Decay Law of Supercritical CO2 Phase Transition-Induced Shock Waves in Rocky Media

Abstract

:1. Introduction

2. Analysis of Characterization Value of Supercritical CO2 Shock Wave

2.1. Supercritical CO2 Phase Change Blast Gas State Parameter Analysis

- Supercritical CO2 phase change blast shock wave generation principle

- 2.

- Derivation of shock wave state parameters for supercritical CO2 phase change blasting

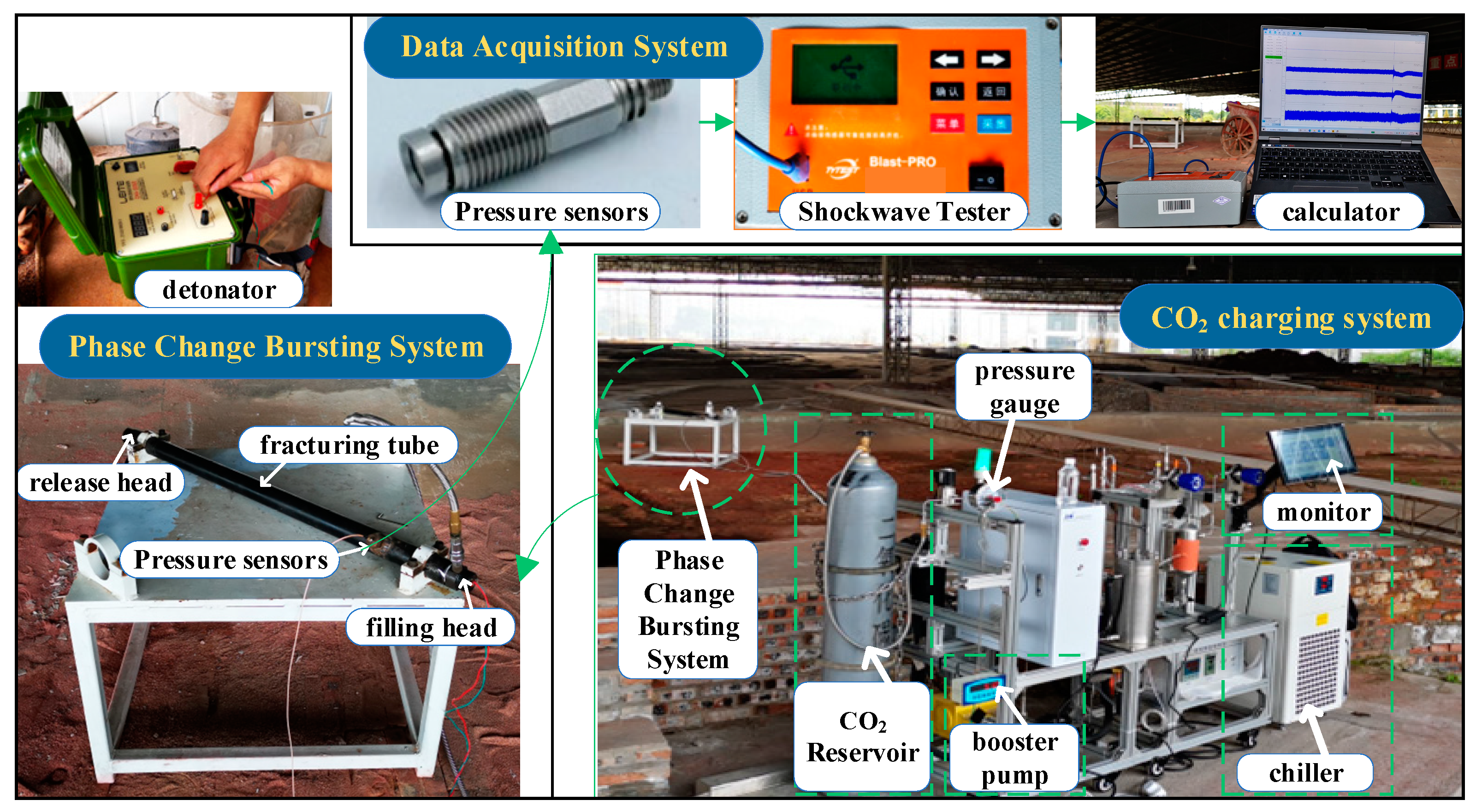

2.2. Supercritical CO2 Phase Transition Shock Test

3. Decay Law of Supercritical CO2 Phase Change Shock Wave

3.1. Modeling the Propagation of Supercritical CO2 Phase Change Shock Waves in Rocky Media

3.2. Decay Law of Supercritical CO2 Phase Transition Shock Wave in the Rock Medium

4. Conclusions

- (1)

