Production of High-Quality Coarse Recycled Aggregates through a Two-Stage Jigging Process

Abstract

:1. Introduction

2. Materials and Methods

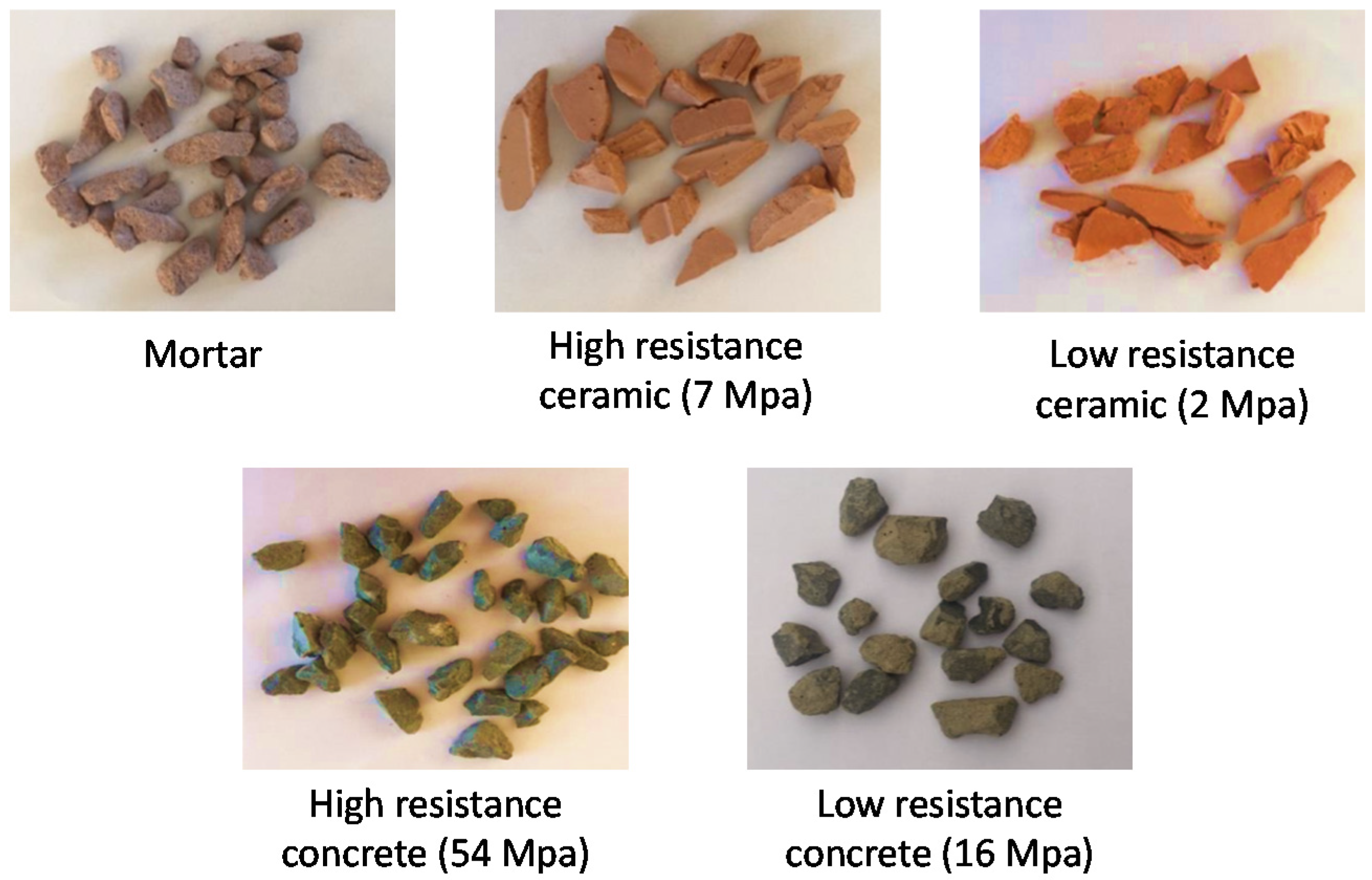

2.1. Samples Preparation

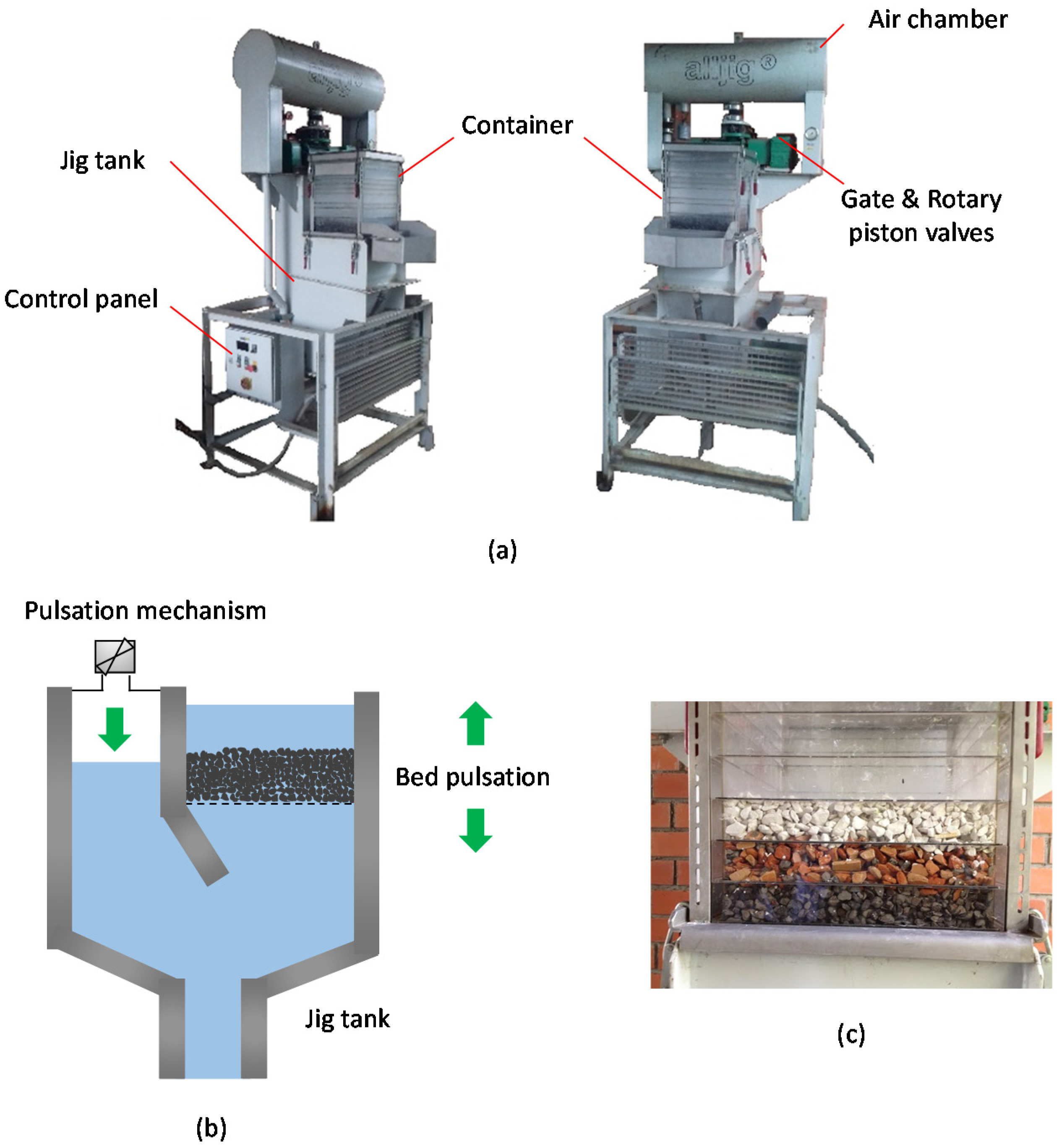

2.2. Jigging Equipment

2.3. Tests Procedure

2.4. Characterization and Analysis

3. Results and Discussion

3.1. Separation Process

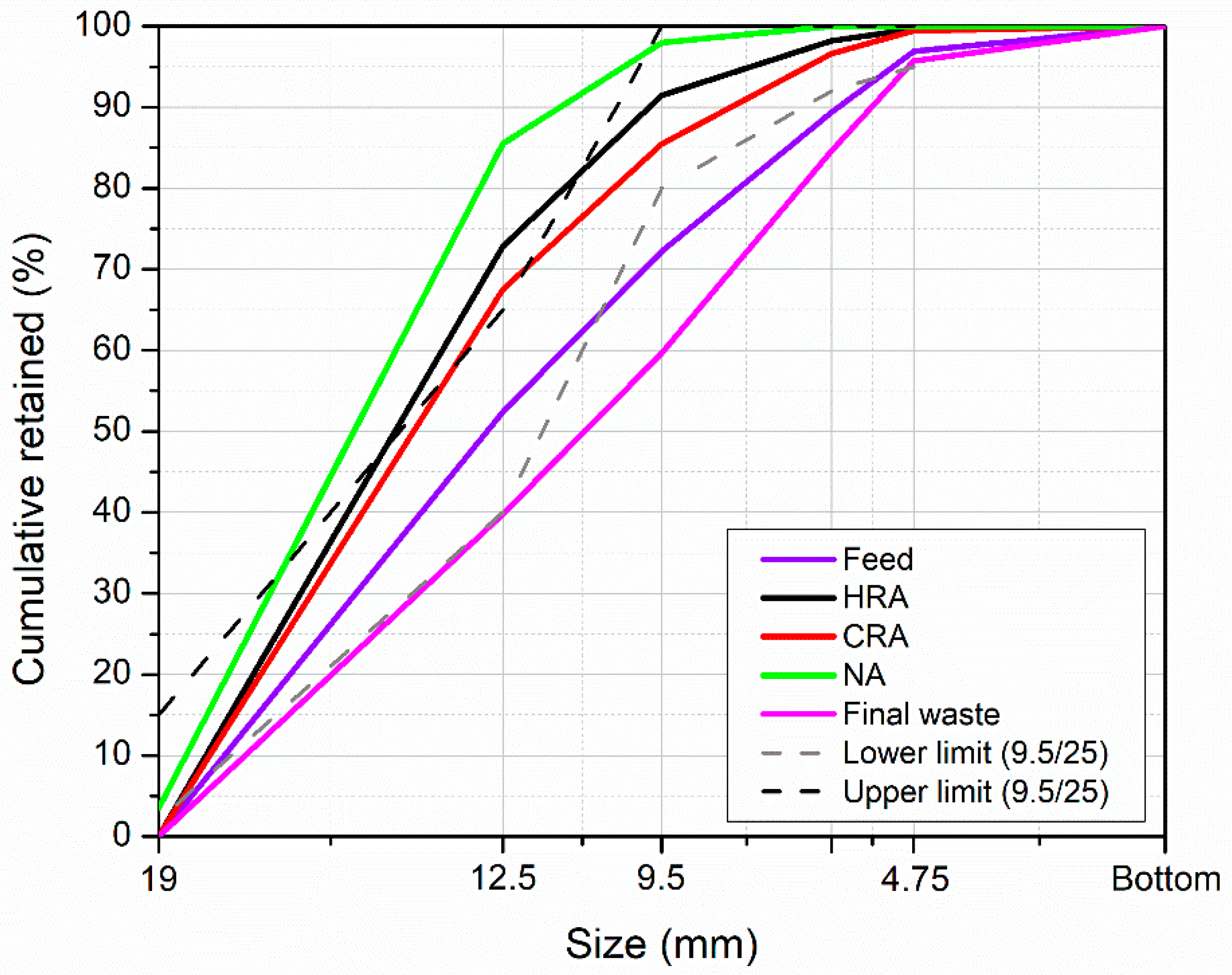

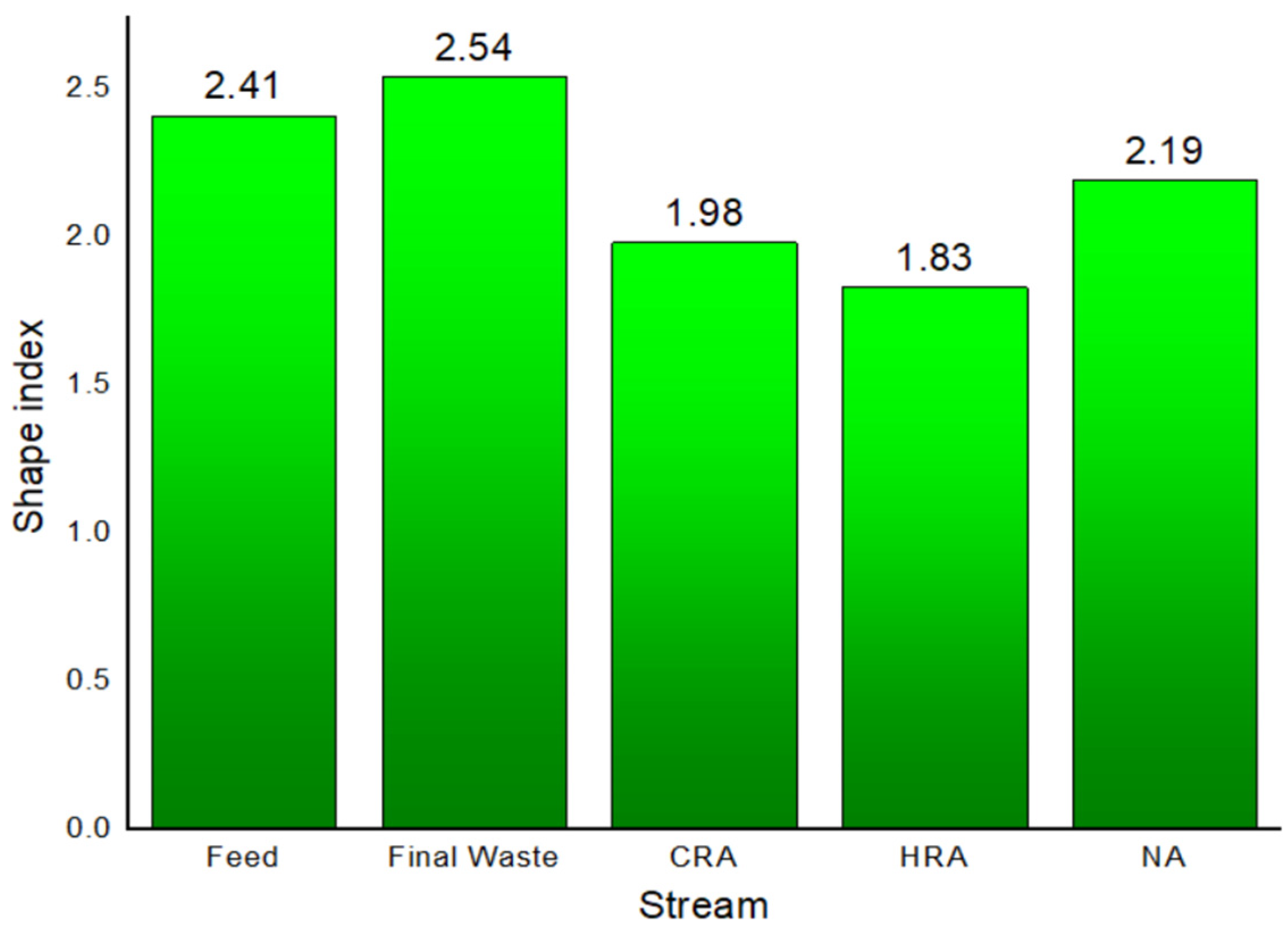

3.2. Properties of Aggregates: Size, Density, and Shape

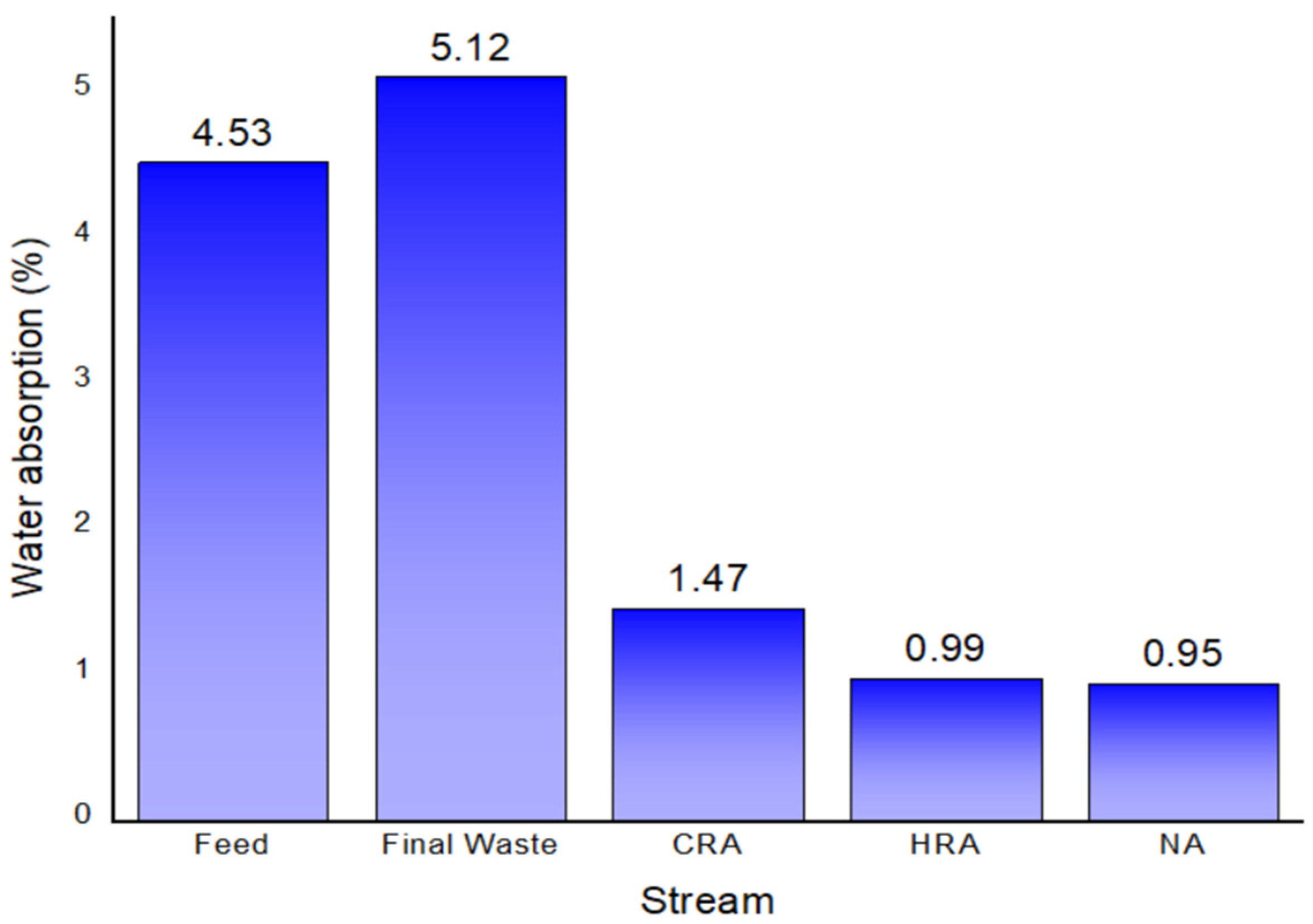

