Challenges in Raw Material Treatment at the Mechanical Processing Stage

Abstract

1. Introduction

- (a)

- reduction in the size of the feed material;

- (b)

- separation of useful mineral from the gangue.

- development of new comminution technologies;

- optimizing the performance of recent applications;

- modeling, simulation, and performance optimization of mechanical processing circuits.

2. Development in Crushing and Grinding Technology

2.1. HPGR Technology

2.2. High Voltage Breakage

2.3. Electromagnetic Mills

3. Circuits Layout and Optimization

3.1. Design Assumptions

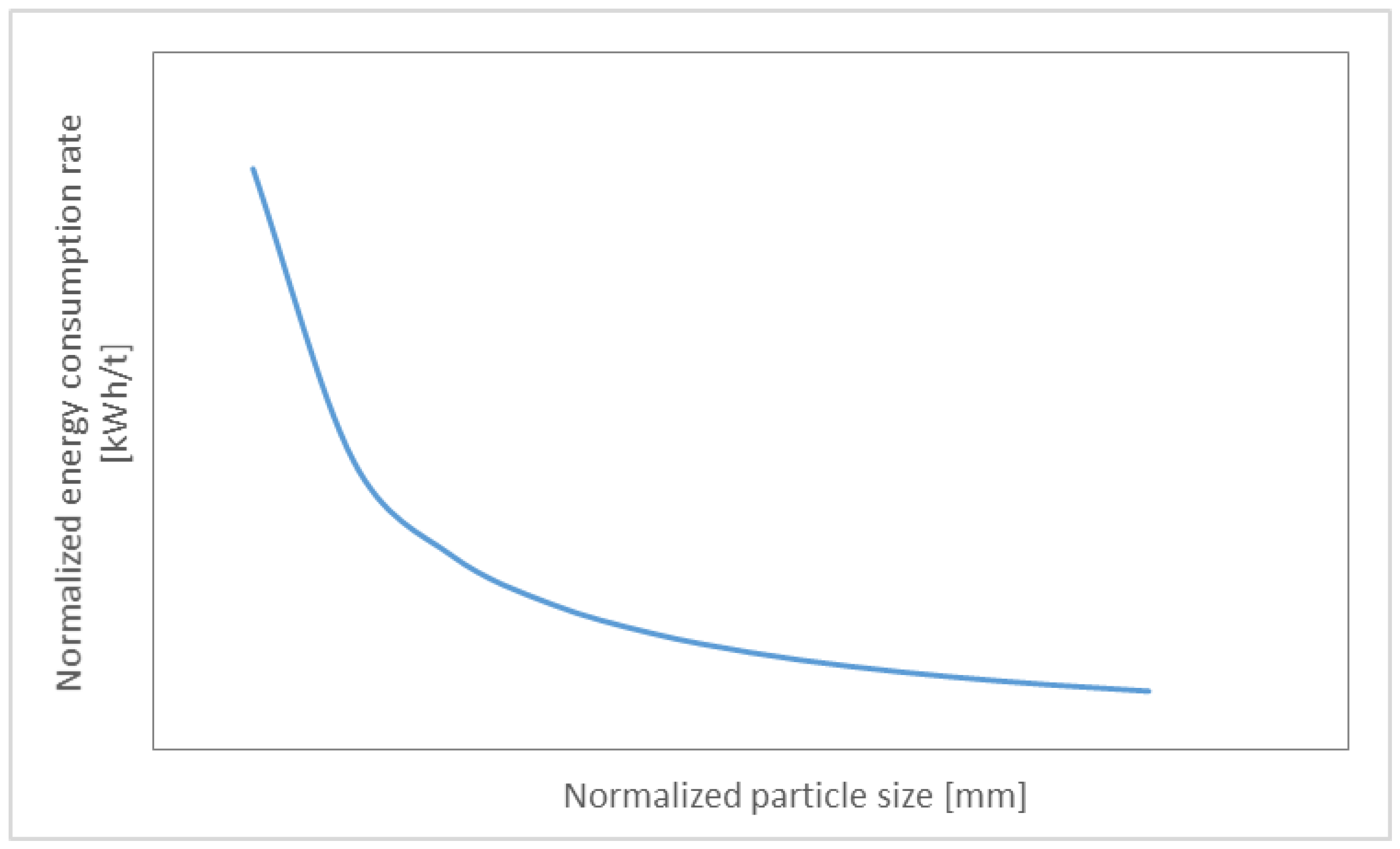

- A reduction in the capacity requirements of downstream grinding stage(s), which allows the installation of smaller grinding devices. More intense disintegration occurs in upstream crushing processes, which requires much less energy than grinding operations (Figure 2). The Figure gives a general idea of relationship between the size of treated material and the required energy for comminution. An exponential increase in the grinding energy can be observed, together with further decreasing the size of already fine material;

