Abstract

China is very rich in tungsten and tin resources, but most of them are finely disseminated with gangues, and thus, fine grinding is required for effective separation, which results in the abundant production of ultra-fine tungsten and tin values into slimes and tailings. The SLon centrifugal separator is highly effective in recovering ultra-fine heavy particles, because it operates on the centrifugal acceleration of particles in the flowing film of a few millimeters thick. The recovery of ultra-fine tungsten minerals from a slime assaying 0.22% WO3, in which 81.85% distributed in −40 µm fraction, was investigated using large-scale SLon-2400 centrifugal separator. Under optimized operating conditions, it produced a primary tungsten concentrate assaying 1.65% WO3 at a high recovery of 77.83%. Moreover, it produced a primary tin concentrate assaying 1.56% Sn at a high recovery of 79.85% from a tin slime assaying 0.27% Sn, in which 74.78% Sn was distributed in −40 µm fraction; then, followed by the flotation cleaning process, a final tin concentrate assaying 16.23% Sn with 66.7% recovery was produced. It was particularly noted that in this large-scale centrifugal separator, the three-conical separation drum stuck with abrasion-resistant ceramic slices on its inner surface played a key role for achieving high constant separation performance. It was concluded that the SLon centrifugal separator has important application prospects for high-efficient recovery of ultra-fine heavy minerals from slimes and tailings.

1. Introduction

Tungsten and tin metals are used in various applications due to their many advantages, such as resistance to corrosion, high melting point, and malleability [1]. China is very rich in tungsten and tin resources, accounting for 60% and 32% of the world [2,3], respectively. However, most of them are low grade and finely disseminated with gangues, so that fine grinding is required for effective separations, which has resulted in the abundant production of ultra-fine tungsten and tin minerals. It was reported that 30–40% of Chinese tungsten and tin were practically lost in slimes and tailings, and they were not effectively recovered. In practice, the efficiency for recovering such ultra-fine values, especially for those with particle size below 20 µm, would be very low even unpractical [4,5,6]. Enhanced gravity separation, i.e., centrifugal separation, has provided a potential method for the recovery of such ultra-fine heavy minerals [7,8,9,10]. For instance, Knelson and Falcon separators were respectively reported effective for separation of fine gold and coal [11,12]; however, their effective applications for ultra-fine tungsten and tin minerals were seldom reported.

Ten years ago, SLon centrifugal separator was reported highly effective for the recovery of fine and ultrafine hematite from tailings [13]. It operates on the centrifugal acceleration of particles in the flowing film of a few millimeters thick, so that heavy particles may settle onto the inner surface of separation drum within a very short time. This centrifugal separator achieves high separation selectivity through a three-conical drum, onto which were stuck with abrasion-resistant ceramic slices [14]. In practice, the fine tailings were first roughed using pulsating high gradient magnetic separation (PHGMS) with 1.0–1.5 mm fine matrix, to produce a primary iron concentrate [15]; then, the primary concentrate was condensed to 20–30% solid concentration and cleaned through SLon centrifugal separator, to obtain the marketable iron concentrate [16]. This PHGMS roughing-centrifugal cleaning process is short and simple, and possesses such advantages as environment-friendliness, low production cost and simple operation, over the widely applied PHGMS roughing-flotation cleaning process. In the past ten years, this kind of centrifugal separator was scaled up and attempted to recover fine and ultra-fine tungsten and tin minerals from slimes and tailings in China, with many successful applications in the industry [17].

This paper introduces the large-scale SLon-2400 centrifugal separator, and its separation performance for the recovery of ultra-fine tungsten and tin minerals from slimes.

