1. Introduction

Martitized grains composed of hematite (α-Fe

2O

3, R

c, ao = 5.038 Å, co = 13.772 Å), goethite (α-FeOOH, Pnma, ao = 9.945 Å, bo = 3.027 Å, co = 4.610 Å) and magnetite (Fe

3O

4, Fd

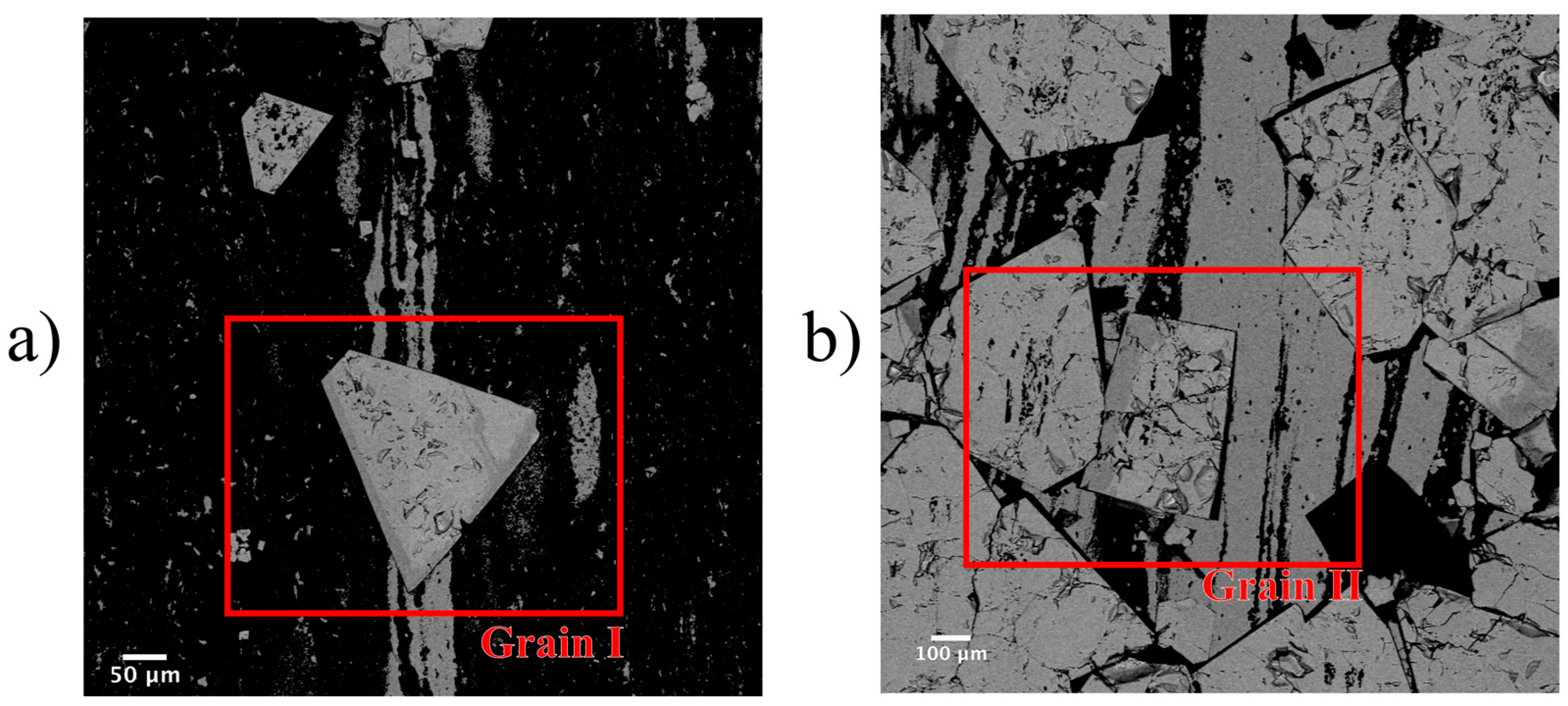

m, ao = 8.393 Å) are the most common constituents of the iron formations called jaspilite (JP) in the Serra Norte deposits of iron ore in the Carajás Mineral Province (CMP). These jaspilites are precursors of the massive layers of high-grade friable hematite ore. Topotactic phase transformation of the martitization process between magnetite and hematite in iron formations has been extensively described in the Quadrilátero Ferrífero (QF) region in Brazil by electron backscatter diffraction (EBSD) [

