Strength Characteristics of Clay–Rubber Waste Mixtures in Low-Frequency Cyclic Triaxial Tests

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fine-Grained Soils

2.2. Rubber Waste

2.3. Red Clay–Rubber (RC-R) and Kaolin–Rubber (K-R) Mixtures

- RC-G-5 (95% red clay with 5% addition of granulate 1–5 mm);

- RC-G-10 (90% red clay with 10% addition of granulate 1–5 mm);

- RC-G-25 (75% red clay with 25% addition of granulate 1–5 mm);

- RC-P-10 (90% red clay with 10% addition of powder 0–1 mm);

- K-G-25 (75% kaolin with 25% addition of granulate 1–5 mm);

- and additionally,

- RC (100% red clay).

3. Test Procedure

3.1. Preparation of Proper Specimens from Red Clay (RC) and a Clay–Rubber Waste Mixture (RC-R and K-R)

3.2. Test Conditions

4. Results and Discussion

4.1. The Effect of Rubber Waste on the Axial Strain during Cyclic Loading

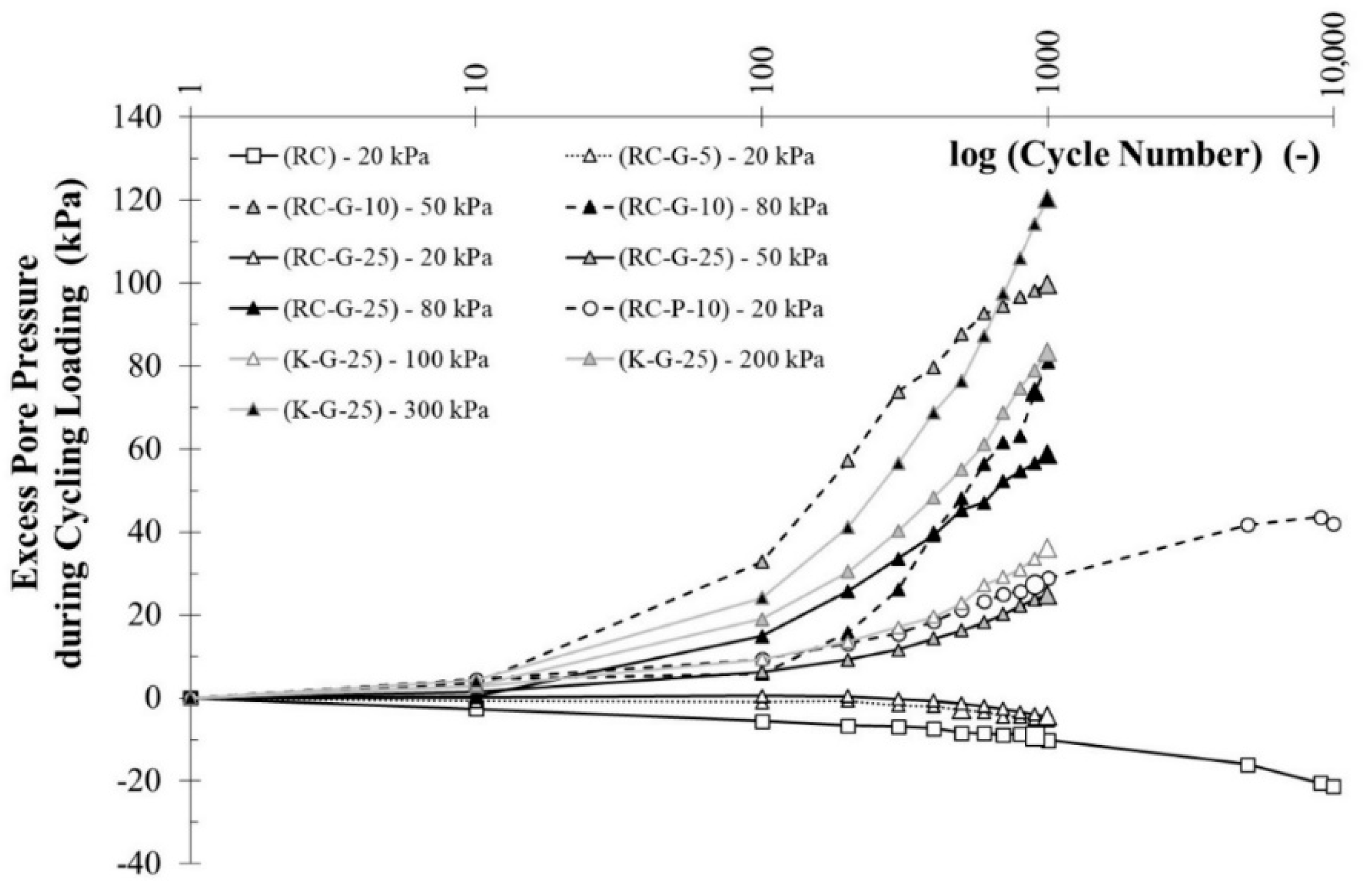

4.2. The Effect of Rubber Waste on the Pore Pressure during Cyclic Loading

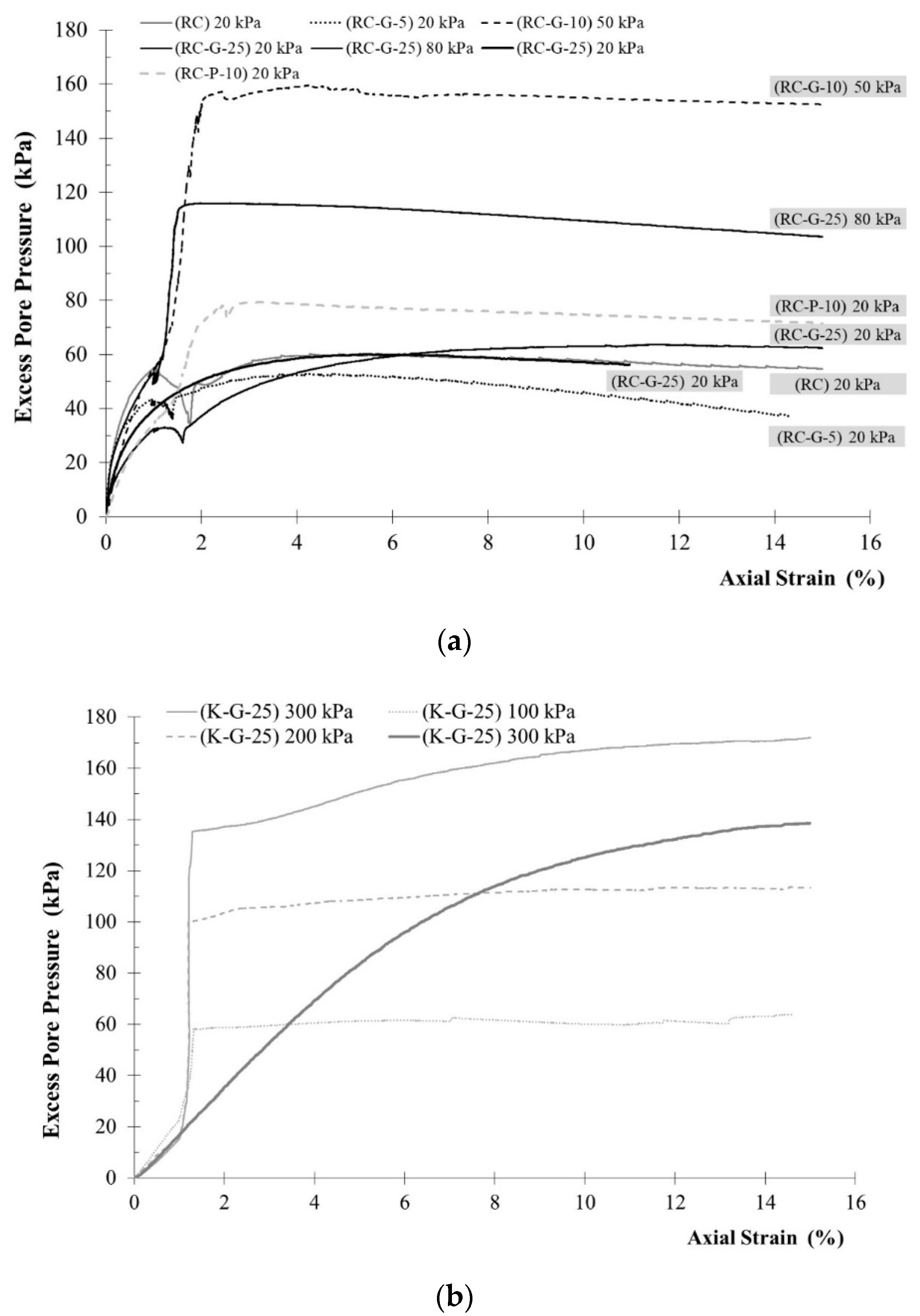

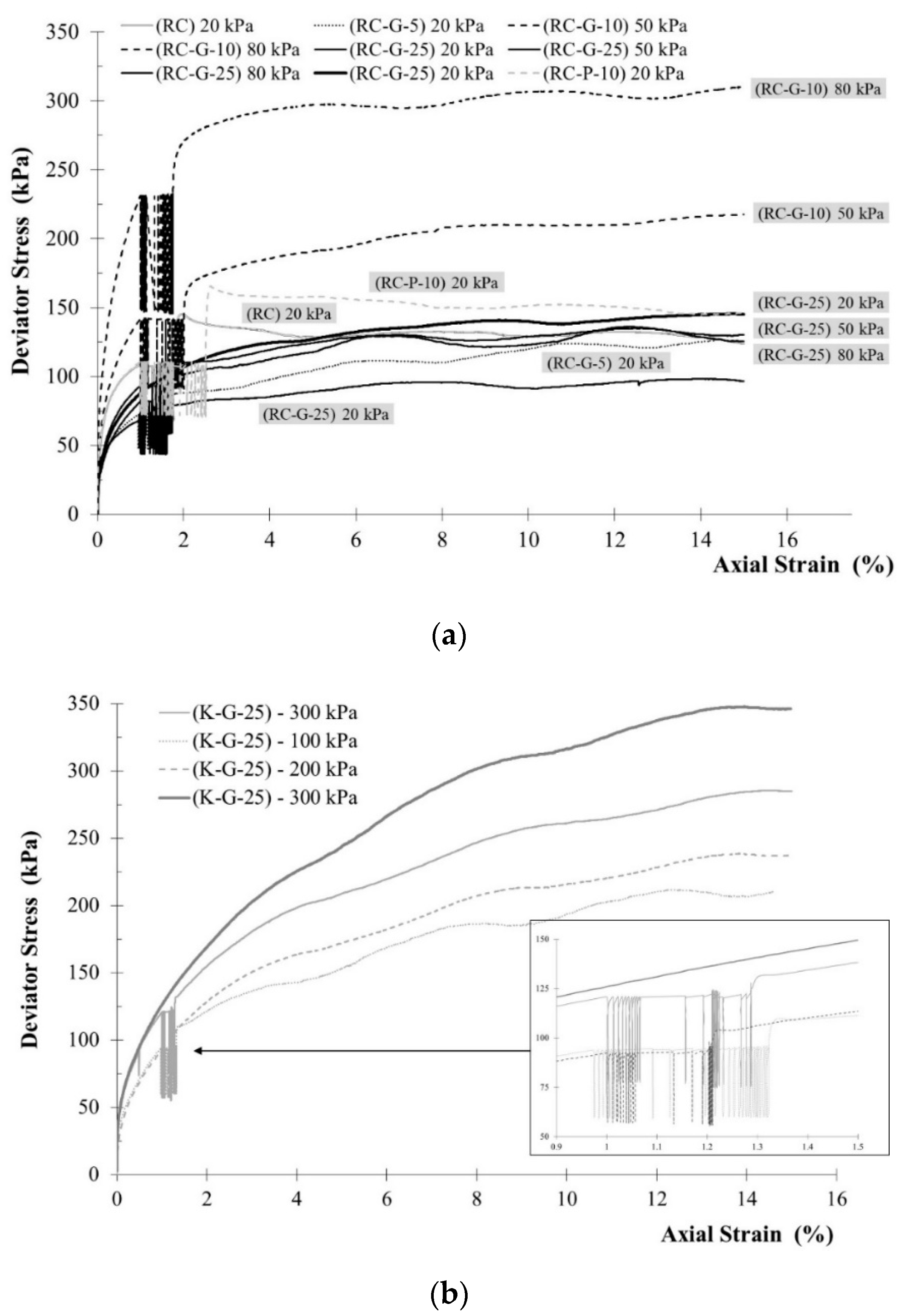

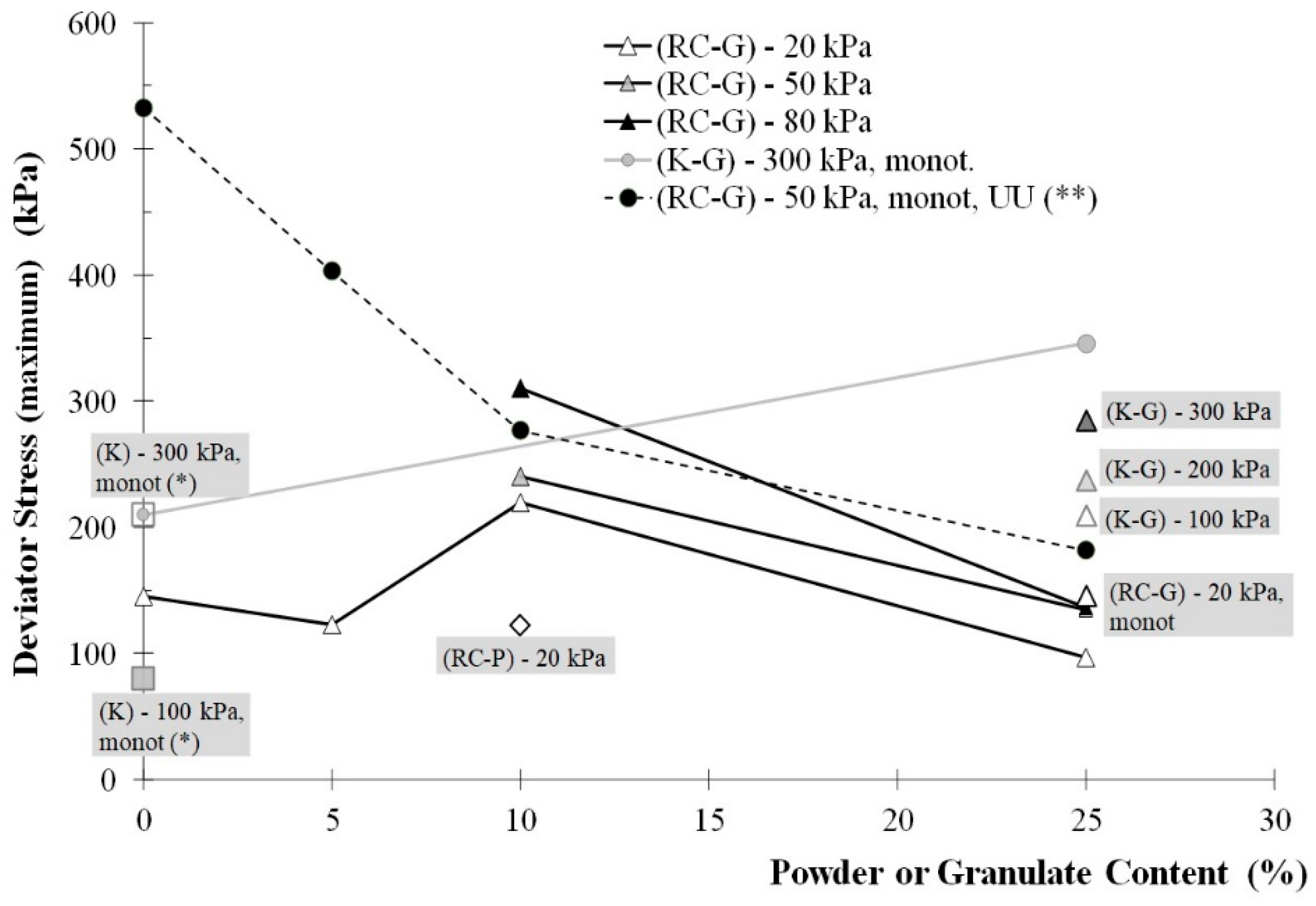

4.3. Analysis of Shear Strength Test Results

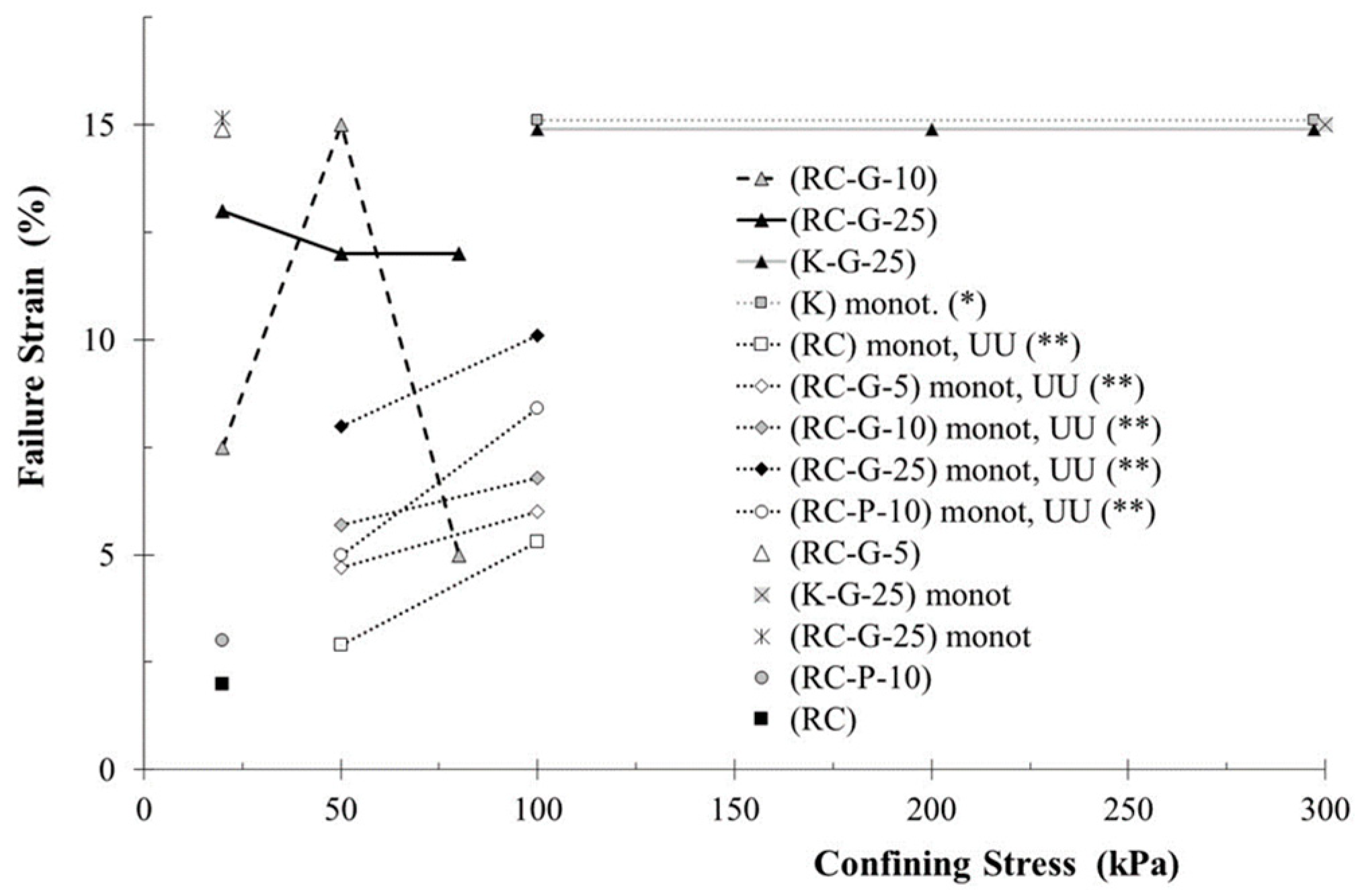

4.4. The Effect of Rubber Waste on Deformability

5. Conclusions

- Cyclic loading

- (low confining pressure σ’3 = 20 kPa and lightly overconsolidated specimens due to its preparation using Proctor’s method)—The addition of 25% granulate to expansive red clay (RC-G-25) does not influence the value Δε1,cyc after 1000 cycles under low confining pressure σ’3 = 20 kPa. Meanwhile, the addition of 10% granulate (RC-G-10) or 10% powder (RC-P-10-20 kPa) caused an axial strain increase of ~30% after 1000 cycles. On the other hand, the addition of 5% granulate (RC-G-5) reduced the axial strain increase by 25% relative to pure clay (RC).