- The optional application of separation within comminution circuits, especially devices based on physical separation, such as jigs [19]. Jig separation has a long history of existence in technological circuits of mechanical processing or raw materials; however, many investigations aiming to improve the process for specific conditions and individual materials have been carried out [20,21]. This cost-efficient technology may give favorable results in the extraction of useful mineral amongst certain particle size fractions. Available results also confirm the potential for the separation of materials with relatively low differences in densities, provided specially designed devices are used [22].

- Decrease in the grinding energy consumption, which decreases the overall energy consumption of the circuit operational costs.

3.2. Simulation in Mineral Processing

- Simulation tools and techniques showing models of behavior of grained material during the specific process, operation of a device, interactions amongst particles of the material, and interactions between the material and device. Various numerical techniques can be used in these simulations. The Discrete Element Method (DEM) is an especially popular technique used for this process, as well as in other disciplines outside mineral processing.

- Models capable of predicting the specific results of process performance. These include the approximation of particle size of comminution product, screening efficiency, comminution ratio, volume of material recycle, and others. These models are either based on theoretical distributions of random variables with confirmed applications in mineral processing or utilize principles of mathematical modeling.

- Description of granular material flow in comminution processes;

- Potential prediction of particle size distribution for selected crushing products;

- Equipment design on the basis of analyzed process behavior;

- Simulation of conveyor transportation operations;

- Description of motion of particles in selected processes of gravitational separation.

4. Modeling Approach

- product 1: the material with increased content of fines, the feed was crushed twice under base pressing force (15 kN);

