Abstract

Revealing the internal structure of diamonds is key to understanding the general regularities of crystal growth and dissolution. This paper presents and summarizes data on the internal structure of diamonds of different morphological types, colors and defect-impurity composition. In order to provide a comprehensive explanation of the stages of diamond growth, crystals and plates were observed, and panchromatic cathodoluminescence and photoluminescence techniques were applied. This article considers the mechanism of tangential growth from existing surfaces (regeneration growth) as an intermediate stage between normal and tangential crystal growth. The regeneration growth is very fast due to the absence of the limiting stage-nucleation of a new atomic layer. Cuboid diamonds were refaceted to stepped octahedrons by the regeneration growth mechanism. A schematic model of crystal habit transformation due to regeneration growth explains the internal structure of crystals in connection with their morphology and thermal history. The main variants of regeneration stage and its morphological manifestations were demonstrated. Most diamonds pass through the regeneration stage, and in many cases, it was a stage of growth termination.

1. Introduction

The morphological diversity of diamond crystals has been thoroughly described [1,2,3,4]. However, some issues of crystal growth remain controversial. An understanding of crystals’ internal structure helps to explain their morphology; many effects are associated with the polycrystalline structure of diamonds [5]. Even in the case of single crystals, studying their internal structure is key to understanding many morphological characteristics [6,7,8,9]. The variety of diamond shapes in nature is a consequence of changes in their growth and dissolution conditions. V. Beskrovanov [10] developed a schematic model of morphology evolution at the main stages of diamond formation. He provided a model of the dependence of the shape and internal structure of diamonds on supersaturation and time. This work is in good agreement with the concept [11]. I. Sunagawa [11] distinguished two growth mechanisms of diamond crystals in nature. The normal growth forms curved cuboid surfaces. The tangential growth forms flat octahedral facets. Further studies of diamonds [9] revealed some types of internal structure and thermal history of crystals, which cannot be explained by these schematic models. Thus, the growth of cubic crystals corresponds to the early stages of crystallogenesis [10,11]. However, cubic crystals always have a very low degree of aggregation of nitrogen defects, which corresponds to low-temperature or short natural annealing. On the other hand, curved cuboid zoning is often observed in the core of octahedral crystals. This zoning is similar to low-temperature cuboids, but their spectroscopic characteristics correspond to diamonds with a long mantle residence time. Normal growth is realized at high supersaturation. It is characterized by multiple spots for atom attachment. In this case, there are many potential cavities, which can trap microinclusions. Nonsingular curved surfaces are formed because of this process. Tangential growth of singular faces implies the opposite situation. Low supersaturation and a flat surface make it difficult for atoms to attach. Ideal singular faces do not exist in natural crystals; small steps or vicinals appear on crystals as a result of emerging dislocations, and these steps help to attach atoms and thus dislocation-driven growth begins. In another case, growth begins with the adsorption of several neighboring atoms on a flat crystal surface, named two-dimensional nucleation [12]. According to the dominant growth mechanism, in the bulk of octahedral crystals, zonal inhomogeneities have the shape of plane-parallel layers. In crystals composed of <100> growth sectors, zonal inhomogeneities have a wavy, in the limit-concentric shape. Therefore, according to the nature of cathodoluminescence zoning in crystals, the <100> and <111> growth sectors of faces are clearly separated and identified.

The change in growth mechanism occurs through tangential growth from the existing surface. In this case, the stage of nucleation of a new layer is absent. This variant is quite common in the internal structure of various minerals, including diamonds. In this case, small steps are formed on the dissolved surface, which then gradually move to singular faces. As a rule, the concept of “regeneration” is interpreted in the literature as the restoration of a destroyed or dissolved crystal.

In our research, the main meaning of the term “regeneration diamond growth” is an intermediate stage in the transition from normal to tangential growth [13]. From the point of view of crystal morphology, this stage corresponds to the progression from cuboid to octahedron. In a supersaturated solution, at an early stage, diamonds grow by normal growth at a very high rate. After a short period (in a relative sense regarding the growth of crystals), nonsingular rough surfaces break up into small sites corresponding to singular faces [14]. The surface of the crystal gains a stepped shape, and the sites propagate in the direction of normal growth. The transition from rough to stepped surfaces is due to the rapid filling of deep potential cavities and, accordingly, a drastic decrease in their amount. The steps formed in this way subsequently merge, enlarge and transform into singular faces of tangential growth. Crystal growth by tangential mechanism is much slower than by the normal one [11]. The growth rate in this case is limited by the stage of two-dimensional nucleation or depends on the presence of screw dislocations.

The transition from the wavy zoning of <100> sectors to stepped regeneration growth in diamond crystals was documented over 40 years ago [15]. Later, the internal structure of crystals with zones of habit transformation during regeneration growth was addressed in many studies [16,17,18]. At the same time, the stage of regeneration growth of s diamond itself has never been investigated before. The existing publications usually address either cuboid zoning or directly flat faces formed by the tangential mechanism.

There is an interesting and long-standing debate about the nature of rounded dodecahedra, of whether it is a form of growth or dissolution [2,3,19]. The paradox inheres in the fact that both sides are right: growth zoning, and thus, growth surfaces of a diamond are often truly curved. However, they determine the shape of individuals only in exceptional circumstances. The observed curved surfaces appear as a result of dissolutions [20,21,22]. Dissolution and etching produce on diamond crystals tetragonal and triangular etch pits [23]. Tetragonal depressions are quite interesting, because they can appear during both growth and etching. The tetragonal etch pits usually appear at the points of dislocation emergence at the surface [24]. Experiments proved that the morphology of the walls of etch pits themselves significantly changes depending on the ratio of CO2:CO and fugacity of O2. When these ratios (as well as the temperature) change, the irregular cavities forming the bottom and the walls of tetrahedral etch pits evolve, through the development of the {100} microfaces, and conversion into {111} faces. The {111} face is the basic shape obtained in etching experiments with high CO2 content. This indicates high diamond oxidation rates in the <111> direction [25,26]. Sonin et al. [27] present the morphology of partially dissolved diamond in a Fe–S melt (sulfur content 15–30 wt.%) at 4.5 GPa and 1450 °C. The authors showed that the surface topography with an imbricate structure in the shape of stepped octahedral plates is formed upon dissolution of crystals. This should be considered in reconstructions of diamond growth history. It appears that experiments on diamond etching/dissolution usually describe in detail experimental conditions and morphology of the samples, but there are few descriptions of the internal structure, and there are no images of zoning. These data would help to understand better and explain the factors affecting certain shapes of etch figures, since not everything depends on external conditions.

Thus, regeneration and etching are the reverse processes that form the {111} faces and surface topography that is hard to distinguish in morphology. These processes may overlap and be repeated within the cycle of crystallogenesis. Today, the discussed concepts and experiments do not identify the regeneration growth of diamond crystals as a separate stage. However, it is actually very common in natural diamonds of any habit. Diamonds with surface topography driven by regeneration growth may be easily confused with etching patterns. However, these two stages of the diamond formation process are entirely different. The regeneration process is fixed by growth zoning and contains the history of crystal formation.

2. Materials and Methods

This paper is based on studies of natural diamond crystals from primary and alluvial deposits in Russia. Most of the investigated crystals were mined from modern alluvial deposits of the Krasnovisherskiy District (Ural Region) and Anabar–Olenek interfluve area. However, the obtained data are applicable for all mantle-derived diamonds. The images in reflected and transmitted light, images via crossed polarizers (XPL) and photoluminescence (PL) were obtained using Leica M205 series optical microscope (OM). Internal inhomogeneity in PL were visualized using laser excitation at 405 and 450 nm, with edge filters 450 and 500 nm, respectively. The cathodoluminescence images (CL) and secondary electron images of the surface topography (SEI) were obtained using a CamScan MX2500 S Scanning Electron Microscope coupled with a QLI/QUA2 detector at an acceleration voltage of 12 kV and beam current of 5–7 nA. The research consisted of 3 stages: (1) observation of the crystal surface, structural aspects of their faces and the internal structure of the near-surface layers; (2) preparation of 0.4–0.8 mm thick plates through the central parts of the crystals, in the <110> and <100> directions; and (3) visualization of their internal structure. CL was used for the near-surface layers, PL and OM were used for the bulk of the plates.