- (confining pressures σ’3 = 50 and 80 kPa)—Addition of 10% granulate (RC-G-10) or powder (RC-P-10) to swelling red clay caused higher strain increases during cyclic loading (~46% and 31%, respectively) than the addition of 25% granulate (a strain increase of ~5%).

- (confining pressure σ’3 = 100 kPa)—Axial strain increases for kaolin–granulate mixtures (K-G-25) were approximately 1.5–2 times lower than for (RC-R).

- Care should be taken when using a red clay–powder mixture because after adding 10% powder (RC-P-10), the axial strain increased by 30% over 1000 cycles and by nearly 100% for 10,000 cycles relative to pure red clay (RC).

- (confining pressure σ’3 = 20 kPa)—The negative excess pore pressure for pure red clay (RC) and (RC-G) mixtures displayed behavior opposite to that of (RC-P-10) mixtures—the pore pressure gradually increased from the beginning of the cyclic loading operation.

- (confining pressures σ’3 = 50 and 80 kPa)—Addition of 25% of the granulate (RC-G-25) to the swelling soil (RC) caused smaller increases in pore pressure (Δucyc = 25 kPa and 59 kPa, respectively) than for 10% of the granulate (RC-G-10): Δucyc = 99 kPa and 81 kPa, respectively.

- It is worth noting that the characteristic decrease in pore pressure (after activation of cyclic loading) at a low confining pressure σ’3 = 20 kPa was due to specimen preparation (in the future, from the method of preparing an embankment, for example). The preliminary compaction of a soil–rubber mixture with Proctor’s energy caused a light overconsolidation of the material. This is favorable for reducing pore pressure increases.

- Post-cyclic loading

- 8.

- (cyclic versus monotonic stage, confining pressure σ’3 = 20 kPa)—The pore pressures induced during the post-cyclic tests were higher than pore pressures induced during monotonic tests (and applied to (RC-G-25) and (RC-P-10)).

- 9.

- Monotonic test and post-cyclic stage (confining pressure σ’3 = 300 kPa)—A strengthening of kaolin–granulate mixture (K-G-25) by Δqmax = +65% and its softening by Δqmax = −18% in the post-cyclic state (as compared to pure kaolin (K)).

- 10.

- The lack of the strengthening of (RC-R) mixtures, except for (RC-G-10) under σ’3 = 20 kPa—Δqmax = 18%. The softening in strength of (RC-G-25) by Δqmax = (−76%) for σ’3 = 50 kPa and by (-128%) at a σ’3 of 80 kPa.

- 11.

- (confining pressure σ’3 = 20 kPa)—The plasticity growth (called ductility in the literature) when increasing the granulate (G) levels (from 10% to 25%) and when increasing the rubber waste particle size (granulate (G) or powder (P)).

- 12.

- (confining pressures σ’3 = 50 and 80 kPa)—The plasticity behaviors of (RC-G-25) and (RC-G-10) were reversed relative to a confining pressure lower than 20 kPa. For (RC-G-25) and σ’3 values of 50 kPa and 80 kPa, the ε1,f was 12%. For (RC-G-10) and a σ’3 of 50 kPa, the ε1,f was 15% but only 5% for a σ’3 of 80 kPa. These results would benefit from additional studies on more specimens.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kalantari, B. Foundations on Expansive Soils: A Review. Res. J. Appl. Sci. Eng. Technol. 2012, 4, 3231–3237. [Google Scholar]

- World Business Council for Sustainable Development Home Page (WBCSD). Available online: https://docs.wbcsd.org/2008/08/EndOfLifeTires-FullReport.pdf (accessed on 10 August 2008).

- Kliszczewicz, B.; Kowalska, M. Numerical Study of the Use of Tyre-Derived-Aggregate (TDA) as the Backfill Above Flexible PVC Pipeline. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Prague, Czech Republic, 15–19 June 2020; Volume 960, pp. 32–44. [Google Scholar] [CrossRef]

- Gromysz, K.; Kowalska, M. Reduction of Vibrations Applied on Structures-Results of Chamber Tests with the Use of Tire Derived Aggregate. Procedia Eng. 2017, 193, 305–312. [Google Scholar] [CrossRef]

- Jurczuk, J. The Application of Rubber Shreds as a Light Filling in Road Embankments; Mostostal Warszawa, S.A., Ed.; Biuro Analiz i Rozwoju: Warsaw, Poland, 2011. [Google Scholar]

- Kowalska, M.; Chmielewski, M. Mechanical Parameters of Rubber-Sand Mixtures for Numerical Analysis of a Road Em-bankment. In Proceedings of the IOP Conference Series, Materials Science and Engineering, Beijing, China, 24–27 October 2017. [Google Scholar]

- Signes, C.H.; Garzón-Roca, J.; Fernández, P.M.; Garrido de la Torre, M.E.; Insa Franco, R. Swelling Potential Reduction of Spanish Argillaceous Marlstone Facies Tap Soil Through the Addition of Crumb Rubber Particles from Scrap Tires. Appl. Clay Sci. 2016, 132, 768–773. [Google Scholar] [CrossRef]

- Sybilski, D. The Application of Rubber Waste in Road Construction. Prz. Bud. 2009, 5, 37–44. [Google Scholar]

- Yoon, S.; Prezzi, M.; Siddiki, N.Z.; Kim, B. Construction of a Test Embankment using a Sand-Tire Shred Mixture as Fill Material. Waste Manag. 2006, 26, 1033–1044. [Google Scholar] [CrossRef]

- Karacasu, M.; Okur, V.; Er, A. A Study on the Rheological Properties of Recycled Rubber-Modified Asphalt Mixtures. Sci. World J. 2015, 2015, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Lo Presti, D. Recycled Tire Rubber Modified Bitumens for Road Asphalt Mixtures: A Literature Review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Xu, X.; Lo, S.H.; Tsang, H.H.; Sheikh, M.N. Earthquake Protection by Tire—Soil Mixtures: Numerical Study. In Proceedings of the New Zealand Society for Earthquake Engineering (NZSEE) Conference, Wellington, New Zealand, 3–5 April 2009. [Google Scholar]

- Kowalska, M. Compactness of Scrap Tyre Rubber Aggregates in Standard Proctor Test. Procedia Eng. 2016, 161, 975–979. [Google Scholar] [CrossRef] [Green Version]

- Ramirez, G.G.D.; Casagrande, M.D.T.; Folle, D.; Pereira, A.; Paulon, V.A. Behavior of Granular Rubber Waste Tire Reinforced Soil for Application in Geosynthetic Reinforced Soil Wall. Rev. IBRACON Estrut. Mater. 2015, 8, 567–576. [Google Scholar] [CrossRef]

- Balasooriya, M.G.B.T.; Kumari, W.G.S.D.; Mallawarachchi, M.A.S.N.; Udakara, D.D.S. Study the Effect of Waste Rubber Materials on Shear Strength of Residual Soils. In Proceedings of the International Conference on Sustainable Built Environment (ICSBE-2012), Ipoh, Malaysia, 23–24 April 2012. [Google Scholar]

- Carraro, J.A.H.; Budagher, E.; Badanagki, M.; Kang, J.B. Sustainable Stabilization of Sulfate-Bearing Soil with Expansive Soil-Rubber Technology; Technical Report No. CDOT-2013-2; Colorado Department of Transportation: Washington, DC, USA, 2013.

