Energy Dissipation and Electromagnetic Radiation Response of Sandstone Samples with a Pre-Existing Crack of Various Inclinations under an Impact Load

Abstract

:1. Introduction

2. Experimental Procedure

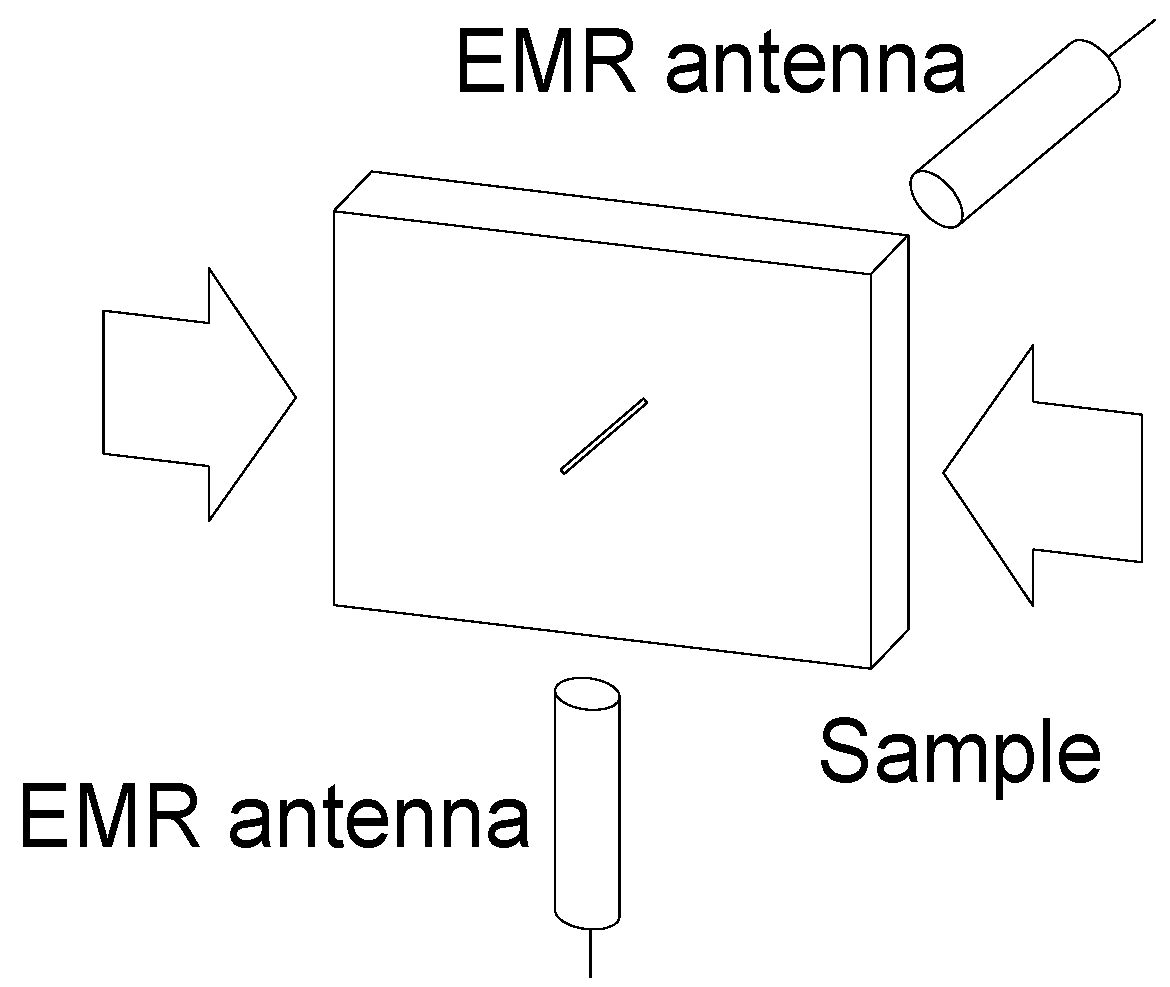

2.1. Experimental System

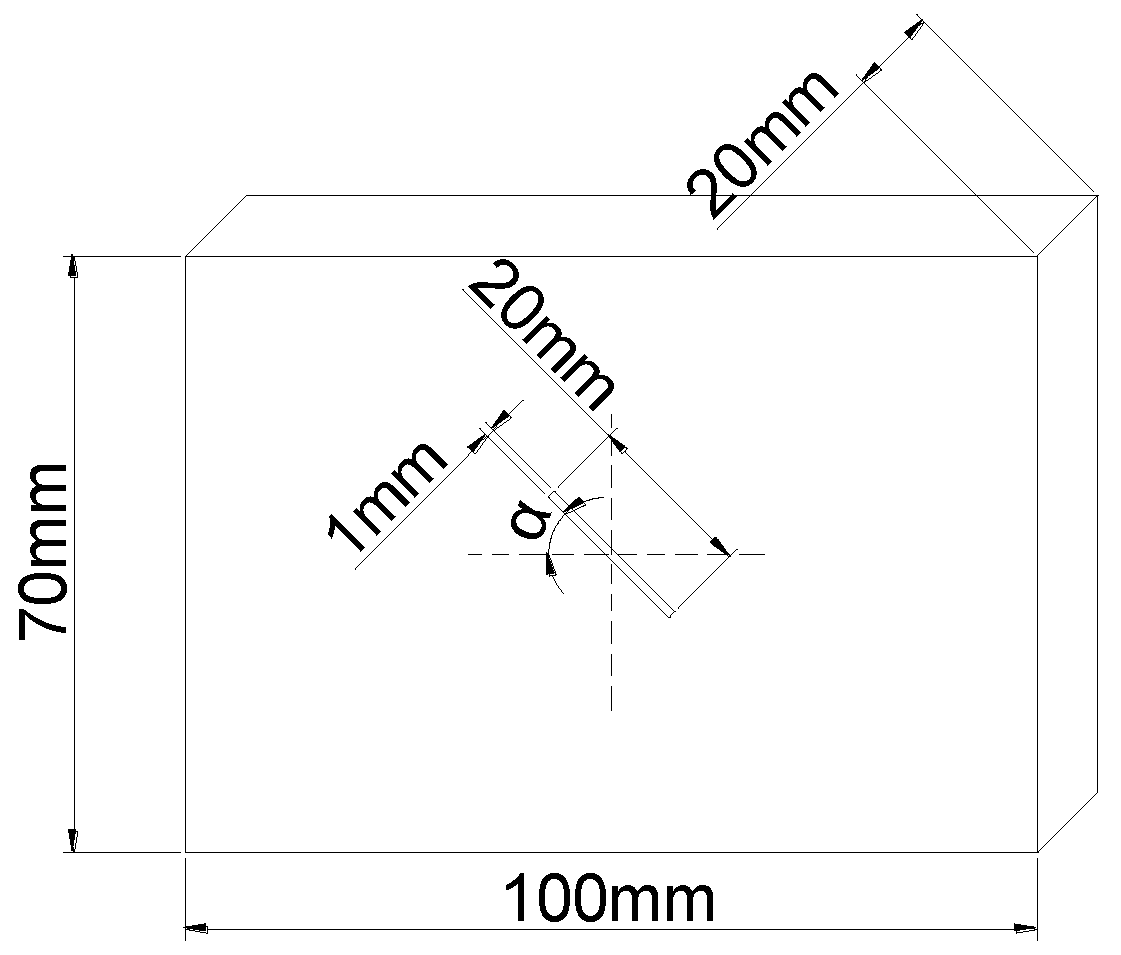

2.2. Experimental Samples

2.3. Principle of the Experiment

3. Experimental Results and Discussion

- (1).

- Started the experimental instrument to ensure that all experimental equipment was in normal working condition, to ensure that the experimental specimen as basically in a state of stress balance during the dynamic loading process and that the test result was reliable.

- (2).

- Used the axial compression loading device to clamp the sample to the set axial compression. Arranged the EMR antenna.

- (3).

- Started the SHPB experimental system and EMR collection system.

- (4).

- Started the impact bar launch system to complete the experiment.

