Prediction of Uniaxial Compression Strength of Limestone Based on the Point Load Strength and SVM Model

Abstract

:1. Introduction

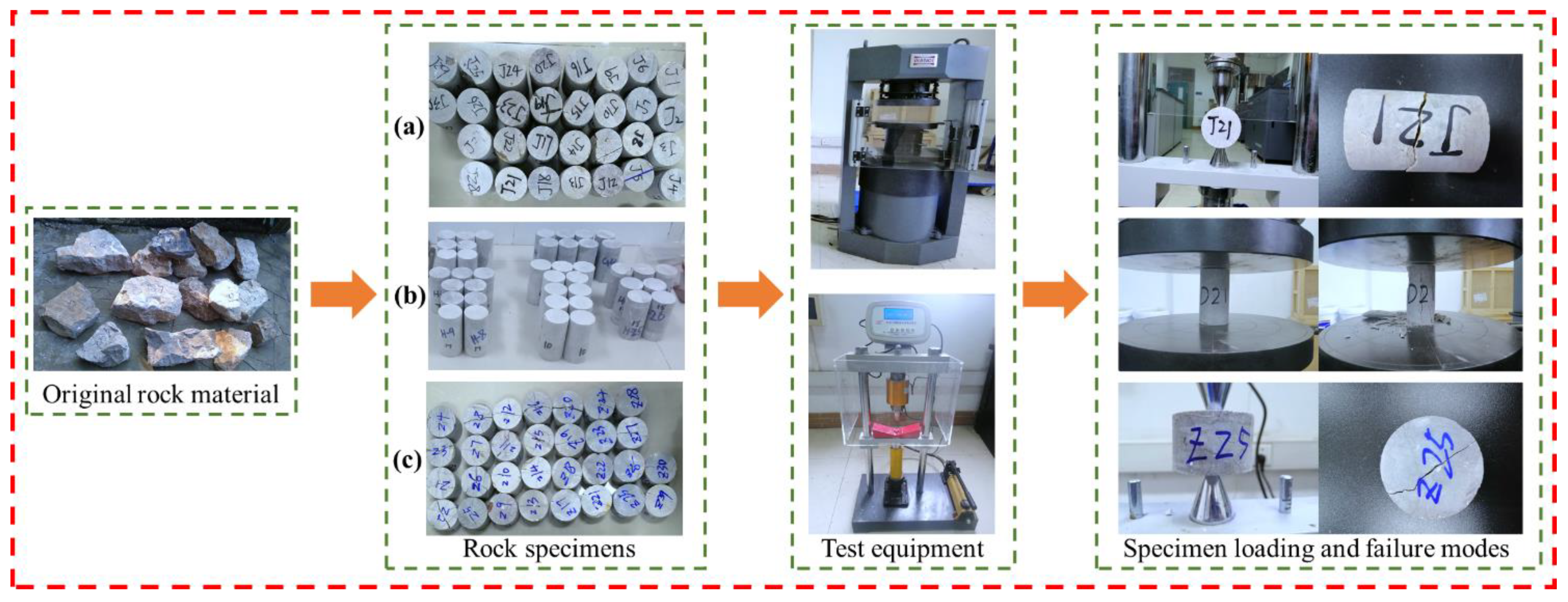

2. Methods and Materials

2.1. Rock Sampling and Fabrication

2.2. Point Load Strength Test

2.3. Uniaxial Compression Strength Test

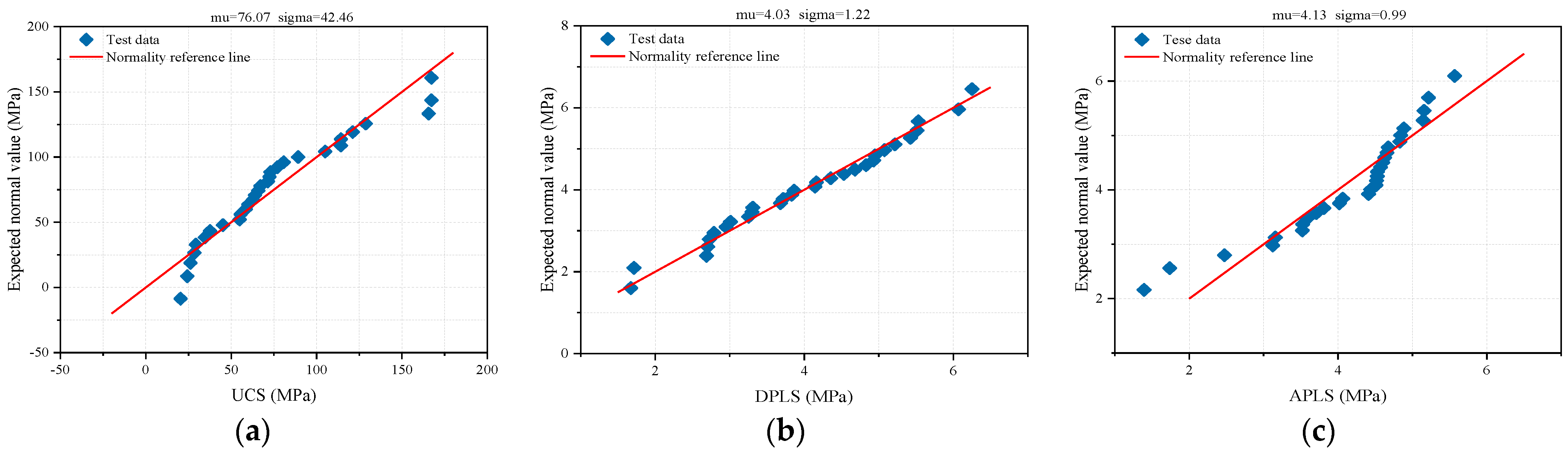

2.4. Data Analysis and Inspection

3. Result and Analysis

3.1. Experimental Data Results

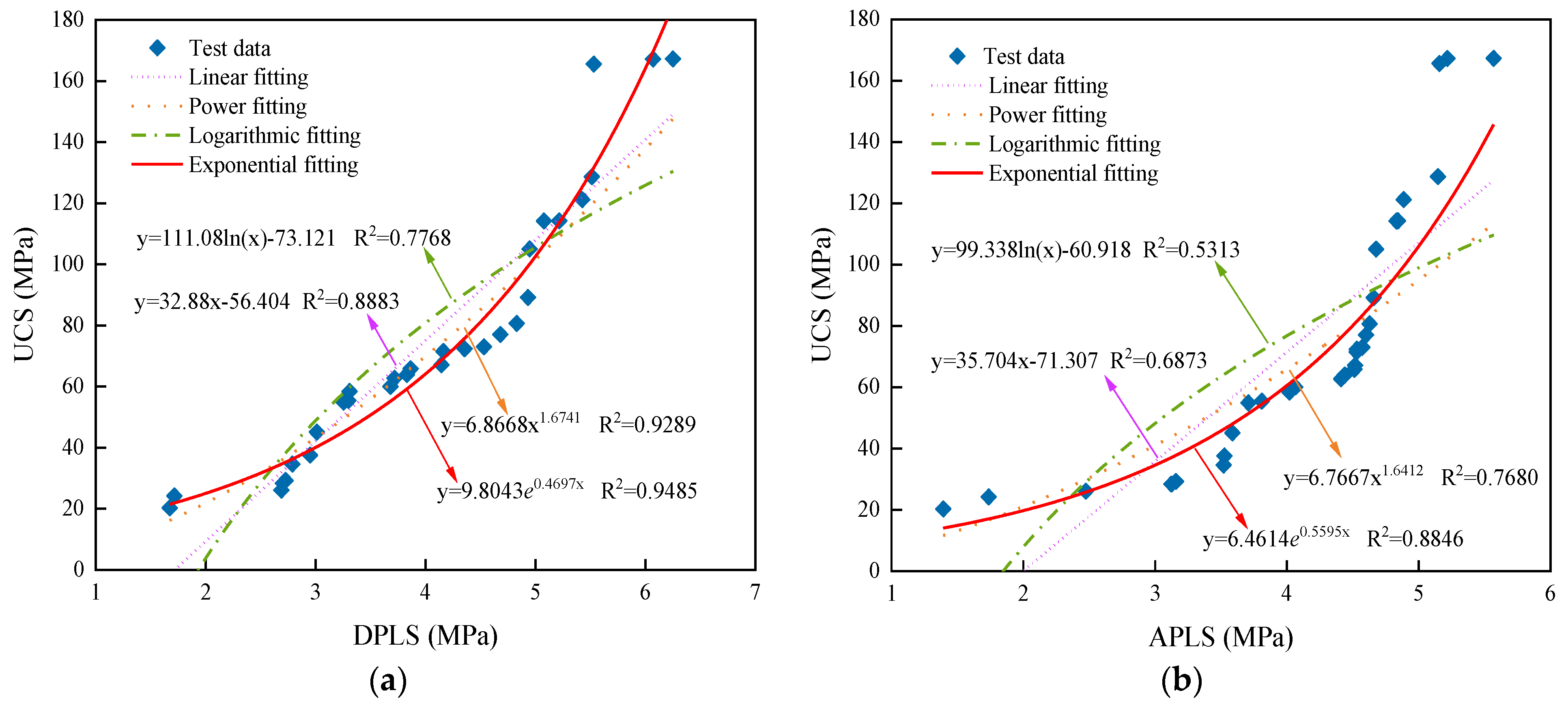

3.2. Discussion and Analysis

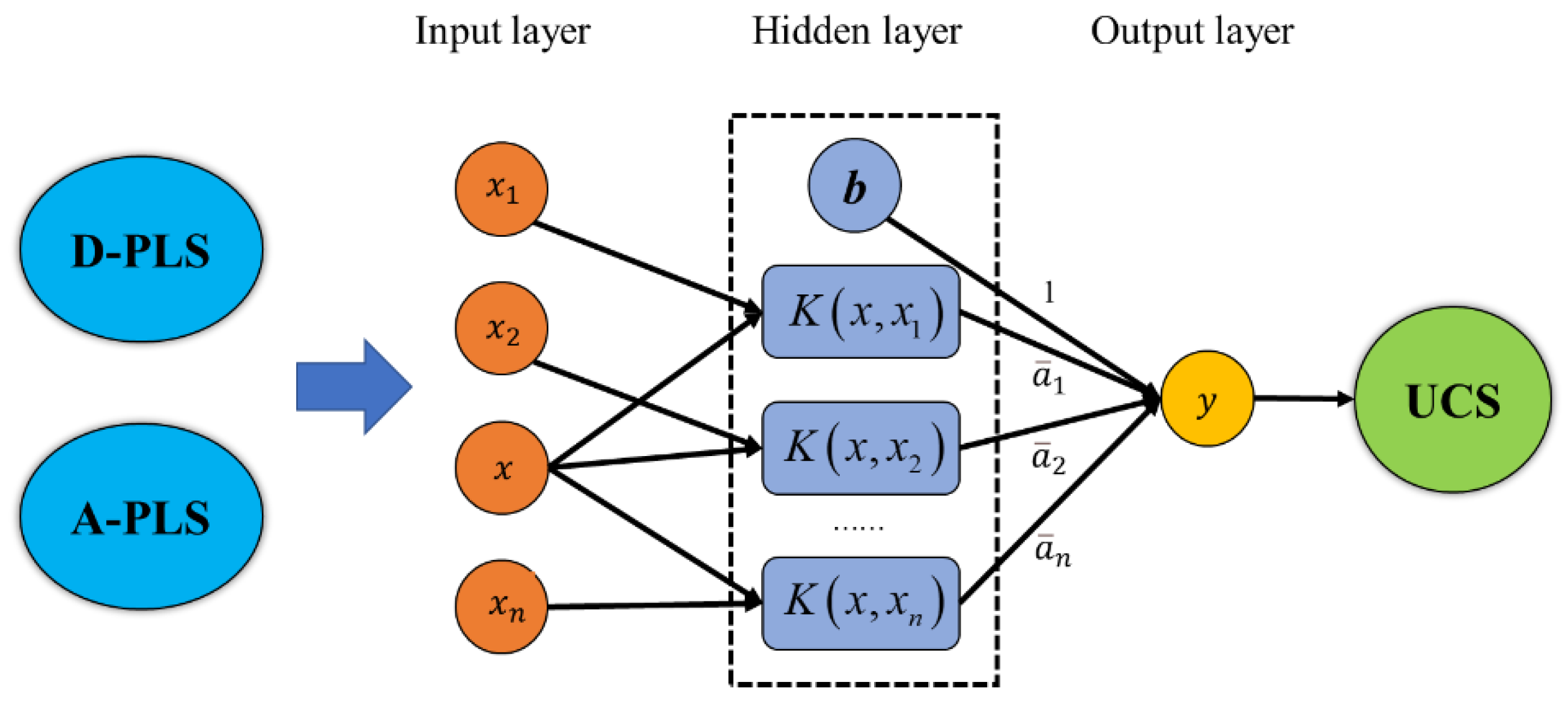

4. Support Vector Machine Model

4.1. Theoretical Basis

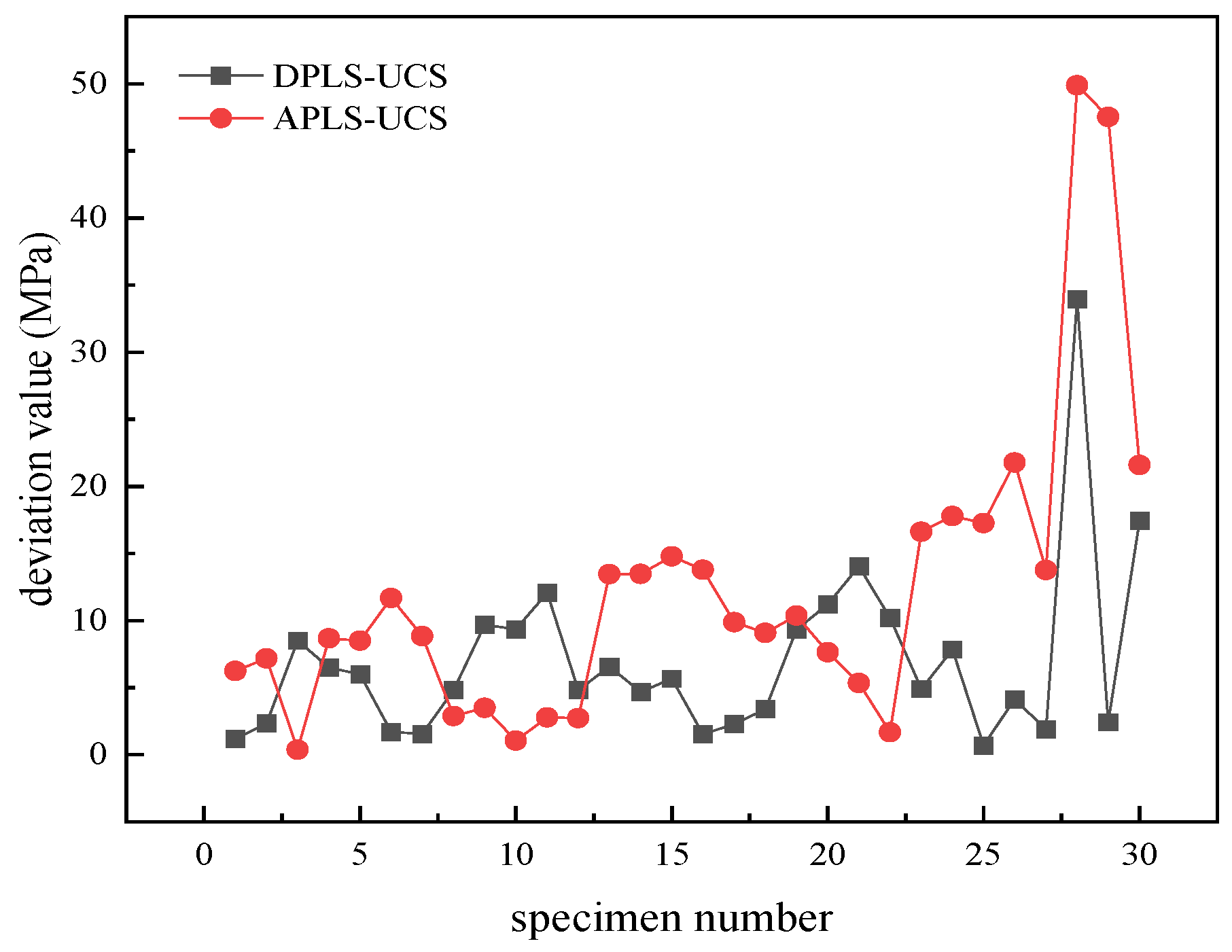

