Energy Evolution Law during Failure Process of Coal–Rock Combination and Roadway Surrounding Rock

Abstract

:1. Introduction

2. Numerical Model Establishment

2.1. Simulation of Coal–Rock Combination

- (1)

- Figure 1 shows the standard specimens, including coal and rocks, were calibrated. The model size was 50 × 100 mm, and the radius expansion method was used to generate the specimens. Generally, the parallel bond model is used to represent dense materials, such as coal and rock [10]. The model included two kinds of contact interfaces: one was an infinitesimal linear elastic interface, and the other was a linear elastic bond interface with a specific size (parallel bond). The mesoscopic parameter setting of the model primarily comprised the particle elastic model and bond strength between particles. Figure 2 shows the stress–strain curve and failure pattern of the calibrated model. After the model was generated, the load was applied to the specimens by moving the upper and lower walls at a loading speed of 0.01 mm/s. The mesoscopic parameters and basic mechanical parameters of coal and rock are listed in Table 1, and the radius, parallel bonding radius, and friction for all lithology are 0.2–0.3 mm, 1, and 0.15, respectively.

- (2)

- Based on the calibrated coal and rocks, five kinds of coal–rock combination with different rock strengths were established. The model size was 50 × 100 mm, and the coal–rock height ratio was 1:1. The model establishment and parameter selection method are the same as those used in step 1. The coal–rock interface adopts a linear contact model [9]. Changes in stress, strain, and energy were monitored and recorded using the fish function during the loading process.