2. The SLon Centrifugal Separator and Characterization of Slimes

2.1. The SLon-2400 Large-Scale Centrifugal Separator and Separation Procedure

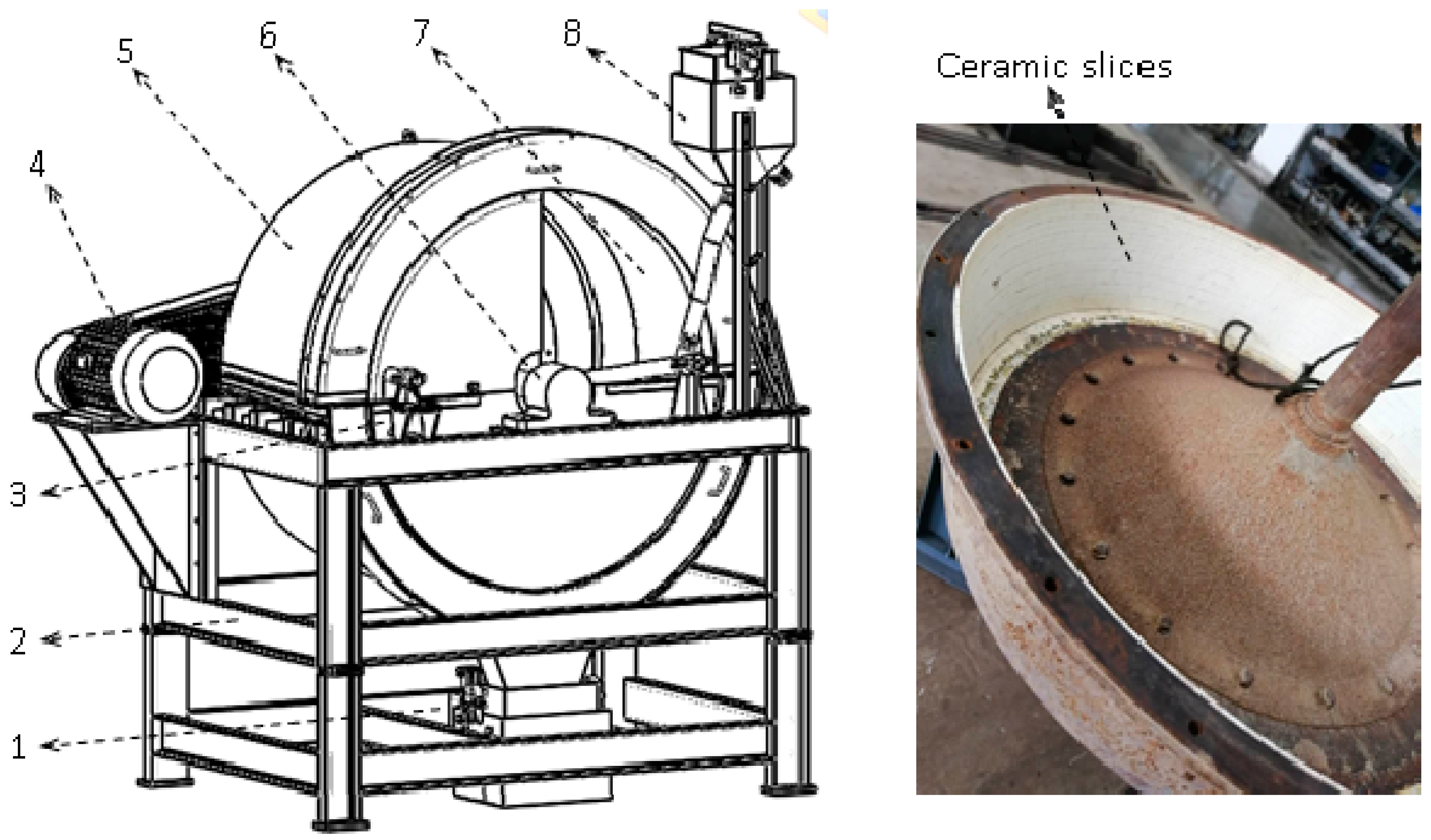

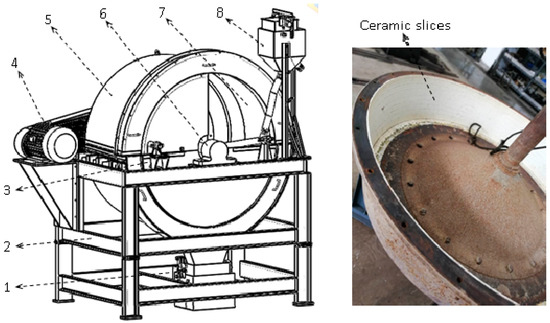

The full-scale and large-scale SLon-2400 (diameter of separation drum) centrifugal separator was used for this investigation. From Figure 1, it mainly consists of a horizontally conical separation drum, support frame, feed and products splitting devices, rinsing water device and air operating control system.

Figure 1.

The SLon-2400 large-scale centrifugal separator (left) and its unique separation drum (right, partial): (1) Product splitting device; (2) support frame; (3) rinsing water device; (4) motor; (5) protective cover; (6) rotating shaft; (7) separation drum; (8) feed device.

The mechanical structure of this full-scale and large-scale centrifugal separator is almost the same as that of SLon-1600 separator [18]. However, this separator, as illustrated in Figure 1, works periodically. When the separator is being operated, the feed material enters into the rotating separation drum as a slurry through the feed device. The slurry is forced onto the inner surface of the drum and rotates with the drum in the form of flowing film. Heavy particles in the film settle down onto the drum surface, due to the centrifugal force, while light particles are driven outward to become tailings via the product splitting device. During the separation process, low-pressured water beams from the rinsing water device were sprayed onto the drum surface to improve the separation selectivity. When a periodical feed was finished, the feed was stopped, and high-pressured water beams were sprayed onto the drum surface to flush down the heavy particles as concentrate product, which goes out of the product splitting device. Then, the next periodical feed begins.