- Based on the C–J theory, the calculation model of CO2 phase transition shock pressure and other state parameters was established, and it was found that the supercritical CO2 phase transition shock wave pressure is closely related to the shock wave velocity. The supercritical CO2 phase transition shock test was carried out to analyze the shock pressure, and it was found that the shear damage formula can fit the test data very well, and the errors are all within 10%.

- (2)

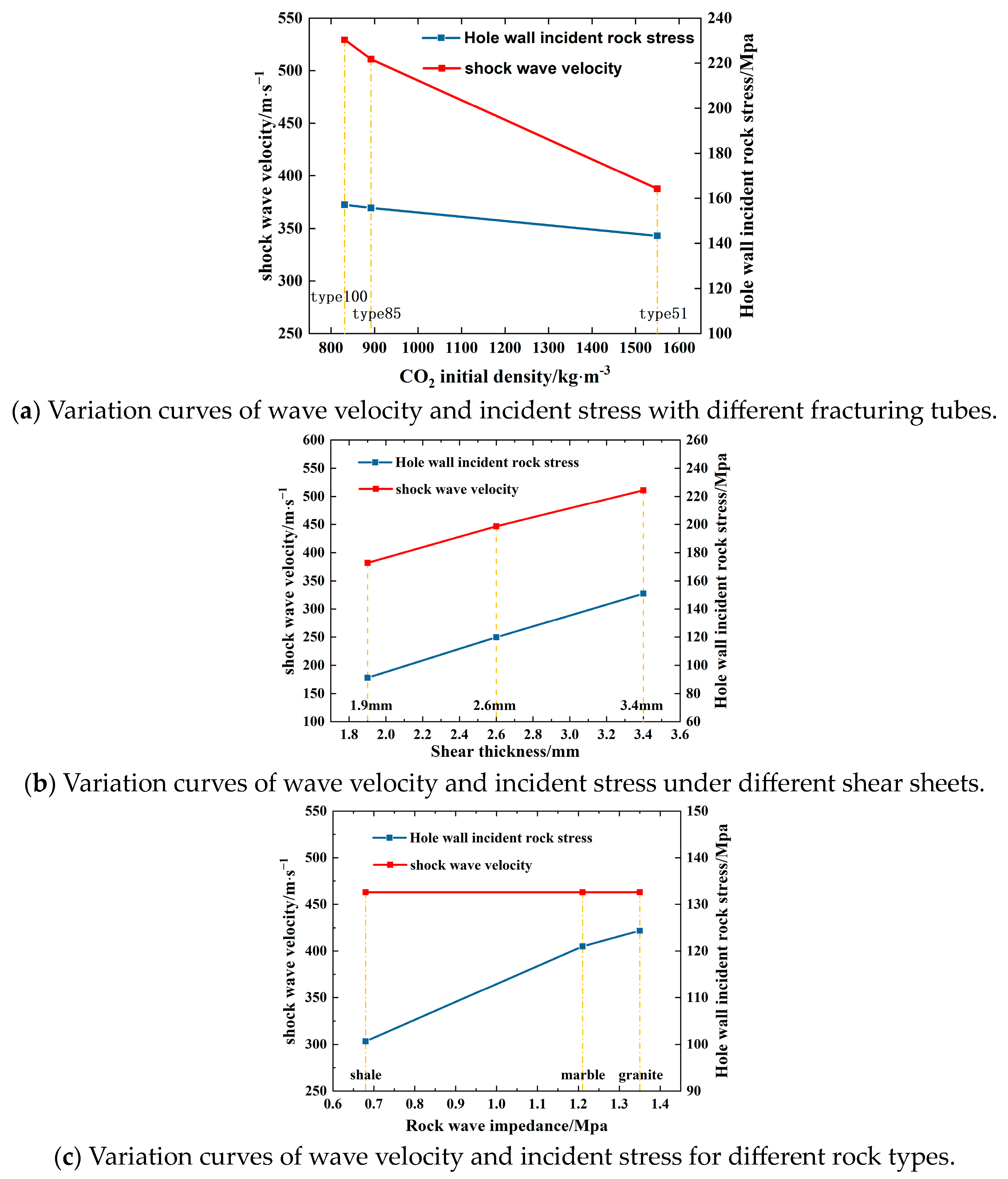

- Through Snell’s theorem, an expression for the stress in the incident rock after the shock wave impact on the hole wall is given. The effects of type 100, 85, and 51 fracturing tubes, the thicknesses of 1.9 mm, 2.6 mm, and 3.4 mm shear sheets, and the performance parameters of three types of rocks, namely, shale, marble, and granite, on the incident rock stress on the borehole wall were further analyzed. It was found that the incident rock stress decreases with the increase in the initial density of CO2 in the fracturing tube, increases linearly with the thickness of the shear sheet, and is positively correlated with the rock wave impedance. Moreover, there is an obvious expansion effect of the incident stress in the borehole wall compared with the CO2 impact pressure, with the expansion coefficients ranging from 1.29 to 1.60.

- (3)

