A Lagrangian Analysis of Tip Leakage Vortex in a Low-Speed Axial Compressor Rotor

Abstract

1. Introduction

2. Methodology

2.1. Lagrangian Method

2.2. Eulerian Q Criterion Method

2.3. Numerical Setups

2.3.1. Experimental Configurations

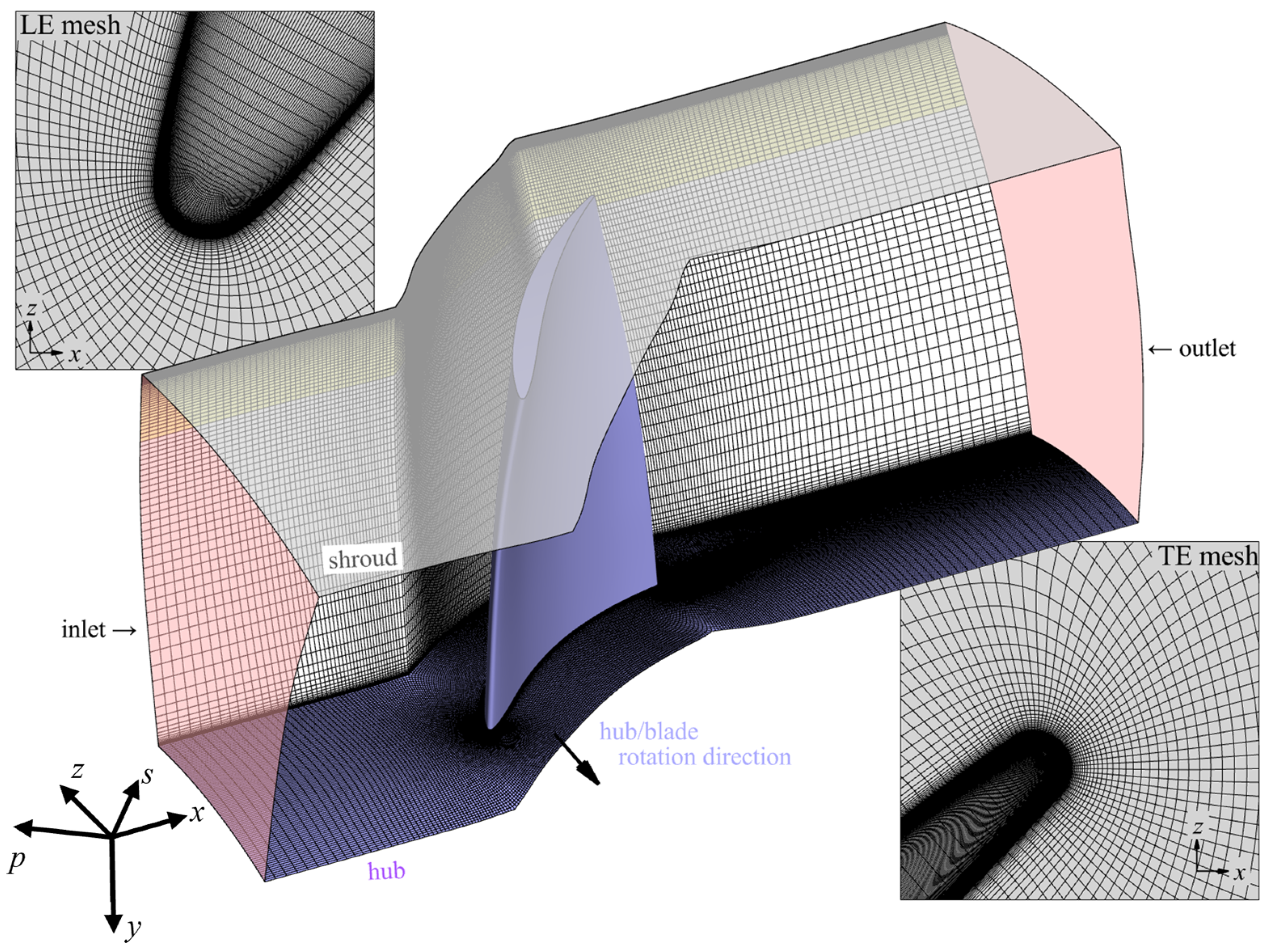

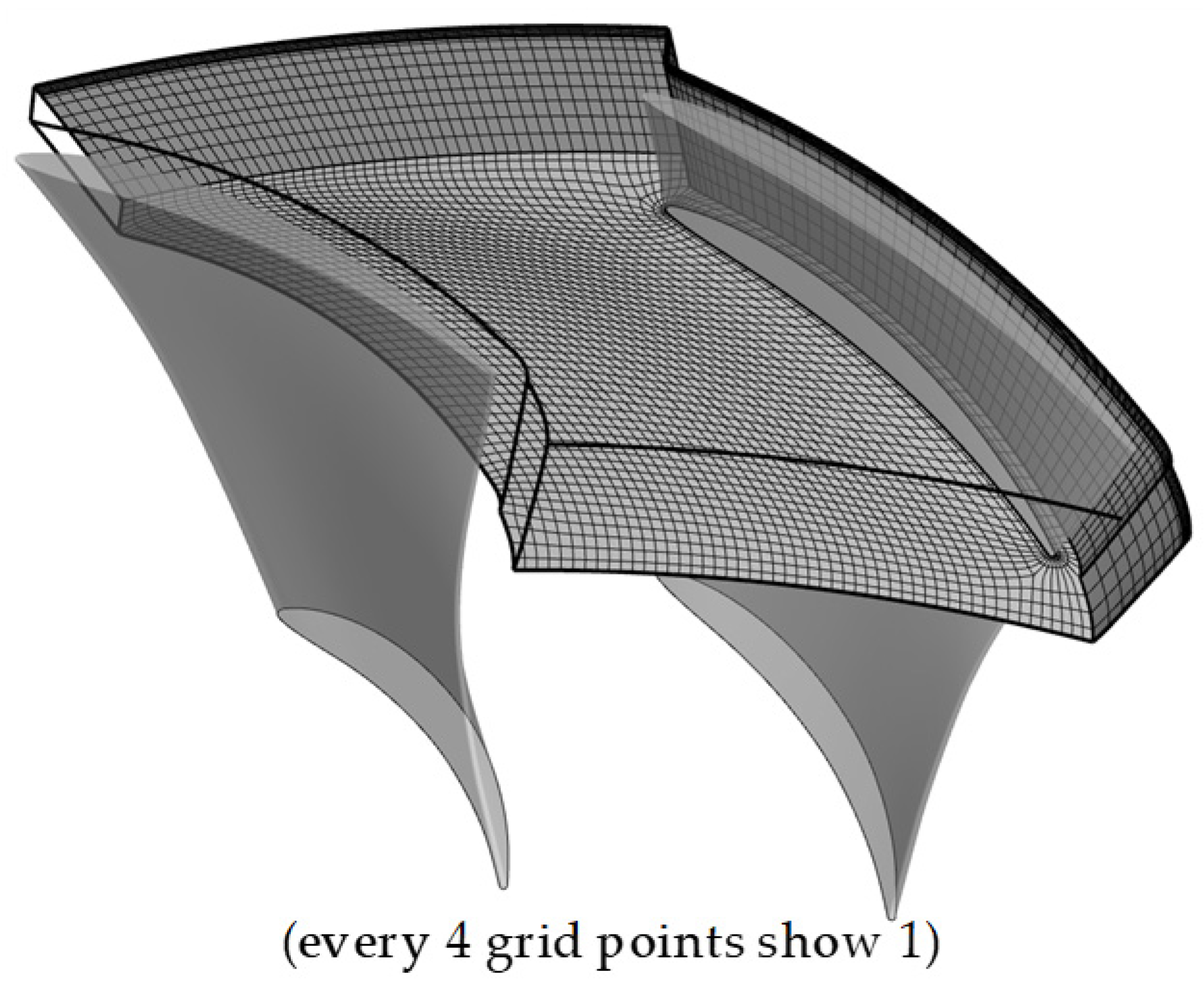