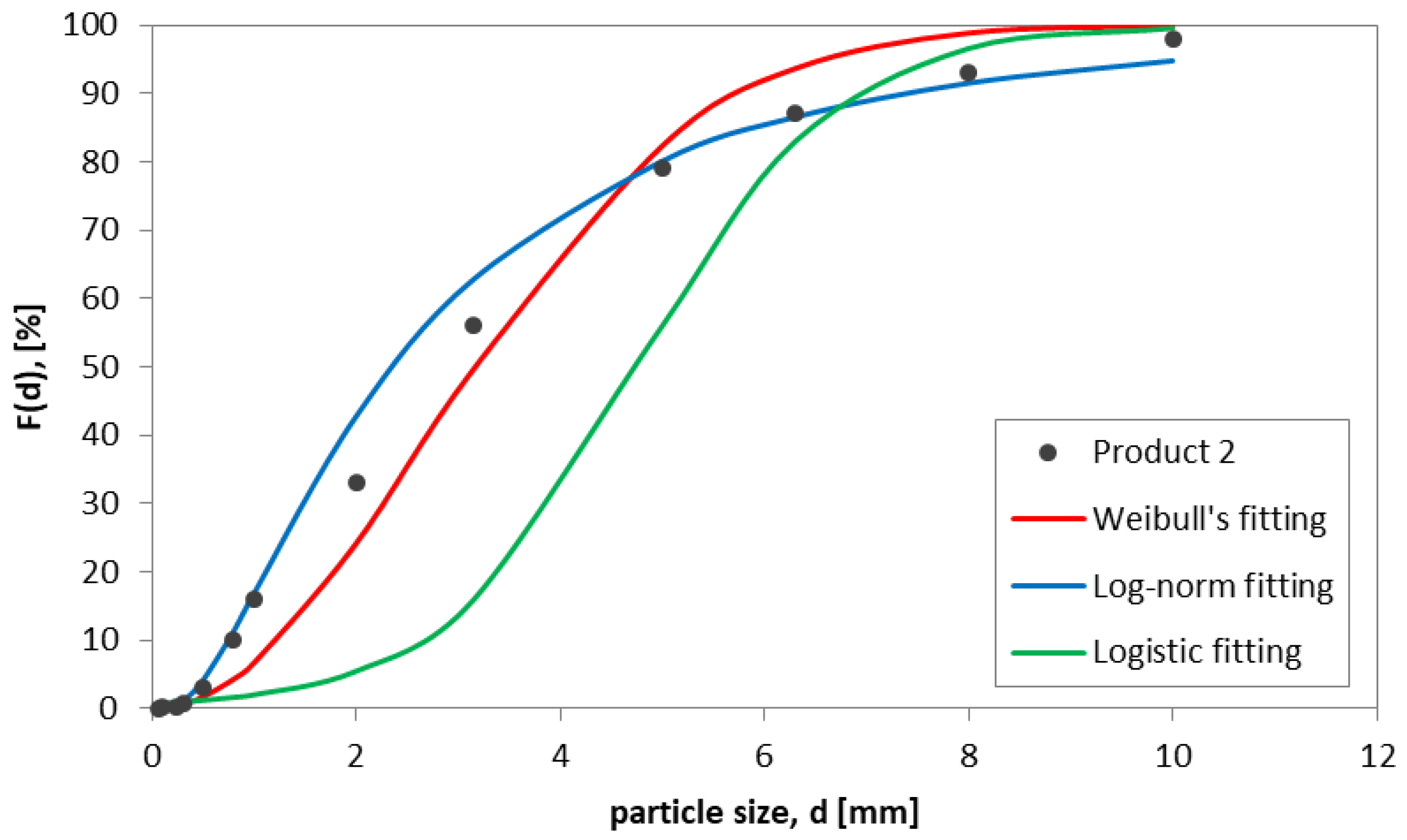

- product 2: the material with relatively lower content of fines—crushed under lower pressing force (10 kN);

