Effects of Temperature-Dependent Conductivity and Magnetic Field on the Radiated Carreau Nanofluid Flow and Entropy Generation

Abstract

:1. Introduction

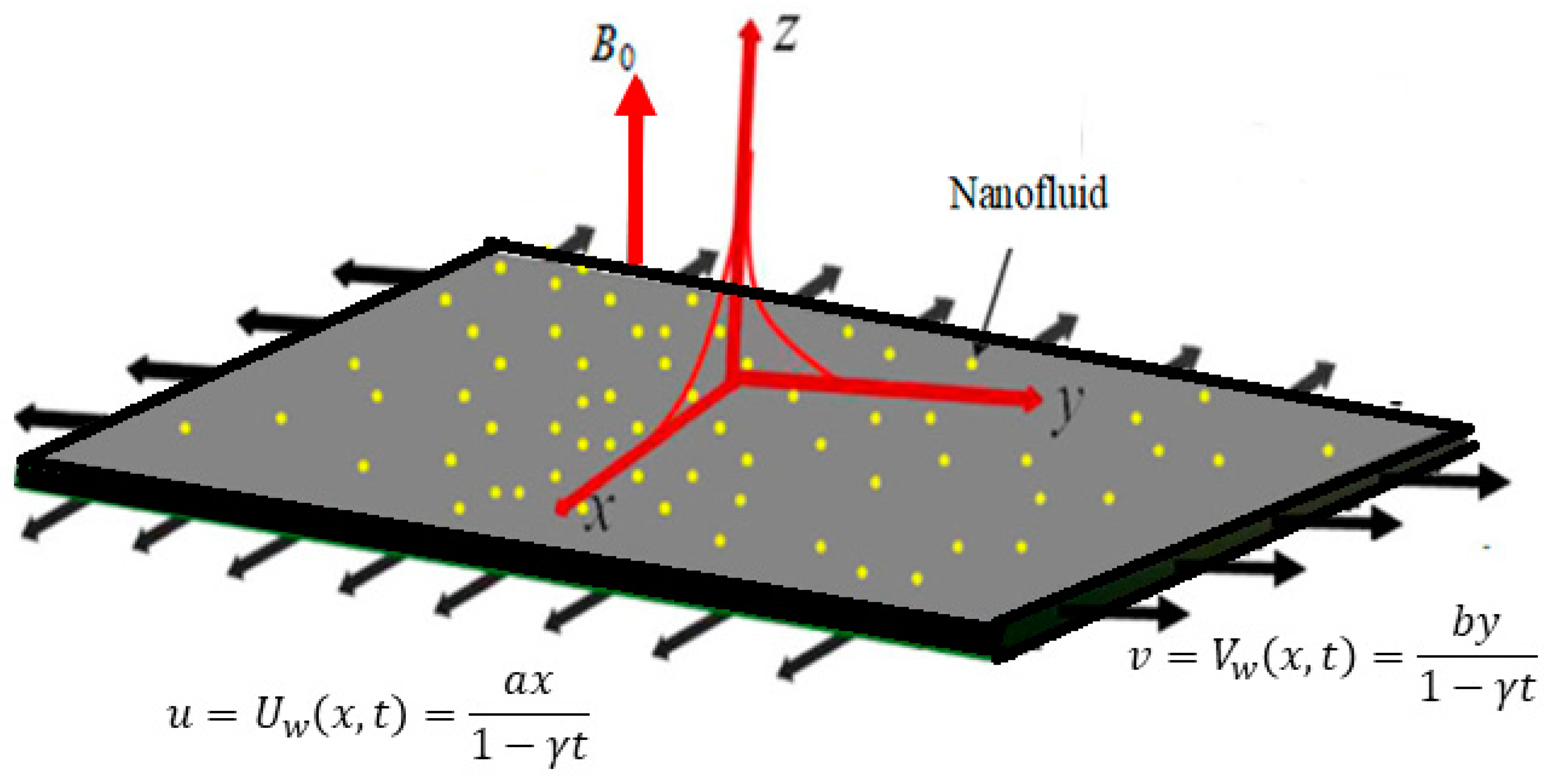

2. Model Development

3. Entropy Generation

4. Numerical Computations