2.3.2. Computational Domain and Numerical Method

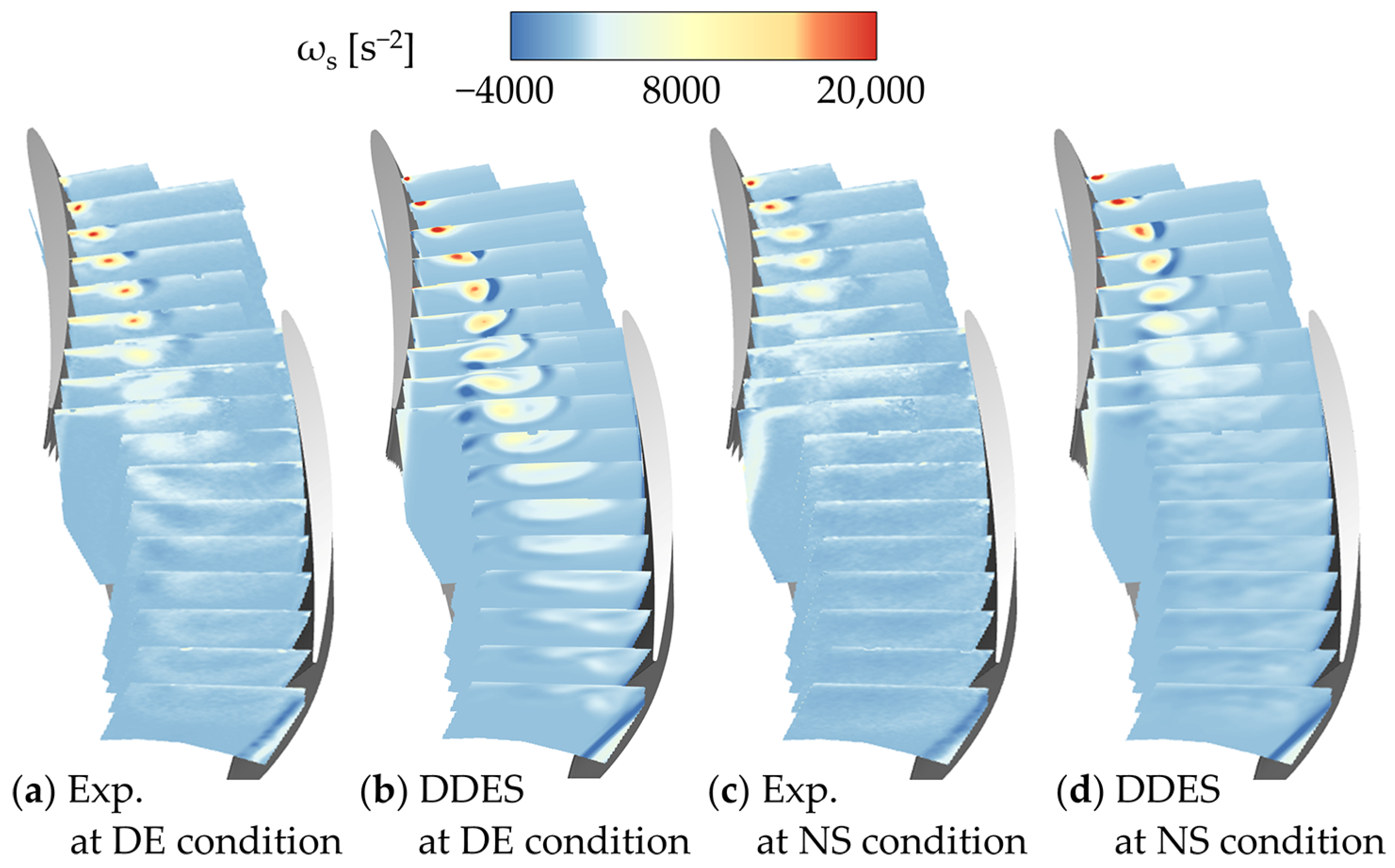

2.3.3. Validation of the Numerical Method

3. Results and Discussion

3.1. Effect of Parameters on the LCS Structure in the Low-Speed Rotor

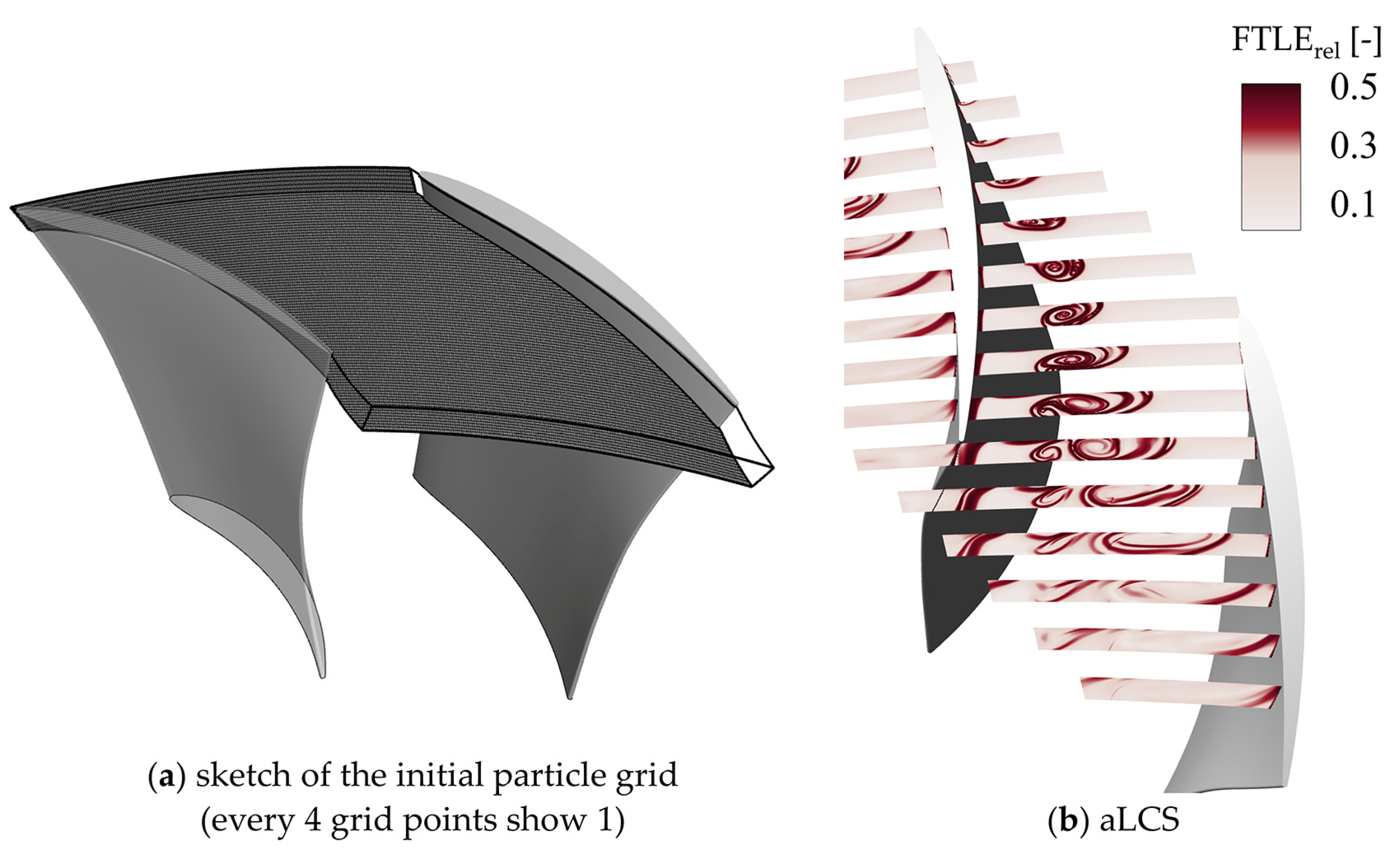