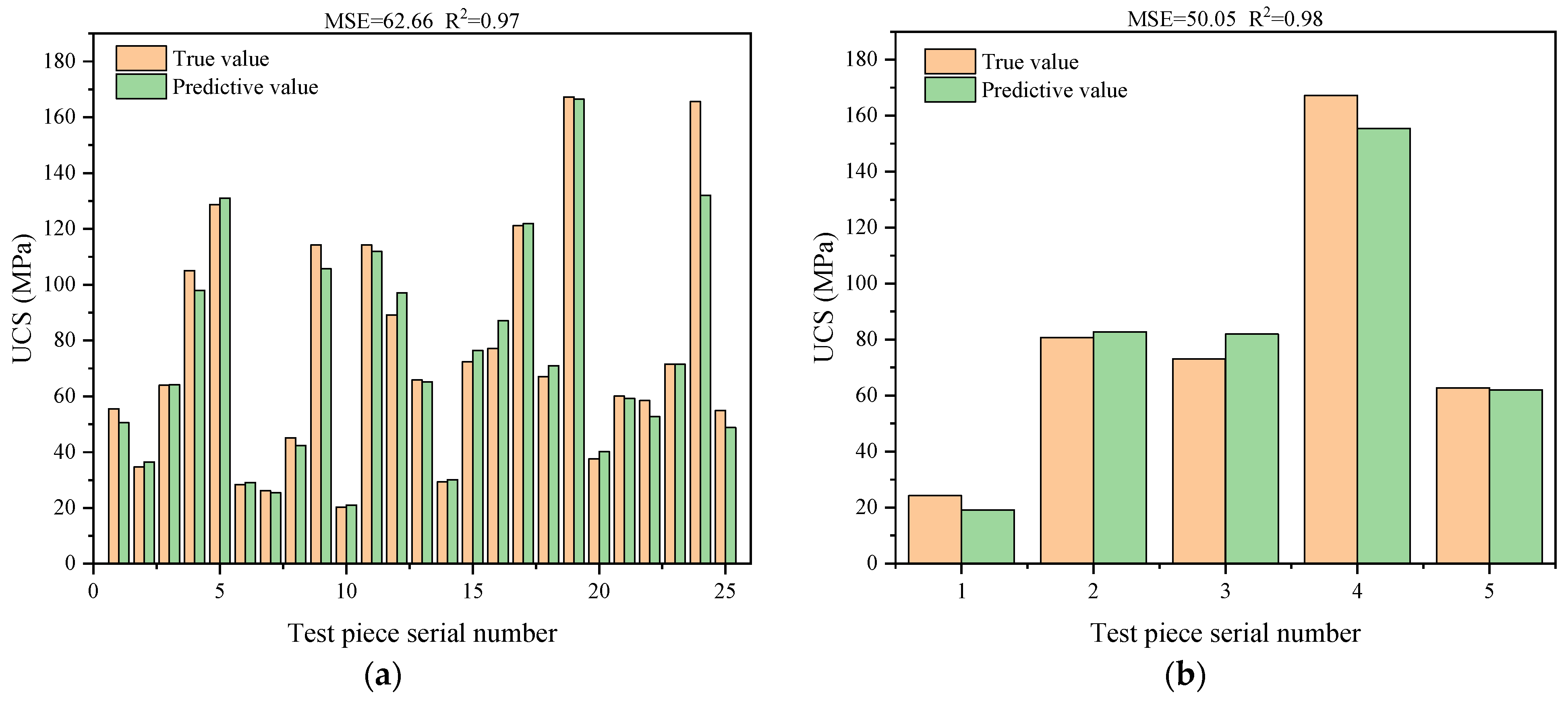

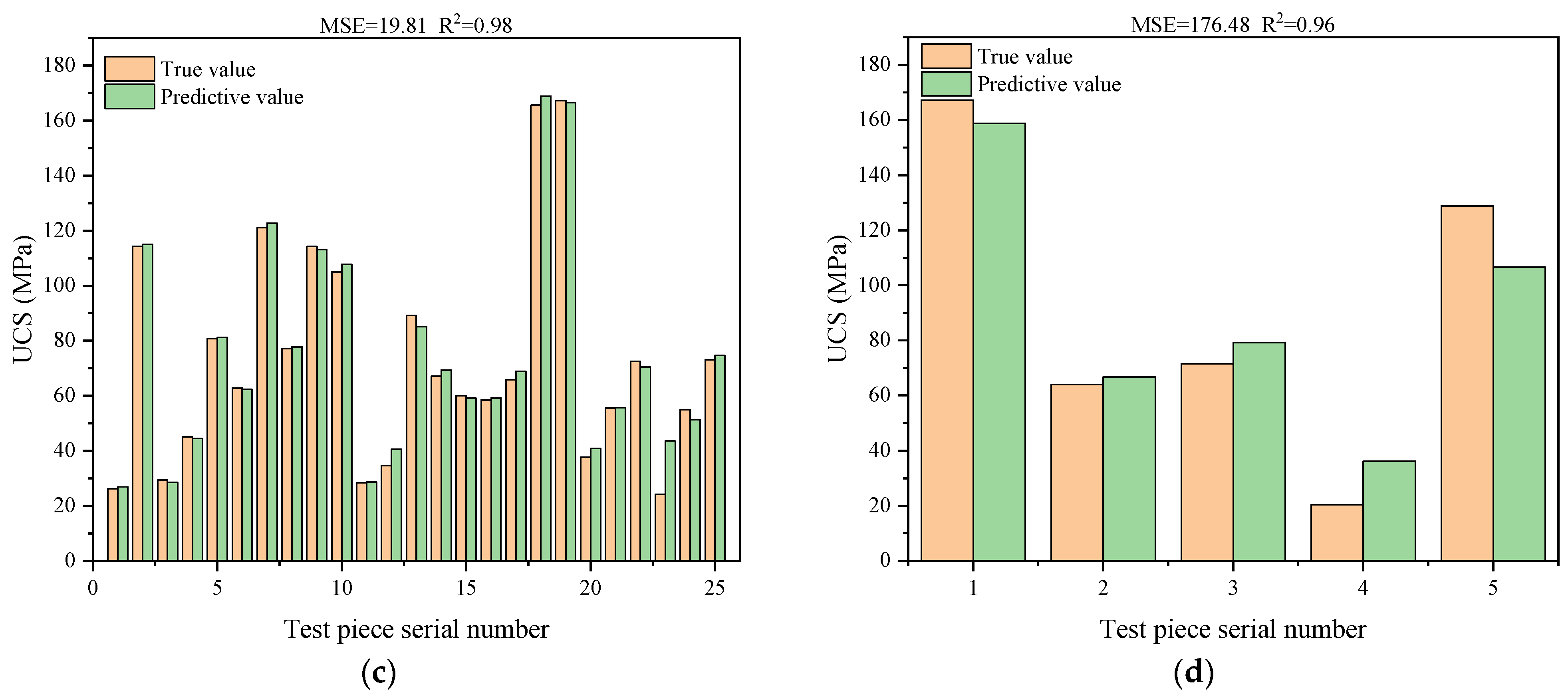

4.2. Model and Results

4.3. Limitations

- The mechanical strength of rock has a high degree of dispersion, and the amount of data used in this model is small, which may easily lead to errors in the prediction of the strength of individual specimens [50]. In order to indicate the accuracy and stability of the model, further research is required of more relevant test data sets for verification.

- This study only focuses on the model relationship between the point load strength and the uniaxial compressive strength. Other indicators involved in the