Coal Moisture Variations in Response to Rainfall Event in Mines and Coal-Fired Power Plant Stockpiles—Part 1: Runoff, Infiltration, and Drainage

Abstract

:1. Introduction

1.1. Background

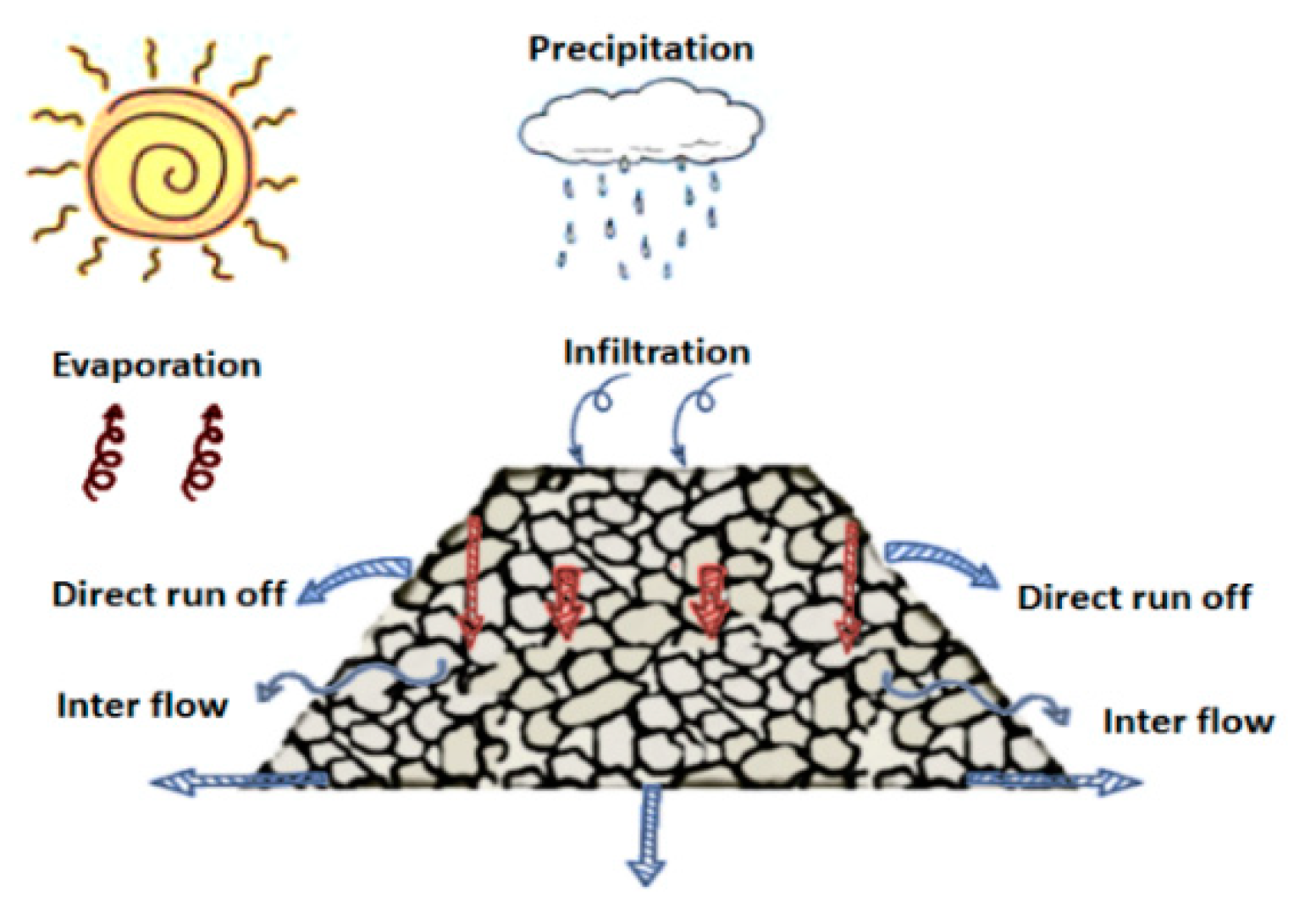

1.2. Mechanics of Water Movement in Stockpiles

2. Experimental Methods

2.1. Materials

2.2. Method and Site Description

2.2.1. Runoff and Infiltration

2.2.2. Gravity Drainage

3. Results and Discussion

3.1. Runoff

3.1.1. Effect of Rainfall Intensity

3.1.2. Effect of Slope Angle

3.1.3. Effect of Particle Size Distribution

3.1.4. Degree of Compaction

3.2. Infiltration Rate

3.3. Gravity Drainage

3.3.1. Effect of Bed Height

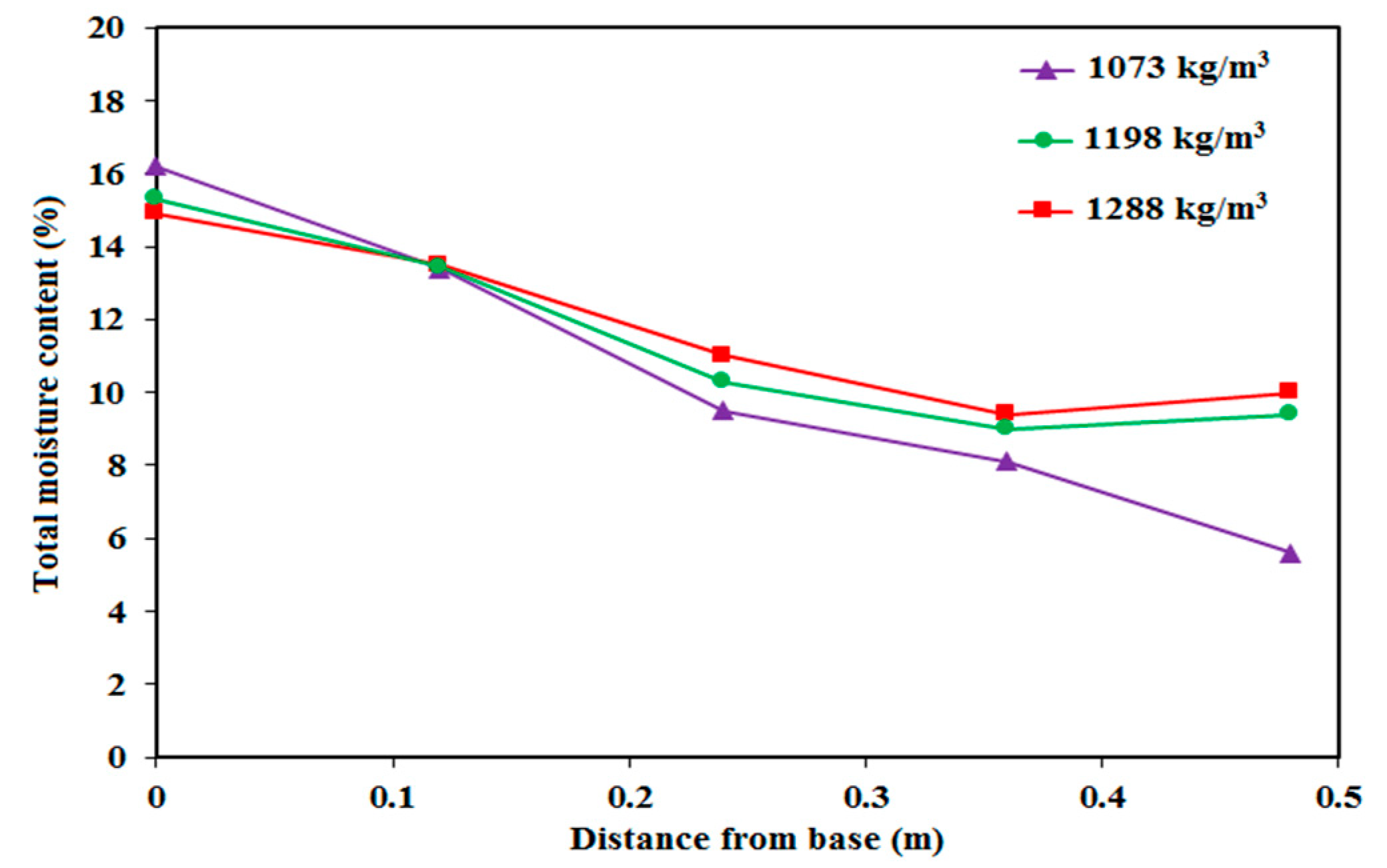

3.3.2. Effect of Degree of Compaction

3.3.3. Effect of Particle Size Ranges

3.3.4. Effect of Coal Type

3.3.5. Data Validation

4. Conclusions

- There was a positive relationship between the proportion of surface runoff, and rainfall intensity, angle of repose, fine content, and the degree of compaction. Results indicated that the final rate of infiltration is dependent on the characteristics of the stockpile surface. A stockpile consisting of coarse particles has much larger infiltration capacity. A smaller angle of repose results in longer contact time between stockpile surface and water, which increases