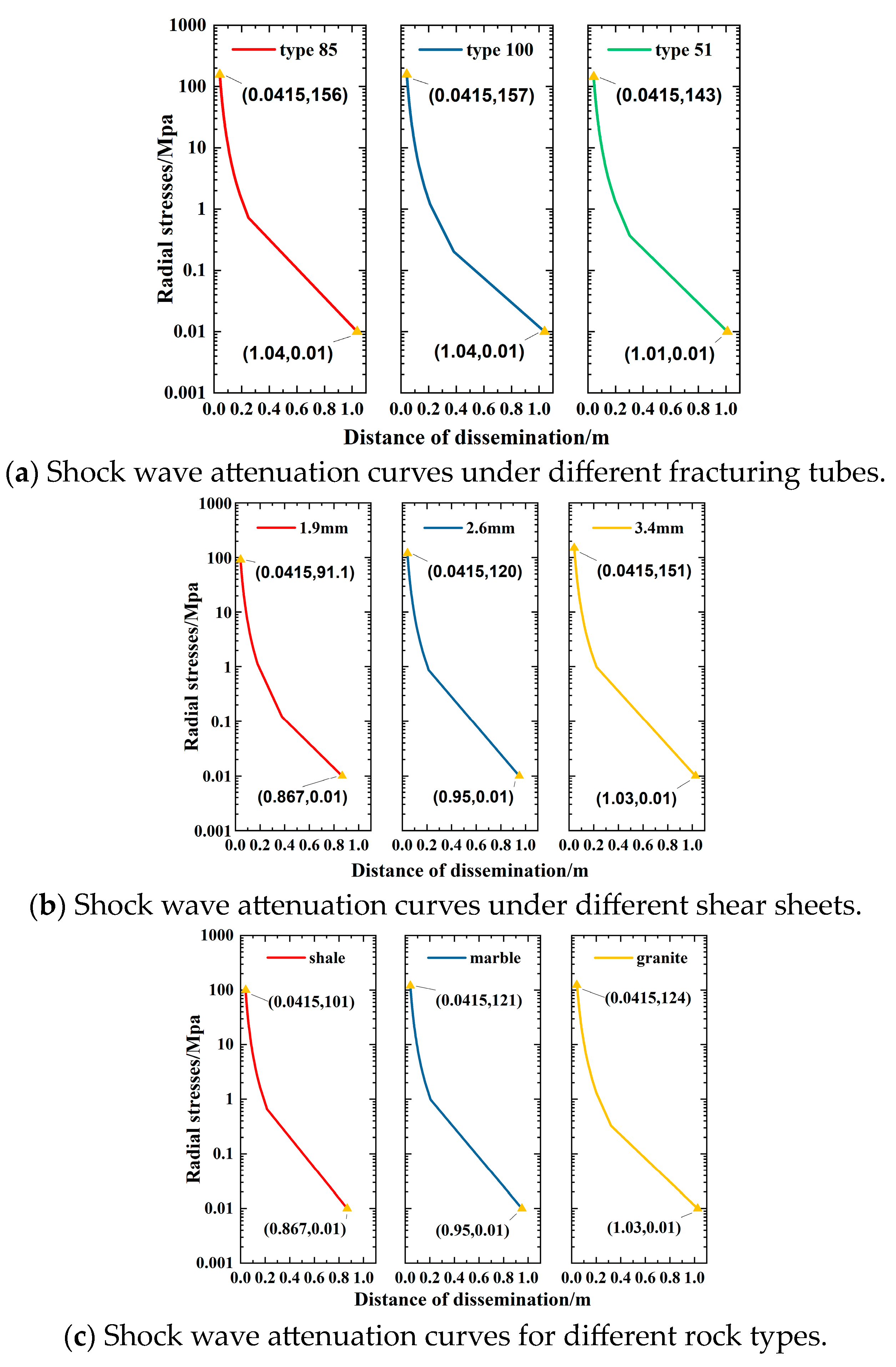

- Based on the change rule of incident rock stress at the borehole wall, the attenuation distance of the shock wave in the rock medium under the influence of three variables was calculated separately, and the rock stress attenuation equation was established under the action of the phase change shock wave. It was found that the radial stress of the rock attenuates with the distance in a logarithmic manner, and with the increase in the distance, the propagation distance of the shock wave in the rock medium decreases with the elevation in the density of the filling of the CO2, and it increases with the thickness of the shear sheet and the increase in the wave impedance in the rock.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Deng, J.; Deng, H.; Ke, B. Peridynamics simulation of rock fracturing under liquid carbon dioxide blasting. Int. J. Damage Mech. 2018, 28, 1038–1052. [Google Scholar] [CrossRef]

- Chen, H.D.; Wang, Z.F.; Qi, L.L.; An, F.H. Effect of liquid carbon dioxide phase change fracturing technology on gas drainage. Arab. J. Geosci. 2017, 10, 314. [Google Scholar] [CrossRef]

- Gao, F.; Tang, L.; Zhou, K.; Zhang, Y.; Ke, B. Mechanism Analysis of Liquid Carbon Dioxide Phase Transition for Fracturing Rock Masses. Energies 2018, 11, 2909. [Google Scholar] [CrossRef]