- Cetin, H.; Fener, M.; Gunaydin, O. Geotechnical Properties of Tire-Cohesive Clayey Soil Mixtures as a Fill Material. Eng. Geol. 2006, 88, 110–120. [Google Scholar] [CrossRef]

- Daud, N.; Yusoff, Z.; Muhammed, A. Ground Improvement of Problematic Soft Soils Using Shredded Waste Tire. In Proceedings of the 6th Jordanian Int. Civil Engineering Conference (JICEC06), Amman, Jordan, 10–12 March 2015. [Google Scholar]

- Soltani, A.; Deng, A.; Taheri, A.; Sridharan, A. Consistency Limits and Compaction Characteristics of Clay Soils Containing Rubber Waste. Proc. Inst. Civ. Eng. Geotech. Eng. 2019, 172, 174–188. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, A.; Pandey, S.; Rana, J. Use of Shredded Tyre Waste in Improving the Geotechnical Properties of Expansive Black Cotton Soil. Géoméch. Geoengin. 2014, 9, 303–311. [Google Scholar] [CrossRef]

- Akbarimehr, D.; Aflaki, E. An Experimental Study on the Effect of Tire Powder on the Geotechnical Properties of Clay Soils. Civ. Eng. J. 2018, 4, 594. [Google Scholar] [CrossRef] [Green Version]

- Kowalska, M.; Jastrzębska, M. Swelling of Cohesive Soil with Rubber Granulate. In Analizy i Doświadczenia w Geoinżynierii; Bzówka, J., Łupieżowiec, M., Eds.; Politechniki Śląskiej: Gliwice, Poland, 2017; Volume 651, pp. 261–270. ISBN 978-8-37-880446-8. [Google Scholar]

- Kowalska, M.; Ptaszek, M. Influence of Rubber and Mineral Admixtures on Selected Swelling Properties of Red Clay. In Proceedings of the 3rd World Multidisciplinary Civil Engineering, Architecture, Urban Planning Symposium (WMCAUS 2018), Prague, Czech Republic, 18–22 June 2018. [Google Scholar] [CrossRef]

- Kalkan, E. Preparation of Scrap Tire Rubber Fiber–Silica Fume Mixtures for Modification of Clayey Soils. Appl. Clay Sci. 2013, 80–81, 117–125. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Mirzababaei, M.; Vanapalli, S.K. Deng Swell–Shrink Behavior of Rubberized Expansive Clays During Alternate Wetting and Drying. Minerals 2019, 9, 224. [Google Scholar] [CrossRef] [Green Version]

- Soltani, A.; Deng, A.; Taheri, A.; Sridharan, A. Swell–Shrink–Consolidation Behavior of Rubber–Reinforced Expansive Soils. Geotech. Test. J. 2019, 42, 761–788. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Mirzababaei, M. Rubber Powder–Polymer Combined Stabilization of South Australian Expansive Soils. Geosynth. Int. 2018, 25, 304–321. [Google Scholar] [CrossRef]

- Tafti, M.F.; Emadi, M.Z. Impact of Using Recycled Tire Fibers on the Mechanical Properties of Clayey and Sandy Soils. Elec-tron. J. Geotech. Eng. 2016, 21, 7113–7125. [Google Scholar]

- Tajdini, M.; Nabizadeh, A.; Taherkhani, H.; Zartaj, H. Effect of Added Waste Rubber on the Properties and Failure Mode of Kaolinite Clay. Int. J. Civ. Eng. 2016, 15, 949–958. [Google Scholar] [CrossRef]

- Jastrzębska, M. Strength Characteristics of Clay-Rubber Waste Mixtures in UU Triaxial Tests. Geosciences 2019, 9, 352. [Google Scholar] [CrossRef] [Green Version]

- Yadav, J.S.; Tiwari, S.K. The Impact of End-of-Life Tires on the Mechanical Properties of Fine-Grained Soil: A Review. Environ. Dev. Sustain. 2019, 21, 485–568. [Google Scholar] [CrossRef]

- Indraratna, B.; Rujikiatkamjorn, C.; Tawk, M.; Heitor, A. Compaction, Degradation and Deformation Characteristics of an Energy Absorbing Matrix. Transp. Geotech. 2019, 19, 74–83. [Google Scholar] [CrossRef]

- Özkul, Z.H.; Baykal, G. Shear Behavior of Compacted Rubber Fiber-Clay Composite in Drained and Undrained Loading. J. Geotech. Geoenviron. Eng. 2007, 133, 767–781. [Google Scholar] [CrossRef]

- Soltani, A.; Taheri, A.; Deng, A.; Nikraz, H. Tyre Rubber and Expansive Soils: Two Hazards, One Solution. Proc. Inst. Civ. Eng. Constr. Mater. 2020, 1–17. [Google Scholar] [CrossRef]

- CEN CWA 14243-2002. In Post-Consumer Tire Materials and Applications; PKN: Warszawa, Poland, 2002.

- ASTM D 6270-08. In Standard Practice for Use a Scrap Tires in Civil Engineering Applications; ASTM: Philadelphia, PA, USA, 2014.

- Das, T.; Singh, B. Strength Behaviour of Cohesive Soil-Fly Ash-Waste Tyre Mixtures. In Proceedings of the SAITM Research Symposium on Engineering Advancements, University of Moratuwa, Malabe, Sri Lanka, 27–28 April 2012; pp. 35–38. [Google Scholar]

- Yadav, J.; Tiwari, S. A Study on the Potential Utilization of Crumb Rubber in Cement Treated Soft Clay. J. Build. Eng. 2017, 9, 177–191. [Google Scholar] [CrossRef]

- Qi, Y.; Indraratna, B. Energy-Based Approach to Assess the Performance of a Granular Matrix Consisting of Recycled Rubber, Steel-Furnace Slag, and Coal Wash. J. Mater. Civ. Eng. 2020, 32, 04020169. [Google Scholar] [CrossRef]

- Qi, Y.; Indraratna, B.; Tawk, M. Use of Recycled Rubber Elements in Track Stabilisation. Geo-Congress 2020, 319, 49–59. [Google Scholar] [CrossRef]

- Akbarimehr, D.; Fakharian, K. Dynamic Shear Modulus and Damping Ratio of Clay Mixed with Waste Rubber using Cyclic Triaxial Apparatus. Soil Dyn. Earthq. Eng. 2021, 140, 106435. [Google Scholar] [CrossRef]

- Indraratna, B.; Qi, Y.; Jayasuriya, C.; Heitor, A.R.; Navaratnarajah, S.K. Use of Rubber Tyre Elements in Track Stabilization. In Proceedings of the 9th Asian Young Geotechnical Engineers Conference, Invited Keynote Lecture, Lahore, Pakistan, 5–7 December 2019; Available online: https://www.researchgate.net/publication/339900917_Use_of_Rubber_Tyre_Elements_in_Track_Stabilization (accessed on 5 December 2019).