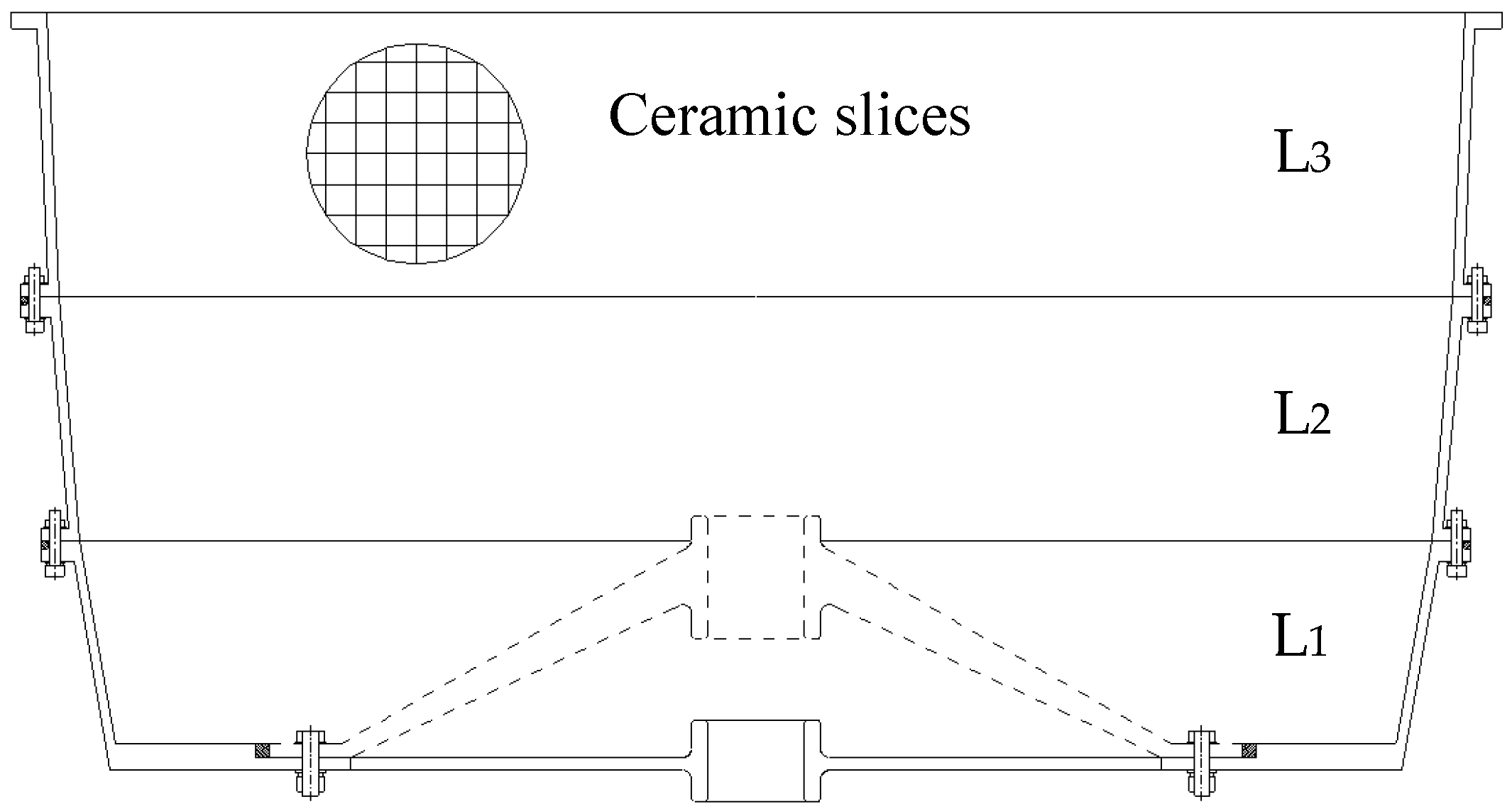

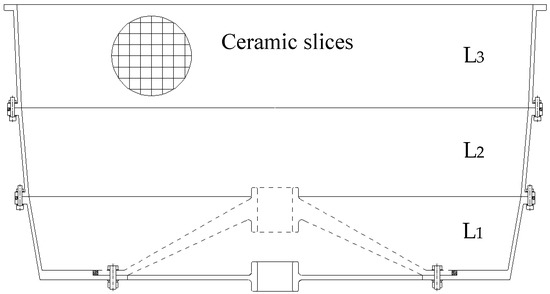

The two most innovative techniques applied in the SLon centrifugal separators are the three-conical separation drum stuck with numerous abrasion-resistant ceramic slices, as shown in Figure 1, and the air operating control system for the periodical separation process. This new drum has played a key role in maintaining the constant high separation performance of the SLon centrifugal separators. The tilting angle of the three-conical drum decreases from L1 to L2 and to L3 fractions along the width of the drum, as shown in Figure 2, to produce a weakly steady turbulent slurry flow on the drum surface. Such a flow pattern is favorable for the selective settling of fine and ultra-fine heavy particles onto the drum surface. This high separation performance is also resulted from the abrasion-resistant ceramic slices stuck onto the drum surface, as the drum surface maintains a fixed surface roughness for more than ten years.

Figure 2.

Three-conical separation drum with abrasion-resistant ceramic slices.

The air operating control system was innovatively applied in the SLon centrifugal separators, to achieve the smooth switch between opening and closing of feed, discharging of concentrate and tailings, and the action of high-pressured water sprays.

The main operating parameters of this SLon-2400 centrifugal separator include centrifugal acceleration (0–60 g, g is gravity acceleration), feed volume flow rate (45–500 L/min), rinsing water flow rate (5–20 L/min) and slurry solid concentration for ultra-fine particles (10–30%).

2.2. Description of Tungsten and Tin Slimes

The tungsten and tin slimes are both from the overflows of thickener and hydrocyclone, which have been produced from the tungsten and tin processing plants of Jiangxi Tungsten Holding Group Company Limited in southern China. From Table 1; Table 2, the tungsten slime is very fine, with 81.52% smaller than 40 μm. The main gangue minerals in the slime are quartz, mica, feldspar, tourmaline, fluorite, chlorite and calcite. More than 95.00% WO3 in the slime is distributed in the form of wolframite.

Table 1.

Chemical compositions of tungsten slime.

Table 2.

Particle size distribution of tungsten slime.

From Table 3 and Table 4, the tin slime is smaller than 40 μm by 74.78%. Most of the tin minerals are distributed in the form of cassiterite, with 31.35% Sn distributed in the −20 μm fraction. Gangue minerals in the slime are mainly quartz, followed by mica, epidote and feldspar.

Table 3.

Chemical compositions of tin slime.

Table 4.

Particle size distribution of tin slime.

It is also noted that 95.85% wolframite and 97.34% cassiterite particles were respectively liberated from gangue minerals, in the two slimes.

