Discrete Dynamics of Balls in Cageless Ball Bearings

Abstract

:1. Introduction

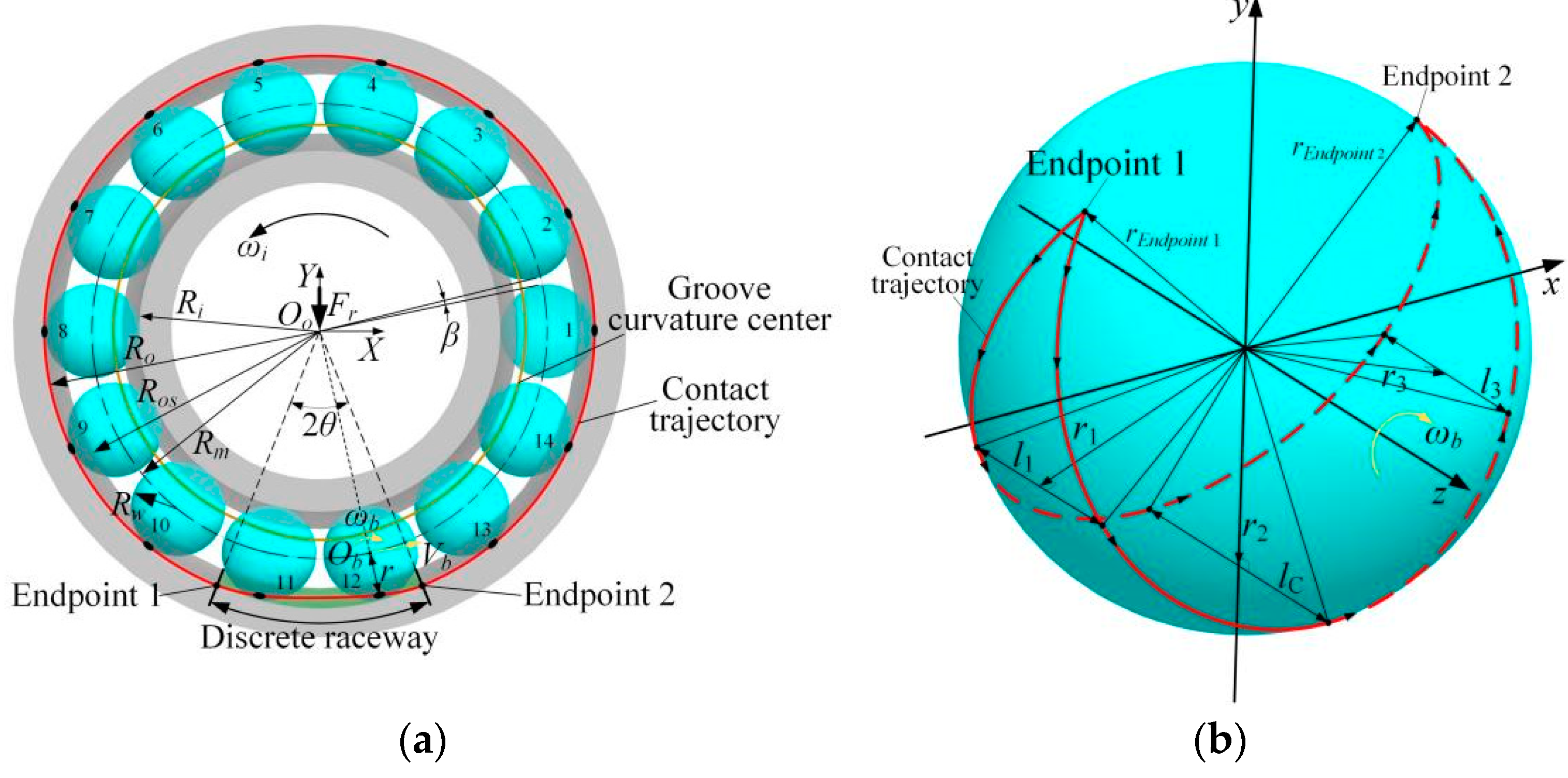

2. Discrete Raceway Principle and the Mathematical Model

2.1. Principle

2.2. Discrete Raceway Mathematical Model

2.3. Constraints for the Discrete Raceway Structures

3. Dynamic Model

3.1. Differential Equation

3.2. Contact Force Calculation

3.3. Friction Calculation

4. Numerical Simulation Results and Analysis

4.1. Initial Value

4.2. Maximum Axial Span and the Circumferential Span Angle

4.3. Results Analysis

5. Experiment

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cuesta, E.N.; Montbrun, N.I.; Rastelli, V.; Diaz, S.E. Simple Model for a Magnetic Bearing System Operating on the Auxiliary Bearing. In Proceedings of the Asme Turbo Expo: Power for Land, Sea, & Air, Reno, NV, USA, 6–9 June 2005. [Google Scholar]

- Fonseca, C.A.; Santos, I.F.; Weber, H.I. Influence of unbalance levels on nonlinear dynamics of a rotor-backup rolling bearing system. J. Sound Vib. 2017, 394, 482–496. [Google Scholar] [CrossRef] [Green Version]

- Sun, G.; Palazzolo, A.; Provenza, A.; Montague, G. Detailed ball bearing model for magnetic suspension auxiliary service. J. Sound Vib. 2004, 269, 933–963. [Google Scholar] [CrossRef]

- Xue, S.; Deng, S.; Zhang, Y.; Chen, G.; Mechatronics, S.O.; University, N.P.; Mechatronics, S.O. Study on Vibration Characteristic of Trilobe Raceway Cylindrical Roller Bearing with Elastic Support. J. Mech. Transm. 2017. [Google Scholar] [CrossRef]

- Lu, Z.; Lu, Y.; Deng, S. Study on load distribution characteristics of cylindrical roller bearings with trilobe raceways. Bearing 2016, 9, 1–6. [Google Scholar]

