelectric Generator

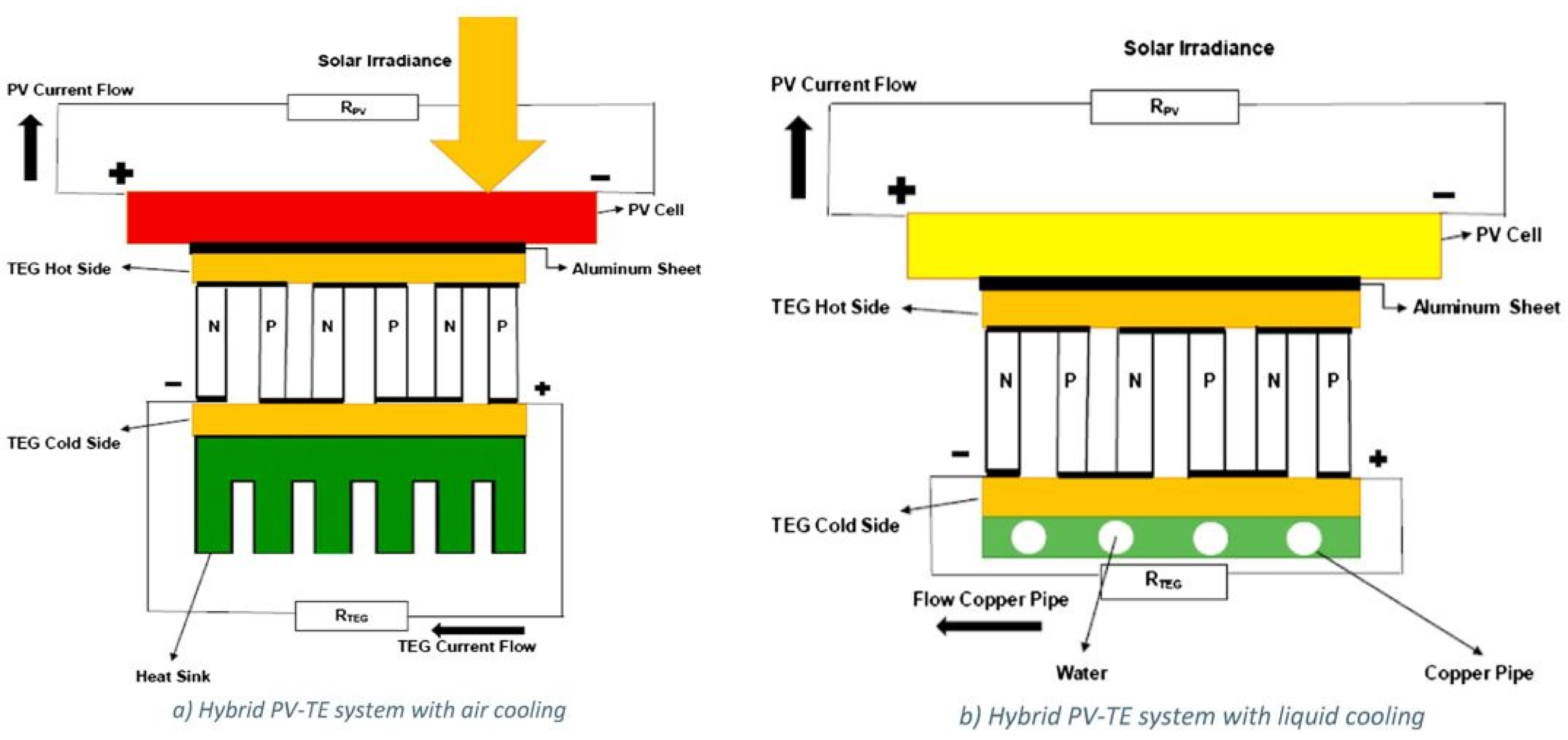

2.3. Hybrid Photovoltaic–Thermoelectric Generator

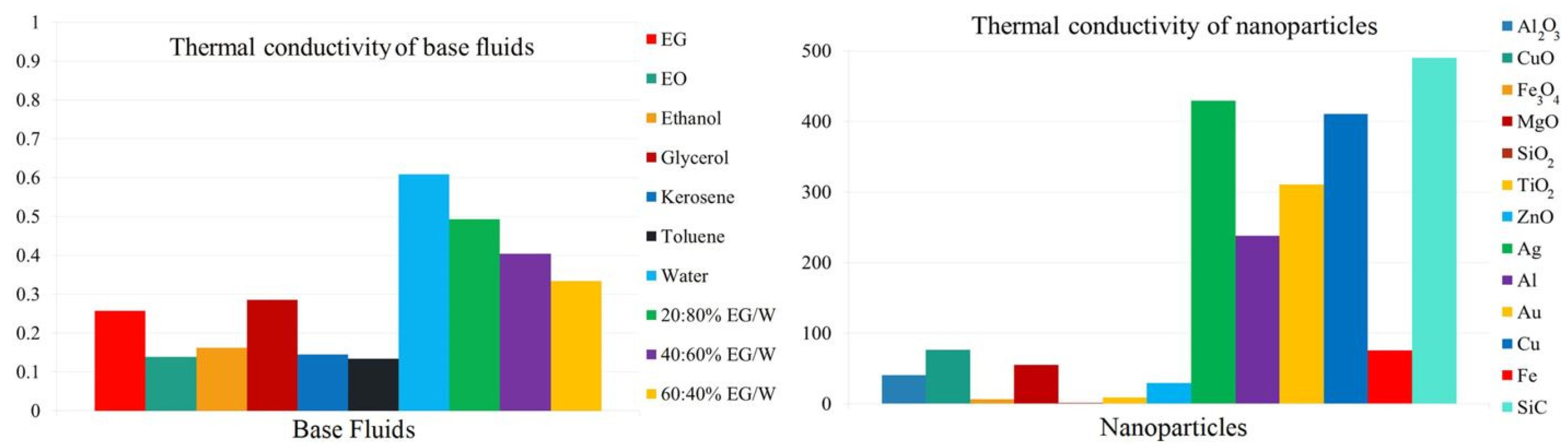

2.4. Nanofluid

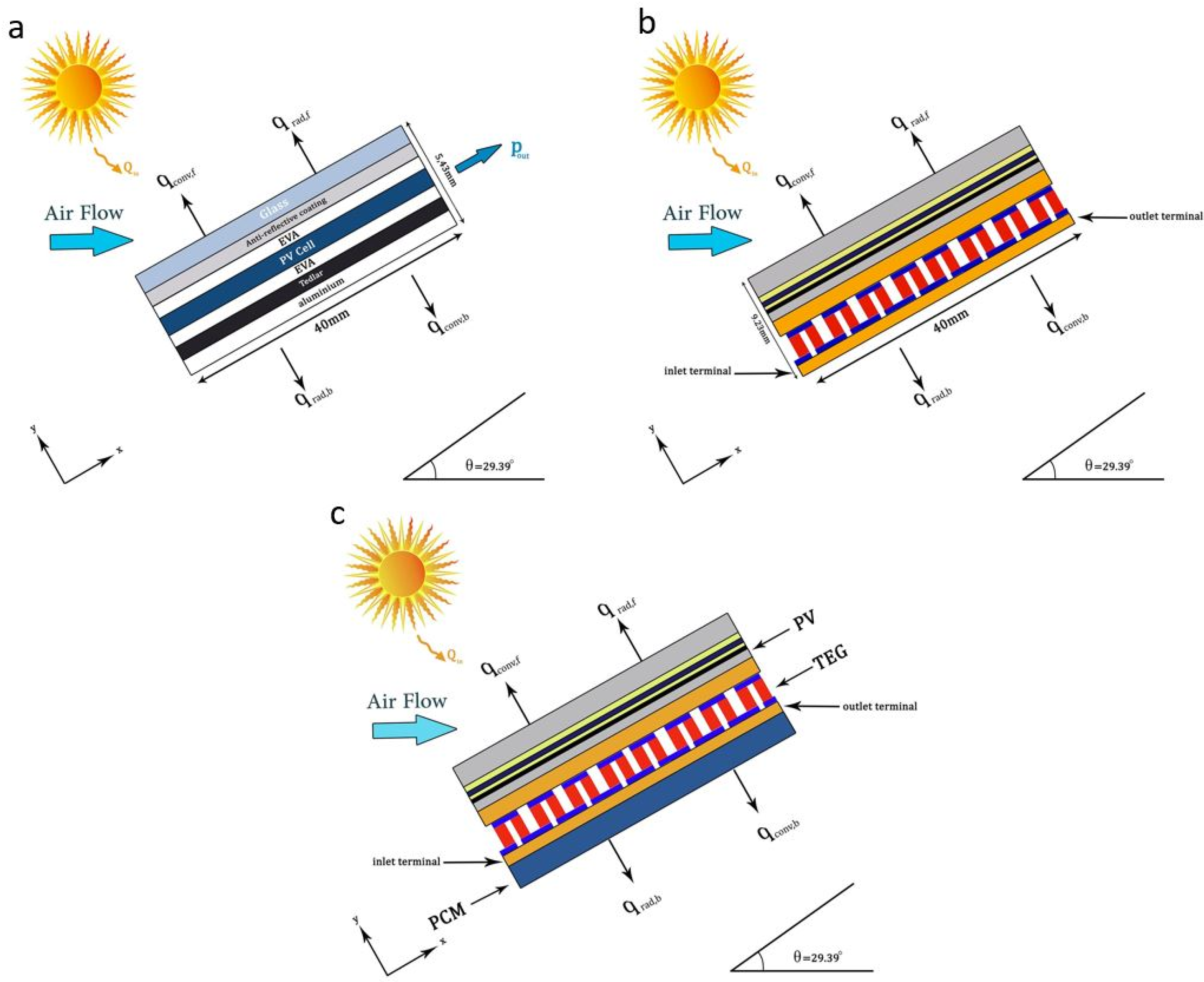

3. Research Studies on Photovoltaic–Thermoelectric Generator System without Thermal Collector

4. Research Studies on Photovoltaic Thermoelectric Generator Systems with Thermal Collector

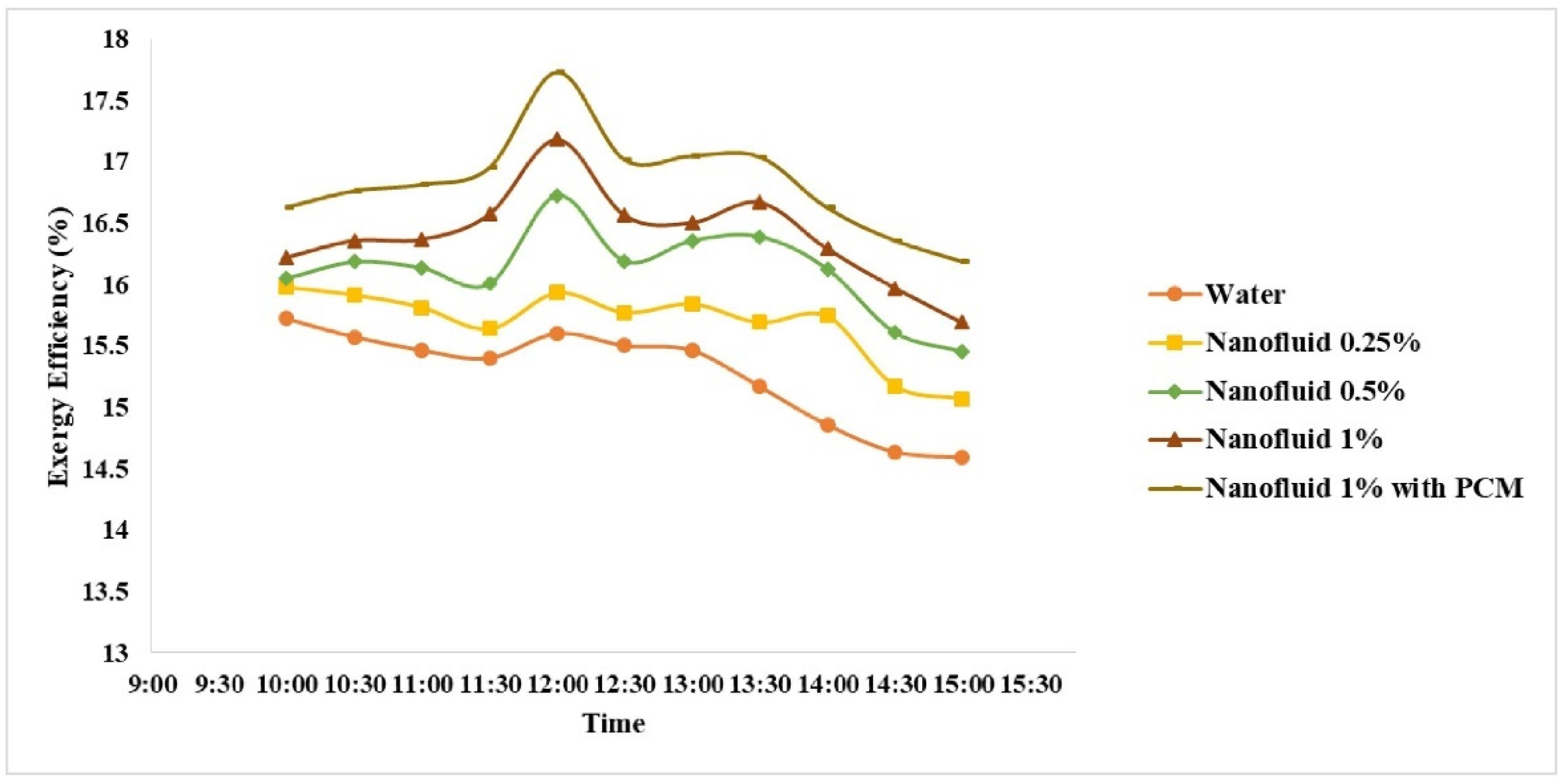

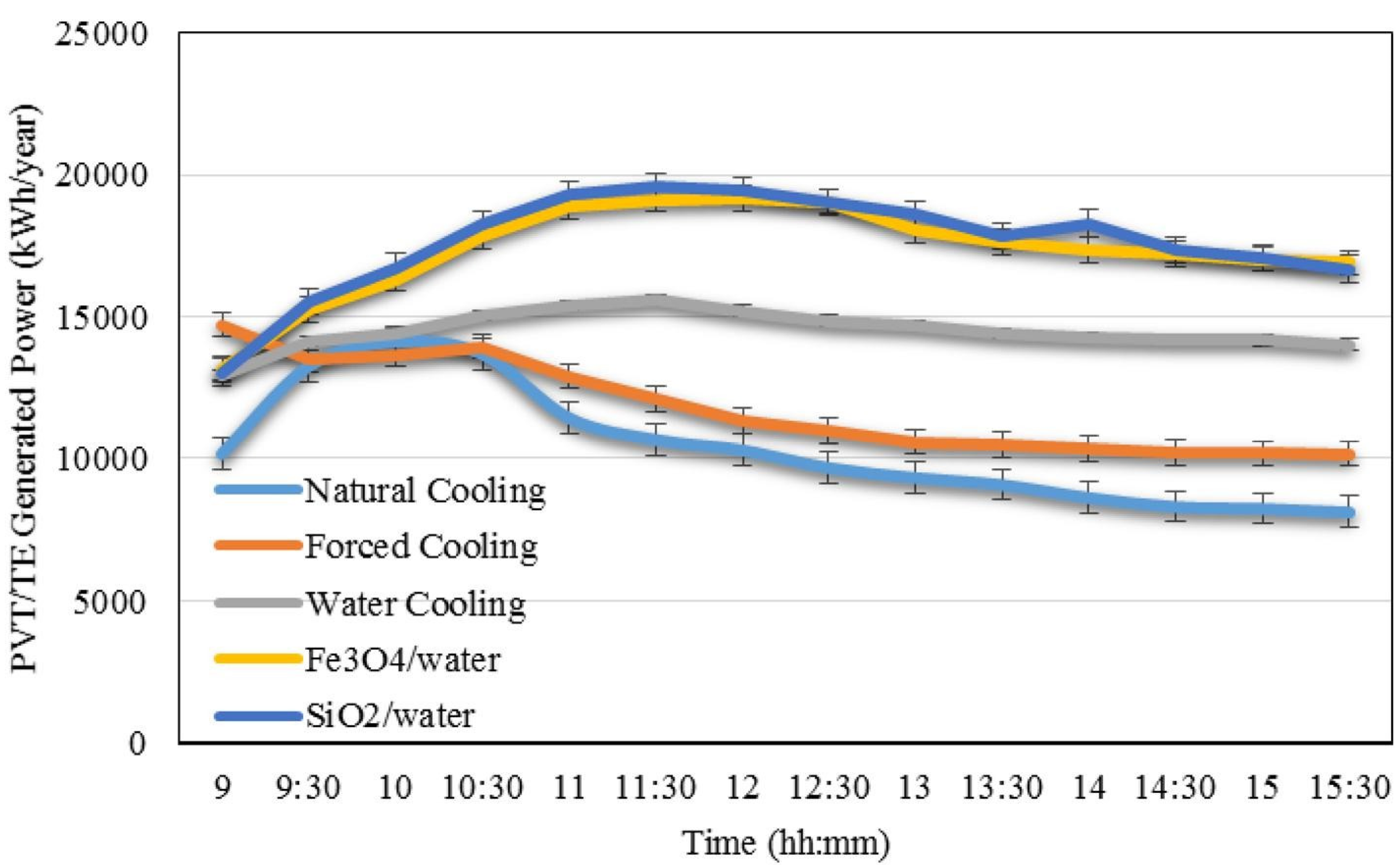

5. Research Studies on Photovoltaic/Thermal–Thermoelectric Generator with Nanofluid Cooling

6. Discussion

7. Conclusions

- (a)

- The PV-TEG system generates superior electrical power output compared to standalone PV system. In addition, the PV/T-TEG system generates electrical as well as thermal power outputs, which further enhances the overall performance of system.

- (b)