1,

2], but there is a lack of data of quantitative crystallographic preferred orientation, phase transformations and mineral characterization within the jaspilites of the Amazonian Craton.

During progressive oxidation and reduction of iron oxides/hydroxides, the cubic, trigonal and orthorhombic lattices of the three minerals are linked by specific topotactic relations related to the oxygen lattice framework, being the hematite, in most cases, the intermediate phase in natural systems. In CMP and in many high-grade iron ore deposits around the world, goethite plays a very important role as the final phase in the transformation process and being a substantial part of the bulk high-grade ore and should be considered in the topotactic transformation chain of natural iron oxides/hydroxides.

The natural transformation process between magnetite, hematite and goethite occurs due to different stabilities in oxidizing domains, whereas in aqueous systems, the stability Eh/pH diagram indicates magnetite in a very restricted alkaline and reducing field, and hematite is stable in a much wider pH range and fO

2. Stability diagrams consistently show the pair magnetite-hematite, but depending on the data used, the goethite can replace hematite in the diagram and be part of the Fe–O

2–H

2O system, or metastable phases as maghemite or other FeOOH polymorphs [

3]. The stability field of goethite broadens as PH

2O increases [

3], which is in conformity with the analyzed samples.

In the cases in which iron oxide’s topotactic phase transformations were analyzed in iron formations by EBSD [

1], orientation relationships have been the most used parameter for describing the crystallographic preferred orientation and the relationship between the oxide/hydroxide phases. Those studies used a simple model of finding coincidental maxima in pole figures (PF) and analyzing inverted pole figures (IPF) in order to describe the parallelism between crystallographic orientations. However, to consider only orientation in the phase transformation analysis is now regarded as a significant loss of information regarding the crystallographic relationships between crystals [

4], and with a complex phase in the system such as goethite, statistics through pole figures showing only orientation planes of low-index crystallographic planes are not enough to describe the transformation process and the necessary rotation angle of misorientation.

Orientation is defined as a passive rotation expressed in coordinates from a crystal reference into a specimen reference system [

4], where orientation information of only one crystal specimen is analyzed. Misorientation can be defined as the difference of orientation between two crystallites, and it is also a passive rotation in 3D space, but in this case, between two crystal references frames, where both orientations are considered and an orientation relationship between two phases [

4,

5]. The grain boundaries can be expressed as a rotation about a common axis to both crystal frames, and this kind of misorientation data, called angle-axis pair description, can be better visualized into a three-dimensional space using Rodrigues–Frank (R-F) vectors [

5] or axis–angle, and in this case, the domain used would be restricted to only the coincidental fundamental zone between the two phases selected [

4]. This new technique for modeling and visualizing misorientaion for topotactic transformation of natural iron oxides and hydroxides samples could lead to a better understanding and characterization of crystallographic relationships between the phases, with the graphic visualization of rotational angles of misorientation necessary for the theoretical parallelism between the phases with low- and high-index crystallographic planes. Thus, this technique considers both rotational angles and axis being then applicable to the study of phase transformation of crystalline phases of different space groups.

This technique can also show how much the phase transformations contribute to the bulk texture of the analyzed grain/rock comparing the total analyzed points and the points belonging to a certain OR cluster, showing how those transformations between oxides and hydroxides are related to important textures in banded iron formations and iron ores in general. In this study, both orientation and misorientation data were considered and used for describing the main crystallographic preferred orientations and relationship between crystals.