- Sarajpoor, S.; Kavand, A.; Zogh, P.; Ghalandarzadeh, A. Dynamic Behavior of Sand-Rubber Mixtures Based on Hollow Cylinder Tests. Constr. Build. Mater. 2020, 251, 118948. [Google Scholar] [CrossRef]

- Akbarimehr, D.; Eslami, A.; Aflaki, E. Geotechnical Behaviour of Clay Soil Mixed with Rubber Waste. J. Clean. Prod. 2020, 271, 122632. [Google Scholar] [CrossRef]

- Andersen, K.H. Behaviour of Clay Subjected to Undrained Cyclic Loading. In Proceedings of the BOSS’76, Trondheim, Norway, 2–5 August 1976; Volume 1, pp. 392–403. [Google Scholar]

- Andersen, K.H.; Lauritzsen, R. Bearing Capacity for Foundations with Cyclic Loads. J. Geotech. Eng. 1988, 114, 540–555. [Google Scholar] [CrossRef]

- Wood, D.M. Laboratory Investigations of the Behaviour of Soils under Cyclic Loading: A review. In Soil Mechanics-Transient and Cyclic Loads; Pande, G.N., Zienkiewicz, O.C., Eds.; Wiley: New York, NY, USA, 1982; Volume 20, pp. 513–582. [Google Scholar]

- Leal, A.N.; Kaliakin, V. Behavior of Cohesive Soils Subjected to Cyclic Loading; An Extensive Review of Pertinent Literature, Research Report; Department of Civil and Environmental Engineering, University of Delaware: Newark, DE, USA, September 2013; Available online: http://nwp.engr.udel.edu/cieg/faculty/kaliakin/CEE_Report_cyclic_13.pdf (accessed on 15 June 2020).

- Sangrey, D.A.; France, J.W. Peak Strength of Clay Soils after a Repeated Loading History. In International Symposium on Soils under Cyclic and Transient Loading; Balkema: Rotterdam, The Netherland, 1980; Volume 1, pp. 421–430. [Google Scholar]

- Matasović, N.; Vucetic, M. Generalized Cyclic-Degradation-Pore-Pressure Generation Model for Clays. J. Geotech. Eng. 1995, 121, 33–42. [Google Scholar] [CrossRef]

- Jastrzębska, M. Investigations of the Behaviour of Cohesive Soils Subject to Cyclic Loads in the Area of Small Deformations; Monograph, D.S., Ed.; Silesian University of Technology Publishers: Gliwice, Poland, 2010. [Google Scholar]

- Kalinowska, M.; Jastrzębska, M. Behaviour of Cohesive Soil Subjected to Low-Frequency Cyclic Loading in Strain-Controlled Tests. Stud. Geotech. Mech. 2015, 36, 21–35. [Google Scholar] [CrossRef] [Green Version]

- Jastrzebska, M. The External and Internal Measurement Impact on Shear Modulus Distribution within Cyclic Small Strains in Triaxal Studies into Cohesive Soil. In Proceedings of the EPJ Web of Conferences, Gliwice, Poland, 10 June 2010; Volume 6, p. 22014. [Google Scholar] [CrossRef] [Green Version]

- Jastrzębska, M.; Sternik, K. Application of Elasto-Plastic Model with Anisotropic Hardening to Analysis of Cyclic Loading of Cohesive Soil. In Proceedings of the International Conference on “Cyclic Behaviour of Soils and Liquefaction Phenomena”, Bochum, Germany, 31 March–2 April 2004; pp. 41–46. [Google Scholar]

- Jastrzębska, M.; Łupieżowiec, M. The Effect of the Rate on the Cyclic Strains in the Cohesive Soils in the Light of Theoretical and Laboratory Tests. In Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 12–16 September 2005; pp. 807–810. [Google Scholar]

- Jastrzębska, M. The Influence of Overconsolidation Ratio on the “Gs-ε1” Dependence for Cyclic Loading of Cohesive Soils in the Range of Small Strains. Studia Geotechnica et Mechanica. Stud. Geotech. Mech. 2010, 32, 17–28. [Google Scholar]

- Jastrzębska, M. The Influence of Selected Parameters of Cyclic Process on Cohesive Soils Shear Characteristics at Small Strains. Arch. Civ. Eng. 2010, 56, 89–107. [Google Scholar] [CrossRef] [Green Version]

- Jastrzębska, M. Influence de l’Amplitude et du Niveau Initial de Déchargement sur la Relation “Gs-ε1” en Cas de Charge-ment Cyclique des Sols Cohésifs dans la Zone de Petites Deformations. Stud. Geotech. Mech. 2010, 32, 17–27. [Google Scholar]

- Yasuhara, K.; Hirao, K.; Hyde, A.F. Effects of Cyclic Loading on Undrained Strength and Compressibility of Clay. Soils Found. 1992, 32, 100–116. [Google Scholar] [CrossRef] [Green Version]

- Vuetic, M.; Dobry, R. Degradation of Marine Clays under Cyclic Loading. J. Geotech. Eng. 1998, 114, 133–149. [Google Scholar] [CrossRef]

- Jastrzębska, M.; Kowalska, M. Triaxial Tests on Weak Cohesive Soils—Some Practical Remarks (part 2). Arch. Civ. Eng. Envi-ron. 2016, 9, 81–94. [Google Scholar] [CrossRef] [Green Version]

- Kowalska, M.; Jastrzębska, M. Triaxial Tests on Weak Cohesive Soils-Some Practical Remarks (Part 1). Arch. Civ. Eng. Environ. 2016, 9, 71–80. [Google Scholar] [CrossRef] [Green Version]

- Jastrzębska, M.; Kalinowska-Pasieka, M. Selected Research Methods in Modern Geotechnical Laboratory. In From the Subsoil to the Soil Parameters; Silesian University of Technology Publishers: Gliwice, Poland, 2015; Volume 313, ISBN 978-83-7880-210-5. [Google Scholar]

- Stempkowska, A. Determination of Properties of Clays and Clinker Masses. Red Clay; AGH University of Science and Technology: Kraków, PL, USA, 2014; Unpublished report. [Google Scholar]

- PN-EN ISO 14688-2:2006. In Geotechnical Investigation and Testing—Determination and Classification of Soils—Part 2: Classification Rules; PKN: Warszawa, Poland, 2006.

