Abstract

This paper is a study of the dynamic mechanics and energy dissipation of saturated layered phyllite. Using the Split-Hopkinson pressure bar system, the mechanical properties and energy dissipation law of the sample during dynamic loading in the test were analyzed. The results show that the weakening effect of water on the phyllite rock body will have a great impact on its mechanical properties, strain rate sensitivity damage mode, and fracture energy dissipation. The values of mechanical parameters such as the modulus of elasticity and compressive strength of the specimens in the test varied with the dip angle of the layer with 0° > 90° > 30° > 60°, and the mechanical parameters of the specimens in the saturated state were smaller than those of the dry specimens. The damage of the sample is mainly in the form of crushing damage at 0° dip angle, shear damage along the laminar surface at 30° and 60°, and destabilization damage of the compression bar at 90° dip angle, with higher fragmentation of the sample in the saturated state. The energy dissipation densities of different inclination samples in the saturated state of schist are greater than those in the dry state, with the highest energy dissipation density in the 0° inclination sample and the lowest in the 90° inclination sample. Both the mean strain rate and compressive strength of the samples showed a multiplicative power relationship with the crushing energy dissipation density of the samples, showing a strong strain rate correlation. These results indicate that the use of rock crushing energy dissipation density can better reflect the strength characteristics of phyllite samples under dynamic loading.

1. Introduction

Layered rock masses are discontinuous media containing macroscopic stratification planes that are widely distributed in nature. Stratified rock masses are mainly divided into metamorphic rock masses, mainly schist, slate, etc., and sedimentary rock masses, mainly sandstone, shale, coal, etc. The special layered structure of layered rock masses compared with other rock masses means that the mechanical properties and damage mode of layered rock masses are made more complicated by the influence of the layer dip angle.

The complex mechanical properties of rock masses have been studied by a large number of scholars and have resulted in a wealth of research. Li et al. [1]. investigated the mechanical properties and damage modes of coal samples with different stratification angles with the help of uniaxial and triaxial test methods. Shi et al. [2]. explored the degree of anisotropy and the action of stratification angle in the relationship between fracture toughness and the tensile strength of mud shale. Ramamurthy [3] obtained typical strength anisotropy curves with the angular distribution based on the results of a large number of tests. Tien et al. [4] evaluated the mechanical properties of layered rock masses and four typical damage modes were studied using simulated materials. However, during the construction of underground projects, such as blasting excavation and drilling, the rock is mainly subjected to dynamic loads.

At present, scholars have also had very fruitful results in the study of dynamic mechanical properties of layered rock and energy consumption of crushing. Mohammad Zaid [5,6,7,8,9,10] used finite element numerical analysis software to analyse the mechanical properties and structural stability of tunnel rocks such as granite, quartzite and basalt under both static and dynamic loads, taking into account the influence of the surrounding environment such as the degree of rock weathering on the strength of the rocks. Rehan Sadique et al. [11] used the coupled Euler–Lagrange method to construct a finite element model to analysis the mechanical properties of the rock under dynamic blasting loads. Fan et al. [12] studied the variation of mechanical parameters and the damage patterns of shales with different layer angles at different temperatures were investigated. Gong et al. [13] examined the energy dissipation characteristics of layered coal during dynamic fracture. Zhao et al. [14] explored the dynamic tensile strength of coal samples under two moisture content conditions, saturated and dry, based on the Brazilian disc tension test. Zhang et al. [15] found that the influence of laminae on the dynamic compression strength and damage mode of layered rocks was significant at low loads by studying the influence of laminae structure on the damage mode of rocks. In the above studies, scholars have investigated the dynamic mechanics and energy dissipation of typical layered rock bodies such as shale and coal rock. It can be found that scholars are much accounted for the study of dynamic energy evolution of rocks and their fragmentation characteristics. In the existing studies, Xie et al. [16,17] pointed out that the dissipation of energy would cause internal damage and loss of strength, while the release of energy was the internal cause of the overall damage to the rock. In terms of dynamic loading, Deng et al. [18] investigated the relationship between energy dissipation and rock fragmentation distribution from two aspects, theoretical analysis and experiments, based on fracture mechanics theory. Feng et al. [19] introduced energy dissipation rate as an index to evaluate the degree of rock deformation damage. Therefore, to carry out the study of crushing energy dissipation of laminated rocks under the action of impact load, and to reveal the intrinsic connection between rock crushing energy consumption and crushing effect. It has very important theoretical significance and engineering application value.

The phyllite is a soft rock with obvious bedding structures, containing a large number of soft stratification planes with obvious anisotropic characteristics, which is easily disintegrated by water [20]. The internal minerals consist of sericite, chlorite, quartz and a small amount of feldspar and carbonaceous and ferruginous material. The internal structure is a fine-grained scaly metamorphic structure with a grain size of less than 0.1 mm, often with small, wrinkled structures on the lamellar surface. At the same time, the fractures among stratification planes also provide places for water to remain, and the weakening effect of water on the internal structure of rock under saturated conditions will change the dynamic mechanical properties and energy dissipation of rock [21].

Therefore, some scholars have conducted preliminary studies on the mechanical properties and fracture energy dissipation of phyllite. Si et al. [22] performed uniaxial compression tests on phyllite and obtained the influence stratification angle had on the mechanical properties and rockburst propensity of phyllite. Villalobos et al. [23] analyzed the effect of stratification on the anisotropic strength of phyllite and obtained the tensile and compressive strength of the rocks at different stratification angles. Zhou et al. [24] conducted a series of triaxial cyclic tests on phyllite to analyze its mechanical properties, energy dissipation and damage characteristics. Compared with the static and dynamic loading test in one dimension, the results of this test will be more in line with the mechanical environment in which the natural state phyllite is damaged. Ma et al. [25] analyzed the degree of influence of water content on the mechanical properties of laminated phyllite rocks and the damage mechanism under microscopic and macroscopic conditions. Compared with the earlier experiments on the macroscopic damage mechanism of phyllite, the microscopic damage mechanism of phyllite done by Ma and other scholars has improved the gap in the damage mechanism of phyllite. Qiu et al. [26] not only analyzed the effect of layered structure on the fracturing behavior of phyllite rocks with different water contents, but also analyzed the effect of layered structure on the dynamic tensile properties of the rock in this state, which complements the shortage of phyllite rocks in terms of dynamic tensile mechanical properties.

From the above research results, it is clear that scholars have conducted research on the mechanical properties of phyllite in static, dynamic and creep conditions. However, there are relatively few research results on the dynamic mechanical properties and energy dissipation of phyllite under different water-bearing environments.

Most of the above-mentioned experiments have been conducted by scholars using the Split-Hopkinson pressure bar (SHPB) test apparatus to investigate the dynamic mechanical aspects of rocks. The device has been continuously improved by Prof. Xi-Bing Li and other scholars, and it has been able to exclude the noise interference in the test well and display the clearly discernible stress waveform [27,28]. Scholars have also used this modified device to study the mechanical properties of common rock masses such as shale [29] and coal rock [30] under static and dynamic loading. However, the strain gauge is affected by the vibration of the rod and other factors, so the data obtained from the test have large errors, and it is very easy to fall off. On the other hand, the device requires a large specimen size and cannot be applied to the study of dynamic mechanical properties of large size rock specimens.

Therefore, in this paper, based on the detached Hopkinson compression bar, impact dynamic tests will be performed on standard phyllite samples with different stratification angles in both dry and saturated states [31] to study the kinetic properties and energy dissipation of layered phyllite samples in dry and saturated states under the same loading pressure, and to analyze the kinetic properties of layered samples and the morphological damage patterns of samples in the two states. From the energy perspective, the energy dissipation law of samples with different stratification angles in two states is obtained, and the relationship between energy dissipation density and strain rate, as well as the relationship between energy dissipation density and dynamic compressive strength are analyzed.

2. SHPB Test Scheme

2.1. Pattern Preparation

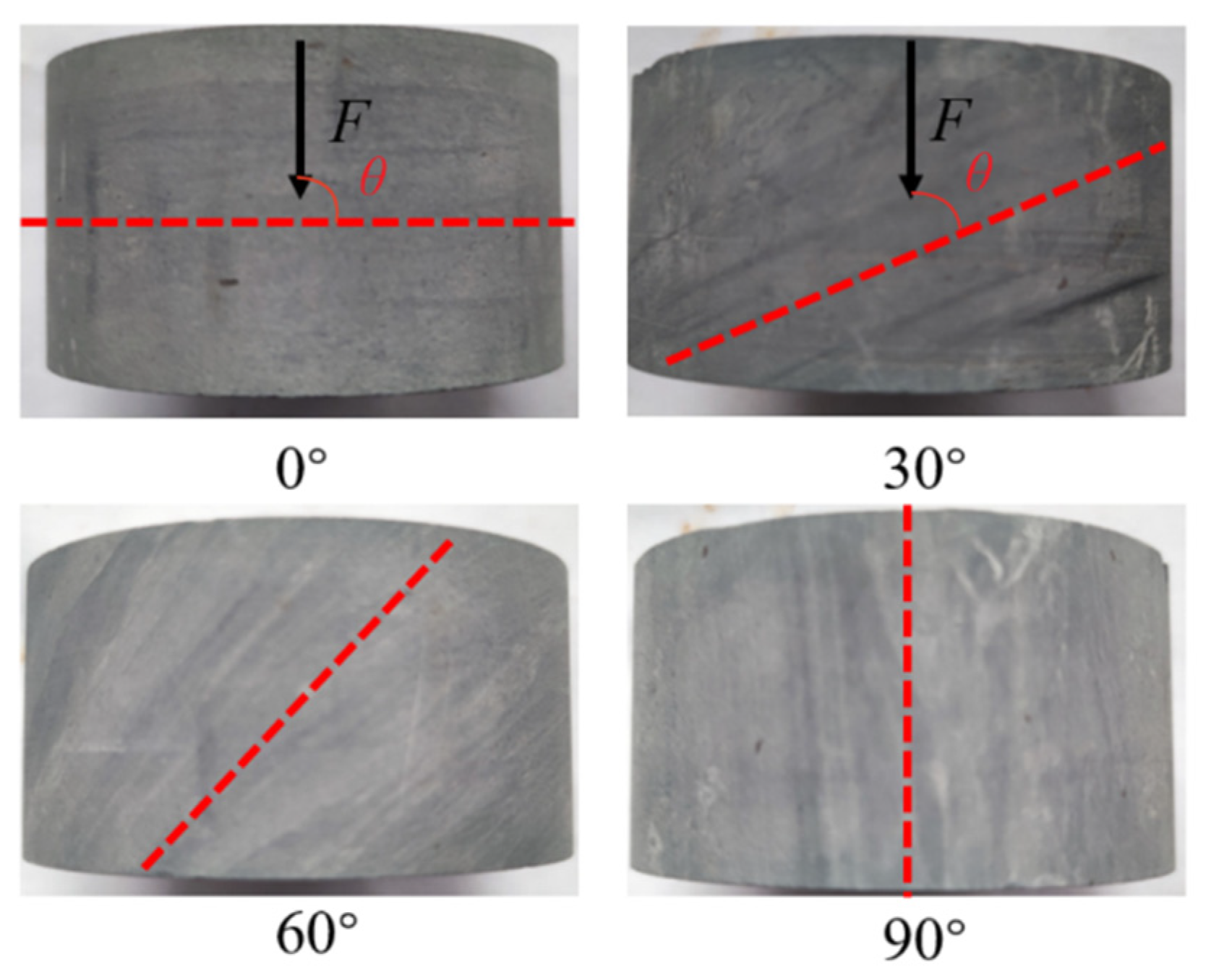

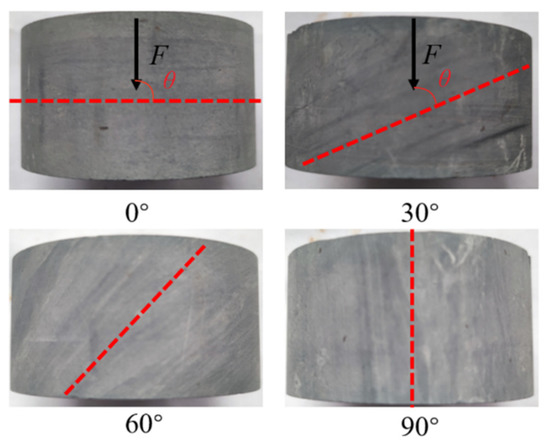

To ensure similar properties, the materials used in the tests are taken from a single intact piece of phyllite. The phyllite is processed into a standard cylinder of 50 mm in diameter and 25 mm in length. The samples are ground and polished so that the roughness of the face is less than 0.02 mm. According to the stratification angles, 0°, 30°, 60°, and 90°, the rock samples are divided into four types, as shown in Figure 1. The rock samples are grouped into dry group A and saturated group B, and the tests are carried out with, respectively, two samples, one for each group, for the above 4 types.