3. Results

3.1. Regeneration Octahedral Zoning in Diamonds: Markers Associated with the Occurrence, Morphological Manifestation, Visualization Features

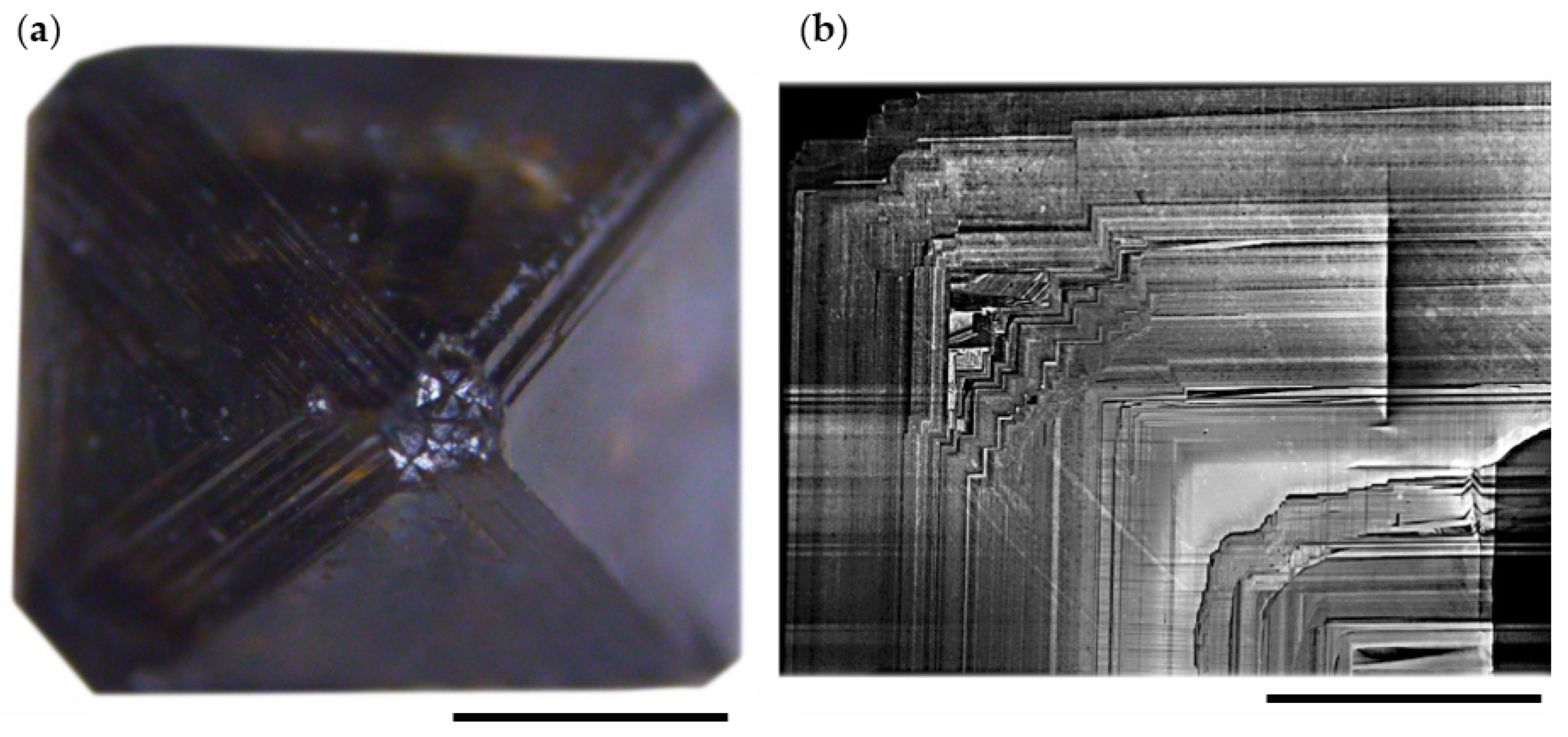

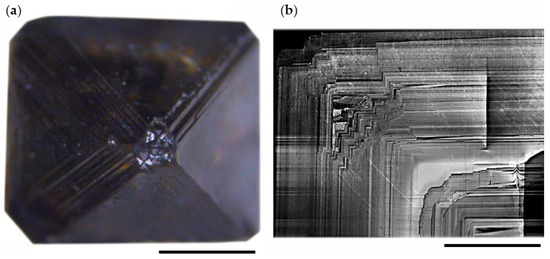

In the classical sense, the process of regeneration is the restoration of a destroyed or dissolved surface. This case is not rare in natural diamond crystals. Figure 1 shows a flat-faceted octahedral diamond crystal with a stepped structure of faces and tetragonal depressions at the vertices. Its internal structure is visualized on a cut through the center of the crystal in the <100> direction. Figure 1b shows a CL fragment of this cross-section of the crystal from the core to the periphery. Several zones are clearly visible, where the rectilinear octahedral zoning is sharply interrupted by the rounded line of the surface of dissolution. After that, a zigzag octahedral zoning of regeneration growth is immediately formed. This is the case of regeneration in the classical sense. Other samples will demonstrate regeneration as a transitional stage from normal to tangential growth. As it turned out, this case is much more common for diamond crystals.

Figure 1.

Flat-faceted octahedral diamond crystal with a stepped structure of faces and tetragonal depressions at the vertices (a), the scale bar is 1 mm; CL image of cross-section part from the center of this crystal in <100> direction (b), the scale bar is 0.3 mm.

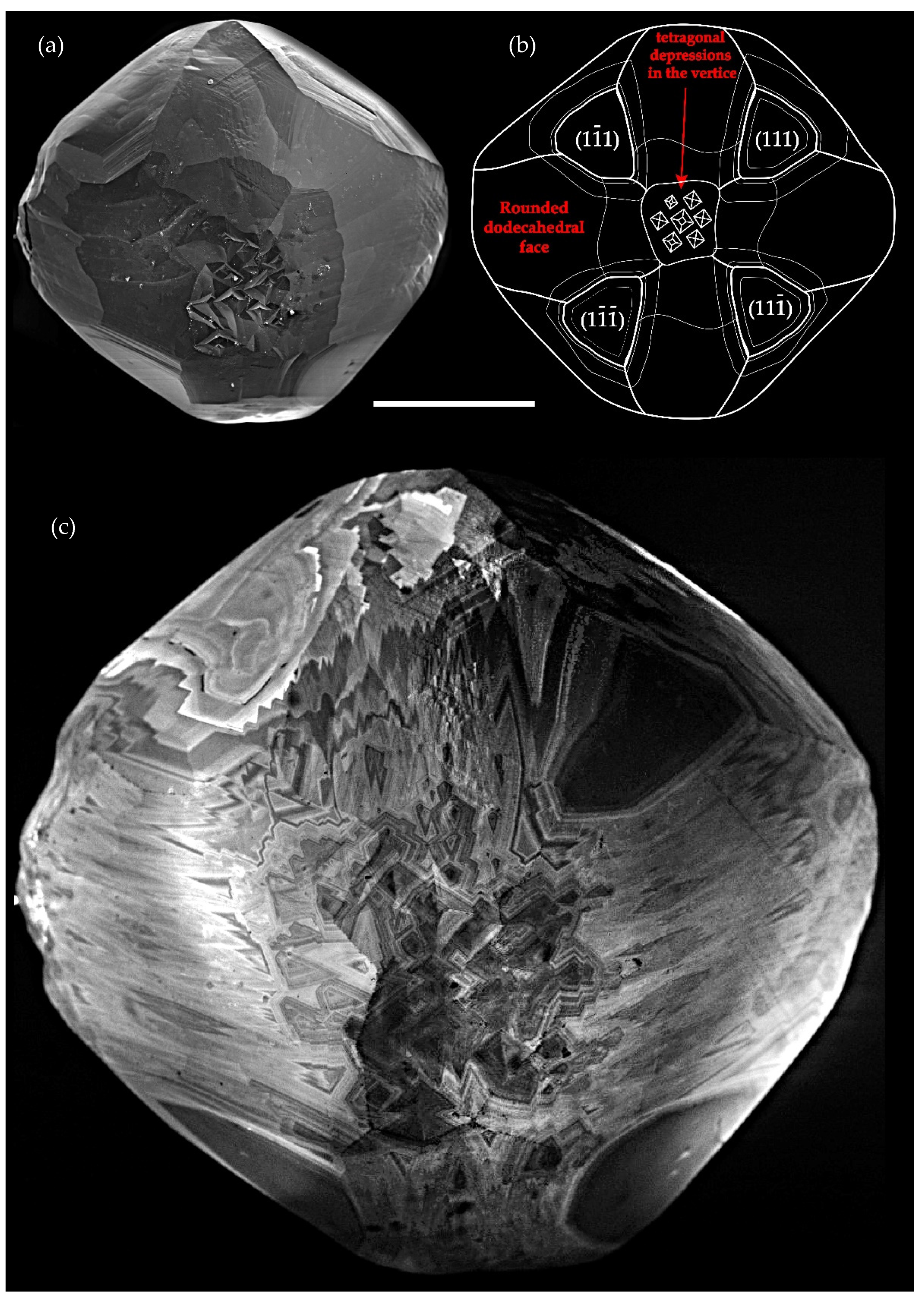

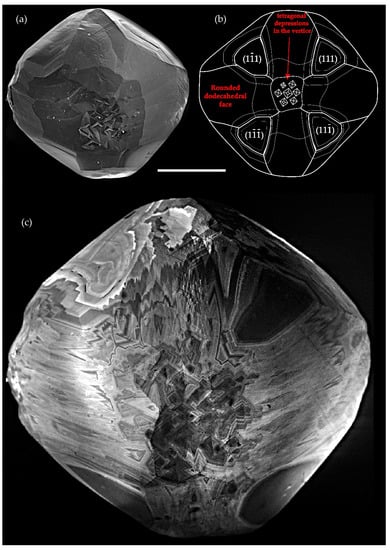

Many crystals of cubic and mixed habits from the Urals placers [28] exhibit external zones composed of finely graded {111} layers. Such grades are formed during tangential regeneration growth over existing curved rough surfaces. In such a case, only tangential growth of the {100} faces occurs. The normal component is due to the existing curved surfaces of the {100} growth pyramids, which are the place of accretion of the {111} regeneration sites. The {111} faces do not grow along the normal direction. This stage of regeneration growth leads to a gradual transformation from crystals of cubic habit into octahedral shape crystals with negative vertices. Regeneration growth can be interrupted at any stage of the transition to singular faces, hence the completely diverse crystal morphology. Many such crystals can be described as an “antiskeletal octahedron” [29]. Figure 2a, b demonstrates a partly dissolved diamond crystal of rounded octahedral habit with tetragonal depressions in vertices. Zigzag-type regeneration zoning {111} is clearly seen on the whole surface of the stone (Figure 2c).

