Strength and Ultrasonic Characteristics of Cemented Paste Backfill Incorporating Foaming Agent

Abstract

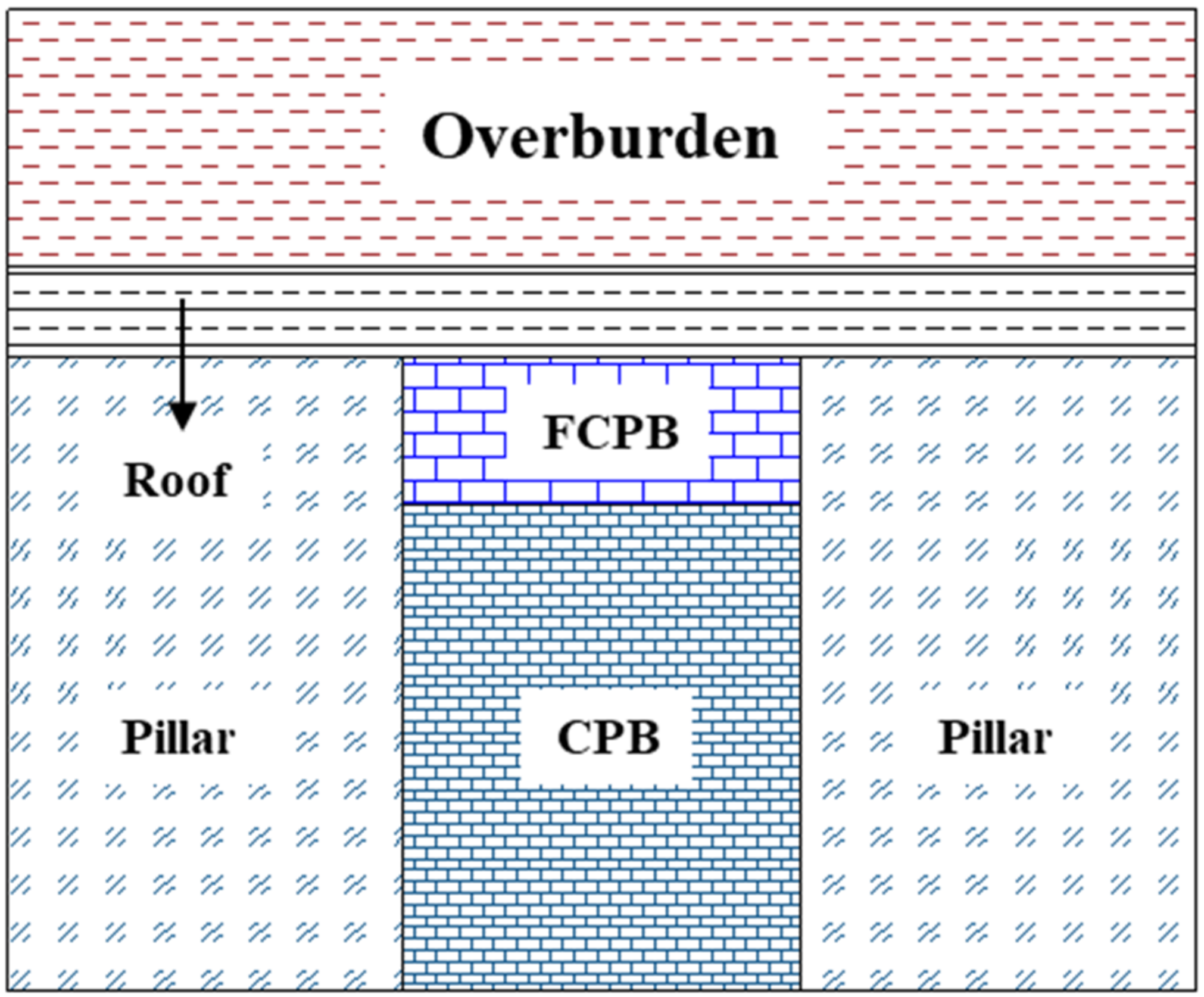

:1. Introduction

2. Materials and Methods

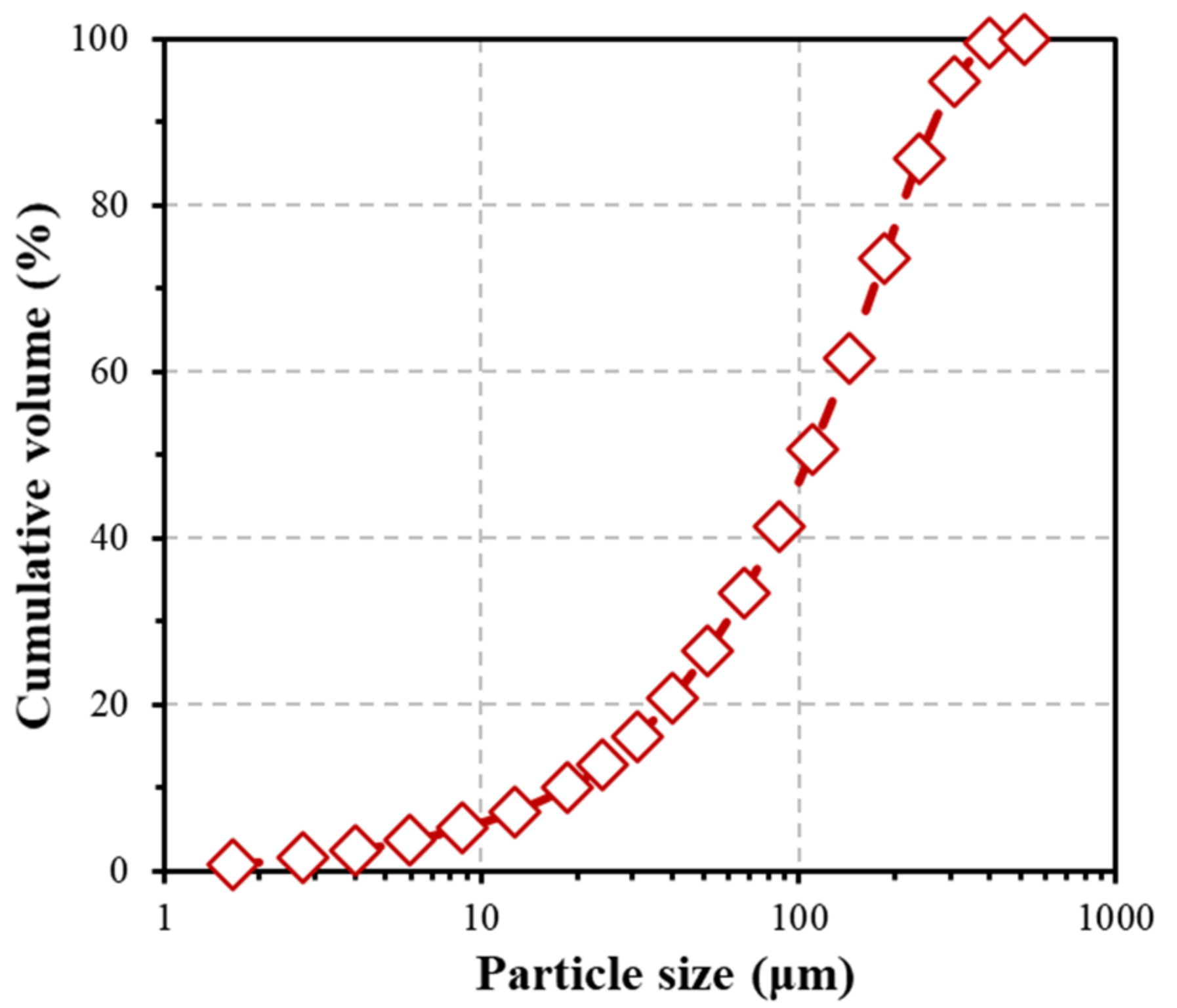

2.1. Raw Materials

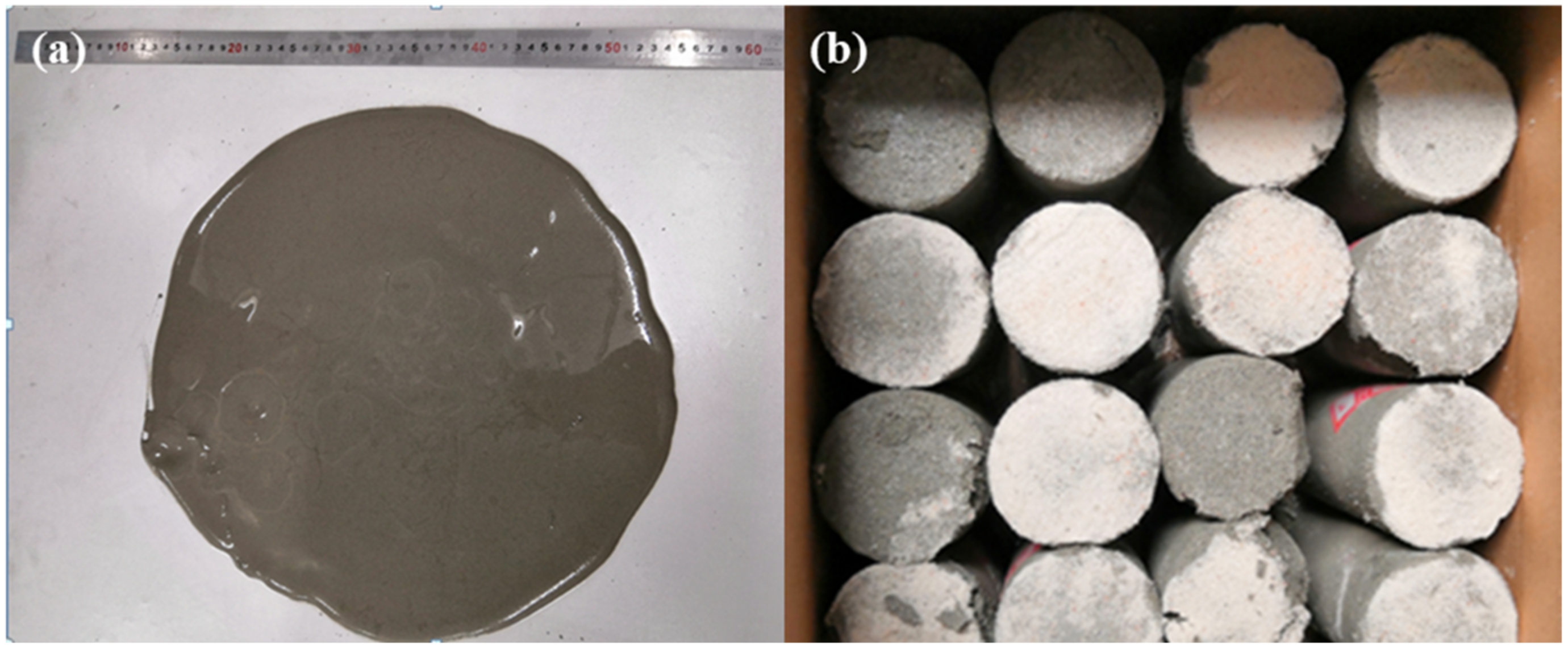

2.2. FCPB Preparation

2.3. Experimental

2.3.1. Expansion Rate and Fluidity Tests

2.3.2. Apparent Density, UPV, and UCS Tests

3. Results and Discussion

3.1. Determination of Admixture Contents

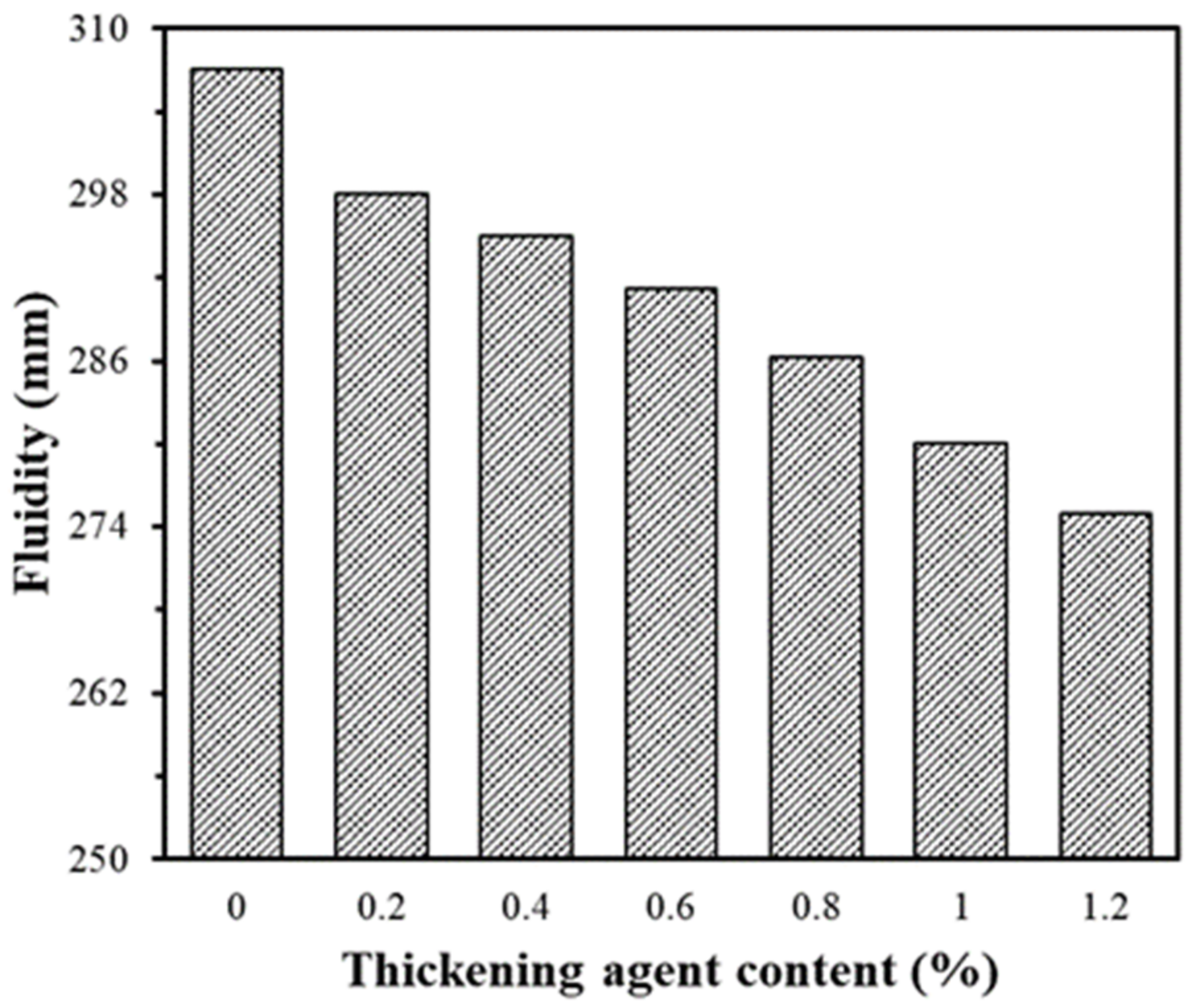

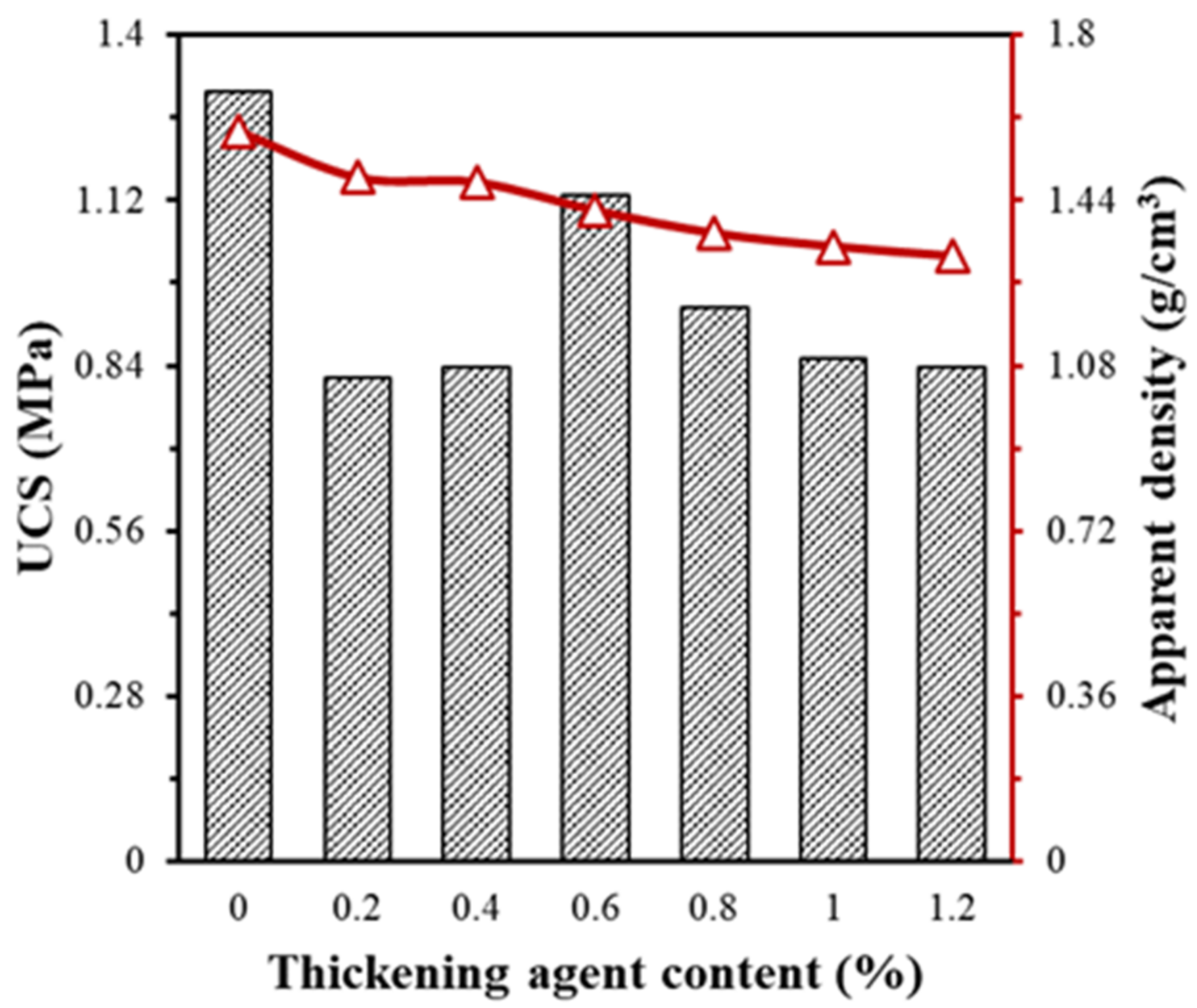

3.1.1. Determination of Thickening Agent Content

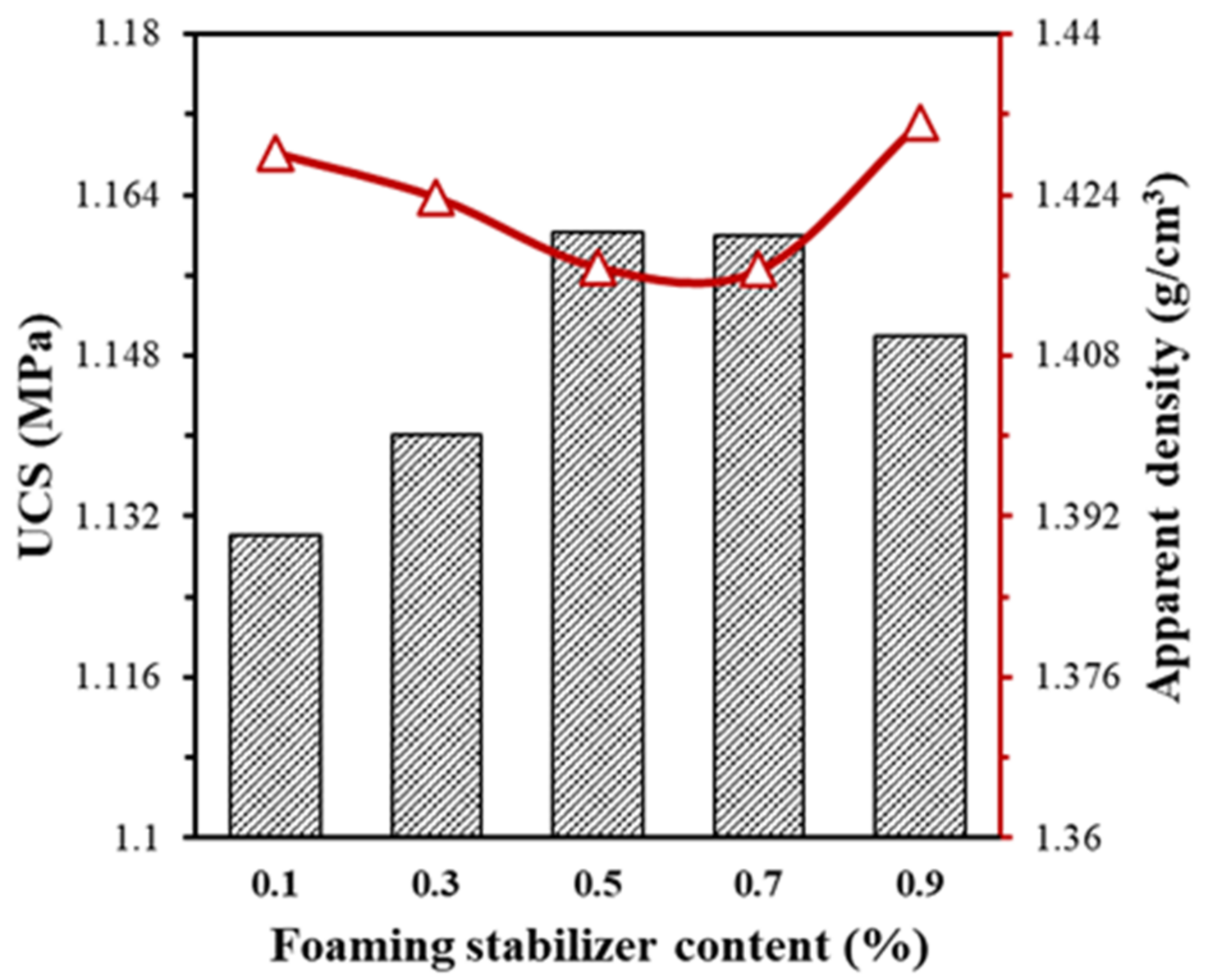

3.1.2. Determination of Foaming Stabilizer Content

3.1.3. Determination of Foaming Agent Content

3.2. Strength Characteristics of FCPB

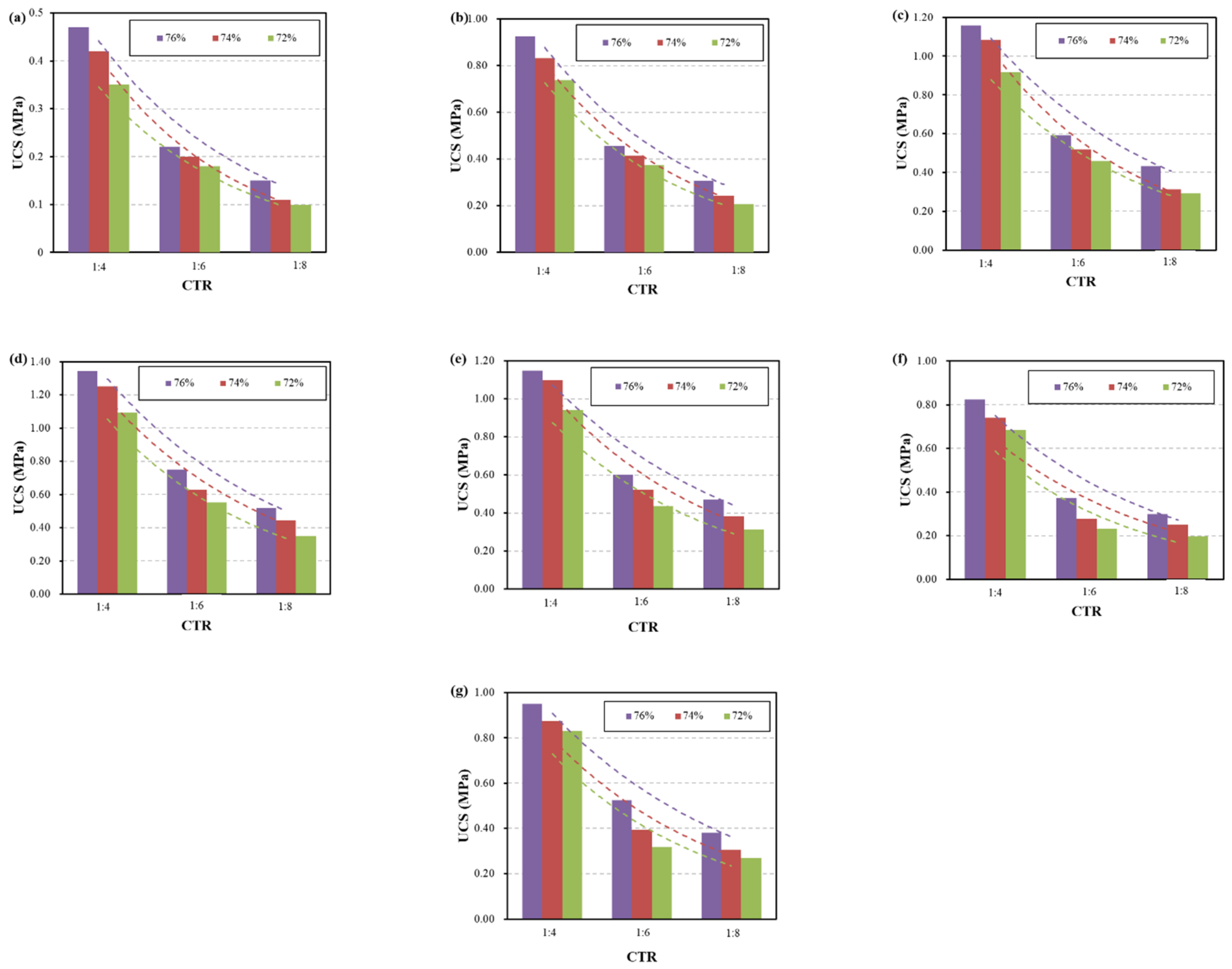

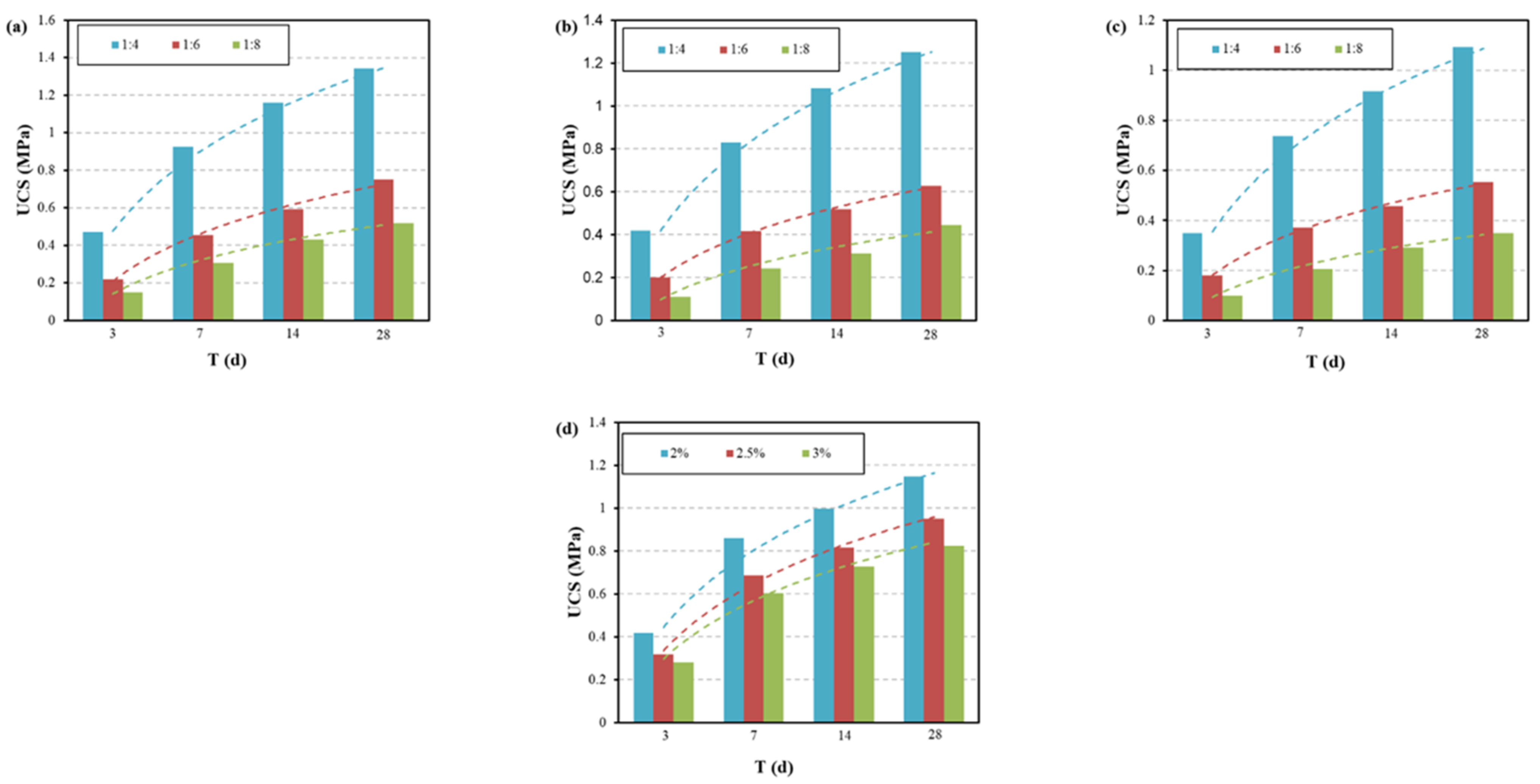

3.2.1. Effect of CTRs on the UCS of FCPB

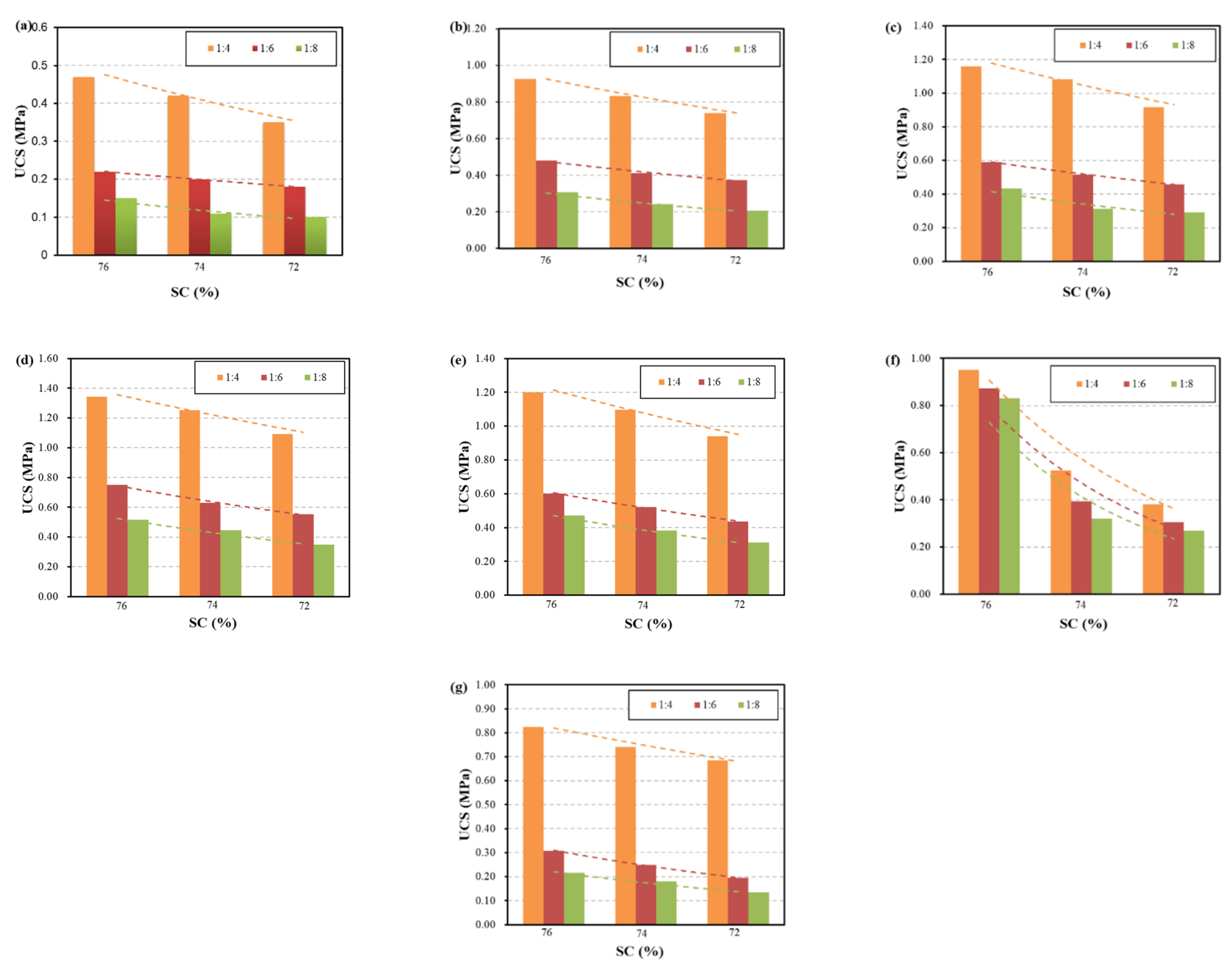

3.2.2. Effect of SCs on the UCS of FCPB

3.2.3. Effect of Ts on the UCS of FCPB

