A Review of Sensor-Based Sorting in Mineral Processing: The Potential Benefits of Sensor Fusion

Abstract

:1. Introduction

2. Review of Sensor-Based Sorting in Mineral Processing

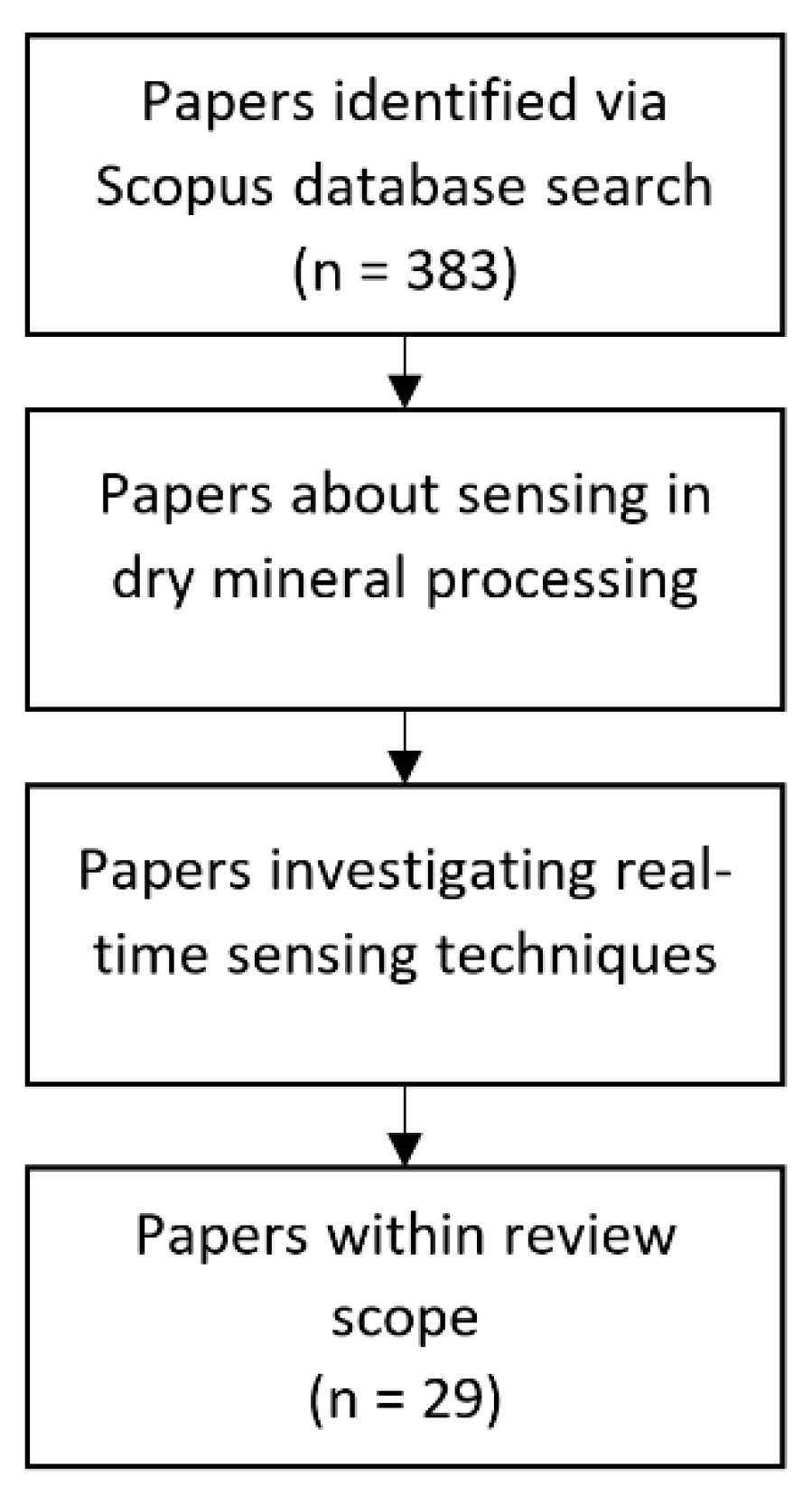

2.1. Search Strategy

2.2. Review Findings

2.2.1. X-ray Fluorescence (XRF)

2.2.2. X-ray Luminescence (XRL) and Optical Fluorescence

2.2.3. X-ray Transmission (XRT)

2.2.4. Prompt Gamma Neutron Activation Analysis (PGNAA)

2.2.5. Optical and Hyperspectral Imaging

3. Sensor Fusion

3.1. Sensor Fusion Classification

3.2. Sensor Fusion Examples

3.3. Limitations on Implementing Sensor Fusion

3.4. Pathways to Implementing Sensor Fusion in Mining

3.4.1. Data Availability

3.4.2. Data Synchronization

3.4.3. Data Analytics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hund, K.; La Porta, D.; Fabregas, T.P.; Laing, T.; Drexhage, J. Minerals for Climate Action: The Mineral Intensity of the Clean Energy Transition; World Bank: Washington, DC, USA, 2020. [Google Scholar]