test, such as specimen loading point spacing D and the minimum cross-sectional width W, have not been involved. The specific relationship between other variables and the uniaxial compressive strength of the rock is not clear.

- In order to better improve the prediction performance and accuracy of the model, it is necessary to better optimize and search the built-in parameters of the established SVM model, such as the penalty factor C and kernel parameter γ. The calculation work in this area can be enhanced in the following research.

5. Conclusions

- Four fitting methods are both used to obtain the formula with the highest correlation coefficient. The most accurate fitting formula and function for APLS and UCS is R = 6.46e0.56Is(50), where R2 is 0.8846, and the most accurate fitting formula for DPLS and UCS is R = 9.80e0.47Is(50), where R2 is 0.9485. The above formulas are all expressed as exponential functions.

- The proposed SVR model can accurately predict the UCS through the PLS. The predicted value is basically the same as the true value, and the maximum error rate is below 15%. The SVM model prediction result is more accurate compared with the traditional fitting methods and it also proves that the SVM algorithm can be better applied to the rock strength prediction scenarios under the condition of small samples.

- For the first time, the APLS and DPLS are both used as an entirety to predict the UCS, and the prediction model M1 was established. By comparing the three models, it is found that in the R2 performance: the correlation coefficient of model M2 is the largest and the correlation coefficient of M3 is the smallest. In the MSE performance, the MSE of model M1 is the smallest and the M3 model is the largest. Combining the R2 and MSE judgment indexes, model M1 has the best overall performance, which indicates that the accuracy of predicting UCS by using APLS together with DPLS is the highest.