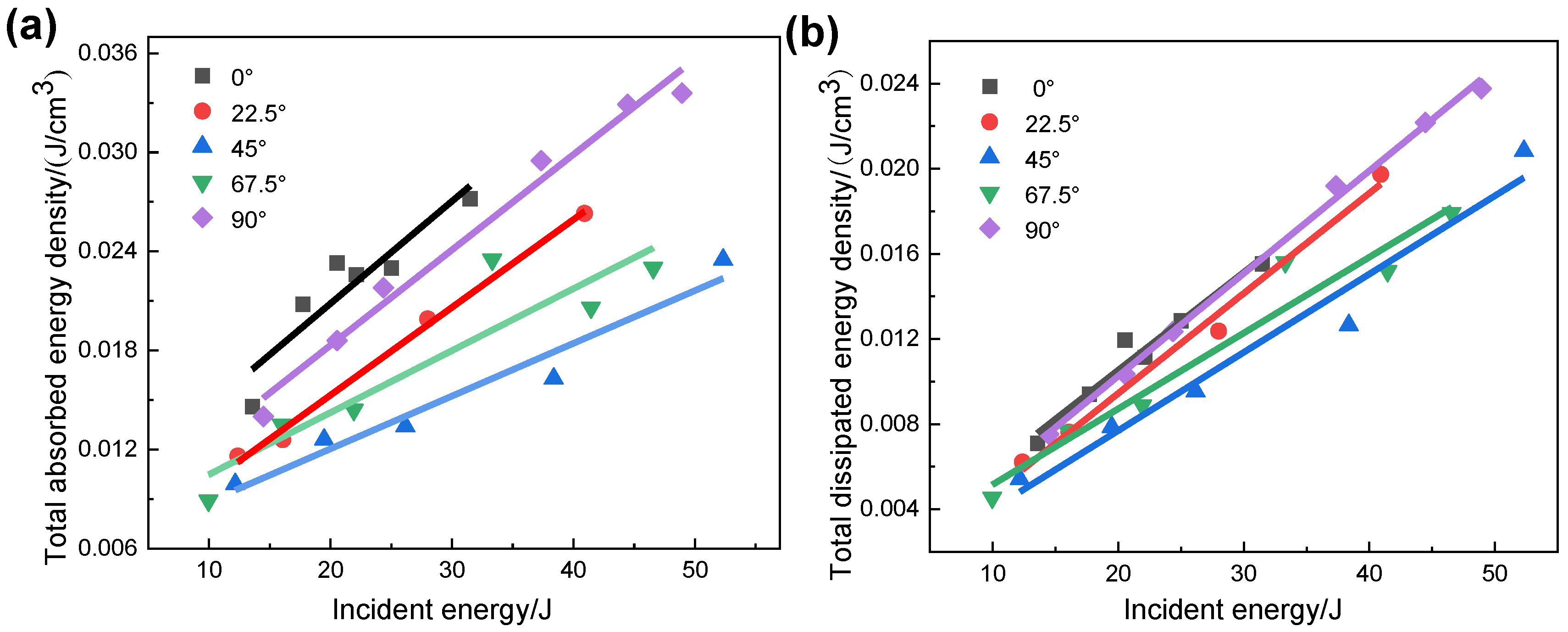

3.1. Energy Dissipation Law of Specimens with Different Inclination Angles

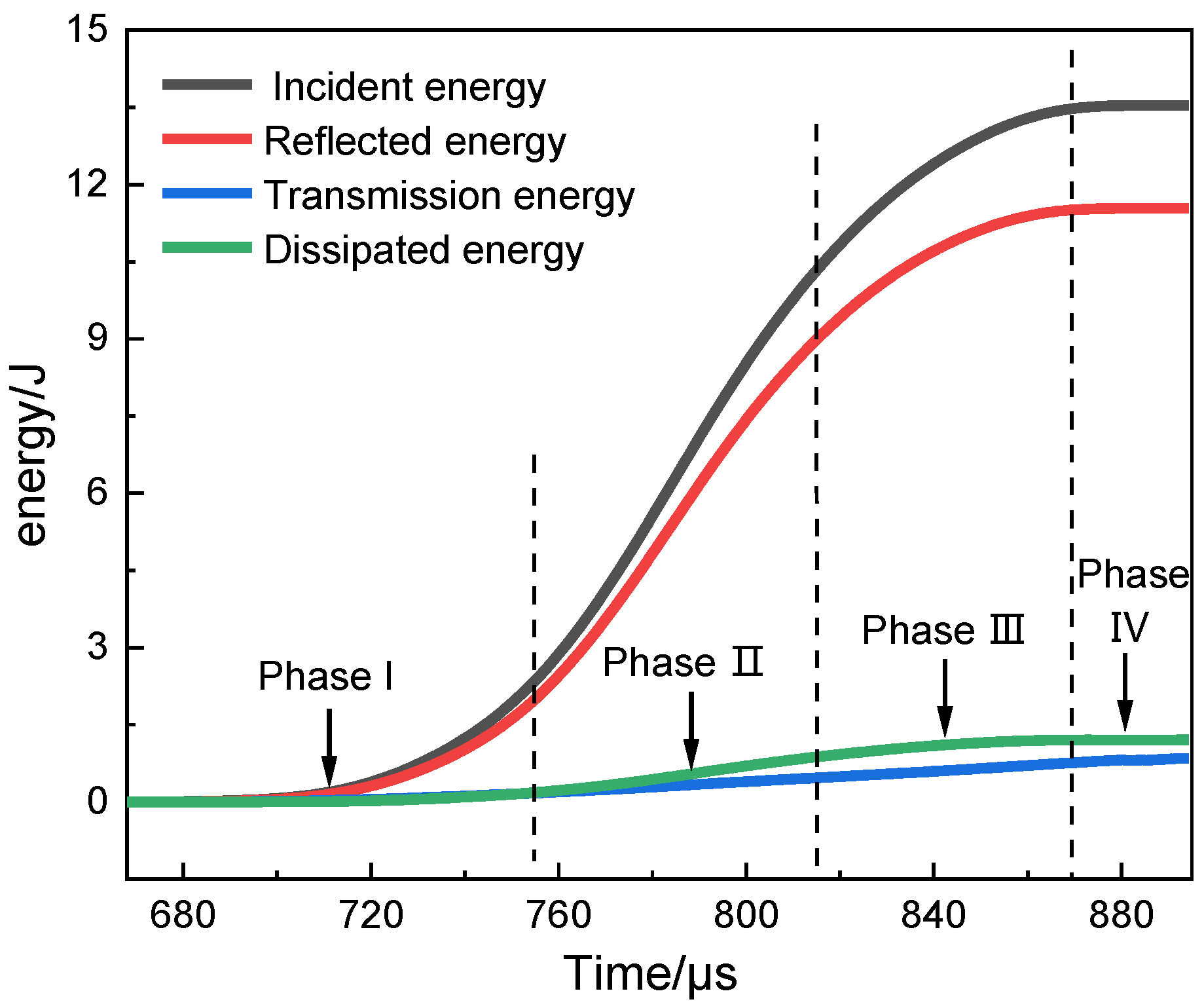

3.1.1. Typical Energy Time History Curve

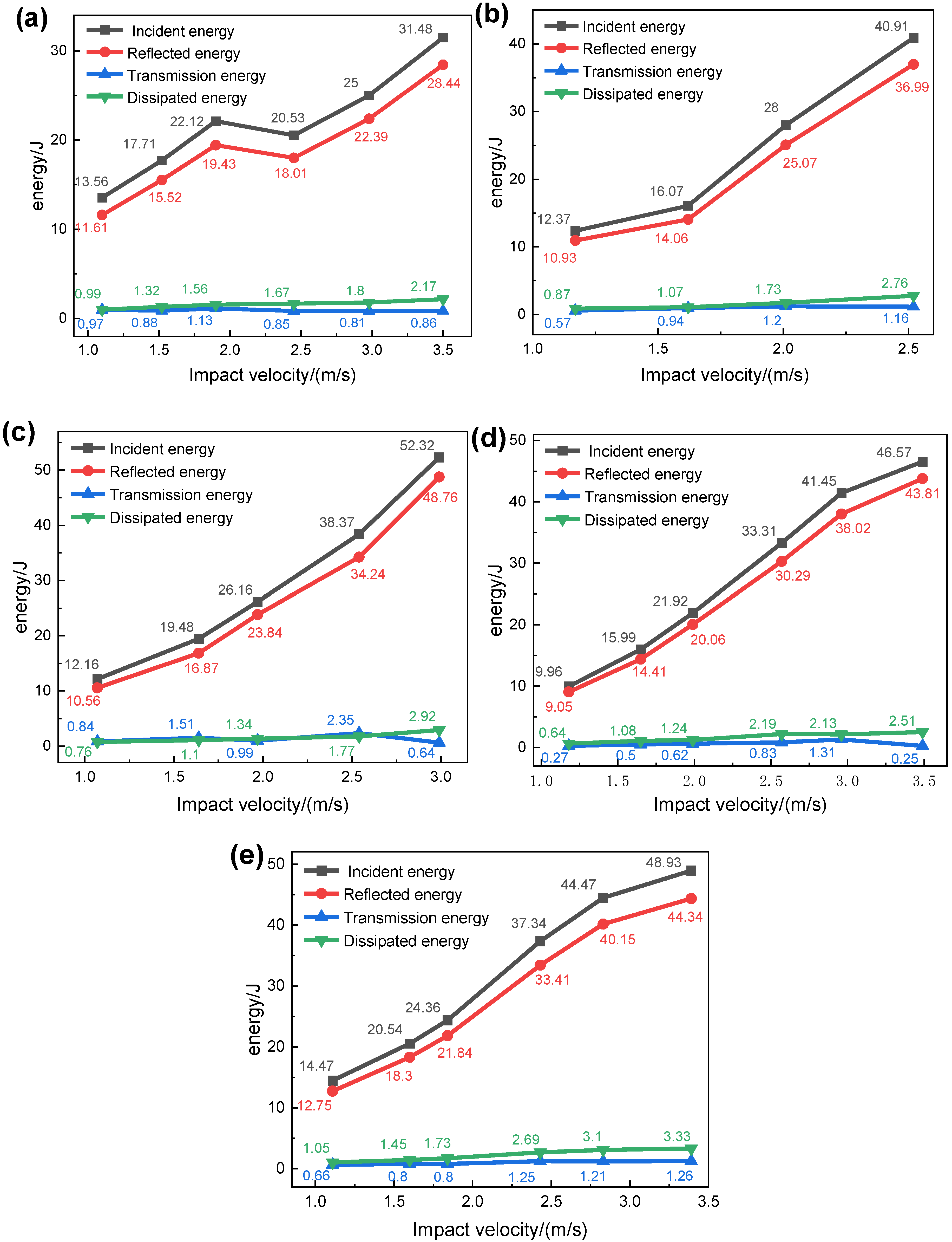

3.1.2. The Relationship between the Energy of the Impact Process and the Impact Velocity

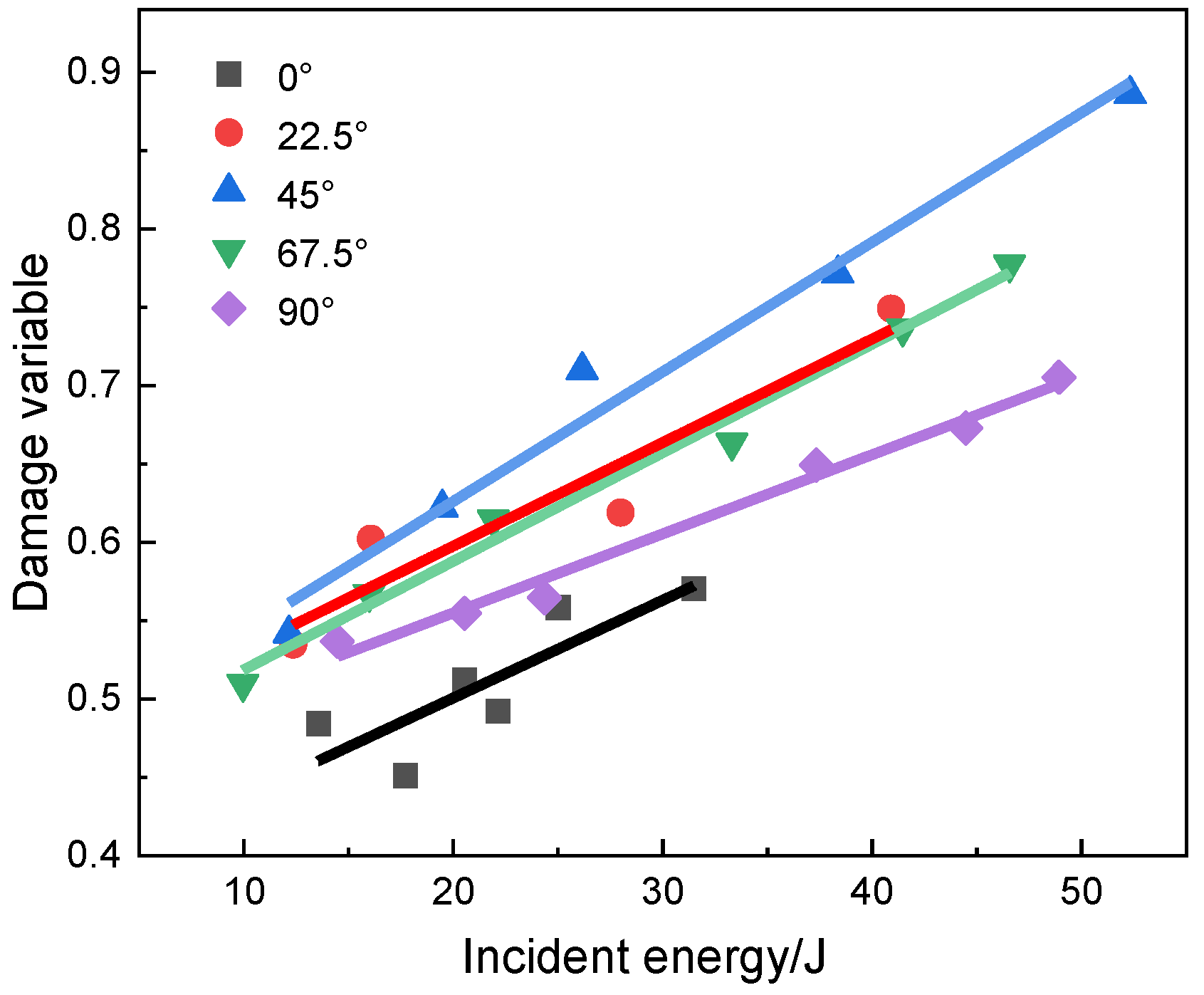

3.2. Calculation of Damage Variables for Specimens with Different Inclination Angles

3.3. Characteristics of the EMR Response of Samples with Different Inclination Angles

3.4. Frequency Characteristics of EMR of Samples with Different Inclination Angles

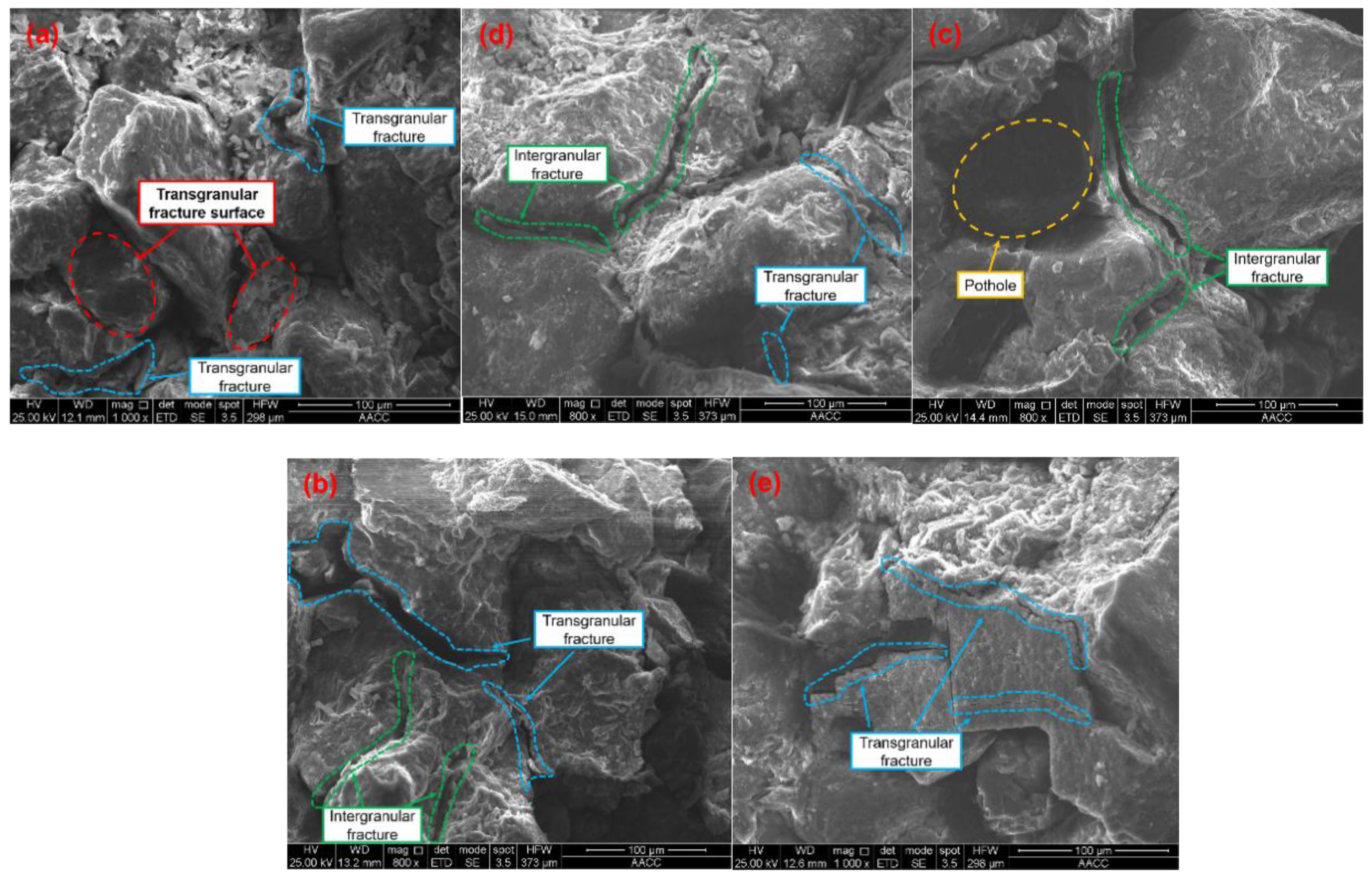

3.5. Analysis of the Energy Dissipation of the Impact Failure of Specimens with Different Inclination Angles