5. Verification of the Numerical Model

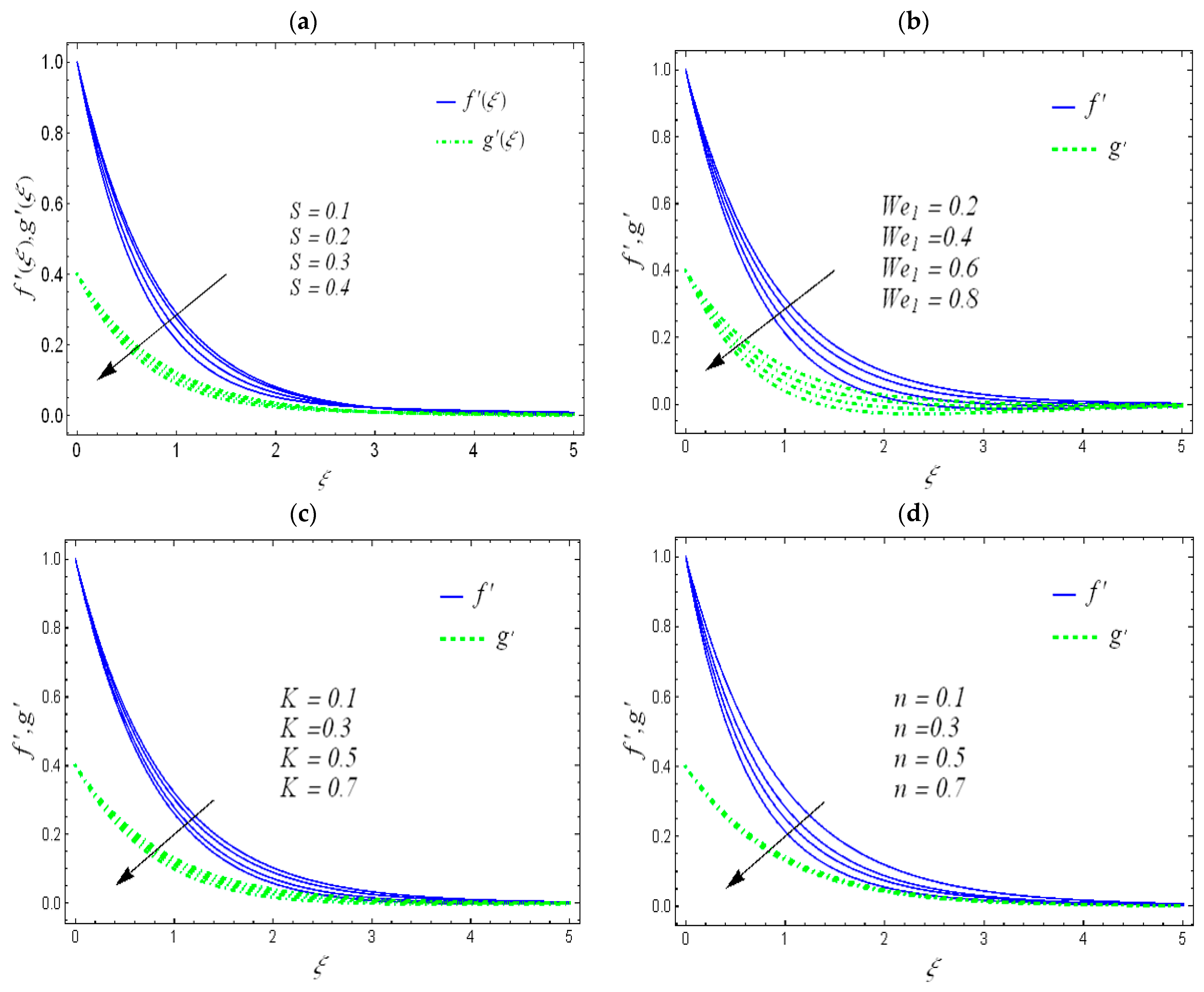

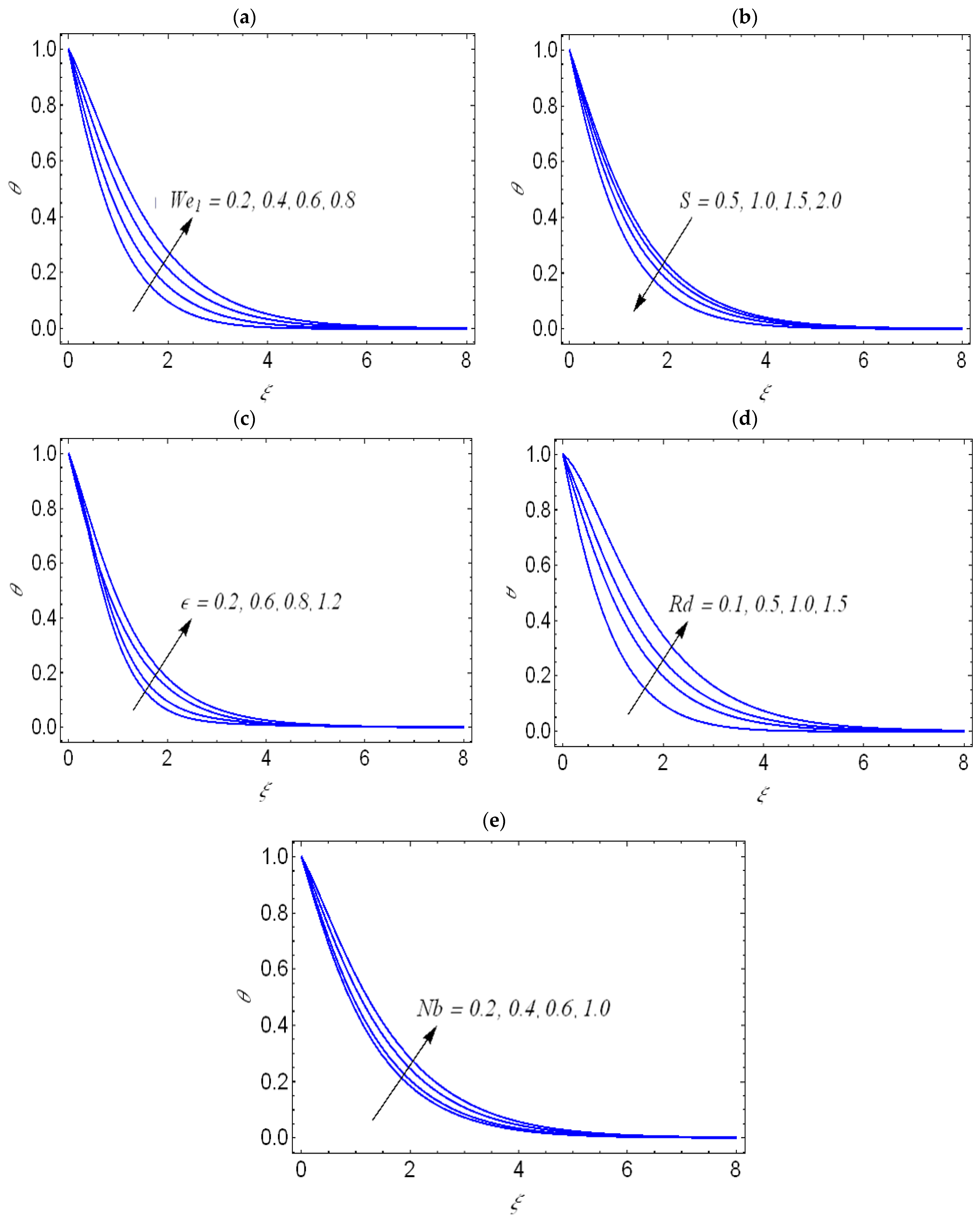

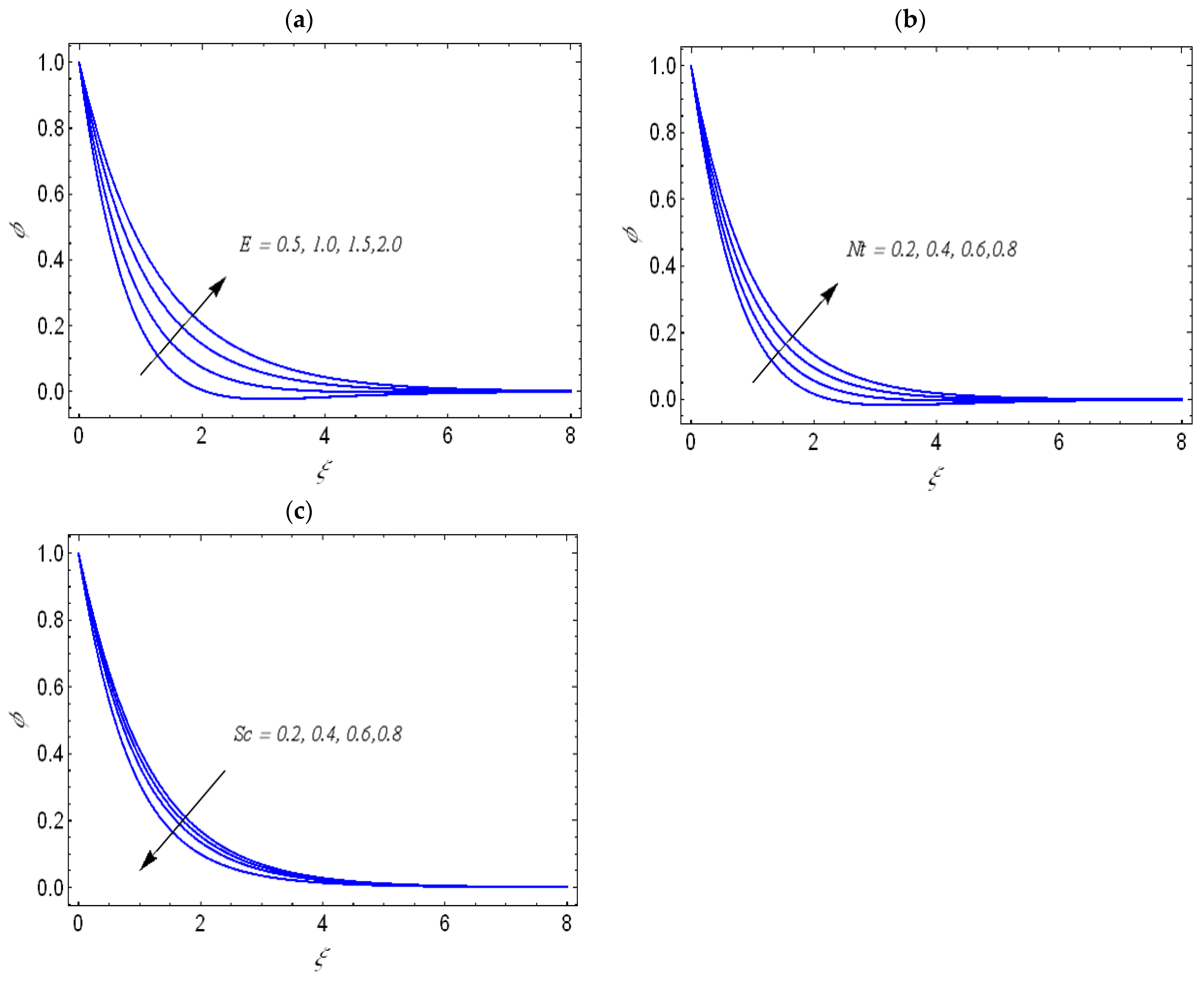

6. Results and Discussion

7. Concluding Remarks

- ❖ A reduction in both horizontal and vertical velocity components is noticed when the Weissenberg number and unsteady parameter are increased.

- ❖ With increasing the behavior index and porosity parameter, the flow intensity becomes less important.

- ❖ The temperature profile increases with the Weissenberg number and radiation parameters.

- ❖ Heat transfer is highly affected by the consideration of variable thermal conductivity.

- ❖ Higher concentrations are encountered with an increase in the activation energy and thermophoresis parameters.