the proportion of rainfall that infiltrates the stockpile. A decrease in the size of interparticulate voids (either through compaction or high fine content) leads to increased surface runoff. To minimise infiltration, stockpile surfaces should be compacted at an angle that minimises the contact time between surface and water, reducing the possibility of erosion occurring.

- Results confirmed that particle size distribution (PSD) plays a large role in determining the extent to which a coal stockpile is dewatered by means of drainage. The −0.5 mm particles had a large effect on the amount of water retained by a coal sample. Increased stockpile height positively influences the degree of dewatering. A comparison between the drainage profiles of the two coal types studied in this investigation showed that high ash and clay mineral content leads to more water being retained by the coal stockpile. It may thus be more difficult to dewater certain coals by means of gravity drainage.

- In Part 2 of this work, the effect of coal particle size and ambient conditions on the rate and depth of moisture evaporation within the stockpile will be reported.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, H.; Zhang, Y.; Qu, B.; Liao, Q.; Wang, H.; Gao, R. Thermodynamic characteristics of methane adsorption about coking coal molecular with different sulfur components: Considering the influence of moisture contents. J. Nat. Gas Sci. Eng. 2021, 94, 104053. [Google Scholar] [CrossRef]

- Liu, L.; Cheng, L.; Zhao, L.T.; Cao, Y.; Wang, C. Investigating the significant variation of coal consumption in china in 2002–2017. Energy 2020, 207, 118307. [Google Scholar] [CrossRef]

- Hartnady, C. South Africa’s diminishing coal reserves. S. Afr. J. Sci. 2010, 106, 1–5. [Google Scholar] [CrossRef] [Green Version]

- South African Energy Sector Report 2019. Available online: http://www.energy.gov.za/files/media/explained/2019-South-African-Energy-Sector-Report.pdf (accessed on 5 April 2021).

- Campbell, Q.P.; Le Roux, M.; Smith, I.G.T. Water-only laboratory coal fractionation using the reflux classifier. Miner. Eng. 2015, 83, 59–63. [Google Scholar] [CrossRef]

- Buckley, A.N.; Nicol, S.K. Investigation Report CET/IR273: Surface-Related Moisture Retention Characteristics of Coal; CSIRO: Sydney, Australia, 1995. [Google Scholar]

- Karthikeyan, M. Minimization of moisture readsorption in dried coal samples. Dry. Technol. 2008, 26, 948–955. [Google Scholar] [CrossRef]

- Nkolele, A. Investigations into the reduction of moisture in fine coal by plant tests with surfactants. J. S. Afr. Inst. Min. Metall. 2004, 104, 171–176. [Google Scholar]