- Cheng, X.; Zhang, Z.; He, S.; Zhu, L. Research Status and Prospects of Liquid Carbon Dioxide Phase Transition Blasting Technology. Coal Mine Blasting 2022, 40, 10–15. [Google Scholar]

- Liu, G.; Wang, H. Application Research on Carbon Dioxide Fracturing Technology. Highway 2018, 63, 72–75. [Google Scholar]

- Lu, T.; Wang, Z.; Yang, H.; Yuan, P.; Han, Y.; Sun, X. Improvement of coal seam gas drainage by under-panel cross-strata stimulation using highly pressurized gas. Int. J. Rock Mech. Min. Sci. 2015, 77, 300–312. [Google Scholar] [CrossRef]

- Xia, J.; Tao, L.; Li, B.; Zhou, M. Carbon dioxide liquid-gas phase change expansion rock breaking technology and application. Eng. Blasting 2018, 24, 50–54. [Google Scholar]

- Guo, Z. Liquid Carbon Dioxide Blasting Cartridges and Field Test Blasts. Blasting 1994, 3, 72–74. [Google Scholar]

- Xu, Y. Development of high pressure gas blasting coal mining technology and its application in China. Blasting 1998, 1, 67–69, 82. [Google Scholar]

- Xue, F.; Xia, C.; Li, G.; Jin, B.; He, Y.; Fu, Y. Safety Threshold Determination for Blasting Vibration of the Lining in Existing Tunnels under Adjacent Tunnel Blasting. Adv. Civ. Eng. 2019, 2019, 8303420. [Google Scholar] [CrossRef]

- Lv, G.; Zhou, C. Characteristics of Blasting Dynamic Damage of Tunnel Fault Zone Grouting Reinforced Perimeter Rock Body. Chin. J. Rock Mech. Eng. 2021, 40, 2038–2047. [Google Scholar]