3. Results and Discussion

3.1. Recovery of Ultra-Fine Tungsten from Slime

3.1.1. Effect of Centrifugal Acceleration on the Separation Performance

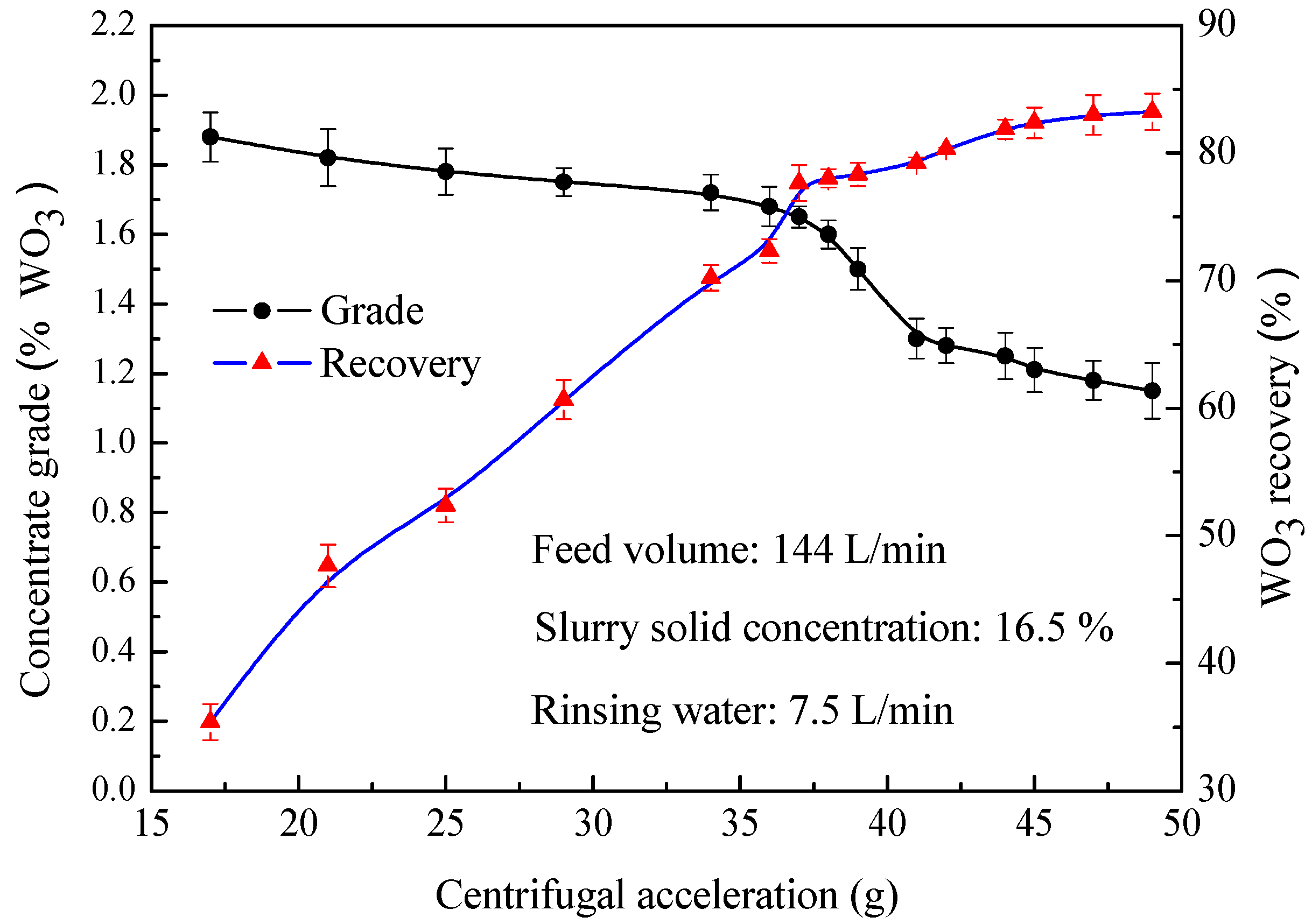

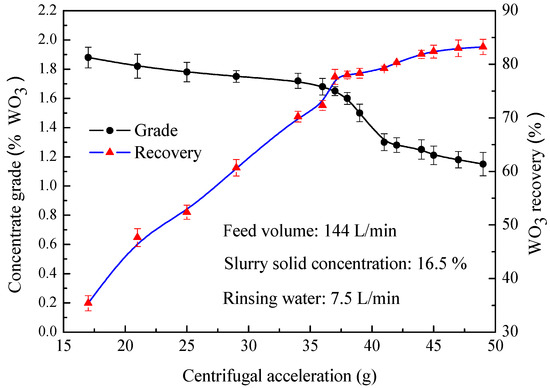

With the feed volume flow rate, feed solid concentration and rinsing water separately maintained at around 144 L/min, 16.5% and 7.5 L/min, the effect of centrifugal acceleration on the separation performance of SLon-2400 the separator was firstly investigated during the industrial operation of the centrifugal separator. From Figure 3, the centrifugal acceleration has a very significant effect on the separation performance of the separator, particularly on the WO3 recovery. As the acceleration was increased from 17 g to 37 g, the concentrate grade slightly reduced with great improvement in the WO3 recovery; after 37 g, the concentrate grade began to decrease significantly with an obvious improvement in the recovery. From Figure 3, the optimum separation performance was achieved when the separator was operated at a centrifugal acceleration of 37 g, where the concentrate grade and recovery were 1.65% WO3 and 77.83%, respectively.

Figure 3.

Effect of centrifugal acceleration on the separation performance of tungsten.

In the centrifugal separation process, the centrifugal force acting onto particles increases with an increase in the centrifugal acceleration. Since the mostly-dominant force in the process, it determines the number of particles going into the heavy concentrate. As illustrated in Figure 3, when the separator was operated at an insufficient centrifugal acceleration, it mainly concentrates the +38 μm coarse wolframite particles, resulting in low recovery. With an increase in the acceleration, more fine wolframite particles went into the concentrate product, and the recovery improved tremendously. However, when the separator was operated at an excessive acceleration, particles were subjected to extremely strong centrifugal force, and a lot of light gangue minerals, as well as more ultra-fine wolframite particles, went into the concentrate product, reducing the concentrate grade and further improving the recovery.

3.1.2. Effect of Slurry Solid Concentration on the Tseparation Performance

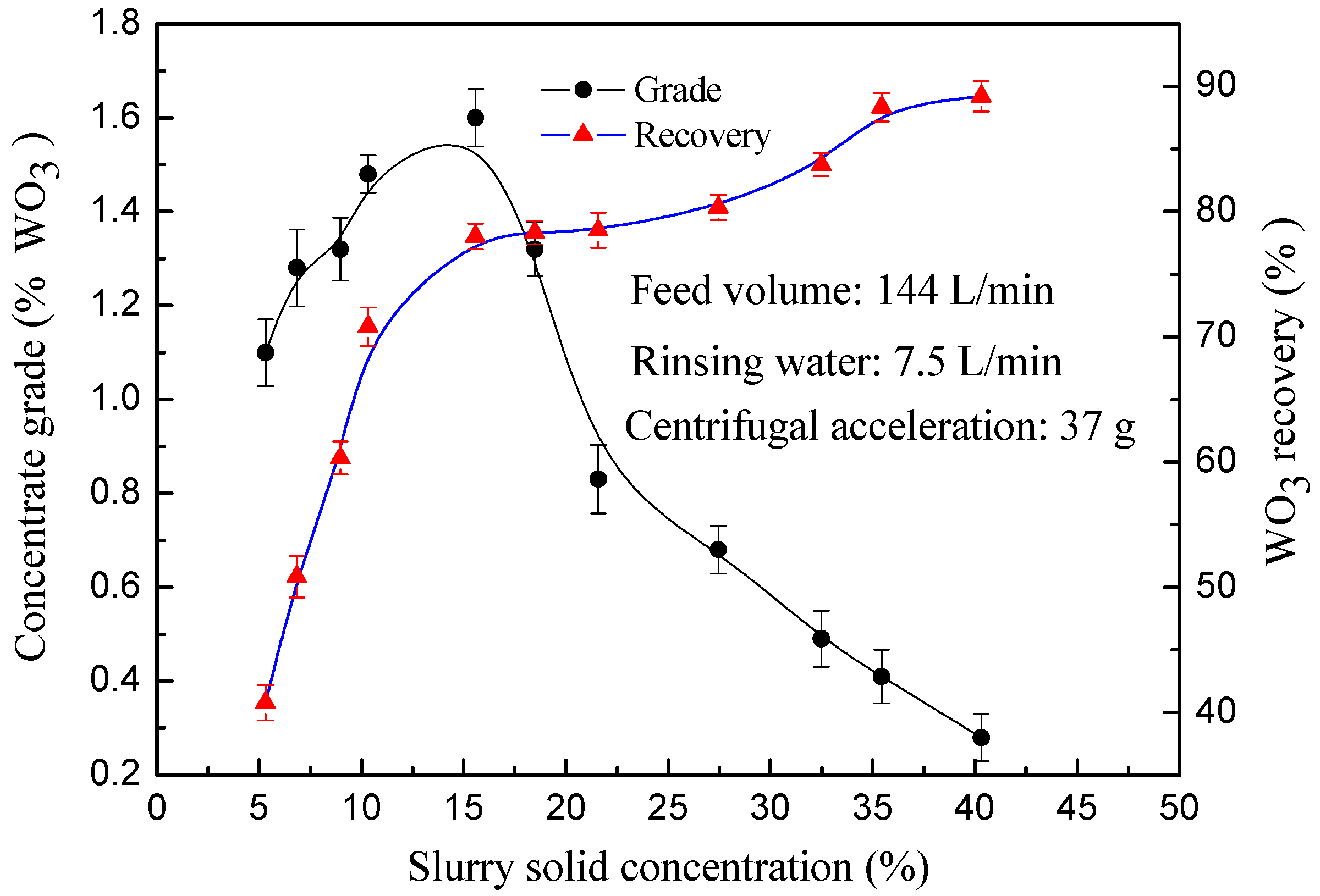

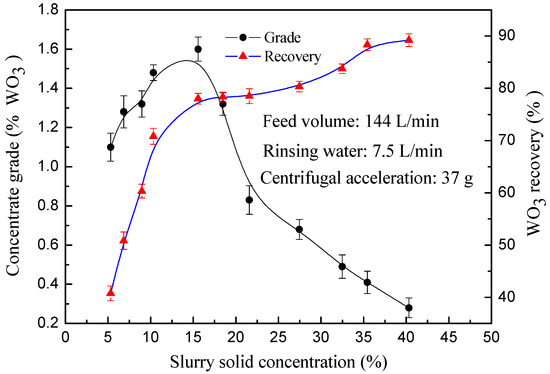

Controlling the centrifugal acceleration, feed volume flow rate and rinsing water at 37 g, 144 L/min and 7.5 L/min, respectively, the effect of slurry solid concentration on the separation performance of the SLon-2400 centrifugal separator was investigated, with the solid concentration increasing from 5% to 40%. From Figure 4, the concentrate grade and WO3 recovery significantly increased with increase in the solid concentration from 5% to 18%, beyond which the concentrate grade decreased sharply, while the recovery was increased further.