- The nanofluid cooling of PV/T-TEG systems depict improved thermal and electrical performances compared to PV/T-TEG systems with conventional cooling fluids.

- (c)

- The thermoelectric leg length has a significant effect on the performance of PV/T-TEG systems. Higher thermoelectric leg length enhances the TEG power output but also increases PV temperature because of an increase in thermal resistance. Therefore, thermoelectric leg length needs to be optimized to maximize the performance of hybrid system.

- (d)

- The performance of hybrid systems degrades due to thermal contact resistance between PVs and the TEG. The thermal contact resistance could be reduced by applying thermal interface materials, enhancing the contact area, and reducing the thermoelectric legs.

- (e)

- The research studies on PV/T-TEG systems with nanofluid cooling are very limited. This area needs to be focused on more for future development and innovation on PV/T-TEG systems. The phase change materials could also be integrated with PV/T-TEG systems without, and with, nanofluid cooling to evaluate and compare the overall performance improvement.

- (f)

- Most of the reviewed research studies focused on numerical and theoretical approaches. The number of experimental works are limited. In addition, three-dimensional numerical models based on thermo–fluid–thermoelectric coupling for PV/T-TEG system have been explored by very few in the literature.

- (g)

- Further research on PV/T-TEG systems focusing on energy and exergy performances, economic, environmental sustainability, and life cycle analysis based on long-term operation needs to be conducted to assure the commercialization of hybrid PV/T-TEG systems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency. WEO 2017. IEA World Energy Outlook. 2017. Available online: https://www.iea.org/reports/world-energy-outlook-2017#section-1-1 (accessed on 19 October 2021).