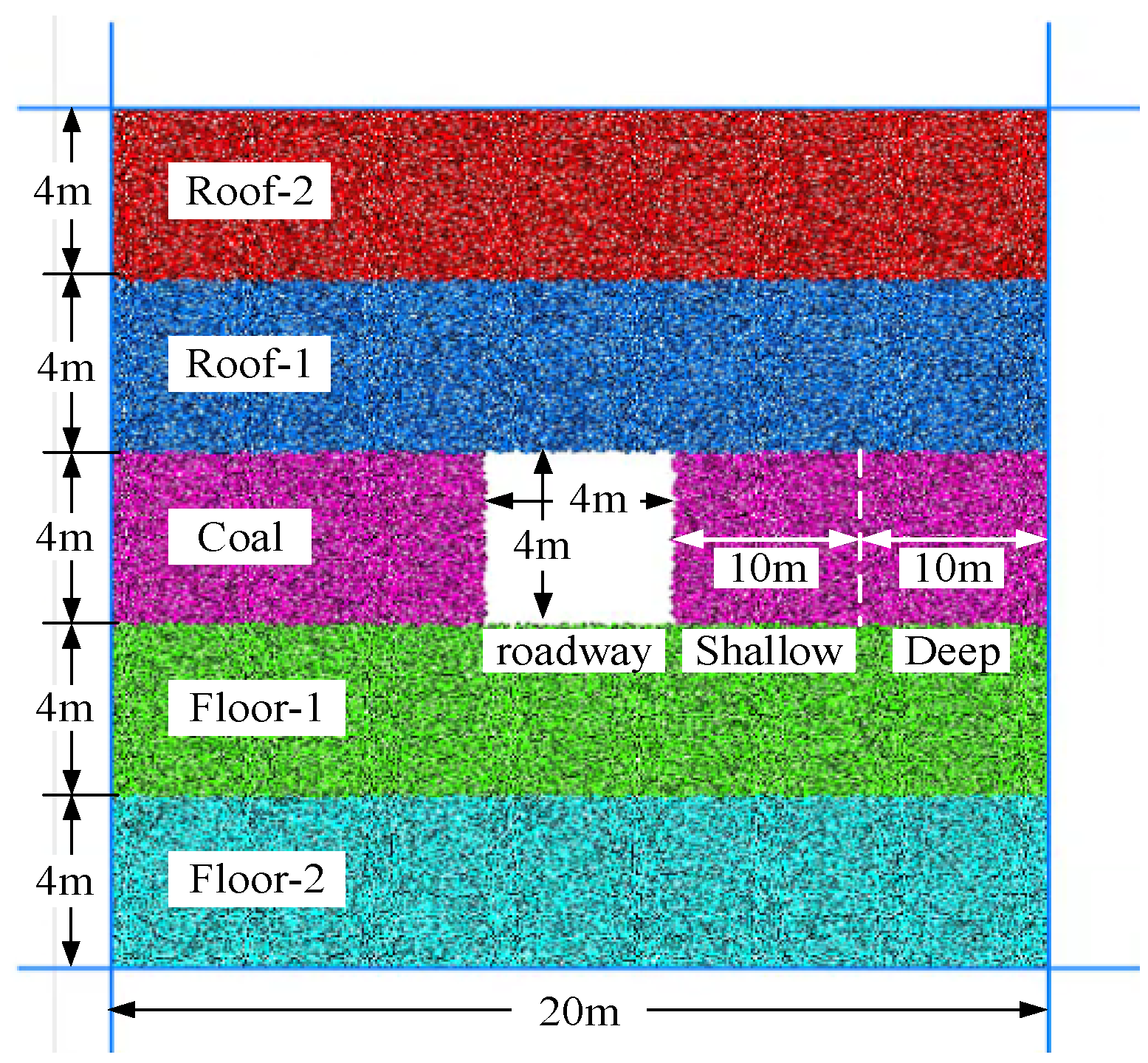

2.2. Simulation of Roadway Surrounding Rock

3. Failure Characteristics and Energy Evolution of Coal–Rock Structure

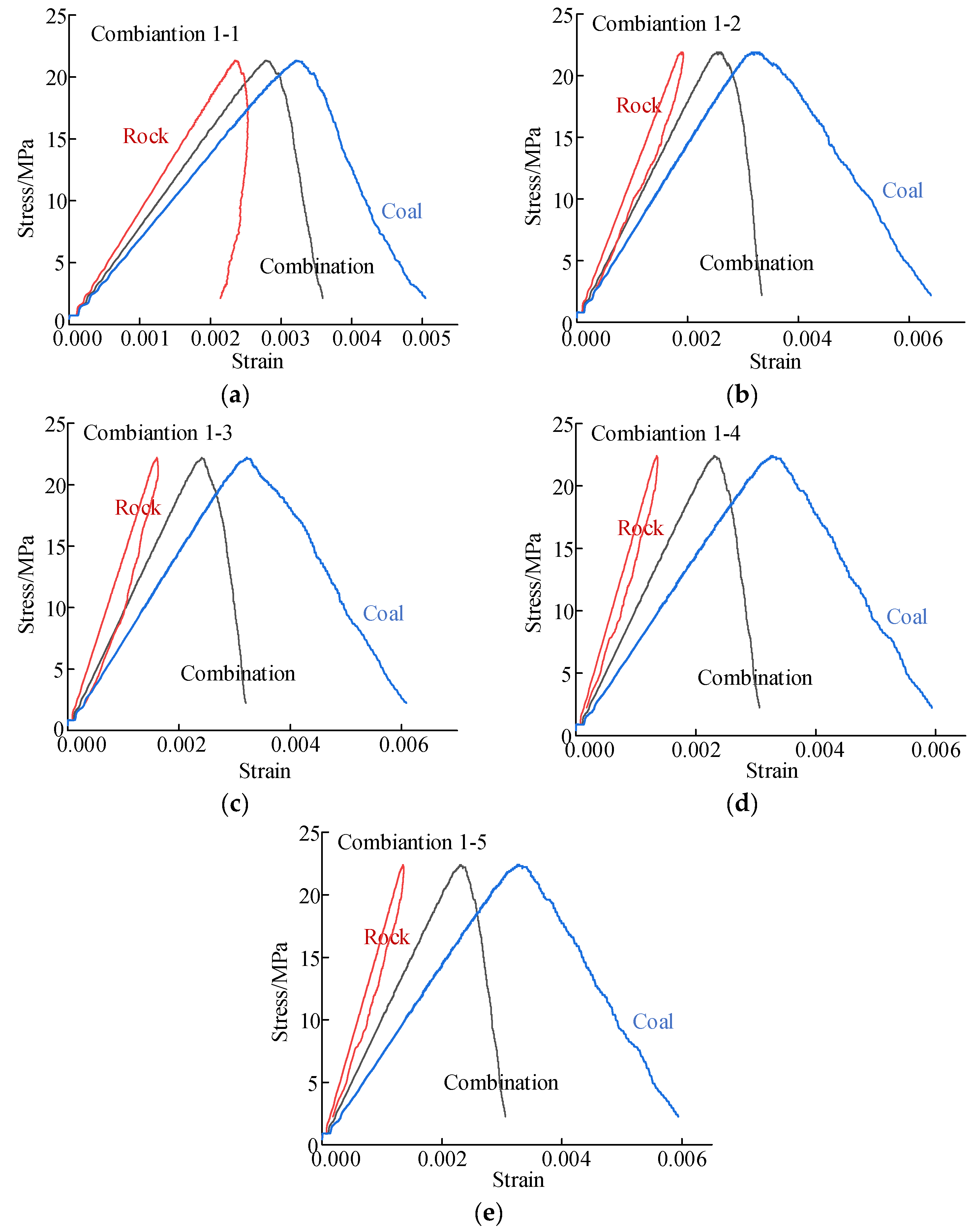

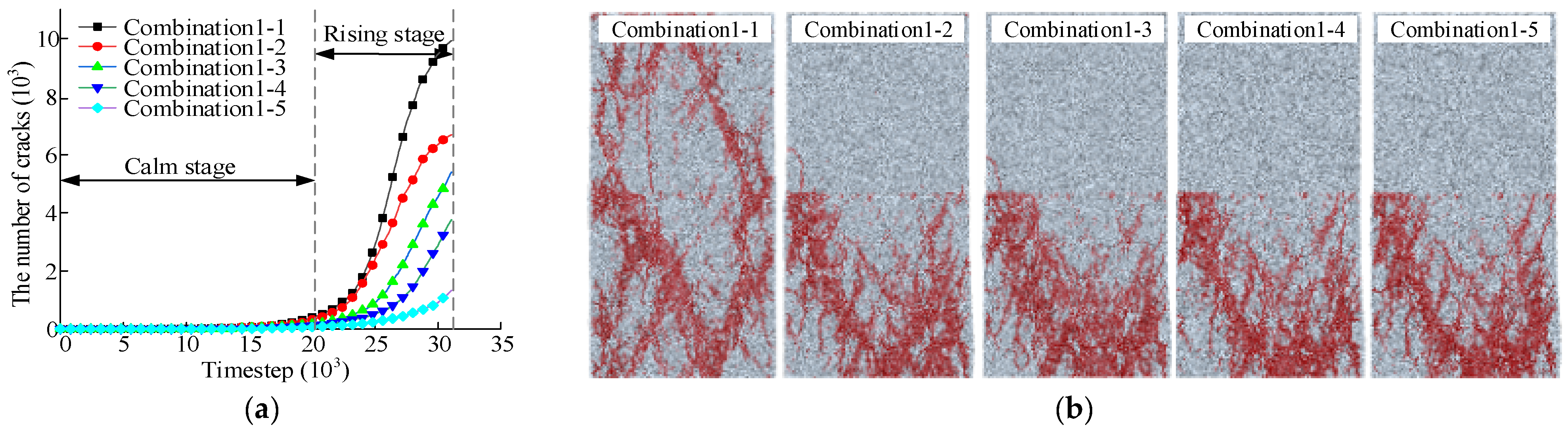

3.1. Stress–Strain Curve and Failure Characteristics of Coal–Rock Structure

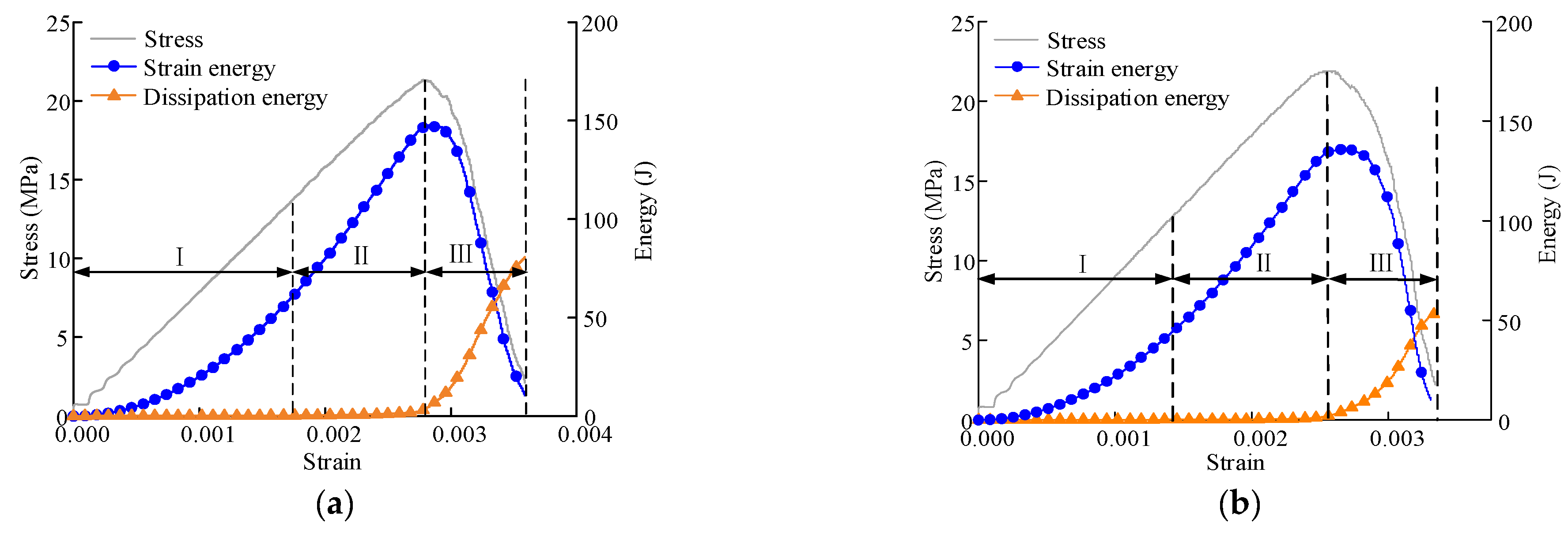

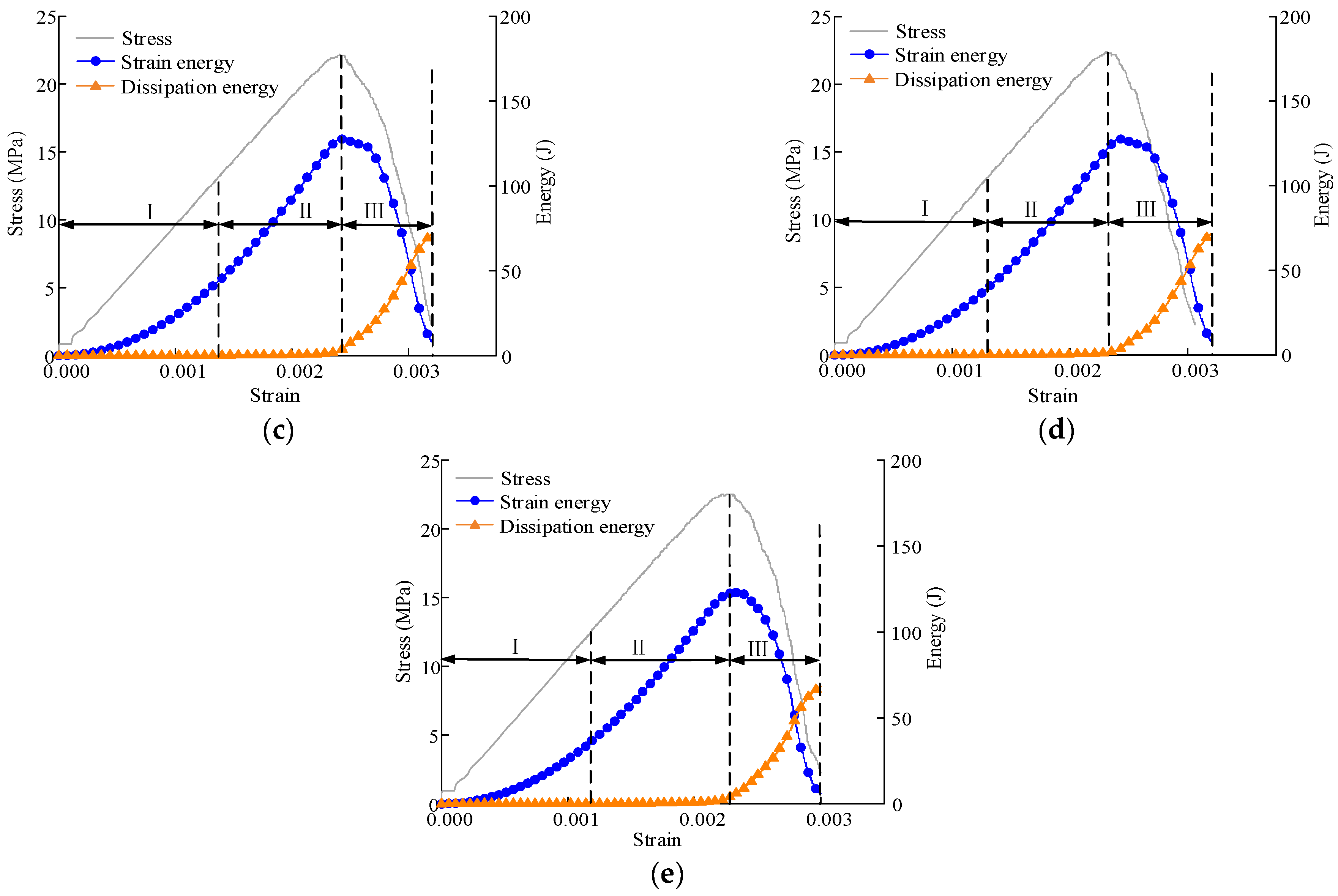

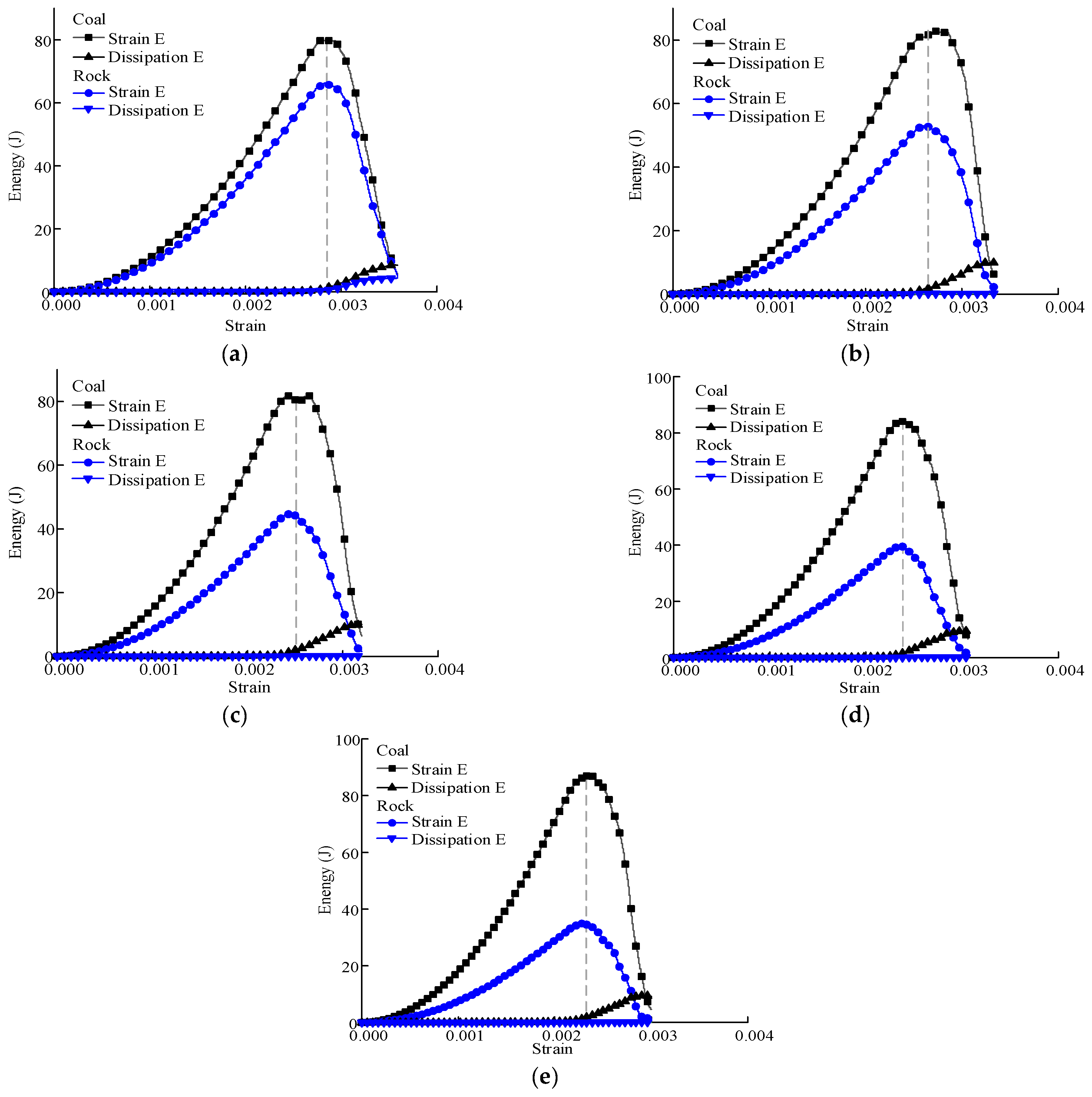

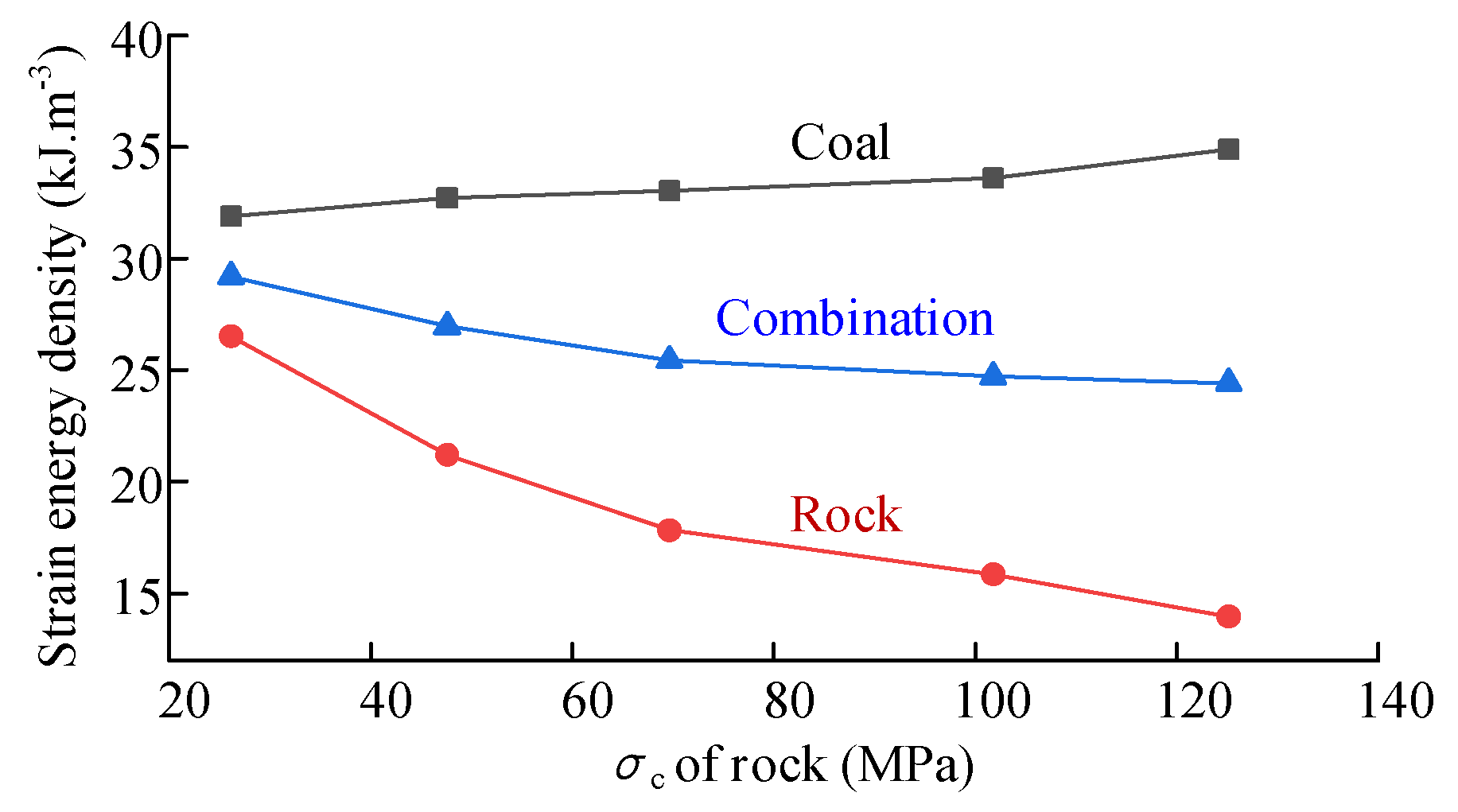

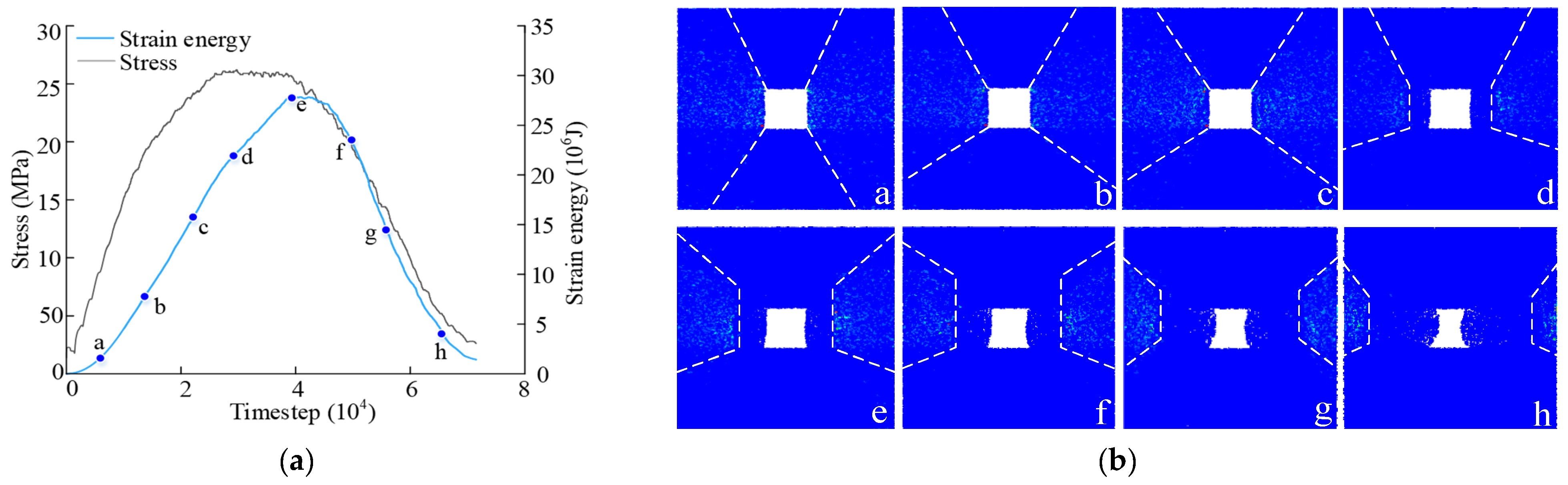

3.2. Energy Evolution of Coal–Rock Structure

4. Failure Pattern and Partition Energy Evolution of Roadway Surrounding Rock

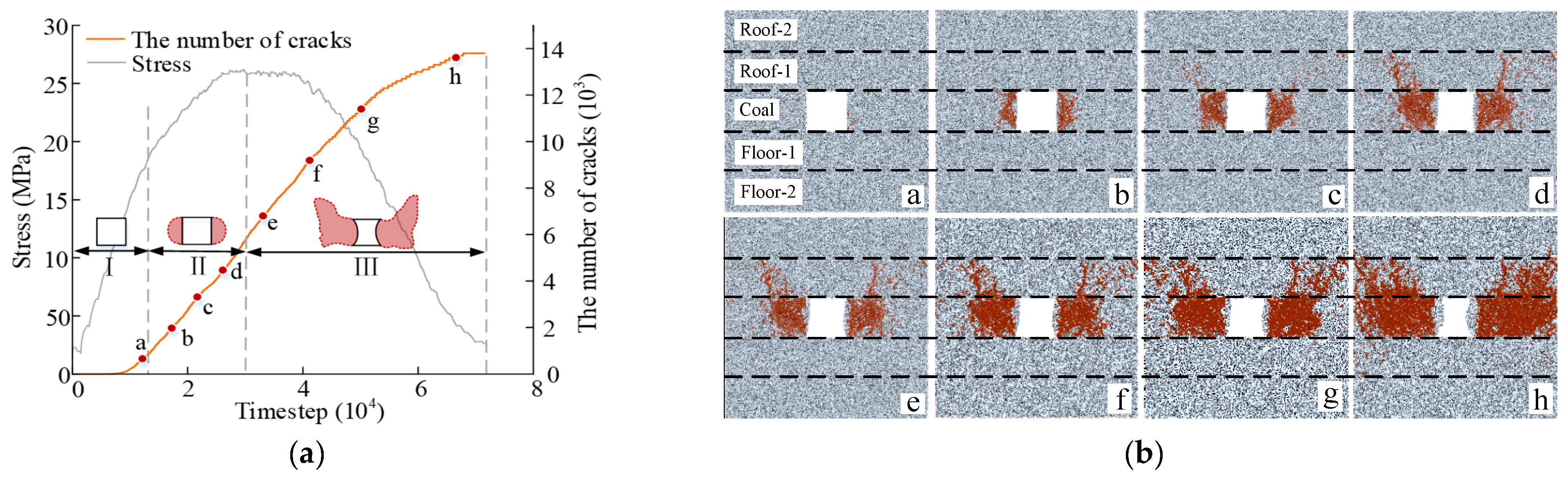

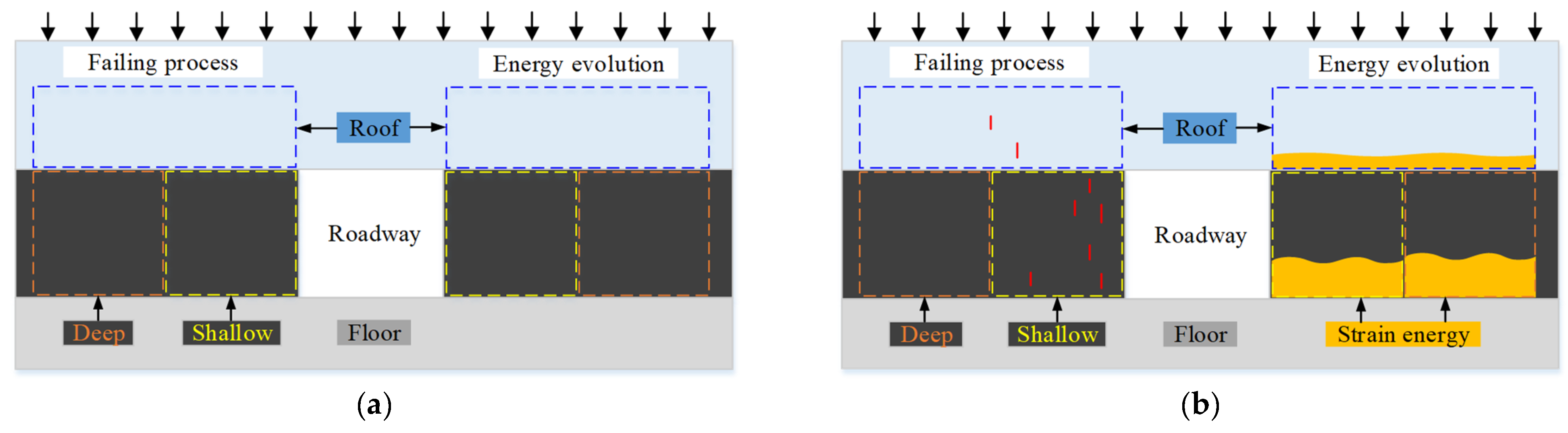

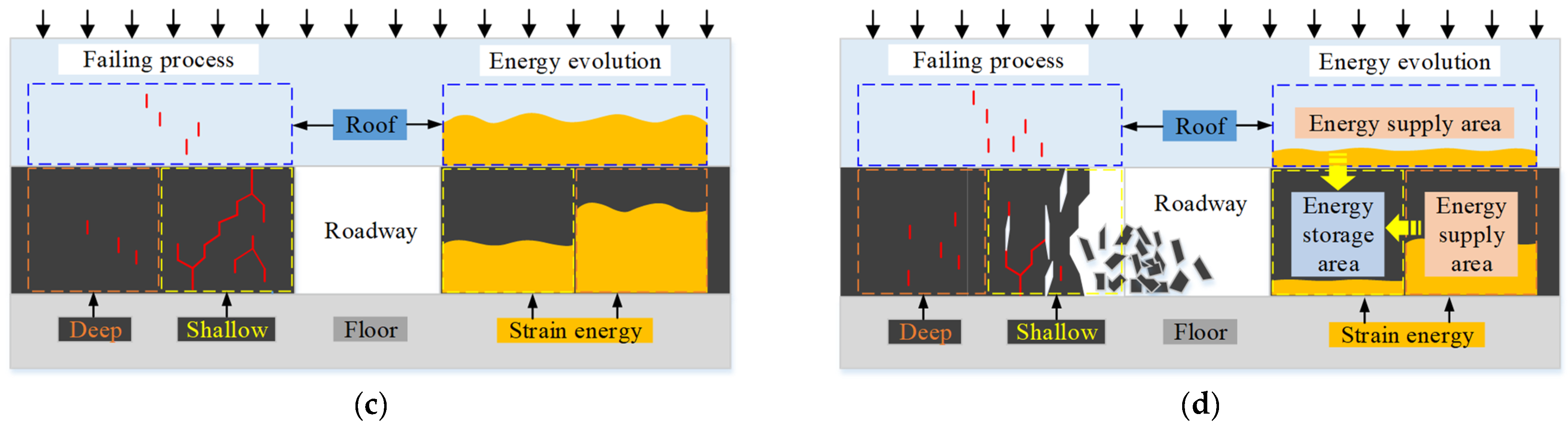

4.1. Failing Pattern of Roadway Surrounding Rock

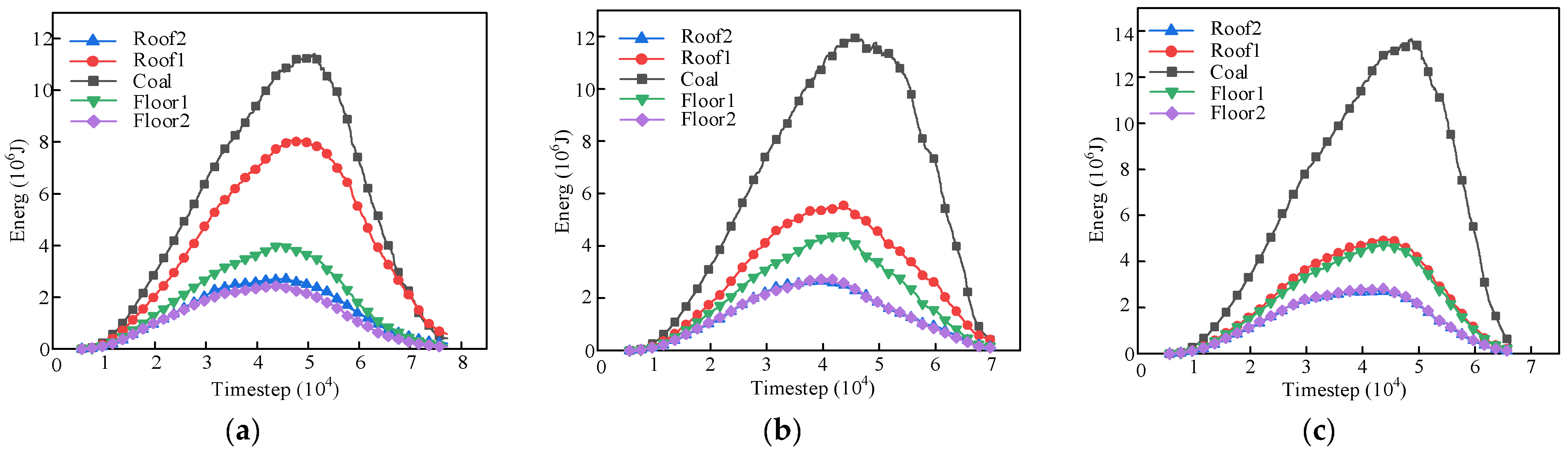

4.2. Partition Energy Evolution of Roadway Surrounding Rock