- ASTM D2487-11. In Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: Philadelphia, PA, USA, 2017.

- PN-EN ISO 17892-5:2017-06. In Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 5: Incremental Loading Oedometer Test; PKN: Warszawa, Poland, 2017.

- Holtz, W.G.; Gibbs, H.J. Engineering Properties of Expansive Clays. Trans. Am. Soc. Civ. Eng. 1956, 121, 641–663. [Google Scholar] [CrossRef]

- Head, K.H. Manual of Soil Laboratory Testing: Soil Classification and Compaction Test, 3rd ed.; Whittles Publishing: Scotland, UK, 2006; Volume 1. [Google Scholar]

- Jastrzębska, M. Calibration and Verification of One-Surface Elasto-Plastic Soil Model of Strongly Non-Linear Anisotropic Strengthening. Ph.D. Thesis, Silesian University of Technology, Gliwice, Poland, 2002. [Google Scholar]

- Akbulut, S.; Arasan, S.; Kalkan, E. Modification of Clayey Soils using Scrap Tire Rubber and Synthetic Fibers. Appl. Clay Sci. 2007, 38, 23–32. [Google Scholar] [CrossRef]

- PKN-CEN ISO/TS 17892-3:2009. In Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 3: Determination of Particle Density—Pycnometer Method; PKN: Warszawa, Poland, 2009.

- PKN-CEN ISO/TS 17892-12:2009. In Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 12: Determination of Atterberg Limits; PKN: Warszawa, Poland, 2009.

- ASTM D422-63:(2007)e2. In Standard Test Method for Particle-Size Analysis of Soils; ASTM International: West Conshohocken, PA, USA, 2007.

- PKN CEN ISO/TS 17892-4:2009. In Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution; PKN: Warszawa, Poland, 2009.

- PN EN 13286-2:2010. In Unbound and Hydraulically Bound Mixtures—Part 2: Test Methods for Laboratory Reference Density and Water Content—Proctor Compaction; PKN: Warszawa, Poland, 2010.

- Kowalska, M.; Rios, S.; Kijanka, M.; Jastrzębska, M. The Use of Scrap Tire Rubber in Geotechnical Engineering. Available online: https://www.researchgate.net/project/The-use-of-scrap-tire-rubber-in-geotechnical-engineering (accessed on 28 October 2016).

- PN-EN ISO 17892-9:2018-05. In Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 9: Consolidated Triaxial Compression Test on Water Saturated; PKN: Warszawa, Poland, 2020.

- Yadav, J.S.; Tiwari, S.K. Effect of Inclusion of Crumb Rubber on the Unconfined Compressive Strength and Wet-Dry Dura-bility of Cement Stabilized Clayey Soil. J. Build. Mater. Struct. 2016, 3, 68–84. [Google Scholar] [CrossRef]

- Głuchowski, A.; Sas, W. Long-Term Cyclic Loading Impact on the Creep Deformation Mechanism in Cohesive Materials. Materials 2020, 13, 3907. [Google Scholar] [CrossRef] [PubMed]

- Hong, Y.; Yang, Z.; Orense, R.P.; Lu, Y. Investigation of Sand–Tire Mixtures as Liquefaction Remedial Measure. In Proceedings of the 10th Pacific Conference on Earthquake Engineering—Building an Earthquake Resilient Pacific. Australian Earthquake Engineering Society, Sydney, Australia, 6–8 November 2015. [Google Scholar]

- Rios, S.; Kowalska, M.; da Fonseca, A.V. Cyclic and Dynamic Behavior of Sand–Rubber and Clay–Rubber Mixtures. Geotech. Geol. Eng. 2021, 1–19. [Google Scholar] [CrossRef]

- Soroush, A.; Soltani-Jigheh, H. Pre- and post-cyclic behavior of mixed clayey soils. Can. Geotech. J. 2009, 46, 115–128. [Google Scholar] [CrossRef]

- Głuchowski, A.; Sas, W.; Soból, E.; Gabryś, K.; Szymański, A. Pore Pressure Behavior of Compacted Clay Under Long-Term Cyclic Loads in Undrained Conditions. In Proceedings of the ECSMGE, Reykjavik, Iceland, 1–6 September 2019. [Google Scholar] [CrossRef]

- Kucharczyk, K.; Głuchowski, A.; Miturski, M.; Sas, W. Influence of Load Frequency on Cohesive Soil Respond. Geosciences 2018, 8, 468. [Google Scholar] [CrossRef] [Green Version]

- Li, L.-L.; Dan, H.-B.; Wang, L.-Z. Undrained Behavior of Natural Marine Clay under Cyclic Loading. Ocean Eng. 2011, 38, 1792–1805. [Google Scholar] [CrossRef]

- Matsui, T.; Ohara, H.; Ito, T. Cyclic Stress-Strain History and Shear Characteristics of Clay. J. Geotech. Eng. Div. 1980, 106, 1101–1120. [Google Scholar] [CrossRef]

- Hanna, A.M.; Javed, K. Design of Foundations on Sensitive Champlain Clay Subjected to Cyclic Loading. J. Geotech. Geoenvironmental Eng. 2008, 134, 929–937. [Google Scholar] [CrossRef]

- Ren, X.-W.; Xu, Q.; Xu, C.-B.; Teng, J.-D.; Lv, S.-H. Undrained Pore Pressure Behavior of Soft Marine Clay under Long-Term Low Cyclic Loads. Ocean Eng. 2018, 150, 60–68. [Google Scholar] [CrossRef]

- Soltani, A.; Taheri, A.; Deng, A.; O’Kelly, B.C. Improved Geotechnical Behavior of an Expansive Soil Amended with Tire-Derived Aggregates Having Different Gradations. Minerals 2020, 10, 923. [Google Scholar] [CrossRef]

| Properties | Red Clay (RC) | Kaolin (K) | Standard Designation |

|---|---|---|---|

| Value | Value | ||

| Specific gravity, Gs (g/cm3) | 2.77 | 2.64 | PKN-CEN ISO/TS 17892-3 [72] |

| Consistency limits: | |||

| Plastic limit, PL (%) | 25 | 20 | PKN-CEN ISO/TS 17892-12 [73] |

| Liquid limit—Casagrande method, LL (%) | 75 | 42 | PKN-CEN ISO/TS 17892-12 [73] |