3.1.1. The Initial Grid of the Particle Trajectory

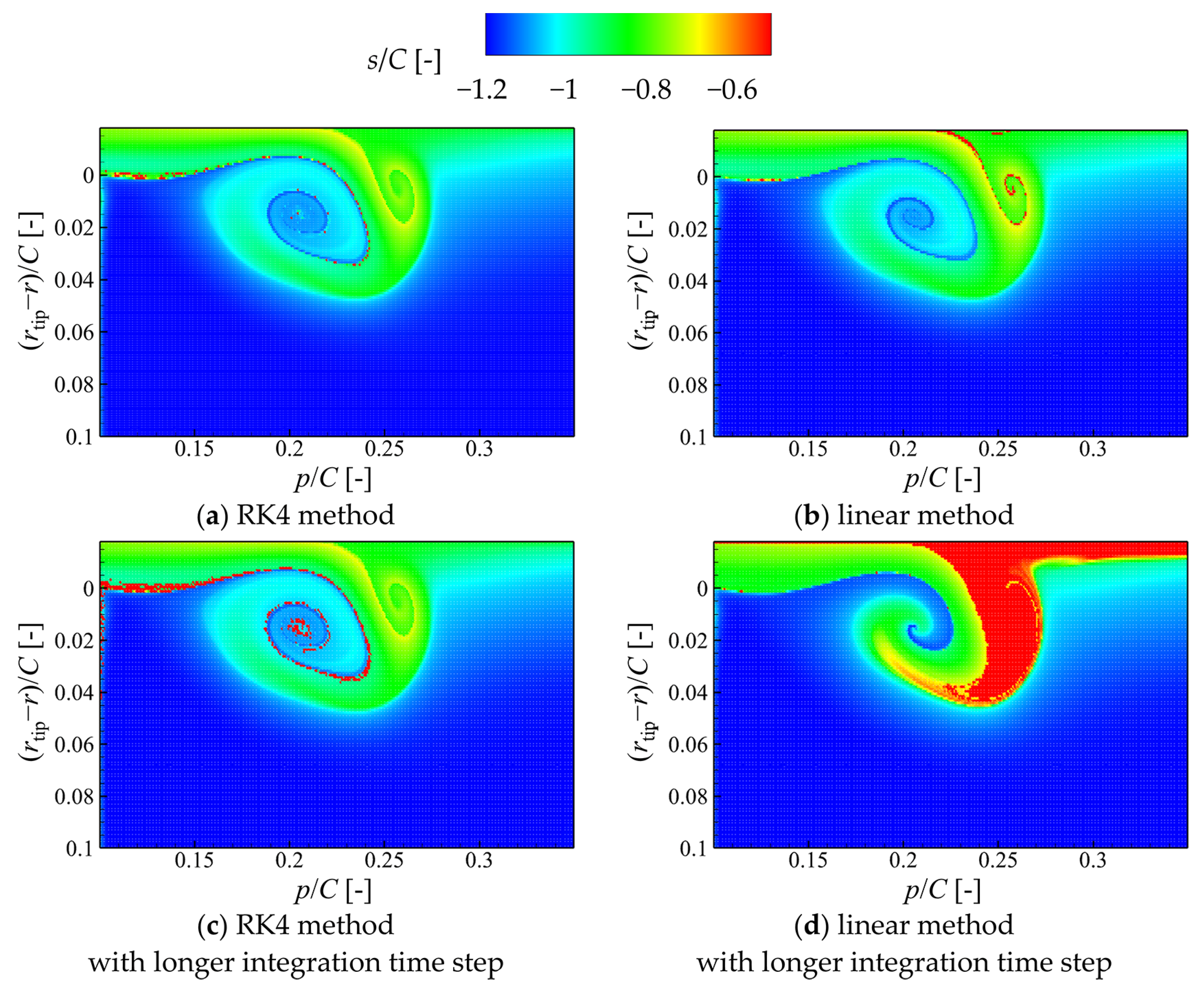

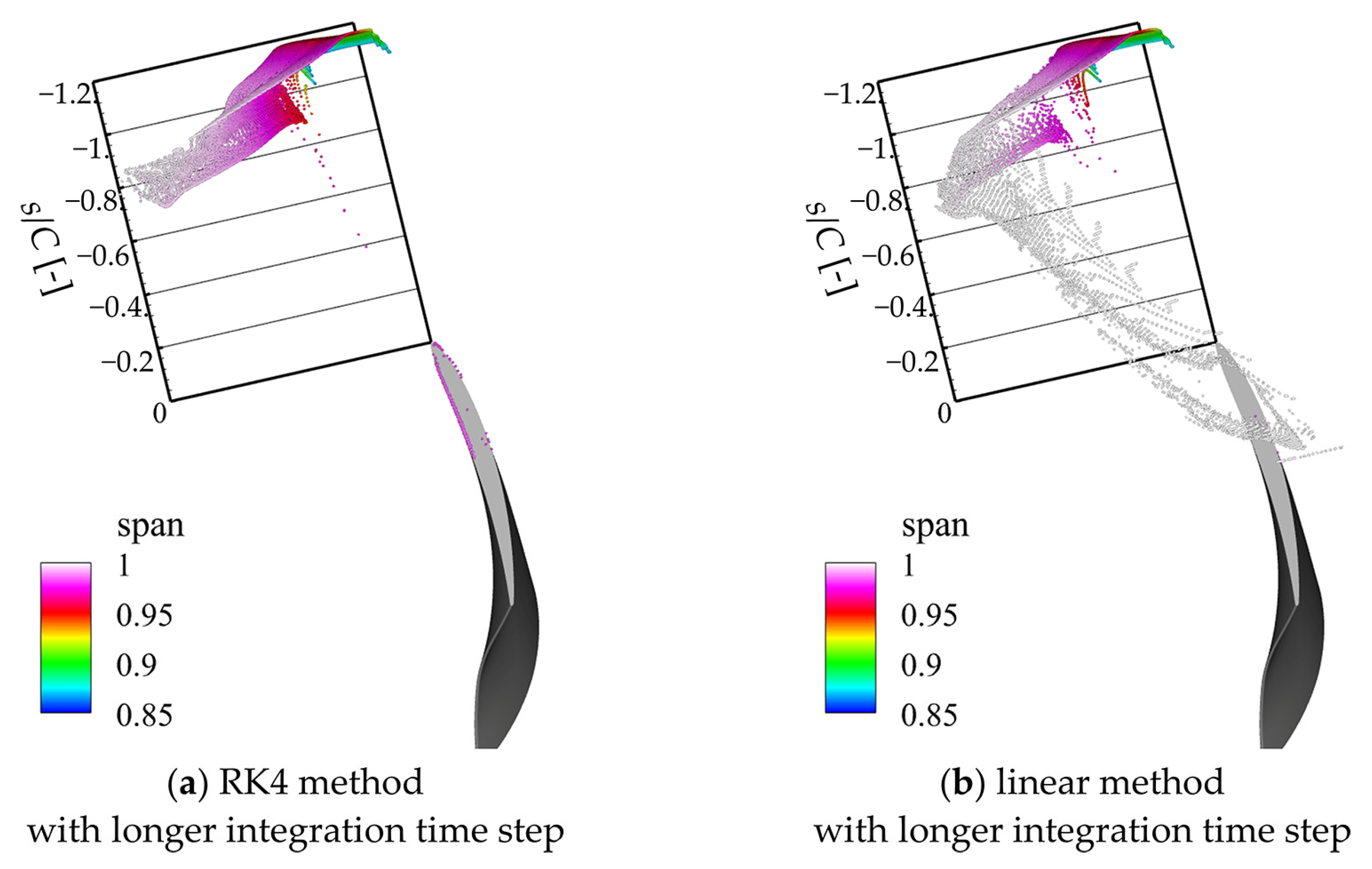

3.1.2. The Time Integration Method

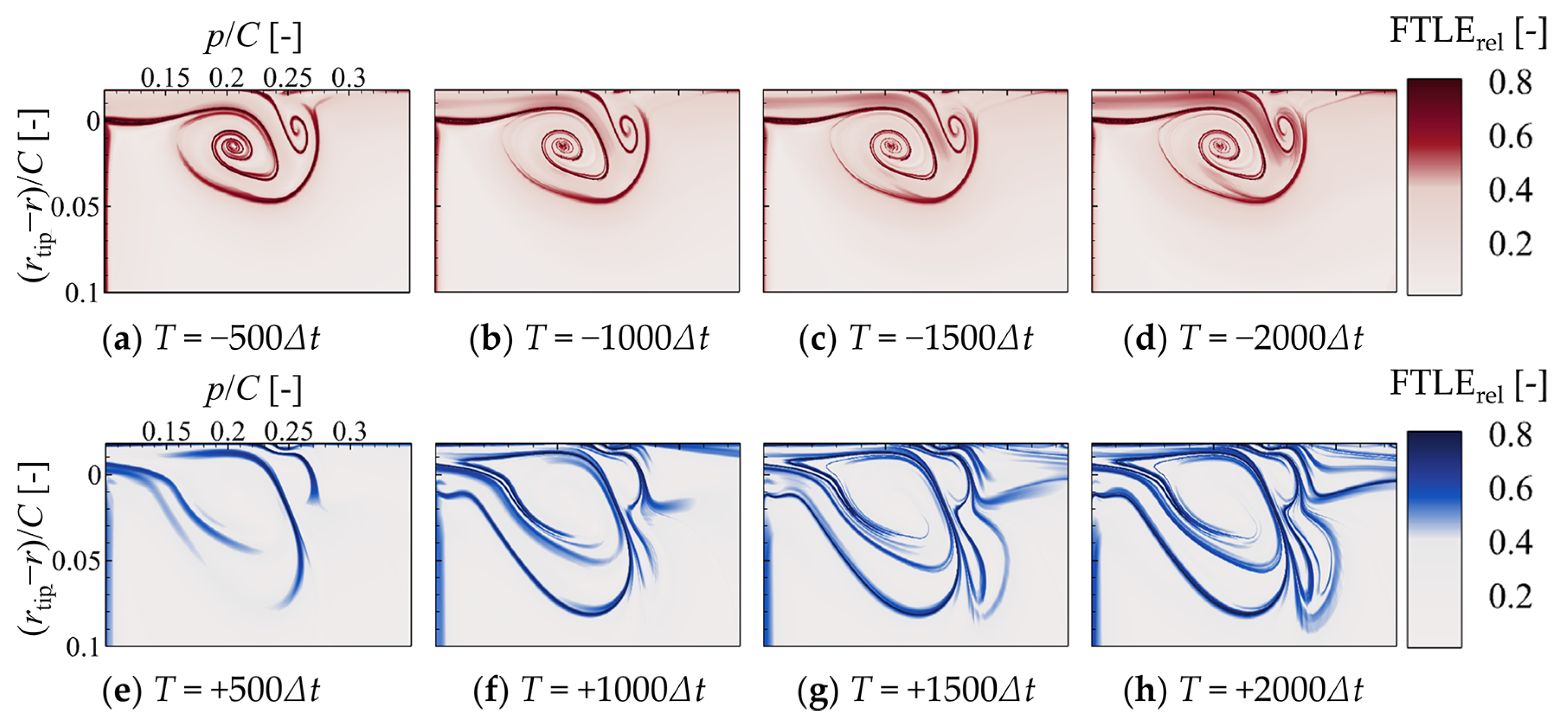

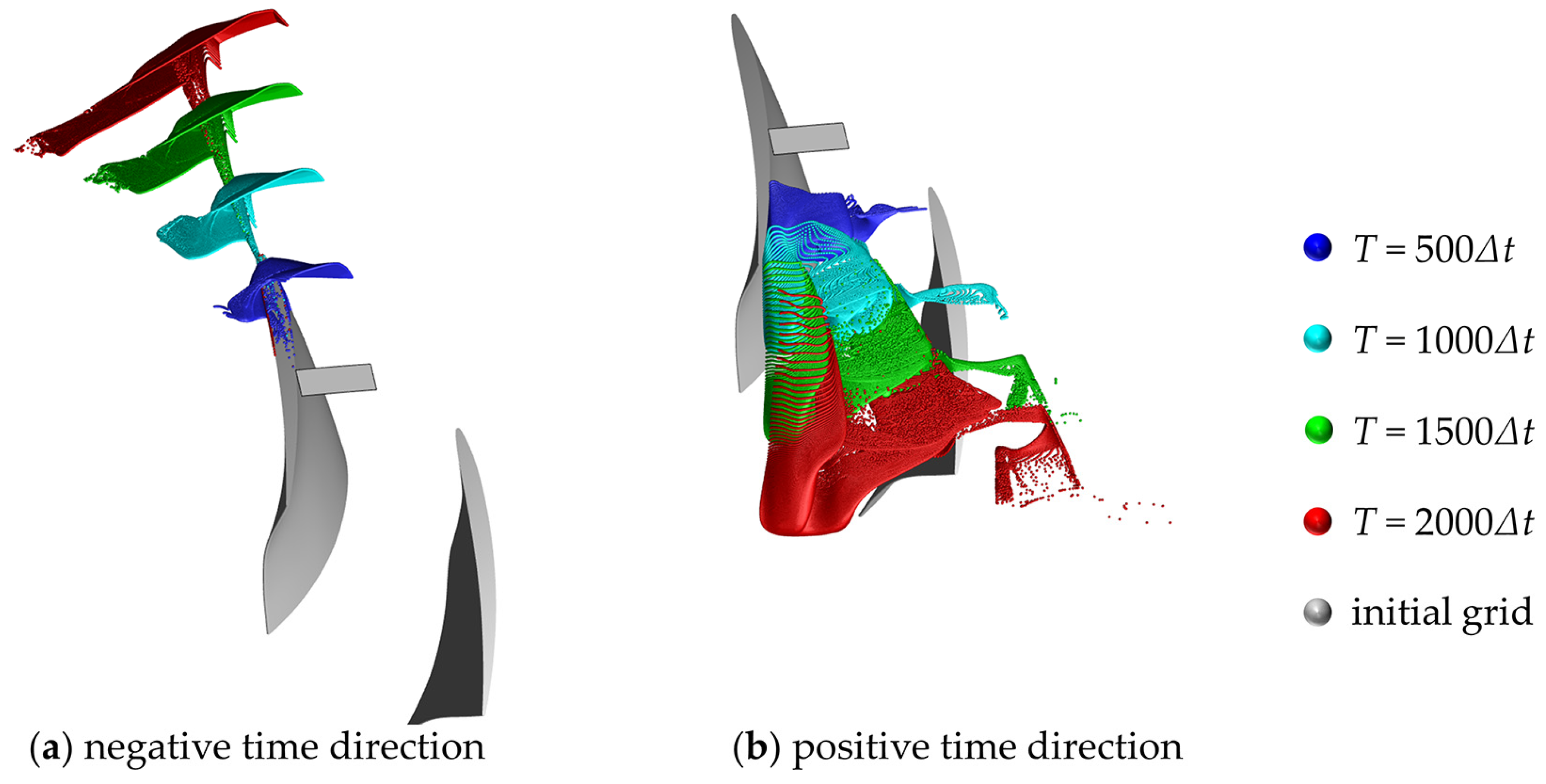

3.1.3. The Integration Time

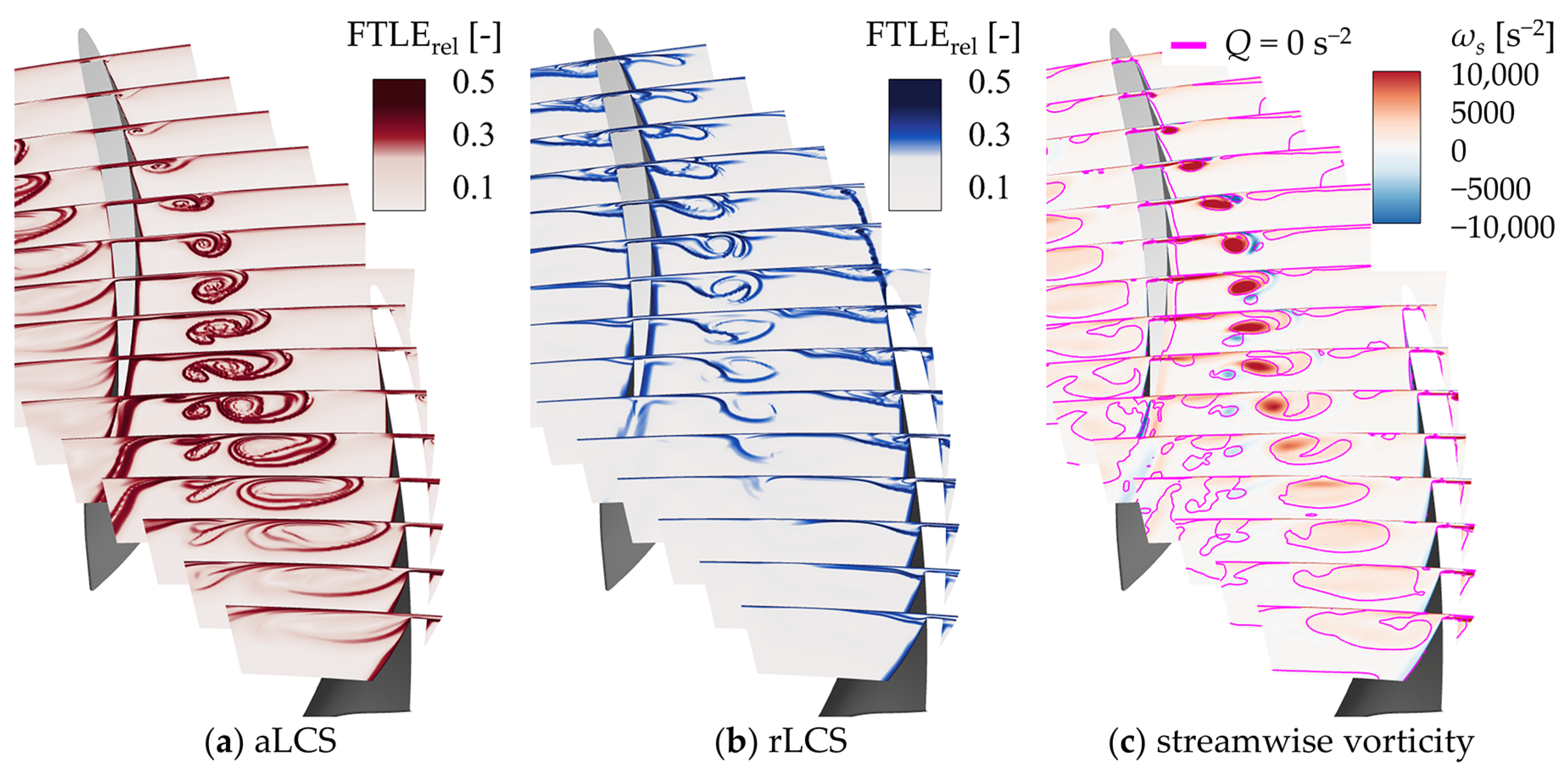