Figure 1.

Schematic diagram of the direction of external dynamic load action and the angle of the sample layers.

Put all the two groups of samples into the drying oven and weighing after drying, soak Group B for 10 days, 20 days, 30 days and 40 days respectively, and then dry the surface water and weighing. As the weight of the samples remains unchanged, the samples are considered to be saturated.

The external dynamic load is uniformly applied perpendicularly along the axis of the cylindrical pattern, and the direction of action is at an angle of θ = (π/2 − α)° with the internal layer of the pattern, as shown in Figure 1.

2.2. Experimental Process

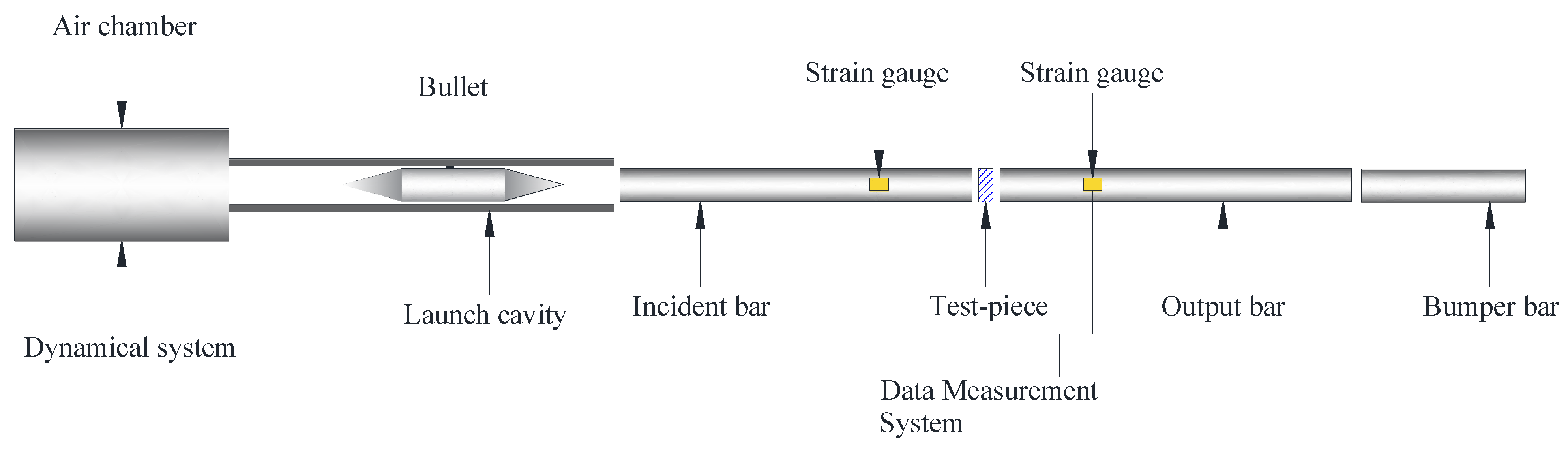

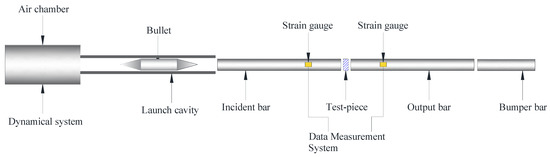

The test is conducted by SHPB system. The system device (LWKJ-HPKS-Y100-3, Luoyang Liwei Technology Co., Ltd., Luoyang, China) mainly consisted of three major parts: main equipment, power system, and data processing system. Among them, the main equipment included: a gas chamber, firing chamber, bullet, rod and its adjustment bracket, energy-absorbing device, and control console composition. The power system consisted of a nitrogen cylinder and a pressure regulator to control the kinetic energy output of the bullet. The data processing system consisted of strain gauges, computer, super dynamic strain gauge (CS-1D) and oscilloscope (DL-750). as shown in Figure 2.

Figure 2.

Schematic diagram of split Hopkinson bar device.

In the test, the input and output rods are 50 mm in diameter, and the sample is loaded with the rod of equal diameter, and strain gauges are glued at the input and output rods 1 m away from the sample. By adjusting the loading air pressure in the gas chamber to a stable 0.4 MPa, the loading rate and incident energy are stabilized so that each specimen obtains a similar impact energy to eliminate the influence of other variables on the test data.

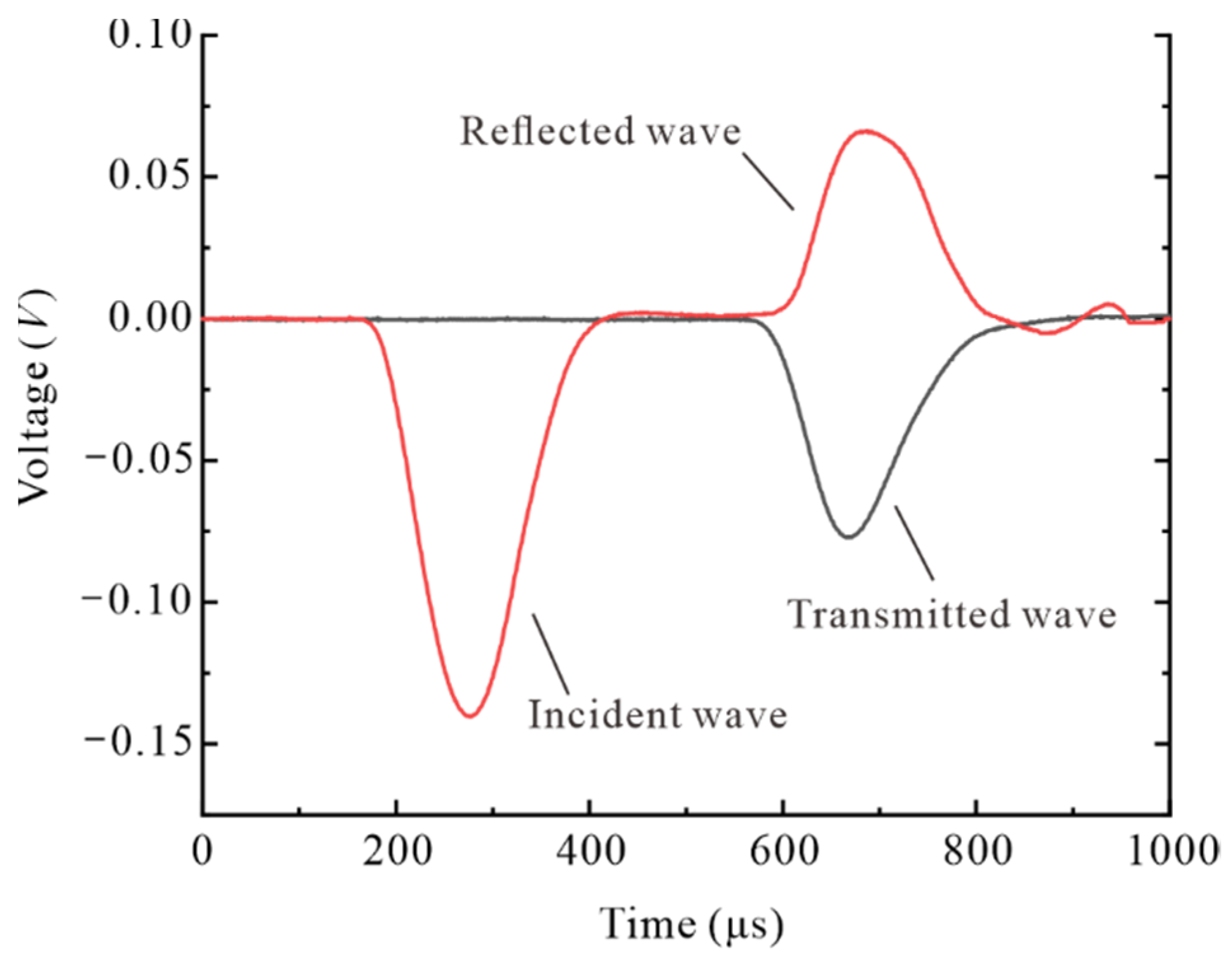

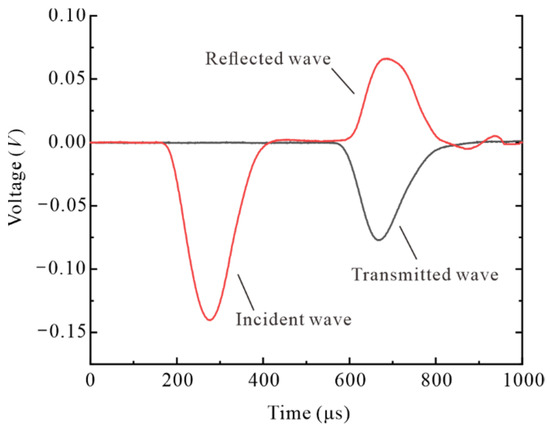

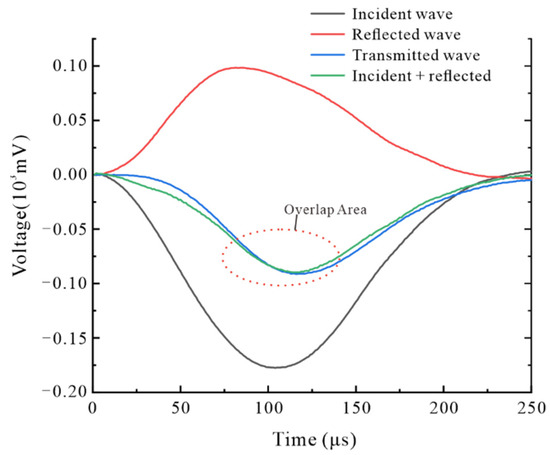

2.3. Stress Equalization

The bullet of the SHPB test device will hit the input rod at high speed under the action of air pressure in the chamber and generate a one-dimensional stress wave inside the input rod that propagates along the input rod toward the sample direction. Due to the difference in wave impedance between the rod and the sample, a portion of the stress wave will be reflected back to the input rod as a reflected wave. The other part will pass through the pattern into the output rod as a transmitted wave. The test will obtain typical incident, reflected and transmitted wave profiles as shown in Figure 3.

Figure 3.

SHPB test incident wave, reflected wave and transmitted wave curves.