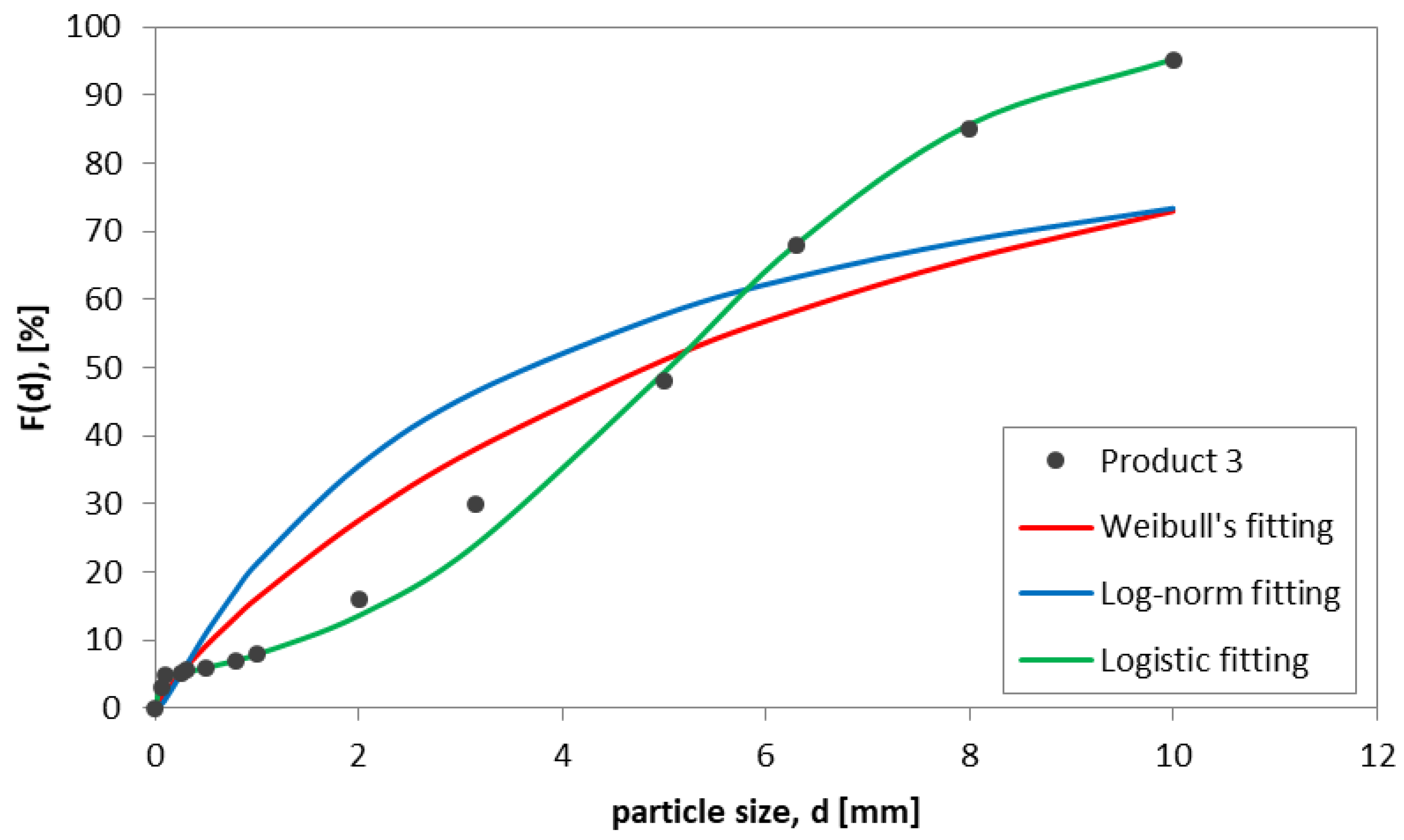

- product 3: the material with balanced content of individual particle size fractions—crushed once under base pressing force (15 kN).

5. Environmental Issues

6. Summary

Funding

Conflicts of Interest

Abbreviations

| HPGR | high-pressure grinding rolls |

| ROM | run-of-mine |

| CAPEX | capital expenditure |

| OPEX | operational expenditure |

| DEM | discrete element method |

| WOS | Web of Science (database) |

| PSD | particle size distribution |

| SEM | scanning electron microscopy |

| MLA | mineral liberation analyzer |

| LS | least squares (method) |

| RRB | Rosin–Rammler–Bennett (distribution) |

| TSP | total suspended particulates |

| SAG | semi-autogenous grinding |

| AG | autogenous grinding |

References

- Gawenda, T. Zasady Doboru Kruszarek Oraz Układów Technologicznych w Produkcji Kruszyw łamanych. Monography No. 304; AGH Public House: Cracow, Poland, 2015. [Google Scholar]

- Tromans, D. Mineral comminution: Energy efficiency considerations. Min. Eng. 2008, 21, 613–620. [Google Scholar] [CrossRef]

- Fuerstenau, D.W.; Abouzeid, Z.M. The energy efficiency of ball milling in comminution. Int. J. Min. Proc. 2002, 67, 161–185. [Google Scholar] [CrossRef]

- Gawenda, T. The influence of rock raw materials comminution in various crushers and crushing stages on the quality of mineral aggregates. Miner. Res. Manag. 2013, 29, 53–65. [Google Scholar] [CrossRef]

- Gawenda, T. Comparative Analysis of Mobile and Stationary Technological Sets for Screening and Grinding. Ann. Set Environ. Prot. 2013, 15, 1318–1335. [Google Scholar]

- Bearman, K. Step change in context of comminution. Min. Eng. 2013, 43–44, 2–11. [Google Scholar] [CrossRef]

- Morrell, S. Predicting the overall specific energy requirement of crushing, high pressure grinding roll and tumbling mill circuits. Min. Eng. 2009, 22, 544–549. [Google Scholar] [CrossRef]

- Wang, C.; Nadolski, S.; Mejia, O.; Drozdiak, J.; Klein, B. Energy and cost comparison of HPGR based circuits with the SABC circuit installed at the Huckleberry Mine. In Proceedings of the 45th Annual Canadian Mineral Processors Operators Conference, Ottawa, ON, Canada, 22–24 January 2013; pp. 121–135. [Google Scholar]

- Klingmann, H.L. HPGR benefits at Golden Queen Soledad Mountain gold heap leaching project. In Proceedings of the Randol Innovative Metallurgy Forum, Perth, Australia, 21–24 August 2005. [Google Scholar]

- Yin, W.; Tang, Y.; Ma, T.; Zuo, W.; Yao, J. Comparison of sample properties and leaching characteristics of gold ore from jaw crusher and HPGR. Min. Eng. 2017, 111, 140–147. [Google Scholar] [CrossRef]

