Design, Simulation and Experimental Evaluation of Hot-Stamped 22MnB5 Steel Autobody Part

Abstract

:1. Introduction

2. Materials and Methods

2.1. Design and Simulation

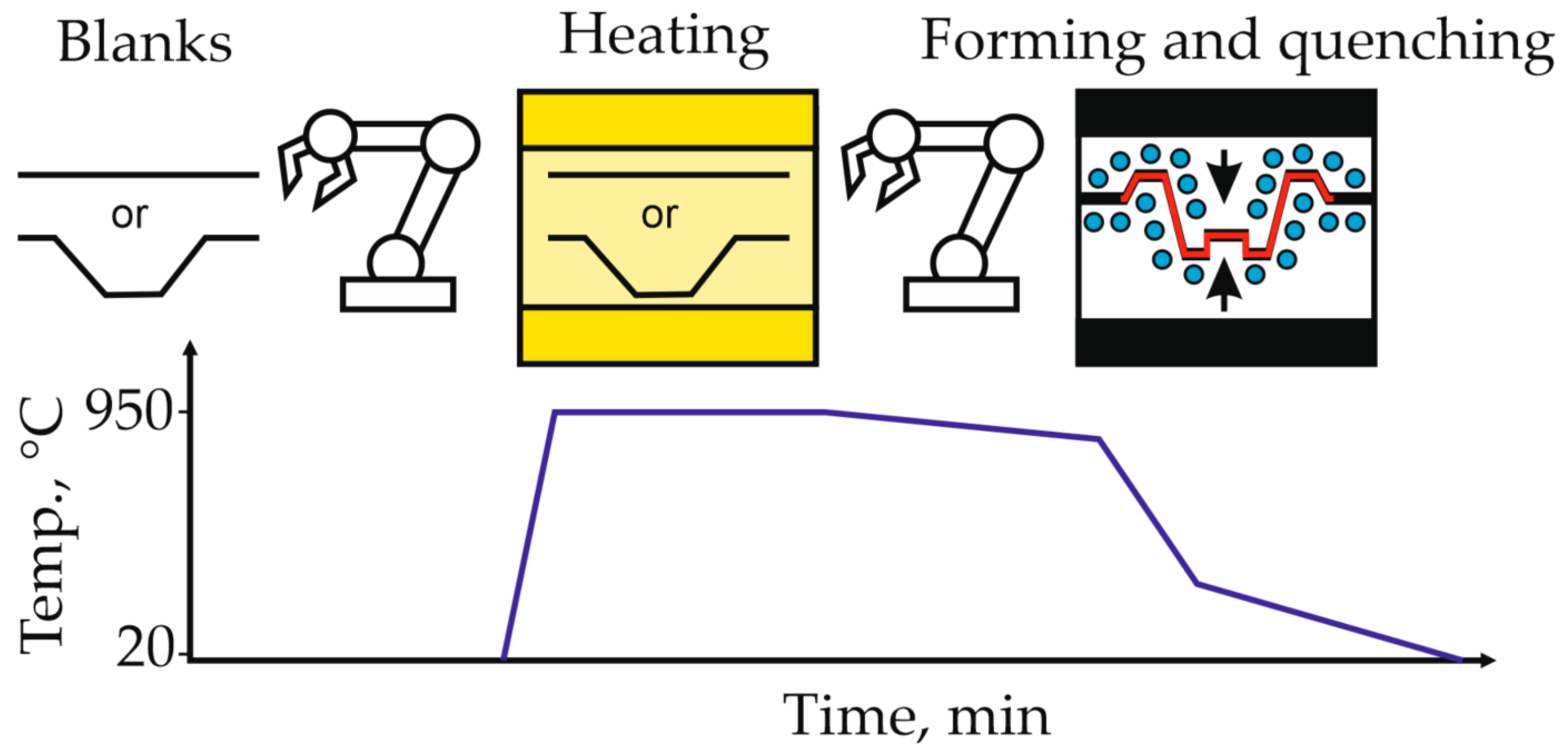

2.2. Experimental Hot Stamping

2.3. Microstructure and Hardness

3. Results and Discussion

3.1. Results of the Numerical Analysis

- -

- A visualization of the stages of forming as a function of the distance between the die and the punch;

- -

- -

- A distribution of thinning for the drawpiece;

- -

- A distribution of the drawpiece hardness and microstructure.