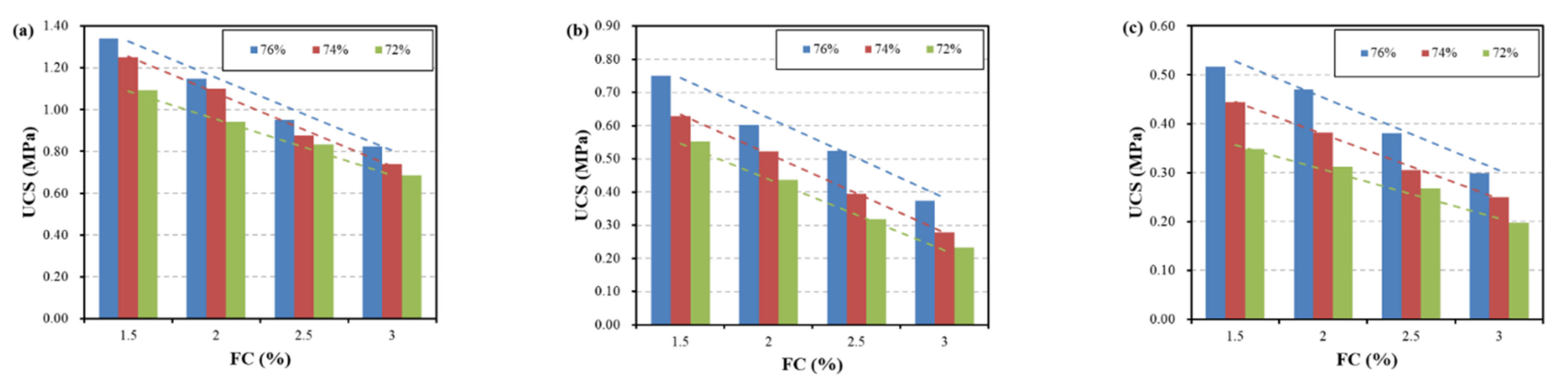

3.2.4. Effect of FCs on the UCS of FCPB

3.2.5. Factor Sensitivity Analysis

3.3. UPV Characteristics of FCPB

3.3.1. Effects of FC, SC, CTR, and T on the UPV of FCPB

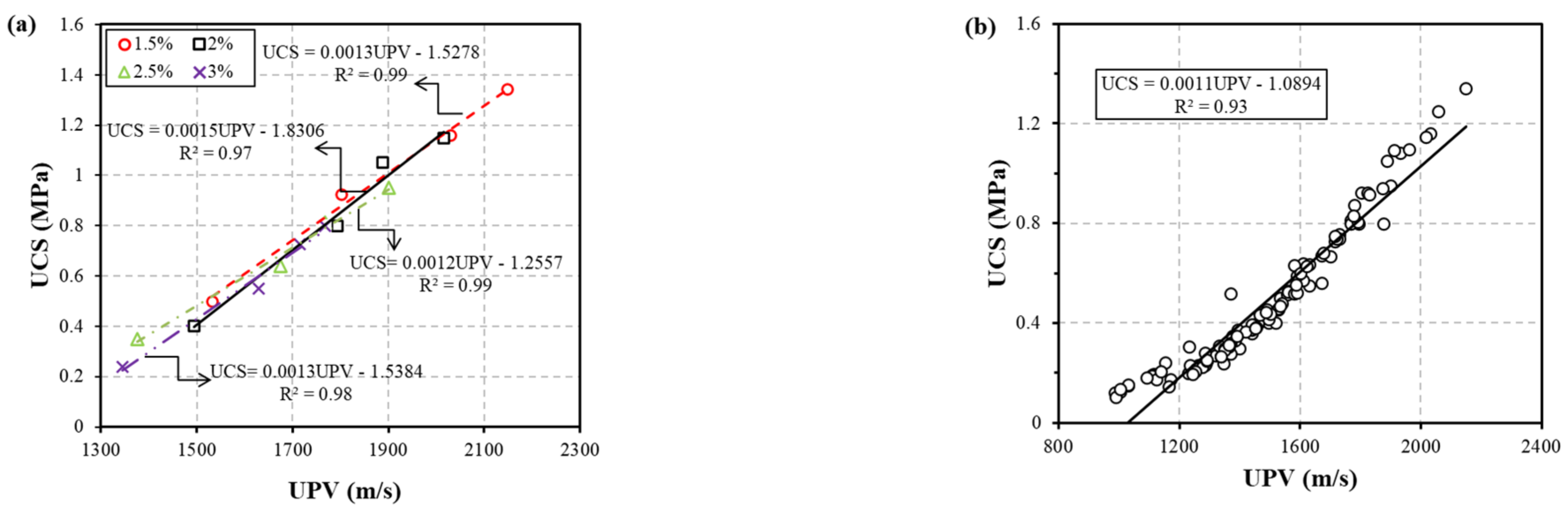

3.3.2. Relationships between UCS and UPV

4. Conclusions

- (1)

- The UCS of FCPB increases first and then decreases with increasing foaming stabilizer content, while the corresponding apparent density changes are the opposite. This is because the adsorption of calcium stearate on the bubble film affects the stability of bubbles in the slurry. The fluidity and apparent density of FCPB always decrease with thickening agent dosage, while the UCS increases first and then decreases. This can be attributed to the fact that polypropylene fiber, the main component of the thickening agent, affects the thickness of the water film on the bubble and the consistency of the slurry, thus affecting the stability and distribution of bubbles. As the FC increases, the expansion rate continues to increase but fluidity decreases. Moreover, the optimal contents of foaming stabilizer, thickening agent, and foaming agent are 0.5%, 0.6%, and 1% to 3%, respectively.