- Mao, Y.; Xia, W.; Xie, G.; Peng, Y. Rapid detection of the total moisture content of coal fine by low-field nuclear magnetic resonance. Measurement 2020, 155, 107564. [Google Scholar] [CrossRef]

- Williams, D.J. Application of unsaturated soil mechanics to product coal dewatering. In Proceedings of the 2006 Australian Mining Technology Conference, Hunter Valley, NSW, Australia, 26–27 September 2006; pp. 223–235. [Google Scholar]

- Osman, H.; Jangam, S.V.; Lease, J.D.; Mujumdar, A.S. Drying of low-rank coal (LRC)—A review of recent patents and innovations. Dry. Technol. 2011, 29, 1763–1783. [Google Scholar] [CrossRef]

- Lu, H.; Guo, X.; Jin, Y.; Gong, X. Effect of moisture on flowability of pulverized coal. Chem. Eng. Res. Des. 2018, 133, 326–334. [Google Scholar] [CrossRef]

- Curran, K.J.; Droppo, I.G.; Irvine, K.N. Hydrology of stockpiled industrial coal exposed to rainfall. Hydrol. Process. 2002, 16, 2781–2790. [Google Scholar] [CrossRef]

- Campbell, Q.; Le Roux, M.; Espag, C. Coal product moisture control using stockpiles. In Proceedings of the XVIII International Coal Preparation Congress, Saint-Petersburg, Russia, 28 June–1 July 2016; Litvinenko, V., Ed.; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Le Roux, M.; Campbell, Q.P. An investigation into an improved method of fine coal dewatering. Miner. Eng. 2003, 16, 999–1003. [Google Scholar] [CrossRef]

- Le Roux, M.; Campbell, Q.P.; Watermeyer, M.S.; de Oliveira, S. The optimization of an improved method of fine coal dewatering. Miner. Eng. 2005, 18, 931–934. [Google Scholar] [CrossRef]

- Goede, J.; Muller, B.; Campbell, Q.P.; Le Roux, M.; Espag, C.B. The effect of particle size on the rate and depth of moisture evaporation from coal stockpiles. J. S. Afr. Inst. Min. Metall. 2016, 116, 353–355. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Ren, T.; Liang, Y.; Wang, Z. A review on numerical solutions to self-heating of coal stockpile: Mechanism, theoretical basis, and variable study. Fuel 2016, 182, 80–109. [Google Scholar] [CrossRef] [Green Version]

- Davis, E.C.; Boegly, W.J. A review of water quality issues associated with coal storage. J. Environ. Qual. 1981, 10, 127–133. [Google Scholar] [CrossRef]

- Agassi, M.; Shainberg, I.; Morin, J. Effect of electrolyte concentration and soil sodicity on the infiltration rate and crust formation. Soil Sci. Soc. Am. J. 1981, 45, 848–851. [Google Scholar] [CrossRef]

- Huang, P.; Wu, P.; Zhao, X. Effects of rainfall intensity, underlying surface and slope gradient on soil infiltration under simulated rainfall experiments. Catena 2012, 104, 93–102. [Google Scholar] [CrossRef]

- Luo, H.; Rong, Y.; Lv, J.; Xie, Y. Runoff erosion processes on artificially constructed conically-shaped overburdened stockpiles with different gravel contents: Laboratory experiments with simulated rainfall. CATENA 2019, 175, 93–100. [Google Scholar] [CrossRef]

- Roberts, J.; Jepsen, R.; Gotthard, D.; Lick, W. Effects of particle size and bulk density on erosion of quartz particles. J. Hydraul. Eng. 1998, 124, 531–538. [Google Scholar] [CrossRef]

- Ekmann, J.M.; Le, P.H. Coal Storage and Transportation. Encycl. Energy 2014, 1, 557–558. [Google Scholar]

- Wels, C.; Louden, S.; Fortin, S. Factors Influencing Net Infiltration into Mine Rock Piles at Questa Mine New Mexico. Available online: https://www.rgc.ca/files/publications/welfin.pdf (accessed on 8 August 2015).