- Through comparison, it is found that model M2 has better prediction performance than model M3, which indicates from the side that the prediction of UCS by using DPLS is more accurate than using APLS. If DPLS and APLS cannot be obtained simultaneously at the engineering site, the point load test method of diametral loading can be preferred.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, A.Q.; Wang, B. Engineering rock mass classification method based on rock mass quality index BQ for rock slope. Chin. J. Rock Mech. Eng. 2014, 33, 699–706. [Google Scholar] [CrossRef]

- Sha, P.; Zhang, Q.T.; Lin, J.; Wu, F.Y. In-situ estimation of uniaxial compression strength of igneous rock based on point load strength. Rock Soil Mech. 2020, 1–10. [Google Scholar] [CrossRef]

- Broch, E.; Franklin, J.A. The point-load strength test. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1972, 9, 669–697. [Google Scholar] [CrossRef]

- Kohno, M.; Maeda, H. Relationship between point load strength index and uniaxial compressive strength of hydrothermally altered soft rocks. Int. J. Rock Mech. Min. Sci. 2012, 50, 147–157. [Google Scholar] [CrossRef]

- Kong, F.; Shang, J. A Validation Study for the Estimation of Uniaxial Compressive Strength Based on Index Tests. Rock Mech. Rock Eng. 2018, 51, 2289–2297. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. Estimating the strength of rock materials. J. South. Afr. Inst. Min. Metall. 1974, 74, 312–320. [Google Scholar] [CrossRef]

- ISRM. Suggested method for determining point load strength. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1985, 22, 51–60. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Determination of the Point Load Strength Index of Rock and Application to Rock Strength Classification. Test Designation D5731−95 Annual Book of ASTM Standards; American Society for Testing and Materials: West Conshohocken, PA, USA, 1995; p. 2. [Google Scholar]

- Tsiambaos, G.; Sabatakakis, N. Considerations on strength of intact sedimentary rocks. Eng. Geol. 2004, 72, 261–273. [Google Scholar] [CrossRef]

- Basu, A.; Kamran, M. Point load test on schistose rocks and its applicability in predicting uniaxial compressive strength. Int. J. Rock Mech. Min. Sci. 2010, 47, 823–828. [Google Scholar] [CrossRef]

- Wong, R.H.; Chau, K.; Yin, J.-H.; Lai, D.T.; Zhao, G.-S. Uniaxial compressive strength and point load index of volcanic irregular lumps. Int. J. Rock Mech. Min. Sci. 2017, 93, 307–315. [Google Scholar] [CrossRef]

- Vallejo, L.E.; Welsh, R.A.; Robinson, M.K. Correlation between unconfined compression and point load strengths for Appalachian rocks. In The 30th US Symposium on Rock Mechanics (USRMS); Rock Mechanics Association: Alexandria, VA, USA, 1989; pp. 461–468. [Google Scholar]

- Quane, S.L.; Russell, K. Rock strength as a metric of welding intensity in pyroclastic deposits. Eur. J. Miner. 2003, 15, 855–864. [Google Scholar] [CrossRef]

- Kılıç, A.; Teymen, A. Determination of mechanical properties of rocks using simple methods. Bull. Int. Assoc. Eng. Geol. 2008, 67, 237–244. [Google Scholar] [CrossRef]

- Sabatakakis, N.; Koukis, G.; Tsiambaos, G.; Papanakli, S. Index properties and strength variation controlled by microstructure for sedimentary rocks. Eng. Geol. 2008, 97, 80–90. [Google Scholar] [CrossRef]

- Yilmaz, I.; Yuksek, G. Prediction of the strength and elasticity modulus of gypsum using multiple regression, ANN, and ANFIS models. Int. J. Rock Mech. Min. Sci. 2009, 46, 803–810. [Google Scholar] [CrossRef]

- Diamantis, K.; Gartzos, E.; Migiros, G. Study on uniaxial compressive strength, point load strength index, dynamic and physical properties of serpentinites from Central Greece: Test results and empirical relations. Eng. Geol. 2009, 108, 199–207. [Google Scholar] [CrossRef]

- Li, D.; Wong, L.N.Y. Point Load Test on Meta-Sedimentary Rocks and Correlation to UCS and BTS. Rock Mech. Rock Eng. 2012, 46, 889–896. [Google Scholar] [CrossRef]

- Mishra, D.; Basu, A. Estimation of uniaxial compressive strength of rock materials by index tests using regression analysis and fuzzy inference system. Eng. Geol. 2013, 160, 54–68. [Google Scholar] [CrossRef]

- Fu, Z.L.; Wang, L. Comparative experimental research on point load strength, uniaxial compression strength and tensile strength for rocks in roof and floor of coal seam. Chin. J. Rock Mechan. Eng. 2013, 32, 88–96. [Google Scholar]

- Kahraman, S. The determination of uniaxial compressive strength from point load strength for pyroclastic rocks. Eng. Geol. 2014, 170, 33–42. [Google Scholar] [CrossRef]

- Anping, L.; Yangshu, L.; Ming, Z. Study on relationship between poit load strength and uniaxial compressive strength of rock. Non-Ferrous Metals 2014, 66, 53–58. [Google Scholar]

- Zhang, J.M.; Tang, Z.C.; Liu, Q.S. Relation between point load index and uniaxial compression strength for igneous rock. Rock Soil Mech. 2015, 36, 595–602. [Google Scholar] [CrossRef]

- Yin, J.-H.; Wong, R.H.; Chau, K.; Lai, D.T.; Zhao, G.-S. Point load strength index of granitic irregular lumps: Size correction and correlation with uniaxial compressive strength. Tunn. Undergr. Space Technol. 2017, 70, 388–399. [Google Scholar] [CrossRef]

- Lin, J.; Sha, P.; Wu, F. Correlation Between Point Loading Index and Uniaxial Compression Strength of Rock-like Material Based on Size Effect. J. Yangtze River Sci. Res. Inst. 2018, 35, 34–44. [Google Scholar]