3.2. Properties and Microstructure Validation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Billur, E. Hot Stamping of Ultra High-Strength Steels; Springer: New York, NY, USA, 2018; ISBN 978-3-319-98868-9. [Google Scholar]

- Karbasian, H.; Tekkaya, A.E. A Review on Hot Stamping. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Neugebauer, R.; Schieck, F.; Polster, S.; Mosel, A.; Rautenstrauch, A.; Schönherr, J.; Pierschel, N. Press Hardening—An Innovative and Challenging Technology. Archiv. Civ. Mech. Eng. 2012, 12, 113–118. [Google Scholar] [CrossRef]

- Grajcar, A.; Skrzypczyk, P.; Wozniak, D. Thermomechanically Rolled Medium-Mn Steels Containing Retained Austenite. Arch. Metall. Mater. 2014, 59, 1691–1697. [Google Scholar] [CrossRef]

- Huang, F.; Chen, Q.; Ding, H.; Wang, Y.; Mou, X.; Chen, J. Automotive Steel with a High Product of Strength and Elongation Used for Cold and Hot Forming Simultaneously. Materials 2021, 14, 1121. [Google Scholar] [CrossRef]

- Derazkola, H.A.; García Gil, E.; Murillo-Marrodán, A.; Méresse, D. Review on Dynamic Recrystallization of Martensitic Stainless Steels during Hot Deformation: Part I—Experimental Study. Metals 2021, 11, 572. [Google Scholar] [CrossRef]

- Li, H.; Wu, X.; Li, G. Prediction of Forming Limit Diagrams for 22MnB5 in Hot Stamping Process. Mater. Eng. Perform. 2013, 22, 2131–2140. [Google Scholar] [CrossRef]

- Liu, S.; Long, M.; Zhang, S.; Zhao, Y.; Zhao, J.; Feng, Y.; Chen, D.; Ma, M. Study on the Prediction of Tensile Strength and Phase Transition for Ultra-High Strength Hot Stamping Steel. Mater. Res. Technol. 2020, 9, 14244–14253. [Google Scholar] [CrossRef]

- Caia, Y.; Halim, F.; Li, G.; Chen, S. Hot Stamping Simulation and Austenite Decomposition Modeling of an Automobile Cross Member. Procedia Eng. 2011, 15, 4902–4907. [Google Scholar] [CrossRef] [Green Version]

- Xu, L.; Chen, L.; Chen, G.; Wang, M. Hot Deformation Behavior and Microstructure Analysis of 25Cr3Mo3NiNb Steel during Hot Compression Tests. Vacuum 2018, 147, 8–17. [Google Scholar] [CrossRef]

- Hein, P.; Wilsius, J. Status and Innovation Trends in Hot Stamping of USIBOR 1500 P. Steel Res. Int. 2008, 79, 85–91. [Google Scholar] [CrossRef]

- Wróbel, I.; Skowronek, A.; Grajcar, A. A Review on Hot Stamping of Advanced High-Strength Steels: Technological-Metallurgical Aspects and Numerical Simulation. Symmetry 2022, 14, 969. [Google Scholar] [CrossRef]

- Autoform Help System. Available online: https://servicecenter.autoform.com (accessed on 1 November 2022).

- Trzepiecinski, T.; Lemu, H.G. Recent Developments and Trends in the Friction Testing for Conventional Sheet Metal Forming and Incremental Sheet Forming. Metals 2020, 10, 47. [Google Scholar] [CrossRef] [Green Version]

- Sajan, M.; Amirthalingam, M.; Chakkingal, U. A Novel Method for the Spring-Back Analysis of a Hot Stamping Steel. Mater. Res. Technol. 2021, 11, 227–234. [Google Scholar] [CrossRef]

- Aydin, H.; Essadiqi, E.; Jung, I.-H.; Yue, S. Development of 3rd Generation AHSS with Medium Mn Content Alloying Compositions. Mater. Sci. Eng. A 2013, 564, 501–508. [Google Scholar] [CrossRef]