3.6. Analysis of the EMR Response to the Impact Damage of Specimens with Different Inclination Angles

3.7. Analysis of the Influence of the Inclination Angle on the EMR Response of the Sample Damage

4. Conclusions

- (1)

- In the process of impact damage, as the energy carried by the stress wave gradually increased, the dissipated energy density and damage degrees of the sample gradually increased, and there was a significant linear relationship. At the same time, the crack inclination had a significant effect on both. Under the same incident energy condition, the sample with α = 45° was mainly characterized by intergranular fracture, the dissipated energy density was the smallest, but the damage degree was the largest. On the contrary, the samples of α = 0° and 90° were dominated by transgranular fracture, the dissipated energy density was the largest, but the damage degrees was the smallest. The α = 22.5° and 67.5° specimens showed the combined characteristics of intergranular fracture and transgranular fracture, and the dissipated energy density and damage degrees were in the middle.

- (2)

- During the impact experiment, the sandstone damage response to EMR had a good incident energy effect; in particular, as the incident energy increased, the free charge density generated by the piezoelectric effect, crack propagation, and friction effects increased, and the EMR energy gradually increased. When the stress wave energy reached a certain threshold, the EMR energy began to rise rapidly.

- (3)

- The EMR signal of the sample with α = 45° mainly originated from crack propagation and frictional electrification. The free electron density was the highest, and the EMR response was relatively strong. However, the EMR signals of the samples with α = 22.5° and 67.5° mainly originated from crack propagation, the free electron density was relatively small, and the EMR response was relatively small. Finally, the EMR signals generated by the α = 0° and 90° samples were mainly derived from the piezoelectric effect and crack propagation, the free electron density was minimized, and the EMR response was correspondingly minimized.

