Impact of Lithologic Heterogeneity on Brittleness of Cenozoic Unconventional Reservoirs (Fine-Grained) in Western Qaidam Basin

Abstract

1. Introduction

2. Geological Setting

3. Sampling, Data Preparation and Methodology

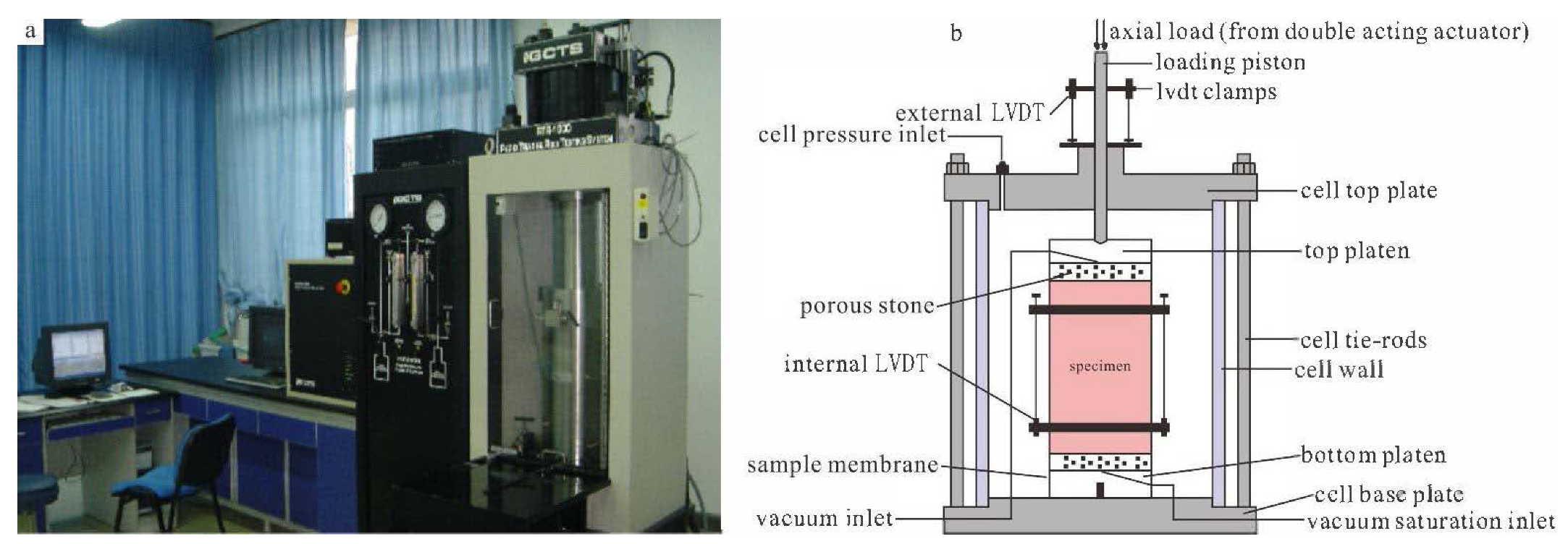

3.1. Triaxial Experiment

3.2. X-ray Diffraction (XRD) Test and Petrographic Analysis

3.3. Microscopic and Ultra-Microscopic Morphological Analysis

4. Results

4.1. Analytical Results

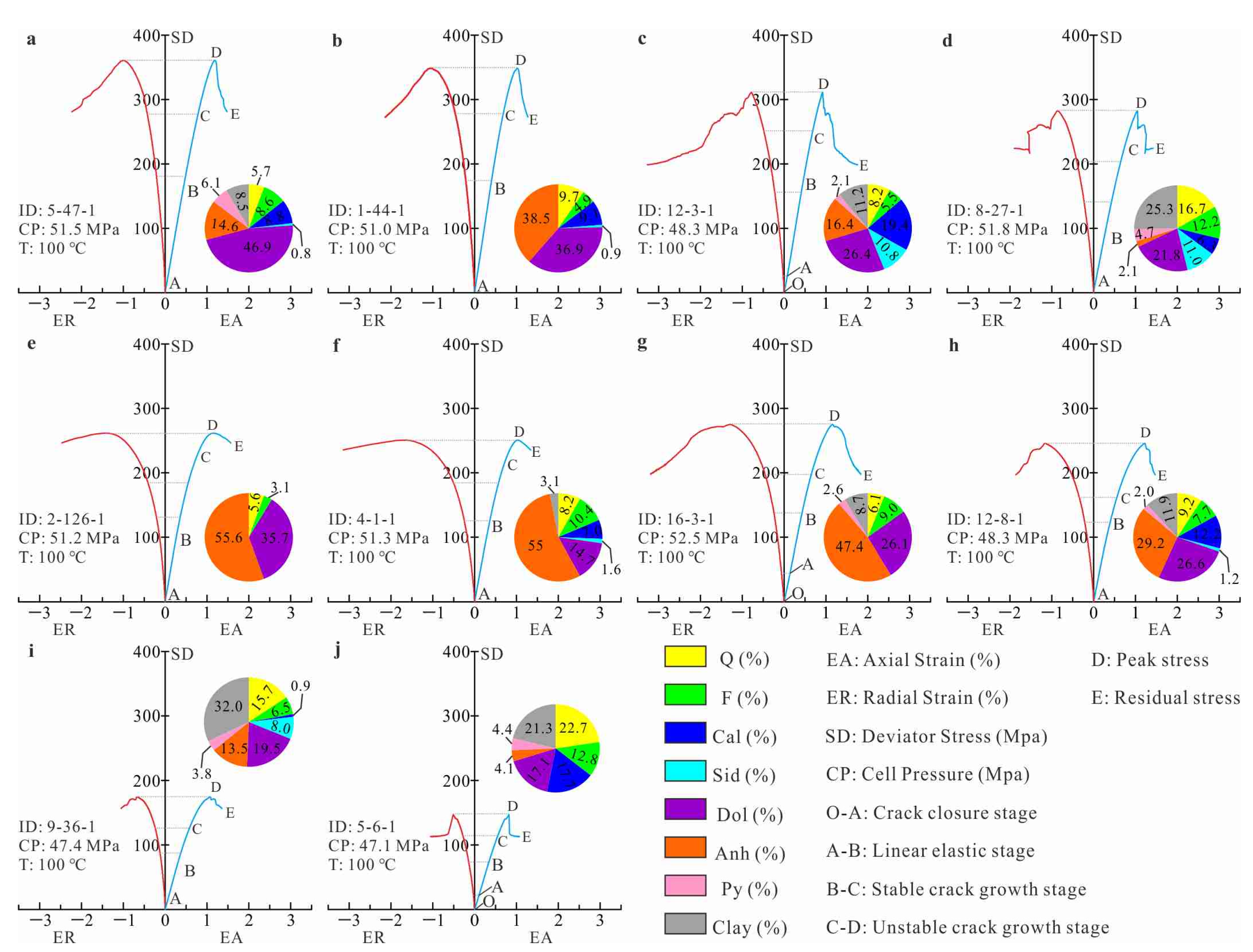

4.2. Stress–Strain Curves

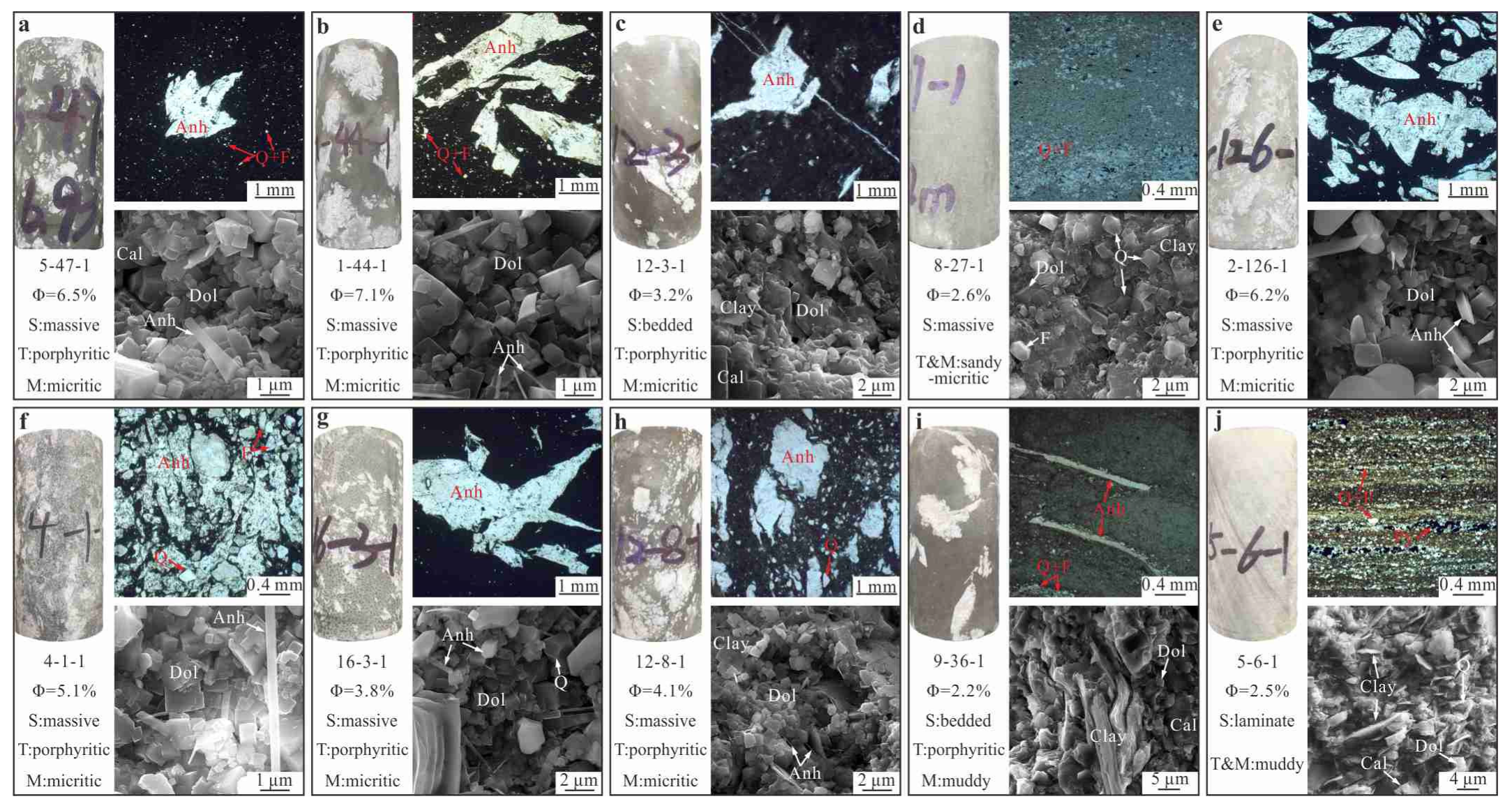

4.3. Petrography Analysis

5. Discussion

5.1. Inapplicability of MBI Equation

| Correlation for MBI | Formation | Lithology | Φ/% | TOC/% | References |

|---|---|---|---|---|---|

| Barnett | Shale bounded by limestone | 6 | 1–3 | Jarvie et al., 2007 [4] | |

| Barnett | Shale bounded by limestone | 6 | 1–3 | Wang and Gale, 2009 [65] | |

| Neuquén Basin, Argentina | Mudstones | 8 | 2.5–3.5 | Glorioso and Rattia, 2012 [61] | |

| Barnett | Shale bounded by limestone | 6 | 1–3 | Jin et al., 2014 [59] |

5.2. Correlation between Mineral and Mechanical Properties