Figure 2.

Partly dissolved diamond crystal of rounded octahedral habit with tetragonal depressions in vertices: (a) SEI of the surface morphology, the scale bar is 1 mm; (b) idealized scheme of crystal faceting; (c) enlarged CL image of the crystal with visualization of the regeneration zoning {111}.

The beginning of the regeneration stage on cuboids is marked by the appearance of {111} steps, forming square-shaped depressions. How can one reveal the regeneration stage on the completely dissolved surfaces of dodecahedra, as well as distinguish regeneration relief from etching? These characteristic features can be perfectly visualized by CL (Figure 2 and Figure 3). The zones of crystal habit transformation during regeneration growth on the surface of dissolved crystals are visualized by specific “redoubt-like” inhomogeneities. Regeneration zoning is highly contrasting, straight and somewhat resembles a mosaic pattern. Separate fragments of rectilinear octahedral zoning resemble vicinal surfaces (Figure 3).

Figure 3.

Enlarged part of the surface of dissolved type Ib yellow cuboid diamond near L3 axis. First steps of {111} regeneration stage are shown-highly contrasting, straight “redoubt-like” inhomogeneities, visualized only in CL. The scale bar is 0.2 mm.

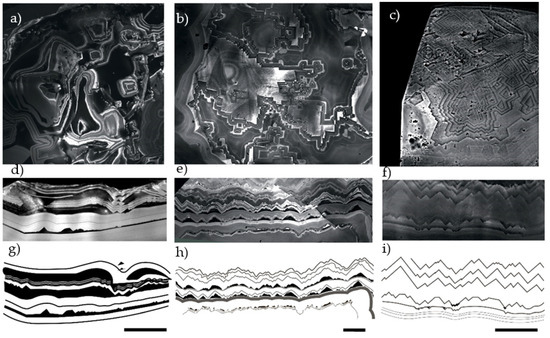

The first row in Figure 4 demonstrates the top view of diamond crystals in the <100> direction. The internal structure is visualized in the CL images and in the surface morphology. These images correspond to vertices with tetragonal depressions of mixed habit and rounded octahedral shape crystals. Figure 4a shows almost only the curvilinear zoning of the {100} sectors. It corresponds to the final stage of cuboid growth before regeneration growth. Figure 4b shows the internal structure along the surface of the diamond, in which both curvilinear (underlying) and regeneration (upper) zoning are visible. This image was obtained due to the difference in surface relief and partial dissolution/etching of the crystal. Figure 4c visualizes regeneration zoning that completely covers the underlying curved surface of the cuboid.

Figure 4.

Different options of the initial transition stage from normal to regeneration growth in rounded diamond crystals. First row (a–c): CL images of the crystal surfaces with tetragonal depressions in <100> direction; regeneration {111} zoning is clearly visualized on the dissolved crystal surface. Second row (d–f): cross-sections of the same crystals on <100> plates, orthogonal to the surfaces in the first row. Third row (g–i): a schematic view of the revealed zoning in the cross-section of the plate. The scale bar is 0.2 mm.

In cross-section of the same crystals (Figure 4, second row), this phenomenon resembles a change from curved zoning to straight zigzag one. Moreover, as shown in Figure 4d–i, this change can occur in completely different ways. The first option (Figure 4d,g) is a barely noticeable sign of octahedral steps with predominantly curved zones. The growth conditions of these zones are so close that some layers contain both normal and zigzag components; apices are replaced by rounded outlines right along the edge of the layer. Additionally, this option is observed when the layers already have stepped zigzag outlines, but the octahedral apices themselves are rounded. Additionally, the next layer does not have rounded outlines. The second option (Figure 4e,h) is the sequence of octahedral and curved zones layer by layer; the conditions constantly change, leading either to normal growth, then back to regeneration growth. The third option (Figure 4f,i) is an abrupt transition (in 1–2 layers) from normal to regeneration growth conditions and the conditions will not return to normal anymore. In all cases, the regeneration transition is almost always marked by black zones in cathodoluminescence imaging, which presumably are near nitrogen-free diamond with H3 luminescence system. These zones seem to accompany the transition from normal growth; they usually appear before the steps or simultaneously with the first zigzag octahedral layer.

3.2. Mechanisms of Diamond Formation and the Place of the Regeneration Stage in the History of Diamond Crystal Growth

On the base of the studied crystals, several variants of transition to {111} regeneration diamond growth can be distinguished. These variants differ in the predominant growth mechanism, consequently, in the type of zoning and the set of impurities. There is an additional stage of crystal habit transformation during regeneration growth.