- IEA. The Role of Critical Minerals in Clean Energy Transitions; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Yergin, D.; Bonakdarpour, M.; Bailey, T.M.; Alekseenko, M.; Beaufils, O.; Hoffman, F.; Mothersole, J.; Rajan, K.; Wlodarczyk, N.; Abbey, T.; et al. The Future of Copper: Will the Looming Supply Gap Short-Circuit the Energy Transition? S&P Global: New York, NY, USA, 2022. [Google Scholar]

- Calvo, G.; Mudd, G.; Valero, A.; Valero, A. Decreasing Ore Grades in Global Metallic Mining: A Theoretical Issue or a Global Reality? Resources 2016, 5, 36. [Google Scholar] [CrossRef] [Green Version]

- Rybak, J.; Khayrutdinov, M.M.; Kuziev, D.A.; Kongar-Syuryun, C.B.; Babyr, N.V. Prediction of the geomechanical state of the rock mass when mining salt deposits with stowing. J. Min. Inst. 2022, 253, 61–70. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.; Ubysz, A.; Faradzhov, V. Models and algorithms of choice of development technology of deposits when selecting the composition of the backfilling mixture. IOP Conf. Ser. Earth Environ. Sci. 2021, 684, 012008. [Google Scholar] [CrossRef]

- Arvidson, B.R.; Wotruba, H. Ore Sorting. In Mineral Processing and Extractive Metallurgy: 100 Years of Innovation; Anderson, C.G., Dunne, R.C., Uhrie, J.L., Eds.; Society for Mining, Metallurgy & Exploration, Incorporated: Englewood, CO, USA, 2014; pp. 209–222. [Google Scholar]

- Robben, C.; Wotruba, H. Sensor-Based Ore Sorting Technology in Mining—Past, Present and Future. Minerals 2019, 9, 523. [Google Scholar] [CrossRef] [Green Version]

- Chelgani, S.C.; Neisiani, A.A. Sensor-Based Separation. In Dry Mineral Processing; Springer: Cham, Switzerland, 2022; pp. 125–148. [Google Scholar] [CrossRef]

- Rutter, J.; Scott, M.; Odiar, N.; Federov, M.; Francois-Bongarcon, D. Quantification of surface sensor representivity of primary crushed ore for bulk ore sorting. In Proceedings of the Preconcentration Digital Conference 2020, Online, 17–18 November 2020; pp. 275–286. [Google Scholar]

- Nayak, P.; Hitch, M.; Bamber, A. Increasing the value of heterogeneous ore deposits by high-resolution deposit-modelling and flexible extraction techniques. Min. Technol. 2017, 126, 139–150. [Google Scholar] [CrossRef]

- Li, L.; Li, G.; Li, H.; Li, G.; Zhang, D.; Klein, B. Bench-scale insight into the amenability of case barren copper ores towards XRF-based bulk sorting. Miner. Eng. 2018, 121, 129–136. [Google Scholar] [CrossRef]

- Oliinyk, T.; Yefimenko, S.; Abdrakhmanova, Z.; Kan, A.; Issatayeva, F. Online ore monitoring using EDXRF method on process conveyor belts at Kazakhmys Corporation LLC operations. E3S Web Conf. 2020, 166, 02010. [Google Scholar] [CrossRef] [Green Version]

- Moffatt, J.E.; Payten, T.B.; Tsiminis, G.; de Prinse, T.J.; Teixeira, L.D.S.; Klantsataya, E.; Ottaway, D.J.; Smith, B.W.; Spooner, N.A. Upconversion Fluorescence in Naturally Occurring Calcium Fluoride. Appl. Spectrosc. 2021, 75, 674–689. [Google Scholar] [CrossRef]

- Zhang, Y.R.; Yoon, N.; Holuszko, M.E. Assessment of coal sortability and washability using dual energy X-ray transmission system. Int. J. Coal Prep. Util. 2021, 2895–2907. [Google Scholar] [CrossRef]

- Akdogan, G.; Bradshaw, S.; Dorfling, C.; Bergmann, C.; Ghosh, T.; Campbell, Q. Characterization of rare earth elements by XRT sorting products of a South African coal seam. Int. J. Coal Prep. Util. 2022, 42, 1071–1087. [Google Scholar] [CrossRef]