Figure 4.

Effect of slurry solid concentration on the separation performance of tungsten.

When the separator was operated at a low slurry solid concentration, the rotating slurry would be in turbulent flow state under the high rotating speed of the drum. In this flow pattern, the separator mainly concentrated coarse wolframite particles, such as +38 μm fraction; it is difficult for fully-liberated fine and ultra-fine minerals to settle onto the drum surface, which reduces the concentrate grade and recovery. With increase in the solid concentration, the viscosity of slurry increases and the rotating slurry turned to flow in the laminar form. In this flow pattern, more fine and ultra-fine wolframite particles went into the concentrate product, significantly improving the concentrate grade and recovery, as shown in Figure 4. But, when the separator was operated at an excessive slurry solid concentrate, the viscosity of slurry reached excessively high and the hindered settling of particles in the rotating flow significantly deteriorated the separation selectivity. Such operations results in the settlement of light gangues onto the drum surface and the significant reduction in concentrate grade.

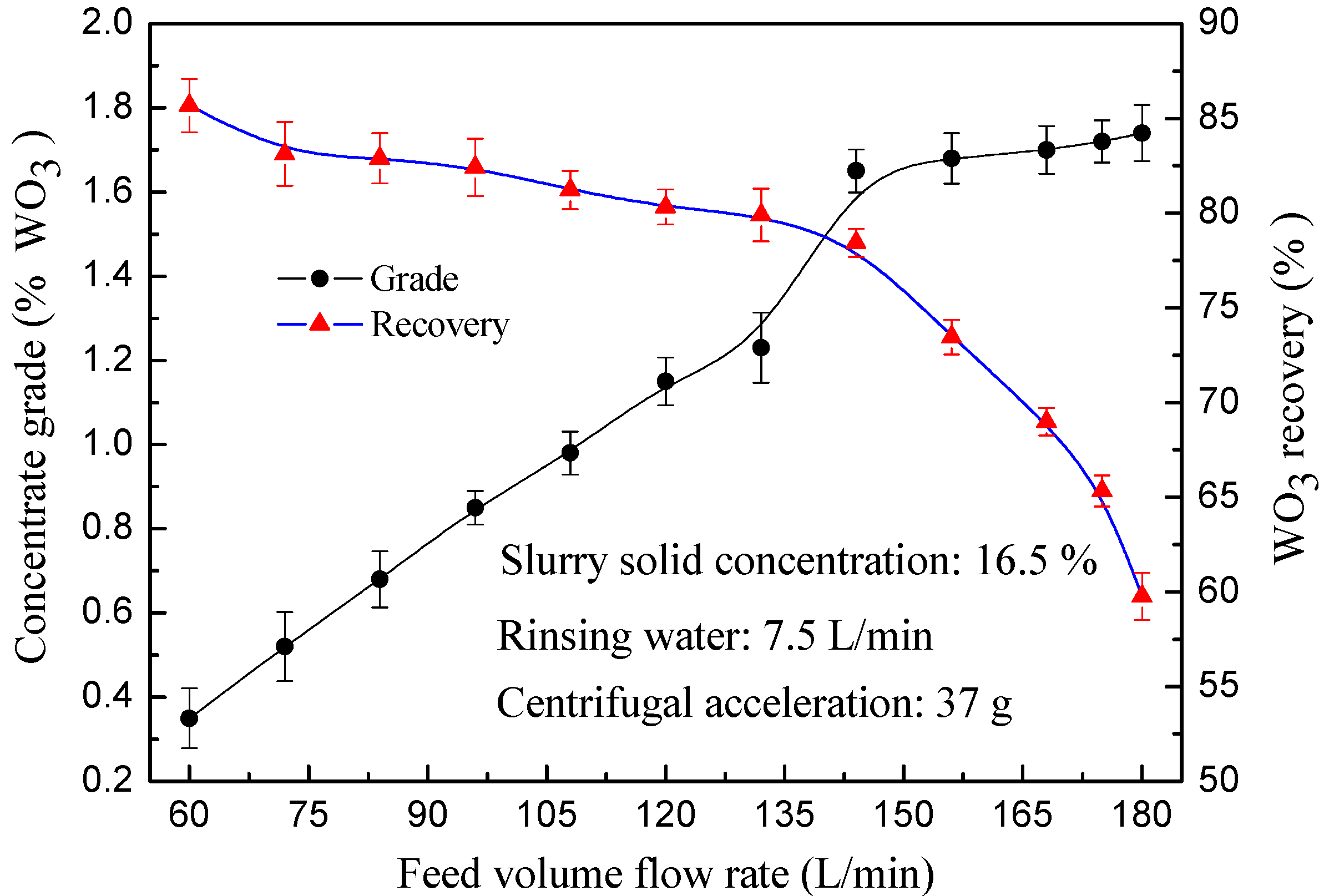

3.1.3. Effect of Feed Volume Flow Rate on the Separation Performance

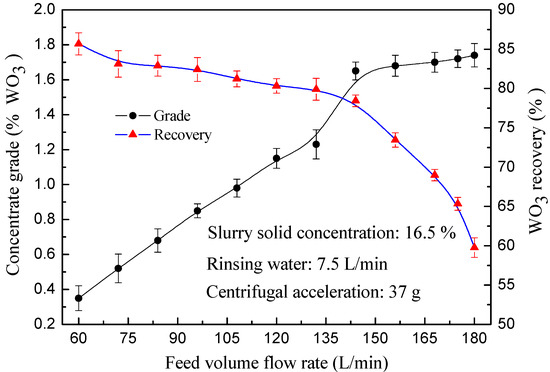

It can be seen from Figure 5, the feed volume flow also has a significant effect on the separation performance of the separator, while the centrifugal acceleration, slurry solid concentration and rinsing water were respectively maintained at 37 g, 16.5% and 7.5 L/min. The concentrate grade significantly improved with an increase in the feed volume flow rate from 60 L/min to 144 L/min, beyond which it improved very slowly. Meanwhile, the WO3 recovery slightly reduced with increase in the feed volume flow rate from 60 L/min to 144 L/min, beyond which it decreased much quickly. Therefore, in this investigation, the optimum feed volume flow rate was controlled at around 144 L/min, to achieve the optimum separation performance.