5.3. Mineralogical Impact on Mechanical Property

5.4. Standard of Reservoir Brittleness Classification and Practical Effect

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Curtis, J.B. Fractured shale-gas systems. AAPG Bull. 2002, 86, 1921–1938. [Google Scholar]

- Montgomery, S.L.; Jarvie, D.M.; Bowker, K.A.; Pollastro, R.M. Mississippian Barnett shale, Fort Worth basin, north-central Texas: Gas-shale play with multi-trillion cubic foot potential. AAPG Bull. 2005, 89, 155–175. [Google Scholar] [CrossRef]

- Wilczynski, P.M.; Domonik, A.; Lukaszewski, P. Brittle Creep and Viscoelastic Creep in Lower Palaeozoic Shales from the Baltic Basin, Poland. Energies 2021, 14, 4633. [Google Scholar] [CrossRef]

- Jarvie, D.M.; Hill, R.J.; Ruble, T.E.; Pollastro, R.M. Unconventional shale-gas systems: The Mississippian Barnett Shale of north-central Texas as one model for thermogenic shale-gas assessment. AAPG Bull. 2007, 91, 475–499. [Google Scholar] [CrossRef]

- Grieser, W.V.; Bray, J.M. Identification of production potential in unconventional reservoirs. In Proceedings of the Production and Operations Symposium, Oklahoma City, Oklahoma, USA, 31 March–3 April 2007; Society of Petroleum Engineers: Houston, TX, USA, 2007. [Google Scholar]