- Kolacz, J. New high definition X-ray sorting system based on X-{MINE} detection technology. IOP Conf. Ser. Mater. Sci. Eng. 2019, 641, 12028. [Google Scholar] [CrossRef] [Green Version]

- Jin, J.; Lin, C.-L.; Miller, J.D.; Zhao, C.; Li, T. X-ray Computed Tomography Evaluation of Crushed Copper Sulfide Ore for Pre-concentration by Ore Sorting. Min. Metall. Explor. 2022, 39, 13–21. [Google Scholar] [CrossRef]

- Assis, V.M.; Henriques, A.B.; Lemos, M.G.; Dumont, J.A. Technological innovation in Córrego do Sítio Mineração—A study of technical and economic aspects by using sensor-based sorting for refractory gold ore. REM Int. Eng. J. 2021, 74, 117–125. [Google Scholar] [CrossRef]

- Zhang, Y.; Yoon, N.; Holuszko, M.E. Assessment of Sortability Using a Dual-Energy X-ray Transmission System for Studied Sulphide Ore. Minerals 2021, 11, 490. [Google Scholar] [CrossRef]

- Veras, M.M.; Young, A.S.; Born, C.R.; Szewczuk, A.; Bastos Neto, A.C.; Petter, C.O.; Sampaio, C.H. Affinity of dual energy X-ray transmission sensors on minerals bearing heavy rare earth elements. Miner. Eng. 2020, 147, 106151. [Google Scholar] [CrossRef]

- Cardenas-Vera, A.; Hesse, M.; Möckel, R.; Gerhard Merker, R.; Heinig, T.; Van Phan, Q. Investigation of Sensor-Based sorting and selective comminution for pre-concentration of an unusual parisite-rich REE ore, South Namxe, Vietnam. Miner. Eng. 2022, 177, 107371. [Google Scholar] [CrossRef]

- Neubert, K.; Wotruba, H. Investigations on the Detectability of Rare-Earth Minerals Using Dual-Energy X-ray Transmission Sorting. J. Sustain. Metall. 2017, 3, 3–12. [Google Scholar] [CrossRef]

- Kern, M.; Tusa, L.; Leißner, T.; van den Boogaart, K.G.; Gutzmer, J. Optimal sensor selection for sensor-based sorting based on automated mineralogy data. J. Clean. Prod. 2019, 234, 1144–1152. [Google Scholar] [CrossRef]

- Robben, C.; Condori, P.; Pinto, A.; Machaca, R.; Takala, A. X-ray-transmission based ore sorting at the San Rafael tin mine. Miner. Eng. 2020, 145, 105870. [Google Scholar] [CrossRef]

- Neto, D.J.; Bergerman, M.G.; Young, A.S.; Petter, C.O. Pre-concentration potential evaluation for a silicate zinc ore by density and sensor-based sorting methods. Rev. Esc. Minas 2019, 72, 335–343. [Google Scholar]

- Nadolski, S.; Samuels, M.; Klein, B.; Hart, C.J.R. Evaluation of bulk and particle sensor-based sorting systems for the New Afton block caving operation. Miner. Eng. 2018, 121, 169–179. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Liu, X.; Wang, L.; Xia, X. Ore image classification based on small deep learning model: Evaluation and optimization of model depth, model structure and data size. Miner. Eng. 2021, 172, 107020. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Y.; Hu, Q.; Zhang, Z.; Liu, Y. Competitive Voting-based Multi-class Prediction for Ore Selection. In Proceedings of the 2020 IEEE 16th International Conference on Automation Science and Engineering (CASE), Hong Kong, China, 20–21 August 2020; pp. 514–519. [Google Scholar]

- Phiri, T.; Glass, H.J.; Mwamba, P. Development of a strategy and interpretation of the NIR spectra for application in automated sorting. Miner. Eng. 2018, 127, 224–231. [Google Scholar] [CrossRef]

- Paranhos, R.S.; Santos, E.G.; Veras, M.M.; Guadagnin, F.; Pasetto, G.A. Performance analysis of optical and X-Ray transmitter sensors for limestone classification in the South of Brazil. J. Mater. Res. Technol. 2020, 9, 1305–1313. [Google Scholar] [CrossRef]

- Basu, R.; Rao, D.S.; Das, D.P. Detection of Economic Minerals in Beach Placer Samples by Machine Learning-Based Microscopic Image Processing. In Proceedings of the 2020 International Conference on Emerging Trends in Information Technology and Engineering (ic-ETITE), Vellore, India, 24–25 February 2020; pp. 1–4. [Google Scholar]