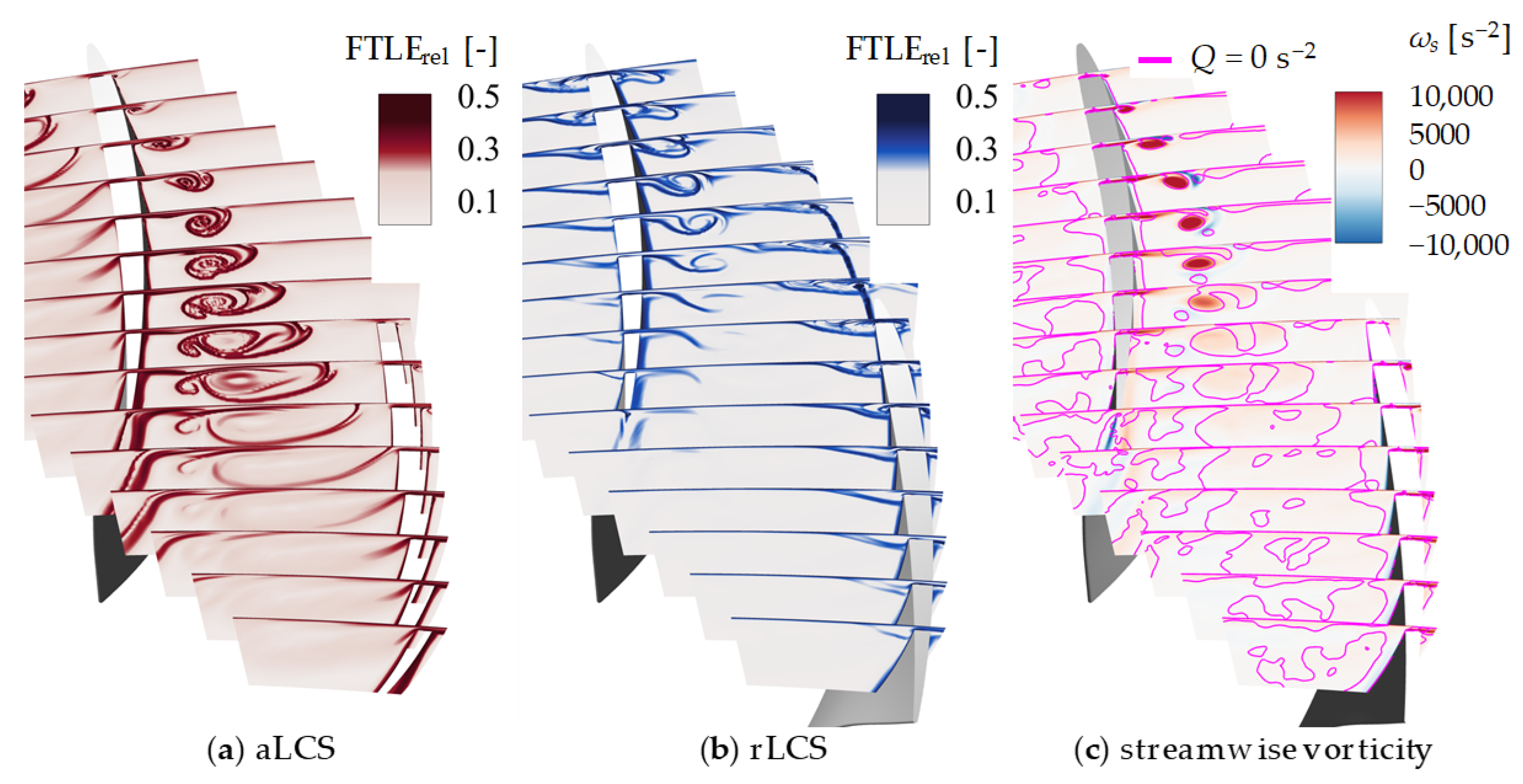

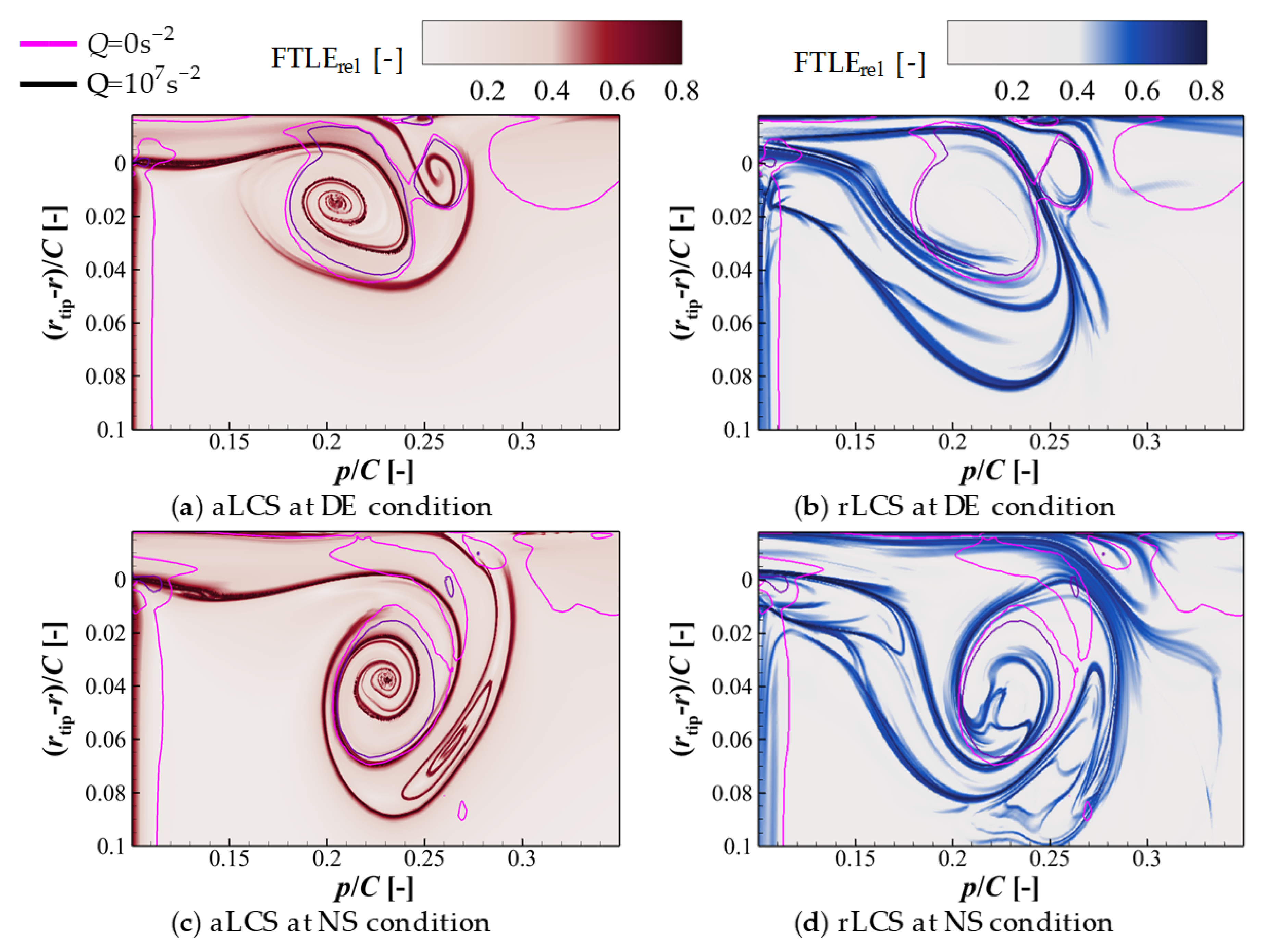

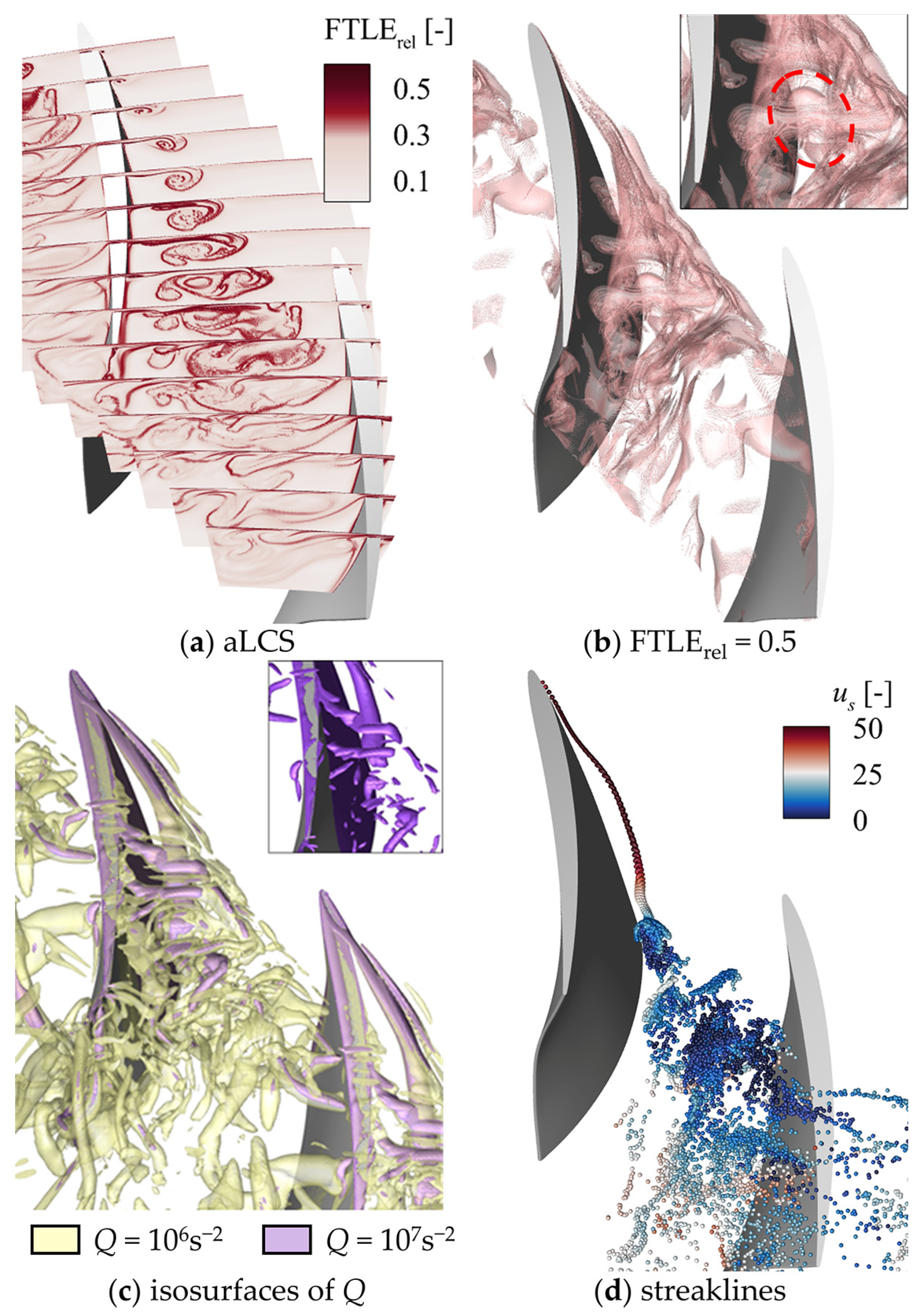

3.2. LCSs of TLF in the Low-Speed Rotor

4. Conclusions

- (1)

- The accuracy of calculating the particle advecting trajectory affects the results of the FTLE field the most. A shorter integration step or higher-order integration method would improve this accuracy.

- (2)

- The clarity of the ridges depends on the density of the initial grid near them. With the complex flow field as the low-speed axial compressor rotor, it is suggested that the general LCSs be detected on the coarse 3D initial grid while a two-layer mesh is then used to capture detailed LCSs.

- (3)

- The LCSs have advantages in identifying the relationships and interactions between vortex structures. The LCSs show a transport barrier between the TLV and the secondary TLV, indicating two separate vortices.