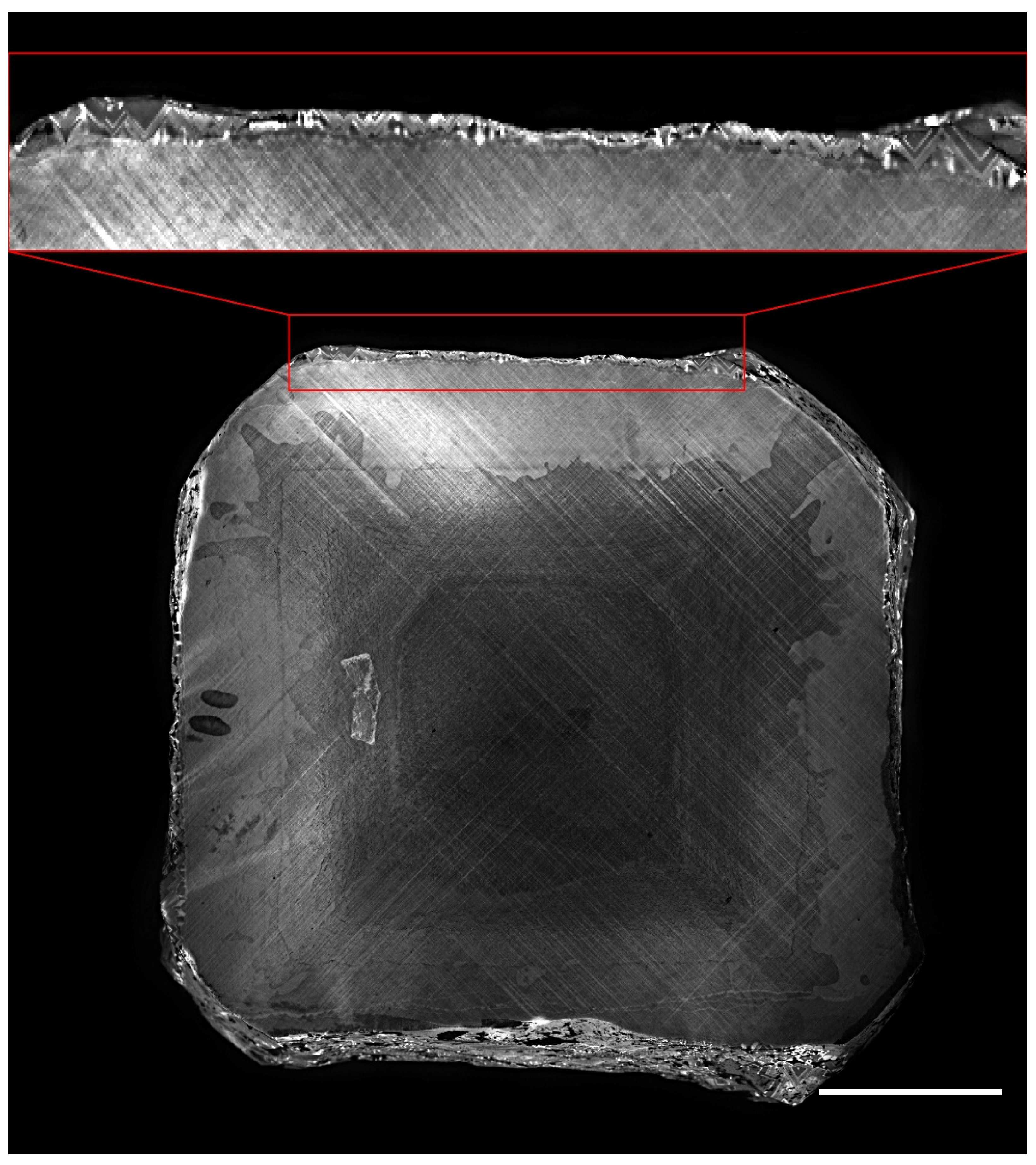

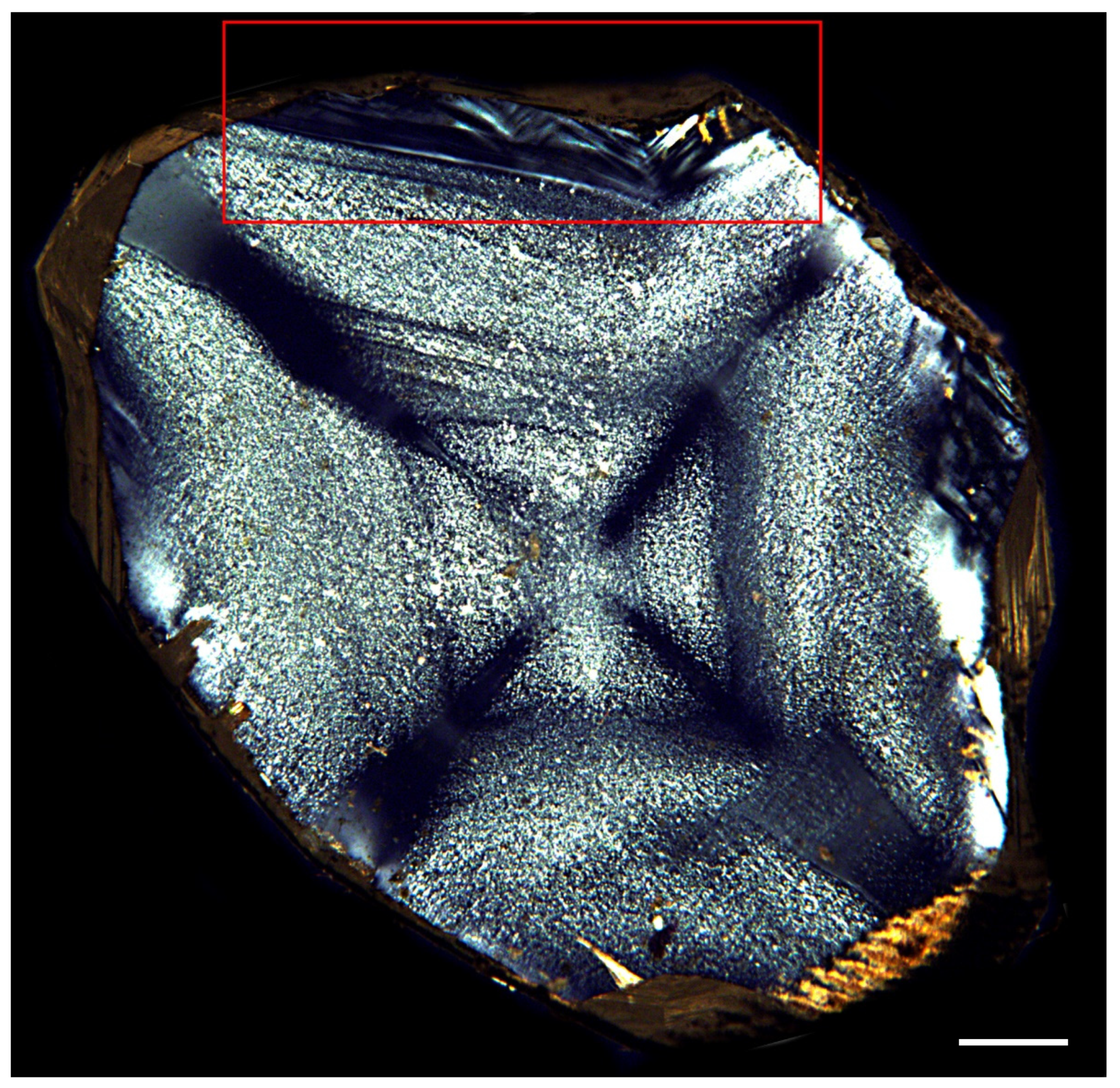

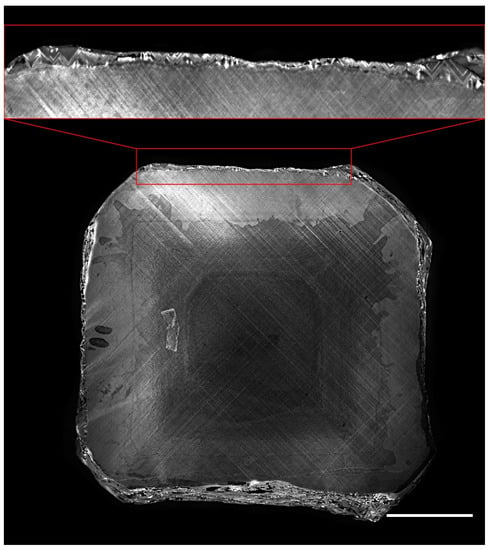

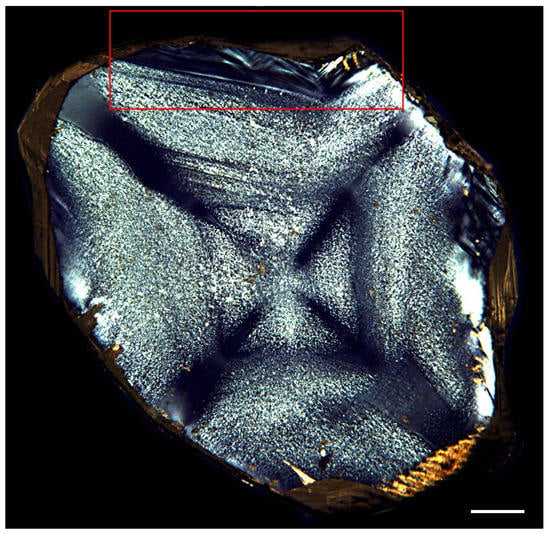

Figure 5 demonstrates the internal structure of a cuboid diamond. The curvilinear zonality of normal growth is shown and surfaces subparallel to the {100}-plane are formed. It is clearly seen on the enlarged part that the final stage of this crystal growth is represented by thin {111} regeneration apices.

Figure 5.

CL image of a plate, cut from the center of cuboid diamond in <100> direction, with internal structure of normal growth. The enlarged part (boxed in red) demonstrates the regeneration zoning in the peripheral zone of the crystal. Thin diagonal lines are {111} layers of plastic deformation, crossing the entire crystal. The scale bar is 1 mm.

Figure 6 demonstrates the internal structure of a mixed habit diamond. The plate was cut from the center of the crystal in the <100> direction. In such crystals, tangential and normal growth is realized simultaneously; both {111} and {100} growth sectors can be visualized. The curvilinear zonality of normal growth is marked by microinclusions; octahedral sectors are transparent. The red box in Figure 6 shows clearly that the final stage of this crystal growth is represented by {111} regeneration apices, free of microinclusions and visible in XPL.

Figure 6.

XPL image of a plate, cut from the center of a mixed habit diamond in the <100> direction. The regeneration zoning in the periphery of the crystal is boxed in red. The scale bar is 1 mm.