- Montgomery, S.L. Permian “Wolfcamp” limestone reservoirs; Powell Ranch Field, eastern Midland Basin. AAPG Bull. 1996, 80, 1349–1365. [Google Scholar]

- Sonnenberg, A.S.; Pramudito, A. Petroleum geology of the giant Elm Coulee field, Williston Basin. AAPG Bull. 2009, 9, 1127–1153. [Google Scholar] [CrossRef]

- Kuhn, P.P.; Primio, R.D.; Hill, R.; Lawrence, J.R.; Horsfield, B. Three-dimensional modeling study of the low-permeability petroleum system of the Bakken Formation. AAPG Bull. 2012, 10, 1867–1897. [Google Scholar] [CrossRef]

- Hentz, T.F.; Ambrose, W.A.; Smith, D.C. Eaglebine play of the southwestern East Texas basin: Stratigraphic and depositional framework of the Upper Cretaceous (Cenomanian-Turonian) Woodbine and Eagle Ford Groups. AAPG Bull. 2013, 12, 2551–2580. [Google Scholar] [CrossRef]

- Fairbanks, M.D.; Ruppel, S.C.; Rowe, H. High-resolution stratigraphy and facies architecture of the Upper Cretaceous (Cenomanian-Turonian) Eagle Ford Group, Central Texas. AAPG Bull. 2016, 3, 379–403. [Google Scholar] [CrossRef]