For this study, we considered four magnetite–hematite orientation relationships. The most common topotactic orientation relationship for the magnetite–hematite is considered and described in [

6,

7] (OR A—

Table 1). High-index orientation relationships have been also described for natural and synthetic samples of hematite when submitted to different and cyclical conditions of temperature and reduction experiments (OR B–D—

Table 1). These OR are described in [

7,

8] and were considered in this study during 3D misorientation analysis.

Those secondary high-index relationships are not necessarily topotactic as they are a result of what is defined by [

8] as magnetite and hematite transformation twinning followed by new generations of recrystallized magnetite and hematite, generating a complex and diverse system of orientation relationships as OR S (

Table 1). For a better quantification of those OR, other equivalent OR in different directions were also considered and analyzed, followed by a briefly analysis of twinning within the samples for magnetite and hematite.

For orientation relationships regarding the transformation stage of hematite to goethite, the expected ORs can be seen in

Table 2. According to [

9], both goethite and hematite can be defined as a distorted hexagonal close packing, whereas goethite has half of its sites filled and hematite two thirds filled. In the goethite structure, the anions are stacked in layers perpendicular to the c-axis (ABA stacking). Similarly, the hematite structure has layers stacked along c-axis but with minor anions and cations changes. Those minor changes result in the elongation of hematite axis, but during the transformation, there are not many changes in the cubic packing structure of both minerals [

9], which indicates that the most reasonable OR expected would be between the parallelism of basal planes (0001)Hem and (001)Ght, with OR α representing the [10–10]Hem|| [100]Ght direction and OR β the [11

0]Hem|| [100]Ght.

The main objectives of this study are to describe the most frequent crystallographic preferred orientation developed during the progressive phase transformation of magnetite to hematite and hematite to goethite and to verify if it is possible to establish a genetic relationship between the phases and if transformation leaves a crystallographic memory up to its last member. This might be useful for evaluating the extent to which the crystallographic orientation of magnetite, hematite and goethite can be attributed to phase transitions and to contribute to the debate of the diagenetic process in jaspilite in Archean banded iron formations and how iron oxides and hydroxides can carry important information regarding environmental changes during geological time due to its easily reactivity and transitioning character.