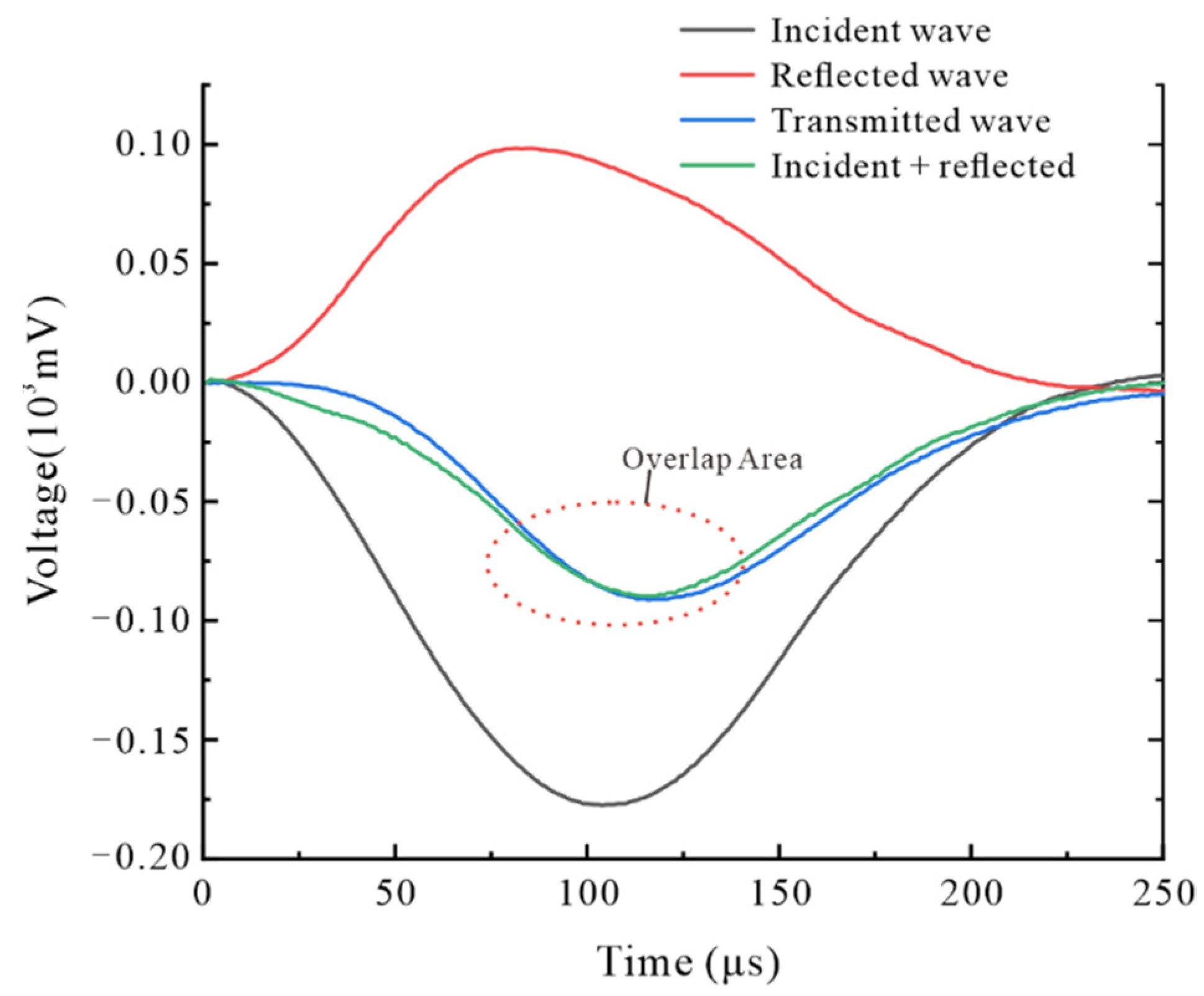

After several reflections and transmissions of the reflected and transmitted waves in a short period of time, the stresses at the input and output ends of the sample tend to be balanced, as shown in Figure 4.

Figure 4.

Stress balance diagram.

In Figure 4, the “incident + reflected” stress wave curve at the incident end overlaps with the “transmitted” stress wave curve at the transmitted end, and the whole is in dynamic equilibrium. This indicates that the energy of the whole phyllite dynamic impact test system is constant, and there is no energy leakage, and there is no mechanical error in the recording instrument, and the data obtained from this test is reliable.

2.4. Calculation of Mechanical Parameters

Based on the One-dimensional hypothesis and uniformity hypothesis, the dynamic mechanical parameters such as the average strain rate , the average strain and the average value of stress at both ends of the rock sample can be determined from the stress waveform, as shown in Equation (1).

where E0 is the modulus of elasticity of the rod of this test device. A0 is the cross-sectional area of the output and input rods, C0 is the elastic wave velocity of the internal stress wave inside the rod at both ends of the sample. L is the geometric thickness of the rock sample. D is the cross-sectional diameter of the rock sample. εI(t) represents the incident strain, εR(t) represents the reflected strain, and εT(t) represents the transmissive strain.

3. Dynamic Mechanical Properties of Saturated Phyllite

3.1. Characteristics of Stress-Strain Curve

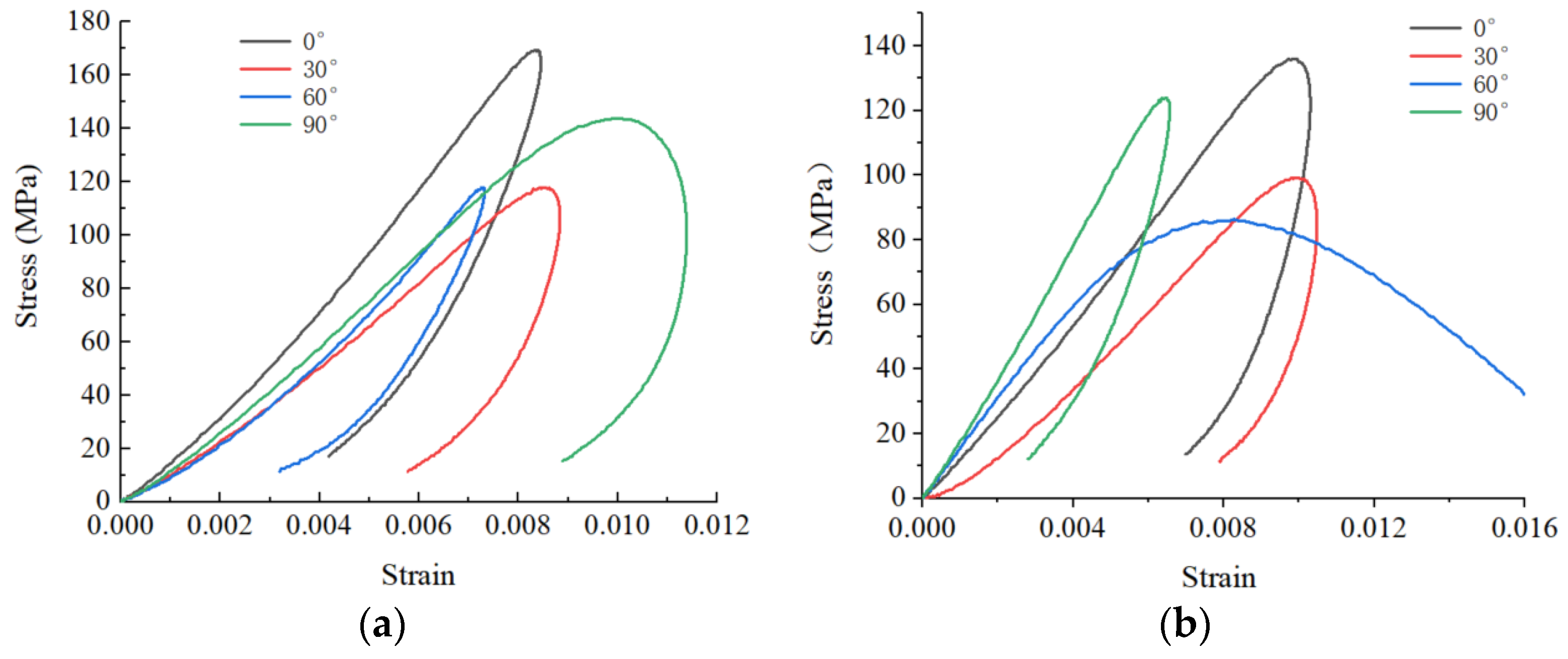

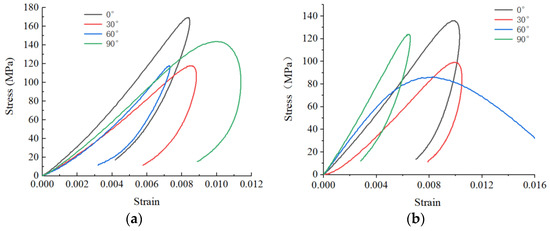

In this test, stress-strain relationship curves will be obtained for different stratification plane angles of phyllite samples in both dry and saturated water-bearing states, as shown in Figure 5.

Figure 5.

Stress-strain curves of samples with different stratification angles: (a) stress-strain curve in dry condition; and (b) saturated stress-strain curve.

From Figure 5, it can be seen that the uniaxial dynamic compressive strengths of the phyllite rock in the saturated state are all less than those in the dry state. In terms of the stratification angle, the uniaxial dynamic compressive strengths vary with the dip angle, 0° > 90° > 30° > 60°. The dynamic compressive strength of the phyllite rock at 60° stratification angle in both states is the lowest, as is its modulus of elasticity.

3.2. Compressive Strength and Modulus of Elasticity Parameter Curves

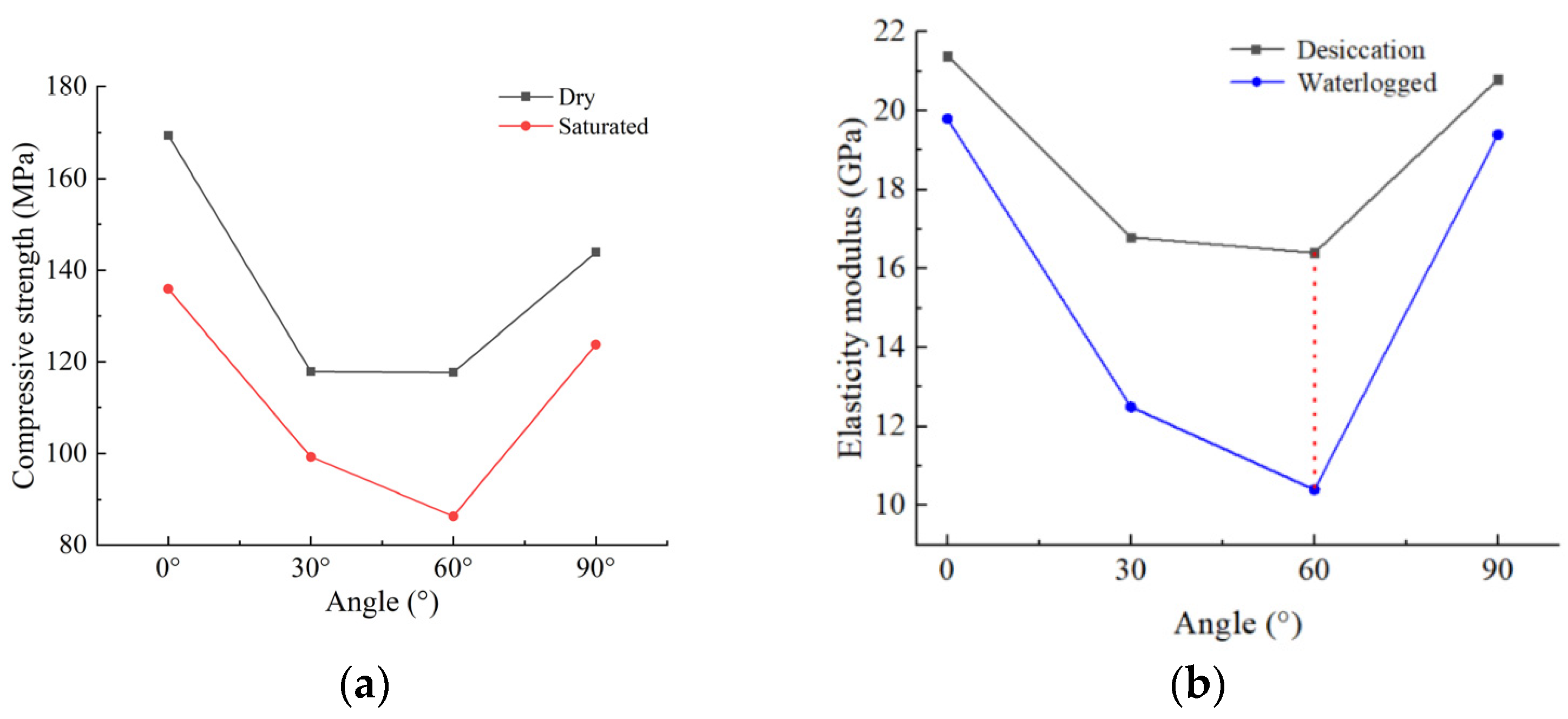

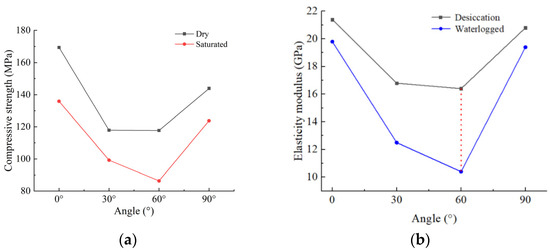

The graphs of rock mechanical parameters such as compressive strength and elastic modulus of the layered rock specimens in the two states are obtained, as shown in Figure 6.