Figure 5.

Effect of the feeding rate on the separation performance of tungsten.

While other operating conditions were optimized, the feed volume flow rate determines the flow depth and axial velocity of the slurry film on the drum surface, thereby affecting the flow pattern of slurry and the settling trajectories of particles in the slurry. As can be seen from Figure 5, at low feed volume flow rates, the slurry film flowed slowly, and the wolframite and light gangue minerals both settled on the drum surface, leading to the low concentrate grade and high recovery. However, after the feed volume flow rate reached 144 L/min, the slurry film flowed too fast on the drum surface, and some of the ultra-fine wolframite particles could not settle down onto the drum surface; this deteriorated the separation performance, as clearly shown in Figure 5.

Considering the processing capacity of SLon-2400 centrifugal separator, a feed volume flow rate around 144 L/min was maintained.

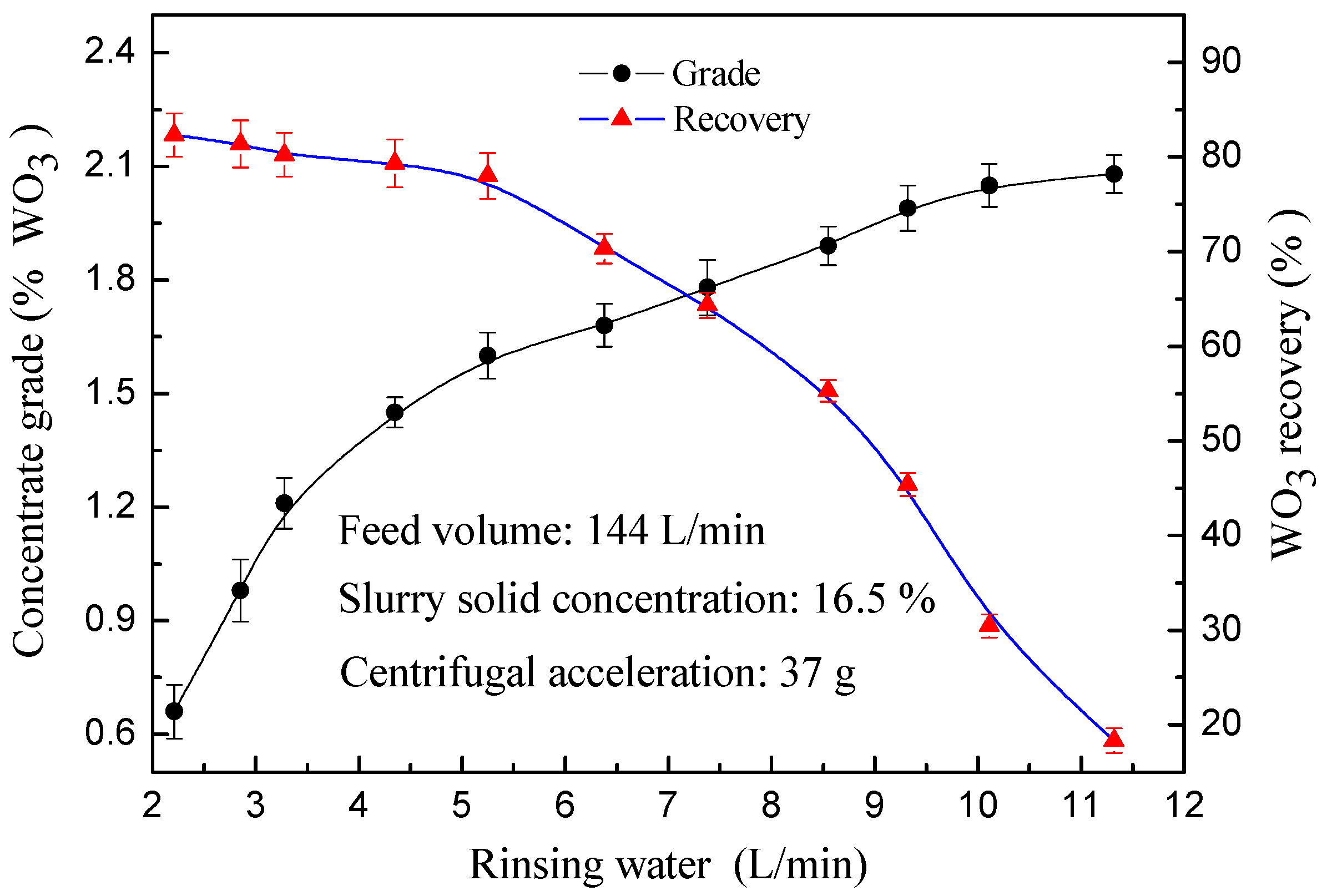

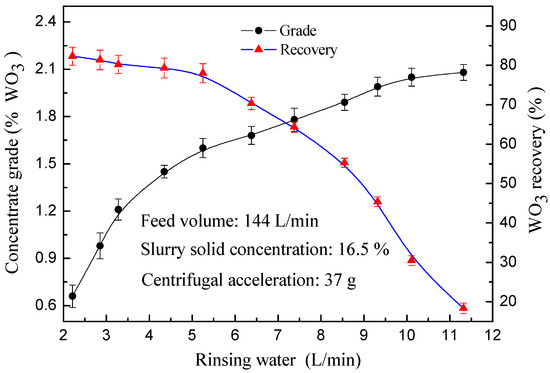

3.1.4. Effect of Rinsing Water on the Separation Performance

Finally, controlling the centrifugal acceleration, feed volume flow rate and slurry solid concentration respectively at 37 g, 144 L/min and 16.5%, the effect of rinsing water was investigated in detail. From Figure 6, the rinsing water has a very significant effect on the separation performance of the separator. When the rinsing water was increased from 2.2 L/min to 5.0 L/min, the concentrate grade increased significantly with a reduction in recovery, particularly after 5.0 L/min.

Figure 6.

Effect of rinsing water on the separation performance of tungsten.