- (4)

- The breakdown patterns of the vortices in the whole flow field can be recognized clearly by the LCSs, which is not true with the Q criterion method, while the streaklines rely on subjective judgment. The aLCSs show the bubble-like and bar-like structure in the isosurfaces corresponding to the bubble and spiral breakdown patterns. The Lagrangian method has great potential in regard to unraveling the mechanism of complex vortex structures and is worth applying more in turbomachinery.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Δt | Physical time step of simulation |

| t | Time of instantaneous flow field |

| s,p | Streamwise and pitchwise coordinate |

| C | Blade tip chord length |

| Q | Second invariant of the velocity gradient tensor |

| T | Integration time |

| u | Velocity |

| ω | Vorticity |

| (x0) | Finite-time Lyapunov exponent |

| FTLErel | Relative finite-time Lyapunov exponent |

| TLV | Tip leakage vortex |

| TLF | Tip leakage flow |

| FTLE | Finite-time Lyapunov exponent |

| aLCS | Attracting Lagrangian coherent structure |

| rLCS | Repelling Lagrangian coherent structure |

| DDES | Delayed detached-eddy simulation |

| DE | Design condition |

| NS | Near-stall condition |

References

- Lakshminarayana, B.; Pouagare, M.; Davino, R. Three-dimensional Flow Field in the Tip Region of a Compressor Rotor Passage-Part I: Mean Velocity Profiles and Annulus Wall Boundary Layer. ASME J. Eng. Power 1982, 104, 760–772. [Google Scholar] [CrossRef]

- Lakshminarayana, B.; Pouagare, M.; Davino, R. Three-dimensional Flow Field in the Tip Region of a Compressor Rotor Passage-Part II: Turbulence Properties. J. Eng. Power 1982, 104, 772–781. [Google Scholar] [CrossRef]

- Furukawa, M.; Inoue, K.; Saiki, K.; Yamada, K. The Role of Tip Leakage Vortex Breakdown in Compressor Rotor Aerodynamics. ASME J. Turbomach. 1999, 121, 469–480. [Google Scholar] [CrossRef]

- Denton, J.D. Loss Mechanisms in Turbomachines. ASME J. Turbomach. 1993, 115, 621–656. [Google Scholar] [CrossRef]

- Kameier, F.; Neise, W. Experimental Study of Tip Clearance Losses and Noise in Axial Turbomachines and Their Reduction. ASME J. Turbomach. 1997, 119, 460–471. [Google Scholar] [CrossRef]

- Day, I.J. Stall, Surge, and 75 Years of Research. ASME J. Turbomach. 2016, 138, 011001. [Google Scholar] [CrossRef]

- Cao, Z.; Zhang, X.; Liang, Y.; Liu, B. Influence of Blade Lean on Performance and Shock Wave/Tip Leakage Flow Interaction in a Transonic Compressor Rotor. J. Appl. Fluid Mech. 2022, 15, 153–167. [Google Scholar] [CrossRef]

- Lu, H.; Yang, Y.; Guo, S.; Huang, Y.; Wang, H.; Zhong, J. Flow Control in Linear Compressor Cascades by Inclusion of Suction Side Dimples at Varying Locations. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 232, 706–721. [Google Scholar] [CrossRef]

- Zhong, F.; Zhou, C. Effects of Tip Gap Size on the Aerodynamic Performance of a Cavity-Winglet Tip in a Turbine Cascade. ASME J. Turbomach. 2017, 139, 101009. [Google Scholar] [CrossRef]

- Green, M.; Rowley, C.; Haller, G. Detection of Lagrangian Coherent Structures in 3D Turbulence. J. Fluid Mech. 2007, 572, 111–120. [Google Scholar] [CrossRef]

- Helmholtz, H. On the Integrals of the Hydrodynamic Equations Corresponding to Vortex Motions. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1867, 33, 485–512. [Google Scholar] [CrossRef]

- Hunt, J.C.; Wray, A.A.; Moin, P. Eddies, Streams, and Convergence Zones in Turbulent Flows. Cent. Turbul. Res. Rep. 1988, CTR-S88, 193–208. [Google Scholar]

- Duda, D.; Yanovych, V.; Uruba, V. Vortex Profiles in Grid Turbulence Observed by PIV. AIP Conf. Proc. 2023, 2672, 020002. [Google Scholar] [CrossRef]

- Chong, M.S.; Perry, A.E.; Cantwell, B.J. A General Classification of Three-Dimensional Flow Fields. Phys. Fluids 1990, 2, 765–777. [Google Scholar] [CrossRef]

- Jeong, J.; Hussain, F. On the Identification of a Vortex. J. Fluid Mech. 1995, 285, 69–94. [Google Scholar] [CrossRef]

- Liu, C.; Xu, H.; Cai, X.; Gao, Y. Liutex and Its Applications in Turbulence Research, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2020; ISBN 978-012-819-023-4. [Google Scholar]

- Zhong, W.; Liu, Y.; Tang, Y. Unsteady Flow Structure of Corner Separation in a Highly Loaded Compressor Cascade. ASME J. Turbomach. 2024, 146, 031003. [Google Scholar] [CrossRef]

- Hou, J.; Liu, Y. Effect of Moving End Wall on Tip Leakage Flow in a Compressor Cascade with Different Clearance Heights. AIP Adv. 2024, 14, 015327. [Google Scholar] [CrossRef]

- Haller, G.; Yuan, G. Lagrangian Coherent Structures and Mixing in Two-Dimensional Turbulence. Phys. D 2000, 147, 352–370. [Google Scholar] [CrossRef]

- D’Ovidio, F.; Fernández, V.; Hernández-García, E.; López, C. Mixing Structures in the Mediterranean Sea from Finite-Size Lyapunov Exponents. Geophys. Res. Lett. 2004, 31, L17203. [Google Scholar] [CrossRef]

- Prants, S. Transport Barriers in Geophysical Flows: A Review. Symmetry 2023, 15, 1942. [Google Scholar] [CrossRef]

- Lekien, F.; Coulliette, C.; Mariano, A.J.; Ryan, E.H.; Shay, L.K.; Haller, G.; Marsden, J. Pollution Release Tied to Invariant Manifolds: A Case Study for The Coast of Florida. Physica D 2005, 210, 1–20. [Google Scholar] [CrossRef]

- Sapsis, T.; Haller, G. Inertial Particle Dynamics in a Hurricane. J. Atmos. Sci. 2009, 66, 2481–2492. [Google Scholar] [CrossRef]

- Shadden, S.C.; Astorino, M.; Gerbeau, J.-F. Computational Analysis of An Aortic Valve Jet with Lagrangian Coherent Structures. Chaos 2010, 20, 017512. [Google Scholar] [CrossRef] [PubMed]

- Shadden, S.C.; Taylor, C.A. Characterization of Coherent Structures in the Cardiovascular System. Ann. Biomed. Eng. 2008, 36, 1152–1162. [Google Scholar] [CrossRef] [PubMed]

- He, G.; Pan, C.; Feng, L.; Gao, Q.; Wang, J. Evolution of Lagrangian Coherent Structures in a Cylinder-Wake Disturbed Flat Plate Boundary Layer. J. Fluid Mech. 2016, 792, 274–306. [Google Scholar] [CrossRef]

- Pan, C.; Wang, J.; Zhang, C. Identification of Lagrangian Coherent Structures in the Turbulent Boundary Layer. Sci. China Ser. G-Phys. Mech. Astron. 2009, 52, 248–257. [Google Scholar] [CrossRef]

- Li, S.; Jiang, N.; Yang, S.; Huang, Y.; Wu, Y. Coherent Structures over Riblets in Turbulent Boundary Layer Studied by Combining Time-Resolved Particle Image Velocimetry (TRPIV), Proper Orthogonal Decomposition (POD), and Finite-Time Lyapunov Exponent (FTLE). Chin. Phys. B. 2018, 27, 104701. [Google Scholar] [CrossRef]

- Rockwood, M.P.; Taira, K.; Green, M.A. Detecting Vortex Formation and Shedding in Cylinder Wakes Using Lagrangian Coherent Structures. AIAA J. 2017, 55, 15–23. [Google Scholar] [CrossRef]

- Olcay, A.B. Investigation of a wake formation for flow over a cylinder using Lagrangian coherent structures. Prog. Comput. Fluid Dyn. 2016, 16, 2. [Google Scholar] [CrossRef]

- Wang, W.; Prants, S.V.; Zhang, J.; Zhang, J.; Wang, L. A Lagrangian Analysis of Vortex Formation in the Wake behind a Transversely Oscillating Cylinder. Regul. Chaot. Dyn. 2018, 23, 583–594. [Google Scholar] [CrossRef]

- Sun, P.N.; Colagrossi, A.; Marrone, S.; Zhang, A.M. Detection of Lagrangian Coherent Structures in the SPH framework. Comput. Methods Appl. Mech. Eng. 2016, 305, 849–868. [Google Scholar] [CrossRef]

- Wang, L.; Wang, P.; Chang, Z.; Huang, B.; Wu, D. A Lagrangian Analysis of Partial Cavitation Growth and Cavitation Control Mechanism. Phys. Fluids 2022, 34, 113329. [Google Scholar] [CrossRef]