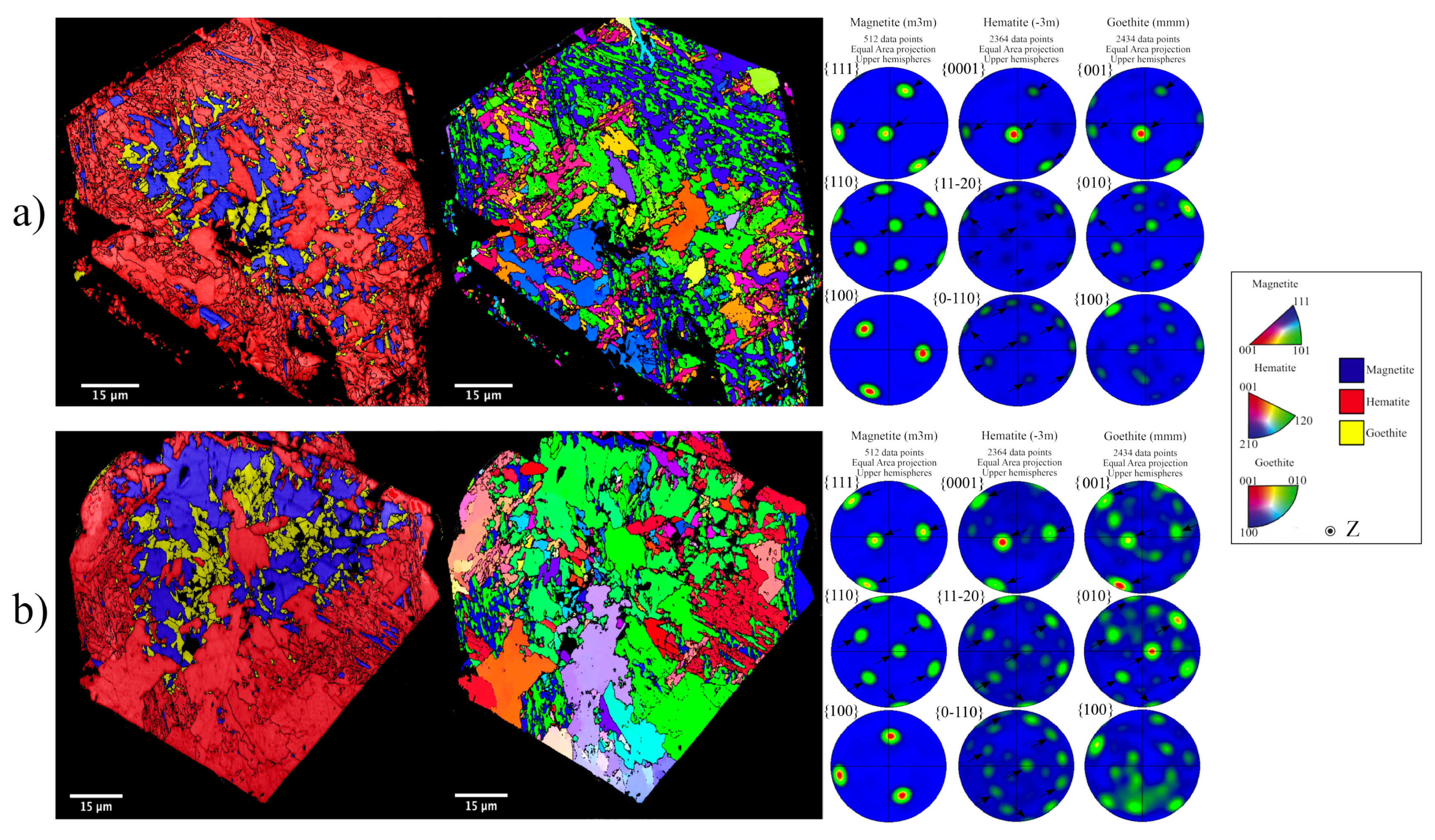

4. Discussion

Orientation relationships between low-index planes can be easily recognized in pole plot figures of all grains analyzed from both samples by coincidental maxima. This preliminary analysis is already satisfactory to evidence an orientation relationship between the planes (111)Mag || (0001)Hem || (001)Ght; [110]Mag || [10

0]Hem || [010]Ght which can be linked with the pairs of topotactic transformation of magnetite–hematite and hematite–goethite [

1,

9,

11]. Those orientation relationships can also be recognized and quantified in misorientation analysis within their appropriate fundamental zone and in pairs. This is evidence that in the grains where the three phases coexist the basal planes of goethite coincides with basal planes of hematite, and the basal planes of hematite coincide with the octahedral planes of magnetite. No evidence of intermediate and metastable phase of maghemite was found in this study.

The first orientation relationship resulting from the transformation process is the OR (111)Mag || (0001)Hem, [110]Mag || [10

0]Hem, here assigned as Type-A clusters. This is the only OR that shows the expected topotactic relationships according to [

8]. Type-A OR is the most common texture in all analyzed grains, contributing from 38.31% to 80.89% to the total misorientations plotted points from the magnetite–hematite interface. The transition between these two minerals and their crystallographic memories are responsible for the main crystallographic texture of the iron formations of the N4WS deposit. Type-A OR is the most common texture among grains due to its abundance. This OR indicates topotaxity between grains of magnetite and hematite in the deposit, which are mainly located inside martitized grains.

The multiple orientation relationships of high-order planes contribute in a minor way to the bulk texture of grains, ranging from 1.38% to 5.95% of total plotted points, although they are still distinguishable from random oriented misorientation points. Type-B orientations are more pronounced in grains belonging to banding domains, especially Grain V and VI which have a total percentage of 2.36% and 4.02% of total points related to clusters of high-order in B. Type-C clusters are not very well-developed in any samples, always ranging from 0.20% to 0.77% of total plotted points. Type-D cluster is more frequent than the previous ORs. The total percentage of Type-D cluster ranges from 0.26% to 3.25% of total plotted points and has an average value of 1.13%. The highest value for Type-D clustering belongs to Grain II from Sample A.