- Desta, F.S.; Buxton, M.W.N. Chemometric Analysis of Mid-Wave Infrared Spectral Reflectance Data for Sulphide Ore Discrimination. Math. Geosci. 2019, 51, 877–903. [Google Scholar] [CrossRef] [Green Version]

- Desta, F.; Buxton, M. Image and Point Data Fusion for Enhanced Discrimination of Ore and Waste in Mining. Minerals 2020, 10, 1110. [Google Scholar] [CrossRef]

- Tuşa, L.; Kern, M.; Khodadadzadeh, M.; Blannin, R.; Gloaguen, R.; Gutzmer, J. Evaluating the performance of hyperspectral short-wave infrared sensors for the pre-sorting of complex ores using machine learning methods. Miner. Eng. 2020, 146, 106150. [Google Scholar] [CrossRef]

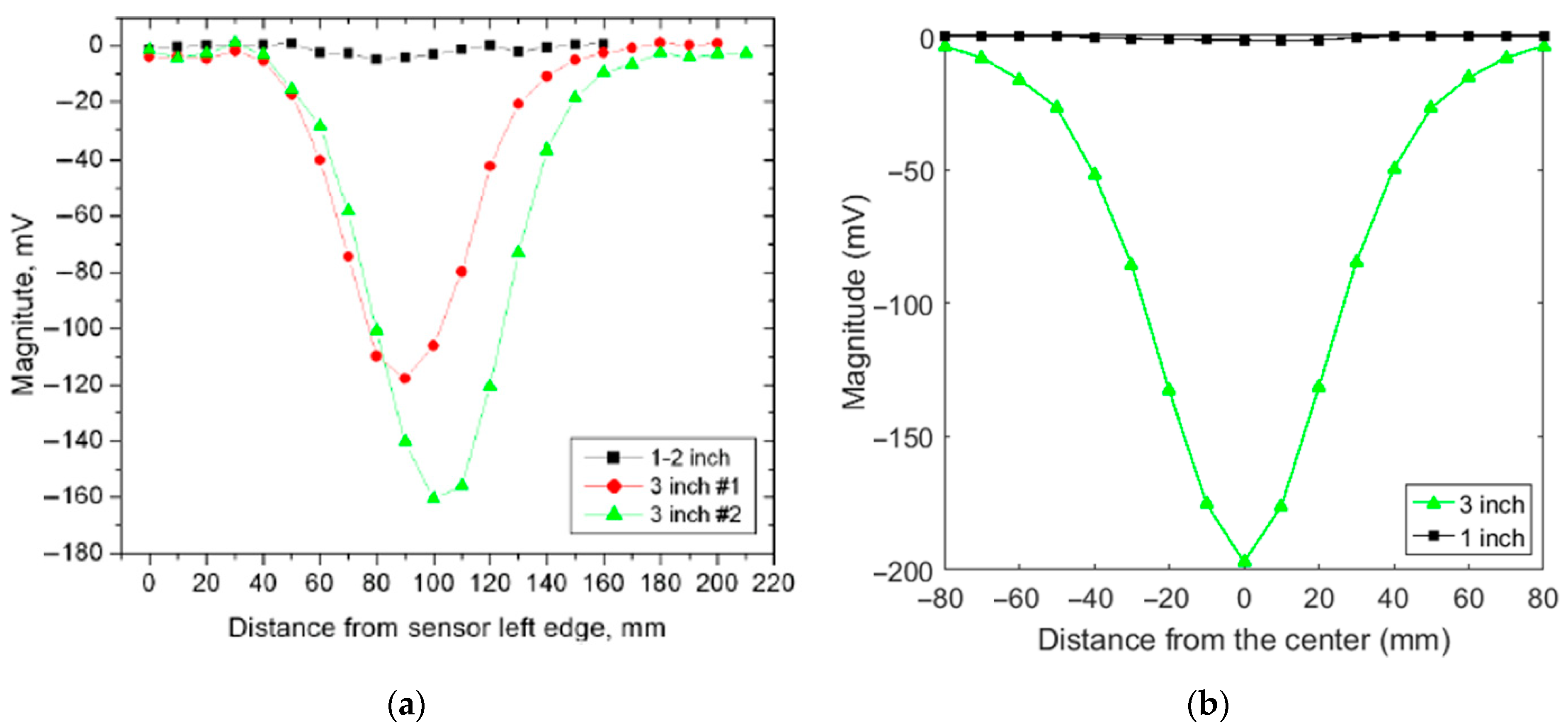

- Tong, L.; Yan, H.; Klein, B.; Khosaba, B.; Bamber, A.S. Effect of mineralogy on the sensor-based sorting of a low grade copper ore using high frequency electromagnetic technology. In Proceedings of the XXVIII International Mineral Processing Congress, Quebec City, QC, Canada, 11–15 September 2016. [Google Scholar]