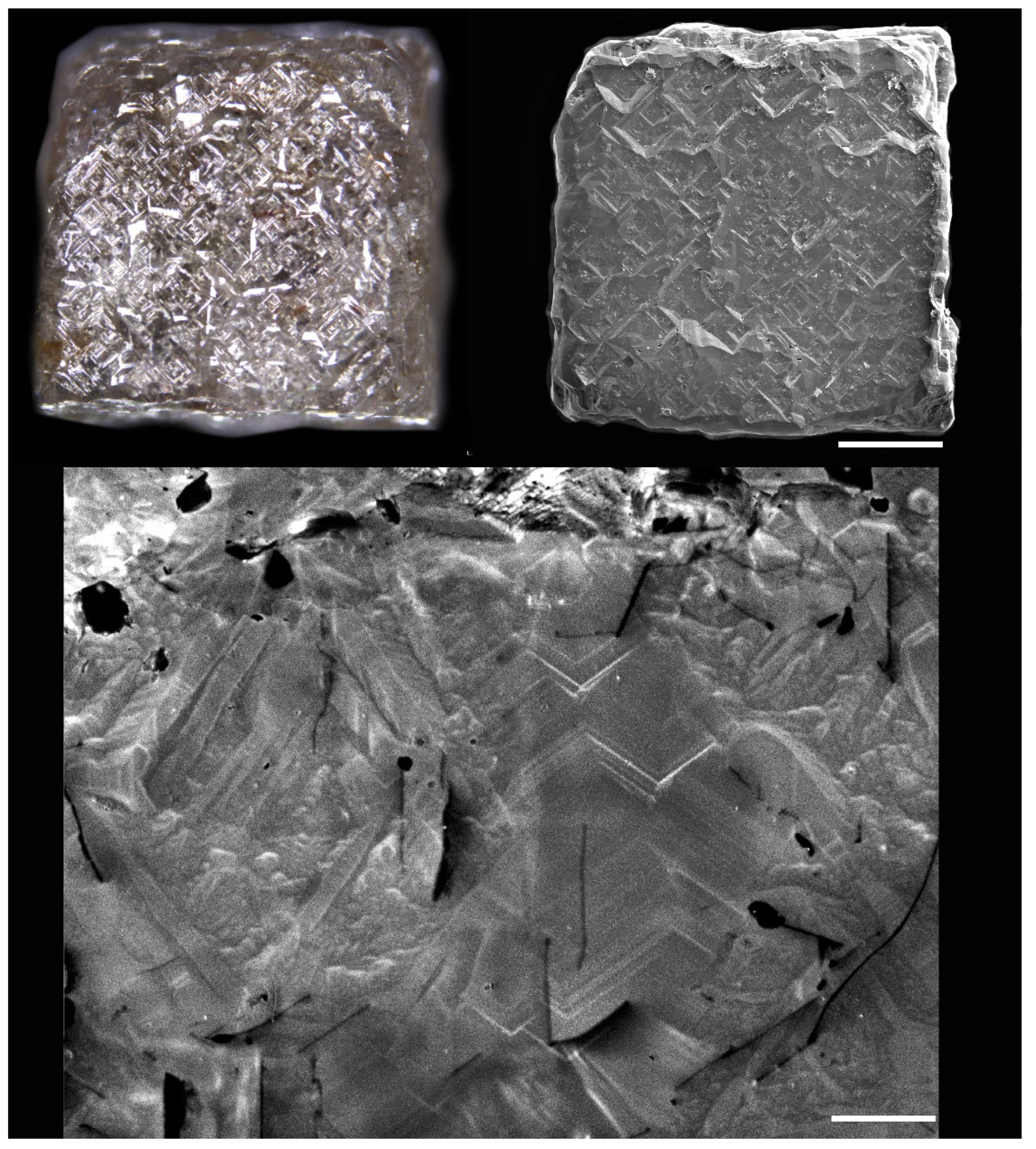

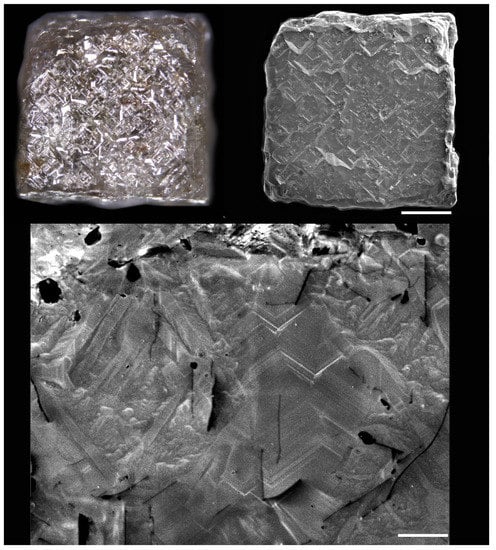

The tangential and normal growth may occur simultaneously in some cases. The first case are mixed habit diamonds. The second is the combination of normal and tangential lamellae. Simultaneous lamellae growth can be revealed in the internal structure of cubic and coated diamonds. Figure 7 shows a cubic crystal with almost no trace of dissolution. There are many tetragonal depressions on its surface. The internal structure of this crystal showed that there are many {111} lamellae. Tetragonal depressions on the crystal are formed at the points of their intersection. In this case, normal growth forms positive areas of the relief; negative forms were filled via tangential growth from existing surfaces.

Figure 7.

A cubic crystal with lamellae of tangential and normal growth in its internal structure. Top row: morphology of the crystal (OM image and SEI, the scale bar is 1 mm); bottom row: CL image of a (110) plate (the scale bar is 50 µm).

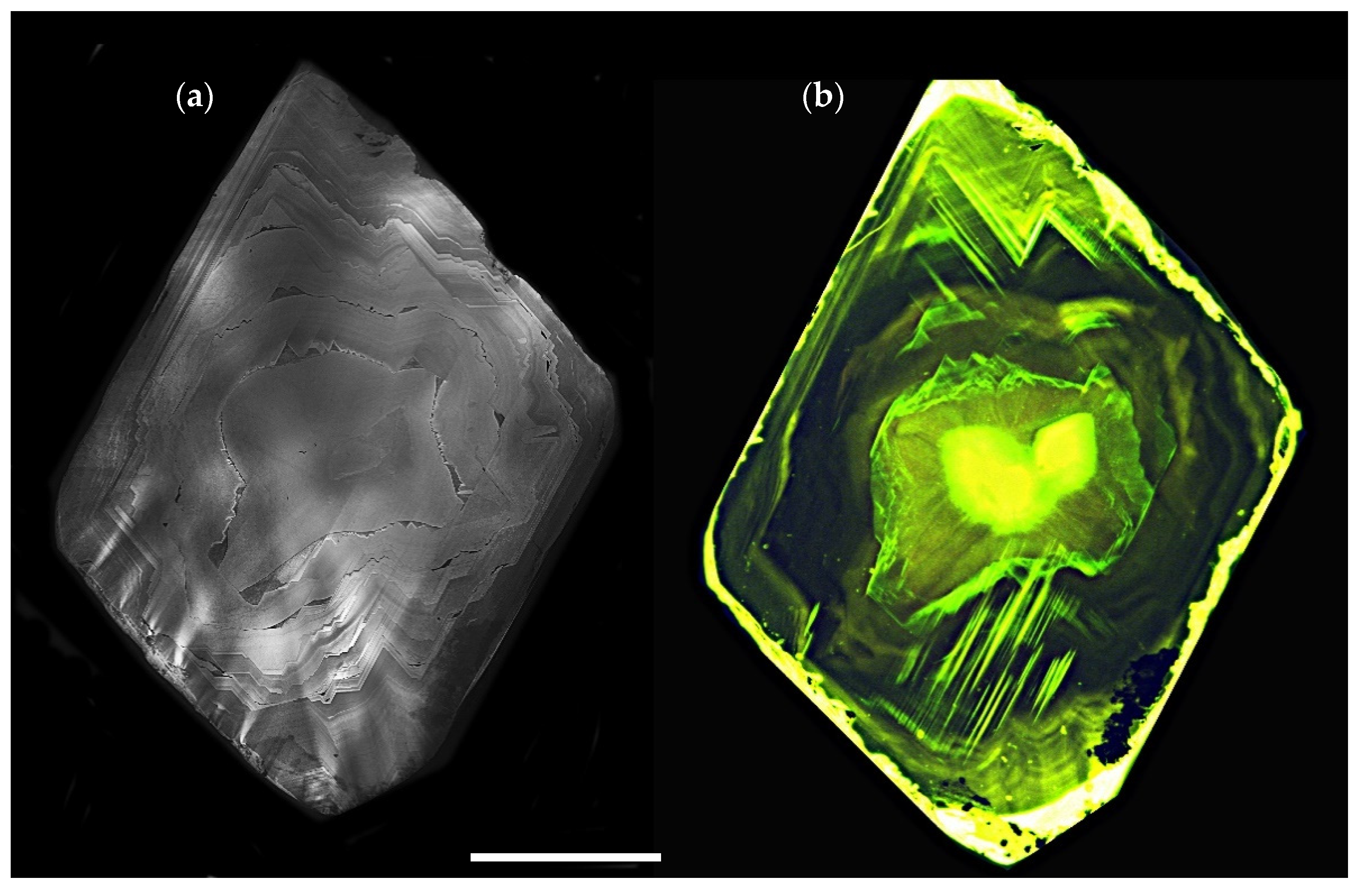

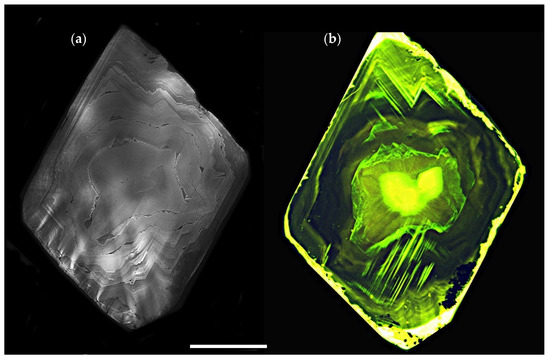

The next object of research are crystals with a large area developed by the {111} regeneration growth mechanism. Figure 8 demonstrates the internal structure of an octahedral diamond with a cuboid core. The octahedral shape of the crystal is fully created by the {111} regeneration growth. There are few transitions from the curvilinear cuboid zonality to the octahedral (regeneration). It reflects in habit transformation. The crystal was transformed from cuboid into an octahedron a few times. According to modern explanations [30], the crystal core is a fibrous cuboid, and the curved cuboid zones are formed only after the regeneration cycle. It is possible to compare the cathodoluminescence (Figure 8a) and photoluminescence (Figure 8b) images of a plate cut out from the center of this octahedral crystal in the <110> direction. The central bright core in the PL corresponds to a fibrous cuboid; its periphery is framed by bright stepped regeneration zoning. Further, the entire intermediate dark region in the PL image consists of curvilinear cuboid zoning. In some places, there are thin layers of regeneration zoning. Finally, the entire bright green region in the peripheral part of the PL image consists of regenerative octahedral zoning, which gradually passes to the rectilinear octahedral zoning of tangential growth.