3.3. Water Absorption

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Menegaki, M.; Damigos, D. A review on current situation and challenges of construction and demolition waste management. Curr. Opin. Green Sustain. Chem. 2018, 13, 8–15. [Google Scholar] [CrossRef]

- Reis, G.S.d.; Quattrone, M.; Ambrós, W.M.; Grigore Cazacliu, B.; Hoffmann Sampaio, C. Current applications of recycled aggregates from construction and demolition: A review. Materials 2021, 14, 1700. [Google Scholar] [CrossRef] [PubMed]

- Alexandridou, C.; Angelopoulos, G.N.; Coutelieris, F.A. Mechanical and durability performance of concrete produced with recycled aggregates from Greek construction and demolition waste plants. J. Clean. Prod. 2018, 176, 745–757. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.; Minocha, A.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete–A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar]

- Butler, L.; West, J.S.; Tighe, S.L. Effect of recycled concrete aggregate properties on mixture proportions of structural concrete. Transp. Res. Rec. 2012, 2290, 105–114. [Google Scholar] [CrossRef]

- Jimenez, J.R.; Ayuso, J.; Agrela, F.; López, M.; Galvín, A.P. Utilisation of unbound recycled aggregates from selected CDW in unpaved rural roads. Resour. Conserv. Recycl. 2012, 58, 88–97. [Google Scholar] [CrossRef]

- Coelho, A.; De Brito, J. Preparation of concrete aggregates from construction and demolition waste (CDW). In Handbook of Recycled Concrete and Demolition Waste; Elsevier: Amsterdam, The Netherlands, 2013; pp. 210–245. [Google Scholar]

- Neto, R.O.; Gastineau, P.; Cazacliu, B.G.; Le Guen, L.; Paranhos, R.S.; Petter, C.O. An economic analysis of the processing technologies in CDW recycling platforms. Waste Manag. 2017, 60, 277–289. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ambrós, W.M. Jigging: A review of fundamentals and future directions. Minerals 2020, 10, 998. [Google Scholar] [CrossRef]

- Ambros, W.M.; Sampaio, C.H.; Cazacliu, B.G.; Miltzarek, G.L.; Miranda, L.R. Usage of air jigging for multi-component separation of construction and demolition waste. Waste Manag. 2017, 60, 75–83. [Google Scholar] [CrossRef] [PubMed]