- Aderibigbe, A.; Valdes, C.C.; Heidari, Z. Integrated rock classification in the Wolfcamp Shale based on reservoir quality and anisotropic stress profile estimated from well logs. Interpretation 2016, 4, SF1–SF18. [Google Scholar] [CrossRef]

- Yergin, D. The Quest: Energy, Security, and the Remaining of the Modern World; Penguin Press: London, UK, 2011; pp. 1–300. [Google Scholar]

- EIA. Technically Recoverable Shale Oil and Shale Gas Resources: An Assessment of 137 Shale Formations in 41 Countries Outside the United States; U.S. Energy Information Administration: Washington, DC, USA, 2013; pp. 1–150. [Google Scholar]

- Li, G.X.; Luo, K.; Shi, D.L. Key technologies, engineering management and important suggestions of shale oil/gas development: Case study of a Duvernay shale project in Western Canada Sedimentary Basin. Pet. Explor. Dev. 2020, 47, 791–802. [Google Scholar] [CrossRef]

- Zhang, S.; Cao, Y.C.; Zhu, R.K.; Xi, K.L.; Wang, J.; Zhu, N.; Hu, R.N. Lithofacies classification of fine grained mixed sedimentary rocks in the Permian Lucaogou Formation, Jimsar sag, Junggar Basin. Earth Sci. Front. 2018, 25, 198. [Google Scholar]

- Deng, Y.; Pu, X.G.; Chen, S.Y.; Yan, J.H.; Shi, Z.N.; Zhang, W.; Han, W.Z. Characteristics and controlling factors of fine-grained mixed sedimentary rocks reservoir: A case study of the 2nd member of Kongdian formation in Cangdong depression, Bohai Bay basin. J. China Univ. Min. Technol. 2019, 48, 1301–1316. [Google Scholar]

- Li, M.W.; Ma, X.X.; Jiang, Q.G.; Li, Z.M.; Pang, X.Q.; Zhang, C.T. Enlightenment from formation conditions and enrichment characteristics of marine shale oil in North America. Pet. Geol. Recovery Effic. 2019, 26, 13–28. [Google Scholar]

- Zhou, L.; Chen, C.; Han, G.; Yang, F.; Ma, J.; Zhou, K.; Zhang, W.; Huang, C. Geological Characteristics and Shale Oil Exploration Potential of Lower First Member of Shahejie Formation in Qikou Sag, Bohai Bay Basin. Earth Sci. (In Chinese with English Abstract). 2019, 44, 2736–2750. [Google Scholar]

- Li, X.; Li, F.; Wang, J.; Wang, B.; Wang, Z.; Sun, X.; Yi, C. Formation and preservation of Eocene lacustrine microbialites in the western Qaidam Basin (northeastern Qinghai-Tibetan Plateau, China): Petrological, mineralogical, and geochemical constraints. Sediment. Geol. 2022, 440, 106257. [Google Scholar] [CrossRef]

- Zou, C.N.; Zhang, G.S.; Yang, Z.; Tao, S.Z.; Hou, L.H.; Zhu, R.K.; Wang, Z.P. Geological concepts, characteristics, resource potential and key techniques of unconventional hydrocarbon: On unconventional petroleum geology. Pet. Explor. Dev. 2013, 40, 385–399. [Google Scholar] [CrossRef]

- Tyson, R.V.; Pearson, T.H. Modern and ancient continental shelf anoxia: An overview. Geol. Soc. Lond. Spec. Publ. 1991, 58, 1–24. [Google Scholar] [CrossRef]

- Zhou, S.; Xia, C.; Zhou, Y. A theoretical approach to quantify the effect of random cracks on rock deformation in uniaxial compression. J. Geophys. Eng. 2018, 15, 627–637. [Google Scholar] [CrossRef]

- Bodziak, R.; Clemons, K.; Stephens, A.; Meek, R. The role of seismic attributes in understanding the hydraulically fracturable limits and reservoir performance in shale reservoirs: An example from the Eagle Ford Shale, south Texas. AAPG Bull. 2014, 98, 2217–2235. [Google Scholar] [CrossRef]

- Dong, T.; Harris, N.B.; Ayranci, K.; Yang, S. The impact of rock composition on geomechanical properties of a shale formation: Middle and Upper Devonian Horn River Group shale, Northeast British Columbia, Canada. AAPG Bull. 2017, 101, 177–204. [Google Scholar] [CrossRef]

- Bustin, A.M.M.; Bustin, R.M. Importance of rock properties on the producibility of gas shales. Int. J. Coal Geol. 2012, 103, 132–147. [Google Scholar] [CrossRef]

- Sone, H.; Zoback, M.D. Mechanical properties of shale-gas reservoir rocks-Part 1: Static and dynamic elastic properties and anisotropy. Geophysics 2013, 78, D381–D392. [Google Scholar] [CrossRef]