In the SLon centrifugal separators, the rinsing water was designed to loosen the settled particles—Which were compactly settled and deposited onto the drum surface, due to the strong centrifugal force. Under the appropriate flushing of water sprays on these settled particles, light particles in the deposits will be effectively released, which significantly improves the separation selectivity. It can be seen from Figure 6, as the volume flow rate of rinsing water was increased, the concentrate grade significantly improved with a slight reduction in recovery. However, after the rinsing water rate reached higher than 5.0 L/min, the recovery reduced significantly, although the concentrate grade was improved. This is because under the strong rinsing water flushing, some of the fine and ultra-fine wolframite particles were impacted down and out of the rotating drum and lost into the tailings flow. It is clear from Figure 6, a rinsing water rate of 5.0–6.0 L/min is suitable for this tungsten slime, under the operating conditions optimized above.

The concentrate obtained under the conditions optimized above, i.e., centrifugal acceleration 37 g, feed volume flow rate around 144 L/min, slurry solid concentration 16.5 and rinsing water 5.2 L/min, was size-by-size analyzed as illustrated in Table 5. It is clear that the SLon-2400 centrifugal separator is capable of recovering ultra-fine wolframites, as it has effectively recovered the wolframite particles in −37 µm fraction (WO3 distribution reaching as high as 89.94%) from the tungsten slime assaying 0.22% WO3.

Table 5.

Size-by-size analysis of concentrate product obtained under optimized conditions.

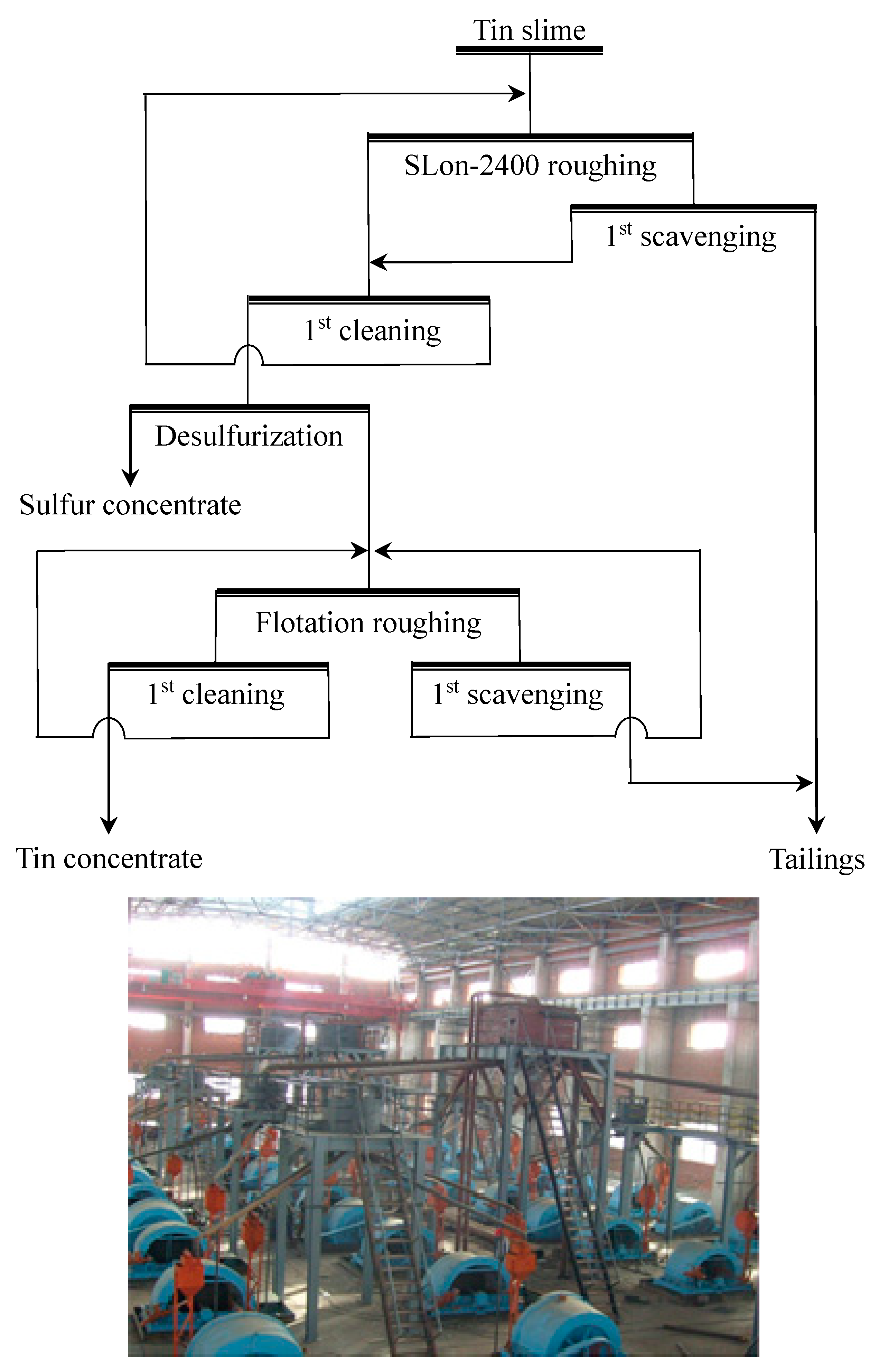

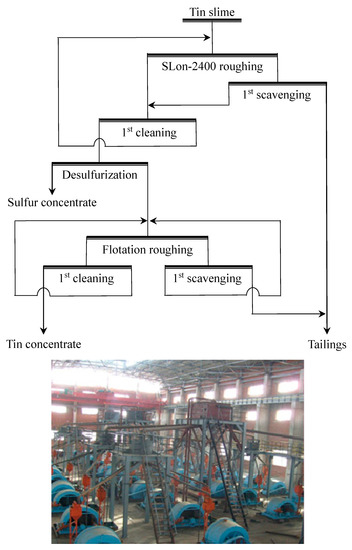

3.2. Recovery of Ultra-Fine Tin from Slime

The SLon-2400 centrifugal separators were also applied to recover ultra-fine cassiterites from the tin slime via a roughing-cleaning-scavenging process, as shown in Figure 7. In the recovering process, the operating parameters of the separator were also respectively optimized as those for the tungsten slime. Then, their primary tin concentrates were combined and desulfurdized through flotation, followed by an optimized roughing-cleaning-scavenging flotation process to produce the final tin concentrate. It can be seen from Table 6, the SLon centrifugal separation process produced a high-grade primary tin concentrate with recovery reaching 79.85% as illustrated in Table 6. In this new process, the SLon centrifugal separators have discarded 86.18% extremely low-grade tailings (0.063% Sn), producing very favorable condition the following flotation process.

Figure 7.

Processing flowsheet with SLon centrifugal separator and flotation for tin slime.

Table 6.

Separation performance for the recovery of ultra-fine cassiterite from slime using SLon centrifugal separation-flotation process.

Compared with the conventional shaking tables-flotation process for tin slime or tailings, this new separation process has such advantages as large processing capacity and high recovery for fine and ultra-fine cassiterites. In the conventional process, the final tin concentrate assays 6.45% Sn, with recovery as low as 33.25% [19].