- (2)

- The UCS of FCPB increases in an exponential manner with SC and CTR, and grows logarithmically with curing time but linearly decreases with higher FC. The increase in porosity because of the increased volume of bubbles leads to a decrease in UCS. CTR has the highest influence on the UCS of FCPB, followed by T, SC, and FC.

- (3)

- As FC increases, the UPV of FCPB linearly decreases. This can be attributed to the significant increase in porosity caused by the increased air bubbles. The UCS and the corresponding UPV have linear relationships with all the tested FCPB samples, regardless of CTR, SC, T, and FC. This indicates that the UPV can be reliably and accurately used to estimate the UCS of FCPB.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fall, M.; Pokharel, M. Coupled effects of sulphate and temperature on the strength development of cemented tailings backfills: Portland cement-paste backfill. Cem. Concr. Compos. 2010, 32, 819–828. [Google Scholar] [CrossRef]

- Xu, W.; Cao, P.; Tian, M. Strength Development and Microstructure Evolution of Cemented Tailings Backfill Containing Different Binder Types and Contents. Minerals 2018, 8, 167. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Feng, M.; Xu, J.; Qiu, P.; Wang, Y.; Han, G. Particle size distribution of cemented rockfill effects on strata stability in filling mining. Minerals 2018, 8, 407. [Google Scholar] [CrossRef] [Green Version]

- Benzaazoua, M.; Fall, M.; Belem, T. A contribution to understanding the hardening process of cemented pastefill. Miner. Eng. 2004, 17, 141–152. [Google Scholar] [CrossRef]

- Dutta, D.; Ghosh, S. The role of delayed water curing in improving the mechanical and microstructural properties of alkali activated fly ash based geopolymer paste blended with slag. World J. Eng. 2019, 16, 103–114. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.; Taheri, A.; Deng, J.; Ke, B. Effects of Superplasticizer on the Hydration, Consistency, and Strength Development of Cemented Paste Backfill. Minerals 2018, 8, 381. [Google Scholar] [CrossRef] [Green Version]