- Raj, A.K.; Kunal, G.; Srinivas, M.; Jayaraj, S. Performance analysis of a double-pass solar air heater system with asymmetric channel flow passages. J. Therm. Anal. Calorim. 2019, 136, 21–38. [Google Scholar] [CrossRef]

- Liu, Y.W.; Feng, H.; Li, H.Y.; Li, L.L. An Improved Whale Algorithm for Support Vector Machine Prediction of Photovoltaic Power Generation. Symmetry 2021, 13, 212. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Li, T.; Xie, X.; Chang, C. The Short-Term Forecasting of Asymmetry Photovoltaic Power Based on the Feature Extraction of PV Power and SVM Algorithm. Symmetry 2020, 12, 1777. [Google Scholar] [CrossRef]

- Ogbomo, O.O.; Amalu, E.H.; Ekere, N.N.; Olagbegi, P.O. A review of photovoltaic module technologies for increased performance in tropical climate. Renew. Sustain. Energy Rev. 2017, 75, 1225–1238. [Google Scholar] [CrossRef] [Green Version]

- Hasan, A.; Sarwar, J.; Shah, A.H. Concentrated photovoltaic: A review of thermal aspects, challenges and opportunities. Renew. Sustain. Energy Rev. 2018, 94, 835–852. [Google Scholar] [CrossRef]

- Indira, S.S.; Vaithilingam, C.A.; Chong, K.K.; Saidur, R.; Faizal, M.; Abubakar, S.; Paiman, S. A review on various configurations of hybrid concentrator photovoltaic and thermoelectric generator system. Sol. Energy 2020, 201, 122–148. [Google Scholar] [CrossRef]

- Shittu, S.; Li, G.; Akhlaghi, Y.G.; Ma, X.; Zhao, X.; Ayodele, E. Advancements in thermoelectric generators for enhanced hybrid photovoltaic system performance. Renew. Sustain. Energy Rev. 2019, 109, 24–54. [Google Scholar] [CrossRef]

- Huen, P.; Daoud, W.A. Advances in hybrid solar photovoltaic and thermoelectric generators. Renew. Sustain. Energy Rev. 2017, 72, 1295–1302. [Google Scholar] [CrossRef]

- Li, G.; Shittu, S.; Diallo, T.M.; Yu, M.; Zhao, X.; Ji, J. A review of solar photovoltaic-thermoelectric hybrid system for electricity generation. Energy 2018, 158, 41–58. [Google Scholar] [CrossRef]

- Irshad, K.; Habib, K.; Saidur, R.; Kareem, M.W.; Saha, B.B. Study of thermoelectric and photovoltaic facade system for energy efficient building development: A review. J. Clean. Prod. 2019, 209, 1376–1395. [Google Scholar] [CrossRef]

- Babu, C.; Ponnambalam, P. The role of thermoelectric generators in the hybrid PV/T systems: A review. Energy Convers. Manag. 2017, 151, 368–385. [Google Scholar] [CrossRef]

- Nazri, N.S.; Fudholi, A.; Bakhtyar, B.; Yen, C.H.; Ibrahim, A.; Ruslan, M.H.; Sopian, K. Energy economic analysis of photovoltaic–thermal-thermoelectric (PVT-TE) air collectors. Renew. Sustain. Energy Rev. 2018, 92, 187–197. [Google Scholar] [CrossRef]

- Chapin, D.M.; Fuller, C.S.; Pearson, G.L. A new silicon p-n junction photocell for converting solar radiation into electrical power. J. Appl. Phys. 1954, 25, 676–677. [Google Scholar] [CrossRef]

- Garud, K.S.; Jayaraj, S.; Lee, M.Y. A review on modeling of solar photovoltaic systems using artificial neural networks, fuzzy logic, genetic algorithm and hybrid models. Int. J. Energy Res. 2021, 45, 6–35. [Google Scholar] [CrossRef]

- Kidegho, G.; Njoka, F.; Muriithi, C.; Kinyua, R. Evaluation of thermal interface materials in mediating PV cell temperature mismatch in PV–TEG power generation. Energy Rep. 2021, 7, 1636–1650. [Google Scholar] [CrossRef]

- Sampaio, P.G.V.; González, M.O.A.; de Vasconcelos, R.M.; dos Santos, M.A.T.; de Toledo, J.C.; Pereira, J.P.P. Photovoltaic technologies: Mapping from patent analysis. Renew. Sustain. Energy Rev. 2018, 93, 215–224. [Google Scholar] [CrossRef]

- Singh, P.; Singh, S.N.; Lal, M.; Husain, M. Temperature dependence of I–V characteristics and performance parameters of silicon solar cell. Sol. Energy Mater. Sol. Cells 2008, 92, 1611–1616. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Y.; Li, K.; Zhuang, J.; Liang, Y.; Pang, Y. Analysis and Suppression of Voltage Violation and Fluctuation with Distributed Photovoltaic Integration. Symmetry 2021, 13, 1894. [Google Scholar] [CrossRef]

- Garud, K.S.; Seo, J.-H.; Cho, C.-P.; Lee, M.-Y. Artificial neural network and adaptive neuro-fuzzy interface system modelling to predict thermal performances of thermoelectric generator for waste heat recovery. Symmetry 2020, 12, 259. [Google Scholar] [CrossRef] [Green Version]

- Garud, K.S.; Patil, M.S.; Seo, J.-H.; Bang, Y.-M.; Cho, C.-P.; Lee, M.-Y. Electrical Performance Comparison between Conventional Pi Shaped and Linear Shaped Thermoelectric Generators. IOP Conf. Ser. Mater. Sci. Eng. 2020, 894, 012001. [Google Scholar] [CrossRef]

- Seo, J.-H.; Garud, K.S.; Lee, M.-Y. Grey relational based Taguchi analysis on thermal and electrical performances of thermoelectric generator system with inclined fins hot heat exchanger. Appl. Therm. Eng. 2021, 184, 116279. [Google Scholar] [CrossRef]

- Garud, K.S.; Seo, J.-H.; Patil, M.S.; Bang, Y.-M.; Pyo, Y.-D.; Cho, C.-P.; Lee, M.-Y. Thermal–electrical–structural performances of hot heat exchanger with different internal fins of thermoelectric generator for low power generation application. J. Therm. Anal. Calorim. 2021, 143, 387–419. [Google Scholar] [CrossRef]

- Elsheikh, M.H.; Shnawah, D.A.; Sabri, M.F.M.; Said, S.B.M.; Hassan, M.H.; Bashir, M.B.A.; Mohamad, M. A review on thermoelectric renewable energy: Principle parameters that affect their performance. Renew. Sustain. Energy Rev. 2014, 30, 337–355. [Google Scholar] [CrossRef]

- Lee, M.-Y.; Seo, J.-H.; Lee, H.-S.; Garud, K.S. Power generation, efficiency and thermal stress of thermoelectric module with leg geometry, material, segmentation and two-stage arrangement. Symmetry 2020, 12, 786. [Google Scholar] [CrossRef]

- Garud, K.S.; Seo, J.-H.; Lee, M.-Y. Effect of guide fin structures and boundary parameters on thermal performances of heat exchanger for waste heat recovery thermoelectric generator. J. Korea Acad. Ind. Coop. Soc. 2021, 22, 30–35. [Google Scholar]

- Goldsmid, H.J.; Giutronich, J.E.; Kaila, M.M. Solar thermoelectric generation using bismuth telluride alloys. Sol. Energy 1980, 24, 435–440. [Google Scholar] [CrossRef]

- Moore, G.; Peterson, W. Solar PV-thermoelectric generator hybrid system: Case studies. In Proceedings of the 10th International Telecommunications Energy Conference, San Diego, CA, USA, 30 October–2 November 1988; pp. 308–311. [Google Scholar]

- Contento, G.; Lorenzi, B.; Rizzo, A.; Narducci, D. Efficiency enhancement of a-Si and CZTS solar cells using different thermoelectric hybridization strategies. Energy 2017, 131, 230–238. [Google Scholar] [CrossRef]