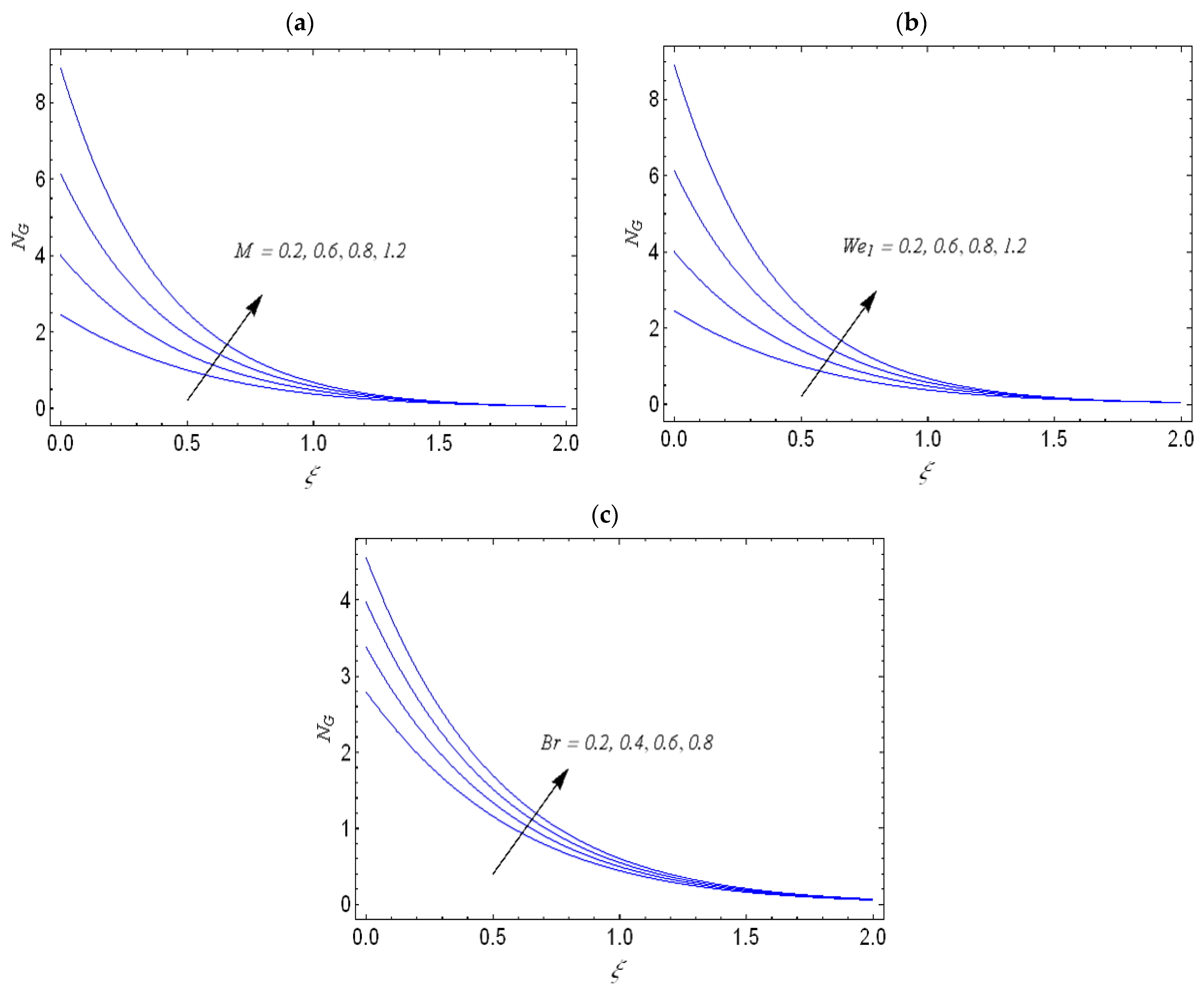

- ❖ Entropy generation is more convenient when the Weissenberg number, Brinkman number, and magnetic parameter are increased.

- ❖ The heat and mass transfers are boosted by the increase in the Weissenberg number.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Irfan, M.; Rafiq, K.; Khan, M.; Waqas, M.; Anwar, M.S. Theoretical analysis of new mass flux theory and Arrhenius activation energy in Carreau nanofluid with magnetic influence. Int. Commun. Heat Mass Transf. 2021, 120, 105051. [Google Scholar] [CrossRef]

- Hsiao, K.L. To promote radiation electrical MHD activation energy thermal extrusion manufacturing system efficiency by using Carreau-Nanofluid with parameters control method. Energy 2017, 130, 486–499. [Google Scholar] [CrossRef]

- Khan, M.I.; Kumar, A.; Hayat, T.; Waqas, M.; Singh, R. Entropy generation in flow of Carreau nanofluid. J. Mol. Liq. 2019, 278, 677–687. [Google Scholar] [CrossRef]

- Waqas, M.; Khan, M.I.; Hayat, T.; Alsaedi, A. Numerical simulation for magneto Carreau nanofluid model with thermal radiation: A revised model. Comput. Methods Appl. Mech. Eng. 2017, 324, 640–653. [Google Scholar] [CrossRef]