| Swelling properties: | |||

| Swelling pressure, σsp (kPa) 1 | 97 | - | PN-EN ISO 17892-5 [67] |

| Free-swell, FS (%) | 31.50 | - | Head [69] |

| Grain size distribution: | ASTM D422 [74] | ||

| Gravel (>2000 μm), (%) | 0 | 0 | |

| Sand (75–2000 μm), (%) | 0 | 2 | |

| Silt (2–75 μm), (%) | 71 | 60 | |

| Clay (<2 μm), (%) | 29 | 38 | PKN CEN ISO/TS 17892-4 [75] |

| Mineralogy: | |||

| Quartz, (%) | 41.8 | - | |

| Kaolinite, (%) | 31.5 | - | |

| Illite, (%) | 19.5 | - | |

| Siderite, (%) | 5.6 | - | |

| Goethite, (%) | 2.0 | - | |

| EC7 2 soil classification | siCl 3 | siCl 3 | PN-EN ISO 14688-2 [65] |

| USCS 4 soil classification | CH 5 | CL 6 | ASTM D2487-11 [66] |

| Compaction characteristics: | PN EN 13286-2 [76] | ||

| Optimum moisture content (OMC), wopt (%) | 18.0 | 19.0 | |

| Maximum dry density, ρdmax (g/cm3) | 1.75 | 1.79 |

| Effective Diameter/Properties | Red Clay | Kaolin | Powder | Granulate |

|---|---|---|---|---|

| d10, (mm) | 0.0008 | 0.0001 | 0.165 | 1.12 |

| d30, (mm) | 0.002 | 0.001 | 0.34 | 1.45 |

| d50, (mm) | 0.0045 | 0.0046 | 0.5 | 2.0 |

| d60, (mm) | 0.008 | 0.008 | 0.58 | 2.35 |

| d90, (mm) | 0.02 | 0.05 | 0.85 | 4.0 |

| Coefficient of uniformity, Cu | 100 | 73 | 3.5 | 2.1 |

| Coefficient of curvature, Cc | 0.63 | 1.25 | 1.2 | 0.8 |

| Symbol of Test | Material | Rubber Content (%) | Type of Test | Total Amplitude A (kPa) | Skempton’s Parameter B (-) | Effective Confining Pressure (Shearing) σ’3 (kPa) | Density ρ for w = 18% (g/cm3) | Initial Void Ratio e0 (-) |

|---|---|---|---|---|---|---|---|---|

| rc1-2 | RC 1 | 0 | C-10000 5 | 38 | 0.86 | 20 | 1.85 | 0.87 |

| rc3-1 | RC-G 2-5 | 5 | C-1000 | 25 | 0.89 | 20 | 1.68 | 0.89 |

| rc5-1 | RC-G-10 | 10 | C-1000 6 | 35 | 0.79 | 20 | 1.62 | 0.90 |

| rc5-3 | 50 | 50 | ||||||

| rc5-4 | 80 | 80 | ||||||

| rc4-1 | RC-G-25 | 25 | C-1000 | 25 | 0.87 | 20 | 1.46 | 0.93 |

| rc4-2 | 35 | 50 | ||||||

| rc4-3 | 31 | 80 | ||||||

| rc4-4 | M 7 | - | 20 | |||||

| rc2-1 | RC-P 3-10 | 10 | C-10000 | 37 | 0.94 | 20 | 1.64 | 0.89 |

| k1-2 | K 4-G-25 | 25 | C-1000 | 35 | 0.95 | 100 | 1.52 | 0.82 |

| k1-3 | 35 | 200 | ||||||

| k1-1 | 44 | 300 | ||||||

| k1-4 | M | - | 300 | |||||

| (8) | K | 0 | M | various | 0.99 | (50–350) | 1.94 | 0.84 for w = 31% |

| Symbol of Test | Material | Increase in Axial Strain after 10/100/1000/10,000 Cycles (%) | Ratio of Reduction in Axial Strain after 10/100/ 1000/10,000 Cycles (-) | Increase in Pore Pressure after 10/100/ 1000/10,000 Cycles (kPa) | Ratio of Reduction in Pore Pressure after 10/100/ 1000/10,000 Cycles (-) |

|---|---|---|---|---|---|

| rc1-2 | RC | 0.12/0.36/ | - | –2.6/–5.6/ | - |

| 0.59/0.77 | –10.2/–21.3 | ||||

| rc3-1 | RC-G-5 | 0.06/0.21/ | 0.5/0.58/ | –0.8/–1.0/ | 0.31/0.18/ |

| 0.44/- | 0.75/- | −5.4/- | 0.53/- | ||

| rc5-1 | RC-G-10 | 0.13/0.43/ | 1.08/1.19/ | - | - |

| 0.77/- | 1.31/- | ||||

| rc5-3 | 0.18/0.51/ | - | 3.6/32.8/ | - | |

| 1.07/- | 99.5/- | ||||

| rc5-4 | 0.14/0.41/ | - | 4.4/5.8/ | - | |

| 0.75/- | 81.0/- | ||||

| rc4-1 | RC-G-25 | 0.10/0.30/ | 0.83/0.83/ | 0.2/0.5/ | –0.08/–0.09/ |

| 0.61/- | 1.03/- | –0.5/- | 0.44/- | ||

| rc4-2 | 0.12/0.36/ | - | 1.5/6.3/ | - | |

| 0.74/- | 24.7/- | ||||

| rc4-3 | 0.10/0.26/ | - | 0.4/14.9/ | - | |

| 0.51/- | 58.6/- | ||||

| rc4-4 | - | - | - | - | |

| rc2-1 | RC-P-10 | 0.22/0.42/ | 1.83/1.17/ | 4.4/9.3/ | –1.7/–1.7/ |

| 0.77/1.52 | 1.31/1.97 | 28.9/42.0 | –2.8/–1.97 | ||

| k1-2 | K-G-25 | 0.05/0.15/ | - | 2.8/9.3/ | - |

| 0.34/- | 36.1/- | ||||

| k1-3 | 0.06/0.17/ | - | 3.0/19.0/ | - | |

| 0.20/- | 83.3/- | ||||

| k1-1 | 0.07/0.19/ | - | 4.2/24.1/ | - | |

| 0.29/- | 120.2/- | ||||

| k1-4 | - | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jastrzębska, M.; Tokarz, K. Strength Characteristics of Clay–Rubber Waste Mixtures in Low-Frequency Cyclic Triaxial Tests. Minerals 2021, 11, 315. https://doi.org/10.3390/min11030315

Jastrzębska M, Tokarz K. Strength Characteristics of Clay–Rubber Waste Mixtures in Low-Frequency Cyclic Triaxial Tests. Minerals. 2021; 11(3):315. https://doi.org/10.3390/min11030315

Chicago/Turabian StyleJastrzębska, Małgorzata, and Krzysztof Tokarz. 2021. "Strength Characteristics of Clay–Rubber Waste Mixtures in Low-Frequency Cyclic Triaxial Tests" Minerals 11, no. 3: 315. https://doi.org/10.3390/min11030315

APA StyleJastrzębska, M., & Tokarz, K. (2021). Strength Characteristics of Clay–Rubber Waste Mixtures in Low-Frequency Cyclic Triaxial Tests. Minerals, 11(3), 315. https://doi.org/10.3390/min11030315