- Tang, Y.; Yin, W.Z.; Wang, J.X.; Zuo, W.R.; Cao, S.H. Effect of HPGR comminution scheme on particle properties and heap leaching of gold. Canadian Metallurg. Quart. 2020, 59, 1–7. [Google Scholar] [CrossRef]

- Saramak, D.; Saramak, A. Potential Benefits in Copper Sulphides Liberation through Application of HRC Device in Ore Comminution Circuits. Minerals 2020, 10, 817. [Google Scholar] [CrossRef]

- Baum, W.; Ausburn, K. HPGR comminution for optimization of copper leaching. Min. Met. Process. 2011, 28, 77–81. [Google Scholar] [CrossRef]

- Ghorbani, Y.; Mainza, A.N.; Petersen, J.; Becker, M.; Franzidis, J.-P.; Kalala, J.T. Investigation of particles with high crack density produced by HPGR and its effect on the redistribution of the particle size fraction in heaps. Min. Eng. 2013, 43–44, 44–51. [Google Scholar] [CrossRef]

- Anders, U. Development and prospects of mineral liberation by electrical pulses. Int. J. Min. Proc. 2010, 97, 31–38. [Google Scholar] [CrossRef]

- Gao, P.; Yuan, S.; Han, Y.; Li, S.; Chen, H. Experimental Study on the Effect of Pretreatment with High-Voltage Electrical Pulses on Mineral Liberation and Separation of Magnetite Ore. Minerals 2017, 7, 153. [Google Scholar] [CrossRef]

- Wolosiewicz-Głąb, M.; Ogonowski, S.; Foszcz, D.; Gawenda, T. Assessment of classification with variable air flow for inertial classifier in dry grinding circuit with electromagnetic mill using partition curves. Physicochem. Probl. Min. Proc. 2018, 54, 440–447. [Google Scholar]

- Saramak, D.; Tumidajski, T.; Gawenda, T.; Naziemiec, Z. Ekologiczne aspekty związane z efektami wysokociśnieniowego rozdrabniania w prasach walcowych. Ann. Set Environ. Prot. 2013, 15, 1580–1593. [Google Scholar]

- Phengsaart, T.; Ito, M.; Hamaya, N.; Tabelin, C.B.; Hiroyoshi, N. Improvement of jig efficiency by shape separation, and a novel method to estimate the separation efficiency of metal wires in crushed electronic wastes using bending behavior and “entanglement factor”. Min. Eng. 2018, 129, 54–62. [Google Scholar] [CrossRef]

- Ambrós, W.M. Jigging: A Review of Fundamentals and Future Directions. Minerals 2020, 10, 998. [Google Scholar] [CrossRef]

- Stempkowska, A.; Gawenda, T.; Naziemiec, Z.; Ostrowski, K.; Saramak, D.; Surowiak, A. Impact of the geometrical parameters of dolomite coarse aggregate on the thermal and mechanic properties of preplaced aggregate concrete. Materials 2020, 13, 4358. [Google Scholar] [CrossRef] [PubMed]

- Gawenda, T. Układ Urządzeń do Produkcji Kruszyw Foremnych. Patent PL 2019, 233689, B1. (In Polish) [Google Scholar]

- Rosario, P.P. Technical and economic assessment of a non-conventional HPGR circuit. Min. Eng. 2017, 103–104, 102–111. [Google Scholar] [CrossRef]

- Weerasekara, N.S.; Powell, M.S.; Cleary, P.W.; Tavares, L.M.; Evertsson, M.; Morrison, R.D.; Quist, J.; Carvalho, R.M. The contribution of DEM to the science ofcomminution. Powder Technol. 2013, 248, 3–24. [Google Scholar] [CrossRef]

- Tavares, L.M.; Rodrigues, V.; Carles, M.S. Padros, B. An effective sphere-based model for breakage simulation in DEM. Powder Technol. 2021, 392, 473–488. [Google Scholar] [CrossRef]

- Jovanovic, I.; Nikolic, D.; Savic, M.; Zivkovic, Z. Batch composition optimization for the copper smelting process on the example of copper smelter in BOR. Environ. Eng. Manag. J. 2016, 15, 791–799. [Google Scholar] [CrossRef]