- Li, M.; Caushaj, A.; Silva, R.; Lowther, D. A neural network for electromagnetic based ore sorting. Compel 2018, 37, 691–703. [Google Scholar] [CrossRef]

- Leiva, C.; Acuña, C.; Castillo, D. Development and Validation of an Online Analyzer for Particle Size Distribution in Conveyor Belts. Minerals 2021, 11, 581. [Google Scholar] [CrossRef]

- Tickner, J.; Ganly, B.; Lovric, B.; O’Dwyer, J. Improving the sensitivity and accuracy of gamma activation analysis for the rapid determination of gold in mineral ores. Appl. Radiat. Isot. 2017, 122, 28–36. [Google Scholar] [CrossRef]

- Duan, B.; Bobicki, E.; Hum, S.V. Application of Microwave Imaging in Detecting Valuable Ores. In Proceedings of the 2021 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting (APS/URSI), Denver, CO, USA, 10–15 July 2021; pp. 1839–1840. [Google Scholar]

- Kurth, H. Optimising Plant Feed Quality and Process Performance Using Geoscan Elemental Analysis; Canadian Institute of Mining, Metallurgy and Petroleum: Montreal, QC, Canada, 2016. [Google Scholar]

- Heckert, M.; Enghardt, S.; Bauch, J. Novel multi-energy X-ray imaging methods: Experimental results of new image processing techniques to improve material separation in computed tomography and direct radiography. PLoS ONE 2020, 15, e0232403. [Google Scholar] [CrossRef] [PubMed]

- Johns, H.E.; Cunningham, J.R. The Physics of Radiology; Charles C. Thomas: Springfield, IL, USA, 1983. [Google Scholar]

- Agostinelli, S.; Allison, J.; Amako, K.; Apostolakis, J.; Araujo, H.; Arce, P.; Asai, M.; Axen, D.; Banerjee, S.; Barrand, G.; et al. GEANT4—A simulation toolkit. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2003, 506, 250–303. [Google Scholar] [CrossRef] [Green Version]

- Allison, J.; Amako, K.; Apostolakis, J.; Arce, P.; Asai, M.; Aso, T.; Bagli, E.; Bagulya, A.; Banerjee, S.; Barrand, G.; et al. Recent developments in Geant4. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2016, 835, 186–225. [Google Scholar] [CrossRef]

- Gal, Y.; Ghahramani, Z. Dropout as a Bayesian Approximation: Representing Model Uncertainty in Deep Learning. In Proceedings of the 33rd International Conference on Machine Learning, New York, NY, USA, 19–24 June 2016; pp. 1050–1059. [Google Scholar]

| Search Term | Papers Remaining |

|---|---|

| sensing OR detector OR sensor | 2,826,453 |

| mineral OR ore | 25,542 |

| sort OR separat OR online OR on line | 2249 |

| NOT remote OR satel OR uav OR data mining OR sinter OR furnac OR soft sens OR mineral oil OR mineral water OR sensory | 1361 |

| Published in 2017 or later AND Language is English | 383 |

| Abstract examination | 29 |

| Sensor Type(s) | Ore/Material | Sorting Type | Findings | Reference |

|---|---|---|---|---|

| XRF | Copper porphyry ore | Particle (Test work) Bulk (Economic analysis) | Testing of six ore samples from different areas of two mines found varying efficiencies of XRF sorting. With a 0.3% Cu cut-off grade XRF sorting achieved recoveries of between 61% and 91% within 22% to 65% of the ore mass resulting in grade improvements of between 40% and 275%. Economic modelling predicted an increase in profit of between 20% and 151%, however, this is likely an overestimate as it is using particle sorting results evaluated with the costs for bulk sorting which would be less selective, particularly with a surface only sensor. | Nayak, Hitch and Bamber [11] |

| XRF | Copper ore | Bulk | Experimental test using low grade copper ore to evaluate the potential for using XRF sensors for bulk sorting. For 250 g samples it was found that 50 spot XRF measurements were sufficient to produce results within 2% of the bulk copper grade. Artificial 250 g material lots were produced with proportions of copper bearing particles ranging from 0%–100%. Surface XRF measurements of the lots were used to evaluate XRF bulk sorting. It was found that the XRF sensor results enabled rejection of 30% of the lots with the retention of 90% of the copper. | Li et al. [12] |

| XRF | Copper and silver ore | Bulk | Testing of XRF sensors installed over conveyors at operational mine sites showed that the sensors could measure the copper and silver grades of processed ore. | Oliinyk et al. [13] |