- Cazacliu, B.; Sampaio, C.H.; Miltzarek, G.; Petter, C.; Le Guen, L.; Paranhos, R.; Huchet, F.; Kirchheim, A.P. The potential of using air jigging to sort recycled aggregates. J. Clean. Prod. 2014, 66, 46–53. [Google Scholar] [CrossRef] [Green Version]

- Sampaio, C.H.; Cazacliu, B.G.; Miltzarek, G.L.; Huchet, F.; Le Guen, L.; Petter, C.O.; Paranhos, R.; Ambrós, W.M.; Oliveira, M.L.S. Stratification in air jigs of concrete/brick/gypsum particles. Constr. Build. Mater. 2016, 109, 63–72. [Google Scholar] [CrossRef]

- Ambrós, W.M.; Sampaio, C.H.; Cazacliu, B.G.; Conceição, P.N.; dos Reis, G.S. Some observations on the influence of particle size and size distribution on stratification in pneumatic jigs. Powder Technol. 2019, 342, 594–606. [Google Scholar] [CrossRef]

- Ambrós, W.M.; Cazacliu, B.G.; Sampaio, C.H. Wall effects on particle separation in air jigs. Powder Technol. 2016, 301, 369–378. [Google Scholar] [CrossRef]

- Mefteh, H.; Kebaïli, O.; Oucief, H.; Berredjem, L.; Arabi, N. Influence of moisture conditioning of recycled aggregates on the properties of fresh and hardened concrete. J. Clean. Prod. 2013, 54, 282–288. [Google Scholar] [CrossRef]

- Taggart, A.F. Handbook of Mineral Dressing; Wiley: Hoboken, NJ, USA, 1945; Volume 1. [Google Scholar]

- Jungmann, A. Building rubble treatment using the alljig in Europe and USA. Aufbereitungstechnik 1997, 38, 543–549. [Google Scholar]

- Xing, W. Quality Improvement of Granular Secondary Raw Building Materials by Separation and Cleansing Techniques. 2004. Available online: https://www.elibrary.ru/item.asp?id=8860917 (accessed on 30 September 2013).

- Peticila, M.; Young, A.; Cazacliu, B.; Sampaio, C.; Veras, M.; Petter, C. Improving the characteristics of recycled aggregates by using mineral processing equipment: Water jig and sensor based sorting. In Proceedings of the 5th International Conference on Sustainable Solid Waste Management, Athens, Greece, 21–24 June 2017. [Google Scholar]

- Khoury, E.; Ambrós, W.; Cazacliu, B.; Sampaio, C.H.; Remond, S. Heterogeneity of recycled concrete aggregates, an intrinsic variability. Constr. Build. Mater. 2018, 175, 705–713. [Google Scholar] [CrossRef]

- Waskow, R.P.; Santos, V.L.G.d.; Tubino, R.M.C. Delineamento amostral de agregados de construção e demolição. Mix Sustentável 2019, 5, 79–88. [Google Scholar] [CrossRef] [Green Version]

- Lyman, G. Review of jigging principles and control. Coal Prep. 1992, 11, 145–165. [Google Scholar] [CrossRef]

- Sampaio, C.H.; Tavares, L.M.M. Beneficiamento Gravimétrico: Uma Introdução aos Processos de Concentração Mineral e Reciclagem de Materiais por Densidade; Editora da UFRGS: Porto Alegre, Brazil, 2005. [Google Scholar]

- Wills, B.A.; Finch, J.A. Wills’ Mineral Processing Technology: An Introduction to the Practical Aspects of ore Treatment and Mineral Recovery; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Waskow, R.P.; Dos Santos, V.L.; Ambrós, W.M.; Sampaio, C.H.; Passuello, A.; Tubino, R.M. Optimization and dust emissions analysis of the air jigging technology applied to the recycling of construction and demolition waste. J. Environ. Manag. 2020, 266, 110614. [Google Scholar] [CrossRef] [PubMed]

- Tam, V.W.; Gao, X.; Tam, C.M.; Chan, C. New approach in measuring water absorption of recycled aggregates. Constr. Build. Mater. 2008, 22, 364–369. [Google Scholar] [CrossRef] [Green Version]

- Leite, M. Evaluation of the Mechanical Properties of Concrete Made with Recycled Aggregates from Construction and Demolition Waste. Federal University of Rio Grande do Sul Porto Alegre 2001. Available online: http://hdl.handle.net/10183/21839 (accessed on 5 March 2022).