- Jiang, H.; Fall, M.; Yilmaz, E.; Li, Y.; Yang, L. Effect of mineral admixtures on flow properties of fresh cemented paste backfill: Assessment of time dependency and thixotropy. Powder Technol. 2020, 372, 258–266. [Google Scholar] [CrossRef]

- Dwivedi, S.; Dwivedi, G. Utilization of recycled hazardous waste bagasse as reinforcement to develop green composite material. World J. Eng. 2020, 17, 399–406. [Google Scholar] [CrossRef]

- Deepa, P.; Laad, M.; Sangita; Singh, R. An overview of use of nanoadditives in enhancing the properties of pavement construction binder bitumen. World J. Eng. 2019, 16, 132–137. [Google Scholar]

- Singh, K.P.; Kumar, A.; Kaushal, D.R. Pressure drop calculation for fly ash slurry using rheological model. World J. Eng. 2019, 16, 751–767. [Google Scholar] [CrossRef]

- Yang, L.; Yilmaz, E.; Li, J.; Liu, H.; Jiang, H. Effect of superplasticizer type and dosage on fluidity and strength behavior of cemented tailings backfill with different solid contents. Constr. Build. Mater. 2018, 187, 290–298. [Google Scholar] [CrossRef]

- Haiqiang, J.; Fall, M.; Cui, L. Yield stress of cemented paste backfill in sub-zero environments: Experimental results. Miner. Eng. 2016, 92, 141–150. [Google Scholar] [CrossRef]

- Qiu, J.-P.; Yang, L.; Xing, J.; Sun, X.-G. Analytical solution for determining the required strength of mine backfill based on its damage constitutive model. Soil Mech. Found. Eng. 2018, 54, 371–376. [Google Scholar] [CrossRef]

- Cao, S.; Yilmaz, E.; Song, W. Evaluation of viscosity, strength and microstructural properties of cemented tailings backfill. Minerals 2018, 8, 352. [Google Scholar] [CrossRef] [Green Version]

- Mishra, P.; Mohanty, M. A review of factors affecting mining operation. World J. Eng. 2020, 17, 457–472. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, L.; Ren, F.; Qiu, J.; Ding, H. Rheological and mechanical properties of cemented foam backfill: Effect of mineral admixture type and dosage. Cem. Concr. Compos. 2020, 112, 103689. [Google Scholar] [CrossRef]