| Fluorine optical fluorescence sensor | Copper porphyry ore | Bulk | Experimental tests on fluorine crystal samples demonstrated fluorine specific up-conversion fluorescence. Tests on artificial samples made by combining a no-fluorine copper ore with fluorite showed that the sensor could measure fluorite content ranging from 1%–100% | Moffatt et al. [14] |

| XRT | Coal | Particle | Experimental tests found a correlation between XRT measurements and the specific gravity (R2 = 0.83) and ash content (R2 = 0.75) of the coal. This enabled estimation of the washability curve for processing the coal. | Zhang, Yoon and Holuszko [15] |

| XRT | Coal/Rare Earth Elements (REE) | Particle | Sampling from the XRT sorting plant showed that the sorters were able to separate the processed coal by ash content into high-grade and low-grade product and waste. Testing showed that REE content was correlated with ash content and that the XRT sorting upgraded the total REE grade in the discard by 21.3% | Akdogan et al. [16] |

| Dual Energy XRT | Copper ore | Particle | Tests on low grade, finely disseminated copper ore showed that sorting using high resolution XRT was able to extract 99.7% of the copper in 68% of the ore mass. | Kolacz [17] |

| Micro-CT and Dual Energy XRT | Copper | Particle | Experimental tests showed that micro-CT imaging could identify the copper content of particles and predict sortability. Pilot XRT sorting tests showed that 90% of the copper could be retained in 69% of the material mass. | Jin et al. [18] |

| XRT and LASER | Gold ore | Particle | Test work on a mine site demonstrated that sequential XRT and LASER based sorting was able to extract 88% of the gold from 50% of the mass. Financial modelling found that the use of sensor-based sorting reduced the cut-off grade from ~2.5 g/t to ~1 g/t. | Assis et al. [19] |

| Dual Energy XRT | Poly-metallic (Au, Ag, Zn, Pb) sulfide ore | Particle | Experimental assessment of XRT sorting potential for sulfide ore. 500 representative particles selected from run of mine ore were investigated using XRT. Archetype sample particles for both high grade ore and waste were chosen and used for material decomposition using XRT data. This resulted in a variable giving the similarity of the sensed particle to the high-grade ore particle or the waste particle. This was found to be effective for classifying ore and waste particles for sorting, with the potential to extract 90% of the sulfides in 55% of the mass. | Zhang, Yoon and Holuszko [20] |

| Dual Energy XRT | Rare Earth Element ore | Particle | Experimental tests showed that the XRT sensor was able to sort the REE ore particles into batches by grade. Setting various cut-off thresholds enabled the recovery of 68%, 89% and 96% of heavy REEs within 3%, 15% and 66% of the mass respectively. | Veras et al. [21] |

| XRT, NIR, Color, LASER | Rare Earth Element ore | Particle | Drill core samples were crushed and the grades of 107 selected particles were determined using ICP-MS. The effectiveness of each sensor type to sort the material into product and waste was determined for a 0.1% cut-off grade. It was found that XRT sorting was the most effective followed by LASER. Color and NIR sorting were not effective. Tests on a larger sample showed that XRT sorting could recover 98% of REE in 30% of the ore mass. | Cardenas-Vera et al. [22] |