- Donath, F.A. Some information squeezed out of rock. Am. Sci. 1970, 58, 54–72. [Google Scholar]

- Ferrill, D.A.; Morris, A.P. Fault zone deformation controlled by carbonate mechanical stratigraphy, Balcones fault system, Texas. AAPG Bull. 2008, 92, 359–380. [Google Scholar] [CrossRef]

- Rickman, R.; Mullen, M.; Petre, E.; Grieser, B.; Kundert, D. A practical use of shale petrophysics for stimulation optimization: All shale plays are not clones of the Barnett Shale. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, Colorado, USA, 21–24 September 2008; SPE-115258-MS. [Google Scholar]

- Enderlin, E.M.; Bartholomaus, T.C. Sharp contrasts in observed and modeled crevasse patterns at Greenland’s marine terminating glaciers. Cryosphere 2020, 14, 4121–4133. [Google Scholar] [CrossRef]

- Geng, Z.; Chen, M.; Jin, Y.; Yang, S.; Yi, Z.C.; Fang, X.; Du, X.Y. Experimental study of brittleness anisotropy of shale in triaxial compression. J. Nat. Gas Sci. Eng. 2016, 36, 510–518. [Google Scholar] [CrossRef]

- Li, Z.; Li, L.; Li, M.; Zhang, L.; Zhang, Z.; Huang, B.; Tang, C. A numerical investigation on the effects of rock brittleness on the hydraulic fractures in the shale reservoir. J. Nat. Gas Sci. Eng. 2018, 50, 22–32. [Google Scholar]

- Bishop, A.W. Progressive failure with special reference to the mechanism causing it. In Proceedings of the Geotechnical Conference, Oslo, Norway; 1967; Volume 2, pp. 142–150. [Google Scholar]

- Buller, D.; Hughes, S.N.; Market, J.; Petre, J.E.; Spain, D.R.; Odumosu, T. Petrophysical evaluation for enhancing hydraulic stimulation in horizontal shale gas wells. In Proceedings of the SPE Annual Technical Conference and Exhibition Society of Petroleum Engineers, Florence, Italy, 19–22 September 2010. [Google Scholar]

- Hucka, V.; Das, B. Brittleness determination of rocks by different methods. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1974, 11, 389–392. [Google Scholar] [CrossRef]

- Labani, M.M.; Rezaee, R. The importance of geochemical parameters and shale composition on rock mechanical properties of gas shale reservoirs: A case study from the Kockatea shale and Carynginia formation from the Perth basin, Western Australia. Rock Mech. Rock Eng. 2015, 48, 1249–1257. [Google Scholar] [CrossRef]

- Heidari, M.; Khanlari, G.R.; Torabi, K.M. Effect of Porosity on Rock Brittleness. Rock Mech. Rock Eng. 2014, 47, 785–790. [Google Scholar]

- Paul, S.; Sun, C.C. Lubrication with magnesium stearate increases tablet brittleness. Powder Technol. 2017, 309, 126–132. [Google Scholar] [CrossRef]

- Tan, W.H.; Ba, J.; Guo, M.Q.; Li, H.; Zhang, L.; Yu, T.; Chen, H. Brittleness characteristics of tight oil siltstones. Appl. Geophys. 2018, 15, 175–187. [Google Scholar] [CrossRef]

- Goodway, B.; Varsek, J.; Abaco, C. Practical applications of P-wave AVO for unconventional gas Resource Plays. CSEG Rec. 2006, 31, 52–65. [Google Scholar]

- Mullen, M.J.; Roundtree, R.; Turk, G.A. A composite determination of mechanical rock properties for stimulation design (what to do when you don’t have a sonic log). In Proceedings of the SPE Rocky Mountain Oil & Gas Technology Symposium, Denver, CO, USA, 16–18 April 2007; SPE-108139-MS. [Google Scholar]

- Tarasov, B.; Potvin, Y. Universal criteria for rock brittleness estimation under triaxial compression. Int. J. Rock Mech. Min. Sci. 2013, 59, 57–69. [Google Scholar] [CrossRef]

- Ge, X.R. Post failure behavior and a brittleplastic model of brittle rock. In Computer Methods and Advances in Geomechanics; AA Balkema Publishers: London, UK, 1997; pp. 151–160. [Google Scholar]

- Shi, G.C.; Ge, X.R.; Lu, Y.D. Experimental study on coeffi cients of brittle stress drop of marble. Chin. J. Rock Mech. Eng. 2006, 25, 1625–1631. [Google Scholar]

- Lu, H.; Xiong, S. Magnetostratigraphy of the Dahonggou section, northern Qaidam Basin and its bearing on Cenozoic tectonic evolution of the Qilian Shan and Altyn Tagh Fault. Earth Planet. Sci. Lett. 2009, 288, 539–550. [Google Scholar]