- Na, H.; Lv, G.; Wang, L.; Liao, L.; Zhang, D.; Guo, L.; Li, W. A new expansion material used for roof-contacted filling based on smelting slag. Sci. Rep. 2021, 11, 2607. [Google Scholar] [CrossRef]

- Hefni, M.; Hassani, F. Experimental Development of a Novel Mine Backfill Material: Foam Mine Fill. Minerals 2020, 10, 564. [Google Scholar] [CrossRef]

- Qiu, J.; Guo, Z.; Li, L.; Zhang, S.; Zhao, Y.; Ma, Z. A Hybrid Artificial Intelligence Model for Predicting the Strength of Foam-Cemented Paste Backfill. IEEE Access 2020, 8, 84569–84583. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Chen, Q.; Yang, C. Feasibility of recycling ultrafine leaching residue by backfill: Experimental and CFD approaches. Minerals 2017, 7, 54. [Google Scholar] [CrossRef] [Green Version]

- Falayi, T.; Ntuli, F.; Okonta, F. Synthesis of a paste backfill geopolymer using pure acidic gold mine tailings. J. Solid Waste Technol. Manag. 2018, 44, 311–320. [Google Scholar] [CrossRef]

- Zhao, H.; Ma, F.; Zhang, Y.; Guo, J. Monitoring and mechanisms of ground deformation and ground fissures induced by cut-and-fill mining in the Jinchuan Mine 2, China. Environ. Earth Sci. 2013, 68, 1903–1911. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, L.; Qiu, J.; Hou, C.; Guo, Z. Fluidity and strength behaviors of cemented foam backfill: Effect of particle size distribution and foaming agent dosage. Bull. Eng. Geol. Environ. 2021, 80, 3177–3191. [Google Scholar] [CrossRef]

- Hefni, M.; Hassani, F.; Nokken, M.; Kermani, M.; Vatne, D. Investigation into the development of foam mine fill. In Proceedings of the Eleventh International Symposium on Mining with Backfill, Perth, WA, Australia, 20–22 May 2014; pp. 49–59. [Google Scholar]

- Zhang, S.; Ren, F.; Guo, Z.; Qiu, J.; Ding, H. Strength and deformation behavior of cemented foam backfill in sub-zero environment. J. Mater. Res. Technol. 2020, 9, 9219–9231. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A.; Chen, Q.; Zhang, Q. A strength prediction model using artificial intelligence for recycling waste tailings as cemented paste backfill. J. Clean. Prod. 2018, 183, 566–578. [Google Scholar] [CrossRef]

- Yin, S.; Wu, A.; Hu, K.; Wang, Y.; Zhang, Y. The effect of solid components on the rheological and mechanical properties of cemented paste backfill. Miner. Eng. 2012, 35, 61–66. [Google Scholar] [CrossRef]

- Fall, M.; Adrien, D.; Célestin, J.C.; Pokharel, M.; Touré, M. Saturated hydraulic conductivity of cemented paste backfill. Miner. Eng. 2009, 22, 1307–1317. [Google Scholar] [CrossRef]

- Qiu, J.; Guo, Z.; Yang, L.; Jiang, H.; Zhao, Y. Effect of tailings fineness on flow, strength, ultrasonic and microstructure characteristics of cemented paste backfill. Constr. Build. Mater. 2020, 263, 120645. [Google Scholar] [CrossRef]

- Yılmaz, T.; Ercikdi, B.; Karaman, K.; Külekçi, G. Assessment of strength properties of cemented paste backfill by ultrasonic pulse velocity test. Ultrasonics 2014, 54, 1386–1394. [Google Scholar] [CrossRef] [PubMed]

- Yan, B.; Zhu, W.; Hou, C.; Yilmaz, E.; Saadat, M. Characterization of early age behavior of cemented paste backfill through the magnitude and frequency spectrum of ultrasonic P-wave. Constr. Build. Mater. 2020, 249, 118733. [Google Scholar] [CrossRef]

- Jiang, H.; Yi, H.; Yilmaz, E.; Liu, S.; Qiu, J. Ultrasonic evaluation of strength properties of cemented paste backfill: Effects of mineral admixture and curing temperature. Ultrasonics 2020, 100, 105983. [Google Scholar] [CrossRef]

- Xu, S.; Suorineni, F.T.; Li, K.; Li, Y. Evaluation of the strength and ultrasonic properties of foam-cemented paste backfill. Int. J. Min. Reclam. Environ. 2017, 31, 544–557. [Google Scholar] [CrossRef]

- Fall, M.; Belem, T.; Samb, S.; Benzaazoua, M. Experimental characterization of the stress-strain behaviour of cemented paste backfill in compression. J. Mater. Sci. 2007, 42, 3914–3922. [Google Scholar] [CrossRef]

- Qiu, J.; Yang, L.; Sun, X.; Xing, J.; Li, S. Strength characteristics and failure mechanism of cemented super-fine unclassified tailings backfill. Minerals 2017, 7, 58. [Google Scholar] [CrossRef] [Green Version]

- Sang, G.; Zhu, Y.; Yang, G.; Zhang, H. Preparation and characterization of high porosity cement-based foam material. Constr. Build. Mater. 2015, 91, 133–137. [Google Scholar] [CrossRef]

- Muhammad, N.; Adnan, M.S.; Yosuff, M.A.M.; Ahmad, K.A. A review of field methods for suspended and bedload sediment measurement. World J. Eng. 2019, 16, 147–165. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.; Qi, C.; Zhang, B.; Guo, L.; Song, K.I.-I.L. Numerical study on the pipe flow characteristics of the cemented paste backfill slurry considering hydration effects. Powder Technol. 2019, 343, 454–464. [Google Scholar] [CrossRef]

- Jiang, H.; Qi, Z.; Yilmaz, E.; Han, J.; Qiu, J.; Dong, C. Effectiveness of alkali-activated slag as alternative binder on workability and early age compressive strength of cemented paste backfills. Constr. Build. Mater. 2019, 218, 689–700. [Google Scholar] [CrossRef]

- Liu, H.; Shi, J.; Qu, H.; Ding, D. An investigation on physical, mechanical, leaching and radiation shielding behaviors of barite concrete containing recycled cathode ray tube funnel glass aggregate. Constr. Build. Mater. 2019, 201, 818–827. [Google Scholar] [CrossRef]

- Jiang, H.; Han, J.; Li, Y.; Yilmaz, E.; Sun, Q.; Liu, J. Relationship between ultrasonic pulse velocity and uniaxial compressive strength for cemented paste backfill with alkali-activated slag. Nondestruct. Test. Eval. 2020, 35, 359–377. [Google Scholar] [CrossRef]

- Prayuda, H.; Monika, F.; Cahyati, M.D. Fresh properties and compressive strength of self compacting concrete with fines aggregate replacement using red brick powder and rice husk ash. World J. Eng. 2020, 17, 473–480. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Arpitha, G.; Gopinath, V. Effect of hybridization on properties of hemp-carbon fibre-reinforced hybrid polymer composites using experimental and finite element analysis. World J. Eng. 2019, 16, 248–259. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Kataria, R. Study on flexural performance of fabricated natural fiber hybrid polypropylene composite: An experimental investigation through designed experiments. World J. Eng. 2019, 16, 389–400. [Google Scholar] [CrossRef]