- Lorenzi, B.; Contento, G.; Sabatelli, V.; Rizzo, A.; Narducci, D. Theoretical Analysis of Two Novel Hybrid Thermoelectric-Photovoltaic Systems Based on Cu2ZnSnS4 Solar Cells. J. Nanosci. Nanotechnol. 2017, 17, 1608–1615. [Google Scholar] [CrossRef]

- Pandya, N.S.; Shah, H.; Molana, M.; Tiwari, A.K. Heat transfer enhancement with nanofluids in plate heat exchangers: A comprehensive review. Eur. J. Mech. B/Fluids 2020, 81, 173–190. [Google Scholar] [CrossRef]

- Pordanjani, A.H.; Aghakhani, S.; Afrand, M.; Mahmoudi, B.; Mahian, O.; Wongwises, S. An updated review on application of nanofluids in heat exchangers for saving energy. Energy Convers. Manag. 2019, 198, 111886. [Google Scholar] [CrossRef]

- Garud, K.S.; Hwang, S.-G.; Lim, T.-K.; Kim, N.; Lee, M.-Y. First and Second Law Thermodynamic Analyses of Hybrid Nanofluid with Different Particle Shapes in a Microplate Heat Exchanger. Symmetry 2021, 13, 1466. [Google Scholar] [CrossRef]

- Garud, K.S.; Lee, M.-Y. Numerical Investigations on Heat Transfer Characteristics of Single Particle and Hybrid Nanofluids in Uniformly Heated Tube. Symmetry 2021, 13, 876. [Google Scholar] [CrossRef]

- Ghalambaz, M.; Hashem Zadeh, S.M.; Veismoradi, A.; Sheremet, M.A.; Pop, I. Free Convection Heat Transfer and Entropy Generation in an Odd-Shaped Cavity Filled with a Cu-Al2O3 Hybrid Nanofluid. Symmetry 2021, 13, 122. [Google Scholar] [CrossRef]

- Sanches, M.; Marseglia, G.; Ribeiro, A.P.; Moreira, A.L.; Moita, A.S. Nanofluids Characterization for Spray Cooling Applications. Symmetry 2021, 13, 788. [Google Scholar] [CrossRef]

- Abbas, N.; Awan, M.B.; Amer, M.; Ammar, S.M.; Sajjad, U.; Ali, H.M.; Jafry, A.T. Applications of nanofluids in photovoltaic thermal systems: A review of recent advances. Phys. A Stat. Mech. Its Appl. 2019, 536, 122513. [Google Scholar] [CrossRef]

- Arun, K.R.; Kunal, G.; Srinivas, M.; Kumar, C.S.; Mohanraj, M.; Jayaraj, S. Drying of untreated Musa nendra and Momordica charantia in a forced convection solar cabinet dryer with thermal storage. Energy 2020, 192, 116697. [Google Scholar] [CrossRef]

- Shittu, S.; Li, G.; Tang, X.; Zhao, X.; Ma, X.; Badiei, A. Analysis of thermoelectric geometry in a concentrated photovoltaic-thermoelectric under varying weather conditions. Energy 2020, 202, 117742. [Google Scholar] [CrossRef]

- Mahmoudinezhad, S.; Atouei, S.A.; Cotfas, P.A.; Cotfas, D.T.; Rosendahl, L.A.; Rezania, A. Experimental and numerical study on the transient behavior of multi-junction solar cell-thermoelectric generator hybrid system. Energy Convers. Manag. 2019, 184, 448–455. [Google Scholar] [CrossRef]

- Lamba, R.; Kaushik, S.C. Solar driven concentrated photovoltaic-thermoelectric hybrid system: Numerical analysis and optimization. Energy Convers. Manag. 2018, 170, 34–49. [Google Scholar] [CrossRef]

- Rezania, A.; Rosendahl, L.A. Feasibility and parametric evaluation of hybrid concentrated photovoltaic-thermoelectric system. Appl. Energy 2017, 187, 380–389. [Google Scholar] [CrossRef]

- Li, G.; Zhou, K.; Song, Z.; Zhao, X.; Ji, J. Inconsistent phenomenon of thermoelectric load resistance for photovoltaic–thermoelectric module. Energy Convers. Manag. 2018, 161, 155–161. [Google Scholar] [CrossRef]

- Motiei, P.; Yaghoubi, M.; GoshtasbiRad, E. Transient simulation of a hybrid photovoltaic-thermoelectric system using a phase change material. Sustain. Energy Technol. Assess. 2019, 34, 200–213. [Google Scholar] [CrossRef]

- Rodrigo, P.M.; Valera, A.; Fernández, E.F.; Almonacid, F.M. Performance and economic limits of passively cooled hybrid thermoelectric generator-concentrator photovoltaic modules. Appl. Energy 2019, 238, 1150–1162. [Google Scholar] [CrossRef]

- Yang, Z.; Li, W.; Chen, X.; Su, S.; Lin, G.; Chen, J. Maximum efficiency and parametric optimum selection of a concentrated solar spectrum splitting photovoltaic cell–thermoelectric generator system. Energy Convers. Manag. 2018, 174, 65–71. [Google Scholar] [CrossRef]

- Li, G.; Shittu, S.; Zhou, K.; Zhao, X.; Ma, X. Preliminary experiment on a novel photovoltaic-thermoelectric system in summer. Energy 2019, 188, 116041. [Google Scholar] [CrossRef]

- Yusuf, A.; Bayhan, N.; Tiryaki, H.; Hamawandi, B.; Toprak, M.S.; Ballikaya, S. Multi-objective optimization of concentrated Photovoltaic-Thermoelectric hybrid system via non-dominated sorting genetic algorithm (NSGA II). Energy Convers. Manag. 2021, 236, 114065. [Google Scholar] [CrossRef]

- Marandi, O.F.; Ameri, M.; Adelshahian, B. The experimental investigation of a hybrid photovoltaic-thermoelectric power generator solar cavity-receiver. Sol. Energy 2018, 161, 38–46. [Google Scholar] [CrossRef]

- Kohan, H.F.; Lotfipour, F.; Eslami, M. Numerical simulation of a photovoltaic thermoelectric hybrid power generation system. Sol. Energy 2018, 174, 537–548. [Google Scholar] [CrossRef]

- Liu, J.; Tang, H.; Zhang, D.; Jiao, S.; Zhou, Z.; Zhang, Z.; Zuo, J. Performance evaluation of the hybrid photovoltaic-thermoelectric system with light and heat management. Energy 2020, 211, 118618. [Google Scholar] [CrossRef]

- Zhang, J.; Xuan, Y. The electric feature synergy in the photovoltaic-Thermoelectric hybrid system. Energy 2019, 181, 387–394. [Google Scholar] [CrossRef]