- Hoffmann Sampaio, C.; Cazacliu, B.G.; Ambrós, W.M.; Kronbauer, M.A.; Tubino, R.; Dal Molin, D.C.; Oliva Moncunill, J.; Miltzarek, G.L.; Waskow, R.P.; Dos Santos, V.L. Characterization of demolished concretes with three different strengths for recycling as coarse aggregate. Minerals 2021, 11, 803. [Google Scholar] [CrossRef]

- Meddah, M.S.; Zitouni, S.; Belâabes, S. Effect of content and particle size distribution of coarse aggregate on the compressive strength of concrete. Constr. Build. Mater. 2010, 24, 505–512. [Google Scholar] [CrossRef]

- Neville, A.M. Propriedades do concreto-5a Edição; Bookman Editora: Sao Paulo, Brasil, 2015. [Google Scholar]

- De Brito, J.; Robles, R. Methodology for the prediction of concrete with recycled aggregates properties. In Proceedings of the International Conference on Excellence in Concrete Construction through Innovation, London, UK, 9–10 September 2008; pp. 477–488. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concreto: Microestrutura, Propriedades e Materiais; Ibracon: Recife-PE, Brazil, 2008. [Google Scholar]

- Bai, G.; Zhu, C.; Liu, C.; Liu, B. An evaluation of the recycled aggregate characteristics and the recycled aggregate concrete mechanical properties. Constr. Build. Mater. 2020, 240, 117978. [Google Scholar] [CrossRef]

- Omary, S.; Ghorbel, E.; Wardeh, G. Relationships between recycled concrete aggregates characteristics and recycled aggregates concretes properties. Constr. Build. Mater. 2016, 108, 163–174. [Google Scholar] [CrossRef]

- Barbudo, A.; De Brito, J.; Evangelista, L.; Bravo, M.; Agrela, F. Influence of water-reducing admixtures on the mechanical performance of recycled concrete. J. Clean. Prod. 2013, 59, 93–98. [Google Scholar] [CrossRef]

- Khoury, E.; Cazacliu, B.; Remond, S. Impact of the initial moisture level and pre-wetting history of recycled concrete aggregates on their water absorption. Mater. Struct. 2017, 50, 229. [Google Scholar] [CrossRef]

- Coelho, A.; De Brito, J. Economic viability analysis of a construction and demolition waste recycling plant in Portugal–part I: Location, materials, technology and economic analysis. J. Clean. Prod. 2013, 39, 338–352. [Google Scholar] [CrossRef]

- Coelho, A.; de Brito, J. Environmental analysis of a construction and demolition waste recycling plant in Portugal–Part I: Energy consumption and CO2 emissions. Waste Manag. 2013, 33, 1258–1267. [Google Scholar] [CrossRef] [PubMed]

- Blaschke, W.; Baic, I. FGX air-vibrating separators for cleaning steam coal–functional and economical parameters. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; p. 012030. [Google Scholar]

| Material/Characteristic | Low Resistance Concrete | High Resistance Concrete | Mortar |

|---|---|---|---|

| Portland cement | 1 | 1 | 1 |

| River sand | 2.94 | 1.78 | 6 |

| Coarse aggregate | 3.56 | 2.56 | - |

| Hydrated lime | - | - | 1 |

| Yellow pigment (Lanxess®) | 0.017 | - | - |

| Blue pigment (Lanxess®) | - | 0.01 | - |

| Brown pigment (Lanxess®) | - | - | 0.05 |

| Silica sand | - | 0.1 | - |

| Water/cement ratio | 0.56 | 0.5 | 0.57 |

| Strength after 28 days (MPa) | 16 | 54 | 7.03 |

| Material | Mass % | Mass % (per Type) | Absolute Density (g/cm3) | Apparent Density (g/cm3) | Bulk Density (g/cm3) | Shape Index |