- Hamrock, B.J.; Anderson, W. Analysis of an arched outer-race ball bearing considering centrifugal forces. J. Lubr. Tech. 1973, 95, 265–271. [Google Scholar] [CrossRef]

- Hamrock, B.J. Ball motion and sliding friction in an arched outer race ball bearing. J. Lubr. Tech. 1975, 97, 202–210. [Google Scholar] [CrossRef]

- Xu, H.; Xu, W. Improvement on design of three-point contact ball bearing. J. Harbin Bear. 2007, 28, 6–7. [Google Scholar]

- Jie, L.I.; Tian, Y.S.; Zhang, H.L.; Gao, Q.; Tan, C.Q. Research on Stiffness Behavior of Three Point Contact Ball Bearing in Consideration of Axial Load. Tuijin Jishu/J. Propuls. Technol. 2018, 39, 419–425. [Google Scholar] [CrossRef]

- Zupan, S.; Prebil, I. Carrying angle and carrying capacity of a large single row ball bearing as a function of geometry parameters of the rolling contact and the supporting structure stiffness. Mech. Mach. Theory 2001, 36, 1087–1103. [Google Scholar] [CrossRef]

- Amasorrain, J.I.; Sagartzazu, X.; Damian, J. Load distribution in a four contact-point slewing bearing. Mech. Mach. Theory 2003, 38, 479–496. [Google Scholar] [CrossRef]

- Leblanc, A.; Nelias, D. Ball motion and sliding friction in a four-contact-point ball bearing. J. Tribol. 2007, 129, 801–808. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.1071.1997&rep=rep1&type=pdf (accessed on 10 October 2022). [CrossRef]

- Halpin, J.D.; Tran, A.N. An analytical model of four-point contact rolling element ball bearings. J. Tribol. 2016, 138, 031404. [Google Scholar] [CrossRef]