- Fu, S.; Ma, D.; Chen, Y.; Zhang, G.; Wu, K. New advance of petroleum and gas exploration in Qaidam Basin. Acta Pet. Sin. 2016, 37, 1–10. [Google Scholar]

- Wang, J.G.; Zhang, D.W.; Yang, S.Y.; Li, X.; Shi, Y.J.; Cui, J.; Zhang, P.; Wang, Y.L.; Yi, D.H.; Chang, H.Y. Sedimentary characteristics and genesis of the salt lake with the upper member of the Lower Ganchaigou Formation from Yingxi sag, Qaidam basin. Mar. Pet. Geol. 2020, 111, 135–155. [Google Scholar] [CrossRef]

- Li, F.; Yan, J.; Algeo, T.; Wu, X. Paleoceanographic conditions following the end-Permian mass extinction recorded by giant ooids (Moyang, South China). Glob. Planet. Chang. 2013, 105, 102–120. [Google Scholar] [CrossRef]

- Li, F.; Yan, J.X.; Burne, R.V.; Chen, Z.Q.; Algeo, T.J.; Zhang, W.; Tian, L.; Gan, Y.L.; Liu, K.; Xie, S.C. Paleo-seawater REE compositions and microbial signatures preserved in laminae of Lower Triassic ooids. Palaeogeogr. Palaeoclimatol. Palaeoecol. 2017, 486, 96–107. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Test Methods of Engineering Rock Mass (GB/T 50266-2013); China Planning Press: Beijing, China, 2013; p. 91. [Google Scholar]

- Meng, Z.; Zhang, J.; Peng, S. Influence of sedimentary environments on mechanical properties of clastic rocks. Environ. Geol. 2006, 51, 113–120. [Google Scholar]

- Zhao, Y.; Zhou, H.; Zhong, J.; Liu, D. Study on the relation between damage and permeability of sandstone at depth under cyclic loading. Int. J. Coal Sci. Technol. 2019, 6, 479–492. [Google Scholar]

- Shao, J.F.; Jia, Y.; Kondo, D. An Elastoplastic Damage Model for Unsaturated Argillites. In Elsevier Geo-Engineering Book Series; Elsevier: Amsterdam, The Netherlands, 2004; pp. 495–500. [Google Scholar]

- Zhou, L.H.; Pu, X.G.; Chen, C.W.; Yang, F.; Xia, J.; Guan, Q.S.; Huang, C.Y. Concept, Characteristics and Prospecting Significance of FineGrained Sedimentary Oil Gas in Terrestrial Lake Basin: A Case from the Second Member of Paleogene Kongdian Formation of Cangdong Sag, Bohai Bay Basin. Earth Sci. 2018, 43, 3625–3639, (In Chinese with English Abstract). [Google Scholar]

- Xiong, L.; Wu, S.; Zhang, S. Mechanical Behavior of a Granite from Wuyi Mountain: Insights from Strain-Based Approaches. Rock Mech. Rock Eng. 2019, 52, 719–736. [Google Scholar] [CrossRef]

- Vincent, J.F.V. Structural Biomaterials; The Macmillan Press: London, UK, 1982; p. 207. [Google Scholar]

- Wong, T.Y.; Bradt, R.C. Microhardness anisotropy of single crystals of calcite, dolomite and magnesite on their cleavage planes. Mater. Chem. Phys. 1992, 30, 261–266. [Google Scholar]

- Palchik, V.; Hatzor, Y.H. The influence of porosity on tensile and compressive strength of porous chalks. Rock Mech. Rock Eng. 2004, 37, 331–341. [Google Scholar]

- Jin, X.; Shah, S.N.; Roegiers, J.C.; Zhang, B. An integrated petrophysics and geomechanics approach for fracability evaluation in shale reservoirs. Soc. Pet. Eng. J. 2015, 20, 518–526. [Google Scholar]

- Mathews, H.L.; Schein, G.; Malone, M. Stimulation of gas shales: They’re all the same-right? In Proceedings of the SPE Hydraulic Fracturing Technology Conference, College Station, Texas, USA, 29–31 January 2007; pp. 29–31. [Google Scholar]

- Glorioso, J.C.; Rattia, A. Unconventional reservoirs: Basic petrophysical concepts for shale gas. In SPE/EAGE European Unconventional Resources Conference & Exhibition-from Potential to Production, Vienna, Austria, 20–22 March 2012; European Association of Geoscientists & Engineers: Houten, The Netherlands, 2012. [Google Scholar]

- Zouaoui, H.; Lecomte-Nana, G.L.; Krichen, M.; Bouaziz, J. Structure, microstructure and mechanical features of ceramic products of clay and non-plastic clay mixtures from Tunisia. Appl. Clay Sci. 2017, 135, 112–118. [Google Scholar]

- Xu, L.; Gao, H.; Xu, J.; Xu, M.; Wang, X.; You, F.; Long, Y. Experimental insights into a novel over-saturated brine cement slurry used in anhydrite formation. Bulg. Chem. Commun. 2017, 49, 214–219. [Google Scholar]

- Hudson, J.A.; Harrison, J.P. Engineering Rock Mechanics, Part 1: An Introduction to the Principles; Elservier Ltd.: Oxford, UK, 1997; p. 429. [Google Scholar]

- Wang, F.P.; Gale, J.F.W. Screening Criteria for Shale-Gas Systems. 2009. Available online: https://archives.datapages.com/data/gcags_pdf/2009/wanggale.htm (accessed on 18 October 2022).