- Liu, Q.-S.; Zheng, T.; Wang, P.; Jiang, J.-P.; Li, N. Adsorption isotherm, kinetic and mechanism studies of some substituted phenols on activated carbon fibers. Chem. Eng. J. 2010, 157, 348–356. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; McKinley, M. Effects of limestone fines on water film thickness, paste film thickness and performance of mortar. Powder Technol. 2014, 261, 33–41. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; Chen, J.J. Adding fly ash microsphere to improve packing density, flowability and strength of cement paste. Powder Technol. 2013, 234, 19–25. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, X. Study on volume stability of chemical foaming cement paste. KSCE J. Civ. Eng. 2017, 21, 2790–2797. [Google Scholar] [CrossRef]

- Ayub, T.; Khan, S.U.; Memon, F.A. Mechanical characteristics of hardened concrete with different mineral admixtures: A review. Sci. World J. 2014, 2014, 875082. [Google Scholar] [CrossRef]

- Cui, Y.; Wang, D.; Zhao, J.; Li, D.; Ng, S.; Rui, Y. Effect of calcium stearate based foam stabilizer on pore characteristics and thermal conductivity of geopolymer foam material. J. Build. Eng. 2018, 20, 21–29. [Google Scholar] [CrossRef]

- Zhang, Y.; Feyerabend, F.; Tang, S.; Hu, J.; Lu, X.; Blawert, C.; Lin, T. A study of degradation resistance and cytocompatibility of super-hydrophobic coating on magnesium. Mater. Sci. Eng. C 2017, 78, 405–412. [Google Scholar] [CrossRef]

- Li, L.G.; Kwan, A.K.H. Effects of superplasticizer type on packing density, water film thickness and flowability of cementitious paste. Constr. Build. Mater. 2015, 86, 113–119. [Google Scholar] [CrossRef]

- Yang, L.; Qiu, J.; Jiang, H.; Hu, S.; Li, H.; Li, S. Use of cemented super-fine unclassified tailings backfill for control of subsidence. Minerals 2017, 7, 216. [Google Scholar] [CrossRef] [Green Version]

- Panchal, S.; Deb, D.; Sreenivas, T. Variability in rheology of cemented paste backfill with hydration age, binder and superplasticizer dosages. Adv. Powder Technol. 2018, 29, 2211–2220. [Google Scholar] [CrossRef]

- Ouattara, D.; Yahia, A.; Mbonimpa, M.; Belem, T. Effects of superplasticizer on rheological properties of cemented paste backfills. Int. J. Miner. Process. 2017, 161, 28–40. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M.; Ouellet, S. Experimental characterization of the influence of tailings fineness and density on the quality of cemented paste backfill. Miner. Eng. 2005, 18, 41–44. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M.; Saa, E.G. Mix proportioning of underground cemented tailings backfill. Tunn. Undergr. Sp. Technol. 2008, 23, 80–90. [Google Scholar] [CrossRef]

- Li, J.; Yilmaz, E.; Cao, S. Influence of Solid Content, Cement/Tailings Ratio, and Curing Time on Rheology and Strength of Cemented Tailings Backfill. Minerals 2020, 10, 922. [Google Scholar] [CrossRef]

- Yang, L.; Xu, W.; Yilmaz, E.; Wang, Q.; Qiu, J. A combined experimental and numerical study on the triaxial and dynamic compression behavior of cemented tailings backfill. Eng. Struct. 2020, 219, 110957. [Google Scholar] [CrossRef]

- Ercikdi, B.; Kesimal, A.; Cihangir, F.; Deveci, H.; Alp, İ. Cemented paste backfill of sulphide-rich tailings: Importance of binder type and dosage. Cem. Concr. Compos. 2009, 31, 268–274. [Google Scholar] [CrossRef]

- Rahman, N.A.; Khairuddin, S.A.A.; Faudzi, M.F.; Asri, M.; Jamaluddin, N.; Jaini, Z. Axial strength of modified fibrous foamed concrete-filled hollow section. World J. Eng. 2019, 17, 175–181. [Google Scholar] [CrossRef]

- Duran, E.; Duran, B.U.; Akay, D.; Boran, F.E. Grey relational analysis between Turkey’s macroeconomic indicators and domestic savings. Grey Syst. Theory Appl. 2017, 7, 45–59. [Google Scholar] [CrossRef]

- Yingliang, Z.; Jingping, Q.; Zhengyu, M.A.; Zhenbang, G.; Hui, L. Effect of superfine blast furnace slags on the binary cement containing high-volume fly ash. Powder Technol. 2020. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Bussière, B.; Mbonimpa, M.; Benzaazoua, M. Curing time effect on consolidation behaviour of cemented paste backfill containing different cement types and contents. Constr. Build. Mater. 2015, 75, 99–111. [Google Scholar] [CrossRef]

| Compounds | SiO2 | Al2O3 | MgO | Fe2O3 | P2O5 | CaO | Na2O | TiO2 | SO3 |

|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 64.4 | 5.65 | 4.28 | 18.04 | 0.35 | 4.77 | 1.01 | 0.09 | 0.76 |

| Group | CTR | SC (%) | Thickening Agent (%) | Foaming Stabilizer (%) | Foaming Agent (%) |

|---|---|---|---|---|---|

| A | 1:4 | 76 | 0 | 0 | 2 |

| 0.2 | |||||

| 0.4 | |||||

| 0.6 | |||||

| 0.8 | |||||

| 1 | |||||

| 1.2 | |||||

| B | 76 | 0.6 | 0.1 | 2 | |

| 0.3 | |||||

| 0.5 | |||||

| 0.7 | |||||

| 0.9 | |||||

| C | 74 | 0.6 | 0.5 | 0 | |

| 1 | |||||

| 2 | |||||

| 3 | |||||

| 4 | |||||

| 5 | |||||

| 6 |

| CTR | T (d) | SC (%) | FC (%) |

|---|---|---|---|

| 1:4 | 3,7,14,28 | 72 | 1.5,2,2.5,3 |

| 3,7,14,28 | 74 | 1.5,2,2.5,3 | |

| 3,7,14,28 | 76 | 1.5,2,2.5,3 | |

| 1:6 | 3,7,14,28 | 72 | 1.5,2,2.5,3 |

| 3,7,14,28 | 74 | 1.5,2,2.5,3 | |

| 3,7,14,28 | 76 | 1.5,2,2.5,3 | |

| 1:8 | 3,7,14,28 | 72 | 1.5,2,2.5,3 |

| 3,7,14,28 | 74 | 1.5,2,2.5,3 | |

| 3,7,14,28 | 76 | 1.5,2,2.5,3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Sun, X.; Yao, W.; Wu, P.; Qiu, J.; Guo, Z.; Liu, N. Strength and Ultrasonic Characteristics of Cemented Paste Backfill Incorporating Foaming Agent. Minerals 2021, 11, 681. https://doi.org/10.3390/min11070681

Xu X, Sun X, Yao W, Wu P, Qiu J, Guo Z, Liu N. Strength and Ultrasonic Characteristics of Cemented Paste Backfill Incorporating Foaming Agent. Minerals. 2021; 11(7):681. https://doi.org/10.3390/min11070681

Chicago/Turabian StyleXu, Xiaochuan, Xiaogang Sun, Wei Yao, Pinqi Wu, Jingping Qiu, Zhenbang Guo, and Na Liu. 2021. "Strength and Ultrasonic Characteristics of Cemented Paste Backfill Incorporating Foaming Agent" Minerals 11, no. 7: 681. https://doi.org/10.3390/min11070681

APA StyleXu, X., Sun, X., Yao, W., Wu, P., Qiu, J., Guo, Z., & Liu, N. (2021). Strength and Ultrasonic Characteristics of Cemented Paste Backfill Incorporating Foaming Agent. Minerals, 11(7), 681. https://doi.org/10.3390/min11070681