- (4)

- During the impact damage process, the main frequency range of EMR was 0~5 kHz. As the energy carried by the stress wave gradually increased, the dominant frequency band of the main frequency expanded from low frequency to high frequency, and the amplitude signal gradually increased. At the same time, the EMR frequency characteristics of samples with different inclination angles were also different. The sample frequency domain was relatively wide, and the amplitude was relatively large. The α = 0° and 90° samples had the narrowest frequency domain and relatively smallest amplitude. This discovery has certain guiding significance for the use of frequency band monitoring in engineering practice. However, the time-frequency response and waveform analysis of EMR under an impact load have not yet been defined.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cai, M.; Brown, E.T. Challenges in the Mining and Utilization of Deep Mineral Resources. Engineering 2017, 3, 432–433. [Google Scholar] [CrossRef]

- He, M.; Xie, H.; Peng, S.; Jiang, Y. Study on rock mechanics in deep mining engineering. Chin. J. Rock Mech. Eng. 2005, 24, 2803–2813. [Google Scholar]

- Jiang, Y.; Pan, Y.; Jiang, F.; Dou, L.; Ju, Y. State of the art review on mechanism and prevention of coal bumps in China. J. China Coal Soc. 2014, 39, 205–213. [Google Scholar]

- Xie, H.; Ju, Y.; Li, L. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles. Chin. J. Rock Mech. Eng. 2005, 24, 3003–3010. [Google Scholar]

- Cheng, Y.; Song, Z.; Jin, J.; Wang, T.; Yang, T. Waveform characterization and energy dissipation of stress wave in sandstone based on modified SHPB tests. Geomech. Eng. 2020, 22, 187–196. [Google Scholar]

- Luo, Y.; Wang, G.; Li, X.; Liu, T.; Mandal, A.K.; Xu, M.; Xu, K. Analysis of energy dissipation and crack evolution law of sandstone under impact load. Int. J. Rock Mech. Min. Sci. 2020, 132, 104359. [Google Scholar] [CrossRef]

- Ping, Q.; Fang, Z.; Ma, D.; Zhang, H. Coupled Static-Dynamic Tensile Mechanical Properties and Energy Dissipation Characteristic of Limestone Specimen in SHPB Tests. Adv. Civ. Eng. 2020, 2020, 7172928. [Google Scholar] [CrossRef] [Green Version]

- Liang, W.; Zhao, J.; Li, Y.; Zhai, Y. Research on the Fractal Characteristics and Energy Dissipation of Basalt Fiber Reinforced Concrete after Exposure to Elevated Temperatures under Impact Loading. Materials 2020, 13, 1902. [Google Scholar] [CrossRef]

- Ma, Q.; Huang, K.; Ma, D. Energy absorption characteristics and theoretical analysis of frozen clay with pre-existing cracks under uniaxial compressive impact load. Cold Reg. Sci. Technol. 2020, 182, 103206. [Google Scholar] [CrossRef]

- Zhou, S.-Q.; Zhou, D.-W.; Zhang, Y.-F.; Wang, W.-J.; Li, D. Research on the Dynamic Mechanical Properties and Energy Dissipation of Expansive Soil Stabilized by Fly Ash and Lime. Adv. Mater. Sci. Eng. 2019, 2019, 5809657. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.; Xia, K.; Zheng, H. Observation of microscopic damage accumulation in brittle solids subjected to dynamic compressive loading. Rev. Sci. Instrum. 2013, 84, 093903. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhai, Y.; Liu, X.; Liang, W. Research on Fractal Characteristics and Energy Dissipation of Concrete Suffered Freeze-Thaw Cycle Action and Impact Loading. Materials 2019, 12, 2585. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Li, Y.; Zhao, F.; Zhou, Y.; Wang, W.; Li, S. Experimental Research on Mechanical and Energy Characteristics of Reinforced Rock under Dynamic Loading. Shock Vib. 2019, 2019, 4356729. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Dai, F.; Zhang, R.; Liu, J. Static and dynamic uniaxial compression tests on coal rock considering the bedding directivity. Environ. Earth Sci. 2015, 73, 5933–5949. [Google Scholar] [CrossRef]

- Song, D.; Wang, E.; Liu, J. Relationship between EMR and dissipated energy of coal rock mass during cyclic loading process. Saf. Sci. 2012, 50, 751–760. [Google Scholar] [CrossRef]

- Yang, D.; Hu, J.; Ding, X. Analysis of energy dissipation characteristics in granite under high confining pressure cyclic load. Alex. Eng. J. 2020, 59, 3587–3597. [Google Scholar] [CrossRef]

- Whittles, D.; Kingman, S.; Lowndes, I.; Jackson, K. Laboratory and numerical investigation into the characteristics of rock fragmentation. Miner. Eng. 2006, 19, 1418–1429. [Google Scholar] [CrossRef]

- Xie, H.; Eng, R.P.; Ju, Y. Energy dissipation of rock deformation and fracture. Chin. J. Rock Mech. Eng. 2004, 23, 3565–3570. [Google Scholar]

- Li, D.; Wang, E.; Li, Z.; Jia, H.; Wang, X.; Kong, X.; Wang, X.; Wang, A. Muhammad, A causal mechanism for anomalous electromagnetic radiations from coal and rock failureElectromagnetic radiation mechanism. Geophysics 2018, 83, E423–E434. [Google Scholar] [CrossRef]

- Qiu, L.; Song, D.; Li, Z.; Liu, B.; Liu, J. Research on AE and EMR response law of the driving face passing through the fault. Saf. Sci. 2019, 117, 184–193. [Google Scholar] [CrossRef]

- Wang, E.Y.; Wang, Y.-G.; Li, Z.H.; Liu, X.F.; Zhao, E.-L. Experimental study on the microwave radiation precursor laws of loading coal in deformation and fracture process. Chin. J. Geophys. 2011, 51, 2429–2436. [Google Scholar]

- Kong, B.; Wang, E.; Li, Z. Regularity and coupling correlation between acoustic emission and electromagnetic radiation during rock heating process. Geomech. Eng. 2018, 15, 1125–1133. [Google Scholar]