- Broz, M.E.; Cook, R.F.; Whitney, D.L. Microhardness, toughness, and modulus of Mohs scale minerals. Am. Mineral. 2006, 91, 135–142. [Google Scholar] [CrossRef]

- Brace, W.F. Behavior of rock salt, limestone, and anhydrite during indentation. J. Geophys. Res. 1960, 65, 1773–1788. [Google Scholar] [CrossRef]

- Räisänen, M. Relationships between texture and mechanical properties of hybrid rocks from the Jaala–Iitti complex, southeastern Finland. Eng. Geol. 2004, 74, 197–211. [Google Scholar] [CrossRef]

| Stratigraphic System | Symbol | Lithology | |||

|---|---|---|---|---|---|

| System | Series | Formation | Member | ||

| Neogene | Miocene | Shangyoushashan | N1sy | Predominated by brown-yellow sandy mudstone, with some argillaceous siltstone and conglomerate interbeds. | |

| Xiayoushashan | N1xy | Red-brown mudstone and sandy mudstone, with some brown-red siltstone and calcareous mudstone interbeds. | |||

| Shangganchaigou | E3-N1sg | Gray mudstone and siltstone develop in the lower part, while the upper part is predominated by brown-yellow mudstone and fine sandstone. | |||

| Paleogene | Oligocene | ||||

| Xiaganchaigou | Upper | E2-3xg2 | Predominated by dark-grey argillaceous-lime dolostone, lime dolostone, dolomitic limestone and calcareous mudstone, some anhydrite-rich beds and halite beds develop in the upper part. | ||

| Eocene | |||||

| Paleocene | Lower | E2-3xg1 | Brown-red mudstone with some grey-white fine sandstone and calcareous mudstone interbeds. | ||

| Lulehe | E1-2l | The brown-red conglomerate, conglomeratic sandstone, sandstone with some mudstone and sandy mudstone interbeds. | |||

| Sample ID | Depth/m | Length/mm | Diameter/mm | Sectional Area/cm2 | Volume/cm3 | Cell Pressure/MPa |

|---|---|---|---|---|---|---|

| 1-44-1 | 4078.37 | 51.28 | 24.79 | 4.83 | 24.75 | 51.03 |

| 5-47-1 | 4122.64 | 48.53 | 24.81 | 4.83 | 23.46 | 51.54 |

| 12-3-1 | 3860.48 | 48.52 | 24.87 | 4.86 | 23.57 | 48.35 |

| 8-27-1 | 4146.50 | 48.03 | 24.75 | 4.81 | 23.11 | 51.83 |

| 2-126-1 | 4096.66 | 48.37 | 24.72 | 4.80 | 23.21 | 51.24 |

| 4-1-1 | 4106.75 | 50.39 | 24.72 | 4.80 | 24.18 | 51.36 |

| 12-8-1 | 3861.30 | 46.71 | 24.77 | 4.82 | 22.51 | 48.34 |

| 16-3-1 | 4202.26 | 48.05 | 24.88 | 4.86 | 23.36 | 52.54 |

| 9-36-1 | 3794.30 | 47.17 | 24.76 | 4.81 | 22.71 | 47.47 |

| 5-6-1 | 3766.90 | 46.88 | 24.79 | 4.83 | 22.63 | 47.16 |

| Sample | Lithology | Depth | Q | F | Cal | Sid | Dol | Anh | Py | Clay | Young’s Modulus | Elastic Limit | Peak Stress | Poisson’s Ratio |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| m | % | MPa | ||||||||||||

| 1-44-1 | Anhydrite dolomite | 4078.37 | 9.70 | 4.90 | 9.10 | 0.90 | 36.90 | 38.50 | nd. | nd. | 43,278.20 | 174.26 | 348.51 | 0.34 |

| 5-47-1 | Anhydrite dolomite | 4122.64 | 5.70 | 8.60 | 8.80 | 0.80 | 46.80 | 14.60 | 6.10 | 8.50 | 37,515.00 | 180.69 | 361.39 | 0.27 |

| 12-3-1 | Dolomite | 3860.48 | 8.20 | 5.50 | 19.40 | 10.80 | 26.40 | 16.40 | 2.10 | 11.20 | 37,965.80 | 156.00 | 311.99 | 0.36 |