- Wang, X.; Hu, S.; Wang, E. Supercritical CO2 Thermal Shock Rock Breaking Technology: Fracturing Principles and Vibration Safety Study. China Civ. Eng. J. 2023, 56, 118–130. [Google Scholar]

- Gao, B.; Yang, Y.J.; Xue, W.L.; Guo, A.H.; Luo, X.D. Experimental Investigation on Influencing Factors of Rock Fragmentation Induced by Carbon Dioxide Phase Transition Fracturing. Shock. Vib. 2021, 2021, 6674485. [Google Scholar] [CrossRef]

- Xia, J.; Dou, B.; Tian, H.; Zheng, J.; Cui, G.; Kashif, M. Research on Initiation of Carbon Dioxide Fracturing Pipe Using the Liquid Carbon Dioxide Phase-Transition Blasting Technology. Energies 2021, 14, 521. [Google Scholar] [CrossRef]

- He, Z.; Zhang, S.; Jiang, N.; Luo, X.; Lei, Y. Experimental Study of CO2 Phase Change Cracking Stress Wave Propagation and Influence Law. Blasting 2022, 39, 133–138. [Google Scholar]

- Sun, K.; Wang, J.; Yu, X.; Li, W. Different Stress Difference Conditions of Supercritical CO2 Gas Explosion Coal Rock Body Gas Wedge: Research on the Expansion Rule of Secondary Cracks. Chin. J. Appl. Mech. 2019, 36, 466–472, 516. [Google Scholar]

- Guo, Y. Analysis of Liquid Carbon Dioxide Phase Change Fracturing Mechanism and Application Effect. Master’s Thesis, Henan University of Science and Technology, Henan, China, 2017. [Google Scholar]

- Ruan, R.; Pan, Z.; Wang, X.; Zhan, W. Study on ground vibration characteristics induced by liquid CO2 blasting technique in bench excavation. J. Vibroeng. 2022, 24, 904–920. [Google Scholar] [CrossRef]

- Li, B.; Wang, E.; Hu, S.; Wang, X.; Liu, B. A Study of Vibration Velocity Attenuation Induced by Pneumatic Rock Breaking with Carbon Dioxide Ice Powder for Safety Assessment. Rock Mech. Rock Eng. 2021, 54, 6481–6493. [Google Scholar] [CrossRef]

- Zhou, S.; Jiang, N.; He, X.; Luo, X.D. Rock Breaking and Dynamic Response Characteristics of Carbon Dioxide Phase Transition Fracturing Considering the Gathering Energy Effect. Energies 2020, 13, 1336. [Google Scholar] [CrossRef]

- Cheng, S. Protection of Adjacent Natural Gas Pipelines during Liquid CO2 Phase Change Rock Breakups. Eng. Blasting 2023, 29, 69–77. [Google Scholar]

- Li, Q.; Luo, D.; Feng, G. Dynamic Characteristics of Liquid CO2 Phase Change Fracturing Using Experimental Technique. Geotech. Geol. Eng. 2019, 37, 3387–3398. [Google Scholar] [CrossRef]

- Dai, J. Dynamic Behaviors and Blasting Theory of Rock; Metallurgical Industry Press: Beijing, China, 2014; pp. 121–132. [Google Scholar]

- Abi, E.; Liu, L.; Pu, Y. A Protective Device for Filling with Supercritical Carbon Dioxide. Chinese Invention Patent P202211460376.1, 10 March 2023. [Google Scholar]

- Abi, E.; Liu, L.; Pu, Y. A Supercritical Carbon Dioxide Tank Buffering Device. Invention Patent P202211526290.4, 28 March 2023. [Google Scholar]

- Chu, H.; Yang, X.; Hou, A.; Yu, Y.; Liang, W. Experimental Study on Simulation of Propagation and Attenuation Law of Explosive Stress Wave in Coal Body. Explos. Shock. Waves 2012, 32, 185–189. [Google Scholar]