Figure 6.

Modulus of elasticity values of samples at different angles in two states: (a) Change in compressive strength; (b) Change in elasticity modulus of the sample.

From Figure 6, it can be seen that the elastic modulus and compressive strength of specimens with different layer dips in the saturated state are reduced, which is due to the weakening effect of water on the internal structure of the rock. The main manifestation is that the difference between the values of the mechanical parameters at 30° and 60° in the dry state is small, while in the saturated state the difference is large.

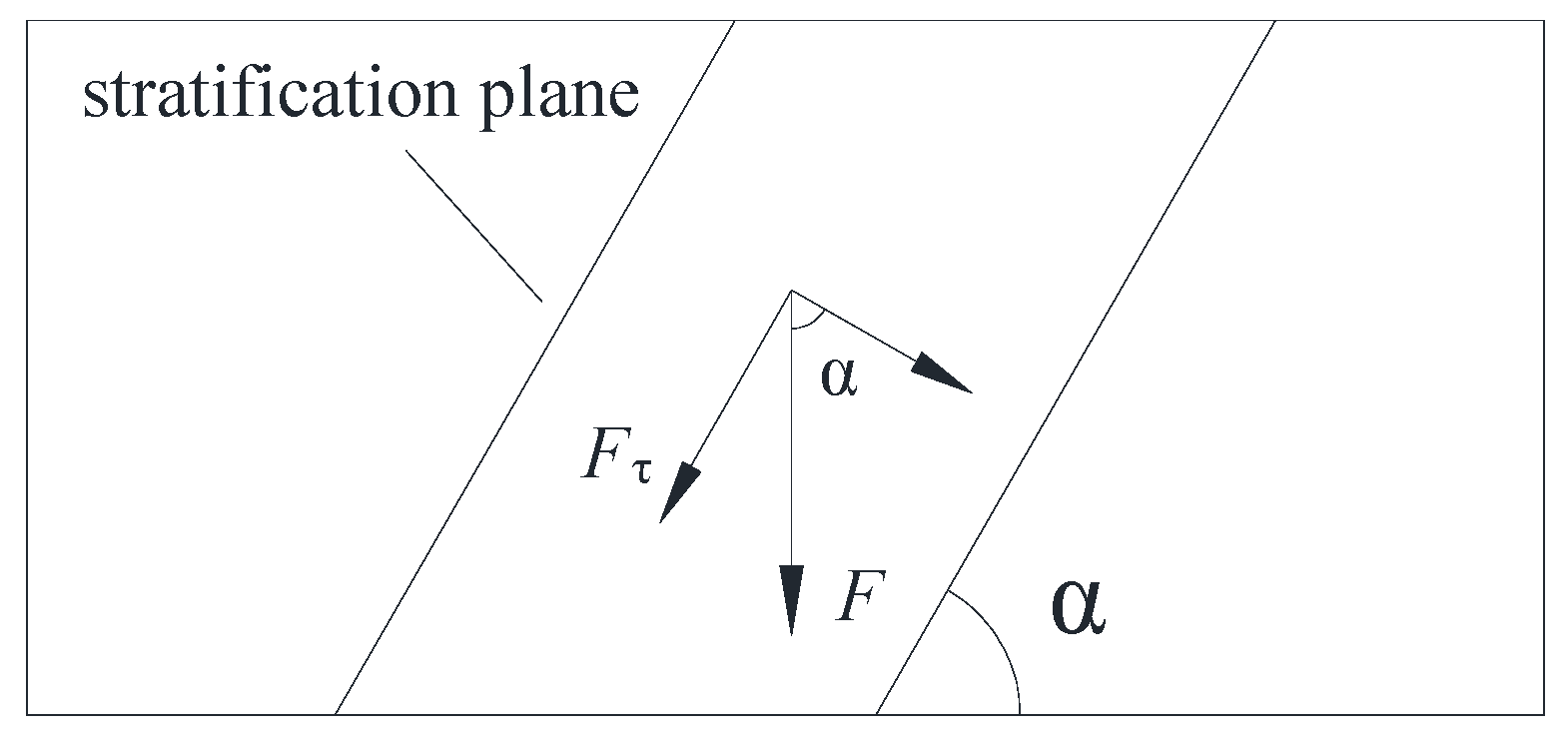

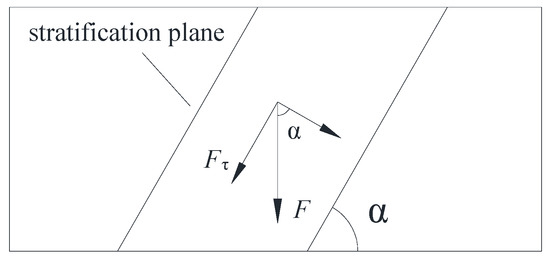

The data shown in Section 2.1 and Section 2.2 are analyzed mechanically in conjunction with the mechanical model of the rock specimen shown in Figure 7 below. It is considered that during the stress–strain deformation of the phyllite specimen by the impact load, the impact force differentiates a shear force Fτ = Fsin α along the layer angle direction (F is the dynamic force equivalent to static), and this shear force will increase with the increase of the layer angle α of the rock sample. In saturated samples, the presence of water can not only reduce the physical and mechanical properties of the rock, but also play the role of lubrication between the weak laminated structural surfaces to reduce the coefficient of friction, making the specimen susceptible to pure shear damage. So, the specimen 60° layered specimen has the smallest modulus of elasticity and compressive strength, and the reduction of modulus of elasticity of 60° layered phyllite in both states is also significantly larger than that of the rest angles. When the layer angle α increases to 90° Fτ = F, at this time the weak layered structural surface does not bear the shear force alone, but shares the compressive stress imposed by F on the pattern with the pattern as a whole. The compressive strength of the rock sample increases substantially, but the structural surface is also more prone to cracking because the layers are oriented in the same direction as the acting force. The layer orientation of the 0° pattern is perpendicular to the direction of the force, which makes the compressive strength of the 90° pattern of the layer angle still slightly lower than that of the 0° pattern. Therefore, the variation of compressive strength and modulus of elasticity with layer angle in this test is 0° > 90° > 30° > 60° for phyllite samples.

Figure 7.

Mechanical model of rock samples.

3.3. Compressive Strength and Average Strain Rate of Specimens

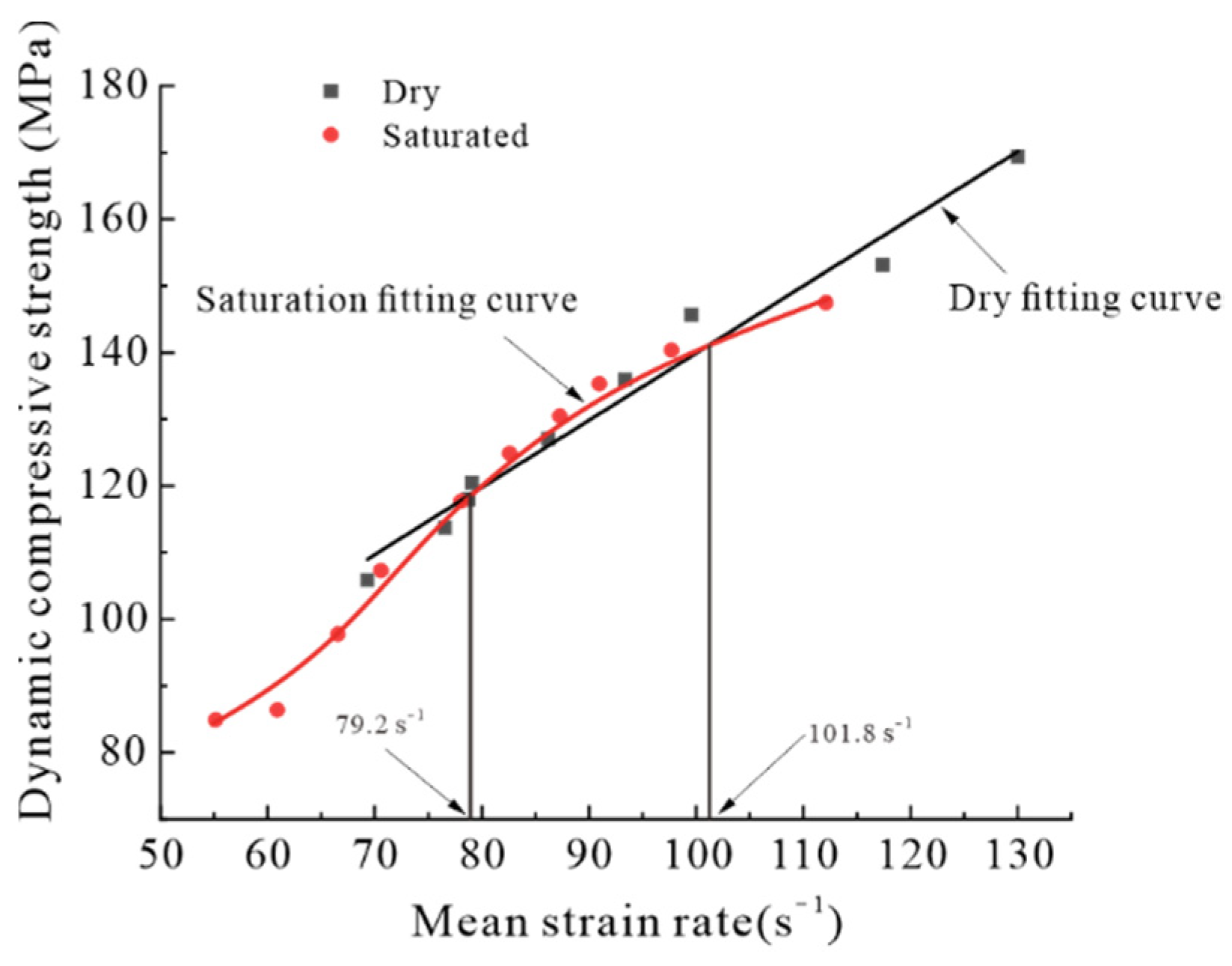

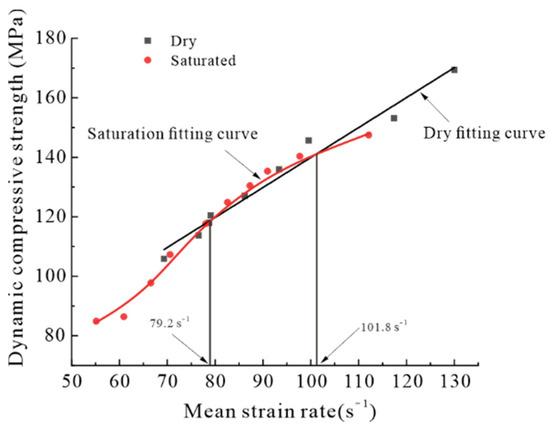

From the fitted curves of the two states in Figure 8, it can be seen that the dynamic compressive strength of the specimen shows a linear correlation with the average strain rate, and the compressive strength increases with the increase of the average strain rate. In contrast to dry specimens, saturated specimens reach their peak compressive strength at an average strain rate below 70 s−1. This indicates that the weakening effect of water greatly reduces the internal structural strength of the specimen, so that each mechanical property of the specimen in the initial state is much lower than the dry state, and the weakening effect of water on the rock is obvious. This situation changes as the average strain rate increases at an average strain rate equal to 79.2 s−1. When the average strain rate is greater than 79.2 s−1 and less than 101.8 s−1, the compressive strength of saturated phyllite specimens at the same average strain rate is greater than that of dry specimens. The bonding force of water in microfractures at this stage has a strengthening effect on the rock structure, which makes the rock strength increase. In the case of a high strain rate with the average strain rate greater than 101.8 s−1, the rock strength is again dominated by the mechanical properties of the rock due to the weakening effect of water on the rock, and the saturated rock strength is less than the dry state at the same average strain rate. At an average strain rate greater than 101.8 s−1, the dry state specimens showed a strong strain rate sensitivity, and the larger the strain rate the greater the compressive strength appreciation of the specimens. The saturated specimens, on the other hand, exhibit a strong strain rate sensitivity at an average strain rate of less than 79.2 s−1. This phenomenon further proves that the presence of water has a multifaceted effect on the mechanical properties of the specimen, and the mode of action is also complex and varied.