- Zhang, J.; Zhai, H.; Wu, Z.; Wang, Y.; Xie, H.; Zhang, M. Enhanced performance of photovoltaic–thermoelectric coupling devices with thermal interface materials. Energy Rep. 2020, 6, 116–122. [Google Scholar] [CrossRef]

- Zhang, J.; Xuan, Y. An integrated design of the photovoltaic-thermoelectric hybrid system. Sol. Energy 2019, 177, 293–298. [Google Scholar] [CrossRef]

- Kossyvakis, D.N.; Voutsinas, G.D.; Hristoforou, E.V. Experimental analysis and performance evaluation of a tandem photovoltaic–thermoelectric hybrid system. Energy Convers. Manag. 2016, 117, 490–500. [Google Scholar] [CrossRef]

- Lamba, R.; Kaushik, S.C. Modeling and performance analysis of a concentrated photovoltaic–thermoelectric hybrid power generation system. Energy Convers. Manag. 2016, 115, 288–298. [Google Scholar] [CrossRef]

- Chen, W.H.; Wang, C.C.; Hung, C.I.; Yang, C.C.; Juang, R.C. Modeling and simulation for the design of thermal-concentrated solar thermoelectric generator. Energy 2014, 64, 287–297. [Google Scholar] [CrossRef]

- Deng, Y.; Zhu, W.; Wang, Y.; Shi, Y. Enhanced performance of solar-driven photovoltaic–thermoelectric hybrid system in an integrated design. Sol. Energy 2013, 88, 182–191. [Google Scholar] [CrossRef]

- Beeri, O.; Rotem, O.; Hazan, E.; Katz, E.A.; Braun, A.; Gelbstein, Y. Hybrid photovoltaic-thermoelectric system for concentrated solar energy conversion: Experimental realization and modeling. J. Appl. Phys. 2015, 118, 115104. [Google Scholar] [CrossRef]

- Li, G.; Zhang, G.; He, W.; Ji, J.; Lv, S.; Chen, X.; Chen, H. Performance analysis on a solar concentrating thermoelectric generator using the micro-channel heat pipe array. Energy Convers. Manag. 2016, 112, 191–198. [Google Scholar] [CrossRef] [Green Version]

- Li, G.; Zhao, X.; Ji, J. Conceptual development of a novel photovoltaic-thermoelectric system and preliminary economic analysis. Energy Convers. Manag. 2016, 126, 935–943. [Google Scholar] [CrossRef] [Green Version]

- Liao, T.; Lin, B.; Yang, Z. Performance characteristics of a low concentrated photovoltaic–thermoelectric hybrid power generation device. Int. J. Therm. Sci. 2014, 77, 158–164. [Google Scholar] [CrossRef]

- Da, Y.; Xuan, Y.; Li, Q. From light trapping to solar energy utilization: A novel photovoltaic–thermoelectric hybrid system to fully utilize solar spectrum. Energy 2016, 95, 200–210. [Google Scholar] [CrossRef]

- Zhou, Y.-P.; He, Y.-L.; Qiu, Y.; Ren, Q.; Xie, T. Multi-scale investigation on the absorbed irradiance distribution of the nanostructured front surface of the concentrated PV-TE device by a MC-FDTD coupled method. Appl. Energy 2017, 207, 18–26. [Google Scholar] [CrossRef]

- Zhu, W.; Deng, Y.; Wang, Y.; Shen, S.; Gulfam, R. High-performance photovoltaic-thermoelectric hybrid power generation system with optimized thermal management. Energy 2016, 100, 91–101. [Google Scholar] [CrossRef]

- Li, D.; Xuan, Y.; Li, Q.; Hong, H. Exergy and energy analysis of photovoltaic-thermoelectric hybrid systems. Energy 2017, 126, 343–351. [Google Scholar] [CrossRef]

- Teffah, K.; Zhang, Y. Modeling and experimental research of hybrid PV-thermoelectric system for high concentrated solar energy conversion. Sol. Energy 2017, 157, 10–19. [Google Scholar] [CrossRef]

- Yin, E.; Li, Q.; Xuan, Y. Thermal resistance analysis and optimization of photovoltaic-thermoelectric hybrid system. Energy Convers. Manag. 2017, 143, 188–202. [Google Scholar] [CrossRef]

- Zhang, J.; Xuan, Y. Investigation on the effect of thermal resistances on a highly concentrated photovoltaic-thermoelectric hybrid system. Energy Convers. Manag. 2016, 129, 1–10. [Google Scholar] [CrossRef]

- Mahmoudinezhad, S.; Qing, S.; Rezaniakolaei, A.; Rosendahl, L.A. Transient model of hybrid concentrated photovoltaic with thermoelectric generator. Energy Procedia 2017, 142, 564–569. [Google Scholar] [CrossRef]

- Mahmoudinezhad, S.; Rezania, A.; Rosendahl, L.A. Behavior of hybrid concentrated photovoltaic-thermoelectric generator under variable solar radiation. Energy Convers. Manag. 2018, 164, 443–452. [Google Scholar] [CrossRef]

- Singh, S.; Ibeagwu, O.I.; Lamba, R. Thermodynamic evaluation of irreversibility and optimum performance of a concentrated PV-TEG cogenerated hybrid system. Sol. Energy 2018, 170, 896–905. [Google Scholar] [CrossRef]

- Cotfas, D.T.; Cotfas, P.A.; Floroian, L.; Floroian, D.I. Study of combined photovoltaic cell/thermoelectric element/solar collector in medium concentrated light. In Proceedings of the 2017 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM) & 2017 Intl Aegean Conference on Electrical Machines and Power Electronics (ACEMP), Brasov, Romania, 25–27 May 2017; pp. 747–752. [Google Scholar]

- Acar, B.; Baş, Ş. Investigation of Energy Generation at Test System Designed by use of Concentrated Photo-Voltaic Panel and Thermoelectric Modules. Int. J. Renew. Energy Res. 2018, 8, 1859–1867. [Google Scholar]

- Bamroongkhan, P.; Lertsatitthanakorn, C.; Soponronnarit, S. Experimental performance study of a solar parabolic dish photovoltaic-thermoelectric generator. Energy Procedia 2019, 158, 528–533. [Google Scholar] [CrossRef]

- Shittu, S.; Li, G.; Zhao, X.; Akhlaghi, Y.G.; Ma, X.; Yu, M. Comparative study of a concentrated photovoltaic-thermoelectric system with and without flat plate heat pipe. Energy Convers. Manag. 2019, 193, 1–14. [Google Scholar] [CrossRef]

- Mahmoudinezhad, S.; Rezania, A.; Cotfas, D.T.; Cotfas, P.A.; Rosendahl, L.A. Experimental and numerical investigation of hybrid concentrated photovoltaic–Thermoelectric module under low solar concentration. Energy 2018, 159, 1123–1131. [Google Scholar] [CrossRef]

- Yin, E.; Li, Q.; Xuan, Y. Optimal design method for concentrating photovoltaic-thermoelectric hybrid system. Appl. Energy 2018, 226, 320–329. [Google Scholar] [CrossRef]