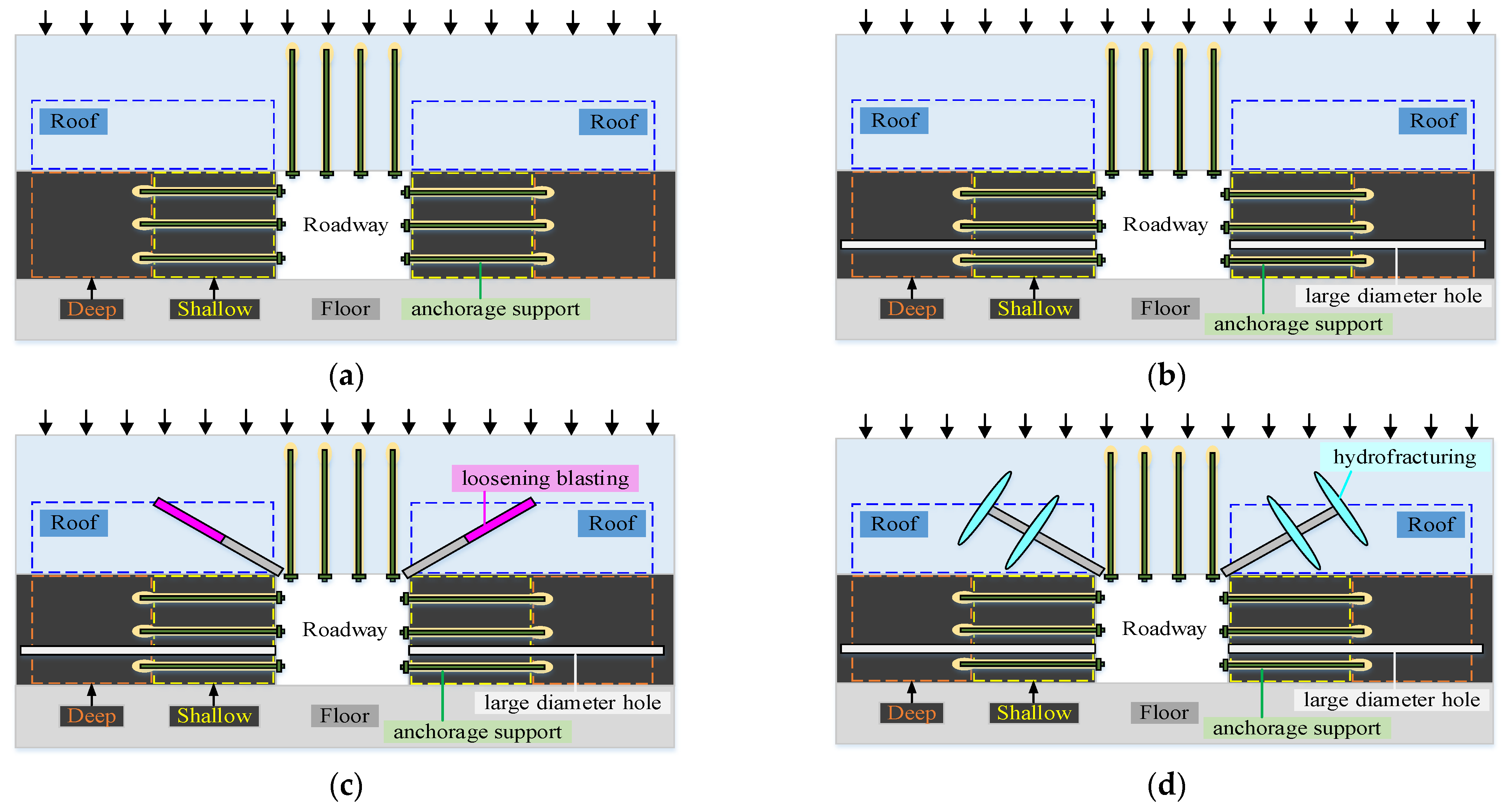

5. Partition Energy Storage Model of Roadway Surrounding Rock and Its Application

6. Conclusions

- (1)

- Coal mass is the main carrier for energy storage during the loading process of a coal–rock structure. With the increase of roof strength, the accumulated strain energy of the roof decreased gradually, but the accumulated strain energy of the shallow coal mass and deep coal mass increased, and a hard roof will improve the energy storage limit of the coal mass.

- (2)

- When the shallow coal mass fails, the roof provides energy to the shallow coal mass in the form of rebound, while the deep elastic coal mass provides energy to the shallow coal mass in the form of lateral expansion. The energy stored in the deep coal mass and the hard roof is the main factor leading to rock burst, and promotes dynamic failing of shallow coal mass.

- (3)