Figure 8.

Dynamic compressive strength versus average strain rate curve.

3.4. Failure Patterns

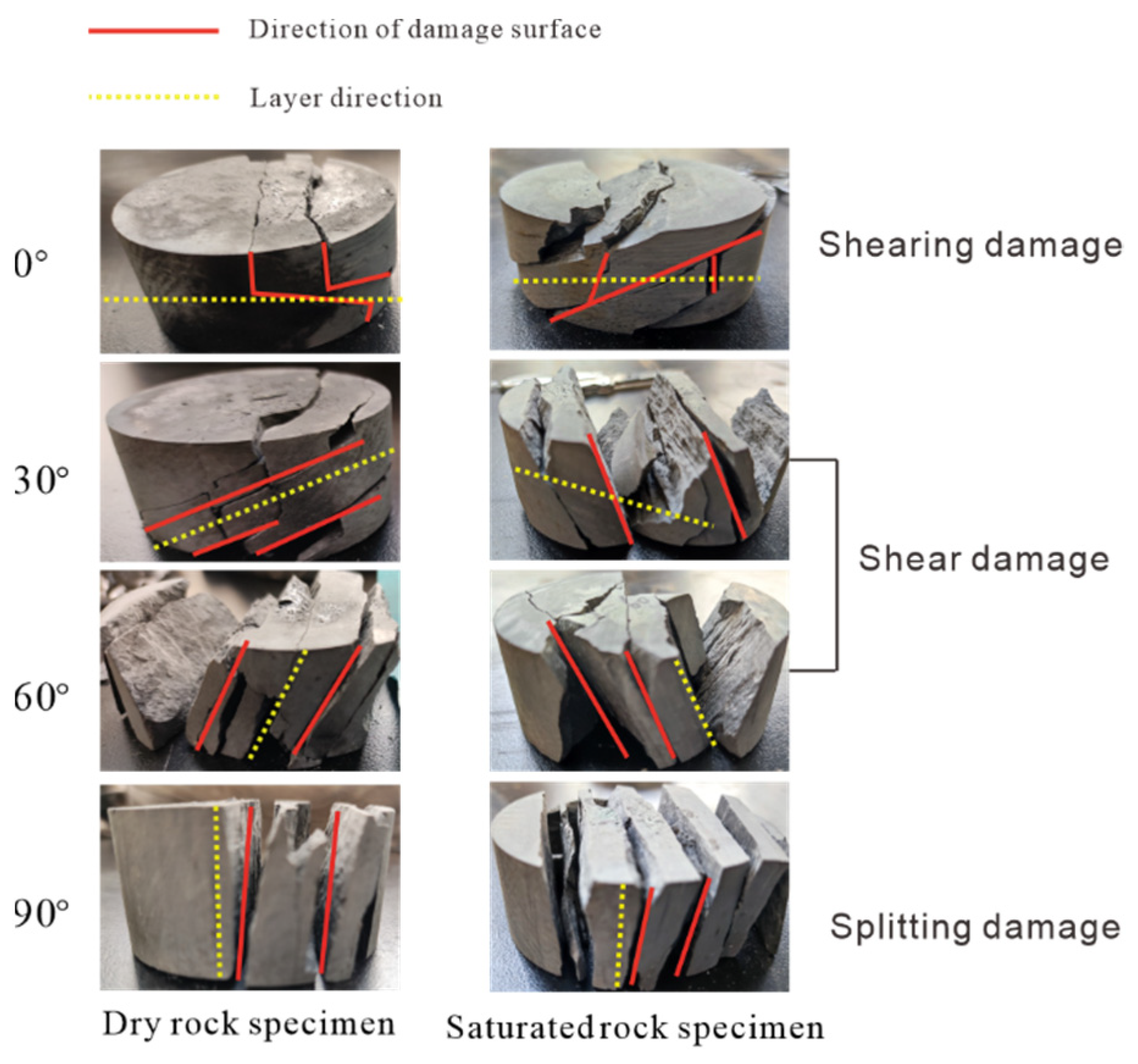

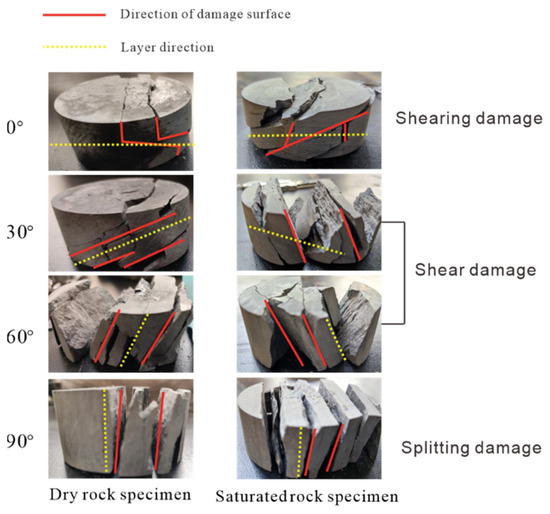

The patterns of deformation damage for phyllite samples after uniaxial compression tests with different water-bearing states at different stratification angles are shown in Figure 9.

Figure 9.

Destruction patterns.

As can be seen from Figure 9, when the stratification angle is 0°, the sample mainly undergoes shear damage in the direction of the vertical stratification, and the damage surface is irregular and obliquely intersects with the sample axis at an angle. When the stratification angle is 30° or 60°, the sample mostly suffers shear damage along the stratification, and there is also some secondary shear damage surface, which shows that the deformation damage of this stratification angle phyllite sample is mainly controlled by the stratification plane of the rock body. When the stratification angle is 90°, the sample is mainly damaged by splitting failure along the axial direction, and some parts of the sample suffer staggered extrusion. The deformation damage pattern is mainly caused by the “compression bar” destabilization among the stratification planes.

According to the damage patterns of rock samples at different water-bearing states, the damage patterns of sample with 0° stratification angle at different water-bearing states are basically the same, which indicates that the saturated state has less influence on the damage pattern of phyllite. As the stratification angle is 30° or 60°, the compressive strength of the sample is mainly controlled by the stratification planes, and water exerts a weakening effect on the rock samples, which reduces the strength of stratification planes and rock mass. Therefore, the saturated sample undergoes shear damage along the stratification planes and also suffers secondary shear damage, which results in a higher fragmentation of the sample. The stratification face of saturated samples at 90° is softened and the strength is reduced, and the axial load applied during the test is almost entirely borne by the rock among the stratification planes, so the damage characteristics of “compression rod” are more obvious, and the fragmentation is more complete than that under dry conditions.

4. Energy Dissipation Law of Saturated Phyllite under Impact Load

4.1. Calculation of Energy Dissipation

During the dynamic impact test of phyllite rock samples using the Hopkinson pressure rod test apparatus, the incident energy WI(t), reflected energy WR(t) and transmitted energy WT(t) of the whole system can be calculated from the following Equation (2) based on the one-dimensional stress wave theory.

Neglecting the energy loss between the pressure rod and the rock sample in the test, the energy consumption WS(t) for the crushing of the rock sample can be obtained based on the law of energy conservation, as shown in Equation (3).

Due to the different sizes of sample in the SHPB test, the energy consumed per unit volume of rock crushing varies. So, the unit volume of rock sample absorption crushing energy consumption is usually used to reflect the sample absorption energy, and the sample energy consumption density can be obtained from the following formula.

where wd is the crushing energy consumption density of the sample and VS is the volume of the sample.

The electrical signals collected by the ultrahigh dynamic strain gauge are converted into energy parameters for different stratification angle according to Equations (1)–(4), as shown in Table 1.

Table 1.

Energy parameters of saturated phyllite samples with different stratification angles.

4.2. Energy Distribution Curves for Different Stratification Angles

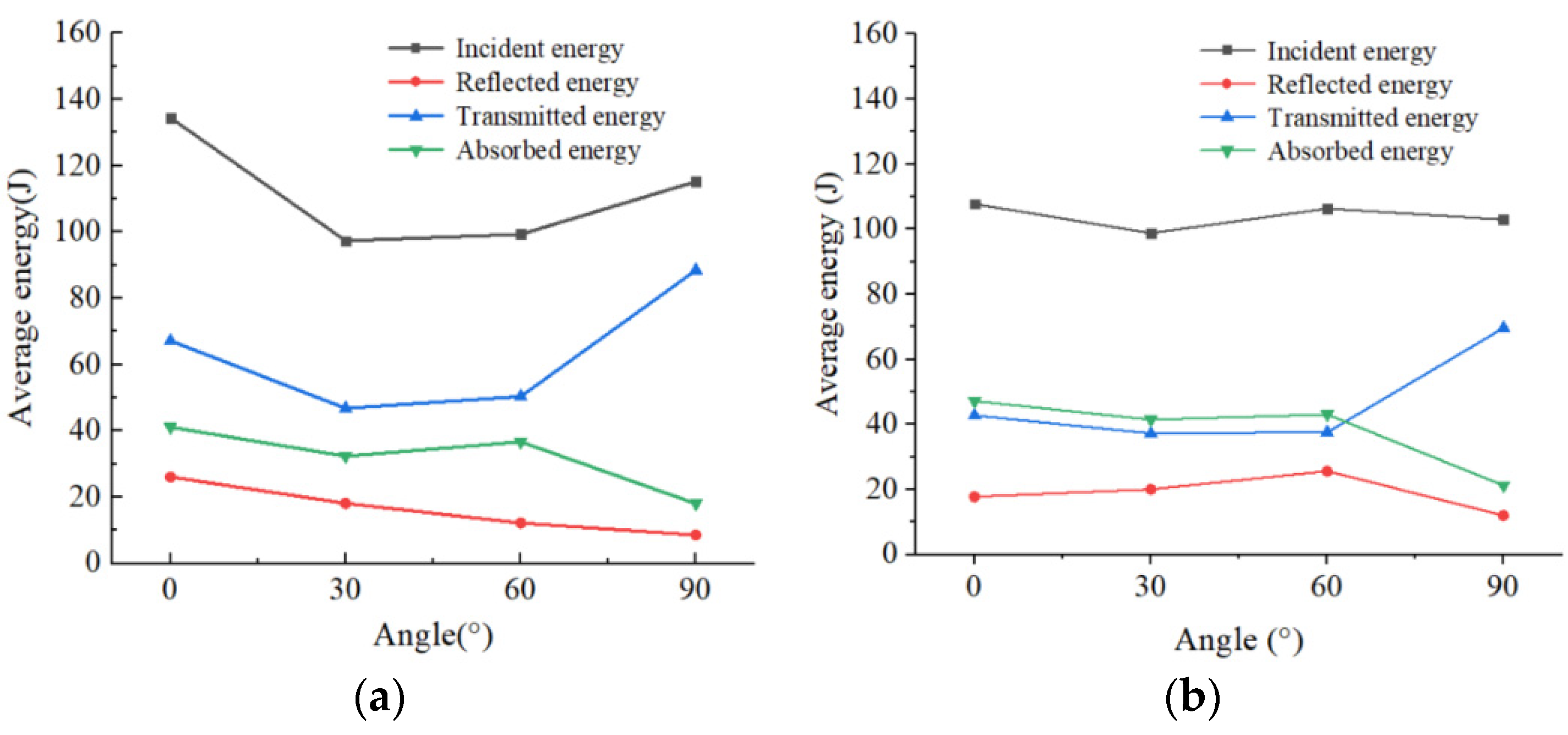

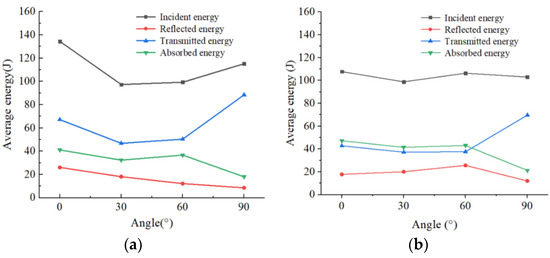

From the data in Table 1, four kinds of energy curve for different stratification angles in two states are obtained, as shown in Figure 10.