- Singh, A.P.; Agrawal, A.; Joshi, D. Contact Mechanics Studies for an Elliptical Curvature Deep Groove Ball Bearing Using Continuum Solid Modeling based on FEM Simulation Approach. IOSR J. Mech. Civ. Eng. 2016, 13, 1–11. [Google Scholar]

- Korolev, A. Influence of geometrical parameters of the working surface of the bearing raceway on its operability. J. Frict. Wear 2015, 36, 189–192. [Google Scholar] [CrossRef]

- Townsend, D.P.; Allen, C.W.; Zaretsky, E.V. Friction Losses in a Lubricated Thrust-Loaded Cageless Angular-Contract Bearing; Nasa Technical Note D-7356; NASA: Washington, DC, USA, 1973. [Google Scholar]

- Zhil’nikov, E.; Balyakin, V.; Lavrin, A. A method for calculating the frictional moment in cageless bearings. J. Frict. Wear 2018, 39, 400–404. [Google Scholar] [CrossRef]

- Helfert, M. Rotorabstürze in Wälzlager-Experimentelle Untersuchung des Rotor-Fanglager-Kontakts. Ph.D. Thesis, Technische Universität, Darmstadt, Germany, 2010. [Google Scholar]

- Cole, M.; Keogh, P.; Burrows, C. The Dynamic Behavior of a Rolling Element Auxiliary Bearing Following Rotor Impact. J. Tribol. 2002, 124, 406–413. [Google Scholar] [CrossRef]

- Kärkkäinen, A. Dynamic Simulations of Rotors during Drop on Retainer Bearings. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2007. [Google Scholar]

- Kärkkäinen, A.; Sopanen, J.; Mikkola, A. Dynamic simulation of a flexible rotor during drop on retainer bearings. J. Sound Vib. 2007, 306, 601–617. [Google Scholar] [CrossRef]

- Wiercigroch, M. Applied nonlinear dynamics of non-smooth mechanical systems. J. Braz. Soc. Mech. Sci. Eng. 2006, 28, 519–526. [Google Scholar] [CrossRef]

- Karpenko, E. Nonlinear Dynamics of a Jeffcott Rotor with Imperfections; University of Aberdeen: Aberdeen, UK, 2003. [Google Scholar]

- Chávez, J.P.; Wiercigroch, M. Bifurcation analysis of periodic orbits of a non-smooth Jeffcott rotor model. Commun. Nonlinear Sci. Numer. Simul. 2013, 18, 2571–2580. [Google Scholar] [CrossRef]

- Halminen, O.; Aceituno, J.F.; Escalona, J.L.; Sopanen, J.; Mikkola, A. Models for dynamic analysis of backup ball bearings of an AMB-system. Mech. Syst. Signal Process. 2017, 95, 324–344. [Google Scholar] [CrossRef]

- Halminen, O.; Aceituno, J.F.; Escalona, J.L.; Sopanen, J.; Mikkola, A. A touchdown bearing with surface waviness: Friction loss analysis. Mech. Mach. Theory 2017, 110, 73–84. [Google Scholar] [CrossRef]

- Ai, X.; Hager, C. Forensic analysis of surface indentations in rolling contact. J. Tribol. 2016, 138, 011101. [Google Scholar] [CrossRef]

- Ming, X.X.; Xie, Z.W. Nonlinear Numerical Simulation of Rotor Dynamics. Appl. Math. Mech. 2015, 36, 677–685. [Google Scholar] [CrossRef]

- Deng, S.E.; Fu, J.H.; Wang, Y.S.; Yang, H.S. Analysis on dynamic characteristics of aero-engine rolling bearing/dual-rotor system. J. Aerosp. Power 2013, 28, 195–204. [Google Scholar]