- The partition energy storage model of roadway surrounding rock is preliminarily established, and the concepts of energy supply zone and energy storage zone are proposed. That is, the shallow coal mass which burst-fails is defined as the energy storage area, the roof and deep elastic coal are defined as the energy supply area, and both of them participate in the rock burst evolution process of near-field roadway surrounding rock.

- (4)

- According to the partition energy storage model of roadway surrounding rock, the rock burst can be controlled according to the principle of “source differentiation”. By evaluating the energy storage characteristics of different areas of roadway surrounding rock, the corresponding measures can be taken to prevent and control rock burst, which is of great significance for rock burst prevention in roadways or tunnels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, T.; Zhang, P.; Guo, W.; Gong, X.; Wang, C.; Chen, Y. Controlling roof with potential rock burst risk through different pre-crack length: Mechanism and effect research. J. Cent. South Univ. 2022, 29, 1–13. [Google Scholar]

- Santosh, K.R.; Asfar, M.k.; Niroj, K.M.; Debashish, M.; Somu, M.; Jai, k.P. Review of preventive and constructive measures for coal mine explosions: An Indian perspective. Int. J. Min. Sci. Techno. 2022, 32, 471–485. [Google Scholar]

- Zhao, T.; Xing, M.; Guo, W.; Wang, C.; Wang, B. Anchoring effect and energy-absorbing support mechanism of large deformation bolt. J. Cent. South Univ. 2021, 28, 572–581. [Google Scholar] [CrossRef]

- Małkowski, P.; Niedbalski, Z.; Majcherczyk, T.; Bednarek, Ł. Underground monitoring as the best way of roadways support design validation in a long time period. Min. Miner. Depos. 2020, 14, 1–14. [Google Scholar] [CrossRef]

- Begalinov, A.; Almenov, T.; Zhanakova, R.; Bektur, B. Analysis of the stress deformed state of rocks around the haulage roadway of the Beskempir field (Kazakhstan). Min. Miner. Depos. 2020, 14, 28–36. [Google Scholar] [CrossRef]