- Ullah, A.Z.; Guo, X.; Gul, T.; Ali, I.; Saeed, A.; Galal, A.M. Thin film flow of the ternary hybrid nanofluid over a rotating disk under the influence of magnetic field due to nonlinear convection. J. Magn. Magn. Mater. 2023, 573, 170673. [Google Scholar] [CrossRef]

- Muhammad, K.; Hayat, T.; Alsaedi, A.; Ahmad, B. Melting heat transfer in squeezing flow of base fluid (water), nanofluid (CNTs + water) and hybrid nanofluid (CNTs + CuO + water). J. Therm. Anal. Calorim. 2021, 143, 1157–1174. [Google Scholar] [CrossRef]

- Rasool, G.; Wakif, A. Numerical spectral examination of EMHD mixed convective flow of second-grade nanofluid towards a vertical Riga plate using an advanced version of the revised Buongiorno’s nanofluid model. J. Therm. Anal. Calorim. 2021, 143, 2379–2393. [Google Scholar] [CrossRef]

- Alqarni, M.S.; Yasmin, S.; Waqas, H.; Khan, S.A. Recent progress in melting heat phenomenon for bioconvection transport of nanofluid through a lubricated surface with swimming microorganisms. Sci. Rep. 2022, 12, 8447. [Google Scholar] [CrossRef]

- Borbora, M.H.; Vasu, B.; Chamkha, A.J. A Review Study of Numerical Simulation of Lid-Driven Cavity Flow with Nanofluids. J. Nanofluids 2023, 12, 589–604. [Google Scholar] [CrossRef]

- Acharya, S. Effect of Cavity Undulations and Thermal Boundary Conditions on Natural Convection and Entropy Generation in CuO-Water/Al2O3-Water Nanofluid. J. Nanofluids 2023, 12, 687–698. [Google Scholar] [CrossRef]

- Shamshuddin, M.D.; Salawu, S.O.; Asogwa, K.K.; Rao, P.S. Thermal exploration of convective transportation of ethylene glycol based magnetized nanofluid flow in porous cylindrical annulus utilizing MOS2 and Fe3O4 nanoparticles with inconstant viscosity. J. Magn. Magn. Mater. 2023, 573, 170663. [Google Scholar] [CrossRef]

- Negi, A.S.; Kumar, A.; Yaseen, M.; Rawat, S.K.; Saini, A. Effects of heat source on the stagnation point flow of a nanofluid over a stretchable sheet with magnetic field and zero mass flux at the surface. Forces Mech. 2023, 11, 100190. [Google Scholar] [CrossRef]

- Maiti, H.; Mukhopadhyay, S. Existence of MHD boundary layer hybrid nanofluid flow through a divergent channel with mass suction and injection. Chem. Eng. J. Adv. 2023, 14, 100475. [Google Scholar] [CrossRef]

- Mabood, F.; Khan, S.U.; Tlili, I. Numerical simulations for swimming of gyrotactic microorganisms with Williamson nanofluid featuring Wu’s slip, activation energy and variable thermal conductivity. Appl. Nanosci. 2020, 13, 131–144. [Google Scholar] [CrossRef]

- Makhdoum, B.M.; Mahmood, Z.; Fadhl, B.M.; Aldhabani, M.S.; Khan, U.; Eldin, S.M. Significance of entropy generation and nanoparticle aggregation on stagnation point flow of nanofluid over stretching sheet with inclined Lorentz force. Arab. J. Chem. 2023, 16, 104787. [Google Scholar] [CrossRef]

- Ge-JiLe, H.; Qayyum, S.; Shah, F.; Khan, M.I.; Khan, S.U. Slip flow of Jeffrey nanofluid with activation energy and entropy generation applications. Adv. Mech. Eng. 2021, 13, 16878140211006578. [Google Scholar] [CrossRef]

- Shah, F.; Khan, S.A.; Al-Khaled, K.; Khan, M.I.; Khan, S.U.; Shah, N.A.; Ali, R. Impact of entropy optimized Darcy-Forchheimer flow in MnZnFe2O4 and NiZnFe2O4 hybrid nanofluid towards a curved surface. ZAMM-J. Appl. Math. Mech. Z. Angew. Math. Mech. 2022, 102, e202100194. [Google Scholar] [CrossRef]