- Roques, S.; Legrand, M.; Cartraud, P.; Stoisser, C.; Pierre, C. Modeling of a rotor speed transient response with radial rubbing. J. Sound Vib. 2010, 329, 527–546. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Zhang, J.; Zhou, E. Automatic discrete failure study of cage free ball bearings based on variable diameter contact. J. Mech. Sci. Technol. 2021, 35, 4943–4952. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Q.; Wang, M.; Pan, C.; Bao, Y. Discrete theory of rolling elements for a cageless ball bearing. J. Mech. Sci. Technol. 2022, 36, 1921–1933. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, Y.; Wang, M. Analysis of Contact Stress Distribution between Rolling Element and Variable Diameter Raceway of Cageless Bearing. Appl. Sci. 2022, 12, 5764. [Google Scholar] [CrossRef]

- Wenbing, T.U.; Haibin, H.E.; Luo, Y.; Xiao, Q. Dynamic skidding behavior of rolling elements under bearing steady working conditions. J. Vib. Shock. 2019, 6. [Google Scholar] [CrossRef]

- Kurvinen, E.; Sopanen, J.; Mikkola, A. Ball bearing model performance on various sized rotors with and without centrifugal and gyroscopic forces. Mech. Mach. Theory 2015, 90, 240–260. [Google Scholar] [CrossRef]

- Gupta, P.K. Advanced Dynamics of Rolling Elements; Springer Science & Business Media: New York, NY, USA, 2012. [Google Scholar]

- Gupta, P.K. Transient ball motion and skid in ball bearings. J. Lubr. Tech. 1975, 97, 261–269. [Google Scholar] [CrossRef]

- Burden, R.L.; Faires, J.D.; Burden, A.M. Numerical Analysis; Cengage Learning: Boston, MA, USA, 2015. [Google Scholar]

- Zhao, Y.; Wu, C. Numerical simulation to research the collision and skidding of rolling elements for cageless bearings. Ind. Lubr. Tribol. 2022, 74, 1101–1109. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Ball radial Rw (mm) | 4.7625 |

| Radius of the outer groove bottom Ro (mm) | 27.765 |

| Radius of the inner groove bottom Ri (mm) | 18.24 |

| Outer Shoulder Radius Ros (mm) | 26 |

| Number of balls N | 14 |

| Inner ring rotation speed ωi (rpm) | 12,000 |

| Radial load Fr (N) | 1500 |

| lC (mm) | Simulation Values of | Difference | ||

|---|---|---|---|---|

| 4.95 | 35 | 1.8153 | 1.8131 | −0.0022 |

| 5 | 30.5 | 1.8176 | 1.8281 | 0.0105 |

| 5.05 | 27.5 | 1.8185 | 1.8323 | 0.0138 |

| 5.1 | 25.2 | 1.8171 | 1.8190 | 0.0019 |

| 5.15 | 23.5 | 1.8183 | 1.7932 | −0.0251 |

| 5.2 | 22 | 1.8156 | 1.7552 | −0.0604 |

| 5.4 | 18.167 | 1.8161 | 1.6589 | −0.1572 |

| 5.6 | 15.774 | 1.8161 | 1.6594 | −0.1567 |

| 5.8 | 14.062 | 1.8161 | 1.5416 | −0.2645 |

| 6 | 12.717 | 1.8160 | 1.4538 | −0.3622 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Zhou, G.; Wang, Q. Discrete Dynamics of Balls in Cageless Ball Bearings. Symmetry 2022, 14, 2242. https://doi.org/10.3390/sym14112242

Zhao Y, Zhou G, Wang Q. Discrete Dynamics of Balls in Cageless Ball Bearings. Symmetry. 2022; 14(11):2242. https://doi.org/10.3390/sym14112242

Chicago/Turabian StyleZhao, Yanling, Gang Zhou, and Qiyu Wang. 2022. "Discrete Dynamics of Balls in Cageless Ball Bearings" Symmetry 14, no. 11: 2242. https://doi.org/10.3390/sym14112242