- Bondarenko, V.; Kovalevska, I.; Cawood, F.; Husiev, O.; Snihur, V.; Jimu, D. Development and testing of an algorithm for calculating the load on support of mine workings. Min. Miner. Depos. 2021, 15, 1–10. [Google Scholar] [CrossRef]

- Łukasz, W.; Joanna, K.; Małgorzata, K. The influence of mining factors on seismic activity during longwall mining of a coal seam. Int. J. Min. Sci. Techno. 2021, 31, 429–437. [Google Scholar]

- Luo, Y.; Gong, F.; Li, X.; Wang, S. Experimental simulation investigation of influence of depth on spalling characteristics in circular hard rock tunnel. J. Cent. South Univ. 2020, 27, 891–910. [Google Scholar] [CrossRef]

- Yang, L.; Gao, F.; Wang, X. Mechanical response and energy partition evolution of coal-rock combinations with different strength ratios. Chin. J. Rock Mech. Eng. 2020, 39, 3297–3305. [Google Scholar]

- Zhao, T.; Yin, Y.; Tan, Y.; Wei, P.; Zou, J. Bursting liability of coal research of heterogeneous coal based on particle flow microscopic test. J. China Coal Soc. 2014, 39, 280–285. [Google Scholar]

- Chen, L.; Guo, W.; Zhang, D.; Zhao, T. Experimental study on the influence of prefabricated fissure size on the directional propagation law of rock type-I crack. Int. J. Rock Mech. Min. Sci. 2022, 160, 105274. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, G.; Xu, W.; Meng, X.; Huang, S.; Zhou, J.; Wang, Y. Experimental investigation on failure process and spatio-temporal evolution of rockburst in granite with a prefabricated circular hole. J. Cent. South Univ. 2022, 27, 2930–2944. [Google Scholar] [CrossRef]

- Dou, L.; He, X.; Ren, T.; He, J.; Wang, Z. Mechanism of coal-gas dynamic disasters caused by the superposition of static and dynamic loads and its control technology. J. China Univ. Min. Technol. 2018, 47, 48–59. [Google Scholar]