- Kong, B.; Wang, E.; Li, Z.; Lu, W. Study on the feature of electromagnetic radiation under coal oxidation and temperature rise based on multifractal theory. Fractals 2019, 27, 1950038. [Google Scholar] [CrossRef]

- Li, D.; Wang, E.; Kong, X.; Zhao, S.; Kong, Y.; Wang, X.; Wang, D.; Liu, Q. Mechanical properties and electromagnetic radiation characteristics of concrete specimens after exposed to elevated temperatures. Constr. Build. Mater. 2018, 188, 381–390. [Google Scholar]

- Li, H.; Shen, R.; Wang, E.; Li, D.; Li, T.; Chen, T.; Hou, Z. Effect of water on the time-frequency characteristics of electromagnetic radiation during sandstone deformation and fracturing. Eng. Geol. 2020, 265, 105451. [Google Scholar] [CrossRef]

- Shen, R.; Li, T.; Li, H.; He, S.; Zhao, E.; Hou, Z.; Chen, T. Study on the effect of water on electromagnetic radiation characteristics of fractured sandstone under load. Environ. Earth Sci. 2021, 80, 87. [Google Scholar] [CrossRef]

- Wang, E.; Jia, H.; Song, D.; Li, N.; Qian, W. Use of ultra-low-frequency electromagnetic emission to monitor stress and failure in coal mines. Int. J. Rock Mech. Min. Sci. 2014, 70, 16–25. [Google Scholar] [CrossRef]

- Shen, R.; Li, H.; Wang, E.; Li, D.; Hou, Z.; Zhang, X.; Han, X. Mechanical behavior and AE and EMR characteristics of natural and saturated coal samples in the indirect tensile process. J. Geophys. Eng. 2019, 16, 753–763. [Google Scholar] [CrossRef]

- Wang, E.; He, X.; Liu, X.; Li, Z.; Wang, C.; Xiao, D. A non-contact mine pressure evaluation method by electromagnetic radiation. J. Appl. Geophys. 2011, 75, 338–344. [Google Scholar] [CrossRef]

- Ai, D.; Zhao, Y.; Wang, Q.; Li, C. Crack propagation and dynamic properties of coal under SHPB impact loading: Experimental investigation and numerical simulation. Theor. Appl. Fract. Mech. 2020, 105, 102393. [Google Scholar] [CrossRef]

- Zhou, Y.; Xia, K.; Li, X.; Li, H.; Ma, G.; Zhao, J.; Zhou, Z.; Dai, F. Suggested methods for determining the dynamic strength parameters and mode-I fracture toughness of rock materials. Int. J. Rock Mech. Min. Sci. 2012, 49, 105–112. [Google Scholar] [CrossRef]

- Li, X.B.; Lok, T.S.; Zhao, J. Dynamic Characteristics of Granite Subjected to Intermediate Loading Rate. Rock Mech. Rock Eng. 2004, 38, 21–39. [Google Scholar] [CrossRef]

- Xu, J.; Liu, S. Analysis of energy dissipation rule during deformation and fracture process of rock under high temperatures in SHPB test. Chin. J. Rock Mech. Eng. 2013, 32, 3109–3115. [Google Scholar]

- Ping, Q.; Ma, Q.; Yuan, P. Energy dissipation analysis of stone specimens in SHPB tensile test. J. Min. Saf. Eng. 2013, 30, 401–407. [Google Scholar]

- Song, L.; Hu, S. Two-wave method and three-wave method in SHPB data processing. Explos. Shock. Waves 2005, 25, 368–373. [Google Scholar]

- Lundberg, B. A split Hopkinson bar study of energy absorption in dynamic rock fragmentation. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 1976, 13, 187–197. [Google Scholar] [CrossRef]

- Hong, L.; Zhou, Z.-L.; Yin, T.-B.; Liao, G.-Y.; Ye, Z.-Y. Energy consumption in rock fragmentation at intermediate strain rate. J. Central South Univ. Technol. 2009, 16, 677–682. [Google Scholar] [CrossRef]

- Li, Z.; Xu, Z.; Xie, H.; Ju, Y.; Ma, X.; Han, Z. Failure experimental study on energy laws of rock under differential dynamic impact velocities. J. China Coal Soc. 2011, 36, 2007–2011. [Google Scholar]

- Zhao, Y.; Gong, S.; Huang, Y. Experimental study on energy dissipation characteristics of coal samples under impact loading. J. China Coal Soc. 2015, 40, 2320–2326. [Google Scholar]

- Song, X.; Li, X.; Li, Z.; Zhang, Z.; Cheng, F.; Chen, P.; Liu, Y. Study on the characteristics of coal rock electromagnetic radiation (EMR) and the main influencing factors. J. Appl. Geophys. 2018, 148, 216–225. [Google Scholar] [CrossRef]

| Crack Inclination/° | Impact Velocity/(m/s) | Incident Energy Wi/J | Reflected Energy Wr/J | Transmission Energy Wt/J | Dissipated Energy Wd/J | Energy Density/(J/cm3) | Dynamic Strength/MPa |