- Jovanovic, I.; Savic, M.; Zivkovic, Z.; Boyanov, B.S. An Linear Programming Model for Batch Optimization in the Ecological Zinc Production. Environ. Model. Assess. 2016, 21, 455–465. [Google Scholar] [CrossRef]

- Saramak, D.; Tumidajski, T.; Skorupska, B. Technological and economic strategies for the optimization of Polish electrolytic copper production plants. Min. Eng. 2010, 23, 757–764. [Google Scholar] [CrossRef]

- Naziemiec, Z.; Saramak, D. Application of partition curves in the assessment of mineral products classification processes. Min. Sci. 2015, 22, 119–129. [Google Scholar]

- Lowrison, G.C. Crushing and Grinding; Butterworths: London, England, 1974. [Google Scholar]

- Brożek, M.; Mączka, W.; Tumidajski, T. Mathematical Models of Grinding Processes; AGH Publishing House: Cracow, Poland, 1995. (In Polish) [Google Scholar]

- Tumidajski, T.; Saramak, D. Methods and Models of Mathematical Statistics in Mineral Processing; AGH Publishing House: Cracow, Poland, 2009; pp. 1–304. [Google Scholar]

- Rosin, P.; Rammler, E. The laws governing the fineness of powdered coal. J. Inst. Fuel 1933, 7, 29–36. [Google Scholar]

- Kołomogorow, A.N. Über das logarithmisch normale Verteilungsgesetz der Dimensionen der Teilchen bei Zerstückelung. Dokl. Akad. Nauk SSSR 1941, 31, 99–101. [Google Scholar]

- Nad, A.; Brożek, M. Application of three-parameter distribution to approximate the particle size distribution function of comminution products of dolomitic type of copper ore. Arch. Min. Sci. 2017, 62, 411–422. [Google Scholar] [CrossRef]

- Chakraborty, M.K.; Ahmad, M.; Singh, R.S.; Pal, D.; Bandopadhyay, C. Determination of the emission rate from various opencast mining operations. Environ. Model. Softw. 2002, 17, 467–480. [Google Scholar] [CrossRef]

- Huertas, J.; Camacho, D.; Huertas, M. Standardized emissions inventory methodology for open pit mining areas. Environ. Sci. Pollut. Res. 2012, 19, 2784–2794. [Google Scholar] [CrossRef]

- Chang, C.-T.; Chang, Y.-M.; Lin, W.-Y.; Wu, M.-C. Fugitive dust emission source profiles and assessment of selected control strategies for particulate matter at gravel processing sites in Taiwan. J. Air Waste Manag. Assoc. 2012, 60, 1262–1268. [Google Scholar] [CrossRef][Green Version]

- Saramak, A.; Naziemiec, Z. Determination of dust emission level for various crushing devices. Min. Sci. 2019, 26, 45–54. [Google Scholar] [CrossRef]

- Cigagna, M.; Dentoni, V.; Grosso, B.; Massacci, G. Emissions of Fugitive Dust from Mine Dumps and Tailing Basins in South-Western Sardinia. In Mine Planning and Equipment Selection; Springer: Cham, Switzerland, 2014. [Google Scholar]

- Tian, S.; Liang, T.; Li, K. Fine road dust contamination in a mining area presents a likely air pollution hotspot and threat to human health. Environ. Intern. 2019, 128, 201–209. [Google Scholar] [CrossRef]

- Saramak, A. Comparative Analysis of Selected Types of Crushing Forces in Terms of Dust Emission. Inżynieria Miner. J. Pol. Miner. Eng. Soc. 2019, 2, 151–154. [Google Scholar]

- Cecala, A.B.; O’Brien, A.D.; Schall, J.; Colinet, J.F.; Franta, R.J.; Schultz, M.J.; Haas, E.J.; Robinson, J.E.; Patts, J.; Holen, B.M.; et al. Dust Control Handbook for Industrial Minerals Mining and Processing, 2nd ed.; National Institute for Occupational Safety and Health: Pittsburgh, PA, USA, 2019.

- Saramak, D.; Wasilewski, S.; Saramak, A. Influence of copper ore comminution in HPGR on downstream minerallurgical processes. Arch. Metall. Mater. 2017, 62, 1689–1694. [Google Scholar] [CrossRef]

- Evaluation of Fugitive Dust Emissions from Mining—Report; PEDCo-Environmental Specialists Inc.: Cincinnati, OH, USA, 1976.