- Ahmad, R.; Zhang, J.; Farooqi, A.; Nauman Aslam, M. Transport Phenomena and Mixing Induced by Vortex Formation in Flow Around Airfoil Using Lagrangian Coherent Structures. Numer. Math. Theor. Meth. Appl. 2019, 12, 1231–1245. [Google Scholar] [CrossRef]

- Tang, J.; Tseng, C.; Wang, N. Lagrangian-Based Investigation of Multiphase Flows by Finite-Time Lyapunov Exponents. Acta. Mech. Sin. 2012, 28, 612–624. [Google Scholar] [CrossRef]

- Tu, H.; Marzanek, M.; Green, M.A.; Rival, D.E. FTLE and Surface-Pressure Signature of Dynamic Flow Reattachment During Delta-Wing Axial Acceleration. AIAA J. 2022, 60, 2178–2194. [Google Scholar] [CrossRef]

- Li, K.; Savari, C.; Barigou, M. Computation of Lagrangian Coherent Structures from Experimental Fluid Trajectory Measurements in a Mechanically Agitated Vessel. Chem. Eng. Sci. 2022, 254, 117598. [Google Scholar] [CrossRef]

- Tseng, C.; Hu, H. Flow Dynamics of a Pitching Foil by Eulerian and Lagrangian Viewpoints. AIAA J. 2016, 54, 712–727. [Google Scholar] [CrossRef]

- Haller, G. Distinguished Material Surfaces and Coherent Structures in Three-Dimensional Fluid Flows. Phys. D 2001, 149, 248–277. [Google Scholar] [CrossRef]

- Shadden, S.C. A Dynamical Systems Approach to Unsteady Systems; California Institute of Technology: Pasadena, CA, USA, 2006. [Google Scholar]

- Haller, G.; Sapsis, T. Lagrangian Coherent Structures and the Smallest Finite-Time Lyapunov Exponent. Chaos 2011, 21, 023115. [Google Scholar] [CrossRef]

- Shadden, S.C.; Lekien, F.; Marsden, J.E. Definition and Properties of Lagrangian Coherent Structures from Finite-Time Lyapunov Exponents in Two-Dimensional Aperiodic Flows. Phys. D 2005, 212, 271–304. [Google Scholar] [CrossRef]

- Lekien, F.; Shadden, S.C.; Marsden, J.E. Lagrangian Coherent Structures in n-Dimensional Systems. J. Math. Phys. 2007, 48, 065404. [Google Scholar] [CrossRef]

- Du, H.; Yu, X.; Zhang, Z.; Liu, B. Relationship Between the Flow Blockage of Tip Leakage Vortex and Its Evolutionary Procedures inside the Rotor Passage of a Subsonic Axial Compressor. J. Therm. Sci. 2013, 22, 522–531. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, S.; Wang, F.; Tang, Y. A Novel Method for Predicting Fluid-Structure Interaction with Large Deformation Based on Masked Deep Neural Network. Phys. Fluids 2024, 36, 027103. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, F.; Zhao, S.; Tang, Y. A Novel Framework for Predicting Active Flow Control by Combining Deep Reinforcement Learning and Masked Deep Neural Network. Phys. Fluids 2024, 36, 037112. [Google Scholar] [CrossRef]

- Spalart, P.R. Philosophies and Fallacies in Turbulence Modeling. Prog. Aerosp. Sci. 2015, 74, 1–15. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, X.; Tang, Y. Investigation of Unsteady Rotor–Stator Interaction and Deterministic Correlation Analysis in a Transonic Compressor Stage. ASME J. Turbomach. 2023, 145, 071004. [Google Scholar] [CrossRef]

- Lee, G.H.; Park, J.I.; Baek, J.H. Performance Assessment of Turbulence Models for the Quantitative Prediction of Tip Leakage Flow in Turbomachines. In Proceedings of the ASME Turbo Expo 2004: Power for Land, Sea, and Air, Volume 5: Turbo Expo 2004, Parts A and B, Vienna, Austria, 14–17 June 2004; pp. 1501–1512. [Google Scholar] [CrossRef]

- Liu, Y.; Zhong, L.; Lu, L. Comparison of DDES and URANS for Unsteady Tip Leakage Flow in an Axial Compressor Rotor. ASME J. Fluids Eng. 2019, 141, 121405. [Google Scholar] [CrossRef]

- Gritskevich, M.S.; Garbaruk, A.V.; Schütze, J.; Menter, F.R. Development of DDES and IDDES Formulations for the k-ω Shear Stress Transport Model. Flow Turbul. Combust. 2012, 88, 431–449. [Google Scholar] [CrossRef]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten Years of Industrial Experience with the SST Turbulence Model. In Turbulence, Heat and Mass Transfer 4; Hanjalic, K., Nagano, Y., Tummers, M.J., Eds.; Begell House: New York, NY, USA; Wallingford, UK, 2003; Volume 4, pp. 625–632. [Google Scholar]

- Tucker, P. Unsteady Computational Fluid Dynamics in Aeronautics; Fluid Mechanics and Its Applications; Springer: Dordrecht, The Netherlands, 2013; Volume 104. [Google Scholar] [CrossRef]

- Li, H.; Su, X.; Yuan, X. Entropy Analysis of the Flat Tip Leakage Flow with Delayed Detached Eddy Simulation. Entropy 2019, 21, 21. [Google Scholar] [CrossRef]

- Hou, J.; Liu, Y.; Zhong, L.; Zhong, W.; Tang, Y. Effect of Vorticity Transport on Flow Structure in the Tip Region of Axial Compressors. Phys. Fluids 2022, 34, 055102. [Google Scholar] [CrossRef]

- Hou, J.; Liu, Y. Evolution of Unsteady Vortex Structures in the Tip Region of an Axial Compressor Rotor. Phys. Fluids 2023, 35, 045107. [Google Scholar] [CrossRef]

| Parameter | Parameter Value |

|---|---|

| Outer diameter | 1.0 m |

| Hub-to-tip ratio | 0.6 |

| Design Speed | 1200 r/min |

| Configuration | Inlet guide vane + Rotor + Stator |

| Number of rotor blades | 17 |

| Mid-span blade chord | 152 mm |

| Mid-span Blade camber angle | 40.8° |

| Mid-span Blade stagger angle | 36.5° |

| Solidity (mid-span) | 1.03 |

| Aspect ratio (mid-span) | 1.32 |

| Rotor tip gap | 3.5 mm |

| Rotor tip gap/blade height | 1.75% |

| Grid No. | Grid Size | Integration Time Step | Integration Time | Time Integration Method |

|---|---|---|---|---|

| 1 | 300(p) × 180(r) | 2.5 Δt | ±2000 Δt | Fourth-order Runge-Kutta |

| 2 | 750(p) × 450(r) | 2.5 Δt | ±2000 Δt | Fourth-order Runge-Kutta |

| Grid Density Level | Grid Size | FTLE Range |

|---|---|---|

| 1 | 150(p) × 90(r) | (−∞, 0.27] |

| 2 | 300(p) × 180(r) | (0.27, 0.56) |

| 3 | 750(p) × 450(r) | [0.56, +∞) |

| 4 | 1500(p) × 900(r) | [0.56, +∞) (partial) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, J.; Liu, Y.; Tang, Y. A Lagrangian Analysis of Tip Leakage Vortex in a Low-Speed Axial Compressor Rotor. Symmetry 2024, 16, 344. https://doi.org/10.3390/sym16030344

Hou J, Liu Y, Tang Y. A Lagrangian Analysis of Tip Leakage Vortex in a Low-Speed Axial Compressor Rotor. Symmetry. 2024; 16(3):344. https://doi.org/10.3390/sym16030344

Chicago/Turabian StyleHou, Jiexuan, Yangwei Liu, and Yumeng Tang. 2024. "A Lagrangian Analysis of Tip Leakage Vortex in a Low-Speed Axial Compressor Rotor" Symmetry 16, no. 3: 344. https://doi.org/10.3390/sym16030344

APA StyleHou, J., Liu, Y., & Tang, Y. (2024). A Lagrangian Analysis of Tip Leakage Vortex in a Low-Speed Axial Compressor Rotor. Symmetry, 16(3), 344. https://doi.org/10.3390/sym16030344