For a better understanding of the high-order orientation relationships, a further analysis of magnetite–magnetite and hematite–hematite grain boundaries is required for identification of twining near CSL boundaries in magnetite and recrystallization twins in hematite. These high-order ORs which are less expressive than Type-A do not indicate topotaxity in the samples but evidence the complex rebalance twinning system of magnetite and hematite crystals when exposed to different temperatures of reduction conditions in a successive phase transformation cycle [

8,

12].

Due to the large overlap of orientation relationships and transformation cycles, it is not possible to verify a genetic relationship between the phases, only that the remnants of such ORs are still preserved in grains of the N4WS deposit. The Serra Norte iron formations are known for their highly preserved jaspilites and for the low intensity of regional metamorphism, unlike iron formations of the QF in which metamorphism was responsible for intensifying the magnetite–hematite transformation [

12].

The martitized grains under low-grade metamorphism provide favorable conditions to preserve their crystallographic memory in different moments of phase transformation and oxidation/reduction conditions. Often those textures are overprinted by the most common orientation relationship of topotactic transformation (Type-A) or other ORs caused by strain. The preservation of high-index orientation relationships in the grain boundary interfaces and in the matrix is evidence of progressive and dynamic cycles of oxidation–reduction and/or a nearby source of heat during the diagenesis.

Whiters and Bursill (1979) used a matrix transformation technique for a better understanding of high order orientation relationships such Type-B to Type-D and the possible models for orientation relationships between magnetite and hematite. Our analyses of natural samples are in consonance with experimental data modeled by their studies, in which transformation-induced orientation relationships were best fitted in a quaternary orientation Hem/MagA/MagT/Hem’/MagB. This most plausible quaternary orientation can be represented as misorientation clusters by the presence of Type-A, Type-B, Type-D and Type-S clusters and explained as follows: topotactic transformation of hematite into magnetite followed by twinning of magnetite (Hem/MagA/MagT) on (-111), represented by Type-A and D clusters, and finally phase transformation of hematite followed by a recrystallization of magnetite forming Type-B and consequentially Type-S clusters (Hem’/MagB). Whiters and Bursill (1979) confirm in their study that Type-D OR is a more reasonable orientation than Type-C, representing a consequence of the first one. Type-B, D and S high-order orientation are an indicative of a complex process of transformation twinning in between the process of topotactic transformation of magnetite and hematite. Type-B orientations are frequently observed in higher temperatures of reduction (773–1273 K) and Type-C and D orientations, in moderate temperatures (473–673 K), where CO/CO

2 gas works as buffers for reduction [

13,

14].

The overlapping of different crystallographic preferred orientations in martitized grains, shows that these grains possibly grew close to a source of heat. The iron (hydro)oxides minerals are susceptible to environmental changes still in solid state during the diagenesis of the pile and also the presence of intrastate percolating fluid. Such oxide-hydroxide grains function as crystallographic markers of the Archean ocean physicochemical conditions and iron formations of the region. Indirectly, the presence of these minerals can be related to the conditions of atmosphere and circulating fluids in contact with iron formations [

15,

16,

17,

18]

The understanding of atmospheric changes in the Archean has changed, and it is already considered that the transition to an oxygenated atmosphere occurred in an oscillatory manner and not abruptly as previously considered [

19]. Iron oxides and hydroxides are extremely susceptible to changes in terrestrial oxidation, and preserved rocks may contain remnants minerals that traces of different temperatures and oxidation/reduction conditions that occurred during the diagenesis process of iron formations.