Figure 10.

Energy relationship curves for different stratification angles: (a) dry state; and (b) saturated state.

As can be seen from Figure 10, the absorbed energy of rock fragmentation at each stratification angle in the saturated state of schist is greater overall than that in the dry state, but the transmitted energy at each angle in its dry state is greater than that in the saturated state. This is due to the fact that the surface tension of water in the saturated state slows down the generation of tiny fissures inside the formula and slightly increases the strength of the rock. This makes the rock-crushing consume more energy. The dry state does not need to consider the effect of water, so the crushing consumes less energy, and the transmission energy is high.

The transmission energies at 90° stratification angle in both dry and saturated states are much higher than the rest of the angles. From the simple two-dimensional mechanical model of the sample shown in Figure 7, it can be seen that the direction of the dynamic force at this angle is consistent with the direction of the stratification plane. Thus, the dynamic force is equivalent to the shear force on the cracks among the stratification planes, which accelerates the extension along the cracks and makes the sample more fragile compared to the rest of the angles [32], and it also consumes less energy. Combined with the above studies on the compressive strength of phyllite, it can be assumed that the internal intact part of the 90° layered sample bears most of the force along the direction of action, and transmits the force to the output rod, which leads the transmission energy at 90°stratification angle being higher than that of the rest angles in both states.

4.3. Stratification Angle and Crushing Energy Consumption Density

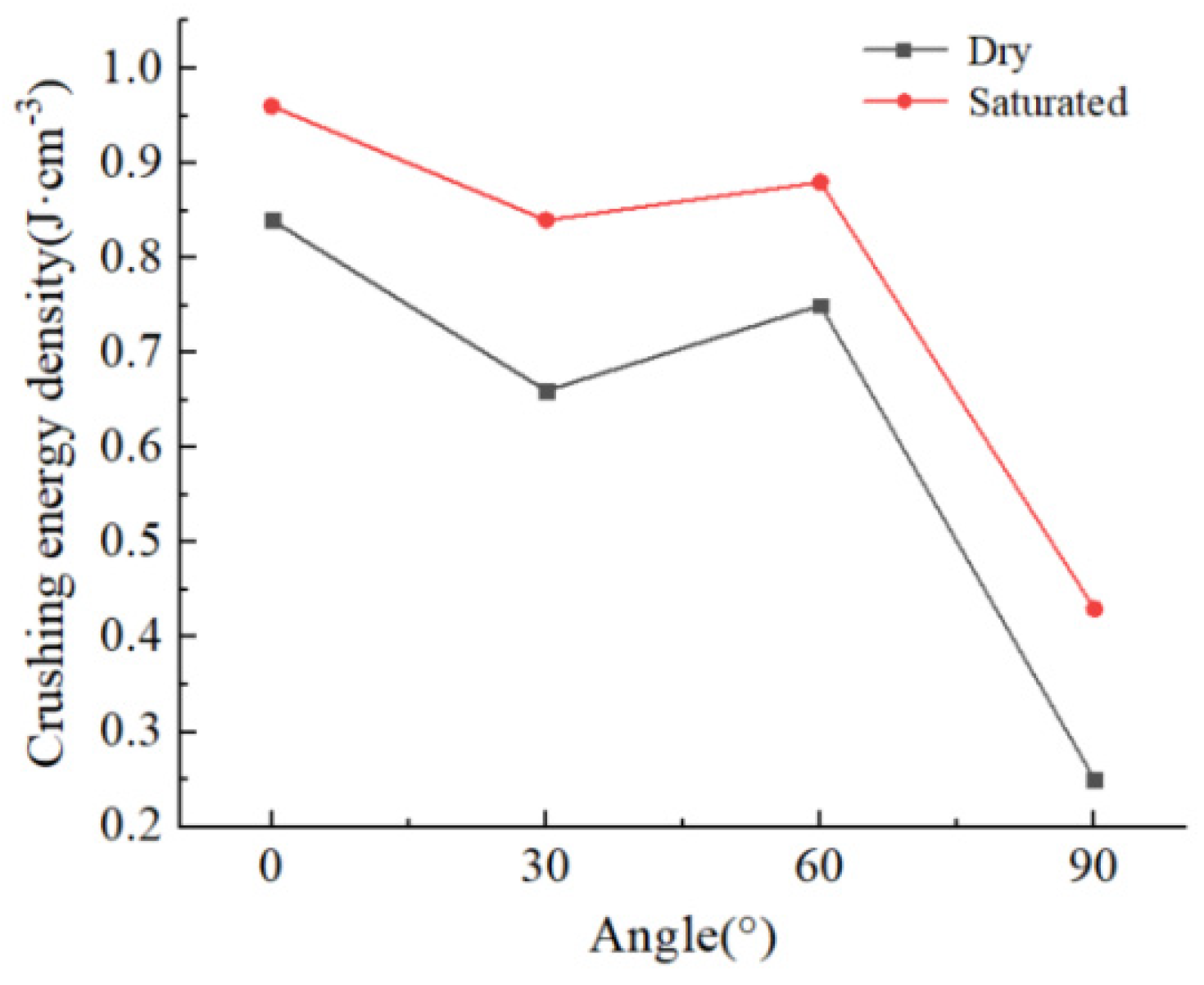

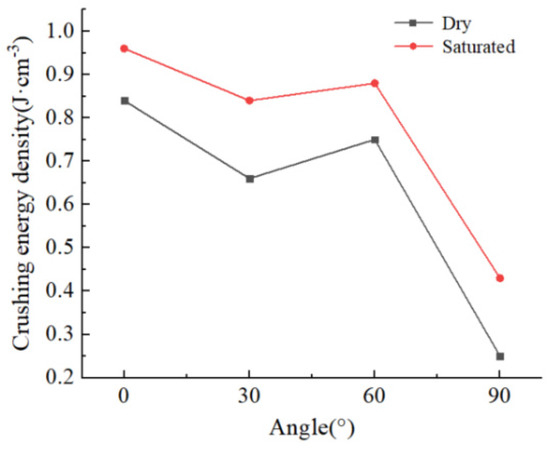

Combining the data in Table 1, the relationship curves among different stratification angles and crushing energy dissipation density of phyllite samples in two states can be derived, as shown in Figure 11.

Figure 11.

The relationship curve between stratification angle and crushing energy consumption density.

From Figure 11, it can be seen that the energy dissipation densities of saturated state with different stratification angles are greater than that of dry state. When the sample is in the saturated state, water will fill the fine fissures inside the sample and increase the density of the sample. Water has a viscous effect on the expansion of the fracture, which can slow down the crushing process of the sample and increase the energy required for the crushing of the sample.

The magnitudes of crushing energy dissipation density of phyllite samples in both states vary with the dip angle of the stratification plane as 0° > 90° > 30° > 60°. The crushing energy consumption at 0°is the highest, while that at 90° is the lowest, which is consistent with the energy consumption of the sample.

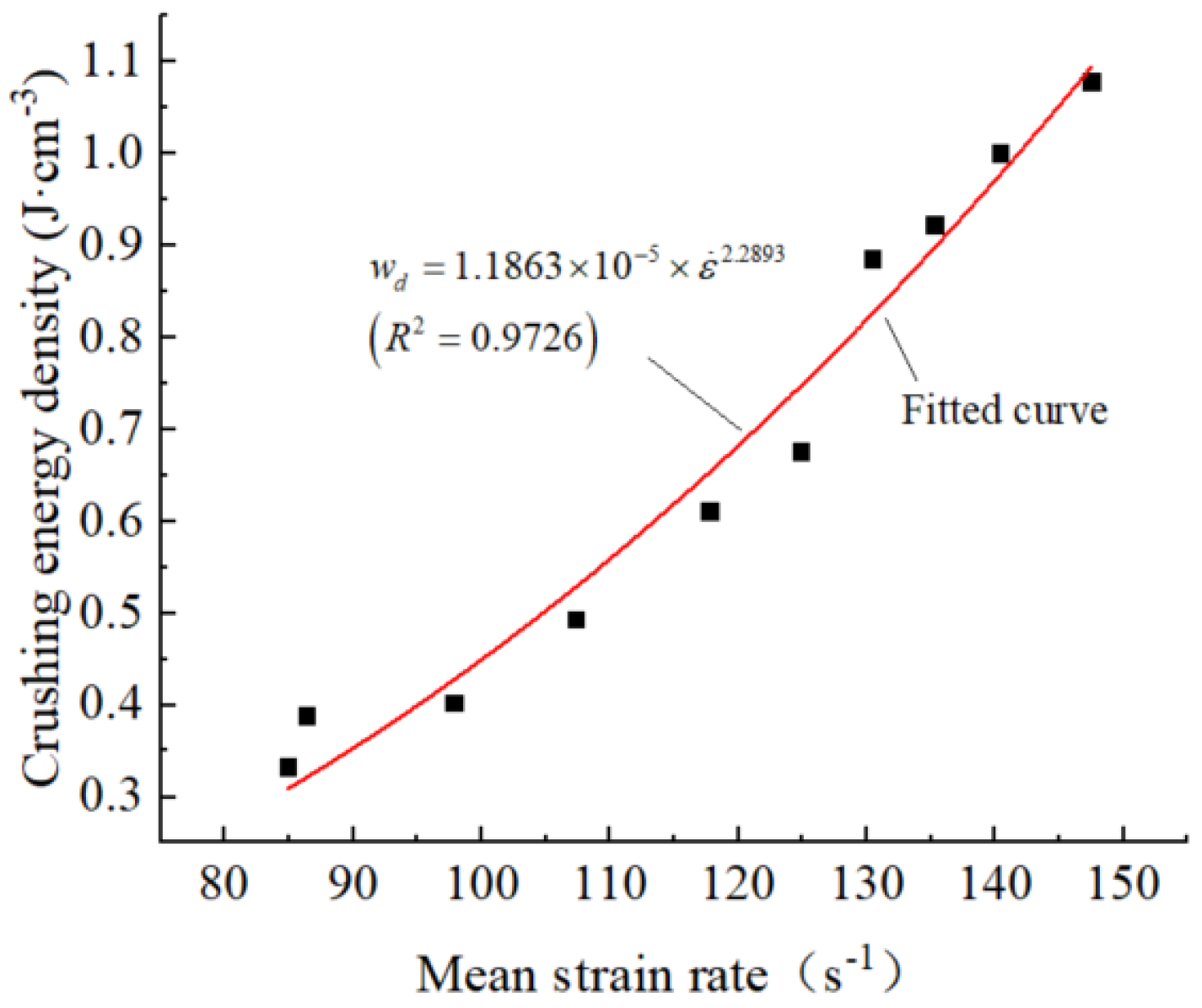

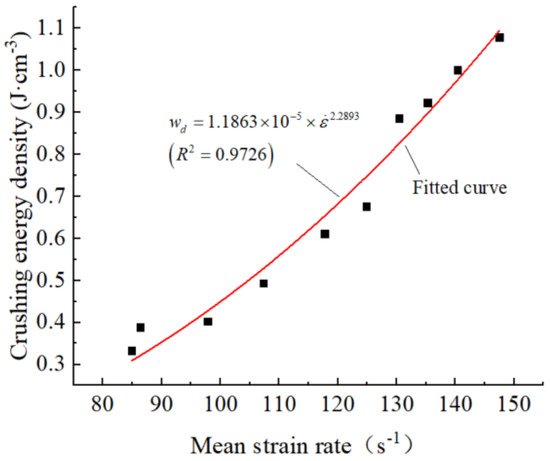

4.4. Crushing Energy Consumption Density and Average Strain Rate

The relationship curve between the sample crushing energy dissipation density and the average strain rate in the SHPB test of phyllite samples is shown in Figure 11.