- Yin, E.; Li, Q.; Xuan, Y. Experimental optimization of operating conditions for concentrating photovoltaic-thermoelectric hybrid system. J. Power Sources 2019, 422, 25–32. [Google Scholar] [CrossRef]

- Shittu, S.; Li, G.; Zhao, X.; Ma, X.; Akhlaghi, Y.G.; Fan, Y. Comprehensive study and optimization of concentrated photovoltaic-thermoelectric considering all contact resistances. Energy Convers. Manag. 2020, 205, 112422. [Google Scholar] [CrossRef]

- Bjørk, R.; Nielsen, K.K. The performance of a combined solar photovoltaic (PV) and thermoelectric generator (TEG) system. Sol. Energy 2015, 120, 187–194. [Google Scholar] [CrossRef] [Green Version]

- Kwan, T.H.; Wu, X. Power and mass optimization of the hybrid solar panel and thermoelectric generators. Appl. Energy 2016, 165, 297–307. [Google Scholar] [CrossRef]

- Zhang, J.; Xuan, Y.; Yang, L. A novel choice for the photovoltaic–thermoelectric hybrid system: The perovskite solar cell. Int. J. Energy Res. 2016, 40, 1400–1409. [Google Scholar] [CrossRef]

- Zhang, H.; Yue, H.; Huang, J.; Liang, K.; Chen, H. Experimental studies on a low concentrating photovoltaic/thermal (LCPV/T) collector with a thermoelectric generator (TEG) module. Renew. Energy 2021, 171, 1026–1040. [Google Scholar] [CrossRef]

- Kolahan, A.; Maadi, S.R.; Kazemian, A.; Schenone, C.; Ma, T. Semi-3D transient simulation of a nanofluid-base photovoltaic thermal system integrated with a thermoelectric generator. Energy Convers. Manag. 2020, 220, 113073. [Google Scholar] [CrossRef]

- Maadi, S.R.; Navegi, A.; Solomin, E.; Ahn, H.S.; Wongwises, S.; Mahian, O. Performance Improvement of a Photovoltaic-Thermal System using a Wavy-strip Insert with and without nanofluids. Energy 2021, 234, 121190. [Google Scholar] [CrossRef]

- Salari, A.; Parcheforosh, A.; Hakkaki-Fard, A.; Amadeh, A. A numerical study on a photovoltaic thermal system integrated with a thermoelectric generator module. Renew. Energy 2020, 153, 1261–1271. [Google Scholar] [CrossRef]

- Wen, X.; Ji, J.; Song, Z.; Li, Z.; Xie, H.; Wang, J. Comparison analysis of two different concentrated photovoltaic/thermal-TEG hybrid systems. Energy Convers. Manag. 2021, 234, 113940. [Google Scholar] [CrossRef]

- Nazri, N.S.; Fudholi, A.; Mustafa, W.; Yen, C.H.; Mohammad, M.; Ruslan, M.H.; Sopian, K. Exergy and improvement potential of hybrid photovoltaic thermal/thermoelectric (PVT/TE) air collector. Renew. Sustain. Energy Rev. 2019, 111, 132–144. [Google Scholar] [CrossRef]

- Babu, C.; Ponnambalam, P. Economic analysis of hybrid Photovoltaic Thermal Configurations: A comparative study. Sustain. Energy Technol. Assess. 2021, 43, 100932. [Google Scholar] [CrossRef]

- Miljkovic, N.; Wang, E.N. Modeling and optimization of hybrid solar thermoelectric systems with thermosyphons. Sol. Energy 2011, 85, 2843–2855. [Google Scholar] [CrossRef] [Green Version]

- Willars-Rodríguez, F.J.; Chávez-Urbiola, E.A.; Vorobiev, P.; Vorobiev, Y.V. Investigation of solar hybrid system with concentrating Fresnel lens, photovoltaic and thermoelectric generators. Int. J. Energy Res. 2017, 41, 377–388. [Google Scholar] [CrossRef]

- Li, C.; Zhang, M.; Miao, L.; Zhou, J.; Kang, Y.P.; Fisher, C.A.J.; Ohno, K.; Shen, Y.; Lin, H. Effects of environmental factors on the conversion efficiency of solar thermoelectric co-generators comprising parabola trough collectors and thermoelectric modules without evacuated tubular collector. Energy Convers. Manag. 2014, 86, 944–951. [Google Scholar] [CrossRef]

- Mohsenzadeh, M.; Shafii, M.B.; Mosleh, H.J. A novel concentrating photovoltaic/thermal solar system combined with thermoelectric module in an integrated design. Renew. Energy 2017, 113, 822–834. [Google Scholar] [CrossRef]

- Kil, T.-H.; Kim, S.; Jeong, D.-H.; Geum, D.-M.; Lee, S.; Jung, S.-J.; Kim, S.; Park, C.; Kim, J.-S.; Baik, J.M.; et al. A highly-efficient, concentrating-photovoltaic/thermoelectric hybrid generator. Nano Energy 2017, 37, 242–247. [Google Scholar] [CrossRef]

- Soltani, S.; Kasaeian, A.; Sokhansefat, T.; Shafii, M.B. Performance investigation of a hybrid photovoltaic/thermoelectric system integrated with parabolic trough collector. Energy Convers. Manag. 2018, 159, 371–380. [Google Scholar] [CrossRef]

- Haiping, C.; Jiguang, H.; Heng, Z.; Kai, L.; Haowen, L.; Shuangyin, L. Experimental investigation of a novel low concentrating photovoltaic/thermal–thermoelectric generator hybrid system. Energy 2019, 166, 83–95. [Google Scholar] [CrossRef]

- Yin, E.; Li, Q.; Xuan, Y. Feasibility analysis of a concentrating photovoltaic-thermoelectric-thermal cogeneration. Appl. Energy 2019, 236, 560–573. [Google Scholar] [CrossRef]

- Sharaf, O.Z.; Orhan, M.F. Comparative thermodynamic analysis of densely-packed concentrated photovoltaic thermal (CPVT) solar collectors in thermally in-series and in-parallel receiver configurations. Renew. Energy 2018, 126, 296–321. [Google Scholar] [CrossRef]

- Shadmehri, M.; Narei, H.; Ghasempour, R.; Shafii, M.B. Numerical simulation of a concentrating photovoltaic-thermal solar system combined with thermoelectric modules by coupling Finite Volume and Monte Carlo Ray-Tracing methods. Energy Convers. Manag. 2018, 172, 343–356. [Google Scholar] [CrossRef]

- Lashin, A.; Turkestani, M.A.; Sabry, M. Concentrated photovoltaic/thermal hybrid system coupled with a thermoelectric generator. Energies 2019, 12, 2623. [Google Scholar] [CrossRef] [Green Version]

- Abdo, A.; Ookawara, S.; Ahmed, M. Performance evaluation of a new design of concentrator photovoltaic and solar thermoelectric generator hybrid system. Energy Convers. Manag. 2019, 195, 1382–1401. [Google Scholar] [CrossRef]