These series of changes show that martitization is a complex process that involves (1) topotactic transformation of magnetite into hematite, and vice versa; (2) a complex twinning transformation system and (3) successive phase changes still in solid state during diagenesis. Such successive transformations are also responsible for a significant change in volume and in the habit of crystal due to the abrupt transformation from a crystal system of high symmetry (cubic) to symmetries of lower symmetry (trigonal and orthorhombic). Continuous and successive phase changes in elongated bands parallel to the banding show that the phase transformation continued even with the increase of the stacking pile during diagenesis.

The temperature of reduction required for generating the ORs of Type B, C and D compiled by [

14] are not consistent with the low temperature metamorphism from the iron formation of the Serra Norte Deposits [

20,

21]. The most reasonable possibility to explain the larger amount of phase transformation in these rocks due to the differences in the temperature of reduction is a source of heat and fluids nearby the iron formations of N4WS during diagenesis.

The orientation relationships of greatest importance in the misorientation analysis of the hematite–goethite transformation interface is Type-α, regarding the orientation (0001)Hem || (001)Ght, [110]Hem || [100]Ght, which implies in a rotation of zero degrees towards the c-axis. This is the most common and abundant texture between these two minerals, and they represent the expected OR and misorientation angle necessary for a topotactic transition between the two phases conserving the oxygen lattice stacking, as expected. A second case less common but also present in the martitized grains samples is Type-β OR regarding a similar orientation of Type-α but now with a 30° rotation towards the c-axis and using first order prism direction as reference. Type-β OR is also an indicative of topotaxity, and it is an expected cluster resultant from the previous and more abundant Type-α.

Type-α clusters contribute from 12.36% to 31.84% to the total of plotted points, thus being the predominant crystallographic texture between these two phases. It was verified that there is topotaxity in the phase transformation between hematite and goethite. Although the density of points is not as vast as in the previous transformation process (magnetite–hematite), Type-α clusters are the most abundant in martitized grains. The twinning process in hematite concomitant with the phase transformation to goethite is implied in other two ORs here called Type-γ and Type-δ, which contribute with 6.39% to 15.28% of the total misorientation points plotted. These ORs with a rotation of approximately 90o are possibly linked with twinning in hematite, creating these ORs between newly topotactic formed goethite and trapezohedron twins in hematite. A further analysis with higher density of points is necessary and recommended for mapping all possible ORs between transformed goethite and other possible hematite twins.

The iron oxides and hydroxides that make up the matrix of both samples show by their pole figures an expected crystallographic orientation where the crystal’s c-axis is perpendicular to the primary rock banding, and the crystals were allowed to grow along their a and b-axis. This is an expected orientation for the microplaty matrix of a non-deformed iron formation, and it shows that crystals have grown and spontaneously transformed during diagenesis.

5. Conclusions

The data demonstrate that in martitization, the transformation of magnetite–hematite–goethite occurs in a topotactic manner, and the crystallographic memory can be checked in any of the directions of the transformation reaction. The orientation relationships Type-A in the magnetite–hematite transformation and Type-α in the hematite-goethite transformation are the main ORs in the analyzed martitized grains and represent the main crystallographic texture of the banded iron formations called jaspilites of the N4WS deposit. It evidences that there is a strong crystallographic control of the phase transformation and that the oxygen lattice framework is preserved through the whole transformation of the three target phases of the Fe-O system.

Other high-index orientation relationships, such as Type-B, Type-C and Type-S, once identified by [

6,

7,

8] in experimental studies, are here evidenced. They are not an indication of topotacticity but a marker of a complex twinning process occurred during diagenesis and different conditions of reduction-temperature in between phase transformation. There is a visible difference between the misorientation characterization of grains and the microplate matrix, which shows a higher prevalence of high-index ORs such as Type-B, demonstrating a different dynamic of crystallographic memory than the posterior formed grains.

The study of crystallographic preferred orientation by three-dimensional misorientation analysis of geological samples, especially iron formations, is still in its beginning, but it represents an excellent tool for characterization and quantification of orientation relationships related to phase transformation, twinning and deformation.