|---|---|---|---|---|---|---|---|

| 0 | 1.1 | 13.56 | 11.61 | 0.97 | 0.99 | 0.0071 | 33.65 |

| 1.52 | 17.71 | 15.52 | 0.88 | 1.32 | 0.0094 | 32.15 | |

| 1.9 | 22.12 | 19.43 | 1.13 | 1.56 | 0.0111 | 37.77 | |

| 2.45 | 20.53 | 18.01 | 0.85 | 1.67 | 0.0120 | 37.28 | |

| 2.98 | 25.00 | 22.39 | 0.81 | 1.80 | 0.0129 | 42.09 | |

| 3.5 | 31.48 | 28.44 | 0.86 | 2.17 | 0.0155 | 37.77 | |

| 22.5 | 1.17 | 12.37 | 10.93 | 0.57 | 0.87 | 0.0062 | 23.19 |

| 1.62 | 16.07 | 14.06 | 0.94 | 1.07 | 0.0076 | 29.70 | |

| 2.01 | 28.00 | 25.07 | 1.20 | 1.73 | 0.0124 | 32.48 | |

| 2.52 | 40.91 | 36.99 | 1.16 | 2.76 | 0.0197 | 31.13 | |

| 45 | 1.07 | 12.16 | 10.56 | 0.84 | 0.76 | 0.0054 | 18.77 |

| 1.64 | 19.48 | 16.87 | 1.51 | 1.10 | 0.0079 | 24.53 | |

| 1.97 | 26.16 | 23.84 | 0.99 | 1.34 | 0.0095 | 25.48 | |

| 2.54 | 38.37 | 34.24 | 2.35 | 1.77 | 0.0127 | 31.92 | |

| 2.99 | 52.32 | 48.76 | 0.64 | 2.92 | 0.0208 | 26.92 | |

| 67.5 | 1.18 | 9.96 | 9.05 | 0.27 | 0.64 | 0.0046 | 24.27 |

| 1.65 | 15.99 | 14.41 | 0.50 | 1.08 | 0.0077 | 30.09 | |

| 1.99 | 21.92 | 20.06 | 0.62 | 1.24 | 0.0089 | 27.14 | |

| 2.57 | 33.31 | 30.29 | 0.83 | 2.19 | 0.0156 | 32.28 | |

| 2.96 | 41.45 | 38.02 | 1.31 | 2.13 | 0.0152 | 32.77 | |

| 3.49 | 46.57 | 43.81 | 0.25 | 2.51 | 0.0179 | 31.30 | |

| 90 | 1.11 | 14.47 | 12.75 | 0.66 | 1.05 | 0.0075 | 26.29 |

| 1.6 | 20.54 | 18.30 | 0.80 | 1.45 | 0.0104 | 31.27 | |

| 1.84 | 24.36 | 21.84 | 0.80 | 1.73 | 0.0123 | 29.07 | |

| 2.43 | 37.34 | 33.41 | 1.25 | 2.69 | 0.0192 | 38.43 | |

| 2.83 | 44.47 | 40.15 | 1.21 | 3.10 | 0.0222 | 41.18 | |

| 3.39 | 48.93 | 44.34 | 1.26 | 3.33 | 0.0238 | 38.23 |

| Crack Inclination/° | Incident Energy/J | Total Absorbed Energy Density u/(J/cm3) | Total Dissipated Energy Density εd/(J/cm3) | Damage Variable/D |

|---|---|---|---|---|

| 0 | 13.56 | 0.0146 | 0.0071 | 0.48 |

| 17.71 | 0.0208 | 0.0094 | 0.45 | |

| 22.12 | 0.0226 | 0.0111 | 0.49 | |

| 20.53 | 0.0233 | 0.0119 | 0.51 | |

| 25.00 | 0.0230 | 0.0128 | 0.55 | |

| 31.48 | 0.0272 | 0.0155 | 0.57 | |

| 22.5 | 12.37 | 0.0116 | 0.0062 | 0.53 |

| 16.07 | 0.0126 | 0.0076 | 0.61 | |

| 28.00 | 0.0199 | 0.0123 | 0.61 | |

| 40.91 | 0.0263 | 0.0197 | 0.74 | |

| 45 | 12.16 | 0.0099 | 0.0054 | 0.54 |

| 19.48 | 0.0126 | 0.0078 | 0.62 | |

| 26.16 | 0.0134 | 0.0095 | 0.71 | |

| 38.37 | 0.0163 | 0.0126 | 0.77 | |

| 52.32 | 0.0235 | 0.0208 | 0.88 | |

| 67.5 | 9.96 | 0.0089 | 0.0045 | 0.51 |

| 15.99 | 0.0135 | 0.0077 | 0.56 | |

| 21.92 | 0.0144 | 0.0088 | 0.61 | |

| 33.31 | 0.0235 | 0.0156 | 0.66 | |

| 41.45 | 0.0206 | 0.0151 | 0.73 | |

| 46.57 | 0.0230 | 0.0179 | 0.77 | |

| 90 | 14.47 | 0.0140 | 0.0075 | 0.53 |

| 20.54 | 0.0186 | 0.0103 | 0.55 | |

| 24.36 | 0.0218 | 0.0123 | 0.56 | |

| 37.34 | 0.0295 | 0.0191 | 0.64 | |

| 44.47 | 0.0329 | 0.0221 | 0.67 | |

| 48.93 | 0.0336 | 0.0237 | 0.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zang, Z.; Li, Z.; Niu, Y.; Tian, H.; Zhang, X.; Li, X.; Ali, M. Energy Dissipation and Electromagnetic Radiation Response of Sandstone Samples with a Pre-Existing Crack of Various Inclinations under an Impact Load. Minerals 2021, 11, 1363. https://doi.org/10.3390/min11121363

Zang Z, Li Z, Niu Y, Tian H, Zhang X, Li X, Ali M. Energy Dissipation and Electromagnetic Radiation Response of Sandstone Samples with a Pre-Existing Crack of Various Inclinations under an Impact Load. Minerals. 2021; 11(12):1363. https://doi.org/10.3390/min11121363

Chicago/Turabian StyleZang, Zesheng, Zhonghui Li, Yue Niu, He Tian, Xin Zhang, Xiaoliang Li, and Muhammad Ali. 2021. "Energy Dissipation and Electromagnetic Radiation Response of Sandstone Samples with a Pre-Existing Crack of Various Inclinations under an Impact Load" Minerals 11, no. 12: 1363. https://doi.org/10.3390/min11121363

APA StyleZang, Z., Li, Z., Niu, Y., Tian, H., Zhang, X., Li, X., & Ali, M. (2021). Energy Dissipation and Electromagnetic Radiation Response of Sandstone Samples with a Pre-Existing Crack of Various Inclinations under an Impact Load. Minerals, 11(12), 1363. https://doi.org/10.3390/min11121363