- Riahi, A.; Ali, A.B.H.; Fadhel, A.; Guizani, A.; Balghouthi, M. Performance investigation of a concentrating photovoltaic thermal hybrid solar system combined with thermoelectric generators. Energy Convers. Manag. 2020, 205, 112377. [Google Scholar] [CrossRef]

- Rejeb, O.; Shittu, S.; Li, G.; Ghenai, C.; Zhao, X.; Ménézo, C.; Bettayeb, M. Comparative investigation of concentrated photovoltaic thermal-thermoelectric with nanofluid cooling. Energy Convers. Manag. 2021, 235, 113968. [Google Scholar] [CrossRef]

- Lekbir, A.; Hassani, S.; Ab Ghani, M.R.; Gan, C.K.; Mekhilef, S.; Saidur, R. Improved energy conversion performance of a novel design of concentrated photovoltaic system combined with thermoelectric generator with advance cooling system. Energy Convers. Manag. 2018, 177, 19–29. [Google Scholar] [CrossRef]

- Soltani, S.; Kasaeian, A.; Sarrafha, H.; Wen, D. An experimental investigation of a hybrid photovoltaic/thermoelectric system with nanofluid application. Sol. Energy 2017, 155, 1033–1043. [Google Scholar] [CrossRef]

- Akbar, A.; Najafi, G.; Gorjian, S.; Kasaeian, A.; Mazlan, M. Performance enhancement of a hybrid photovoltaic-thermal-thermoelectric (PVT-TE) module using nanofluid-based cooling: Indoor experimental tests and multi-objective optimization. Sustain. Energy Technol. Assess. 2021, 46, 101276. [Google Scholar] [CrossRef]

- Rajaee, F.; Rad, M.A.V.; Kasaeian, A.; Mahian, O.; Yan, W.M. Experimental analysis of a photovoltaic/thermoelectric generator using cobalt oxide nanofluid and phase change material heat sink. Energy Convers. Manag. 2020, 212, 112780. [Google Scholar] [CrossRef]

- Soltani, S.; Kasaeian, A.; Lavajoo, A.; Loni, R.; Najafi, G.; Mahian, O. Exergetic and enviromental assessment of a photovoltaic thermal-thermoelectric system using nanofluids: Indoor experimental tests. Energy Convers. Manag. 2020, 218, 112907. [Google Scholar] [CrossRef]

- Wu, Y.-Y.; Wu, S.-Y.; Xiao, L. Performance analysis of photovoltaic–thermoelectric hybrid system with and without glass cover. Energy Convers. Manag. 2015, 93, 151–159. [Google Scholar] [CrossRef]

| Reference | Year | Performance Index |

|---|---|---|

| Indira et al. [7] | 2020 | Summary of various experimental and numerical studies on different configurations of concentrated PV-TEG system |

| Shittu et al. [8] | 2019 | Review on concepts and applications of PVs, TEG, and PV-TEG systems and current research focus areas in PV-TEG systems |

| Huen and Daoud [9] | 2017 | Summary of research studies to understand the concept of PVs and thermoelectric and optimize the PV-TEG system |

| Li et al. [10] | 2018 | Review on feasibility, type, and performance of PV-TEG system for electricity generation |

| Irshad et al. [11] | 2019 | Review on energy efficient buildings using hybrid technology of PV-TEG system |

| Babu and Ponnambalam [12] | 2017 | Review on performance of PV/T, solar thermal-TEG and PV-TEG system |

| Nazri et al. [13] | 2018 | Review on energy and economic of air collector-based PV/T-TEG system |

| Parameters | PV | Flat PV-TEG | Cavity PV-TEG |

|---|---|---|---|

| Sum of lifetime cost (USD) | 7.72 | 38.13 | 190.75 |

| Sum of lifetime electrical energy (kWh) | 8.37 | 6.74 | 20.22 |

| Cost of energy (USD/kWh) | 6.06 | 37.26 | 62.5 |

| Levelized cost of energy (USD/kWh) | 0.922 | 5.65 | 9.432 |

| Configuration | Thermal Efficiency (%) | Electrical Efficiency (%) |

|---|---|---|

| Water-without TEG Water-with TEG | 47.35 46.13 | 6.76 7.26 |

| Water-without TEG Water-with TEG | 57.28 55.07 | 13.26 14.64 |

| Al2O3 nanofluid-without TEG Al2O3 nanofluid-without TEG | 60.5 59.2 | 12.6 13.1 |

| Systems | Thermal Efficiency (%) | PV Efficiency (%) | TEG Efficiency (%) |

|---|---|---|---|

| PV/T | 55.28 | 13.58 | - |

| PV/T-TEG | 53.26 | 13.60 | 1.11 |

| Mass Flow Rate (kg/s) | Thermal Exergy Rate (W) | PV Exergy Rate (W) | TEG Exergy Rate (W) | Overall Exergy Efficiency (%) |

|---|---|---|---|---|

| 0.001 | 1.4283 | 33.0565 | 72.9198 | 0.3695 |

| 0.004 | 1.1717 | 33.3498 | 76.3994 | 0.3816 |

| 0.01 | 0.9431 | 33.6283 | 77.2690 | 0.3848 |

| 0.02 | 0.7502 | 33.8777 | 77.4840 | 0.3857 |

| 0.04 | 0.6512 | 34.2677 | 77.1934 | 0.3857 |

| 0.07 | 0.6499 | 34.8021 | 76.4662 | 0.3851 |

| 0.09 | 0.6301 | 35.0636 | 76.0966 | 0.3846 |

| 0.12 | 0.5945 | 35.3737 | 75.6492 | 0.3840 |

| 0.15 | 0.5591 | 35.6188 | 75.2896 | 0.3835 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garud, K.S.; Hwang, S.-G.; Han, J.-W.; Lee, M.-Y. Review on Performance Enhancement of Photovoltaic/Thermal–Thermoelectric Generator Systems with Nanofluid Cooling. Symmetry 2022, 14, 36. https://doi.org/10.3390/sym14010036

Garud KS, Hwang S-G, Han J-W, Lee M-Y. Review on Performance Enhancement of Photovoltaic/Thermal–Thermoelectric Generator Systems with Nanofluid Cooling. Symmetry. 2022; 14(1):36. https://doi.org/10.3390/sym14010036

Chicago/Turabian StyleGarud, Kunal Sandip, Seong-Guk Hwang, Jeong-Woo Han, and Moo-Yeon Lee. 2022. "Review on Performance Enhancement of Photovoltaic/Thermal–Thermoelectric Generator Systems with Nanofluid Cooling" Symmetry 14, no. 1: 36. https://doi.org/10.3390/sym14010036

APA StyleGarud, K. S., Hwang, S.-G., Han, J.-W., & Lee, M.-Y. (2022). Review on Performance Enhancement of Photovoltaic/Thermal–Thermoelectric Generator Systems with Nanofluid Cooling. Symmetry, 14(1), 36. https://doi.org/10.3390/sym14010036