- Rajkumar, D.; Reddy, A.S.; Narayana, P.S.; Jagadeshkumar, K.; Chamkha, A.J. Pulsating magnetohydrodynamic flow of Fe3O4-blood based micropolar nanofluid between two vertical porous walls with Cattaneo–Christov heat flux and entropy generation. J. Magn. Magn. Mater. 2023, 571, 170564. [Google Scholar] [CrossRef]

- Derikv, M.; Solari, M.S.; Toghraie, D. Entropy generation and forced convection analysis of ethylene glycol/MWCNTs-Fe3O4 non-Newtonian nanofluid in a wavy microchannel with hydrophobic surfaces on. J. Taiwan Inst. Chem. Eng. 2023, 143, 104707. [Google Scholar] [CrossRef]

- Irfan, M.; Khan, M.; Khan, W.A. Numerical analysis of unsteady 3D flow of Carreau nanofluid with variable thermal conductivity and heat source/sink. Results Phys. 2017, 7, 3315–3324. [Google Scholar] [CrossRef]

- Hayat, T.; Aziz, A.; Muhammad, T.; Alsaedi, A. Numerical simulation for three-dimensional flow of Carreau nanofluid over a nonlinear stretching surface with convective heat and mass conditions. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 55. [Google Scholar] [CrossRef]

- Sharidan, S.; Mahmood, M.; Pop, I. Similarity solutions for the unsteady boundary layer flow and heat transfer due to a stretching sheet. Appl. Mech. Eng. 2006, 11, 647. [Google Scholar]

- Chamkha, A.J.; Aly, A.M.; Mansour, M.A. Similarity solution for unsteady heat and mass transfer from a stretching surface embedded in a porous medium with suction/injection and chemical reaction effects. Chem. Eng. Commun. 2010, 197, 846–858. [Google Scholar] [CrossRef]

- Shiner, J.S. (Ed.) Entropy and Entropy Generation: Fundamentals and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2001; Volume 18. [Google Scholar]

| Sharidan et al. [22] | Chamkha et al. [23] | Present Results | |

|---|---|---|---|

| 0.8 | −1.261042 | −1.261512 | −1.26105 |

| 1.2 | −1.377722 | −1.378052 | −1.37773 |

| 2.0 | −1.587362 | - | −1.58735 |

| 0.3 | 0.2 | 0.3 | 0.3 | ||

| 0.4 | |||||

| 0.6 | |||||

| 0.5 | 0.5 | ||||

| 1.0 | |||||

| 1.5 | |||||

| 0.2 | |||||

| 0.4 | |||||

| 0.6 | |||||

| 0.2 | |||||

| 0.4 | |||||

| 0.5 |

| 0.3 | |||||||

| 0.4 | |||||||

| 0.6 | |||||||

| 1.0 | |||||||

| 1.5 | |||||||

| 2.0 | |||||||

| 0.5 | |||||||

| 1.0 | |||||||

| 1.5 | |||||||

| 0.2 | |||||||

| 0.3 | |||||||

| 0.5 | |||||||

| 0.7 | |||||||

| 0.8 | |||||||

| 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, S.U.; Safra, I.; Ghachem, K.; Albalawi, H.; Labidi, T.; Kolsi, L. Effects of Temperature-Dependent Conductivity and Magnetic Field on the Radiated Carreau Nanofluid Flow and Entropy Generation. Symmetry 2023, 15, 1847. https://doi.org/10.3390/sym15101847

Khan SU, Safra I, Ghachem K, Albalawi H, Labidi T, Kolsi L. Effects of Temperature-Dependent Conductivity and Magnetic Field on the Radiated Carreau Nanofluid Flow and Entropy Generation. Symmetry. 2023; 15(10):1847. https://doi.org/10.3390/sym15101847

Chicago/Turabian StyleKhan, Sami Ullah, Imen Safra, Kaouther Ghachem, Hind Albalawi, Taher Labidi, and Lioua Kolsi. 2023. "Effects of Temperature-Dependent Conductivity and Magnetic Field on the Radiated Carreau Nanofluid Flow and Entropy Generation" Symmetry 15, no. 10: 1847. https://doi.org/10.3390/sym15101847

APA StyleKhan, S. U., Safra, I., Ghachem, K., Albalawi, H., Labidi, T., & Kolsi, L. (2023). Effects of Temperature-Dependent Conductivity and Magnetic Field on the Radiated Carreau Nanofluid Flow and Entropy Generation. Symmetry, 15(10), 1847. https://doi.org/10.3390/sym15101847