As can be seen from Figure 12, the crushing energy density of the phyllite sample has a significant strain rate correlation and a strong multiplicative power relationship between the two.

Figure 12.

Relationship between crushing energy dissipation density and average strain rate of phyllite samples.

The reason for this is that as the strain rate of the sample under the impact load increases, the number of new cracks produced by the deformation of the sample increases and the more energy is absorbed by the sample breaking, the density of energy dissipated by the sample breaking also increases.

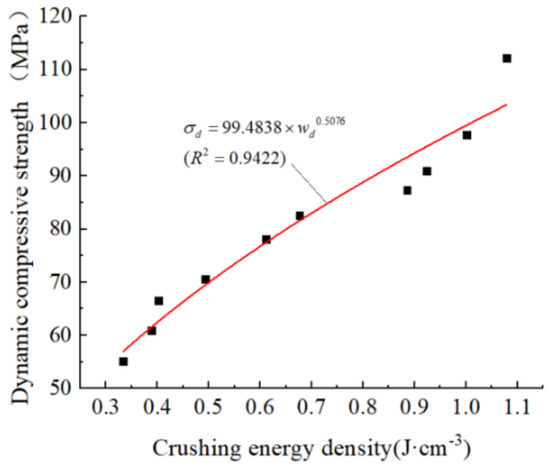

4.5. Dynamic Strength of Samples and Crushing Energy Consumption Density

The dynamic strength of rocks is an important component in the dynamic mechanic parameters of materials, and the dependence of dynamic compressive strength on strain rate has been widely recognized [33,34,35,36]. Since rock deformation is closely related to energy changes, and the deformation is the combined result of energy dissipation and energy release [37,38], the dynamic strength of the rock material can be described by the crushing energy dissipation density.

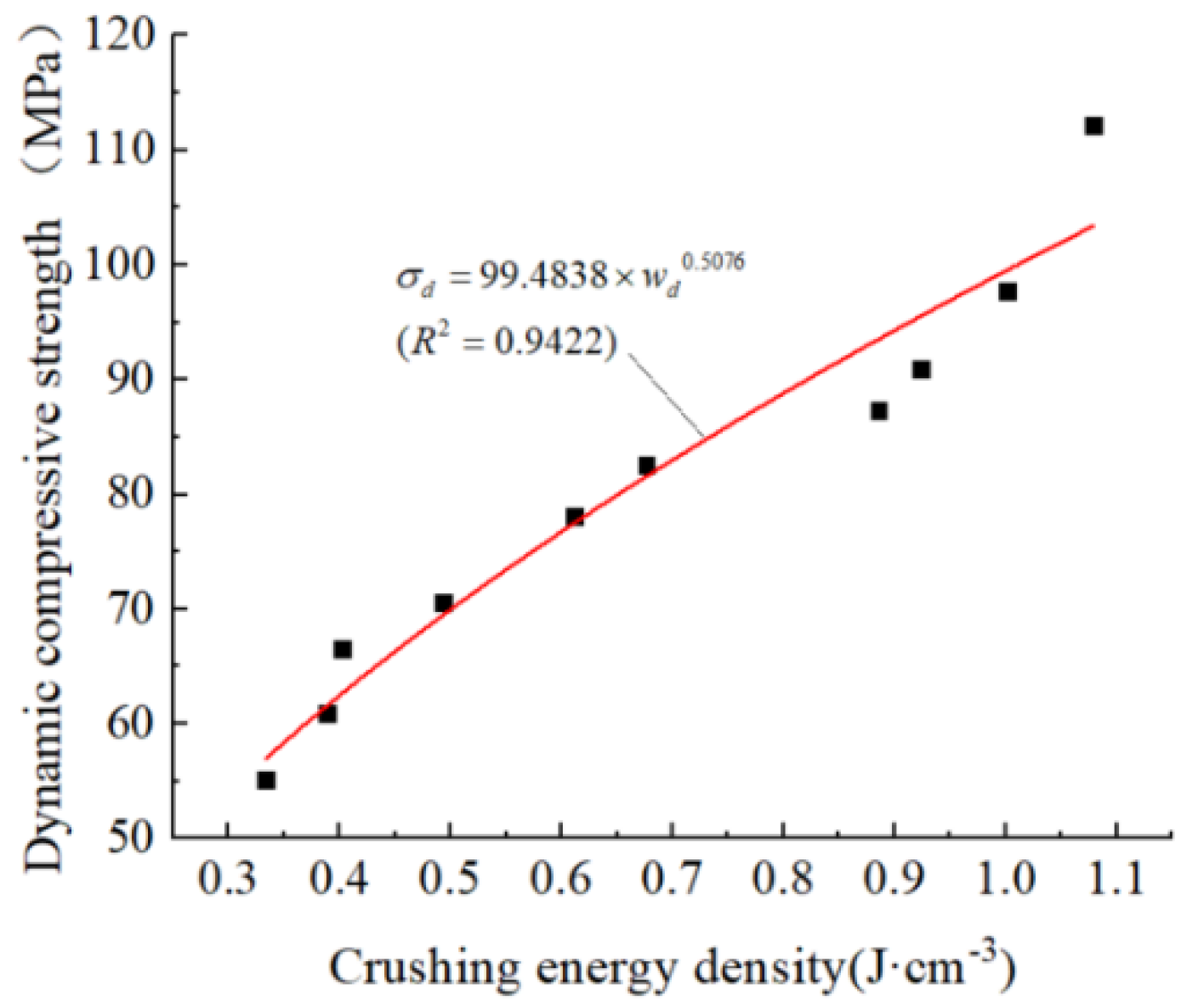

The relationship curve between the compressive strength of the sample and the energy dissipation density in this Hopkinson compression bar dynamic load impact test on phyllite samples is shown in Figure 13.

Figure 13.

Relationship between dynamic compressive strength and crushing energy dissipation density of phyllite samples.

As can be seen from Figure 13, the compressive strength and energy dissipation density of the phyllite sample in the Hopkinson compression bar dynamic load impact test both show a strong multiplicative power relationship.

The reason for this analysis is that, as the energy absorbed by the sample during rock crushing is dissipated in the expansion of cracks and the formation and enlargement of new surfaces, the higher the capacity of the rock material to absorb energy during the crushing process, the greater the number of internal microcrack extensions. This means that the energy absorbed by the sample is mainly dissipated in the damage evolution and deformation damage of the rock. As the energy absorbed in the sample increases, a deformation hysteresis occurs in the sample, resulting in a greater increase in the dynamic strength of the phyllite sample. Therefore, the use of the sample crushing energy consumption density can better reflect the essential characteristics of the strength of sandstone samples under external loading.

5. Analysis of Mechanical Properties and Energy Dissipation of Layered Phyllite

As seen from the results of the uniaxial dynamic compression tests on the phyllite at different stratification angles under two water-bearing states, the stratification angle and water-bearing state have significant effects on the damage characteristics and energy dissipation of the phyllite.

5.1. Analysis Stratification Angle and Crushing Energy Consumption

For the phyllite samples, as the dip angle of the stratification plane is 0°, compression damage of the interstratified rocks mainly occurs, and the stiffness is mainly provided by the rock-forming minerals with the bundle formation. The stiffness of the rocks among the stratification planes is better exploited, so the elasticity modulus of phyllite and the energy consumed by rock crushing are relatively large. As the dip angle of the stratification plane is 60°, the deformation is mainly controlled by the weak structural surface, stratification plane, and the shear damage along the direction of stratification plane is easy to occur, while the deformation resistance of stratification plane is much lower than that of interstratified rocks, so the elasticity modulus of stratification plane is the smallest. As the dip angle is 90°, the mechanical effect is similar to the compression bar destabilization of the interbedded rocks, and the compressive strength of the interbedded rocks is given full play, so the elasticity modulus of phyllite is relatively larger. The damage is mainly in the form of splitting damage, so the energy required to break the phyllite along the stratification plane is smaller, and the energy consumption for breaking is lower.

The dynamic compressive strength of phyllite samples shows an exponent relation with the crushing energy density, while the crushing energy density also has an exponent relation with the average strain rate, which indicates a strong correlation between the compressive strength and the average strain rate of phyllite rock, and this correlation is reflected in the energy scale as the rock crushing energy dissipation density.

5.2. Water Sensitivity Analysis

With the same stratification angle, the elasticity modulus in the dry state is greater than that in the saturated state, which is mainly because the softening effect of water reduces the stiffness of phyllite mineral particles and reduces the elasticity modulus and compressive strength.

Compared with the dry samples, the variation pattern of elastic modulus and compressive strength of saturated samples with the stratification angle is basically the same as that of the dry samples, but the peak elastic modulus decreases at all angles. Among which, the elastic modulus at 60° stratification angle shows the steepest descent. The main reason is that the deformation is mainly controlled by the stratification plane when the dip angle of the stratification plane is 60°, and water plays a lubricating role for the stratification plane. The shear damage of the sample occurs under a small axial force, and the radial strain during the damage is very limited, so the elasticity modulus is minimal when the dip angle of the stratification plane is 60°.

5.3. Influence of Stratification Angle and Mechanism of Water-Sensitive Joint Action

The deformation and damage patterns of phyllite are more complicated under different combinations of stratification angle and water-bearing state. This is mainly reflected in the different influences that water-bearing states have on the elastic modulus of phyllite under different dips of stratification plane. Overall, the influence of the water-bearing state both on the elastic modulus and on the dynamic compressive strength varies with the dip angle of stratification plane as 60° > 30° > 90° > 0°. The main reason is that the different combinations of the normal direction of the stratification plane and the axial force direction lead to different contribution degrees of weak structural surface to the compressive properties of phyllite. As the dip angle of the stratification plane is 60° or 30°, the compressive properties of phyllite are mainly controlled by the stratification plane. As the dip angle of the stratification plane is 0° or 90°, the compressive properties of the phyllite are controlled by both the stratification plane and interbedded rocks, and the stratification plane are much more sensitive to water than the interbedded rocks.

6. Conclusions

Dynamic compression tests on saturated layered phyllite samples at the same air pressure are conducted with the help of a modified split Hopkinson rod with a 50 mm diameter compression rod. The dynamic mechanical properties and energy dissipation law of saturated layered phyllite are analyzed. A total of four conclusions were summarized as follows.