- Wang, W. Drill Hole and Blast; Coal Industry Press: Beijing, China, 1984; pp. 1–13. [Google Scholar]

| Serial Number | Fracturing Tube Models | Activator Mass/g | Shear Thickness/mm |

|---|---|---|---|

| 1 | 51 | 70 | 3.4 |

| 2 | 51 | 70 | 2.6 |

| 3 | 51 | 90 | 3.4 |

| 4 | 51 | 90 | 2.6 |

| 5 | 51 | 90 | 1.9 |

| 6 | 51 | 120 | 2.6 |

| 7 | 51 | 120 | 1.9 |

| 8 | 51 | 120 | 3.4 |

| Condition No. | Fracturing Tube Types | Shear Thickness/mm | Rock Type |

|---|---|---|---|

| 1 | 51 | 3.4 | granite |

| 2 | 85 | 3.4 | granite |

| 3 | 100 | 3.4 | granite |

| 4 | 85 | 1.9 | marble |

| 5 | 85 | 2.6 | marble |

| 6 | 85 | 3.4 | marble |

| 7 | 100 | 2.6 | shale |

| 8 | 100 | 2.6 | marble |

| 9 | 100 | 2.6 | granite |

| Type | Outer Diameter/mm | Volume/m3 | CO2 Filled Mass/kg | Initial Density/kg·m−3 |

|---|---|---|---|---|

| Type 51 | 51 | 5.8 × 10−4 | 0.9 | 1.55 × 103 |

| Type 85 | 83 | 1.57 × 10−3 | 1.4 | 8.92 × 102 |

| Type 100 | 95 | 4.21 × 10−3 | 3.5 | 8.31 × 102 |

| Rock Name | Density/kg·m−3 | Rock Wave Impedance/MPa |

|---|---|---|

| Shale | 2.0 | 0.68 |

| Marble | 2.7 | 1.21 |

| Granite | 2.67 | 1.35 |

| Serial Number | CO2 Initial Density/k·m−3 | CO2 Impact Pressure/MPa | Rock Wave Impedance/MPa | Shock Wave Velocity/m·s−1 | Incident Stress/MPa | Expansion Factor |

|---|---|---|---|---|---|---|

| 1 | 1.55 × 103 | 101.69 | 1.35 | 387.61 | 143.37 | 1.41 |

| 2 | 8.92 × 102 | 101.69 | 1.35 | 510.95 | 155.72 | 1.53 |

| 3 | 8.31 × 102 | 101.69 | 1.35 | 529.37 | 157.20 | 1.55 |

| 4 | 8.92 × 102 | 56.83 | 1.21 | 381.97 | 91.12 | 1.60 |

| 5 | 8.92 × 102 | 77.76 | 1.21 | 446.80 | 119.87 | 1.54 |

| 6 | 8.92 × 102 | 101.69 | 1.21 | 510.95 | 150.99 | 1.48 |

| 7 | 8.31 × 102 | 77.76 | 0.68 | 462.91 | 100.66 | 1.29 |

| 8 | 8.31 × 102 | 77.76 | 1.21 | 462.91 | 120.99 | 1.56 |

| 9 | 8.31 × 102 | 77.76 | 1.35 | 462.91 | 124.33 | 1.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Zeng, Q.; Wei, F.; Liu, L.; Wu, F.; Li, H. Decay Law of Supercritical CO2 Phase Transition-Induced Shock Waves in Rocky Media. Symmetry 2023, 15, 1802. https://doi.org/10.3390/sym15091802

Zhang J, Zeng Q, Wei F, Liu L, Wu F, Li H. Decay Law of Supercritical CO2 Phase Transition-Induced Shock Waves in Rocky Media. Symmetry. 2023; 15(9):1802. https://doi.org/10.3390/sym15091802

Chicago/Turabian StyleZhang, Jie, Qifu Zeng, Fangqiang Wei, Lu Liu, Fayou Wu, and Haotian Li. 2023. "Decay Law of Supercritical CO2 Phase Transition-Induced Shock Waves in Rocky Media" Symmetry 15, no. 9: 1802. https://doi.org/10.3390/sym15091802

APA StyleZhang, J., Zeng, Q., Wei, F., Liu, L., Wu, F., & Li, H. (2023). Decay Law of Supercritical CO2 Phase Transition-Induced Shock Waves in Rocky Media. Symmetry, 15(9), 1802. https://doi.org/10.3390/sym15091802