- Yin, D.; Chen, S.; Chen, B.; Jiang, N.; Meng, T.; Wang, W. Simulation study on effects of coal persistent joint on strength and failure characteristics of rock-coal combined body. Geomech. Eng. 2018, 15, 1113–1114. [Google Scholar]

- Chen, S.; Yin, D.; Zhang, B.; Ma, H.; Liu, X. Mechanical characteristics and progressive failure mechanism of roof–coal pillar structure. Chin. J. Rock Mech. Eng. 2017, 36, 33–43. [Google Scholar]

- Zuo, J.; Pei, J.; Liu, J.; Peng, R.; Li, Y. Investigation on acoustic emission behavior and its time-space evolution mechanism in failure process of coal-rock combined body. Chin. J. Rock Mech. Eng. 2011, 30, 1564–1570. [Google Scholar]

- Lu, J.; Yin, G.; Gao, H.; Li, X.; Zhang, D.; Deng, B.; Wu, M.; Li, M. True triaxial experimental study of disturbed compound dynamic disaster in deep underground coal mine. Rock Mech. Rock Eng. 2020, 53, 2347–2364. [Google Scholar] [CrossRef]

- Deniz, T.; Ihsan, B.T.; Ted, k. Investigating different methods used for approximating pillar loads in longwall coal mines. Int. J. Min. Sci. Techno. 2021, 31, 23–32. [Google Scholar]

- Xie, H.; Peng, R.; Ju, Y.; Zhou, H. On energy analysis of rock failure. Chin. J. Rock Mech. Eng. 2005, 24, 2603–2608. [Google Scholar]

- He, M.; Zhao, F.; Cai, M.; Du, S. A novel experimental technique to simulate pillar burst in laboratory. Rock Mech. Rock Eng. 2015, 48, 1833–1848. [Google Scholar] [CrossRef]

- Bobet, A.; Einstein, H.H. Fracture coalescence in rock-type materials under uniaxial and biaxial compression. Int. J. Rock Mech. Min. Sci. 1998, 35, 863–888. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, F. Energy evolution mechanism in process of sandstone failure and energy strength criterion. J. Appl. Geophys. 2018, 154, 21–28. [Google Scholar] [CrossRef]

- Zuo, J.; Song, H.; Chen, Y.; Li, Y. Post-peak progressive failure characteristics and nonlinear model of coal-rock combined body. J. China Coal Soc. 2018, 43, 3265–3272. [Google Scholar]

- Feng, G.; Chen, B.; Jiang, Q.; Xiao, Y.; Niu, W.; Li, P. Excavation-induced microseismicity and rockburst occurrence: Similarities and differences between deep parallel tunnels with alternating soft-hard strata. J. Cent. South Univ. 2021, 28, 582–594. [Google Scholar] [CrossRef]

- Yu, M.; Zuo, J.; Sun, Y.; Mi, C.; Li, Z. Investigation on fracture models and ground pressure distribution of thick hard rock strata including weak interlayer. Int. J. Min. Sci. Techno. 2022, 32, 137–153. [Google Scholar] [CrossRef]

- Pan, Y.; Geng, L.; Li, Z. Research on evaluation indices for impact tendency and danger of coal seam. J. China Coal Soc. 2010, 35, 1975–1978. [Google Scholar]

- Christopher, M. Protecting miners from coal bursts during development above historic mine workings in Harlan County, KY. Int. J. Min. Sci. Techno. 2021, 31, 111–116. [Google Scholar]

- Zhang, S.; Li, Y.; Shen, B.; Sun, X.; Gao, L. Effective evaluation of pressure relief drilling for reducing rock bursts and its application in underground coal mines. Int. J. Rock Mech. Min. Sci. 2019, 114, 7–16. [Google Scholar] [CrossRef]

- Meng, F.; Zhou, H.; Wang, Z.; Zhang, L.; Kong, L.; Li, S.; Zhang, C. Experimental study on the prediction of rockburst hazards induced by dynamic structural plane shearing in deeply buried hard rock tunnels. Int. J. Rock Mech. Min. Sci. 2016, 86, 210–223. [Google Scholar] [CrossRef]

- Guo, W.; Zhang, D.; Zhao, T.; Li, Y.; Zhao, Y.; Wang, C.; Wu, W. Influence of rock strength on the mechanical characteristics and energy evolution law of gypsum-rock combination specimen under cyclic loading-unloading condition. Int. J. Geomech. 2022, 22, 04022034. [Google Scholar] [CrossRef]

- Tan, Y.; Guo, W.; Zhao, T.; Meng, X. Coal rib burst mechanism in deep roadway and“stress relief-support reinforcement”synergetic control and prevention. J. China Coal Soc. 2020, 45, 66–81. [Google Scholar]

| Lithology | Mesoscopic Parameter Calibration | Macroscopic Mechanical Properties | |||

|---|---|---|---|---|---|

| Density (kg∙m−3) | Parallel Bond Modulus (MPa) | σc (MPa) | εc | Elasticity Modulus (MPa × 103) | |

| Coal | 1800 | 4.00 × 109 | 14.821 | 0.00198 | 7.458 |

| Rock-1 | 2500 | 5.00 × 109 | 26.166 | 0.00304 | 9.469 |

| Rock-2 | 2500 | 6.00 × 109 | 47.592 | 0.00415 | 12.270 |

| Rock-3 | 2500 | 7.00 × 109 | 69.659 | 0.00515 | 14.079 |

| Rock-4 | 2500 | 8.00 × 109 | 101.8 | 0.00636 | 16.423 |

| Rock-5 | 2500 | 9.00 × 109 | 125.14 | 0.00679 | 19.052 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Guo, W.; Zhao, T.; Zhao, Y.; Chen, Y.; Zhang, X. Energy Evolution Law during Failure Process of Coal–Rock Combination and Roadway Surrounding Rock. Minerals 2022, 12, 1535. https://doi.org/10.3390/min12121535

Zhang D, Guo W, Zhao T, Zhao Y, Chen Y, Zhang X. Energy Evolution Law during Failure Process of Coal–Rock Combination and Roadway Surrounding Rock. Minerals. 2022; 12(12):1535. https://doi.org/10.3390/min12121535

Chicago/Turabian StyleZhang, Dongxiao, Weiyao Guo, Tongbin Zhao, Yongqiang Zhao, Yang Chen, and Xiufeng Zhang. 2022. "Energy Evolution Law during Failure Process of Coal–Rock Combination and Roadway Surrounding Rock" Minerals 12, no. 12: 1535. https://doi.org/10.3390/min12121535

APA StyleZhang, D., Guo, W., Zhao, T., Zhao, Y., Chen, Y., & Zhang, X. (2022). Energy Evolution Law during Failure Process of Coal–Rock Combination and Roadway Surrounding Rock. Minerals, 12(12), 1535. https://doi.org/10.3390/min12121535