Figure 8.

Internal structure of an octahedral diamond crystal after its complete transition from normal to regeneration growth (alternating between these two stages) and subsequent transition to tangential growth: (a) CL image and (b) PL image. Plate was cut from the center of the crystal in the <110> direction. The scale bar is 2 mm.

4. Discussion

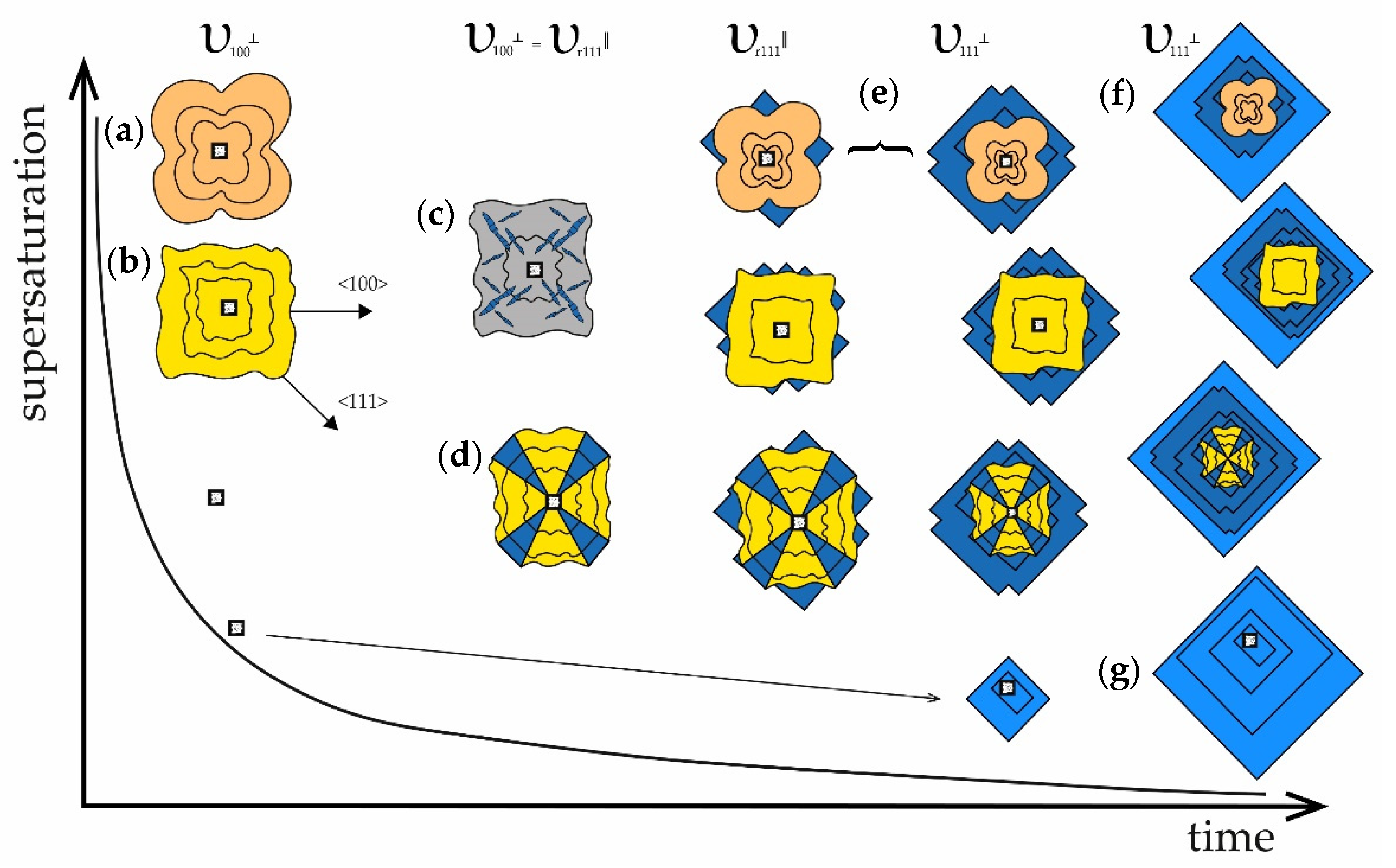

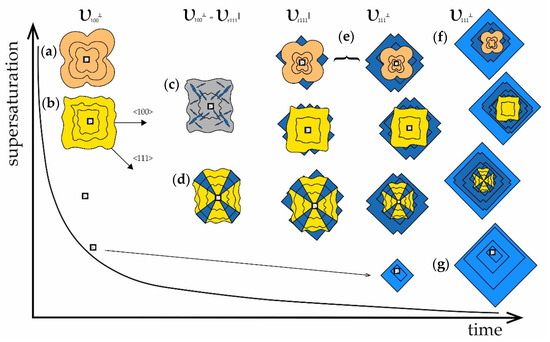

The mechanism of normal growth is the fastest; it propagates the surface preferably in the <100> direction (growth rate in normal direction υ100┴). This stage is the shortest, since it has the highest supersaturation and growth rate. Crystals can probably nucleate only at this stage [10]. Diffusion limitation should prevail here. Normal growth is divided into “fibrous” and “cuboid” growth [30]. In the studied cases, both options occur and then the regeneration behaves in the same way. Some large crystals grown under such conditions have been discovered. In some cases, such crystals formed independently, while in other cases, the small cores of octahedral diamonds were revealed.

The regeneration growth of the {111} faces is the tangential one with the rate υr111║. Regarding the range of supersaturation, regeneration growth occupies an intermediate position between the tangential and normal growth mechanisms. One of its key features is the absence of the facet nucleation stage (two-dimensional nucleation), in the case of tangential growth. Regeneration growth corresponds to the early stage of a flat-faced polyhedron formation, and stops after the formation of a convex polyhedron. Its rate in the <111> direction υr111║ is much lower than the rate of normal in the <100> direction (υr111║ << υ100┴).

However, with a decrease in supersaturation, the growth rates can be equal (υr111║ = υ100┴); in this case, crystals of mixed habit or {111} lamellar-containing crystals grow. In such crystals with “mixed” growth, the regeneration of octahedral zoning begins to develop again or for the first time, with a further decrease in the growth rate. The growth rate of this zoning, as it was mentioned, is lower than normal growth rate, and it is much higher than the tangential one. When the tangential regeneration growth continues, the crystal gradually transforms into an octahedron; a schematic diagram of this process was demonstrated by Zedgenizov et al. [18].

With a further decrease in supersaturation, the normal growth stops (υ100┴ = 0), but the change of crystal habit due to tangential growth takes place. This stage is longer than the first one, but the degree of nitrogen aggregation along the growth zones in such crystals does not change. Spectroscopic features of the regeneration stage diamond are the same as of conventional octahedrons.

When the habit transformation terminates, the growth rate is limited by two-dimensional nucleation or dislocation growth. This is the longest stage; the normal component of the growth rate (υ111┴) is several orders of magnitude less than υr111║. At this stage, the central cubic core of “cloudy” octahedral diamonds is annealed to the level of the rest of the octahedral crystal; there is enough time for the transformation of nitrogen defects A → B1. Based on the analysis of the internal structure of crystals and general models of the crystallization kinetics, it can be affirmed that υ100┴ >> υr111║ >> υ111┴. Growth rates of the above-mentioned components differ by orders of magnitude under the conditions corresponding to each mechanism.

At the new stage of diamond formation, due to the moving fluid-saturated kimberlite melt [31] and an increase in carbon supersaturation, the coat on diamonds grew by the normal mechanism, along with regeneration filling of cavities of the growing surface. V. Beskrovanov identified this stage as a regression stage, but with regard to the dominant growth mechanism, it corresponds to the stages I–II of the next crystallogenesis cycle [10]. Coated diamonds are rare; this fact can be explained by the local character of the fluid melt flow where the coat grows.