- Holmes, N.S.; Morawska, L.A. Review of dispersion modeling and its application to the dispersion of particles: An overview of different dispersion models available. Atmos. Environ. 2006, 40, 5902–5928. [Google Scholar] [CrossRef]

- Prakash, J.; Singh, G.; Pal, A.K. Air pollution dispersion modeling performance for mining complex. Environ. We Int. J. Sci. Technol. 2010, 5, 205–222. [Google Scholar]

- Chaulya, S.K.; Chakraborty, M.K.; Ahmad, M.; Singh, R.S.; Bondyopadhay, C.; Mondal, G.C.; Pal, D. Development of empirical formulae to determine emission rate from various opencast coal mining operations. Water Air Soil Pollut. 2002, 140, 21–55. [Google Scholar] [CrossRef]

- Chaulya, S.K.; Ahmad, M.; Singh, R.S.; Bandopadhyay, L.K.; Bondyopadhay, C.; Mondal, G.C. Validation of two air quality models for Indian mining conditions. Environ. Monit. Assess. 2002, 82, 23–43. [Google Scholar] [CrossRef] [PubMed]

- Saramak, A.; Naziemiec, Z.; Saramak, D. Analysis of noise emission for selected crushing devices. Min. Sci. 2016, 23, 145–154. [Google Scholar] [CrossRef]

- Saramak, D. Simulation of comminution effects in HPGR for the feed material variable content of fine particles. Miner. Res. Manag. 2015, 31, 123–136. [Google Scholar]

- Calvo, G.; Mudd, G.; Valero, A.; Valero, A. Decreasing Ore Grades in Global Metallic Mining: A Theoretical Issue or a Global Reality? Resources 2016, 5, 36. [Google Scholar] [CrossRef]

| Type of Benefit | Unit | Type of Comminution Technology | ||

|---|---|---|---|---|

| HPGR | Electromagnetic Mill | Electric Pulses | ||

| Unit energy consumption | kWh/Mg | 2–4 | 50–150 | 3–5 |

| Benefits in mineral liberation compared to conventional crushing | % | 10–20 | 10–15 | 10–15 |

| Benefits in useful mineral recovery compared to conventional crushing: hydrometallurgy | % | 2–8 | No data | 15–70 |

| Benefits in useful mineral recovery compared to conventional crushing: flotation | % | 1–4 | 5–20 | up to 20 |

| Plant-scale operation of the technology | - | Yes | No | No |

| Energy savings compared to conventional crushing circuit | % | Up to 30 | No data | No data |

| Capacity increases compared to conventional crushing circuit | % | 0–15 | No data | No data |

| Approximation Function | Approximation Formula |

|---|---|

| Weibull’s distribution | |

| Log-norm distribution | |

| Logistic distribution |

| Approximation Function | Approximation Error | ||

|---|---|---|---|

| Product 1 | Product 2 | Product 3 | |

| Weibull’s distribution | 1.67 | 7.78 | 15.25 |

| Log-norm distribution | 4.59 | 3.79 | 12.92 |

| Logistic distribution | 10.26 | 17.06 | 2.05 |

| Processing Stage | Relative Emission (Primary Crushing = 1) [43] | Total Emission [mg/m3] [44] |

|---|---|---|

| Primary crushing | 1 | 2.8 |

| Secondary crushing | 3 [45] | 3.2 |

| Tertiary crushing | 51 (dry), 2 (wet) | 30 |

| Screening (dry) | 214 | No data |

| Screening (wet) | 12 | No data |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saramak, D. Challenges in Raw Material Treatment at the Mechanical Processing Stage. Minerals 2021, 11, 940. https://doi.org/10.3390/min11090940

Saramak D. Challenges in Raw Material Treatment at the Mechanical Processing Stage. Minerals. 2021; 11(9):940. https://doi.org/10.3390/min11090940

Chicago/Turabian StyleSaramak, Daniel. 2021. "Challenges in Raw Material Treatment at the Mechanical Processing Stage" Minerals 11, no. 9: 940. https://doi.org/10.3390/min11090940

APA StyleSaramak, D. (2021). Challenges in Raw Material Treatment at the Mechanical Processing Stage. Minerals, 11(9), 940. https://doi.org/10.3390/min11090940