- Chen, J.Q.; Wei, Z.A. Comparison of rock strength from different point load tests and the uniaxial compression strength. Chin. J. Geol. Hazard Control 2018, 29, 72–77. [Google Scholar] [CrossRef]

- Li, H.P.; Wu, Y.Y.; Ge, C. The relation between point load strength and compression and tensile strength of marble. Sci. Technol. Eng. 2019, 19, 294–299. [Google Scholar]

- Zhang, C.L.; Zhang, C.P.; Xu, J. Comparison Test of Rock Point Load Strength and Uniaxial Compres-sion Strength. Chin. J. Undergr. Space Eng. 2015, 11, 447–451. [Google Scholar]

- Fan, J.; Guo, Z.; Tao, Z.; Wang, F. Method of equivalent core diameter of actual fracture section for the determination of point load strength index of rocks. Bull. Int. Assoc. Eng. Geol. 2021, 80, 4575–4585. [Google Scholar] [CrossRef]

- Mozumder, R.A.; Laskar, A.I. Prediction of unconfined compressive strength of geopolymer stabilized clayey soil using Artificial Neural Network. Comput. Geotech. 2015, 69, 291–300. [Google Scholar] [CrossRef]

- Heidari, M.; Khanlari, G.R.; Kaveh, M.T.; Kargarian, S. Predicting the Uniaxial Compressive and Tensile Strengths of Gypsum Rock by Point Load Testing. Rock Mech. Rock Eng. 2012, 45, 265–273. [Google Scholar] [CrossRef]

- Shao, Y.; Yan, C.H.; Ma, Q.H. Correlation Analysis of Dayangshan Rock Strength in Suzhou. J. Yangtze River Sci. Res. Inst. 2015, 32, 107–110. [Google Scholar]

- Zhang, Y.Y.; Li, K.G. The Correlation Between the Point Load Strength and Uniaxial Compression Strength of Several Kinds of Rocks. Metal Mine 2017, 19–23. [Google Scholar]

- Zhang, Y.; Zhao, G.F.; Wei, X.; Li, H. A multifrequency ultrasonic approach to extracting static modulus and damage characteristics of rock. Int. J. Rock Mech. Min. Sci. 2021, 148, 104925. [Google Scholar] [CrossRef]

- Lei, S.; Kang, H.P.; Gao, F.Q.; Zhang, X. Point load strength test of fragile coal samples and predictive analysis of uniaxial compression strength. Coal Sci. Technol. 2019, 47, 107–113. [Google Scholar] [CrossRef]

- Liu, Q.S.; Zhao, Y.F.; Zhang, X.P.; Kong, X.X. Study and discussion on point load test for evaluating rock strength of TBM tunnel constructed in Limestone. Rock Soil Mech. 2018, 39, 977–984. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban Rural Development of the People’s Republic of China. GB/T 50218-2014 Standard for Engineering Classification of Rock Mass; China Planning Press: Beijing, China, 2014.

- Ministry of Housing and Urban Rural Development of the People’s Republic of China. GB/T 50266-2013 Standard for Test Methods of Engineering Rock Mass; China Planning Press: Beijing, China, 2013.

- Gupta, D.; Natarajan, N. Prediction of uniaxial compressive strength of rock samples using density weighted least squares twin support vector regression. Neural Comput. Appl. 2021, 33, 15843–15850. [Google Scholar] [CrossRef]

- Sain, S.R.; Vapnik, V.N. The Nature of Statistical Learning Theory. Technometrics 1996, 38, 409. [Google Scholar] [CrossRef]

- Kang, F.; Xu, Q.; Li, J. Slope reliability analysis using surrogate models via new support vector machines with swarm intelligence. Appl. Math. Model. 2016, 40, 6105–6120. [Google Scholar] [CrossRef]

- Zhou, J.; Huang, S.; Wang, M.; Qiu, Y. Performance evaluation of hybrid GA–SVM and GWO–SVM models to predict earthquake-induced liquefaction potential of soil: A multi-dataset investigation. Eng. Comput. 2021, 1–19. [Google Scholar] [CrossRef]

- Li, E.; Zhou, J.; Shi, X.; Armaghani, D.J.; Yu, Z.; Chen, X.; Huang, P. Developing a hybrid model of salp swarm algorithm-based support vector machine to predict the strength of fiber-reinforced cemented paste backfill. Eng. Comput. 2020, 37, 3519–3540. [Google Scholar] [CrossRef]

- Syah, R.; Ahmadian, N.; Elveny, M.; Alizadeh, S.M.; Hosseini, M.; Khan, A. Implementation of artificial intelligence and support vector machine learning to estimate the drilling fluid density in high-pressure high-temperature wells. Energy Rep. 2021, 7, 4106–4113. [Google Scholar] [CrossRef]

- Joana, C.; Petra, T.; Maisa, N.; Timo, J.; Vahid, F. Machine-learning models for activity class prediction: A comparative study of feature selection and classification algorithms. Gait Posture 2021, 89, 45–53. [Google Scholar]

- Wang, Y.; Qiao, C.S.; Sun, C.H.; Liu, K.Y. Forecasting model of safe thickness for roof of karst cave tunnel based on support vector machines. Rock Soil Mech. 2006, 1000–1004. [Google Scholar] [CrossRef]

- Huang, W.Y.; Tong, M.M.; Ren, Z.H. Nonlinear combination forecast of gas emission amount based on SVM. J. China Univ. Min. Technol. 2009, 38, 234–239. [Google Scholar]