In general, the morphology and habit of the crystal can change significantly depending on the duration of the growth stages by normal and tangential mechanisms, as well as the dissolution and subsequent regeneration stages. When crystals with polycentric growth dissolve, their surface can become more complex, since etch pits are overlaid on the growth relief. Thus, the complex morphology of diamonds is often associated with the change of crystal habit during regeneration growth. The high rate of regeneration growth allows all crystals of a cubic or mixed habit (crystals of initial steps of crystallogenesis) to pass through the stage of habit transformation.

Figure 9 summarizes the results and presents the final schematic diagram (upgraded and updated from [10]) of the diamond formation process. The diagram is based on the main mechanisms of diamond growth and takes into account the most important regeneration stage. It is remarkable that all the stages of this diagram are completely reversible and interchangeable. One crystal can be pure cuboid all the way to the rim. Another crystal can reach a flat-faced octahedral morphology, having moved all the way from the fibrous core, or it can grow by a tangential mechanism almost immediately. Additionally, after going through all these options, the crystal can return to the beginning or achieve any of the stages for the first time. Additionally, it can grow with a constant alternation of only two stages, for example. That is, in the process of diamond crystal growth, there are hardly any separate reservoirs for the growth of only cuboids or only flat-faced crystals. Additionally, it is also unlikely that in most cases, there is depth zoning for the formation of a particular crystal type in the mantle.

Figure 9.

Scheme of evolution of diamond crystal morphology and internal structure in one crystallogenesis cycle (upgraded from [10]) due to a change in the dominant growth mechanism: (a) normal mechanism, concentric zoning; (b) normal mechanism, wavy zoning; (c) (111) growth of lamellar cubic crystals; (d) simultaneous growth by normal and tangential mechanisms; (e) change of crystal habit during regeneration growth; (f,g) tangential growth. The nucleation of crystals is possible only at the stages (a,b). The images are arranged according to the black graph line. The components of the growth rate that determine the crystal shape are shown.

A number of works [32,33,34,35] described octahedral crystals with a central core consisting of a “fibrous” cuboid. The general feature of such crystals is that, after the formation of fibrous cube, the stage of regeneration with {111} apices begins and continues almost until the end of crystal growth. Such crystals are not rare. Rondeau et al. [33] proposed three models of formation of such crystals: (1) the fibrous diamond grows fast in a medium with a high driving force, then the crystal is moved and the fibrous cuboid serves as a seed for the growth of an octahedron; (2) fibrous growth during the first stage of the rise of kimberlite, which stopped in the upper mantle (in the diamond stability field), then the crystal stays under these conditions and grows by tangential mechanism, and then it is moved to the surface; (3) the crystal grows in a reservoir with a high driving force, which gradually decreases, and at the critical point, transitions to tangential growth-ascending kimberlite melt before eruption onto the surface. A crystal that passes through all the stages from the schematic diagram (Figure 9) is shown in Figure 8. It hardly fits these three interesting hypotheses. The third option seems to be the most possible. The stages from diagram may alternate in different sequences. If the fluctuations of the growth conditions are so weak that the growth mechanism can change almost for each new layer, then there is no significant difference in the dependence of the crystal growth pathway on its internal structure.

Most likely, the vast majority of diamond crystals stay in the close conditions and depths. The difference is that during their crystallization from the melt, there is irregular supply of material, irregular composition, location and orientation of the seed in the volume of the medium. There is also uneven supersaturation in the volume of the growth medium, uneven temperature and pressure distribution in different parts of crystallization volume, and irregular chemical composition of the medium. Therefore, crystals with completely different morphology and properties can grow within one hypothetic chamber or vein. However, their further way to the surface may differ significantly (growth rate, time, temperatures, etc.). In this case, the formation of annealing-driven and many other types of defect-impurity centers occur. It seems that initially there were not so many of them. Then, the “natural treatment” occurred. Another argument to support this position is the advancements in synthetic diamond manufacturing technology. It is possible to reproduce the morphology of crystals, to produce more than half of defect-impurity centers in diamond crystals, to anneal and improve the quality of crystals in laboratories. These achievements are possible due to the ability to vary the growth process parameters, temperature, pressure and growth medium composition inside a growth cell up to 8 cm in diameter.

Regeneration growth and formation of growth-related tetragonal depressions is confirmed by experiments on growing synthetic diamond crystals by a high-temperature high-pressure gradient method in the Fe3N–C system [36], S–C system [37], and Fe5Ni4S8–C system [38]. In the Fe3N–C system at a pressure of 7 GPa, a temperature of 1650 °C and synthesis time of 20 h, the regeneration growth of {111} faces on cubo-octahedral seed crystals was observed with the habit change into an octahedron, and its vertices were formed by growth-related tetragonal depressions. In the S–C system at pressures 6.3–7.5 GPa, temperatures 1700–2000 °C and synthesis time of 9–40 h, the regeneration growth of {111} faces in the <100> direction, forming tetragonal depressions, was also observed on diamond crystals. During the interaction of pentlandite melt and carbon at the P–T parameters of 7 GPa and 1550–1800 °C, {111} regeneration surfaces developed on the {100} faces of diamond seed crystals. Therefore, diamond regeneration processes are common in Fe–S melts at the parameters close to 7 GPa and 1700 °C. Moreover, a complete regeneration of crystals does not take long (from 10 to 40 h), which once again confirms a high growth rate.

Diamond synthesis by the chemical vapor deposition (CVD) technique also reveals the formation of regeneration layers and tetragonal depressions. This occurs under certain conditions when the synthesis temperature is increased [39]. Tallaire et al. grew CVD layers in the <100> direction. At temperatures above 900 °C, a typical stepped structure of the crystal surface (with tetragonal depressions) was observed (T = 920 °C, growth rate 7 μm/h). Under the same conditions and at rather low temperature, the surface remained smooth (870 °C, 6 μm/h). It should be noted that, in general, the process of CVD growth of diamond crystals on a substrate is similar to the described phenomenon of regeneration growth. For the preparation of the substrate, its surface is deviated from the singular face and then etched to form an atomic scale stepped surface [40]. Under these conditions, carbon atoms will settle on the steps and the growth of a singular crystal face by layer-by-layer tangential mechanism takes place.

Synthetic diamond crystals grow by tangential mechanism; however, the morphology of the crystals may reveal various simple forms. It takes from 10 to 12 days to grow large (up to 20 ct) nitrogen-free and dislocation-free synthetic crystals. Synthetic diamonds rarely grow via the normal mechanism [41,42], because the parameters and medium are specially selected to provide fast and high-quality growth.

Therefore, based on growth experiments and theoretical background, it is fair to say that the formation of natural cuboids and mixed-habit crystals was very fast. In some cases, only minor part of crystals reached the stage of flat faces growth. The formation of flat-faceted octahedrons was the only relatively long stage of diamond growth. Subsequently, there were some differences in the conditions of mantle residence of the crystals: cuboids were not exposed to prolonged annealing, while mixed-habit and octahedral crystals (flat-faced and regenerated ones) could be exposed to prolonged annealing in the mantle. Moreover, there is a number of deposits with only flat-faced crystals without signs of normal growth in the internal structure. It apparently had specific conditions with initial slower growth rate.

5. Conclusions

Regeneration growth is a very important stage in diamond crystallogenesis. Diamond crystals may grow up to 50% by {111} regeneration layers. Such octahedral layers often determine the morphology of crystals; they are clearly visualized in the internal structure. The regeneration growth of {111} faces is realized between the stages of normal growth and tangential growth. It causes a change in the habit forms of diamond crystals and is responsible for the diversity of their morphology.

Author Contributions

Writing—original draft preparation, sample preparation, and PL visualization, I.V.K.; conceptualization, editing, and provision of samples, E.A.V.; CL visualization, A.V.A. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully acknowledge the financial support from the Russian Science Foundation, grant number 21-77-20026.