- Espag, C. Water Transport Mechanisms in Coal Stockpiles. Master’s Thesis, North-West University, Potchefstroom, South Africa, 2015; p. 14. [Google Scholar]

| Parameters | Coal A | Coal B | Standard |

|---|---|---|---|

| Inherent moisture content (%) | 2.5 | 2.6 | ISO 11722: 1999 |

| Ash content (%) | 35.6 | 15.9 | ISO 1171: 2010 |

| Volatile matter (%) | 19.0 | 25.2 | ISO 562: 2010 |

| Fixed carbon (%) | 42.9 | 56.4 | -N/A |

| Gross Calorific Value (CV) (MJ/kg) | 19.24 | 26.89 | ISO 1928: 2009 |

| Grade (based on CV) | Grade D-III | Grade B | CKS 561-1982 |

| Mineral | Weight (%) | |

|---|---|---|

| Coal A | Coal B | |

| Calcite | 0.43 | 1.14 |

| Dolomite | 0.42 | 0.97 |

| Graphite | 66.15 | 83.29 |

| Gypsum | 1.79 | 0.11 |

| Hematite | 0.33 | 0.00 |

| Kaolinite | 21.85 | 12.66 |

| Muscovite | 2.25 | 0.79 |

| Pyrite | 0.71 | 0.17 |

| Quartz | 5.91 | 0.89 |

| Siderite | 0.16 | 0.00 |

| Rainfall Intensity (mm/h) | Slope Angle (°) | Size Range (mm) |

|---|---|---|

| Without compaction (ρ = 997 kg/m3) | ||

| 174–220–290 | 20–30–38 | (−53 + 6.7), (−53 + 0), (−6.7 + 0) |

| With compaction (ρ = 1069–1157 kg/m3) | ||

| 174–220–290 | 20–30–38 | (−53 + 0) |

| Column Height (m) | Coal Type | Size Range (mm) | ρ (kg/m3) | Layer of Fines (−0.5 mm) |