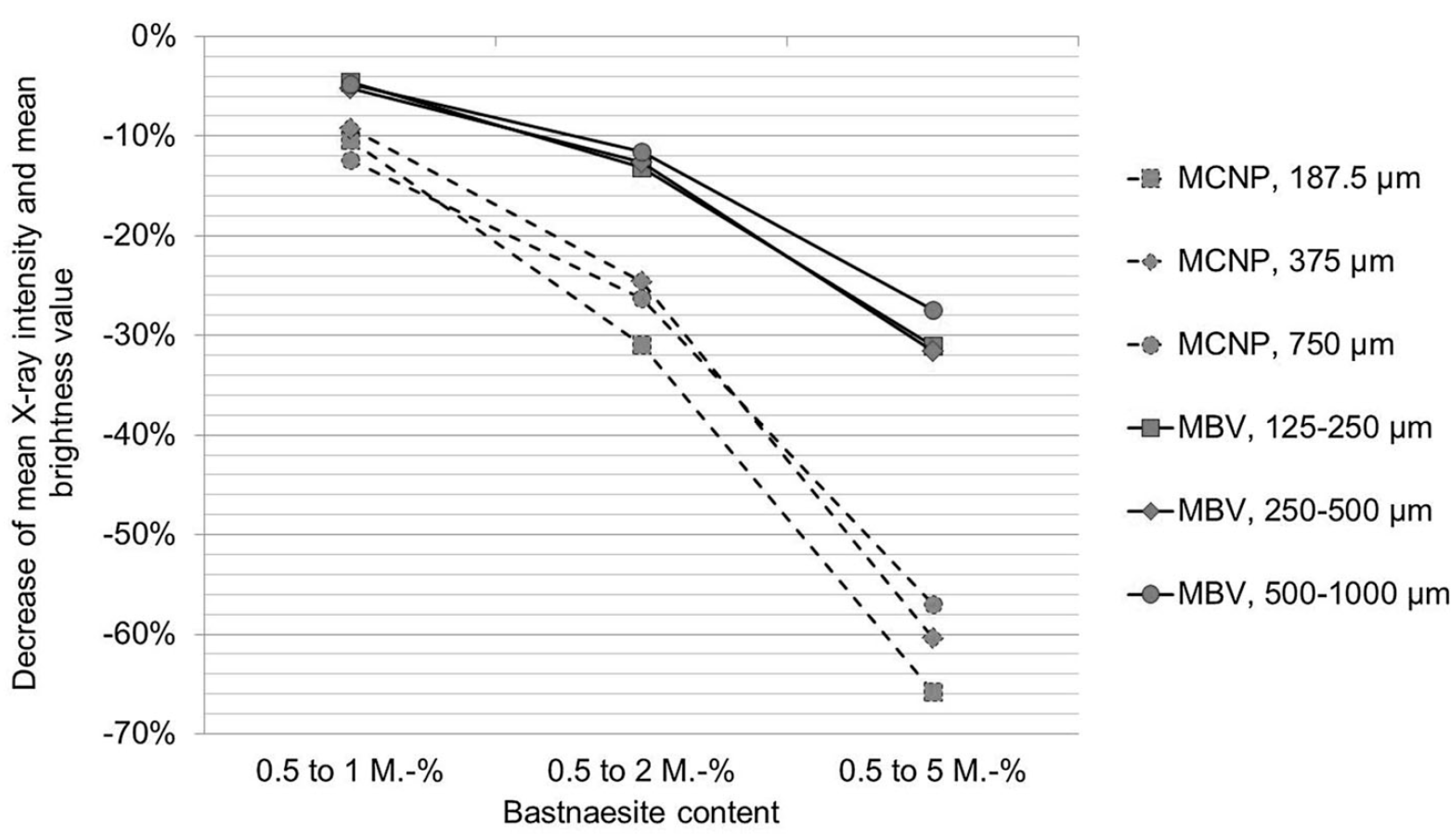

| XRT | Rare Earth Element ore | Particle | Experimental tests and Monte Carlo simulations of artificial particle samples consisting of REE-bearing minerals and quartz were used to determine the effect of REE mineral grade on X-ray transmission. The experiments showed that the transmission was reduced progressively by 5%–30% as the REE grade was increased from 0.5% to 1%–5%. Simulations predicted roughly double the decrease which was attributed to oversimplification of the model. Both methods indicated XRT was well suited to REE sorting. It was also found that the heterogeneity of the XRT could be related to the REE grain size. | Neubert and Wotruba [23] |

| Dual Energy XRT and Infrared Imaging (SWIR) | Tin ore | Particle | Experimental tests showed that using SWIR imaging to detect chlorite content enabled sorting of skarn ore to extract 70% of the cassiterite while rejecting 75% of the gangue. Tests also showed that for mica schist ore, XRT-based density sorting enabled the extraction of 95% of cassiterite with rejection of 45% of the gangue. | Kern et al. [24] |

| XRT | Tin ore | Particle | Test work on ore samples determined that XRT-based sorting could extract 93% of the tin within 26% of the mass. When implemented on site it was found that the sorting extracted 90% of tin within 19% of the mass. | Robben et al. [25] |

| Dual Energy XRT | Zinc ore | Particle | Experimental tests showed that XRT sorting could extract 93% of the zinc within 70% of the mass. | Neto et al. [26] |

| PGNAA and XRF | Copper Gold Porphyry ore | Bulk (PGNAA) and Particle (XRF) | Test work on ore samples showed that PGNAA and XRF sensors were able to measure accurately the copper and gold content of the bulk ore and ore particles respectively. XRF sorting was able to extract 90% of the copper in 40% of the mass. Economic analysis evaluating the use of PGNAA bulk sorting to discard waste and select intermediate grade ore for XRF particle sorting found that the combined sorting could increase NSR by 6.5%. | Nadolski et al. [27] |

| Optical | Coal | Particle | Deep learning neural networks were able to sort high-grade coal from low-grade waste using optical imaging with a classification efficiency of 90%–96%. | Liu et al. [28] |