Acknowledgments

The authors are appreciative to Oded Navon for detailed and constructive review, that helped to significantly improve this manuscript. The authors are also very grateful to Kolyadin A.V. and Aneli I.D. for their comprehensive assistance in research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Fersman, A. Crystallography of Diamond; Izd-vo AN SSSR: Moscow, Russia, 1955; p. 566. (In Russian) [Google Scholar]

- Orlov, Y. The Mineralogy of the Diamond; John Wiley and Sons: New York, NY, USA, 1977; p. 235. [Google Scholar]

- Kukharenko, A. Diamonds of the Urals; Gosgeolizdat: Moscow, Russia, 1955; p. 515. (In Russian) [Google Scholar]

- Bartoshinskii, Z.; Kvasnitsa, V. Crystal Morphology of Kimberlite Diamonds; Naukova Dumka: Kiev, Ukraine, 1991. (In Russian) [Google Scholar]

- Pavlushin, A.; Zedgenizov, D.; Vasil’ev, E.; Kuper, K. Morphology and Genesis of Ballas and Ballas Like Diamonds. Crystals 2021, 11, 17. [Google Scholar] [CrossRef]

- Varshavsky, A. Anomalous Birefringence and Internal Morphology of Diamond; Nauka Publishing House: Moscow, Russia, 1968; p. 92. (In Russian) [Google Scholar]

- Rondeau, B.; Fritsch, E.; Guiraud, M.; Chalain, J.-P.; Notari, F. Three historical ‘asteriated’ hydrogen-rich diamonds: Growth history and sector-dependent impurity incorporation. Diam. Relat. Mater 2004, 13, 1658–1673. [Google Scholar] [CrossRef]

- Bulanova, G.; Smith, C.; Kohn, S.; Speich, L. Natural diamond growth conditions recorded by their internal structures. In Proceedings of the 11th International Kimberlite Conference Extended Abstract, Gaborone, Botswana, 18–22 September 2017. No. 11 IKC-4523. [Google Scholar]

- Kaminsky, F.; Khachatryan, G. The relationship between the distribution of nitrogen impurity centers in diamond crystals and their internal structure and mechanism of growth. Lithos 2004, 77, 255–271. [Google Scholar] [CrossRef]

- Beskrovanov, V. The Diamond Ontogeny; Nauka: Novosibirsk, Russia, 2000; p. 165. (In Russian) [Google Scholar]

- Sunagawa, I. Growth and morphology of diamond crystals under stable and metastable conditions. J. Cryst. Growth 1990, 99, 1156–1161. [Google Scholar] [CrossRef]

- Krasnova, N.; Petrov, T. Genesis of Mineral Individuals and Aggregates; Nevsky Courier Press: St. Petersburg, Russia, 1995; p. 228. (In Russian) [Google Scholar]

- Askhabov, A. Regeneration of Crystals; Nauka: Leningrad, Russia, 1979. (In Russian) [Google Scholar]

- Petrov, T.; Treivus, E.; Punin, Y.; Kasatkin, A. Crystal Growing from Solutions; Nedra: Leningrad, Russia, 1983; p. 200. (In Russian) [Google Scholar]

- Genshaft, Y.; Yakubova, S.; Volkova, L. Internal morphology of natural diamonds. In Investigation of High-Pressure Minerals; Genshaft, Y.S., Ed.; Publishing House of the Institute of Physics of the Earth: Moscow, Russia, 1977; pp. 5–131. (In Russian) [Google Scholar]

- Smirnova, Y. Internal Structure and Distribution of Carbon Isotopes in Natural Diamonds with Inclusions of Ultrabasic and Eclogite Paragenesis; Moscow, Russia, 1995; p. 27, (In Russian) . Available online: https://earthpapers.net/vnutrennee-stroenie-i-raspredelenie-izotopov-ugleroda-v-prirodnyh-almazah-s-vklyucheniyami-ultraosnovnogo-i-eklogitovogo (accessed on 11 December 2021).

- Mironov, V. Diamonds; ES-TE Press: Moscow, Russia, 2001; p. 97. (In Russian) [Google Scholar]

- Zedgenizov, D.; Harte, B.; Shatsky, V.S.; Politov, a.; Rylov, G.; Sobolev, N. Directional chemical variations in diamonds showing octahedral following cuboid growth. Contrib. Mineral. Petrol. 2006, 151, 45–57. [Google Scholar] [CrossRef]

- Moore, M.; Lang, A. On the origin of the rounded dodecahedral habit of natural Diamond. J. Cryst. Growth 1974, 26, 133–139. [Google Scholar] [CrossRef]

- Khokhryakov, A. Experimental study of the formation of rounded diamond crystals. Exp. Geosci. 2000, 9, 134–135. [Google Scholar]

- Khokhryakov, A.; Pal’yanov, Y. The evolution of diamond morphology in the process of dissolution: Experimental data. Amer. Miner 2007, 92, 909–917. [Google Scholar] [CrossRef]

- Rakin, V. Morphology of Ural-Type Diamonds; RIO UrO RAN: Yekaterinburg, Russia, 2013. (In Russian) [Google Scholar]

- Pandya, N.S.; Tolansky, S. The etching of diamond. Proc. R. Soc. L. 1954, A225, 40–48. [Google Scholar]

- Khokhryakov, A.; Nechaev, D.; Palyanov, Y.; Kuper, K. The dislocation structure of diamond crystals grown on seeds in the Mg-C system. Diamond Relat. Mater. 2016, 70, 1. [Google Scholar] [CrossRef]

- Fedortchouk, Y.; Canil, D.; Semenets, E. Mechanisms of diamond oxidation and their bearing on the fluid composition in kimberlite magmas. Am. Mineral. 2007, 92, 1200–1212. [Google Scholar] [CrossRef]

- Fedortchouk, Y.; Canil, D. Diamond oxidation at atmospheric pressure: Development of surface features and the effect of oxygen fugacity. Eur. J. Mineral 2009, 21, 623–635. [Google Scholar] [CrossRef]

- Sonin, V.; Zhimulev, E.; Chepurov, A.; Pomazanskiy, B.; Afanasiev, V.; Chepurov, A. Incipient stages of transformation of round natural diamonds under dissolution in Fe-S melt at high pressure. Litosfera 2019, 19, 945–952. [Google Scholar] [CrossRef]

- Klepikov, I.; Vasilev, E.; Antonov, A. Growth Nature of Negative Relief Forms of Diamonds from Ural Placer Deposits. Crystallogr. Rep. 2020, 65, 300–306. [Google Scholar] [CrossRef]

- Mironov, V. Pyramids <001> and <011> in natural diamond. AIP Conf. Proc. 2019, 2069, 40006. [Google Scholar]

- Moore, M.; Lang, A. On the internal structure of natural diamonds of cubic habit. Philos. Mag. 1972, 26, 1313–1325. [Google Scholar] [CrossRef]

- Navon, O.; Hutcheon, I.; Rossman, G.; Wasserburg, G. Mantle-derived fluids in diamond micro-inclusions. Nature 1988, 335, 784–789. [Google Scholar] [CrossRef]

- Izraeli, E.; Harris, J.; Navon, O. Brine inclusions in diamonds: A new upper mantle fluid. Earth Planet. Sci. Lett. 2001, 187, 323–332. [Google Scholar] [CrossRef]

- Rondeau, B.; Fritsch, E.; Moore, M.; Thomassot, E.; Sirakiane, J.-F. On the growth of natural octahedral diamond upon a fibrous core. J. Cryst. Growth 2007, 287–293. [Google Scholar] [CrossRef]

- Skuzovatov, S.; Zedgenizov, D.; Shatsky, V.; Ragozin, A.; Kuper, K. Composition of cloudy microinclusions in octahedral diamonds from the Internatsional’naya kimberlite pipe (Yakutia). Russ. Geol. Geophys. 2011, 52, 85–96. [Google Scholar] [CrossRef]

- Skuzovatov, S.; Zedgenizov, D.; Howell, D.; Griffin, W. Various growth environments of cloudy diamonds from the Malobotuobia kimberlite field (Siberian craton). Lithos 2016, 265, 96–107. [Google Scholar] [CrossRef]

- Borzdov, Y.; Pal’yanov, Y.; Kupriyanov, I.; Gusev, V.; Khokhryakov, A.; Sokol, A.; Efremov, A. HPHT synthesis of diamond with high nitrogen content from an Fe3N–C system. Diam. Relat. Mater. 2002, 11, 1863–1870. [Google Scholar] [CrossRef]

- Palyanov, Y.; Kupriyanov, I.; Borzdov, Y.; Sokol, A.; Khokhryakov, A. Diamond Crystallization from a Sulfur-Carbon System at HPHT Conditions. Cryst. Growth Des. 2009, 9, 2922–2926. [Google Scholar] [CrossRef]

- Palyanov, Y.; Borzdov, Y.; Ovchinnikov, I.; Sobolev, N. Experimental Study of the Interaction between Pentlandite Melt and Carbon at Mantle PT Parameters: Condition of Diamond and Graphite Crystallization. Dokl. Earth Sci. 2003, 392, 1026–1029. [Google Scholar]

- Tallaire, A.; Achard, J.; Silva, F.; Brinza, O.; Gicquel, A. Growth of large size diamond single crystals by plasma assisted chemical vapour deposition: Recent achievements and remaining challenges. C. R. Phys. 2013, 14, 169–184. [Google Scholar] [CrossRef]

- Yang, N. Novel Aspects of Diamond: From Growth to Applications; Springer: Cham, Switzerland, 2019; p. 507. [Google Scholar]

- Bureau, H.; Langenhorst, F.; Auzende, A.-L.; Frost, D.; Estève, I.; Siebert, J. The growth of fibrous, cloudy and polycrystalline diamonds. Geochim. Cosmochim. Acta 2012, 77, 202–214. [Google Scholar] [CrossRef]

- Bulienkov, N.; Zheligovskaya, E.; Blaut-Blachev, A. Natural and Synthetic Diamond Crystals of Fibrous and Rough-Lamellar Structure and Structural Mechanism of Their Normal Growth. Nanotechnol. Russ. 2016, 11, 377–386. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).