- Hsu, C.W.; Lin, C.J. A comparison of methods for multiclass support vector machines. IEEE Trans. Neural Netw. 2002, 13, 415–425. [Google Scholar]

- Wang, Q.; Sun, H.B.; Jiang, B. A method for predicting uniaxial compressive strength of rock mass based on digital drilling test technology and support vector machine. Rock Soil Mech. 2019, 40, 1221–1228. [Google Scholar] [CrossRef]

- Teymen, A.; Mengüç, E.C. Comparative evaluation of different statistical tools for the prediction of uniaxial compressive strength of rocks. Int. J. Min. Sci. Technol. 2020, 30, 785–797. [Google Scholar] [CrossRef]

| NO. | Year | Authors | Rock Type | Equations | R2 |

|---|---|---|---|---|---|

| 1 | 1985 | ISRM [7] | granite, marble et al. | R = (20~25) Is(50) | - |

| 2 | 1989 | Vallejo et al. [12] | granite | R = 12.6 Is(50)R = 17.4 Is(50) | - |

| 3 | 2003 | Quane, S.L., Russell, J.K. [13] | welded ignimbrite | R = 3.86 (Is(50))2 + 5.65 Is(50) | - |

| 4 | 2004 | Tsiambaos et al. [9] | limestone | R = 7.3 (Is(50))1.71 | 0.90 |

| 5 | 2008 | KiliÇ, A., Teymen, A. [14] | limestone, tuff et al. | R = 100 ln(Is(50)) + 13.9 | 0.99 |

| 6 | 2008 | Sabatakakis, N. et al. [15] | limestone, sandstone | R = 28 Is(50) | 0.73 |

| 7 | 2009 | Yilmaz, Yuksek [16] | sandstone, conglomerate | R = 12.4 Is(50) − 9.08 | 0.85 |

| 8 | 2009 | Diamantis, K, et al. [17] | serpentinites | R = 16.45 e0.39Is(50) | 0.89 |

| 9 | 2010 | Basu, A. et al. [10] | apatite | R = 11.103 Is(50) + 37.66 | 0.86 |

| 10 | 2012 | Kohno, M., Maeda, H. [4] | volcaniclastic, tuff | R = 16.4 Is(50) | 0.90 |

| 11 | 2013 | LI.D, Wong, L. [18] | metasandstone | R = 21.27 Is(50) | - |

| 12 | 2013 | Mishra, D.A., Basu, A. [19] | granite, schist, sandstone | R = 14.63 Is(50) | 0.94 |

| 13 | 2013 | FUZhiliang, et al. [20] | sandstone, mudstone | R = 7.201 Is(50) + 14.074 (Axial) R = 13.938 Is(50) + 17.529 (Diametral) | 0.99 0.97 |

| 14 | 2014 | Kahraman, S. [21] | ignimbrite | R = 7.73 (Is(50))1.25 | 0.91 |

| 15 | 2014 | LI anping et al. [22] | sandstone, mudstone | R = 14.933 ln(Is(50)) + 89.012 | 0.79 |

| 16 | 2015 | ZHANG Jianming et al. [23] | granite, andesite | R = −0.66 (Is(50))2 + 21.15 Is(50) | 0.94 |

| 17 | 2017 | Jian-Hua Yin et al. [24] | granite | R = 21.605 Is(50) | 0.74 |

| 18 | 2017 | Robina H.C. Wong et al. [11] | granite, tuff | R = 18.897 Is(50) | 0.87 |

| 19 | 2018 | LIN jun et al. [25] | cement block | R = 29.87 Is(50) − 2.242 | 0.99 |

| 20 | 2018 | CHEN Jiaqi, WEI Zuoan [26] | limestone, sandstone | R = 22.72 (Is(50))0.82 (Irregular) R = 26.24 (Is(50))0.72 (Regular) | 0.86 |

| 21 | 2019 | LI Hongpeng et al. [27] | marble | R = 21.28 Is(50) | - |

| 22 | 2020 | SHA Peng et al. [2] | igneous | R = 0.14 (Is(50))2 + 13.25 Is(50) | 0.93 |

| Model Name | Penalty Factor C | Sensitive Parameter γ |

|---|---|---|

| M1 | 256.75 | 1.13 |

| M2 | 226.27 | 1.41 |

| M3 | 362.04 | 2.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Wang, Y.; Xie, X. Prediction of Uniaxial Compression Strength of Limestone Based on the Point Load Strength and SVM Model. Minerals 2021, 11, 1387. https://doi.org/10.3390/min11121387

Li S, Wang Y, Xie X. Prediction of Uniaxial Compression Strength of Limestone Based on the Point Load Strength and SVM Model. Minerals. 2021; 11(12):1387. https://doi.org/10.3390/min11121387

Chicago/Turabian StyleLi, Shaoqian, Yu Wang, and Xuebin Xie. 2021. "Prediction of Uniaxial Compression Strength of Limestone Based on the Point Load Strength and SVM Model" Minerals 11, no. 12: 1387. https://doi.org/10.3390/min11121387

APA StyleLi, S., Wang, Y., & Xie, X. (2021). Prediction of Uniaxial Compression Strength of Limestone Based on the Point Load Strength and SVM Model. Minerals, 11(12), 1387. https://doi.org/10.3390/min11121387