|---|---|---|---|---|---|---|

| Low resistance ceramic | 15.14 | 29.70 | 2.43 | 2.22 | 1.23 | 2.94 |

| High resistance ceramic | 14.56 | 2.47 | 2.35 | 1.18 | 2.66 | |

| Low resistance concrete | 18.83 | 38.64 | 2.48 | 2.46 | 1.53 | 1.87 |

| High resistance concrete | 19.81 | 2.77 | 2.76 | 1.50 | 2.00 | |

| Mortar | 31.66 | 31.66 | 2.10 | 2.04 | 1.28 | 2.34 |

| Σ | 100.0 | 100.0 | - | - | - |

| Light Material | Dense Material | CC |

|---|---|---|

| High resistance concrete | Mortar | 1.61 |

| High resistance concrete | Low resistance ceramic | 1.48 |

| High resistance concrete | High resistance ceramic | 1.31 |

| High resistance concrete | Low resistance concrete | 1.21 |

| Low resistance concrete | Mortar | 1.33 |

| Low resistance concrete | High resistance ceramic | 1.08 |

| Low resistance concrete | Low resistance ceramic | 1.22 |

| High resistance ceramic | Mortar | 1.23 |

| High resistance ceramic | Low resistance ceramic | 1.13 |

| Low resistance ceramic | Mortar | 1.09 |

| Nomenclature | Description |

|---|---|

| NA | Natural aggregate |

| RA | Recycled aggregate |

| MA | Mixed aggregate |

| CRA | Conventional recycled aggregate |

| HRA | High-quality recycled aggregate |

| Stream | Feed | Final Waste | Concentrate | MA | CRA | HRA |

|---|---|---|---|---|---|---|

| Mortar | 31.66% | 44.00% | 11.90% | 40.00% | 7.20% | 0.00% |

| LS ceramics | 15.14% | 23.40% | 3.10% | 13.80% | 0.40% | 0.30% |

| HS ceramics | 14.56% | 16.60% | 3.40% | 4.90% | 1.00% | 0.00% |

| LS concrete | 18.83% | 7.40% | 32.00% | 21.10% | 32.50% | 56.80% |

| HS concrete | 19.81% | 8.60% | 49.60% | 18.20% | 58.90% | 42.90% |

| Σ | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% |

| Stream | Final Waste | Concentrate | MA | CRA | HRA |

|---|---|---|---|---|---|

| Mortar | 85.79% | 14.21% | 11.82% | 2.39% | 0.00% |

| LS ceramics | 92.49% | 7.51% | 7.06% | 0.17% | 0.21% |

| HS ceramics | 88.85% | 11.15% | 9.07% | 0.31% | 0.00% |

| LS concrete | 27.41% | 72.59% | 11.27% | 12.32% | 41.85% |

| HS concrete | 22.06% | 77.94% | 9.89% | 41.11% | 32.15% |

| Stream | Concrete Recovery (Mass %) | |

|---|---|---|

| Without MA Recycling | With MA Recycling | |

| Conventional RA | 27.61% | 27.80% |

| High Quality RA | 37.04% | 37.29% |

| MA recycling | - | 10.59% |

| Σ | 64.65% | 75.24% |

| Properties | Feed | Final Waste | CRA | HRA | NA |

|---|---|---|---|---|---|

| Absolute density (g/cm3) | 2.68 | 2.59 | 2.78 | 2.81 | 2.93 |

| Apparent density (g/cm3) | 2.51 | 2.49 | 2.62 | 2.71 | 2.90 |

| Bulk density (g/cm3) | 1.27 | 1.46 | 1.60 | 1.96 | 1.57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gschwenter, V.L.S.; Tubino, R.M.C.; Ambrós, W.M.; Miltzarek, G.L.; Sampaio, C.H.; Moncunill, J.O.; Cazacliu, B.G.; Dal Molin, D.C.C. Production of High-Quality Coarse Recycled Aggregates through a Two-Stage Jigging Process. Minerals 2022, 12, 532. https://doi.org/10.3390/min12050532

Gschwenter VLS, Tubino RMC, Ambrós WM, Miltzarek GL, Sampaio CH, Moncunill JO, Cazacliu BG, Dal Molin DCC. Production of High-Quality Coarse Recycled Aggregates through a Two-Stage Jigging Process. Minerals. 2022; 12(5):532. https://doi.org/10.3390/min12050532

Chicago/Turabian StyleGschwenter, Viviane L. S., Rejane M. C. Tubino, Weslei M. Ambrós, Gerson L. Miltzarek, Carlos Hoffmann Sampaio, Josep Oliva Moncunill, Bogdan Grigore Cazacliu, and Denise C. C. Dal Molin. 2022. "Production of High-Quality Coarse Recycled Aggregates through a Two-Stage Jigging Process" Minerals 12, no. 5: 532. https://doi.org/10.3390/min12050532

APA StyleGschwenter, V. L. S., Tubino, R. M. C., Ambrós, W. M., Miltzarek, G. L., Sampaio, C. H., Moncunill, J. O., Cazacliu, B. G., & Dal Molin, D. C. C. (2022). Production of High-Quality Coarse Recycled Aggregates through a Two-Stage Jigging Process. Minerals, 12(5), 532. https://doi.org/10.3390/min12050532