| Optical | Coal | Particle | Testing showed that machine learning based analysis of optical images enabled classification of coal into four different qualities with efficiencies of 78%–90% for a variety of algorithms. Using a majority vote of the algorithms improved classification accuracy to 92%. | Zhang et al. [29] |

| NIR | Copper ore | Particle | Testing of ore samples showed minimal NIR signal for copper minerals amongst iron bearing minerals while calcite showed a strong NIR signal. This indicated the NIR sorting could sort high carbonate waste from the copper ore. | Phiri, Glass and Mwamba [30] |

| Optical and XRT | Marble | Particle | Testing showed that optical sorting was able to classify particles as marble or waste with an accuracy of up to 85%–98% for particle sizes from 25–70 mm. XRT sorting was found to be ineffective due to the similar densities of marble and the host rock. | Paranhos et al. [31] |

| Optical | Mineral Sands | Particle | Experimental tests on mineral sands samples showed that machine learning based analysis of optical images was able to classify the mineral components of the sand with 91% efficiency. | Basu, Rao and Das [32] |

| Infrared Imaging (MWIR and LWIR) | Poly-metallic (Cu, Zn, Pb) sulfide ore | Particle | Tests demonstrated that the accuracy for classifying particles as ore/waste was up to 90%, 86% and 85% for the combined FTIR, MWIR and LWIR spectra respectively. | Desta and Buxton [33] |

| Infrared Imaging (VNIR, SWIR, MWIR and LWIR) | Poly-metallic (Cu, Zn, Pb) sulfide ore | Particle | Experimental tests showed that fusion of the results for all the measured IR spectra was able to be used to classify the particles as ore or waste with an accuracy of 87%–95% depending on cut-off grade (3%, 5%, 7%) and classification algorithm (K-means and SVC). Fused datasets provided an improvement of 0%–3% in classification probability over the best performing single spectra. | Desta and Buxton [34] |

| Infrared Imaging (VNIR and SWIR) | Tin ore and copper-gold porphyry ore | Particle | Tests showed that sorting based on machine learning classification of hyperspectral data was able to recover 90% of the desired metal in 27% and 43% of the mass for the tin and copper ore respectively. | Tusa et al. [35] |

| Inductive electromagnetic impedance sensor | Aluminum ore | Particle | Finite Element Method simulations of the sensor response to an ore particle model showed that the simulations were able to reproduce published experimental results by Tong et al. [36] and that the sensor response increased for higher aluminum grades. Simulated detector responses for a range of modelled ore particles were used as a dataset to train a neural network classification algorithm to sort the material into waste and product based on an aluminum cut-off grade of 2%. Testing of the algorithm found that ore and waste were classified correctly 82% and 97% of the time respectively. | Li et al. [37] |

| Camera based particle size distribution sensor | Copper ore | Bulk | On-site tests showed that the sensor could extract the sizes of 60% of the visible large (20 mm–250 mm) particles on the surface of conveyed copper ore. The particle size distribution could be found for particle sizes over 20 mm. | Leiva, Acuña and Castillo [38] |

| Gamma Activation Analysis | Gold ore | Bulk | Experimental tests demonstrated that the GAA sensor could accurately measure the gold grade of ore and concentrate samples for gold concentrations from 0.1–4000 ppm | Tickner et al. [39] |

| Microwave Imaging | Gold and silver ore | Particle | The microwave imaging response to sample ore particles built from micro-CT and QEMSCAN data was simulated. It was found that the imaging technique could detect even small inclusions of the highly conductive gold and silver. | Duan, Bobicki and Hum [40] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peukert, D.; Xu, C.; Dowd, P. A Review of Sensor-Based Sorting in Mineral Processing: The Potential Benefits of Sensor Fusion. Minerals 2022, 12, 1364. https://doi.org/10.3390/min12111364

Peukert D, Xu C, Dowd P. A Review of Sensor-Based Sorting in Mineral Processing: The Potential Benefits of Sensor Fusion. Minerals. 2022; 12(11):1364. https://doi.org/10.3390/min12111364

Chicago/Turabian StylePeukert, Dylan, Chaoshui Xu, and Peter Dowd. 2022. "A Review of Sensor-Based Sorting in Mineral Processing: The Potential Benefits of Sensor Fusion" Minerals 12, no. 11: 1364. https://doi.org/10.3390/min12111364

APA StylePeukert, D., Xu, C., & Dowd, P. (2022). A Review of Sensor-Based Sorting in Mineral Processing: The Potential Benefits of Sensor Fusion. Minerals, 12(11), 1364. https://doi.org/10.3390/min12111364