4. Conclusions

The SLon centrifugal separator operates on the centrifugal acceleration of particles in the flowing film of a few millimeters thick. The separator is highly effective in recovering ultra-fine heavy particles. In the separator, an innovative three-conical separation drum stuck with abrasion-resistant ceramic slices on its inner surface was used, which is favorable for the selective settling of fine and ultra-fine heavy particles onto the drum surface. Moreover, an air operating control system was used, which has contributed to the effective industrialization of the separators.

Under the optimized conditions, the large-scale SLon-2400 centrifugal separator has produced a tungsten concentrate assaying 1.65% WO3 with recovery reaching as high as 77.83%, from the tungsten slime assaying 0.22% WO3 with 81.85% WO3 distributed in the −40 µm fraction. Furthermore, it has produced a tin concentrate assaying 1.56% Sn at a high recovery of 79.85% from the tin slime assaying 0.27% Sn with 74.78% Sn distributed in the −40 µm fraction; and followed by flotation a final tin concentrate assaying 16.23% Sn with 66.7% recovery was produced.

In conclusion, the SLon centrifugal separator has important application prospects for high-efficient recovery of ultra-fine heavy minerals from slimes and tailings.

Author Contributions

Conceptualization, L.C.; methodology, X.R.; software, T.X.; validation, L.C. and Y.P.; formal analysis, T.X.; investigation, T.X.; resources, T.X.; data curation, M.X.; writing—original draft preparation, T.X.; writing—review and editing, T.X.; visualization, L.C.; supervision, L.C.; project administration, Y.R.; funding acquisition, L.C. All authors have read and agreed to the published version of the manuscript.

Funding

The Key Program for Applied Basic Research of Yunnan Province in China (Grant No. 2016FA051), Jiangxi Tungsten Holding Group Company Limited (Grant No. JW-16B-03), the Science and Technology Project of Jiangxi Province (Grant No. 20141BBE50013).

Conflicts of Interest

The authors declare there is no conflicts of interest regarding the publication of this paper.

References

- Angadi, S.I.; Sreenivas, H.; Jeon, H.; Baek, S.; Mishra, B.K. A review of cassiterite beneficiation fundamentals and plant practices. Miner. Eng. 2015, 70, 178–200. [Google Scholar] [CrossRef]

- Gao, Y. The characteristics and research advances of mineral processing technologies of Chinese tungsten resources. China Tungsten Ind. 2018, 45, 44–46. (In Chinese) [Google Scholar]

- Zhang, J.; Ding, J.; Nan, G. The characteristics and potential of tin resources in China. Geol. China 2015, 42, 839–851. (In Chinese) [Google Scholar]

- Foucaud, Y.; Dehine, Q.; Filippov, L.O.; Filippova, I.V. Application of Falcon centrifuge as a cleaner alternative from complex tungsten ore processing. Minerals 2019, 9, 448. [Google Scholar] [CrossRef]

- Burt, R.O.; Korinek, G.; Young, S.R.; Deveau, C. Ultrafine tantalum recovery strategies. Miner. Eng. 1995, 8, 859–870. [Google Scholar] [CrossRef]

- Ergün, L.; Ersayin, S. Studies on pinched sluice concentration. Part I: The effects of operating variables and sluice geometry on the performance of pinched sluices. Miner. Eng. 2002, 15, 423–435. [Google Scholar] [CrossRef]

- Jones, T.A. Efficient enhanced gravity recovery of Zircon using the Kelsey centrifugal jig. In Proceedings of the DMS and Gravity Concentration Operations and Technology in South Africa, Johannesburg, South Africa, 18–20 July 2006; pp. 87–108. [Google Scholar]

- Majumder, A.K.; Barnwal, J.P. Modelling of enhanced gravity separator-present status. Miner. Process. Extra. Met. Rev. 2006, 27, 61–86. [Google Scholar] [CrossRef]

- Liu, D.; Wang, Y.; Jiang, T.; Sun, W.; Hu, Y. Study on pre-concentration efficiency of wolframite from tungsten ore using gravity and magnetic separations. Physicochem. Probl. Miner. Process. 2016, 52, 718–728. [Google Scholar]

- Fitzpatrick, R.; Hegarty, P.; Fergusson, K.; Rollinson, G.; Xie, W.; Mildren, T. Optimisation of a multi-gravity separator with novel modifications for the recovery of ferberite. Minerals 2018, 8, 191. [Google Scholar] [CrossRef]

- Tripathy, A.; Bagchi, S.; Biswal, S.K.; Meikap, B.C. Study of particle hydrodynamics and misplacement in liquid–solid fluidized bed separator. Chem. Eng. Res. Des. 2017, 117, 520–532. [Google Scholar] [CrossRef]

- Udaya Bhaskar, K.; Govindarajan, B.; Barnwal, J.P.; Venugopal, R.; Jakhu, M.R.; Rao, T.C. Performance and modeling studies of an MGS for graphite rejection in a lead concentrate. Int. J. Miner. Process. 2002, 67, 59–70. [Google Scholar] [CrossRef]

- Chen, L.; Ren, N.; Xiong, D. Application of SLon continuous centrifugal separators in recovering fine iron minerals from mining tailings. Met. Mine 2008, 1, 86–88. [Google Scholar]

- Chen, L.; Xiong, D.; Huang, H.; Peng, Z.; Xiong, T.; Rao, Y.; Zeng, J. A three-Conical Drum for SLon Centirfugal Separator. Chinese Invention Patent 20191022606.X, 27 August 2019. [Google Scholar]

- Zhang, H.; Zeng, J.; Xie, H.; Guan, C.; Chen, L. Enhanced separation for ilmenite tailings with a novel HGMS-flotation process. Sep. Sci. Technol. 2017, 2, 24–28. [Google Scholar] [CrossRef]

- Chen, L.; Ren, N.; Xiong, D. Experimental study on performance of a continuous centrifugal separator for reconcentrating fine hematite. Int. J. Miner. Process. 2008, 87, 9–16. [Google Scholar] [CrossRef]

- Zhong, N. Application of SLon centrifugal separator to separating fine tungsten in Dajishan. Nonferr. Met. (Miner. Process. Sect.) 2016, 2, 79–81. [Google Scholar]

- Chen, L.; Liu, S.; Wen, S. Performance of a full-scale continuous centrifugal separator in reconcentrating fine hematite from tailings. Miner. Metall. Proc. 2010, 27, 133–140. [Google Scholar]

- Lan, J.; Ji, X.; Rao, R. The flotation experimental study on one tin slime in Guangxi. Yunnan Metall. 2016, 45, 47–53. (In Chinese) [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).