- Dharavath, B.; Morchhale, A.; Singh, S.K.; Kotkunde, N.; Naik, M.T. Experimental Determination and Theoretical Prediction of Limiting Strains for ASS 316L at Hot Forming Conditions. Mater. Eng. Perform. 2020, 29, 4766–4778. [Google Scholar] [CrossRef]

- Li, S.; Luo, H. Medium-Mn Steels for Hot Forming Application in the Automotive Industry. Int. J. Miner. Metall. Mater 2021, 28, 741–753. [Google Scholar] [CrossRef]

- Zambrano, V.; Mueller-Roemer, J.; Sandberg, M.; Talasila, P.; Zanin, D.; Larsen, P.G.; Loeschner, E.; Thronicke, W.; Pietraroia, D.; Landolfi, G.; et al. Industrial Digitalization in the Industry 4.0 Era: Classification, Reuse and Authoring of Digital Models on Digital Twin Platforms. Array 2022, 14, 100176. [Google Scholar] [CrossRef]

- Yanagimoto, J.; Banabic, D.; Banu, M.; Madej, Ł. Simulation of Metal Forming—Visualization of Invisible Phenomena in the Digital Era. CIRP Ann. 2022, 71, 599–622. [Google Scholar] [CrossRef]

- Lin, J.; Mohamed, M.; Balint, D.; Dean, T. The Development of Continuum Damage Mechanics-Based Theories for Predicting Forming Limit Diagrams for Hot Stamping Applications. Int. J. Damage Mech. 2014, 23, 684–701. [Google Scholar] [CrossRef]

- Cui, J.; Sun, G.; Xu, J.; Huang, X.; Li, G. A Method to Evaluate the Formability of High-Strength Steel in Hot Stamping. Mater. Des. 2015, 77, 95–109. [Google Scholar] [CrossRef]

- Çavuşoğlu, O.; Çavuşoğlu, O.; Yılmazoğlu, A.G.; Üzel, U.; Aydın, H.; Güral, A. Microstructural Features and Mechanical Properties of 22MnB5 Hot Stamping Steel in Different Heat Treatment Conditions. Mater. Res. Technol. 2020, 9, 10901–10908. [Google Scholar] [CrossRef]

- Venturato, G.; Novella, M.; Bruschi, S.; Ghiotti, A.; Shivpuri, R. Effects of Phase Transformation in Hot Stamping of 22MnB5 High Strength Steel. Procedia Eng. 2017, 183, 316–321. [Google Scholar] [CrossRef]

- Klassen, C.M.; Smith, R.D.L.; Daun, K.J. Characterizing the AlSi Coating on 22MnB5 Steel Using Raman Spectroscopy. Mater. Charact. 2022, 189, 112002. [Google Scholar] [CrossRef]

| Chemical Element | C | Mn | B | Cr | Si | Al | Ti | N |

|---|---|---|---|---|---|---|---|---|

| wt. % | 0.19–0.22 | 1.10–1.40 | 0.0008–0.0050 | 0.10–0.35 | Max 0.40 | Max 0.08 | Max 0.045 | Max 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skowronek, A.; Wróbel, I.; Grajcar, A. Design, Simulation and Experimental Evaluation of Hot-Stamped 22MnB5 Steel Autobody Part. Symmetry 2022, 14, 2625. https://doi.org/10.3390/sym14122625

Skowronek A, Wróbel I, Grajcar A. Design, Simulation and Experimental Evaluation of Hot-Stamped 22MnB5 Steel Autobody Part. Symmetry. 2022; 14(12):2625. https://doi.org/10.3390/sym14122625

Chicago/Turabian StyleSkowronek, Adam, Ireneusz Wróbel, and Adam Grajcar. 2022. "Design, Simulation and Experimental Evaluation of Hot-Stamped 22MnB5 Steel Autobody Part" Symmetry 14, no. 12: 2625. https://doi.org/10.3390/sym14122625

APA StyleSkowronek, A., Wróbel, I., & Grajcar, A. (2022). Design, Simulation and Experimental Evaluation of Hot-Stamped 22MnB5 Steel Autobody Part. Symmetry, 14(12), 2625. https://doi.org/10.3390/sym14122625