| 8-27-1 | Argillaceous dolomite | 4146.50 | 16.70 | 12.20 | 6.30 | 11.00 | 21.80 | 2.10 | 4.70 | 25.30 | 33,328.90 | 141.06 | 282.64 | 0.35 |

| 2-126-1 | Anhydrite dolomite | 4096.66 | 5.60 | 3.10 | nd. | nd. | 35.70 | 55.50 | nd. | nd. | 37,191.00 | 131.02 | 262.04 | 0.38 |

| 4-1-1 | Anhydrite dolomite | 4106.75 | 8.20 | 10.40 | 7.00 | 1.60 | 14.70 | 55.00 | nd. | 3.10 | 35,145.70 | 125.66 | 251.32 | 0.22 |

| 12-8-1 | Anhydrite argillaceous dolomite | 3861.30 | 9.20 | 7.70 | 12.20 | 1.20 | 26.60 | 29.20 | 2.00 | 11.90 | 32,191.70 | 123.15 | 246.30 | 0.37 |

| 16-3-1 | Anhydrite dolomite | 4202.26 | 6.10 | 9.00 | nd. | nd. | 26.10 | 47.30 | 2.60 | 8.70 | 32,399.10 | 137.80 | 275.59 | 0.38 |

| 9-36-1 | Argillaceous dolomite | 3794.30 | 15.70 | 6.50 | 0.90 | 8.00 | 19.50 | 13.50 | 3.80 | 32.00 | 23,921.70 | 87.45 | 174.90 | 0.22 |

| 5-6-1 | Argillaceous dolomite | 3766.90 | 22.70 | 12.80 | 17.70 | nd. | 17.10 | 4.10 | 4.40 | 21.30 | 21,812.50 | 73.65 | 147.31 | 0.27 |

| Mineral | Chemical Formula | Crystal System | Cleavage | Mohs Hardness | Microhardness /GPa | References |

|---|---|---|---|---|---|---|

| talc | Mg3Si4O10(OH)2 | monoclinic | perfect {001} | 1 | 0.14 ± 0.03 | Broz et al., 2006 [66] |

| gypsum | CaSO4·2H2O | monoclinic | perfect {010}, good {100} | 2 | 0.61 ± 0.15 | |

| anhydrite | CaSO4 | orthorhombic | perfect {010}, good {001} | 2–3 | 1.32 ± 0.13 | Brace, 1960 [67] |

| calcite | CaCO3 | trigonal | perfect {1010} | 3 | 1.49 ± 0.11 | Broz et al., 2006 [66] |

| dolomite | CaMg(CO3)2 | trigonal | perfect {1011}, perfect {1011} | 3.5–4 | 3.35 ± 0.33 | Wong and Bradt, 1992 [57] |

| orthoclase | KAlSi3O8 | monoclinic | perfect {001}, good {010} | 6 | 6.87 ± 0.66 | Broz et al., 2006 [66] |

| quartz | SiO2 | trigonal | none | 7 | 12.2 ± 0.61 |

| Grade | Mineral Composition (%) | Petrography | Mechanics (MPa) | Porosity (%) | |||

|---|---|---|---|---|---|---|---|

| Dolomite | Clay | Structure | Skeleton Texture | Young’s Modulus | Peak Stress | ||

| good | >30 | <10 | massive | micritic | >37,000 | >260 | ≥6.0 |

| medium | 20–30 | <20 | massive/bedded | micritic | >32,000 | >240 | ≥3.5 |

| poor | <20 | <40 | massive/bedded/laminated | argillaceous | >20,000 | >140 | ≥1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Wu, K.; Wang, J.; Yang, S.; Zhang, Q.; Zhang, Q. Impact of Lithologic Heterogeneity on Brittleness of Cenozoic Unconventional Reservoirs (Fine-Grained) in Western Qaidam Basin. Minerals 2022, 12, 1443. https://doi.org/10.3390/min12111443

Li X, Wu K, Wang J, Yang S, Zhang Q, Zhang Q. Impact of Lithologic Heterogeneity on Brittleness of Cenozoic Unconventional Reservoirs (Fine-Grained) in Western Qaidam Basin. Minerals. 2022; 12(11):1443. https://doi.org/10.3390/min12111443

Chicago/Turabian StyleLi, Xiang, Kunyu Wu, Jiangong Wang, Shaoyong Yang, Qinghui Zhang, and Qiang Zhang. 2022. "Impact of Lithologic Heterogeneity on Brittleness of Cenozoic Unconventional Reservoirs (Fine-Grained) in Western Qaidam Basin" Minerals 12, no. 11: 1443. https://doi.org/10.3390/min12111443

APA StyleLi, X., Wu, K., Wang, J., Yang, S., Zhang, Q., & Zhang, Q. (2022). Impact of Lithologic Heterogeneity on Brittleness of Cenozoic Unconventional Reservoirs (Fine-Grained) in Western Qaidam Basin. Minerals, 12(11), 1443. https://doi.org/10.3390/min12111443