|---|---|---|---|---|

| 0.48 | A | (−53 + 0); (−53 + 0.5) | 1073–1198–1288 | 0–3–6 cm |

| 2 | A | (−53 + 0); (−53 + 0.5); (−53 + 1) | 1073 | Without layer of fines |

| 2 | B | (−53 + 0); (−53 + 6.7); (−6.7 + 0) | 1069 | Without layer of fines |

| Column Height (m) | Size Range | ρ (kg/m3) | Retained Water (kg) |

|---|---|---|---|

| 0.48 | −53 to 0 mm | 1073 | 3.63 |

| 1073 | 4.27 | ||

| Average | 3.95 | ||

| 2 | −53 to 0 mm | 1044 | 9.29 |

| 1054 | 9.51 | ||

| Average | 9.40 | ||

| ρ (kg/m3) | Retained Water (kg) |

|---|---|

| 1073 | 3.63 |

| 4.27 | |

| 3.78 | |

| Average | 3.89 |

| 1198 | 4.17 |

| 4.63 | |

| 4.2 | |

| Average | 4.33 |

| 1288 | 4.51 |

| 4.06 | |

| 4.93 | |

| Average | 4.5 |

| Size Range | Layer of Fines | Retained Water (kg) |

|---|---|---|

| −53 to 0 mm | Without layer of fines | 3.63 |

| 4.27 | ||

| Average | 3.95 | |

| −53 to 0.5 mm | Without layer of fines | 2.99 |

| 2.37 | ||

| Average | 2.68 | |

| −53 to 0 mm | 3 cm | 3.86 |

| 3.34 | ||

| Average | 3.60 | |

| −53 to 0 mm | 6 cm | 4.91 |

| 5.99 | ||

| Average | 5.45 | |

| Coal Type | Size Range | ρ (kg/m3) | Retained Water (kg) |

|---|---|---|---|

| A | −53 to 0 mm | 1029 | 9.29 |

| 1044 | 9.51 | ||

| Average | 9.40 | ||

| −53 to 0.5 mm | 1012 | 8.00 | |

| 985 | 8.20 | ||

| Average | 8.1 | ||

| −53 to 1 mm | 989 | 7.88 | |

| 1024 | 7.67 | ||

| Average | 7.77 | ||

| B | 53 to 0 mm | 879 | 3.85 |

| 879 | 3.78 | ||

| 879 | 4.68 | ||

| Average | 4.1 | ||

| −53 to 6.7 mm | 659 | 0.88 | |

| 659 | 1.20 | ||

| 659 | 2.16 | ||

| Average | 1.41 | ||

| −6.7 to 0 mm | 743 | 6.41 | |

| 743 | 5.07 | ||

| 743 | 5.01 | ||

| Average | 5.49 | ||

| Time Period | Position | Input (kg) | Initial Mass (kg) | Final Mass (kg) | Accumulated (kg) | Output (kg) | Actual out (kg) | Difference (kg) |

|---|---|---|---|---|---|---|---|---|

| Days 0–2 (2 days) | A | 20.00 | 2.4 | 2.81 | 0.41 | 19.59 | ||

| B | 19.59 | 2.67 | 1.92 | −0.75 | 20.34 | |||

| C | 20.34 | 2.81 | 2.23 | −0.58 | 20.92 | |||

| D | 20.92 | 2.44 | 2.72 | 0.28 | 20.64 | 18.52 | 2.12 | |

| Days 2–4 (2 days) | A | 0.00 | 2.81 | 2.24 | −0.57 | 0.57 | ||

| B | 0.57 | 1.92 | 2.32 | 0.4 | 0.17 | |||

| C | 0.17 | 2.81 | 2.30 | 0.08 | 0.09 | |||

| D | 0.09 | 2.72 | 2.71 | 0.02 | 0.02 | 0.00 | 0.02 | |

| Days 4–7 (3 days) | A | 0.00 | 2.24 | 1.96 | −0.28 | 0.28 | ||

| B | 0.28 | 2.32 | 2.24 | −0.08 | 0.08 | |||

| C | 0.08 | 2.30 | 2.27 | −0.03 | 0.03 | |||

| D | 0.03 | 2.71 | 2.48 | −0.23 | 0.23 | 0.00 | 0.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Campbell, Q.P.; le Roux, M.; Nakhaei, F. Coal Moisture Variations in Response to Rainfall Event in Mines and Coal-Fired Power Plant Stockpiles—Part 1: Runoff, Infiltration, and Drainage. Minerals 2021, 11, 1365. https://doi.org/10.3390/min11121365

Campbell QP, le Roux M, Nakhaei F. Coal Moisture Variations in Response to Rainfall Event in Mines and Coal-Fired Power Plant Stockpiles—Part 1: Runoff, Infiltration, and Drainage. Minerals. 2021; 11(12):1365. https://doi.org/10.3390/min11121365

Chicago/Turabian StyleCampbell, Quentin Peter, Marco le Roux, and Fardis Nakhaei. 2021. "Coal Moisture Variations in Response to Rainfall Event in Mines and Coal-Fired Power Plant Stockpiles—Part 1: Runoff, Infiltration, and Drainage" Minerals 11, no. 12: 1365. https://doi.org/10.3390/min11121365

APA StyleCampbell, Q. P., le Roux, M., & Nakhaei, F. (2021). Coal Moisture Variations in Response to Rainfall Event in Mines and Coal-Fired Power Plant Stockpiles—Part 1: Runoff, Infiltration, and Drainage. Minerals, 11(12), 1365. https://doi.org/10.3390/min11121365