(1) Under the same loading pressure, the stress–strain relationship curves show that the uniaxial dynamic compressive strength of the saturated phyllite is smaller than that of the dry phyllite. This is caused by the weakening effect of water on the rock structure caused by the reduction of the mechanical properties of the rock body. Another reason is the change in the mode of force action caused by the layered structure, which makes the values of compressive strength and mechanical parameters of 60° layered phyllite rocks are the lowest, and the decrease in saturation is obvious. The strain rate sensitivity of the compressive strength of phyllite in the two states is different, and the effect of water on the mechanical properties of phyllite is mainly a weakening effect;

(2) In the case of constant incident energy, the fragmentation dissipation energy is affected by both the stratification angle and the saturation environment. At the same angle, the energy consumption of saturated phyllite crushing is greater than that at the dry state. The analysis results from the fact that the bonding force of water in the microscopic crevices slows down the generation of tiny cracks inside the formula. This makes the rock crushing consume more energy, while the dry state does not have to consider the effect of water, so it consumes less energy and has a high transmission energy. In the same state, the crushing damage process of 0° layered phyllite has higher energy consumption, and the splitting damage of 90° layered phyllite has the lowest energy consumption and energy consumption density. Phyllite at 60° or 30°stratification angle suffers shear damage along the stratification plane, and the energy consumption density is relatively low;

(3) In the SHPB test of phyllite samples, the crushing energy dissipation density has a significant correlation with the strain rate and increases dramatically with the growth of the average strain rate, and the above two indexes shows a strong exponent relationship. The dynamic compressive strength of the phyllite samples also shows a strong exponent relation with the crushing energy density. Therefore, the crushing energy density can better reflect the essential strength characteristics under external loading.

Author Contributions

This article was written by five writers. Conceptualization, Y.P. and G.L.; methodology, Y.P.; software, G.L.; validation, Y.P.; data curation, Y.S.; writing—original draft preparation, G.L.; writing—review and editing, G.L.; supervision, L.W.; funding acquisition, Q.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Hubei Key Laboratory of Disaster Prevention and Mitigation, China Three Gorges University, Open Research Foundation of Engineering Research Center of Rock-Soil Drilling & Excavation and Protection, grant number 2020KJZ06 and 202108. The APC was funded by Open Research Foundation of Hubei Key Laboratory of Disaster Prevention and Mitigation, China Three Gorges University, grant number 2020KJZ06.

Data Availability Statement

All data in this article were obtained from the authors’ independent experiments and data processing using Origin software.

Acknowledgments

This work is supported by the Open Research Foundation of Hubei Key Laboratory of Disaster Prevention and Mitigation (China Three Gorges University) (Grant No. 2020KJZ06). Open Research Foundation of Engineering Research Center of Rock-Soil Drilling & Excavation and Protection (Grant No. 202108).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li, Y.; Zhao, B.; Yang, J.; Sun, J.; Huang, W.; Li, Z.; Wang, B. Experimental Study on the Influence of Confining Pressure and Bedding Angles on Mechanical Properties in Coal. Minerals 2022, 12, 345. [Google Scholar] [CrossRef]

- Shi, Z.; Zhao, Y.; Danesh, N.N.; Zhang, X.; Tang, T. Role of bedding plane in the relationship between Mode-I fracture toughness and tensile strength of shale. Bull. Eng. Geol. Environ. 2022, 81, 81. [Google Scholar] [CrossRef]

- Ramamurthy, T. Strength and modulus responses of anisotropic rocks. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1994, 31, 313–329. [Google Scholar]

- Tien, Y.M.; Kuo, M.C. A failure criterion for transversely isotropic rocks. Int. J. Rock Mech. Min. Sci. 2001, 38, 399–412. [Google Scholar] [CrossRef]

- Zaid, M. Three-dimensional finite element analysis of urban rock tunnel under static loading condition: Effect of the rock weathering. Geomech. Eng. 2021, 25, 99–109. [Google Scholar]

- Zaid, M. Dynamic stability analysis of rock tunnels subjected to impact loading with varying UCS. Geomech. Eng. 2021, 24, 505–518. [Google Scholar]

- Zaid, M. Preliminary Study to Understand the Effect of Impact Loading and Rock Weathering in Tunnel Constructed in Quartzite. Geotech. Geol. Eng. 2021, 1–29. [Google Scholar] [CrossRef]

- Zaid, M.; Mishra, S. Numerical Analysis of Shallow Tunnels Under Static Loading: A Finite Element Approach. Geotech. Geol. Eng. 2021, 39, 2581–2607. [Google Scholar] [CrossRef]

- Zaid, M.; Sadique, R.; Alam, M.M. Blast Resistant Analysis of Rock Tunnel Using Abaqus: Effect of Weathering. Geotech. Geol. Eng. 2021, 40, 809–832. [Google Scholar] [CrossRef]

- Zaid, M.; Shah, I.A. Numerical Analysis of Himalayan Rock Tunnels under Static and Blast Loading. Geotech. Geol. Eng. 2021, 39, 5063–5083. [Google Scholar]

- Sadique, R.; Zaid, M.; Alam, M.M. Rock Tunnel Performance Under Blast Loading through Finite Element Analysis. Geotech. Geol. Eng. 2021, 40, 35–56. [Google Scholar] [CrossRef]

- Fan, X.; Luo, N.; Liang, H.; Sun, X.; Zhai, C.; Xie, L. Dynamic Breakage Characteristics of Shale with Different Bedding Angles under the Different Ambient Temperatures. Rock Mech. Rock Eng. 2021, 54, 3245–3261. [Google Scholar] [CrossRef]

- Shuang, G.; Zhen, W.; Lei, Z. Dynamic fracture mechanics and energy distribution rate response characteristics of coal containing bedding structure. PLoS ONE 2021, 16, e0247908. [Google Scholar]

- Zhao, Y.; Liu, S.; Jiang, Y.; Wang, K.; Huang, Y. Dynamic Tensile Strength of Coal under Dry and Saturated Conditions. Rock Mech. Rock Eng. 2015, 49, 1709–1720. [Google Scholar] [CrossRef]

- Zhang, X.; Ou, X.; Gong, F.; Yang, J. Effects of Bedding on The Dynamic Compressive Properties of Low Anisotropy Slate. Rock Mech. Rock Eng. 2018, 52, 981–990. [Google Scholar] [CrossRef]

- Xie, H.; Ju, Y.; Li, L. Rock strength and overall damage criterion based on the principle of energy dissipation and release. J. Rock Mech. Eng. 2005, 1, 3003–3010. [Google Scholar]

- Xie, H.; Peng, R.D.; Ju, Y. Analysis of energy dissipation during rock deformation and damage. J. Rock Mech. Eng. 2004, 21, 3565–3570. [Google Scholar]

- Deng, Y.; Chen, M.; Jin, Y.; Zou, D. Theoretical analysis and experimental research on the energy dissipation of rock crushing based on fractal theory. J. Nat. Gas Sci. Eng. 2016, 33, 231–239. [Google Scholar] [CrossRef]

- Feng, J.; Wang, E.; Chen, X.; Ding, H. Energy dissipation rate: An indicator of coal deformation and failure under static and dynamic compressive loads. Int. J. Min. Sci. Technol. 2018, 28, 397–406. [Google Scholar] [CrossRef]

- Ramamurthy, T.; Venkatappa, R.; Singh, J. Engineering behaviour of phyllites. Eng. Geol. 1993, 33, 209–225. [Google Scholar] [CrossRef]

- Amour, F.; Christensen, H.F.; Hajiabadi, M.R.; Nick, H.M. Effects of Porosity and Water Saturation on the Yield Surface of Upper Cretaceous Reservoir Chalks From the Danish North Sea. J. Geophys. Res. Solid Earth 2021, 126, e2020JB020608. [Google Scholar] [CrossRef]

- Si, X.-F.; Huang, L.-Q.; Li, Z.-B.; Gong, F.-Q.; Liu, X.-L. Mechanical properties and rockburst proneness of phyllite under uniaxial compression. Trans. Nonferrous Met. Soc. China 2021, 31, 3862–3878. [Google Scholar] [CrossRef]

- Villalobos, F.A.; Rodriguez, P.A.; Vera, M. Study of the anisotropic tensile and compressive strength of a foliated phyllite. Proc. Inst. Civ. Eng. Geotech. Eng. 2021, 1–12. [Google Scholar] [CrossRef]

- Yang, Z.; Su, S.; Peng, L. Mechanical Behavior, Energy Release, and Crack Distribution Characteristics of Water-Saturated Phyllite under Triaxial Cyclic Loading. Adv. Civ. Eng. 2021, 2021, 3681439. [Google Scholar]

- Ma, L.H.; Chen, J.; Zhao, Y.F.; Zhang, C.; Liu, R.; Ren, S. Water Content and Bedding Angle Effects on the Mechanical Properties and Micro-/Macro-Failure Mechanism of Phyllite. Arab. J. Sci. Eng. 2022, 1–19. [Google Scholar] [CrossRef]

- Qiu, J.; Li, D.; Li, X. Dynamic failure of a phyllite with a low degree of metamorphism under impact Brazilian test. Int. J. Rock Mech. Min. Sci. 2017, 94, 10–17. [Google Scholar] [CrossRef]

- Xu, J.; Li, X. The dynamical loading on rock with different loading wave shapes conventional SHPB. J. Cent. South Univ. Technol. 1998, 5, 57–59. [Google Scholar] [CrossRef]

- Hong, L.; Li, X.; Liu, X.; Zhou, Z.; Ye, Z.; Yin, T. Stress uniformity process of specimens in SHPB test under different loading conditions of rectangular and half-sine input waves. Trans. Tianjin Univ. 2008, 14, 450–456. [Google Scholar] [CrossRef]

- Yang, G.; Bi, J.; Li, X.; Liu, J.; Feng, Y. SHPB Testing and Analysis of Bedded Shale under Active Confining Pressure. J. Eng. 2020, 2020, 5034902. [Google Scholar] [CrossRef]

- Xie, B.; Ai, D.; Yang, Y. An automatic pixel-level crack identification method for coals experiencing SHPB impact tests. J. Geophys. Eng. 2019, 16, 297–308. [Google Scholar] [CrossRef]

- Chen, R.; Nie, Z.Y.; Peng, Y.; Xu, Y.; Yao, W. A Dynamic Hydraulic Fracturing Test Technology Based on Split Hopkinson Pressure Bar System. Exp. Mech. 2022, 62, 813–822. [Google Scholar] [CrossRef]

- Li, B.; Ye, X.; Dou, Z.; Zhao, Z.; Li, Y.; Yang, Q. Shear Strength of Rock Fractures Under Dry, Surface Wet and Saturated Conditions. Rock Mech. Rock Eng. 2020, 53, 2605–2622. [Google Scholar] [CrossRef]

- Bauer, S.J.; Song, B.; Sanborn, B. Dynamic compressive strength of rock salts. Int. J. Rock Mech. Min. Sci. 2019, 113, 112–120. [Google Scholar] [CrossRef]

- Braunagel, M.J.; Griffith, W.A. The Effect of Dynamic Stress Cycling on the Compressive Strength of Rocks. Geophys. Res. Lett. 2019, 46, 6479–6486. [Google Scholar] [CrossRef]

- Liu, S.; Xu, J. Experimental and Numerical Analysis of Qinling Mountain Engineered Rocks during Pulse-Shaped SHPB Test. Int. J. Nonlinear Sci. Numer. Simul. 2015, 16, 165–171. [Google Scholar] [CrossRef]

- Feng, P.; Liu, B.; Tang, R.; Wei, M.; Zhang, Y.; Li, H. Dynamic Fracture Behaviors and Fragment Characteristics of Pre-compressed Flawed Sandstones. Int. J. Mech. Sci. 2022, 220, 107162. [Google Scholar] [CrossRef]

- Xie, H.; Li, L.; Ju, Y.; Peng, R.; Yang, Y. Energy analysis for damage and catastrophic failure of rocks. Sci. China Technol. Sci. 2011, 54, 199–209. [Google Scholar] [CrossRef]

- Shan, P.; Lai, X.; Liu, X. Correlational Analytical Characterization of Energy Dissipation-Liberation and Acoustic Emission during Coal and Rock Fracture Inducing by Underground Coal Excavation. Energies 2019, 12, 2382. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).